fuel tank capacity DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 19 of 2889

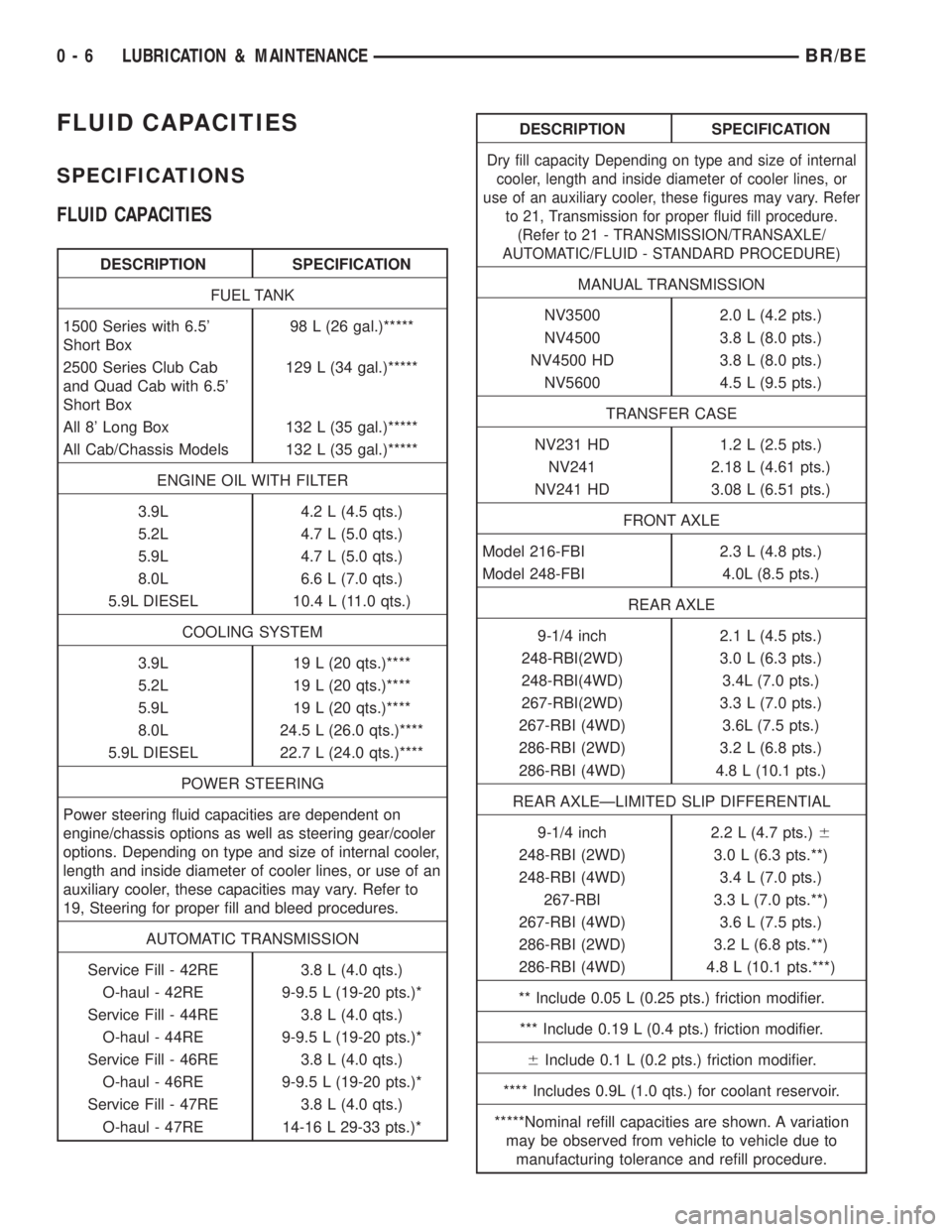

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

DESCRIPTION SPECIFICATION

FUEL TANK

1500 Series with 6.5'

Short Box98 L (26 gal.)*****

2500 Series Club Cab

and Quad Cab with 6.5'

Short Box129 L (34 gal.)*****

All 8' Long Box 132 L (35 gal.)*****

All Cab/Chassis Models 132 L (35 gal.)*****

ENGINE OIL WITH FILTER

3.9L 4.2 L (4.5 qts.)

5.2L 4.7 L (5.0 qts.)

5.9L 4.7 L (5.0 qts.)

8.0L 6.6 L (7.0 qts.)

5.9L DIESEL 10.4 L (11.0 qts.)

COOLING SYSTEM

3.9L 19 L (20 qts.)****

5.2L 19 L (20 qts.)****

5.9L 19 L (20 qts.)****

8.0L 24.5 L (26.0 qts.)****

5.9L DIESEL 22.7 L (24.0 qts.)****

POWER STEERING

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cooler

options. Depending on type and size of internal cooler,

length and inside diameter of cooler lines, or use of an

auxiliary cooler, these capacities may vary. Refer to

19, Steering for proper fill and bleed procedures.

AUTOMATIC TRANSMISSION

Service Fill - 42RE 3.8 L (4.0 qts.)

O-haul - 42RE 9-9.5 L (19-20 pts.)*

Service Fill - 44RE 3.8 L (4.0 qts.)

O-haul - 44RE 9-9.5 L (19-20 pts.)*

Service Fill - 46RE 3.8 L (4.0 qts.)

O-haul - 46RE 9-9.5 L (19-20 pts.)*

Service Fill - 47RE 3.8 L (4.0 qts.)

O-haul - 47RE 14-16 L 29-33 pts.)*

DESCRIPTION SPECIFICATION

Dry fill capacity Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these figures may vary. Refer

to 21, Transmission for proper fluid fill procedure.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC/FLUID - STANDARD PROCEDURE)

MANUAL TRANSMISSION

NV3500 2.0 L (4.2 pts.)

NV4500 3.8 L (8.0 pts.)

NV4500 HD 3.8 L (8.0 pts.)

NV5600 4.5 L (9.5 pts.)

TRANSFER CASE

NV231 HD 1.2 L (2.5 pts.)

NV241 2.18 L (4.61 pts.)

NV241 HD 3.08 L (6.51 pts.)

FRONT AXLE

Model 216-FBI 2.3 L (4.8 pts.)

