display DODGE RAM 2001 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2806 of 2889

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

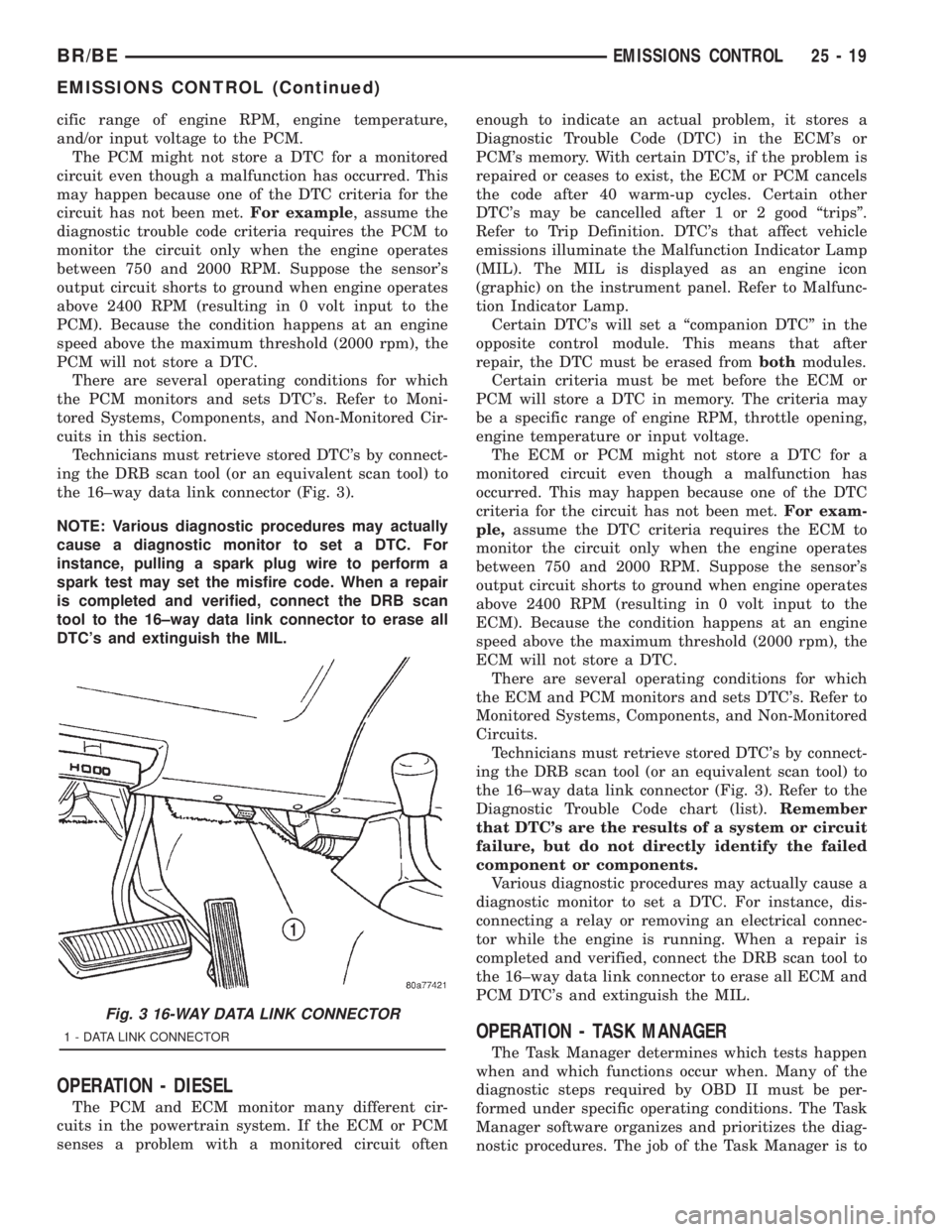

Technicians must retrieve stored DTC's by connect-

ing the DRB scan tool (or an equivalent scan tool) to

the 16±way data link connector (Fig. 3).

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, connect the DRB scan

tool to the 16±way data link connector to erase all

DTC's and extinguish the MIL.

OPERATION - DIESEL

The PCM and ECM monitor many different cir-

cuits in the powertrain system. If the ECM or PCM

senses a problem with a monitored circuit oftenenough to indicate an actual problem, it stores a

Diagnostic Trouble Code (DTC) in the ECM's or

PCM's memory. With certain DTC's, if the problem is

repaired or ceases to exist, the ECM or PCM cancels

the code after 40 warm-up cycles. Certain other

DTC's may be cancelled after 1 or 2 good ªtripsº.

Refer to Trip Definition. DTC's that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). The MIL is displayed as an engine icon

(graphic) on the instrument panel. Refer to Malfunc-

tion Indicator Lamp.

Certain DTC's will set a ªcompanion DTCº in the

opposite control module. This means that after

repair, the DTC must be erased frombothmodules.

Certain criteria must be met before the ECM or

PCM will store a DTC in memory. The criteria may

be a specific range of engine RPM, throttle opening,

engine temperature or input voltage.

The ECM or PCM might not store a DTC for a

monitored circuit even though a malfunction has

occurred. This may happen because one of the DTC

criteria for the circuit has not been met.For exam-

ple,assume the DTC criteria requires the ECM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

ECM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

ECM will not store a DTC.

There are several operating conditions for which

the ECM and PCM monitors and sets DTC's. Refer to

Monitored Systems, Components, and Non-Monitored

Circuits.

Technicians must retrieve stored DTC's by connect-

ing the DRB scan tool (or an equivalent scan tool) to

the 16±way data link connector (Fig. 3). Refer to the

Diagnostic Trouble Code chart (list).Remember

that DTC's are the results of a system or circuit

failure, but do not directly identify the failed

component or components.

Various diagnostic procedures may actually cause a

diagnostic monitor to set a DTC. For instance, dis-

connecting a relay or removing an electrical connec-

tor while the engine is running. When a repair is

completed and verified, connect the DRB scan tool to

the 16±way data link connector to erase all ECM and

PCM DTC's and extinguish the MIL.

OPERATION - TASK MANAGER

The Task Manager determines which tests happen

when and which functions occur when. Many of the

diagnostic steps required by OBD II must be per-

formed under specific operating conditions. The Task

Manager software organizes and prioritizes the diag-

nostic procedures. The job of the Task Manager is to

Fig. 3 16-WAY DATA LINK CONNECTOR

1 - DATA LINK CONNECTOR

BR/BEEMISSIONS CONTROL 25 - 19

EMISSIONS CONTROL (Continued)

Page 2808 of 2889

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within6375

RPM and load is within610% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

²If the MIL is ON and any other emissions DTC

was set (not an OBD II monitor), a good trip occurs

when the Oxygen Sensor Monitor and Catalyst Mon-

itor have been completed, or two minutes of engine

run time if the Oxygen Sensor Monitor and Catalyst

Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfire

Warm-Up Cycles

Once the MIL has been extinguished by the Good

Trip Counter, the PCM automatically switches to a

Warm-Up Cycle Counter that can be viewed on the

DRB III. Warm-Up Cycles are used to erase DTCs

and Freeze Frames. Forty Warm-Up cycles must

occur in order for the PCM to self-erase a DTC and

Freeze Frame. A Warm-Up Cycle is defined as fol-

lows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

BR/BEEMISSIONS CONTROL 25 - 21

EMISSIONS CONTROL (Continued)

Page 2809 of 2889

can determine under what vehicle operating condi-

tions the failure occurred.

The data stored in Freeze Frame is usually

recorded when a system fails the first time for two

trip faults. Freeze Frame data will only be overwrit-

ten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or

by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays informa-

tion about engine operation during a monitor. Abso-

lute MAP (engine load) and Engine RPM are stored

in this window when a failure occurs. There are two

different Similar conditions Windows: Fuel System

and Misfire.

FUEL SYSTEM

²Fuel System Similar Conditions WindowÐ

An indicator that 'Absolute MAP When Fuel Sys Fail'

and 'RPM When Fuel Sys Failed' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Fuel Sys FailÐ The

stored MAP reading at the time of failure. Informs

the user at what engine load the failure occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Fuel Sys FailÐ The stored RPM

reading at the time of failure. Informs the user at

what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²Upstream O2S VoltsÐ A live reading of the

Oxygen Sensor to indicate its performance. For

example, stuck lean, stuck rich, etc.

²SCW Time in Window (Similar Conditions

Window Time in Window)Ð A timer used by the

PCM that indicates that, after all Similar Conditions

have been met, if there has been enough good engine

running time in the SCW without failure detected.

This timer is used to increment a Good Trip.

²Fuel System Good Trip CounterÐATrip

Counter used to turn OFF the MIL for Fuel System

DTCs. To increment a Fuel System Good Trip, the

engine must be in the Similar Conditions Window,

Adaptive Memory Factor must be less than cali-

brated threshold and the Adaptive Memory Factormust stay below that threshold for a calibrated

amount of time.

²Test Done This TripÐ Indicates that the

monitor has already been run and completed during

the current trip.

MISFIRE

²Same Misfire Warm-Up StateÐ Indicates if

the misfire occurred when the engine was warmed up

(above 160É F).

²In Similar Misfire WindowÐ An indicator

that 'Absolute MAP When Misfire Occurred' and

'RPM When Misfire Occurred' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Misfire OccurredÐ

The stored MAP reading at the time of failure.

