warning DODGE RAM 2001 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 480 of 2889

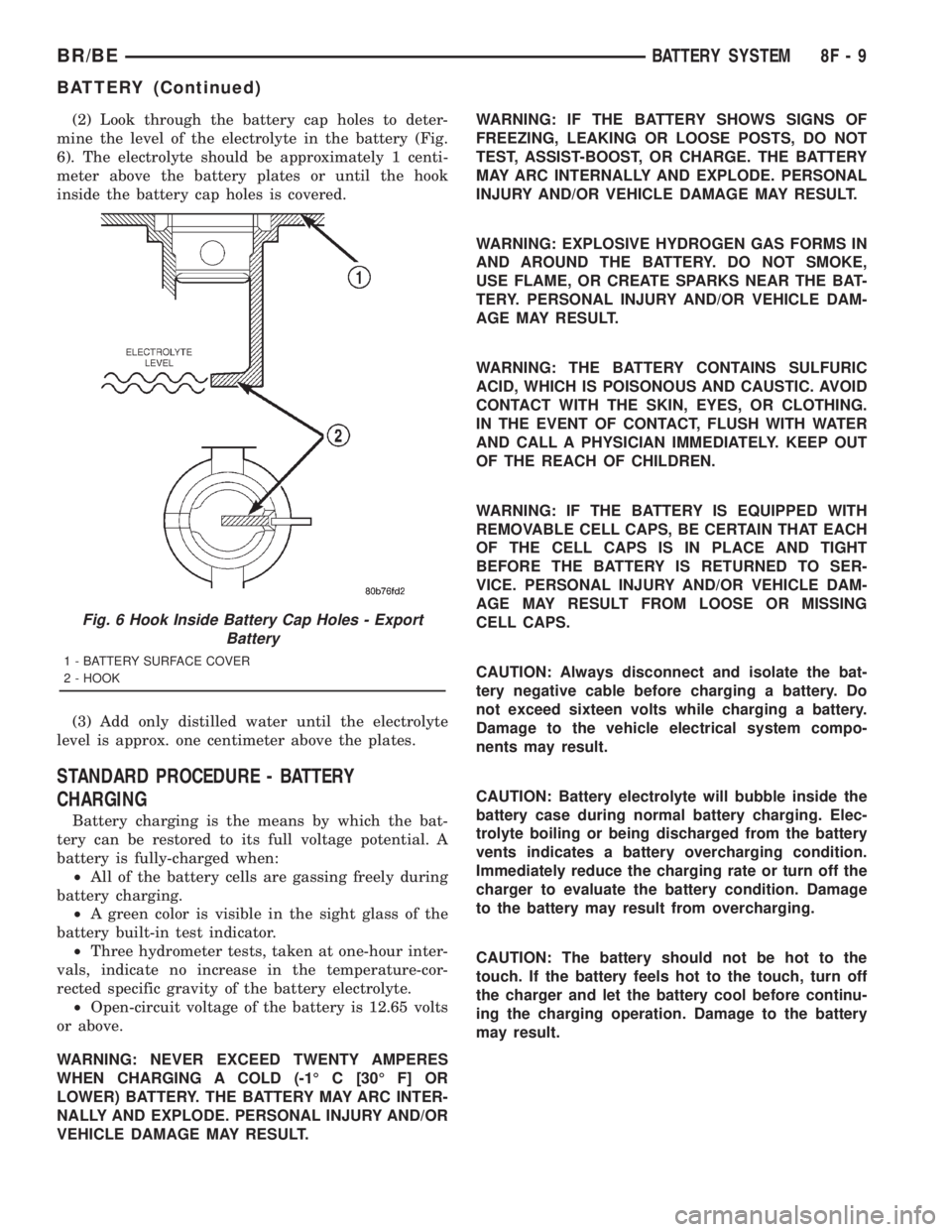

(2) Look through the battery cap holes to deter-

mine the level of the electrolyte in the battery (Fig.

6). The electrolyte should be approximately 1 centi-

meter above the battery plates or until the hook

inside the battery cap holes is covered.

(3) Add only distilled water until the electrolyte

level is approx. one centimeter above the plates.

STANDARD PROCEDURE - BATTERY

CHARGING

Battery charging is the means by which the bat-

tery can be restored to its full voltage potential. A

battery is fully-charged when:

²All of the battery cells are gassing freely during

battery charging.

²A green color is visible in the sight glass of the

battery built-in test indicator.

²Three hydrometer tests, taken at one-hour inter-

vals, indicate no increase in the temperature-cor-

rected specific gravity of the battery electrolyte.

²Open-circuit voltage of the battery is 12.65 volts

or above.

WARNING: NEVER EXCEED TWENTY AMPERES

WHEN CHARGING A COLD (-1É C [30É F] OR

LOWER) BATTERY. THE BATTERY MAY ARC INTER-

NALLY AND EXPLODE. PERSONAL INJURY AND/OR

VEHICLE DAMAGE MAY RESULT.WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

CAUTION: Always disconnect and isolate the bat-

tery negative cable before charging a battery. Do

not exceed sixteen volts while charging a battery.

Damage to the vehicle electrical system compo-

nents may result.

CAUTION: Battery electrolyte will bubble inside the

battery case during normal battery charging. Elec-

trolyte boiling or being discharged from the battery

vents indicates a battery overcharging condition.

Immediately reduce the charging rate or turn off the

charger to evaluate the battery condition. Damage

to the battery may result from overcharging.

CAUTION: The battery should not be hot to the

touch. If the battery feels hot to the touch, turn off

the charger and let the battery cool before continu-

ing the charging operation. Damage to the battery

may result.

Fig. 6 Hook Inside Battery Cap Holes - Export

Battery

1 - BATTERY SURFACE COVER

2 - HOOK

BR/BEBATTERY SYSTEM 8F - 9

BATTERY (Continued)

Page 482 of 2889

in a completely discharged battery. At first, the

charging current (amperage) will be low. As the bat-

tery charges, the specific gravity of the electrolyte

will gradually rise.

The Battery Charging Time Table gives an indica-

tion of the time required to charge a typical battery

at room temperature based upon the battery state-of-

charge and the charger capacity.

BATTERY CHARGING TIME TABLE

Charging

Amperage5 Amps10

Amps20 Amps

Open Circuit

VoltageHours Charging @ 21É C

(70É F)