Model 248-FBI 4.0L (8.5 pts.)

REAR AXLE

9-1/4 inch 2.1 L (4.5 pts.)

248-RBI(2WD) 3.0 L (6.3 pts.)

248-RBI(4WD) 3.4L (7.0 pts.)

267-RBI(2WD) 3.3 L (7.0 pts.)

267-RBI (4WD) 3.6L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.)

286-RBI (4WD) 4.8 L (10.1 pts.)

REAR AXLEÐLIMITED SLIP DIFFERENTIAL

9-1/4 inch 2.2 L (4.7 pts.)6

248-RBI (2WD) 3.0 L (6.3 pts.**)

248-RBI (4WD) 3.4 L (7.0 pts.)

267-RBI 3.3 L (7.0 pts.**)

267-RBI (4WD) 3.6 L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.**)

286-RBI (4WD) 4.8 L (10.1 pts.***)

** Include 0.05 L (0.25 pts.) friction modifier.

*** Include 0.19 L (0.4 pts.) friction modifier.

6Include 0.1 L (0.2 pts.) friction modifier.

**** Includes 0.9L (1.0 qts.) for coolant reservoir.

*****Nominal refill capacities are shown. A variation

may be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure.

0 - 6 LUBRICATION & MAINTENANCEBR/BE

Page 1488 of 2889

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL DELIVERY - GASOLINE................1

FUEL INJECTION - GASOLINE..............28FUEL DELIVERY - DIESEL.................54

FUEL INJECTION - DIESEL.................87

FUEL DELIVERY - GASOLINE

TABLE OF CONTENTS

page page

FUEL DELIVERY - GASOLINE

DESCRIPTION............................2

OPERATION.............................2

DIAGNOSIS AND TESTING..................2

FUEL PRESSURE LEAK DOWN TEST........2

STANDARD PROCEDURE...................3

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE...........................3

SPECIFICATIONS.........................4

SPECIAL TOOLS..........................4

FUEL FILTER/PRESSURE REGULATOR

DESCRIPTION............................5

OPERATION.............................5

REMOVAL...............................5

INSTALLATION............................6

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION............................7

OPERATION.............................7

DIAGNOSIS AND TESTING..................8

FUEL GAUGE SENDING UNIT..............8

REMOVAL...............................8

INSTALLATION............................9

FUEL LINES

DESCRIPTION............................9

FUEL PUMP

DESCRIPTION............................9

OPERATION.............................9

DIAGNOSIS AND TESTING..................9

FUEL PUMP CAPACITY TEST..............9FUEL PUMP PRESSURE TEST............10

FUEL PUMP AMPERAGE TEST............10

FUEL PUMP MODULE

DESCRIPTION...........................12

OPERATION.............................13

REMOVAL..............................13

INSTALLATION...........................13

FUEL RAIL

DESCRIPTION...........................15

OPERATION.............................15

REMOVAL..............................16

INSTALLATION...........................18

FUEL TANK

DESCRIPTION...........................19

OPERATION.............................19

REMOVAL..............................19

INSTALLATION...........................20

INLET FILTER

REMOVAL..............................22

INSTALLATION...........................22

QUICK CONNECT FITTING

DESCRIPTION...........................22

STANDARD PROCEDURE..................22

QUICK-CONNECT FITTINGS..............22

ROLLOVER VALVE

DESCRIPTION...........................25

REMOVAL..............................26

INSTALLATION...........................27

BR/BEFUEL SYSTEM 14 - 1

Page 1489 of 2889

FUEL DELIVERY - GASOLINE

DESCRIPTION - FUEL DELIVERY SYSTEM

The fuel delivery system consists of:

²the fuel pump module containing the electric

fuel pump, fuel filter/fuel pressure regulator, rollover

valve (certain modules), fuel gauge sending unit (fuel

level sensor) and a separate fuel filter located at bot-

tom of pump module

²fuel tubes/lines/hoses

²quick-connect fittings

²fuel injector rail

²fuel injectors

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

OPERATION - FUEL DELIVERY SYSTEM

Fuel is returned through the fuel pump module

and back into the fuel tank through the fuel filter/

fuel pressure regulator. A separate fuel return line

from the engine to the tank is not used with any gas-

oline powered engine.

The fuel tank assembly consists of: the fuel tank,

fuel pump module assembly, fuel pump module lock-

nut/gasket and rollover valve(s) (refer to 25, Emis-

sion Control System for rollover valve information).

A fuel filler/vent tube assembly using a pressure/

vacuum, 1/4 turn fuel filler cap is used. The fuel

filler tube contains a flap door located below the fuel

fill cap.