Informs the user at what engine load the failure

occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Misfire OccurredÐ The stored

RPM reading at the time of failure. Informs the user

at what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²200 Rev CounterÐ Counts 0±100 720 degree

cycles.

²SCW Cat 200 Rev CounterÐ Counts when in

similar conditions.

²SCW FTP 1000 Rev CounterÐ Counts 0±4

when in similar conditions.

²Misfire Good Trip CounterÐ Counts up to

three to turn OFF the MIL.

²Misfire DataÐ Data collected during test.

²Test Done This TripÐ Indicates YES when the

test is done.

OPERATION - NON-MONITORED CIRCUITS -

GAS ENGINES

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

causing driveability problems. The PCM might not

store diagnostic trouble codes for these conditions.

However, problems with these systems may cause the

PCM to store diagnostic trouble codes for other sys-

tems or components.EXAMPLE:a fuel pressure

problem will not register a fault directly, but could

cause a rich/lean condition or misfire. This could

cause the PCM to store an oxygen sensor or misfire

diagnostic trouble code

25 - 22 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2837 of 2889

BODY INTERIOR

INSPECTION - COMPASS

NOTE: Set variance after calibration.

(1) Calibrate and set compass variance (Fig. 26), if

so equipped (use appropriate procedures in service

information).

(2) Remove protective film from overhead console,

if equipped.

INSPECTION - FIT AND FINISH

(1) Remove any interior covers.

(2) Inspect the instrument panel, glove box door

(Fig. 27) and interior moldings for even gaps and

alignments.

(3) Check that the door panel material is clean,

free from wrinkles and installed correctly.

(4) Check that the seat material is clean, secure

and free of wrinkles.

(5) Check that the carpet is clean, secure and free

of wrinkles.

(6) Check that the headliner is clean, free of lint

and dirt smudges.

INSPECTION - LIGHTS AND SWITCHES

(1) Remove protective film from all switch bezels.

(2) Operate and visually inspect all interior lights

and switches, including:

²Dome/map lamps

²Vanity mirror lamps

²Glove box light²Ashtray light

²Cigar lighter light

²All gauge lights

²Radio display

²Door-mounted lights, if equipped

²Illuminated entry system, if equipped

(3) Visually inspect and operate all exterior lights

and their switches, including:

NOTE: Headlamp aim is preset during vehicle

assembly.

²Headlights, including high beam, optical horn

(ªflash to passº) and daylight running lamps (DRL's)

(Fig. 28)

²Tail/stop lamps (including center high-mounted

stop lamp)

²Parking lights Turn signals Brake lights (includ-

ing center high mounted stop lamp)

²Emergency flashers (Fig. 29)

²Fog/driving lights, if equipped

²Off-road or other lights, if equipped

²Cargo bed lights, if equipped

(4) Check ignition switch for proper operation in

all positions (accessory, lock, on, start and off).

INSPECTION - SEAT BELTS, SHOULDER

BELTS, RETRACTORS AND HEAD RESTRAINTS

(1) Inspect all seat belts and harnesses to ensure

that they connect and hold properly.

(2) Inspect the condition of the belts and anchors.

(3) Inspect for proper seat belt retraction.

Fig. 26 COMPASS OPERATION

Fig. 27 GLOVE BOX DOOR

30 - 12 NEW VEHICLE PREPARATIONBR/BE

Page 2840 of 2889

ROAD TEST

DESCRIPTION - ROAD TEST INSPECTION

The following items must be inspected during the

road test portion of the new vehicle inspection.

²Check neutral safety switch operation

²Check operation of shift/clutch interlock system

²Check operation of gauges and warning lights

²Check horn operation

²Check operation of turn signals and emergency

flashers

²Check all mirror adjustments, including day/

night function

²Check windshield wipers for proper wipe pattern

and intermittent mode (if equipped)

²Check washer spray pattern

²Check heater, defroster and air conditioning for

proper operation

²Check that the fan operates quietly

²Check the rear window defroster (if equipped)

²Leave air selection lever in the fresh air position

²Check the rear heater and air conditioning for

proper operation

²Check the rear air register locations

²Check that the indicator lamps operate properly

²Check the operation of the radio, cassette and/or

compact disc player, and that sound quality is good

²Ensure that the clock displays the correct time

²Check that the trip computer/maintenance

reminder operates in all modes

²Check all speed control functions

²Check the service brakes to ensure that they

stop the vehicle in a straight line, without noise,

shudder or vibration

²Check the brake warning light

²Check the parking brake operation

²Check the engine's performance

²Check the transmission's performance for

smooth, quiet operation. If the vehicle is a 4x4, check

that the transfer case shifts easily among all ranges

²Check Autostick function (if equipped)

²Check the vehicle's steering and handling

²The steering wheel should be centered when

traveling in a straight line

²The vehicle should not pull or vibrate

²Check for squeaks, rattles and wind noise

²Check any other vehicle aspects you believe are

important, but that may not be included on the New

Vehicle Preparation Form

²Fill fuel tank with specified grade of fuel

INSPECTION - FUEL

Fill fuel tank with specified grade of gasoline (reg-

ular, midgrade or premium).

INSPECTION - OTHER

As part of DaimlerChrysler's Customer One philos-

ophy, the ªOtherº blank is provided on the New Vehi-

cle Preparation Form. This is designed to encourage

you to check any aspects of vehicle operation that

you believe are important to your customers, but that

do not appear elsewhere on the form.

INSPECTION - SQUEAKS, RATTLES AND WIND

NOISE

(1) Make sure that the instrument panel, glove

box, seats, steering wheel and column are free from

squeaks and rattles. Tighten any obvious loose fas-

teners.

(2) Check that the windows and doors are free

from squeaks, rattles and wind noise.

(3) Check that the vehicle exterior is free from

squeaks, rattles and noise, front and rear.

(4) Make sure that all interior panels are free from

squeaks and rattles.

INSPECTION - STEERING AND HANDLING

(1) Check that the power assist works properly (if

equipped). Steering should not require excessive

effort.

(2) Make sure the steering wheel does not vibrate

at idle or road speed.

(3) Ensure that the steering wheel is centered

when traveling straight ahead.

(4) Check that the vehicle does not drift to one

side.

(5) Make sure that the vehicle does not vibrate/

shake.

INSPECTION - TRANSMISSION/TRANSFER

CASE

AUTOMATIC TRANSMISSION

(1) Make sure that the park lock holds the vehicle

With the vehicle on a grade, put automatic trans-

mission in PARK and slowly release the service

brake to see if park lock holds. If it does not hold, the

transmission requires further service.

(2) Make sure shift lever operates easily/ smoothly

(Fig. 36).

Check for smooth shifting. Check for proper

upshifting and downshifting.

MANUAL TRANSMISSION

(1) Check that the shifter operates easily (Fig. 38).

(2) Make sure that the clutch operates smoothly

(Fig. 37).

(3) Look for proper synchronization.

The gears should not grind.

BR/BENEW VEHICLE PREPARATION 30 - 15

Page 2842 of 2889

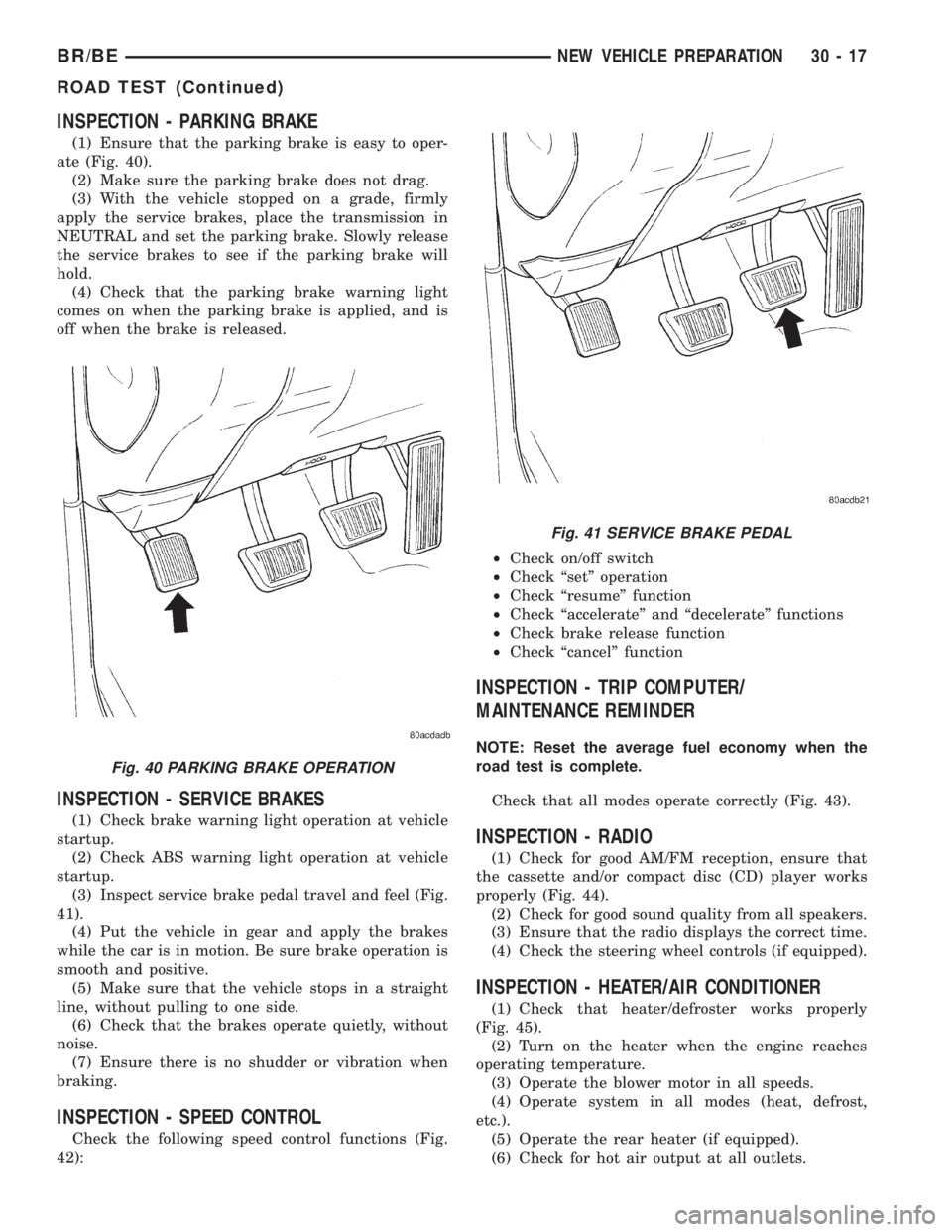

INSPECTION - PARKING BRAKE

(1) Ensure that the parking brake is easy to oper-

ate (Fig. 40).