12.25 to 12.49 6 hours 3 hours 1.5

hours

12.00 to 12.24 10 hours 5 hours 2.5

hours

10.00 to 11.99 14 hours 7 hours 3.5

hours

Below 10.00 18 hours 9 hours 4.5

hours

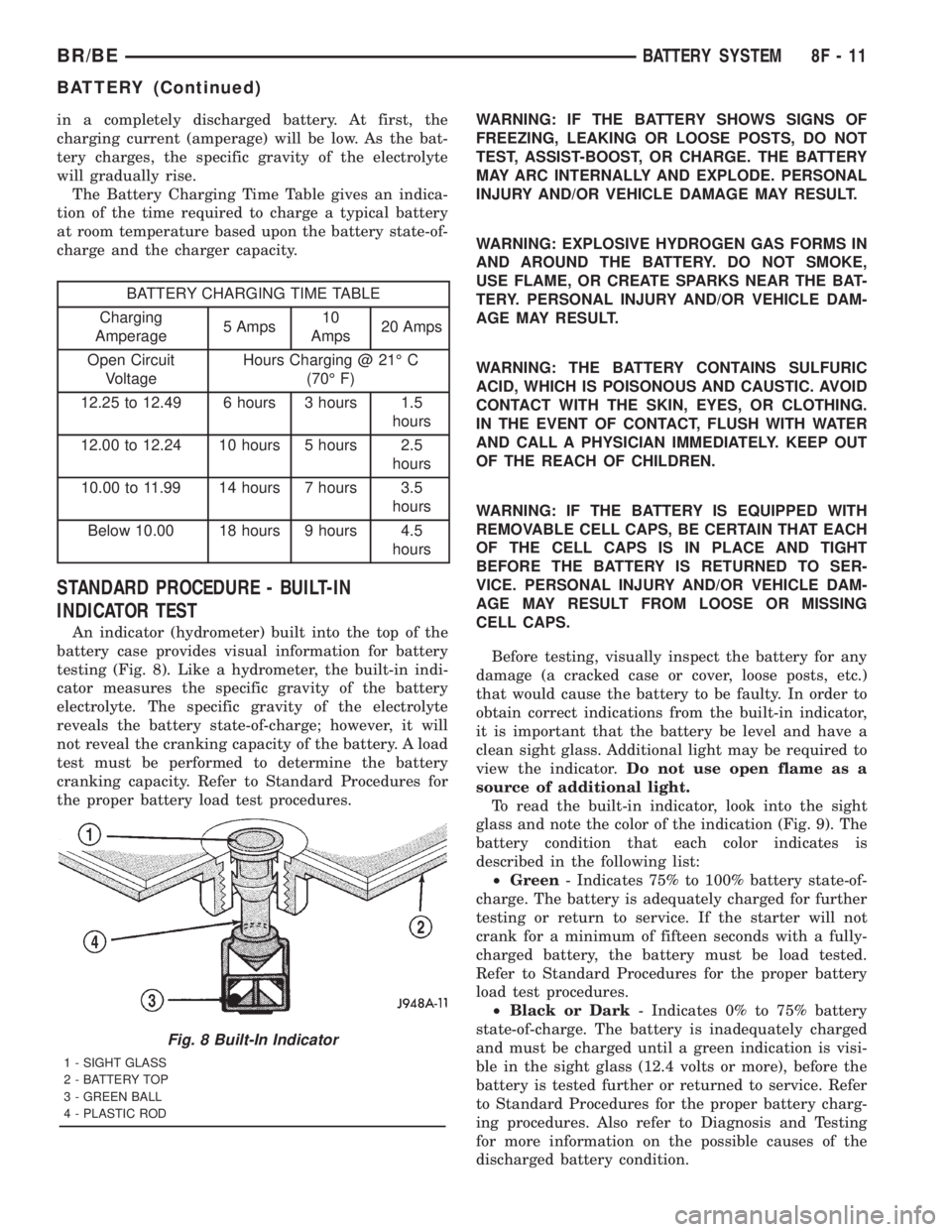

STANDARD PROCEDURE - BUILT-IN

INDICATOR TEST

An indicator (hydrometer) built into the top of the

battery case provides visual information for battery

testing (Fig. 8). Like a hydrometer, the built-in indi-

cator measures the specific gravity of the battery

electrolyte. The specific gravity of the electrolyte

reveals the battery state-of-charge; however, it will

not reveal the cranking capacity of the battery. A load

test must be performed to determine the battery

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures.WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

Before testing, visually inspect the battery for any

damage (a cracked case or cover, loose posts, etc.)

that would cause the battery to be faulty. In order to

obtain correct indications from the built-in indicator,

it is important that the battery be level and have a

clean sight glass. Additional light may be required to

view the indicator.Do not use open flame as a

source of additional light.

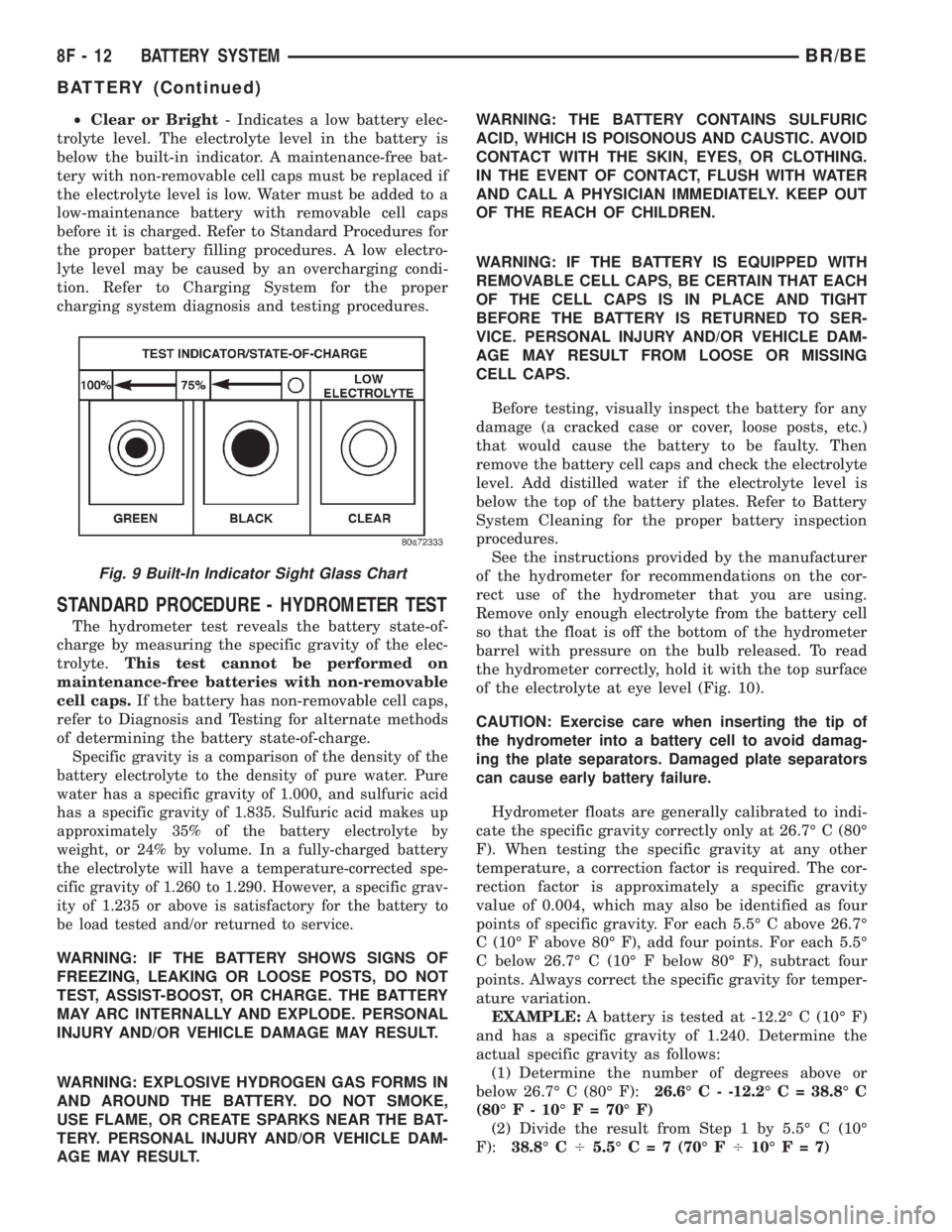

To read the built-in indicator, look into the sight

glass and note the color of the indication (Fig. 9). The

battery condition that each color indicates is

described in the following list:

²Green- Indicates 75% to 100% battery state-of-

charge. The battery is adequately charged for further

testing or return to service. If the starter will not

crank for a minimum of fifteen seconds with a fully-

charged battery, the battery must be load tested.