Also to be considered part of the fuel system is the

evaporation control system. This is designed to

reduce the emission of fuel vapors into the atmo-

sphere. The description and function of the Evapora-

tive Control System is found in 25, Emission Control

Systems.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

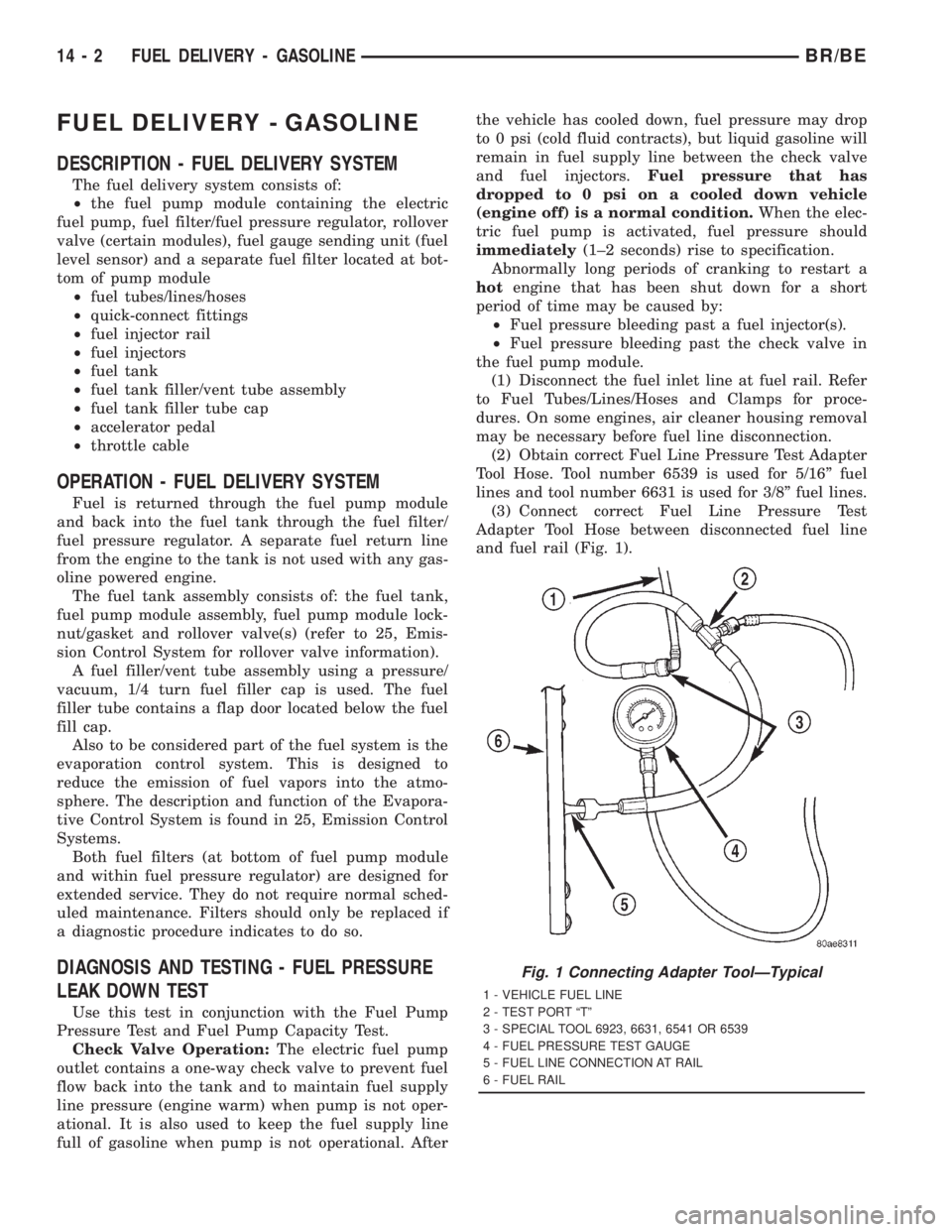

DIAGNOSIS AND TESTING - FUEL PRESSURE

LEAK DOWN TEST

Use this test in conjunction with the Fuel Pump

Pressure Test and Fuel Pump Capacity Test.

Check Valve Operation:The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply line

full of gasoline when pump is not operational. Afterthe vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline will

remain in fuel supply line between the check valve

and fuel injectors.Fuel pressure that has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition.When the elec-

tric fuel pump is activated, fuel pressure should

immediately(1±2 seconds) rise to specification.

Abnormally long periods of cranking to restart a

hotengine that has been shut down for a short

period of time may be caused by:

²Fuel pressure bleeding past a fuel injector(s).

²Fuel pressure bleeding past the check valve in

the fuel pump module.

(1) Disconnect the fuel inlet line at fuel rail. Refer

to Fuel Tubes/Lines/Hoses and Clamps for proce-

dures. On some engines, air cleaner housing removal

may be necessary before fuel line disconnection.

(2) Obtain correct Fuel Line Pressure Test Adapter

Tool Hose. Tool number 6539 is used for 5/16º fuel

lines and tool number 6631 is used for 3/8º fuel lines.

(3) Connect correct Fuel Line Pressure Test

Adapter Tool Hose between disconnected fuel line

and fuel rail (Fig. 1).