(2) Make sure the parking brake does not drag.

(3) With the vehicle stopped on a grade, firmly

apply the service brakes, place the transmission in

NEUTRAL and set the parking brake. Slowly release

the service brakes to see if the parking brake will

hold.

(4) Check that the parking brake warning light

comes on when the parking brake is applied, and is

off when the brake is released.

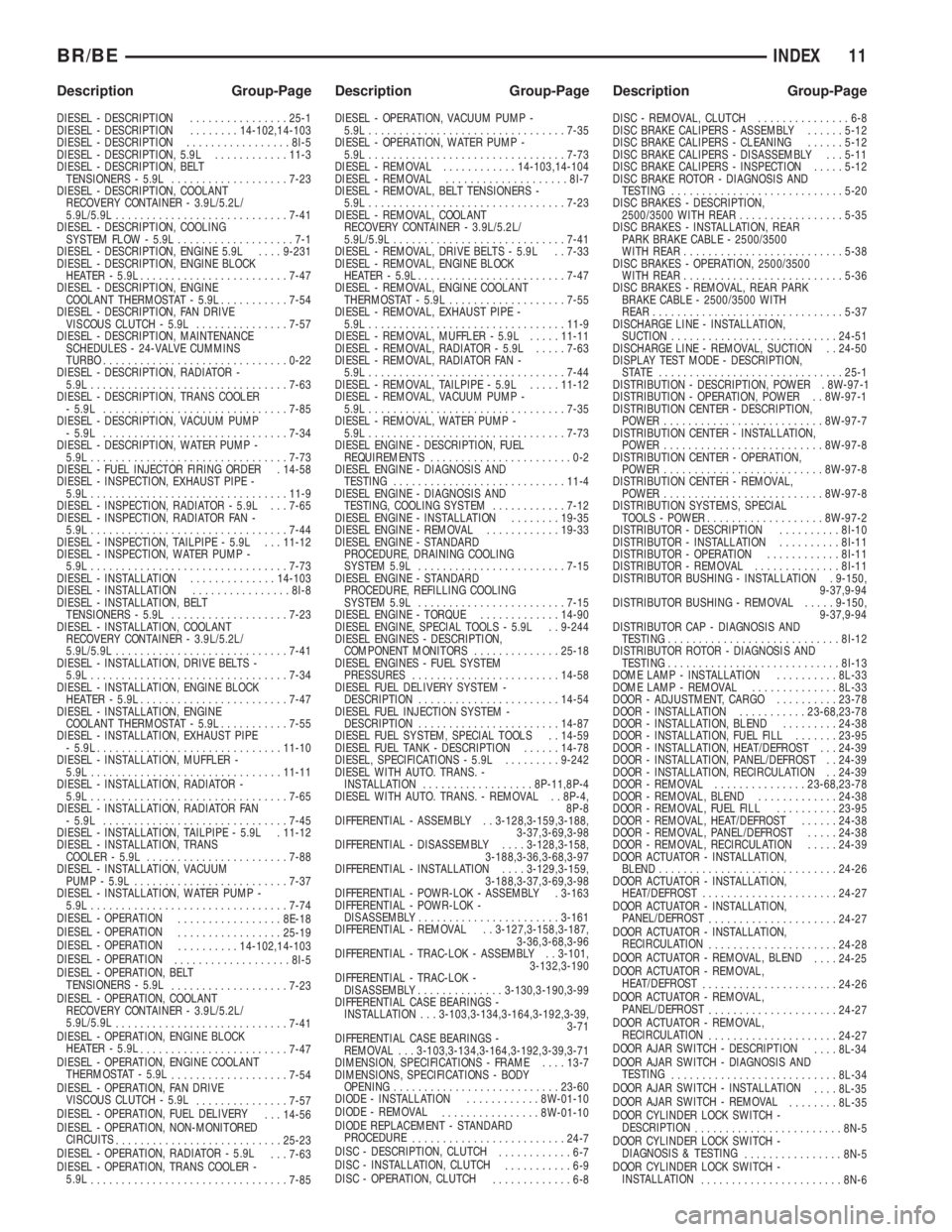

INSPECTION - SERVICE BRAKES

(1) Check brake warning light operation at vehicle

startup.

(2) Check ABS warning light operation at vehicle

startup.

(3) Inspect service brake pedal travel and feel (Fig.

41).

(4) Put the vehicle in gear and apply the brakes

while the car is in motion. Be sure brake operation is

smooth and positive.

(5) Make sure that the vehicle stops in a straight

line, without pulling to one side.

(6) Check that the brakes operate quietly, without

noise.

(7) Ensure there is no shudder or vibration when

braking.

INSPECTION - SPEED CONTROL

Check the following speed control functions (Fig.

42):²Check on/off switch

²Check ªsetº operation

²Check ªresumeº function

²Check ªaccelerateº and ªdecelerateº functions

²Check brake release function

²Check ªcancelº function

INSPECTION - TRIP COMPUTER/

MAINTENANCE REMINDER

NOTE: Reset the average fuel economy when the

road test is complete.

Check that all modes operate correctly (Fig. 43).

INSPECTION - RADIO

(1) Check for good AM/FM reception, ensure that

the cassette and/or compact disc (CD) player works

properly (Fig. 44).

(2) Check for good sound quality from all speakers.

(3) Ensure that the radio displays the correct time.

(4) Check the steering wheel controls (if equipped).

INSPECTION - HEATER/AIR CONDITIONER

(1) Check that heater/defroster works properly

(Fig. 45).

(2) Turn on the heater when the engine reaches

operating temperature.

(3) Operate the blower motor in all speeds.

(4) Operate system in all modes (heat, defrost,

etc.).

(5) Operate the rear heater (if equipped).

(6) Check for hot air output at all outlets.

Fig. 40 PARKING BRAKE OPERATION

Fig. 41 SERVICE BRAKE PEDAL

BR/BENEW VEHICLE PREPARATION 30 - 17

ROAD TEST (Continued)

Page 2858 of 2889

DIESEL - DESCRIPTION................25-1

DIESEL - DESCRIPTION........14-102,14-103

DIESEL - DESCRIPTION.................8I-5

DIESEL - DESCRIPTION, 5.9L............11-3

DIESEL - DESCRIPTION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - DESCRIPTION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-41

DIESEL - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L...................7-1

DIESEL - DESCRIPTION, ENGINE 5.9L....9-231

DIESEL - DESCRIPTION, ENGINE BLOCK

HEATER - 5.9L........................7-47

DIESEL - DESCRIPTION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-54

DIESEL - DESCRIPTION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-57

DIESEL - DESCRIPTION, MAINTENANCE

SCHEDULES - 24-VALVE CUMMINS

TURBO..............................0-22

DIESEL - DESCRIPTION, RADIATOR -

5.9L................................7-63

DIESEL - DESCRIPTION, TRANS COOLER

- 5.9L..............................7-85

DIESEL - DESCRIPTION, VACUUM PUMP

- 5.9L..............................7-34

DIESEL - DESCRIPTION, WATER PUMP -

5.9L................................7-73

DIESEL - FUEL INJECTOR FIRING ORDER . 14-58

DIESEL - INSPECTION, EXHAUST PIPE -

5.9L................................11-9

DIESEL - INSPECTION, RADIATOR - 5.9L . . . 7-65

DIESEL - INSPECTION, RADIATOR FAN -

5.9L................................7-44

DIESEL - INSPECTION, TAILPIPE - 5.9L . . . 11-12

DIESEL - INSPECTION, WATER PUMP -

5.9L................................7-73

DIESEL - INSTALLATION..............14-103

DIESEL - INSTALLATION................8I-8

DIESEL - INSTALLATION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - INSTALLATION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-41