Refer to Standard Procedures for the proper battery

load test procedures.

²Black or Dark- Indicates 0% to 75% battery

state-of-charge. The battery is inadequately charged

and must be charged until a green indication is visi-

ble in the sight glass (12.4 volts or more), before the

battery is tested further or returned to service. Refer

to Standard Procedures for the proper battery charg-

ing procedures. Also refer to Diagnosis and Testing

for more information on the possible causes of the

discharged battery condition.

Fig. 8 Built-In Indicator

1 - SIGHT GLASS

2 - BATTERY TOP

3 - GREEN BALL

4 - PLASTIC ROD

BR/BEBATTERY SYSTEM 8F - 11

BATTERY (Continued)

Page 483 of 2889

²Clear or Bright- Indicates a low battery elec-

trolyte level. The electrolyte level in the battery is

below the built-in indicator. A maintenance-free bat-

tery with non-removable cell caps must be replaced if

the electrolyte level is low. Water must be added to a

low-maintenance battery with removable cell caps

before it is charged. Refer to Standard Procedures for

the proper battery filling procedures. A low electro-

lyte level may be caused by an overcharging condi-

tion. Refer to Charging System for the proper

charging system diagnosis and testing procedures.

STANDARD PROCEDURE - HYDROMETER TEST

The hydrometer test reveals the battery state-of-

charge by measuring the specific gravity of the elec-

trolyte.This test cannot be performed on

maintenance-free batteries with non-removable

cell caps.If the battery has non-removable cell caps,

refer to Diagnosis and Testing for alternate methods

of determining the battery state-of-charge.

Specific gravity is a comparison of the density of the

battery electrolyte to the density of pure water. Pure

water has a specific gravity of 1.000, and sulfuric acid

has a specific gravity of 1.835. Sulfuric acid makes up

approximately 35% of the battery electrolyte by

weight, or 24% by volume. In a fully-charged battery

the electrolyte will have a temperature-corrected spe-

cific gravity of 1.260 to 1.290. However, a specific grav-

ity of 1.235 or above is satisfactory for the battery to

be load tested and/or returned to service.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

Before testing, visually inspect the battery for any

damage (a cracked case or cover, loose posts, etc.)

that would cause the battery to be faulty. Then

remove the battery cell caps and check the electrolyte

level. Add distilled water if the electrolyte level is

below the top of the battery plates. Refer to Battery

System Cleaning for the proper battery inspection

procedures.

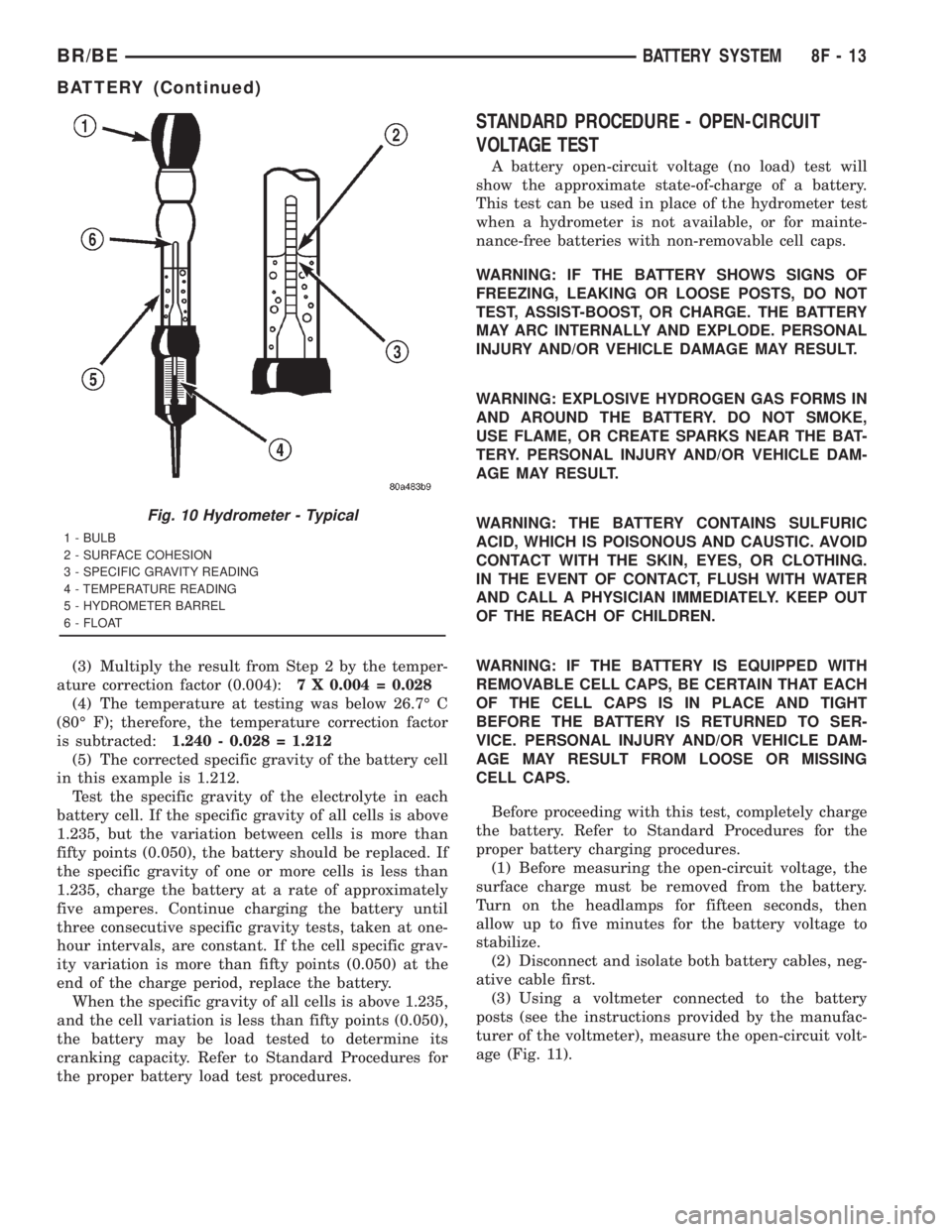

See the instructions provided by the manufacturer

of the hydrometer for recommendations on the cor-

rect use of the hydrometer that you are using.

Remove only enough electrolyte from the battery cell

so that the float is off the bottom of the hydrometer

barrel with pressure on the bulb released. To read

the hydrometer correctly, hold it with the top surface

of the electrolyte at eye level (Fig. 10).

CAUTION: Exercise care when inserting the tip of

the hydrometer into a battery cell to avoid damag-

ing the plate separators. Damaged plate separators

can cause early battery failure.