Fig. 1 Connecting Adapter ToolÐTypical

1 - VEHICLE FUEL LINE

2 - TEST PORT ªTº

3 - SPECIAL TOOL 6923, 6631, 6541 OR 6539

4 - FUEL PRESSURE TEST GAUGE

5 - FUEL LINE CONNECTION AT RAIL

6 - FUEL RAIL

14 - 2 FUEL DELIVERY - GASOLINEBR/BE

Page 1495 of 2889

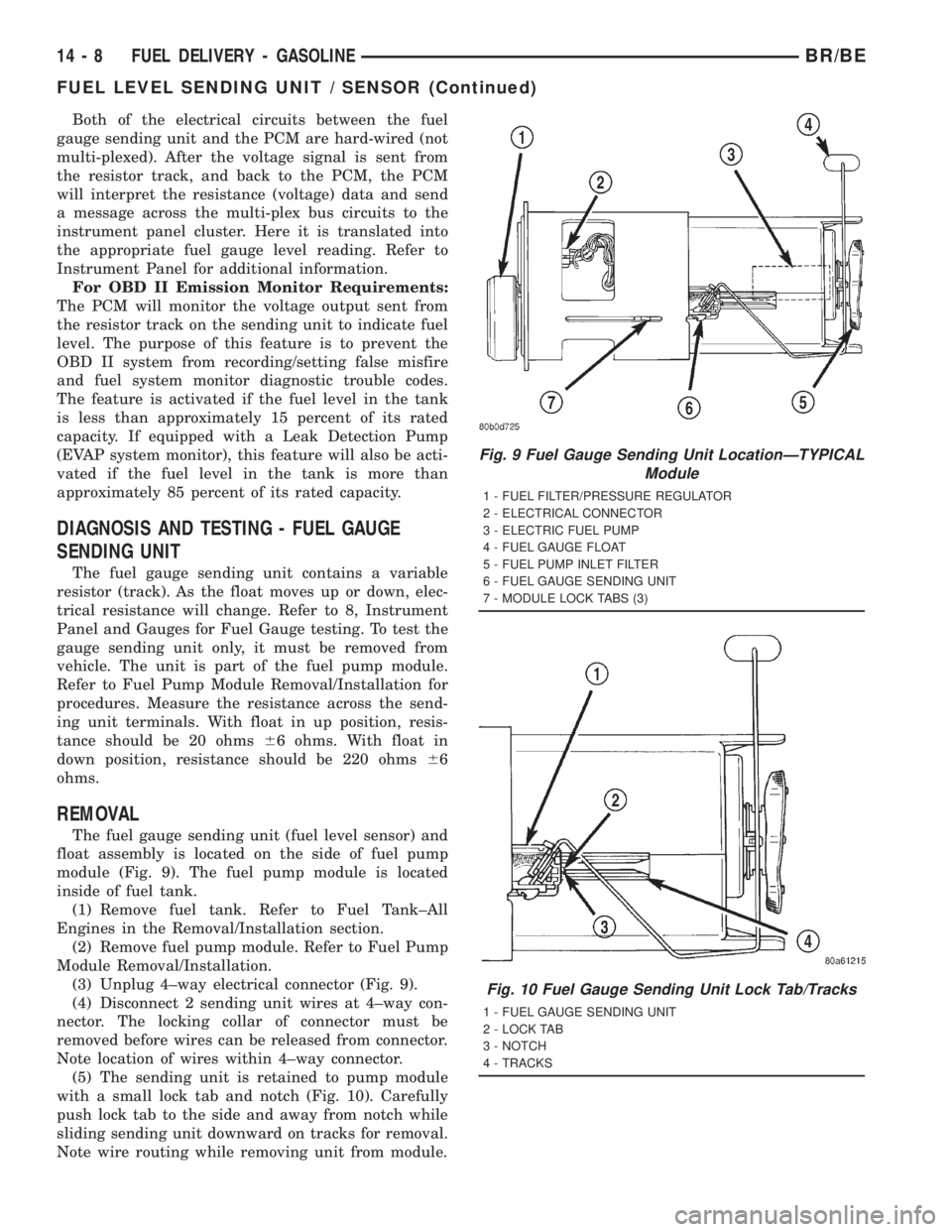

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

For OBD II Emission Monitor Requirements:

The PCM will monitor the voltage output sent from

the resistor track on the sending unit to indicate fuel

level. The purpose of this feature is to prevent the

OBD II system from recording/setting false misfire

and fuel system monitor diagnostic trouble codes.

The feature is activated if the fuel level in the tank

is less than approximately 15 percent of its rated

capacity. If equipped with a Leak Detection Pump

(EVAP system monitor), this feature will also be acti-

vated if the fuel level in the tank is more than

approximately 85 percent of its rated capacity.

DIAGNOSIS AND TESTING - FUEL GAUGE

SENDING UNIT

The fuel gauge sending unit contains a variable

resistor (track). As the float moves up or down, elec-

trical resistance will change. Refer to 8, Instrument

Panel and Gauges for Fuel Gauge testing. To test the

gauge sending unit only, it must be removed from

vehicle. The unit is part of the fuel pump module.

Refer to Fuel Pump Module Removal/Installation for

procedures. Measure the resistance across the send-

ing unit terminals. With float in up position, resis-

tance should be 20 ohms66 ohms. With float in

down position, resistance should be 220 ohms66

ohms.

REMOVAL

The fuel gauge sending unit (fuel level sensor) and

float assembly is located on the side of fuel pump

module (Fig. 9). The fuel pump module is located

inside of fuel tank.

(1) Remove fuel tank. Refer to Fuel Tank±All

Engines in the Removal/Installation section.

(2) Remove fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(3) Unplug 4±way electrical connector (Fig. 9).

(4) Disconnect 2 sending unit wires at 4±way con-

nector. The locking collar of connector must be

removed before wires can be released from connector.

Note location of wires within 4±way connector.

(5) The sending unit is retained to pump module

with a small lock tab and notch (Fig. 10). Carefully

push lock tab to the side and away from notch while

sliding sending unit downward on tracks for removal.

Note wire routing while removing unit from module.

Fig. 9 Fuel Gauge Sending Unit LocationÐTYPICAL

Module

1 - FUEL FILTER/PRESSURE REGULATOR

2 - ELECTRICAL CONNECTOR

3 - ELECTRIC FUEL PUMP

4 - FUEL GAUGE FLOAT

5 - FUEL PUMP INLET FILTER

6 - FUEL GAUGE SENDING UNIT

7 - MODULE LOCK TABS (3)

Fig. 10 Fuel Gauge Sending Unit Lock Tab/Tracks

1 - FUEL GAUGE SENDING UNIT

2 - LOCK TAB

3 - NOTCH

4 - TRACKS

14 - 8 FUEL DELIVERY - GASOLINEBR/BE

FUEL LEVEL SENDING UNIT / SENSOR (Continued)

Page 1496 of 2889

INSTALLATION

The fuel gauge sending unit (fuel level sensor) and

float assembly is located on the side of fuel pump

module (Fig. 9). The fuel pump module is located

inside of fuel tank.

(1) Position sending unit into tracks. Note wire

routing.

(2) Push unit on tracks until lock tab snaps into

notch.

(3) Connect 2 sending unit wires into 4±way con-

nector and install locking collar.

(4) Connect 4±way electrical connector to module.

(5) Install fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(6) Install fuel tank. Refer to Fuel Tank±All

Engines in the Removal/Installation section.

FUEL LINES

DESCRIPTION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES, FIT-

TINGS OR LINES, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL SYSTEM

PRESSURE RELEASE PROCEDURE IN THIS GROUP.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped:The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

FUEL PUMP

DESCRIPTION

The fuel pump is located inside of the fuel pump

module. A 12 volt, permanent magnet, electric motor

powers the fuel pump.

OPERATION

Voltage to operate the electric pump is supplied

through the fuel pump relay.Fuel is drawn in through a filter at the bottom of

the module and pushed through the electric motor

gearset to the pump outlet.

Check Valve Operation:The pump outlet con-

tains a one-way check valve to prevent fuel flow back

into the tank and to maintain fuel supply line pres-

sure (engine warm) when pump is not operational. It

is also used to keep the fuel supply line full of gaso-

line when pump is not operational. After the vehicle

has cooled down, fuel pressure may drop to 0 psi

(cold fluid contracts), but liquid gasoline will remain

in fuel supply line between the check valve and fuel

injectors.Fuel pressure that has dropped to 0

psi on a cooled down vehicle (engine off) is a

normal condition.Refer to the Fuel Pressure Leak

Down Test for more information.

DIAGNOSIS AND TESTING - FUEL PUMP

CAPACITY TEST

Before performing this test, verify fuel pump

pressure. Refer to Fuel Pump Pressure Test.