DIESEL - INSTALLATION, DRIVE BELTS -

5.9L................................7-34

DIESEL - INSTALLATION, ENGINE BLOCK

HEATER - 5.9L........................7-47

DIESEL - INSTALLATION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-55

DIESEL - INSTALLATION, EXHAUST PIPE

- 5.9L..............................11-10

DIESEL - INSTALLATION, MUFFLER -

5.9L...............................11-11

DIESEL - INSTALLATION, RADIATOR -

5.9L................................7-65

DIESEL - INSTALLATION, RADIATOR FAN

- 5.9L..............................7-45

DIESEL - INSTALLATION, TAILPIPE - 5.9L . 11-12

DIESEL - INSTALLATION, TRANS

COOLER - 5.9L.......................7-88

DIESEL - INSTALLATION, VACUUM

PUMP - 5.9L.........................7-37

DIESEL - INSTALLATION, WATER PUMP -

5.9L................................7-74

DIESEL - OPERATION

.................8E-18

DIESEL - OPERATION

.................25-19

DIESEL - OPERATION

..........14-102,14-103

DIESEL - OPERATION

...................8I-5

DIESEL - OPERATION, BELT

TENSIONERS - 5.9L

...................7-23

DIESEL - OPERATION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L

............................7-41

DIESEL - OPERATION, ENGINE BLOCK

HEATER - 5.9L

........................7-47

DIESEL - OPERATION, ENGINE COOLANT

THERMOSTAT - 5.9L

...................7-54

DIESEL - OPERATION, FAN DRIVE

VISCOUS CLUTCH - 5.9L

...............7-57

DIESEL - OPERATION, FUEL DELIVERY

. . . 14-56

DIESEL - OPERATION, NON-MONITORED

CIRCUITS

...........................25-23

DIESEL - OPERATION, RADIATOR - 5.9L

. . . 7-63

DIESEL - OPERATION, TRANS COOLER -

5.9L

................................7-85DIESEL - OPERATION, VACUUM PUMP -

5.9L................................7-35

DIESEL - OPERATION, WATER PUMP -

5.9L................................7-73

DIESEL - REMOVAL............14-103,14-104

DIESEL - REMOVAL....................8I-7

DIESEL - REMOVAL, BELT TENSIONERS -

5.9L................................7-23

DIESEL - REMOVAL, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-41

DIESEL - REMOVAL, DRIVE BELTS - 5.9L . . 7-33

DIESEL - REMOVAL, ENGINE BLOCK

HEATER - 5.9L........................7-47

DIESEL - REMOVAL, ENGINE COOLANT

THERMOSTAT - 5.9L...................7-55

DIESEL - REMOVAL, EXHAUST PIPE -

5.9L................................11-9

DIESEL - REMOVAL, MUFFLER - 5.9L.....11-11

DIESEL - REMOVAL, RADIATOR - 5.9L.....7-63

DIESEL - REMOVAL, RADIATOR FAN -

5.9L................................7-44

DIESEL - REMOVAL, TAILPIPE - 5.9L.....11-12

DIESEL - REMOVAL, VACUUM PUMP -

5.9L................................7-35

DIESEL - REMOVAL, WATER PUMP -

5.9L................................7-73

DIESEL ENGINE - DESCRIPTION, FUEL

REQUIREMENTS.......................0-2

DIESEL ENGINE - DIAGNOSIS AND

TESTING............................11-4

DIESEL ENGINE - DIAGNOSIS AND

TESTING, COOLING SYSTEM............7-12

DIESEL ENGINE - INSTALLATION........19-35

DIESEL ENGINE - REMOVAL............19-33

DIESEL ENGINE - STANDARD

PROCEDURE, DRAINING COOLING

SYSTEM 5.9L........................7-15

DIESEL ENGINE - STANDARD

PROCEDURE, REFILLING COOLING

SYSTEM 5.9L........................7-15

DIESEL ENGINE - TORQUE.............14-90

DIESEL ENGINE, SPECIAL TOOLS - 5.9L . . 9-244

DIESEL ENGINES - DESCRIPTION,

COMPONENT MONITORS..............25-18

DIESEL ENGINES - FUEL SYSTEM

PRESSURES........................14-58

DIESEL FUEL DELIVERY SYSTEM -

DESCRIPTION.......................14-54

DIESEL FUEL INJECTION SYSTEM -

DESCRIPTION.......................14-87

DIESEL FUEL SYSTEM, SPECIAL TOOLS . . 14-59

DIESEL FUEL TANK - DESCRIPTION......14-78

DIESEL, SPECIFICATIONS - 5.9L.........9-242

DIESEL WITH AUTO. TRANS. -

INSTALLATION..................8P-11,8P-4

DIESEL WITH AUTO. TRANS. - REMOVAL . . 8P-4,

8P-8

DIFFERENTIAL - ASSEMBLY . . 3-128,3-159,3-188,

3-37,3-69,3-98

DIFFERENTIAL - DISASSEMBLY....3-128,3-158,

3-188,3-36,3-68,3-97

DIFFERENTIAL - INSTALLATION....3-129,3-159,

3-188,3-37,3-69,3-98

DIFFERENTIAL - POWR-LOK - ASSEMBLY . 3-163

DIFFERENTIAL - POWR-LOK -

DISASSEMBLY.......................3-161

DIFFERENTIAL - REMOVAL . . 3-127,3-158,3-187,

3-36,3-68,3-96

DIFFERENTIAL - TRAC-LOK - ASSEMBLY . . 3-101,

3-132,3-190

DIFFERENTIAL - TRAC-LOK -

DISASSEMBLY..............3-130,3-190,3-99

DIFFERENTIAL CASE BEARINGS -

INSTALLATION . . . 3-103,3-134,3-164,3-192,3-39,

3-71

DIFFERENTIAL CASE BEARINGS -

REMOVAL . . . 3-103,3-134,3-164,3-192,3-39,3-71

DIMENSION, SPECIFICATIONS - FRAME....13-7

DIMENSIONS, SPECIFICATIONS - BODY

OPENING...........................23-60

DIODE - INSTALLATION............8W-01-10

DIODE - REMOVAL

................8W-01-10

DIODE REPLACEMENT - STANDARD

PROCEDURE

.........................24-7

DISC - DESCRIPTION, CLUTCH

............6-7

DISC - INSTALLATION, CLUTCH

...........6-9

DISC - OPERATION, CLUTCH

.............6-8DISC - REMOVAL, CLUTCH...............6-8

DISC BRAKE CALIPERS - ASSEMBLY......5-12

DISC BRAKE CALIPERS - CLEANING......5-12

DISC BRAKE CALIPERS - DISASSEMBLY . . . 5-11

DISC BRAKE CALIPERS - INSPECTION.....5-12

DISC BRAKE ROTOR - DIAGNOSIS AND

TESTING............................5-20

DISC BRAKES - DESCRIPTION,

2500/3500 WITH REAR.................5-35

DISC BRAKES - INSTALLATION, REAR

PARK BRAKE CABLE - 2500/3500

WITH REAR..........................5-38

DISC BRAKES - OPERATION, 2500/3500

WITH REAR..........................5-36

DISC BRAKES - REMOVAL, REAR PARK

BRAKE CABLE - 2500/3500 WITH

REAR...............................5-37

DISCHARGE LINE - INSTALLATION,

SUCTION...........................24-51

DISCHARGE LINE - REMOVAL, SUCTION . . 24-50

DISPLAY TEST MODE - DESCRIPTION,

STATE ..............................25-1

DISTRIBUTION - DESCRIPTION, POWER . 8W-97-1

DISTRIBUTION - OPERATION, POWER . . 8W-97-1

DISTRIBUTION CENTER - DESCRIPTION,

POWER..........................8W-97-7

DISTRIBUTION CENTER - INSTALLATION,

POWER..........................8W-97-8

DISTRIBUTION CENTER - OPERATION,

POWER..........................8W-97-8

DISTRIBUTION CENTER - REMOVAL,

POWER...........................8W-97-8

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER...................8W-97-2