Hydrometer floats are generally calibrated to indi-

cate the specific gravity correctly only at 26.7É C (80É

F). When testing the specific gravity at any other

temperature, a correction factor is required. The cor-

rection factor is approximately a specific gravity

value of 0.004, which may also be identified as four

points of specific gravity. For each 5.5É C above 26.7É

C (10É F above 80É F), add four points. For each 5.5É

C below 26.7É C (10É F below 80É F), subtract four

points. Always correct the specific gravity for temper-

ature variation.

EXAMPLE:A battery is tested at -12.2É C (10É F)

and has a specific gravity of 1.240. Determine the

actual specific gravity as follows:

(1) Determine the number of degrees above or

below 26.7É C (80É F):26.6É C - -12.2É C = 38.8É C

(80É F - 10É F = 70É F)

(2) Divide the result from Step 1 by 5.5É C (10É

F):38.8É C45.5ÉC=7(70É F410ÉF=7)

Fig. 9 Built-In Indicator Sight Glass Chart

8F - 12 BATTERY SYSTEMBR/BE

BATTERY (Continued)

Page 484 of 2889

(3) Multiply the result from Step 2 by the temper-

ature correction factor (0.004):7 X 0.004 = 0.028

(4) The temperature at testing was below 26.7É C

(80É F); therefore, the temperature correction factor

is subtracted:1.240 - 0.028 = 1.212

(5) The corrected specific gravity of the battery cell

in this example is 1.212.

Test the specific gravity of the electrolyte in each

battery cell. If the specific gravity of all cells is above

1.235, but the variation between cells is more than

fifty points (0.050), the battery should be replaced. If

the specific gravity of one or more cells is less than

1.235, charge the battery at a rate of approximately

five amperes. Continue charging the battery until

three consecutive specific gravity tests, taken at one-

hour intervals, are constant. If the cell specific grav-

ity variation is more than fifty points (0.050) at the

end of the charge period, replace the battery.

When the specific gravity of all cells is above 1.235,

and the cell variation is less than fifty points (0.050),

the battery may be load tested to determine its

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures.

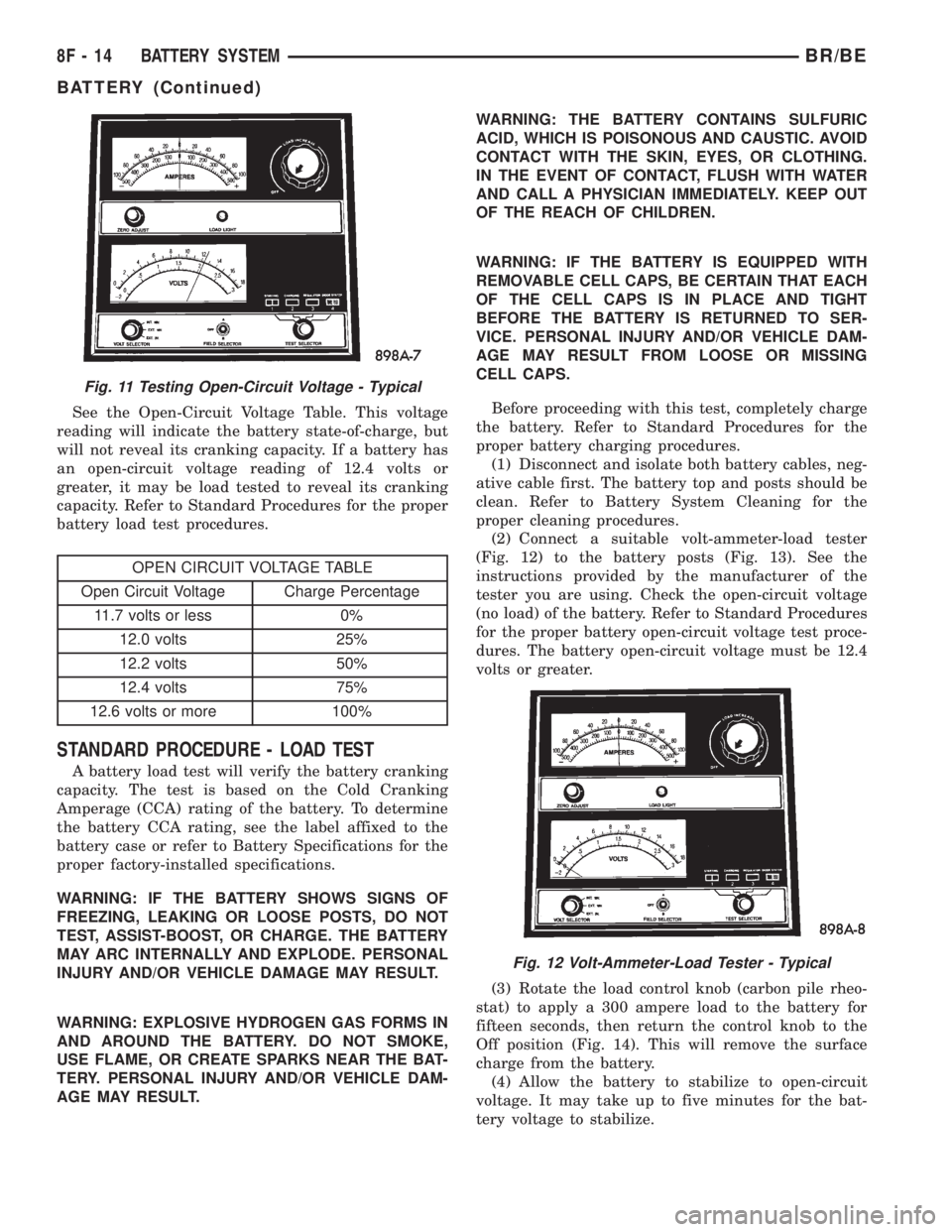

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used in place of the hydrometer test

when a hydrometer is not available, or for mainte-

nance-free batteries with non-removable cell caps.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

Before proceeding with this test, completely charge

the battery. Refer to Standard Procedures for the

proper battery charging procedures.

(1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 11).

Fig. 10 Hydrometer - Typical

1 - BULB

2 - SURFACE COHESION

3 - SPECIFIC GRAVITY READING

4 - TEMPERATURE READING

5 - HYDROMETER BARREL

6 - FLOAT

BR/BEBATTERY SYSTEM 8F - 13

BATTERY (Continued)

Page 485 of 2889

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity. Refer to Standard Procedures for the proper

battery load test procedures.