Use this test in conjunction with the Fuel Pres-

sure Leak Down Test.

(1) Release fuel system pressure. Refer to Fuel

Pressure Release Procedure.

(2) Disconnect fuel supply line at fuel rail. Refer to

Quick-Connect Fittings. Some engines may require

air cleaner housing removal before line disconnection.

(3) Obtain correct Fuel Line Pressure Test Adapter

Tool Hose. Tool number 6539 is used for 5/16º fuel

lines and tool number 6631 is used for 3/8º fuel lines.

(4)

Connect correct Fuel Line Pressure Test Adapter

Tool Hose into disconnected fuel supply line. Insert other

end of Adaptor Tool Hose into a graduated container.

(5) Remove fuel fill cap.

(6) To activate fuel pump and pressurize system,

obtain DRBtscan tool and actuate ASD Fuel System

Test.

(7) A good fuel pump will deliver at least 1/4 liter

of fuel in 7 seconds. Do not operate fuel pump for

longer than 7 seconds with fuel line disconnected as

fuel pump module reservoir may run empty.

(a) If capacity is lower than specification, but

fuel pump can be heard operating through fuel fill

cap opening, check for a kinked/damaged fuel sup-

ply line somewhere between fuel rail and fuel

pump module.

(b) If line is not kinked/damaged, and fuel pres-

sure is OK, but capacity is low, replace fuel filter/

fuel pressure regulator. The filter/regulator may be

serviced separately on certain applications. Refer

to Fuel Filter/Fuel Pressure Regulator Removal/In-

stallation for additional information.

(c) If both fuel pressure and capacity are low,

replace fuel pump module assembly. Refer to Fuel

Pump Module Removal/Installation.

BR/BEFUEL DELIVERY - GASOLINE 14 - 9

FUEL LEVEL SENDING UNIT / SENSOR (Continued)

Page 1497 of 2889

DIAGNOSIS AND TESTING - FUEL PUMP

PRESSURE TEST

Use this test in conjunction with the Fuel Pump

Capacity Test, Fuel Pressure Leak Down Test and Fuel

Pump Amperage Test found elsewhere in this group.

Check Valve Operation:The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply line

full of gasoline when pump is not operational. After

the vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline will

remain in fuel supply line between the check valve

and fuel injectors.Fuel pressure that has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition.When the elec-

tric fuel pump is activated, fuel pressure should

immediately(1±2 seconds) rise to specification.

All fuel systems are equipped with a fuel tank

module mounted, combination fuel filter/fuel pressure

regulator. The fuel pressure regulator is not con-

trolled by engine vacuum.

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE EVEN WITH THE ENGINE

OFF. BEFORE DISCONNECTING FUEL LINE AT

FUEL RAIL, THIS PRESSURE MUST BE RELEASED.

REFER TO THE FUEL SYSTEM PRESSURE

RELEASE PROCEDURE.

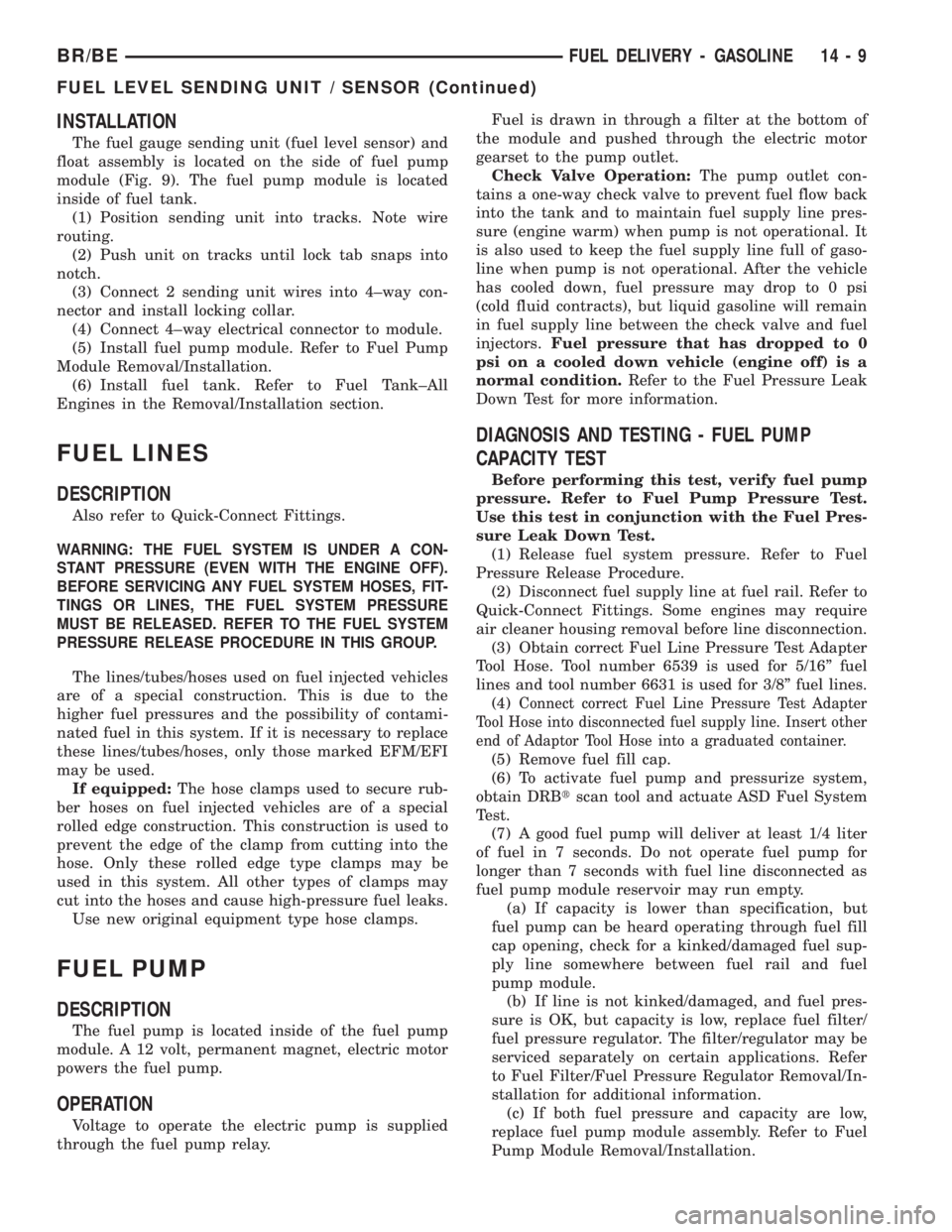

(1) Remove protective cap at fuel rail test port.