DISTRIBUTOR - DESCRIPTION..........8I-10

DISTRIBUTOR - INSTALLATION..........8I-11

DISTRIBUTOR - OPERATION............8I-11

DISTRIBUTOR - REMOVAL..............8I-11

DISTRIBUTOR BUSHING - INSTALLATION . 9-150,

9-37,9-94

DISTRIBUTOR BUSHING - REMOVAL.....9-150,

9-37,9-94

DISTRIBUTOR CAP - DIAGNOSIS AND

TESTING............................8I-12

DISTRIBUTOR ROTOR - DIAGNOSIS AND

TESTING............................8I-13

DOME LAMP - INSTALLATION..........8L-33

DOME LAMP - REMOVAL..............8L-33

DOOR - ADJUSTMENT, CARGO..........23-78

DOOR - INSTALLATION...........23-68,23-78

DOOR - INSTALLATION, BLEND.........24-38

DOOR - INSTALLATION, FUEL FILL.......23-95

DOOR - INSTALLATION, HEAT/DEFROST . . . 24-39

DOOR - INSTALLATION, PANEL/DEFROST . . 24-39

DOOR - INSTALLATION, RECIRCULATION . . 24-39

DOOR - REMOVAL...............23-68,23-78

DOOR - REMOVAL, BLEND.............24-38

DOOR - REMOVAL, FUEL FILL..........23-95

DOOR - REMOVAL, HEAT/DEFROST......24-38

DOOR - REMOVAL, PANEL/DEFROST.....24-38

DOOR - REMOVAL, RECIRCULATION.....24-39

DOOR ACTUATOR - INSTALLATION,

BLEND.............................24-26

DOOR ACTUATOR - INSTALLATION,

HEAT/DEFROST......................24-27

DOOR ACTUATOR - INSTALLATION,

PANEL/DEFROST

.....................24-27

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION

.....................24-28

DOOR ACTUATOR - REMOVAL, BLEND

....24-25

DOOR ACTUATOR - REMOVAL,

HEAT/DEFROST

......................24-26

DOOR ACTUATOR - REMOVAL,

PANEL/DEFROST

.....................24-27

DOOR ACTUATOR - REMOVAL,

RECIRCULATION

.....................24-27

DOOR AJAR SWITCH - DESCRIPTION

....8L-34

DOOR AJAR SWITCH - DIAGNOSIS AND

TESTING

...........................8L-34

DOOR AJAR SWITCH - INSTALLATION

....8L-35

DOOR AJAR SWITCH - REMOVAL

........8L-35

DOOR CYLINDER LOCK SWITCH -

DESCRIPTION

........................8N-5

DOOR CYLINDER LOCK SWITCH -

DIAGNOSIS & TESTING

................8N-5

DOOR CYLINDER LOCK SWITCH -

INSTALLATION

.......................8N-6

BR/BEINDEX 11

Description Group-Page Description Group-Page Description Group-Page

Page 2869 of 2889

MANIFOLD - INSTALLATION, INTAKE.....9-111,

9-166,9-223,9-302,9-53

MANIFOLD - OPERATION, EXHAUST.....9-112,

9-168,9-224,9-55

MANIFOLD - OPERATION, FUEL DRAIN . . . 14-86

MANIFOLD - OPERATION, INTAKE . . 9-109,9-165,

9-52

MANIFOLD - REMOVAL, EXHAUST . . 9-112,9-168,

9-225,9-303,9-55

MANIFOLD - REMOVAL, FUEL DRAIN.....14-86

MANIFOLD - REMOVAL, INTAKE . . . 9-110,9-166,

9-222,9-301,9-53

MANIFOLD LEAKAGE - DIAGNOSIS AND

TESTING, INTAKE......9-110,9-165,9-222,9-53

MANUAL BLEEDING - STANDARD

PROCEDURE..........................5-7

MANUAL, NV3500....................21-41

MANUAL, NV4500....................21-83

MANUAL TRANSMISSION - DIAGNOSIS

AND TESTING..............21-3,21-46,21-93

MANUAL TRANSMISSION -

INSTALLATION, SHIFT BOOT...........23-122

MANUAL TRANSMISSION - REMOVAL,

SHIFT BOOT........................23-122

MANUAL TRANSMISSION, SPECIAL

TOOLS - NV5600....................21-127

MAP SENSOR - INSTALLATION.........14-104

MARKER LAMP - INSTALLATION........8L-23

MARKER LAMP - REMOVAL............8L-22

MASTER CYLINDER - DESCRIPTION......5-29

MASTER CYLINDER - INSTALLATION.......5-30

MASTER CYLINDER - OPERATION........5-29

MASTER CYLINDER - REMOVAL..........5-30

MASTER CYLINDER BLEEDING -

STANDARD PROCEDURE................5-30

MASTER CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING..............5-29

MATCH MOUNTING - STANDARD

PROCEDURES........................22-2

MATS - INSTALLATION, CARPETS AND

FLOOR............................23-123

MATS - REMOVAL, CARPETS AND

FLOOR............................23-123

MEASUREMENT - STANDARD

PROCEDURES, CASTER CORRECTION......2-3

MEASUREMENTS, SPECIFICATIONS -

BODY GAP AND FLUSH................23-56

MEASURING TIMING CHAIN STRETCH -

INSPECTION..........9-114,9-170,9-227,9-58

MECHANICAL - DIAGNOSIS AND

TESTING...............9-120,9-175,9-6,9-63

MECHANICAL - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS..........9-232