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

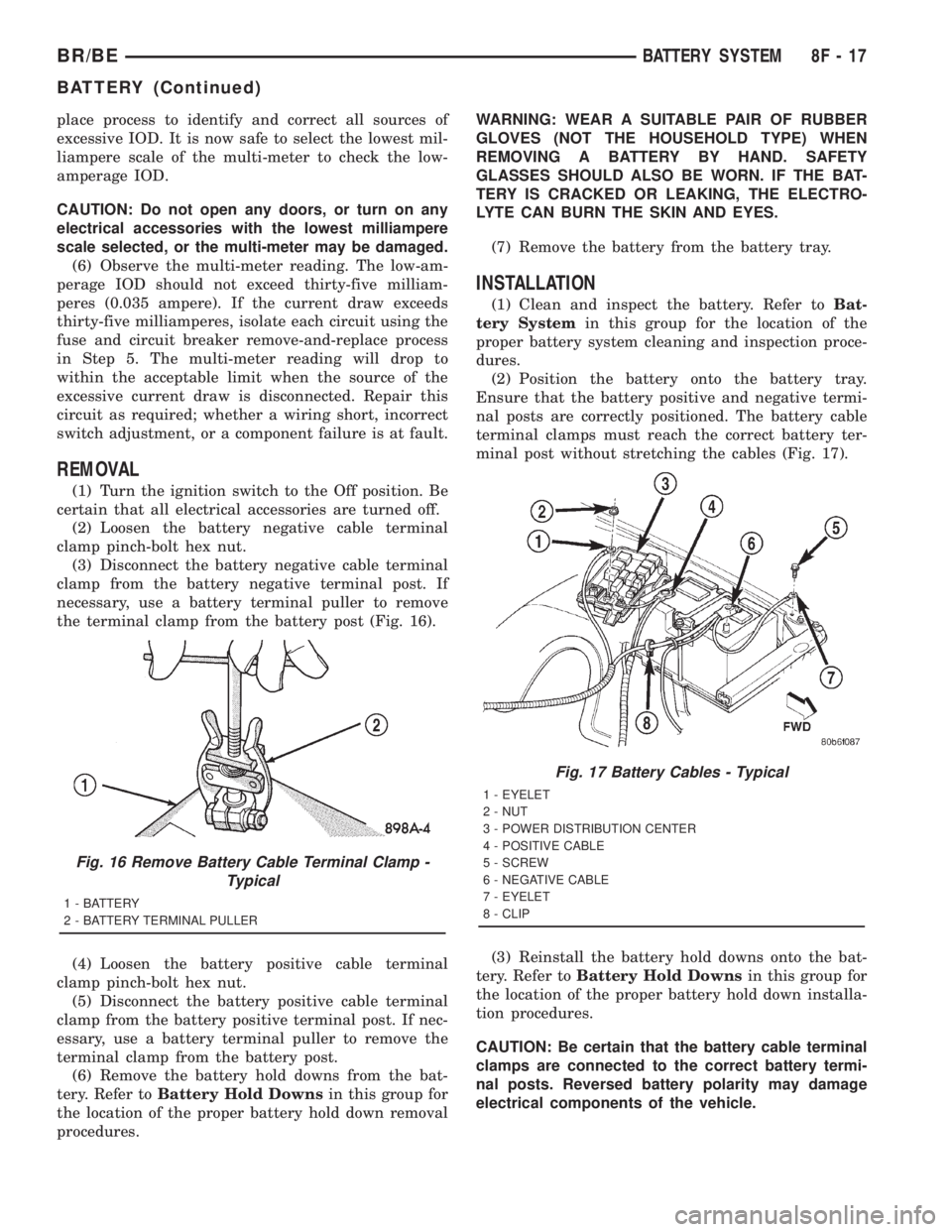

STANDARD PROCEDURE - LOAD TEST

A battery load test will verify the battery cranking

capacity. The test is based on the Cold Cranking

Amperage (CCA) rating of the battery. To determine

the battery CCA rating, see the label affixed to the

battery case or refer to Battery Specifications for the

proper factory-installed specifications.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

Before proceeding with this test, completely charge

the battery. Refer to Standard Procedures for the

proper battery charging procedures.

(1) Disconnect and isolate both battery cables, neg-

ative cable first. The battery top and posts should be

clean. Refer to Battery System Cleaning for the

proper cleaning procedures.

(2) Connect a suitable volt-ammeter-load tester

(Fig. 12) to the battery posts (Fig. 13). See the

instructions provided by the manufacturer of the

tester you are using. Check the open-circuit voltage

(no load) of the battery. Refer to Standard Procedures

for the proper battery open-circuit voltage test proce-

dures. The battery open-circuit voltage must be 12.4

volts or greater.

(3) Rotate the load control knob (carbon pile rheo-

stat) to apply a 300 ampere load to the battery for

fifteen seconds, then return the control knob to the

Off position (Fig. 14). This will remove the surface

charge from the battery.

(4) Allow the battery to stabilize to open-circuit

voltage. It may take up to five minutes for the bat-

tery voltage to stabilize.

Fig. 11 Testing Open-Circuit Voltage - Typical

Fig. 12 Volt-Ammeter-Load Tester - Typical

8F - 14 BATTERY SYSTEMBR/BE

BATTERY (Continued)

Page 488 of 2889

place process to identify and correct all sources of

excessive IOD. It is now safe to select the lowest mil-

liampere scale of the multi-meter to check the low-

amperage IOD.

CAUTION: Do not open any doors, or turn on any

electrical accessories with the lowest milliampere

scale selected, or the multi-meter may be damaged.

(6) Observe the multi-meter reading. The low-am-

perage IOD should not exceed thirty-five milliam-

peres (0.035 ampere). If the current draw exceeds

thirty-five milliamperes, isolate each circuit using the

fuse and circuit breaker remove-and-replace process

in Step 5. The multi-meter reading will drop to

within the acceptable limit when the source of the

excessive current draw is disconnected. Repair this

circuit as required; whether a wiring short, incorrect

switch adjustment, or a component failure is at fault.