Connect the 0±414 kPa (0-60 psi) fuel pressure gauge

(from gauge set 5069) to test port pressure fitting on

fuel rail (Fig. 11).The DRBtIII Scan Tool along

with the PEP module, the 500 psi pressure

transducer, and the transducer-to-test port

adapter may also be used in place of the fuel

pressure gauge.

(2) Start and warm engine and note pressure

gauge reading. Fuel pressure should be 339 kPa634

kPa (49.2 psi65 psi) at idle.

(3) If engine runs, but pressure is below 44.2 psi,

check for a kinked fuel supply line somewhere

between fuel rail and fuel pump module. If line is not

kinked, but specifications for either the Fuel Pump

Capacity, Fuel Pump Amperage or Fuel Pressure

Leak Down Tests were not met, replace fuel pump

module assembly. Refer to Fuel Pump Module

Removal/Installation.

(4) If operating pressure is above 54.2 psi, electric

fuel pump is OK, but fuel pressure regulator is defec-

tive. Replace fuel filter/fuel pressure regulator. Refer

to Fuel Filter/Fuel Pressure Regulator Removal/In-

stallation for more information.

(5) Install protective cap to fuel rail test port.

DIAGNOSIS AND TESTING - FUEL PUMP

AMPERAGE TEST

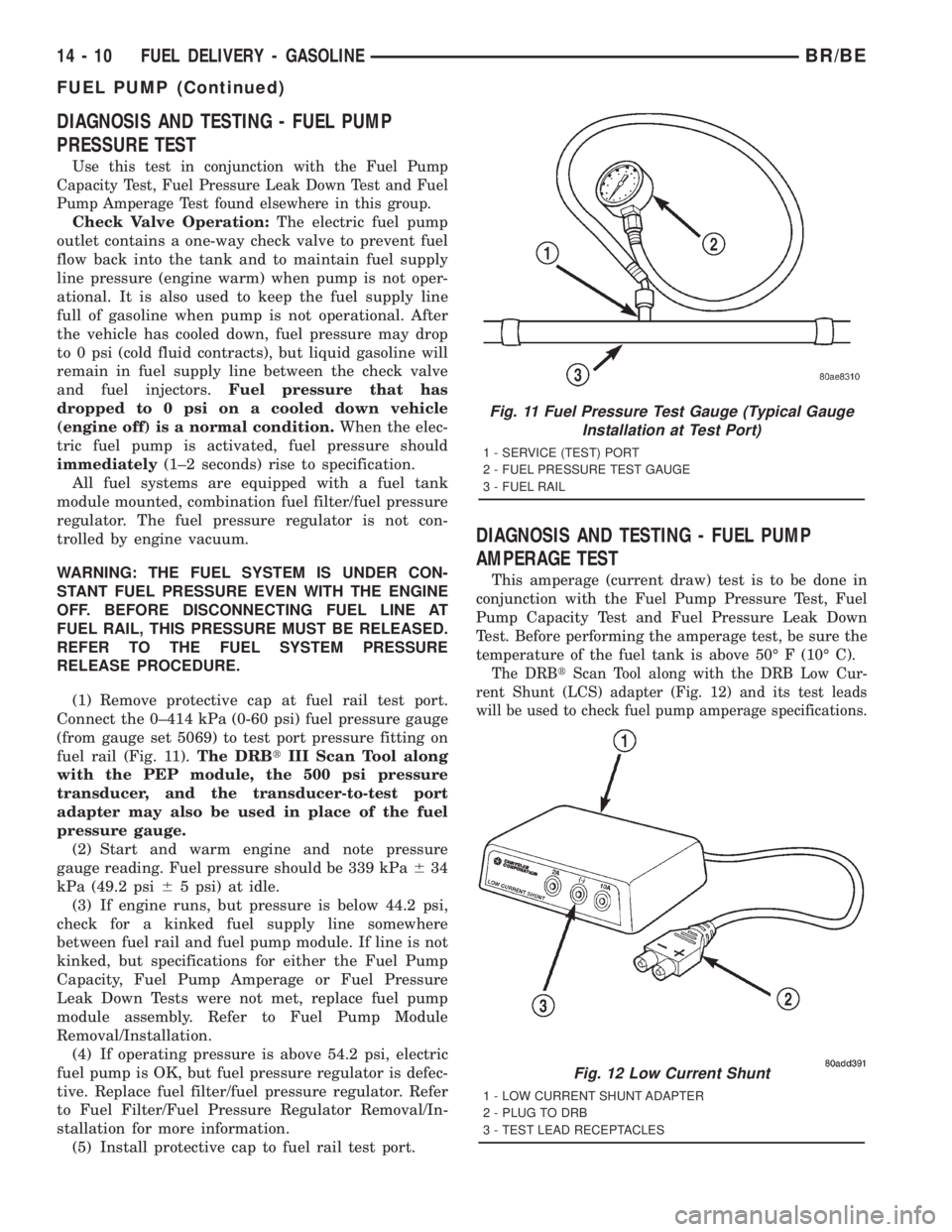

This amperage (current draw) test is to be done in

conjunction with the Fuel Pump Pressure Test, Fuel

Pump Capacity Test and Fuel Pressure Leak Down

Test. Before performing the amperage test, be sure the

temperature of the fuel tank is above 50É F (10É C).

The DRBtScan Tool along with the DRB Low Cur-

rent Shunt (LCS) adapter (Fig. 12) and its test leads

will be used to check fuel pump amperage specifications.