MECHANISM - ADJUSTMENT, SHIFT....21-252,

21-423,21-596,21-769

MECHANISM - DESCRIPTION, SHIFT....21-251,

21-422,21-595,21-768

MECHANISM - INSTALLATION, SHIFT.....21-89

MECHANISM - OPERATION, SHIFT......21-251,

21-422,21-595,21-768

MECHANISM - REMOVAL, SHIFT........21-88

MEDIUM DUTY TRUCK MAINTENANCE

SCHEDULE (8.0L 2500 & 3500

MODELS - CALIFORNIA ONLY) -

DESCRIPTION........................0-13

METRIC SYSTEM - DESCRIPTION......Intro.-6

MILE, SPECIFICATIONS - TIRE

REVOLUTIONS PER....................22-9

MINI-TRIP COMPUTER - DIAGNOSIS &

TESTING, COMPASS..................8M-10

MIRROR - DESCRIPTION, AUTOMATIC

DAY / NIGHT........................8N-10

MIRROR - DESCRIPTION, SIDEVIEW.....8N-13

MIRROR - DIAGNOSIS AND TESTING,

AUTOMATIC DAY/NIGHT...............8N-11

MIRROR - DIAGNOSIS AND TESTING,

SIDEVIEW..........................8N-13

MIRROR - INSPECTION................30-19

MIRROR - INSTALLATION, AUTOMATIC

DAY / NIGHT........................8N-12

MIRROR - INSTALLATION, REAR VIEW

. . 23-126

MIRROR - INSTALLATION, SIDE VIEW

....23-97

MIRROR - LOW MOUNTED -

INSTALLATION, SIDE VIEW

.............23-98

MIRROR - LOW MOUNTED - REMOVAL,

SIDE VIEW

..........................23-98

MIRROR - OPERATION, AUTOMATIC DAY

/ NIGHT

............................8N-11MIRROR - OPERATION, SIDEVIEW.......8N-13

MIRROR - REMOVAL, AUTOMATIC DAY /

NIGHT.............................8N-12

MIRROR - REMOVAL, REAR VIEW......23-126

MIRROR - REMOVAL, SIDE VIEW........23-97

MIRROR - REMOVAL, SIDEVIEW........8N-14

MIRROR FLAG - INSTALLATION, SIDE

VIEW..............................23-74

MIRROR FLAG - REMOVAL, SIDE VIEW . . . 23-74

MIRROR GLASS - INSTALLATION, SIDE

VIEW..............................23-98

MIRROR GLASS - REMOVAL, SIDE VIEW . . 23-98

MIRROR GRID - DESCRIPTION, HEATED . . . 8G-4

MIRROR GRID - DIAGNOSIS AND

TESTING, HEATED.....................8G-4

MIRROR GRID - OPERATION, HEATED.....8G-4

MIRROR SUPPORT BRACKET -

INSTALLATION, REARVIEW............23-126

MIRROR SWITCH - DESCRIPTION........8G-3

MIRROR SWITCH - DESCRIPTION,

POWER............................8N-12

MIRROR SWITCH - DIAGNOSIS AND

TESTING, HEATED.....................8G-3

MIRROR SWITCH - INSTALLATION,

POWER............................8N-13

MIRROR SWITCH - OPERATION..........8G-3

MIRROR SWITCH - OPERATION, POWER . . 8N-12

MIRROR SWITCH - REMOVAL, POWER . . . 8N-12

MIRROR SYSTEM - DESCRIPTION,

HEATED..............................8G-1

MIRROR SYSTEM - DIAGNOSIS AND

TESTING, HEATED.....................8G-2

MIRROR SYSTEM - OPERATION, HEATED . . 8G-2

MIRRORS - DESCRIPTION, POWER......8N-10

MIRRORS - OPERATION, POWER........8N-10

MODE - DESCRIPTION, CIRCUIT

ACTUATION TEST.....................25-1

MODE - DESCRIPTION, STATE DISPLAY

TEST...............................25-1

MODES OF OPERATION - DESCRIPTION . . . 8E-14

MODULE - DESCRIPTION, AIRBAG

CONTROL...........................8O-6

MODULE - DESCRIPTION, BODY

CONTROL/CENTRAL TIMER..............8E-1

MODULE - DESCRIPTION, DAYTIME

RUNNING LAMP......................8L-9

MODULE - DESCRIPTION, FUEL PUMP....14-12

MODULE - DESCRIPTION, FUEL TANK....14-78

MODULE - DESCRIPTION, WIPER.......8R-14

MODULE - DIAGNOSIS AND TESTING,

CENTRAL TIMER......................8E-4

MODULE - INSTALLATION, AIRBAG

CONTROL...........................8O-8

MODULE - INSTALLATION, BODY

CONTROL/CENTRAL TIMER..............8E-6

MODULE - INSTALLATION, DAYTIME

RUNNING LAMP......................8L-9

MODULE - INSTALLATION, ENGINE

CONTROL..........................8E-14

MODULE - INSTALLATION, FUEL PUMP . . . 14-13

MODULE - INSTALLATION, FUEL TANK....14-79

MODULE - INSTALLATION, POWERTRAIN

CONTROL..........................8E-20

MODULE - INSTALLATION, WIPER.......8R-15

MODULE - OPERATION, AIRBAG

CONTROL...........................8O-6

MODULE - OPERATION, BODY

CONTROL/CENTRAL TIMER..............8E-3

MODULE - OPERATION, DAYTIME

RUNNING LAMP......................8L-9

MODULE - OPERATION, FUEL PUMP.....14-13

MODULE - OPERATION, FUEL TANK......14-78

MODULE - OPERATION, WIPER.........8R-14

MODULE - REMOVAL, AIRBAG CONTROL . . 8O-7

MODULE - REMOVAL, BODY CONTROL/

CENTRAL TIMER......................8E-5

MODULE - REMOVAL, DAYTIME

RUNNING LAMP......................8L-9

MODULE - REMOVAL, ENGINE CONTROL . . 8E-14

MODULE - REMOVAL, FUEL PUMP.......14-13

MODULE - REMOVAL, FUEL TANK.......14-78

MODULE - REMOVAL, POWERTRAIN

CONTROL..........................8E-19

MODULE - REMOVAL, WIPER

...........8R-14

MOLDING - INSTALLATION, ROOF JOINT

. . 23-91

MOLDING - REMOVAL, ROOF JOINT

......23-91

MOLDINGS - INSTALLATION, BODY SIDE

. . 23-87

MOLDINGS - REMOVAL, BODY SIDE

.....23-87MOLEX - INSTALLATION, CONNECTOR . 8W-01-9

MOLEX - REMOVAL, CONNECTOR.....8W-01-9

MONITORED SYSTEMS - DESCRIPTION . . . 25-15

MONITORS - DIESEL ENGINES -

DESCRIPTION, COMPONENT............25-18

MONITORS - GAS ENGINES -

DESCRIPTION, COMPONENT............25-18

MOTOR - ASSEMBLY, AXLE VACUUM . . 3-33,3-65

MOTOR - DESCRIPTION, AXLE VACUUM . . . 3-29,

3-62

MOTOR - DESCRIPTION, BLOWER.......24-32

MOTOR - DESCRIPTION, ENGINE

STARTER ...........................8F-39

MOTOR - DESCRIPTION, IDLE AIR

CONTROL..........................14-41

MOTOR - DESCRIPTION, LUMBAR.......8N-18

MOTOR - DESCRIPTION, POWER LOCK....8N-6

MOTOR - DESCRIPTION, RECLINER......8N-20

MOTOR - DESCRIPTION, WINDOW......8N-26

MOTOR - DIAGNOSIS AND TESTING,

BLOWER...........................24-33

MOTOR - DIAGNOSIS AND TESTING,

POWER LOCK........................8N-7

MOTOR - DIAGNOSIS AND TESTING,

STARTER ...........................8F-39

MOTOR - DIAGNOSIS AND TESTING,

VACUUM........................3-31,3-63

MOTOR - DIAGNOSIS AND TESTING,

WINDOW...........................8N-26

MOTOR - DISASSEMBLY, AXLE VACUUM . . 3-33,

3-65

MOTOR - INSTALLATION, AXLE VACUUM . . 3-33,

3-65

MOTOR - INSTALLATION, BLOWER......24-33

MOTOR - INSTALLATION, ENGINE

STARTER ...........................8F-41

MOTOR - OPERATION, AXLE VACUUM . 3-30,3-62

MOTOR - OPERATION, BLOWER.........24-32

MOTOR - OPERATION, ENGINE STARTER . . 8F-39

MOTOR - OPERATION, IDLE AIR

CONTROL..........................14-41

MOTOR - OPERATION, LUMBAR........8N-18

MOTOR - OPERATION, POWER LOCK.....8N-6

MOTOR - OPERATION, RECLINER.......8N-21

MOTOR - REMOVAL, AXLE VACUUM . . 3-33,3-65

MOTOR - REMOVAL, BLOWER..........24-33

MOTOR - REMOVAL, ENGINE STARTER . . . 8F-40

MOTOR - REMOVAL, WINDOW..........8N-26

MOTOR RELAY - DESCRIPTION,

BLOWER...........................24-22

MOTOR RELAY - DESCRIPTION, ENGINE

STARTER ...........................8F-42

MOTOR RELAY - DIAGNOSIS AND

TESTING, BLOWER...................24-22

MOTOR RELAY - INSTALLATION,

BLOWER...........................24-23

MOTOR RELAY - INSTALLATION, ENGINE

STARTER ...........................8F-43

MOTOR RELAY - OPERATION, BLOWER . . . 24-22

MOTOR RELAY - OPERATION, ENGINE

STARTER ...........................8F-42

MOTOR RELAY - REMOVAL, BLOWER....24-23

MOTOR RELAY - REMOVAL, ENGINE

STARTER ...........................8F-43

MOTOR RESISTOR BLOCK -

DESCRIPTION, BLOWER...............24-23

MOTOR RESISTOR BLOCK - DIAGNOSIS

AND TESTING, BLOWER...............24-24

MOTOR RESISTOR BLOCK -

INSTALLATION, BLOWER..............24-24

MOTOR RESISTOR BLOCK - OPERATION,

BLOWER...........................24-23

MOTOR RESISTOR BLOCK - REMOVAL,

BLOWER...........................24-24

MOTOR SWITCH - DESCRIPTION,

BLOWER...........................24-24

MOTOR SWITCH - DIAGNOSIS AND

TESTING, BLOWER...................24-25

MOTOR SWITCH - OPERATION, BLOWER . . 24-25

MOTOR SWITCH - REMOVAL, BLOWER

. . . 24-25

MOUNT - INSTALLATION, FRONT

. . . 9-100,9-156,

9-213,9-290,9-43

MOUNT - INSTALLATION, REAR

....9-101,9-158,

9-213,9-291,9-44

MOUNT - REMOVAL, FRONT

. 9-100,9-156,9-213,

9-290,9-43

MOUNT - REMOVAL, REAR

. . 9-101,9-157,9-213,

9-291,9-44

22 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2880 of 2889

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................23-61

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................13-9

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................24-8

SPECIFICATIONS, TORQUE - FUEL

DELIVERY...........................14-4

SPECIFICATIONS, TORQUE - GAS FUEL

INJECTION..........................14-35

SPECIFICATIONS, TORQUE -

GENERATOR/CHARGING SYSTEM........8F-28

SPECIFICATIONS, TORQUE - IGNITION.....8I-2

SPECIFICATIONS, TORQUE - STARTING

SYSTEM............................8F-38

SPEED CONTROL - INSPECTION.........30-17

SPEED CONTROL SERVO - DESCRIPTION . . 8P-5

SPEED CONTROL SERVO -

INSTALLATION.......................8P-10

SPEED CONTROL SERVO - OPERATION....8P-5

SPEED CONTROL SERVO - REMOVAL.....8P-6

SPEED CONTROL SYSTEM -

DESCRIPTION........................8P-1

SPEED CONTROL SYSTEM - OPERATION . . . 8P-2

SPEED CONTROL SYSTEM - TORQUE.....8P-4

SPEED INPUT - DESCRIPTION, VEHICLE . . . 8P-1

SPEED SENSOR - DESCRIPTION . 21-253,21-424,

21-597,21-770

SPEED SENSOR - OPERATION . . . 21-253,21-424,

21-597,21-770

SPEEDOMETER - DESCRIPTION...........8J-30

SPEEDOMETER - OPERATION...........8J-30

SPLASH SHIELD - INSTALLATION, REAR . . 23-96

SPLASH SHIELD - REMOVAL, REAR......23-96

SPLASH SHIELDS - INSTALLATION,

FRONT END.........................23-92

SPLASH SHIELDS - REMOVAL, FRONT

END ...............................23-92

SPLICE LOCATIONS - DESCRIPTION . . . 8W-95-1

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-12

SPLIT BENCH - INSTALLATION, SEAT....23-134

SPLIT BENCH - INSTALLATION, SEAT

BACK.............................23-136

SPLIT BENCH - INSTALLATION, SEAT

BACK COVER.......................23-138

SPLIT BENCH - INSTALLATION, SEAT

CUSHION COVER....................23-140

SPLIT BENCH - INSTALLATION, SEAT