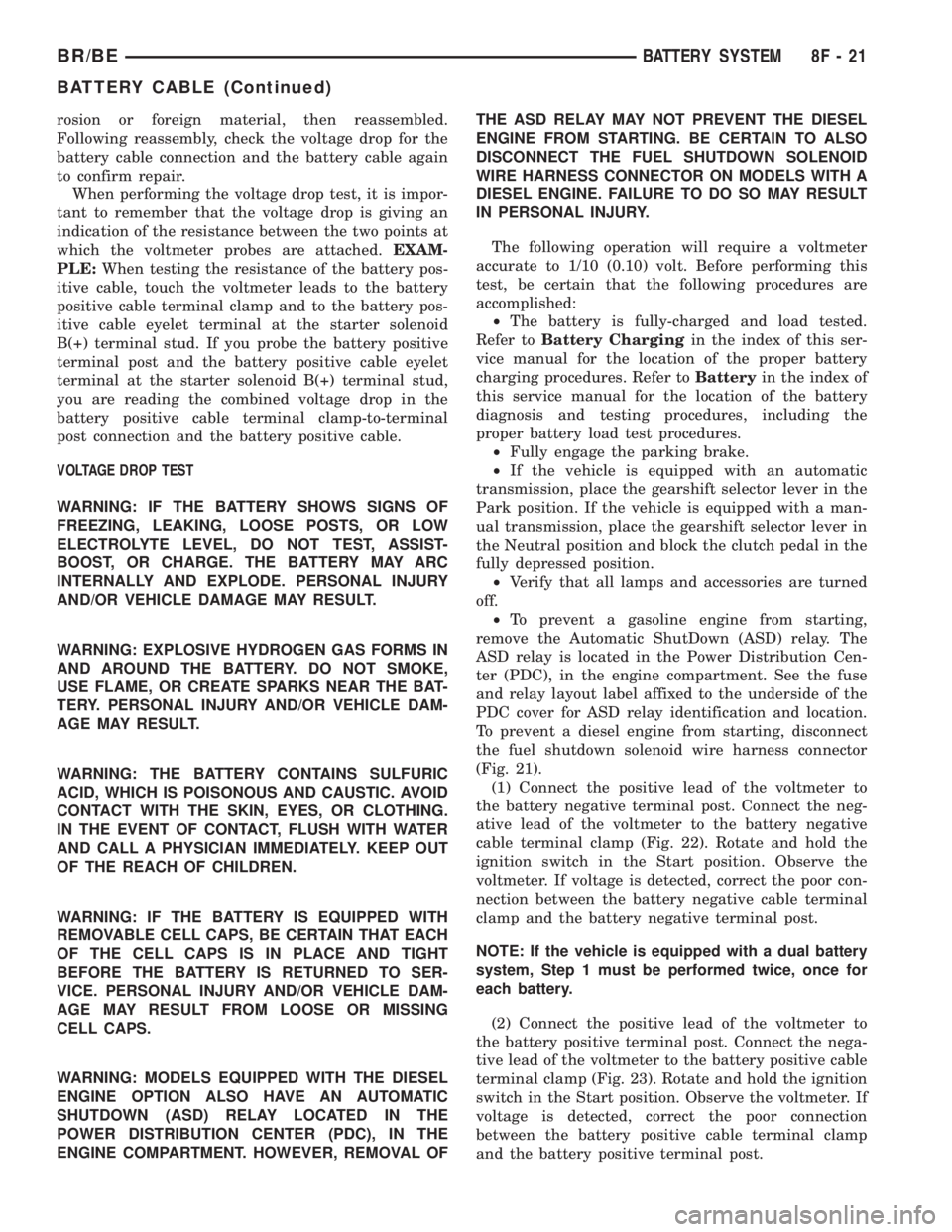

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post (Fig. 16).

(4) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post.

(6) Remove the battery hold downs from the bat-

tery. Refer toBattery Hold Downsin this group for

the location of the proper battery hold down removal

procedures.WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN

REMOVING A BATTERY BY HAND. SAFETY

GLASSES SHOULD ALSO BE WORN. IF THE BAT-

TERY IS CRACKED OR LEAKING, THE ELECTRO-

LYTE CAN BURN THE SKIN AND EYES.

(7) Remove the battery from the battery tray.

INSTALLATION

(1) Clean and inspect the battery. Refer toBat-

tery Systemin this group for the location of the

proper battery system cleaning and inspection proce-

dures.

(2) Position the battery onto the battery tray.

Ensure that the battery positive and negative termi-

nal posts are correctly positioned. The battery cable

terminal clamps must reach the correct battery ter-

minal post without stretching the cables (Fig. 17).

(3) Reinstall the battery hold downs onto the bat-

tery. Refer toBattery Hold Downsin this group for

the location of the proper battery hold down installa-

tion procedures.

CAUTION: Be certain that the battery cable terminal

clamps are connected to the correct battery termi-

nal posts. Reversed battery polarity may damage

electrical components of the vehicle.

Fig. 16 Remove Battery Cable Terminal Clamp -

Typical

1 - BATTERY

2 - BATTERY TERMINAL PULLER

Fig. 17 Battery Cables - Typical

1 - EYELET

2 - NUT

3 - POWER DISTRIBUTION CENTER

4 - POSITIVE CABLE

5 - SCREW

6 - NEGATIVE CABLE

7 - EYELET

8 - CLIP

BR/BEBATTERY SYSTEM 8F - 17

BATTERY (Continued)

Page 492 of 2889

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING, LOOSE POSTS, OR LOW

ELECTROLYTE LEVEL, DO NOT TEST, ASSIST-

BOOST, OR CHARGE. THE BATTERY MAY ARC

INTERNALLY AND EXPLODE. PERSONAL INJURY

AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

WARNING: MODELS EQUIPPED WITH THE DIESEL

ENGINE OPTION ALSO HAVE AN AUTOMATIC

SHUTDOWN (ASD) RELAY LOCATED IN THE

POWER DISTRIBUTION CENTER (PDC), IN THE

ENGINE COMPARTMENT. HOWEVER, REMOVAL OFTHE ASD RELAY MAY NOT PREVENT THE DIESEL

ENGINE FROM STARTING. BE CERTAIN TO ALSO

DISCONNECT THE FUEL SHUTDOWN SOLENOID

WIRE HARNESS CONNECTOR ON MODELS WITH A

DIESEL ENGINE. FAILURE TO DO SO MAY RESULT

IN PERSONAL INJURY.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

Refer toBattery Chargingin the index of this ser-

vice manual for the location of the proper battery

charging procedures. Refer toBatteryin the index of

this service manual for the location of the battery

diagnosis and testing procedures, including the

proper battery load test procedures.

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent a gasoline engine from starting,

remove the Automatic ShutDown (ASD) relay. The

ASD relay is located in the Power Distribution Cen-

ter (PDC), in the engine compartment. See the fuse

and relay layout label affixed to the underside of the

PDC cover for ASD relay identification and location.

To prevent a diesel engine from starting, disconnect

the fuel shutdown solenoid wire harness connector

(Fig. 21).

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable terminal clamp (Fig. 22). Rotate and hold the

ignition switch in the Start position. Observe the

voltmeter. If voltage is detected, correct the poor con-

nection between the battery negative cable terminal

clamp and the battery negative terminal post.

NOTE: If the vehicle is equipped with a dual battery

system, Step 1 must be performed twice, once for

each battery.

(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

terminal clamp (Fig. 23). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor connection

between the battery positive cable terminal clamp

and the battery positive terminal post.

BR/BEBATTERY SYSTEM 8F - 21

BATTERY CABLE (Continued)