Fig. 11 Fuel Pressure Test Gauge (Typical Gauge

Installation at Test Port)

1 - SERVICE (TEST) PORT

2 - FUEL PRESSURE TEST GAUGE

3 - FUEL RAIL

Fig. 12 Low Current Shunt

1 - LOW CURRENT SHUNT ADAPTER

2 - PLUG TO DRB

3 - TEST LEAD RECEPTACLES

14 - 10 FUEL DELIVERY - GASOLINEBR/BE

FUEL PUMP (Continued)

Page 1499 of 2889

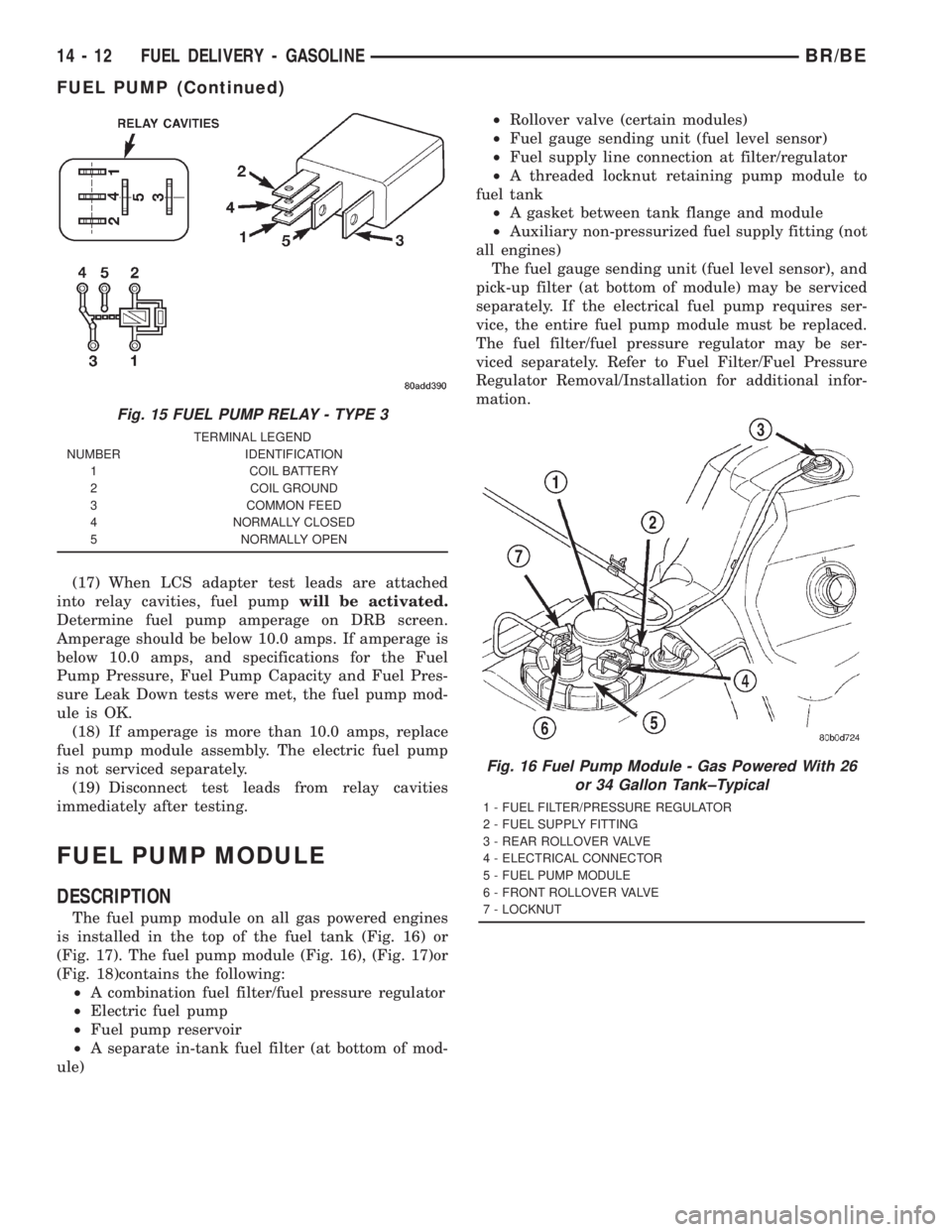

(17) When LCS adapter test leads are attached

into relay cavities, fuel pumpwill be activated.

Determine fuel pump amperage on DRB screen.

Amperage should be below 10.0 amps. If amperage is

below 10.0 amps, and specifications for the Fuel

Pump Pressure, Fuel Pump Capacity and Fuel Pres-

sure Leak Down tests were met, the fuel pump mod-

ule is OK.

(18) If amperage is more than 10.0 amps, replace

fuel pump module assembly. The electric fuel pump

is not serviced separately.

(19) Disconnect test leads from relay cavities

immediately after testing.