TRACK............................23-142

SPLIT BENCH - REMOVAL, SEAT.......23-134

SPLIT BENCH - REMOVAL, SEAT BACK . . 23-135

SPLIT BENCH - REMOVAL, SEAT BACK

COVER............................23-137

SPLIT BENCH - REMOVAL, SEAT

CUSHION COVER....................23-139

SPLIT BENCH - REMOVAL, SEAT TRACK . 23-142

SPOOL VALVE - INSTALLATION..........19-26

SPOOL VALVE - REMOVAL.............19-24

SPRING - DESCRIPTION........2-11,2-22,2-28

SPRING - INSTALLATION.......2-12,2-22,2-29

SPRING - OPERATION..........2-11,2-22,2-28

SPRING - REMOVAL...........2-11,2-22,2-28

SPRING AND SHOCK - DIAGNOSIS AND

TESTING............................2-26

SPRINGS - INSTALLATION, VALVES AND

VALVE .............................9-199

SPRINGS - REMOVAL, VALVES AND

VALVE .............................9-197

SPRINGS - STANDARD PROCEDURE,

VALVES, GUIDES.............9-138,9-25,9-82

SPRINGS, INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE-

VALVES,GUIDES.....................9-253

SPROCKETS - INSTALLATION, TIMING

BELT/CHAIN...........9-115,9-170,9-227,9-58

SPROCKETS - REMOVAL, TIMING

BELT/CHAIN...........9-114,9-170,9-226,9-57

SQUEAKS, RATTLES AND WIND NOISE -

INSPECTION........................30-15

STABILIZER BAR - DESCRIPTION . 2-12,2-22,2-30

STABILIZER BAR - INSTALLATION....2-12,2-23,

2-30

STABILIZER BAR - OPERATION

. . 2-12,2-22,2-30

STABILIZER BAR - REMOVAL

....2-12,2-22,2-30

STANCHION COVER - INSTALLATION

....23-143

STANCHION COVER - REMOVAL

........23-143

STANDARD CAB - INSTALLATION

........8O-19STANDARD CAB - REMOVAL...........8O-18

STARTER MOTOR - DESCRIPTION,

ENGINE............................8F-39

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-39

STARTER MOTOR - INSTALLATION,

ENGINE............................8F-41

STARTER MOTOR - OPERATION, ENGINE . . 8F-39

STARTER MOTOR - REMOVAL, ENGINE . . . 8F-40

STARTER MOTOR RELAY -

DESCRIPTION, ENGINE................8F-42

STARTER MOTOR RELAY -

INSTALLATION, ENGINE................8F-43

STARTER MOTOR RELAY - OPERATION,

ENGINE............................8F-42

STARTER MOTOR RELAY - REMOVAL,

ENGINE............................8F-43

STARTER RELAY - DIAGNOSIS AND

TESTING...........................8F-42

STARTING - DESCRIPTION.............8F-32

STARTING - OPERATION...............8F-32

STARTING - STANDARD PROCEDURE,

JUMP...............................0-27

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-33

STARTING SYSTEM - SPECIFICATIONS,

TORQUE............................8F-38

STARTING SYSTEM, SPECIFICATIONS.....8F-38

STATE DISPLAY TEST MODE -

DESCRIPTION........................25-1

STATIONARY GLASS - DESCRIPTION....23-145

STATIONARY GLASS - OPERATION......23-145

STEERING - DESCRIPTION..............19-1

STEERING - OPERATION................19-1

STEERING AND HANDLING -

INSPECTION........................30-15

STEERING COLUMN OPENING COVER -

INSTALLATION......................23-116

STEERING COLUMN OPENING COVER -

REMOVAL.........................23-115

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER.......19-4

STEERING GEAR HOUSING PLUG -

INSTALLATION.......................19-27

STEERING GEAR HOUSING PLUG -

REMOVAL..........................19-27

STEERING GEAR LEAKAGE - DIAGNOSIS

AND TESTING, POWER................19-14

STEERING GEAR, SPECIAL TOOLS -

POWER............................19-20

STEERING GEAR, SPECIFICATIONS -

POWER............................19-19

STEERING LINKAGE, SPECIAL TOOLS....19-39,

19-42

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-31

STEERING PUMP, SPECIAL TOOLS -

POWER............................19-36

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-2

STEERING SYSTEM - STANDARD

PROCEDURE, FLUSHING POWER........19-32

STEERING WHEEL - INSTALLATION......19-13

STEERING WHEEL - REMOVAL..........19-13

STEM SEAL - INSTALLATION, VALVE.....9-198

STEM SEALS - REMOVAL, VALVE........9-197

STEPS - NEW VEHICLE PREPARATION

FORM, FINAL........................30-22

STOP LAMP - INSTALLATION, CENTER

HIGH MOUNTED......................8L-6

STOP LAMP - REMOVAL, CENTER HIGH

MOUNTED...........................8L-6

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED...............8L-6

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED......................8L-6

STORAGE - DESCRIPTION, PRE

DELIVERY..........................30-19

STORAGE - STANDARD PROCEDURE,

PRE DELIVERY......................30-20

STORAGE BIN - INSTALLATION

.........23-116

STORAGE BIN - REMOVAL

............23-116

STOWAGE TRAY - INSTALLATION, REAR

FLOOR

............................23-121

STOWAGE TRAY - REMOVAL, REAR

FLOOR

............................23-121

STRAP - INSTALLATION, CAB-TO- BED

GROUND

...........................8A-14STRAP - INSTALLATION, ENGINE-TO-

BODY GROUND......................8A-13

STRAP - INSTALLATION, HEATER CORE

GROUND...........................8A-15

STRAP - REMOVAL, CAB-TO- BED

GROUND...........................8A-14

STRAP - REMOVAL, ENGINE-TO-BODY

GROUND...........................8A-13

STRAP - REMOVAL, HEATER CORE

GROUND...........................8A-14

STRETCH - INSPECTION, MEASURING

TIMING CHAIN........9-114,9-170,9-227,9-58

STRIKER - ADJUSTMENT, LATCH.......23-102

STRIKER - INSTALLATION, GLOVE BOX

LATCH ............................23-113

STRIKER - INSTALLATION, LATCH . 23-102,23-65,

23-73

STRIKER - LOWER - INSTALLATION,

LATCH .............................23-82

STRIKER - LOWER - REMOVAL, LATCH . . . 23-82

STRIKER - REMOVAL, GLOVE BOX

LATCH ............................23-113

STRIKER - REMOVAL, LATCH....23-102,23-65,

23-73

STRIKER - UPPER - INSTALLATION,

LATCH .............................23-82

STRIKER - UPPER - REMOVAL, LATCH . . . 23-82

STRIPE - INSTALLATION, TAPE..........23-88

STRIPE - REMOVAL, TAPE.............23-88

STRIPES AND DECALS - INSTALLATION,

BODY..............................23-87

STRIPES AND DECALS - REMOVAL,

BODY..............................23-87

STRUCTURAL ADHESIVE LOCATIONS,

SPECIFICATIONS.....................23-44

STUDS - INSTALLATION...............22-12

STUDS - REMOVAL...................22-12

SUCTION AND DISCHARGE LINE -

INSTALLATION.......................24-51

SUCTION AND DISCHARGE LINE -

REMOVAL..........................24-50

SUN VISOR - INSTALLATION..........23-127

SUN VISOR - REMOVAL..............23-127

SUPPLIES - DESCRIPTION, 5 VOLT......8E-17

SUPPLIES - OPERATION, 5 VOLT........8E-19

SUPPLY - DIAGNOSIS AND TESTING,

VACUUM............................8P-2

SUPPLY RESTRICTIONS - DIAGNOSIS

AND TESTING, FUEL..................14-56

SUPPORT - INSTALLATION, LUMBAR....23-133

SUPPORT - REMOVAL, LUMBAR.......23-133

SUPPORT BRACKET - INSTALLATION,

REARVIEW MIRROR.................23-126

SUPPORT PLATE - INSTALLATION........5-32

SUPPORT PLATE - REMOVAL............5-32

SUPPRESSION COMPONENTS -

DESCRIPTION, RADIO NOISE...........8A-12

SUPPRESSION COMPONENTS -

DIAGNOSIS AND TESTING, RADIO

NOISE.............................8A-12

SUSPENSION - STANDARD

PROCEDURES, ALIGNMENT LINK/COIL.....2-5

SUSPENSION, SPECIAL TOOLS -

INDEPENDENT FRONT...................2-9

SUSPENSION, SPECIAL TOOLS -

LINK/COIL...........................2-16

SUSPENSION-REAR, SPECIAL TOOLS.....2-28

SWITCH - DESCRIPTION

...............8P-12

SWITCH - DESCRIPTION, A/C HIGH

PRESSURE

.........................24-20

SWITCH - DESCRIPTION, A/C LOW

PRESSURE

.........................24-21

SWITCH - DESCRIPTION, BLOWER

MOTOR

............................24-24

SWITCH - DESCRIPTION, BRAKE LAMP

....8L-4

SWITCH - DESCRIPTION, CLUTCH

PEDAL POSITION

.....................6-22

SWITCH - DESCRIPTION, DOOR AJAR

....8L-34

SWITCH - DESCRIPTION, DOOR

CYLINDER LOCK

......................8N-5

SWITCH - DESCRIPTION, DRIVER

POWER SEAT

.......................8N-16

SWITCH - DESCRIPTION, DRIVER SEAT

HEATER

.............................8G-7

SWITCH - DESCRIPTION, HEADLAMP

....8L-18

SWITCH - DESCRIPTION, HORN

..........8H-4

SWITCH - DESCRIPTION, IGNITION

......19-11

BR/BEINDEX 33

Description Group-Page Description Group-Page Description Group-Page

Page 2882 of 2889

TANK MODULE - DESCRIPTION, FUEL....14-78

TANK MODULE - INSTALLATION, FUEL....14-79

TANK MODULE - OPERATION, FUEL......14-78

TANK MODULE - REMOVAL, FUEL.......14-78

TAPE STRIPE - INSTALLATION..........23-88

TAPE STRIPE - REMOVAL..............23-88

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC............9-151,9-206,9-38,9-95

TASK MANAGER - DESCRIPTION........25-15

TASK MANAGER - OPERATION..........25-19

TEMP SENSOR - 3.9L/5.2L/5.9L -

DESCRIPTION, ENGINE COOLANT.........7-48

TEMP SENSOR - 3.9L/5.2L/5.9L -

INSTALLATION, ENGINE COOLANT........7-48

TEMP SENSOR - 3.9L/5.2L/5.9L -

OPERATION, ENGINE COOLANT..........7-48

TEMP SENSOR - 3.9L/5.2L/5.9L -

REMOVAL, ENGINE COOLANT............7-48

TEMP SENSOR - DESCRIPTION,

AMBIENT..........................8M-11

TEMP SENSOR - INSTALLATION,

AMBIENT..........................8M-13

TEMP SENSOR - OPERATION, AMBIENT . . 8M-11

TEMP SENSOR - REMOVAL, AMBIENT . . . 8M-12

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE............................8J-19

TEMPERATURE GAUGE - OPERATION,

ENGINE............................8J-19

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY...........................8F-29

TEMPERATURE SENSOR - DESCRIPTION,

FUEL..............................14-99

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION . . . 21-262,21-433,21-606,21-779

TEMPERATURE SENSOR - DIAGNOSIS &

TESTING, AMBIENT..................8M-12

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-29

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-29

TEMPERATURE SENSOR - OPERATION,

FUEL.............................14-100

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION . . . 21-262,21-433,21-606,21-779