Page 501 of 2889

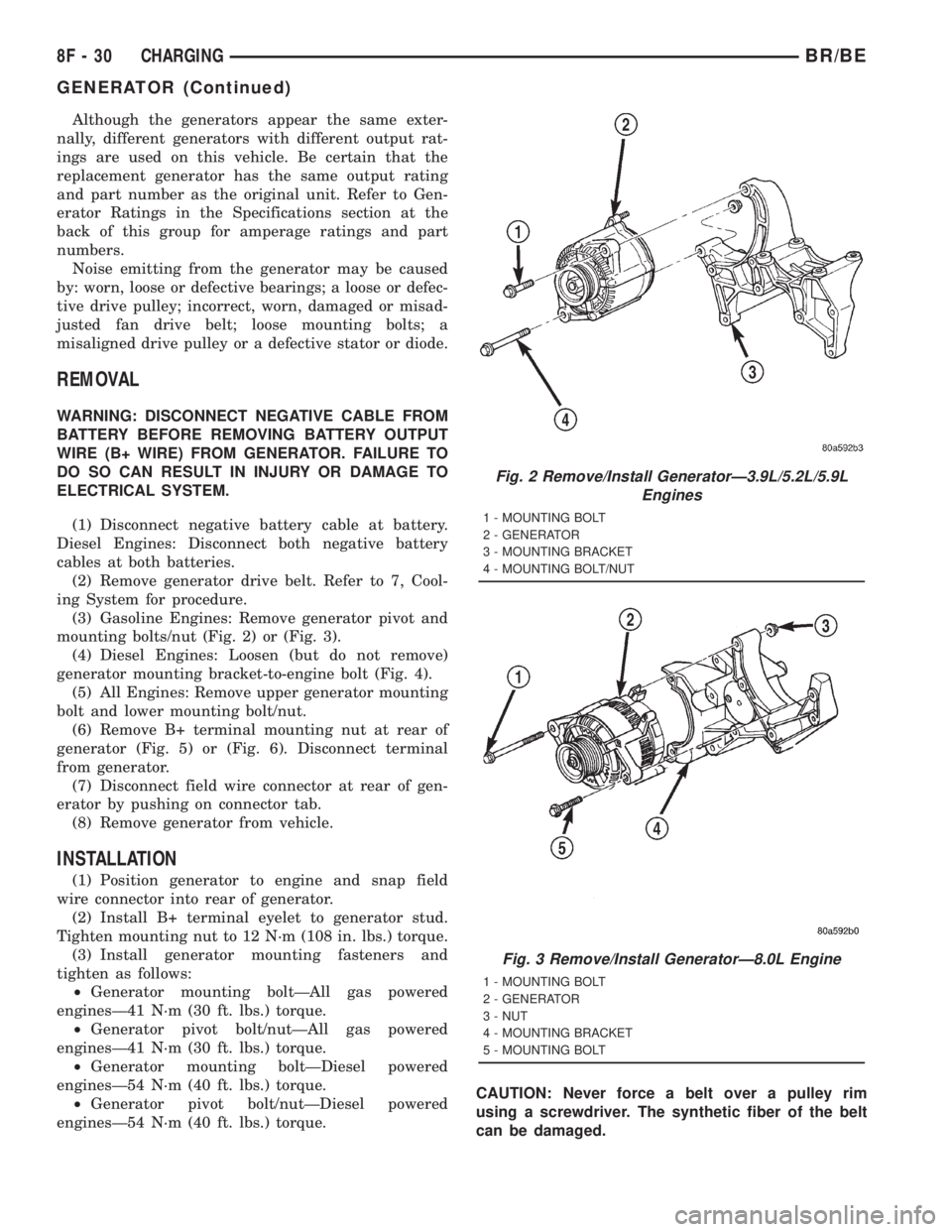

Although the generators appear the same exter-

nally, different generators with different output rat-

ings are used on this vehicle. Be certain that the

replacement generator has the same output rating

and part number as the original unit. Refer to Gen-

erator Ratings in the Specifications section at the

back of this group for amperage ratings and part

numbers.

Noise emitting from the generator may be caused

by: worn, loose or defective bearings; a loose or defec-

tive drive pulley; incorrect, worn, damaged or misad-

justed fan drive belt; loose mounting bolts; a

misaligned drive pulley or a defective stator or diode.

REMOVAL

WARNING: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE (B+ WIRE) FROM GENERATOR. FAILURE TO

DO SO CAN RESULT IN INJURY OR DAMAGE TO

ELECTRICAL SYSTEM.

(1) Disconnect negative battery cable at battery.

Diesel Engines: Disconnect both negative battery

cables at both batteries.

(2) Remove generator drive belt. Refer to 7, Cool-

ing System for procedure.

(3) Gasoline Engines: Remove generator pivot and

mounting bolts/nut (Fig. 2) or (Fig. 3).

(4) Diesel Engines: Loosen (but do not remove)

generator mounting bracket-to-engine bolt (Fig. 4).

(5) All Engines: Remove upper generator mounting

bolt and lower mounting bolt/nut.

(6) Remove B+ terminal mounting nut at rear of

generator (Fig. 5) or (Fig. 6). Disconnect terminal

from generator.

(7) Disconnect field wire connector at rear of gen-

erator by pushing on connector tab.

(8) Remove generator from vehicle.

INSTALLATION

(1) Position generator to engine and snap field

wire connector into rear of generator.

(2) Install B+ terminal eyelet to generator stud.

Tighten mounting nut to 12 N´m (108 in. lbs.) torque.

(3) Install generator mounting fasteners and

tighten as follows:

²Generator mounting boltÐAll gas powered

enginesÐ41 N´m (30 ft. lbs.) torque.

²Generator pivot bolt/nutÐAll gas powered

enginesÐ41 N´m (30 ft. lbs.) torque.

²Generator mounting boltÐDiesel powered

enginesÐ54 N´m (40 ft. lbs.) torque.

²Generator pivot bolt/nutÐDiesel powered

enginesÐ54 N´m (40 ft. lbs.) torque.CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

Fig. 2 Remove/Install GeneratorÐ3.9L/5.2L/5.9L

Engines

1 - MOUNTING BOLT

2 - GENERATOR

3 - MOUNTING BRACKET

4 - MOUNTING BOLT/NUT

Fig. 3 Remove/Install GeneratorÐ8.0L Engine

1 - MOUNTING BOLT

2 - GENERATOR

3 - NUT

4 - MOUNTING BRACKET

5 - MOUNTING BOLT

8F - 30 CHARGINGBR/BE

GENERATOR (Continued)

Page 505 of 2889

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Starter ring gear faulty. 1. Refer to Starter Motor in Removal and Installation.

Remove starter motor to inspect starter ring gear.

Replace starter ring gear, if required.

2. Starter motor faulty. 2. If all other starting system components and circuits test

OK, replace the starter motor assembly.

STARTER DOES NOT

DISENGAGE.1. Starter motor

improperly installed.1. Refer to Starter Motor in the Removal and Installation

section of this group. Tighten the starter mounting

hardware to the correct tightness specifications.

2. Starter relay faulty. 2. Refer to Starter Relay in the Diagnosis and Testing

section of this group. Replace starter relay, if required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch, if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace starter motor.

INSPECTION

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. Before removing any unit

from starting system for repair or diagnosis, perform

the following inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO 8, PASSIVE RESTRAINT SYS-

TEMS, BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

²Battery- Visually inspect battery for indica-

tions of physical damage and loose or corroded cable

connections. Determine the state-of-charge and

cranking capacity of battery. Charge or replace bat-

tery, if required. Refer toBatteryin 8, Battery.

Note: If equipped with diesel engine, a dual bat-

tery system is used, and both batteries must be

inspected.

²Ignition Switch- Visually inspect ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinder.

²Clutch Pedal Position Switch- If equipped

with manual transmission, visually inspect clutch

pedal position switch for indications of physical dam-

age and loose or corroded wire harness connections.

Refer toClutch Pedal Position Switchin 6,

Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, visually inspect park/

neutral position switch for indications of physical

damage and loose or corroded wire harness connec-tions. Refer toPark/Neutral Position Switchin

21, Transmission.

²Starter Relay- Visually inspect starter relay

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Motor- Visually inspect starter motor

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Solenoid- Visually inspect starter sole-

noid for indications of physical damage and loose or

corroded wire harness connections.

²Wiring- Visually inspect wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to 8, Wiring Diagrams.

TESTING

COLD CRANKING TEST

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. The battery must be fully-

charged and load-tested before proceeding. Refer to

Batteryin 8, Battery.