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-29

TENSIONER - ADJUSTMENT, CABLE.......5-40

TENSIONER - DESCRIPTION, TIMING

BELT/CHAIN..........................9-57

TENSIONER - OPERATION, TIMING

BELT/CHAIN..........................9-57

TENSIONERS - 3.9L/5.2L/5.9L -

DESCRIPTION, BELT...................7-19

TENSIONERS - 3.9L/5.2L/5.9L -

INSTALLATION, BELT...................7-20

TENSIONERS - 3.9L/5.2L/5.9L -

OPERATION, BELT.....................7-19

TENSIONERS - 3.9L/5.2L/5.9L -

REMOVAL, BELT......................7-20

TENSIONERS - 5.9L DIESEL -

DESCRIPTION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

INSTALLATION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

OPERATION, BELT.....................7-23

TENSIONERS - 5.9L DIESEL - REMOVAL,

BELT ...............................7-23

TENSIONERS - 8.0L - DESCRIPTION,

BELT ...............................7-20

TENSIONERS - 8.0L - INSTALLATION,

BELT ...............................7-22

TENSIONERS - 8.0L - OPERATION, BELT . . . 7-20

TENSIONERS - 8.0L - REMOVAL, BELT.....7-21

TERMINAL - INSTALLATION.........8W-01-11

TERMINAL - REMOVAL.............8W-01-11

TEST - DIAGNOSIS AND TESTING, FUEL

INJECTOR.....................14-53,14-95

TEST - DIAGNOSIS AND TESTING, FUEL

PRESSURE LEAK DOWN

................14-2

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP AMPERAGE

....................14-10

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP CAPACITY

......................14-9

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP PRESSURE

....................14-10

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE

. . 21-144,21-315,21-487,

21-658TEST - DIAGNOSIS AND TESTING,

POWR-LOKY........................3-161

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-3

TEST - INSPECTION WINDSHIELD

WIPERS/WASHERS, ROAD.............30-18

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-11

TEST - STANDARD PROCEDURE,

HYDROMETER.......................8F-12

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-15

TEST - STANDARD PROCEDURE, LOAD . . . 8F-14

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE...............8F-13

TEST - STANDARD PROCEDURE,

VERIFICATION........................8O-5

TEST INSPECTION - DESCRIPTION,

ROAD..............................30-15

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION..........................25-1

TEST MODE - DESCRIPTION, STATE

DISPLAY............................25-1

TETHER - INSTALLATION, CHILD.........8O-9

TETHER - REMOVAL, CHILD.............8O-9

THEFT SECURITY - DESCRIPTION,

VEHICLE............................8Q-1

THEFT SECURITY - OPERATION, VEHICLE . . 8Q-2

THEFT SECURITY SYSTEM - DIAGNOSIS

AND TESTING, VEHICLE................8Q-3

THERMOSTAT - 3.9L/5.2L/5.9L -

DESCRIPTION, ENGINE COOLANT.........7-49

THERMOSTAT - 3.9L/5.2L/5.9L -

INSTALLATION, ENGINE COOLANT........7-50

THERMOSTAT - 3.9L/5.2L/5.9L -

OPERATION, ENGINE COOLANT..........7-49

THERMOSTAT - 3.9L/5.2L/5.9L -

REMOVAL, ENGINE COOLANT............7-49

THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE COOLANT.........7-54

THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE COOLANT........7-55

THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE COOLANT..........7-54

THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE COOLANT............7-55

THERMOSTAT - 8.0L - DESCRIPTION,

ENGINE COOLANT.....................7-52

THERMOSTAT - 8.0L - INSTALLATION,

ENGINE COOLANT.....................7-53

THERMOSTAT - 8.0L - OPERATION,

ENGINE COOLANT.....................7-52

THERMOSTAT - 8.0L - REMOVAL,

ENGINE COOLANT.....................7-52

THERMOSTAT - DIAGNOSIS AND

TESTING....................7-49,7-52,7-54

THOMAS AND BETTS - INSTALLATION,

CONNECTOR.....................8W-01-10

THOMAS AND BETTS - REMOVAL,

CONNECTOR......................8W-01-9

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM......21-159,21-330,

21-502,21-673

THREADED HOLE REPAIR -

DESCRIPTION......................Intro.-6

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN . 9-11,9-125,9-181,

9-238,9-68

THROTTLE BODY - DESCRIPTION........14-48

THROTTLE BODY - OPERATION.........14-48

THROTTLE CONTROL CABLE -

INSTALLATION.................14-105,14-50

THROTTLE CONTROL CABLE -

REMOVAL....................14-104,14-50

THROTTLE POSITION SENSOR -

DESCRIPTION.......................14-51

THROTTLE POSITION SENSOR -

OPERATION.........................14-51

THROTTLE VALVE CABLE -

ADJUSTMENTS, TRANSMISSION

. 21-254,21-425,

21-598,21-771

THROTTLE VALVE CABLE -

DESCRIPTION

....21-253,21-424,21-597,21-770

TIMER MODULE - DESCRIPTION, BODY

CONTROL/CENTRAL

...................8E-1

TIMER MODULE - DIAGNOSIS AND

TESTING, CENTRAL

....................8E-4

TIMER MODULE - INSTALLATION, BODY

CONTROL/CENTRAL

...................8E-6TIMER MODULE - OPERATION, BODY

CONTROL/CENTRAL...................8E-3

TIMER MODULE - REMOVAL, BODY

CONTROL/CENTRAL...................8E-5

TIMING - DIAGNOSIS AND TESTING,

FUEL INJECTION PUMP...............14-66

TIMING BELT / CHAIN COVER(S) -

INSTALLATION........9-113,9-169,9-226,9-56

TIMING BELT / CHAIN COVER(S) -

REMOVAL............9-113,9-169,9-225,9-56

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION........9-115,9-170,9-227,9-58

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL............9-114,9-170,9-226,9-57

TIMING BELT/CHAIN TENSIONER -

DESCRIPTION........................9-57

TIMING BELT/CHAIN TENSIONER -

OPERATION..........................9-57

TIMING CHAIN STRETCH - INSPECTION,

MEASURING..........9-114,9-170,9-227,9-58

TIMING, SPECIFICATIONS - IGNITION......8I-3

TIPS - CLEANING, APPEARANCE........30-21

TIRE - DESCRIPTION, SPARE............22-9

TIRE AND WHEEL BALANCE -

STANDARD PROCEDURES...............22-4

TIRE AND WHEEL RUNOUT - DIAGNOSIS

AND TESTING........................22-1

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING........................22-8

TIRE PRESSURES - INSPECTION.........30-8

TIRE REVOLUTIONS PER MILE,

SPECIFICATIONS......................22-9

TIRE ROTATION - STANDARD

PROCEDURES........................22-2

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING........................22-7

TIRE WINCH - INSTALLATION, SPARE....13-10

TIRE WINCH - REMOVAL, SPARE........13-10

TIRES - DESCRIPTION.............22-5,22-6

TO GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT.............8W-01-6

TO GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR SHORT....8W-01-7

TO OIL COOLER - INSTALLATION, AIR.....7-88

TO OIL COOLER - REMOVAL, AIR.........7-87

TO OIL COOLER - REMOVAL, WATER......7-87

TO USE WIRING DIAGRAMS -

DESCRIPTION, HOW................8W-01-1

TOOLS - 5.2L ENGINE, SPECIAL..........9-77

TOOLS - 5.9L DIESEL ENGINE, SPECIAL . . 9-244

TOOLS - 5.9L ENGINE, SPECIAL.........9-134

TOOLS - 8.0L ENGINE, SPECIAL.........9-188

TOOLS - AUDIO SYSTEMS, SPECIAL......8A-4

TOOLS - BASE BRAKES, SPECIAL.........5-4

TOOLS - COOLING, SPECIAL.............7-18

TOOLS - DIESEL FUEL SYSTEM,

SPECIAL...........................14-59

TOOLS - FRONT AXLE, SPECIAL..........3-58

TOOLS - FRONT AXLES, SPECIAL.........3-25

TOOLS - FUEL SYSTEM, SPECIAL . . . 14-36,14-4

TOOLS - HEADLAMP ALIGNMENT,

SPECIAL............................8L-4

TOOLS - INDEPENDENT FRONT

SUSPENSION, SPECIAL..................2-9

TOOLS - LINK/COIL SUSPENSION,

SPECIAL

............................2-16

TOOLS - NV5600 MANUAL

TRANSMISSION, SPECIAL

.............21-127

TOOLS - OVERHEAD CONSOLE

SYSTEMS, SPECIAL

...................8M-8

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL

................8W-97-2

TOOLS - POWER STEERING GEAR,

SPECIAL

...........................19-20

TOOLS - POWER STEERING PUMP,

SPECIAL

...........................19-36

TOOLS - PROPELLER SHAFT, SPECIAL

......3-8

TOOLS - RE TRANSMISSION, SPECIAL

. . 21-534,

21-704

TOOLS - RE TRANSMISSIONS, SPECIAL

. 21-188,

21-359

TOOLS - STEERING LINKAGE, SPECIAL

. . . 19-39,

19-42

TOOLS - SUSPENSION-REAR, SPECIAL

....2-28

TOOLS, AIRBAG SYSTEM - SPECIAL

......8O-6

TOOLS, WIRING/TERMINAL - SPECIAL

. 8W-01-8

BR/BEINDEX 35

Description Group-Page Description Group-Page Description Group-Page