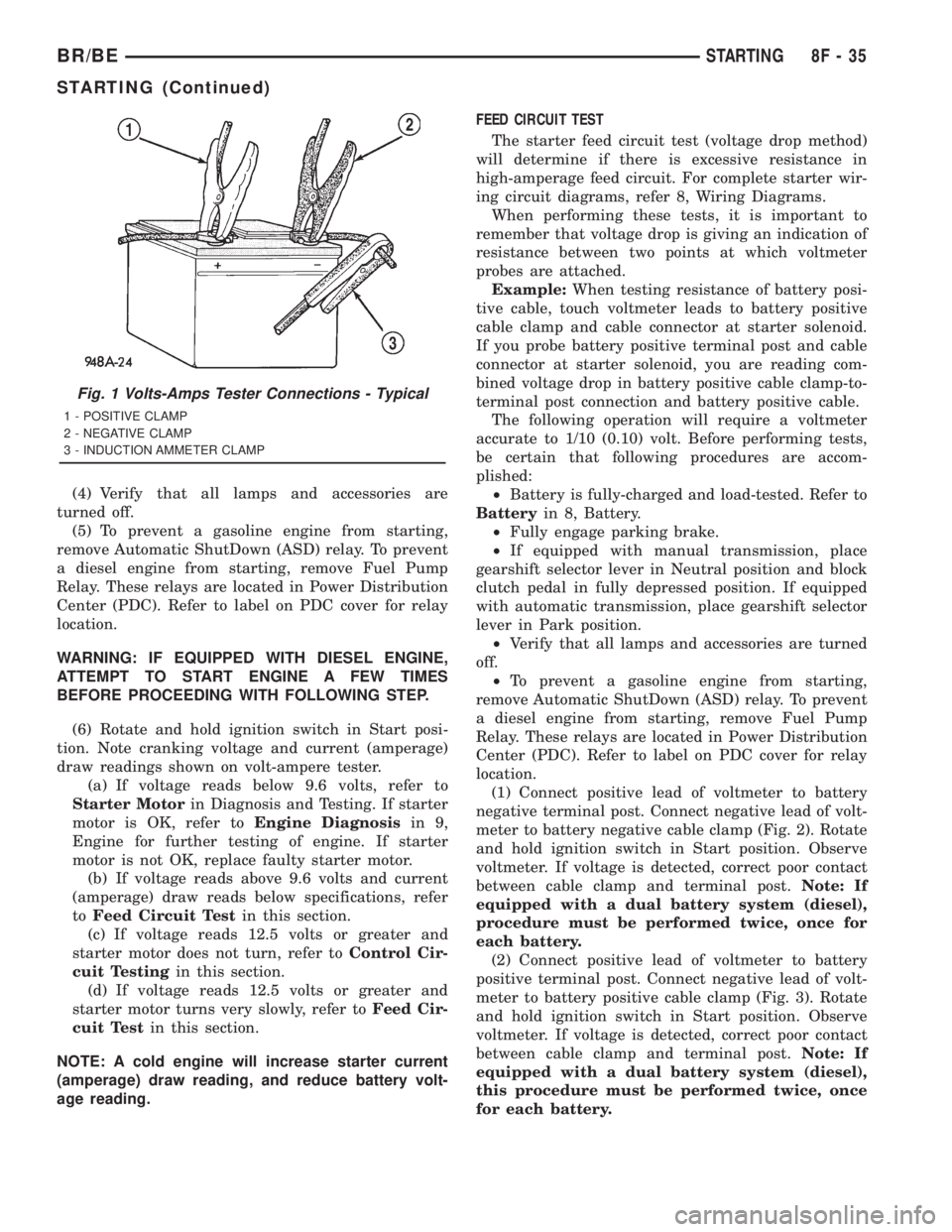

(1) Connect volt-ampere tester to battery terminals

(Fig. 1). See instructions provided by manufacturer of

volt-ampere tester being used.Note: If equipped

with dual battery system (diesel), tester should

be connected to driver side battery only. Also,

tester current reading must be taken from bat-

tery positive cable lead that connects to starter

motor.

(2) Fully engage parking brake.

(3) If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

8F - 34 STARTINGBR/BE

STARTING (Continued)

Page 506 of 2889

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent a gasoline engine from starting,

remove Automatic ShutDown (ASD) relay. To prevent

a diesel engine from starting, remove Fuel Pump

Relay. These relays are located in Power Distribution

Center (PDC). Refer to label on PDC cover for relay

location.

WARNING: IF EQUIPPED WITH DIESEL ENGINE,

ATTEMPT TO START ENGINE A FEW TIMES

BEFORE PROCEEDING WITH FOLLOWING STEP.

(6) Rotate and hold ignition switch in Start posi-

tion. Note cranking voltage and current (amperage)

draw readings shown on volt-ampere tester.

(a) If voltage reads below 9.6 volts, refer to

Starter Motorin Diagnosis and Testing. If starter

motor is OK, refer toEngine Diagnosisin 9,

Engine for further testing of engine. If starter

motor is not OK, replace faulty starter motor.

(b) If voltage reads above 9.6 volts and current

(amperage) draw reads below specifications, refer

toFeed Circuit Testin this section.

(c) If voltage reads 12.5 volts or greater and

starter motor does not turn, refer toControl Cir-

cuit Testingin this section.

(d) If voltage reads 12.5 volts or greater and

starter motor turns very slowly, refer toFeed Cir-

cuit Testin this section.

NOTE: A cold engine will increase starter current

(amperage) draw reading, and reduce battery volt-

age reading.FEED CIRCUIT TEST

The starter feed circuit test (voltage drop method)

will determine if there is excessive resistance in

high-amperage feed circuit. For complete starter wir-

ing circuit diagrams, refer 8, Wiring Diagrams.

When performing these tests, it is important to

remember that voltage drop is giving an indication of

resistance between two points at which voltmeter

probes are attached.

Example:When testing resistance of battery posi-

tive cable, touch voltmeter leads to battery positive

cable clamp and cable connector at starter solenoid.

If you probe battery positive terminal post and cable

connector at starter solenoid, you are reading com-

bined voltage drop in battery positive cable clamp-to-

terminal post connection and battery positive cable.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing tests,

be certain that following procedures are accom-

plished:

²Battery is fully-charged and load-tested. Refer to

Batteryin 8, Battery.

²Fully engage parking brake.

²If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

²Verify that all lamps and accessories are turned

off.

²To prevent a gasoline engine from starting,

remove Automatic ShutDown (ASD) relay. To prevent

a diesel engine from starting, remove Fuel Pump

Relay. These relays are located in Power Distribution

Center (PDC). Refer to label on PDC cover for relay

location.

(1) Connect positive lead of voltmeter to battery

negative terminal post. Connect negative lead of volt-

meter to battery negative cable clamp (Fig. 2). Rotate

and hold ignition switch in Start position. Observe

voltmeter. If voltage is detected, correct poor contact

between cable clamp and terminal post.Note: If

equipped with a dual battery system (diesel),

procedure must be performed twice, once for

each battery.

(2) Connect positive lead of voltmeter to battery

positive terminal post. Connect negative lead of volt-

meter to battery positive cable clamp (Fig. 3). Rotate

and hold ignition switch in Start position. Observe

voltmeter. If voltage is detected, correct poor contact

between cable clamp and terminal post.Note: If

equipped with a dual battery system (diesel),

this procedure must be performed twice, once

for each battery.

Fig. 1 Volts-Amps Tester Connections - Typical

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

BR/BESTARTING 8F - 35

STARTING (Continued)