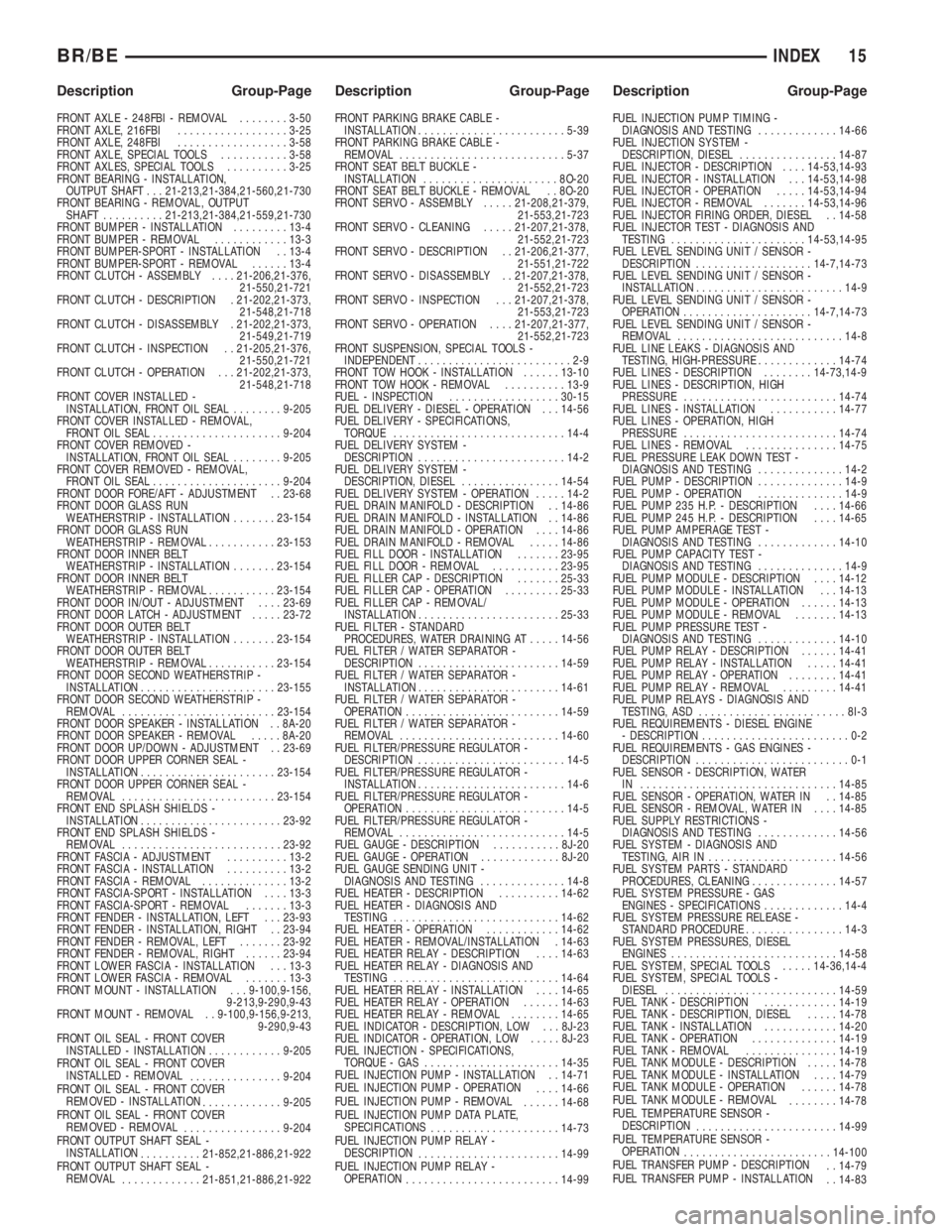

FUEL PUMP MODULE

DESCRIPTION

The fuel pump module on all gas powered engines

is installed in the top of the fuel tank (Fig. 16) or

(Fig. 17). The fuel pump module (Fig. 16), (Fig. 17)or

(Fig. 18)contains the following:

²A combination fuel filter/fuel pressure regulator

²Electric fuel pump

²Fuel pump reservoir

²A separate in-tank fuel filter (at bottom of mod-

ule)²Rollover valve (certain modules)

²Fuel gauge sending unit (fuel level sensor)

²Fuel supply line connection at filter/regulator

²A threaded locknut retaining pump module to

fuel tank

²A gasket between tank flange and module

²Auxiliary non-pressurized fuel supply fitting (not

all engines)

The fuel gauge sending unit (fuel level sensor), and

pick-up filter (at bottom of module) may be serviced

separately. If the electrical fuel pump requires ser-

vice, the entire fuel pump module must be replaced.

The fuel filter/fuel pressure regulator may be ser-

viced separately. Refer to Fuel Filter/Fuel Pressure

Regulator Removal/Installation for additional infor-

mation.

Fig. 15 FUEL PUMP RELAY - TYPE 3

TERMINAL LEGEND

NUMBER IDENTIFICATION

1 COIL BATTERY

2 COIL GROUND

3 COMMON FEED

4 NORMALLY CLOSED

5 NORMALLY OPEN

Fig. 16 Fuel Pump Module - Gas Powered With 26

or 34 Gallon Tank±Typical

1 - FUEL FILTER/PRESSURE REGULATOR

2 - FUEL SUPPLY FITTING

3 - REAR ROLLOVER VALVE

4 - ELECTRICAL CONNECTOR

5 - FUEL PUMP MODULE

6 - FRONT ROLLOVER VALVE

7 - LOCKNUT

14 - 12 FUEL DELIVERY - GASOLINEBR/BE

FUEL PUMP (Continued)

Page 2862 of 2889

FRONT AXLE - 248FBI - REMOVAL........3-50

FRONT AXLE, 216FBI..................3-25

FRONT AXLE, 248FBI..................3-58

FRONT AXLE, SPECIAL TOOLS...........3-58

FRONT AXLES, SPECIAL TOOLS..........3-25

FRONT BEARING - INSTALLATION,

OUTPUT SHAFT . . . 21-213,21-384,21-560,21-730

FRONT BEARING - REMOVAL, OUTPUT

SHAFT..........21-213,21-384,21-559,21-730

FRONT BUMPER - INSTALLATION.........13-4

FRONT BUMPER - REMOVAL............13-3

FRONT BUMPER-SPORT - INSTALLATION . . 13-4

FRONT BUMPER-SPORT - REMOVAL......13-4

FRONT CLUTCH - ASSEMBLY....21-206,21-376,

21-550,21-721

FRONT CLUTCH - DESCRIPTION . 21-202,21-373,

21-548,21-718

FRONT CLUTCH - DISASSEMBLY . 21-202,21-373,

21-549,21-719

FRONT CLUTCH - INSPECTION . . 21-205,21-376,

21-550,21-721

FRONT CLUTCH - OPERATION . . . 21-202,21-373,

21-548,21-718

FRONT COVER INSTALLED -

INSTALLATION, FRONT OIL SEAL........9-205

FRONT COVER INSTALLED - REMOVAL,

FRONT OIL SEAL.....................9-204

FRONT COVER REMOVED -

INSTALLATION, FRONT OIL SEAL........9-205

FRONT COVER REMOVED - REMOVAL,

FRONT OIL SEAL......................9-204

FRONT DOOR FORE/AFT - ADJUSTMENT . . 23-68

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION.......23-154

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL...........23-153

FRONT DOOR INNER BELT

WEATHERSTRIP - INSTALLATION.......23-154

FRONT DOOR INNER BELT

WEATHERSTRIP - REMOVAL...........23-154

FRONT DOOR IN/OUT - ADJUSTMENT....23-69

FRONT DOOR LATCH - ADJUSTMENT.....23-72

FRONT DOOR OUTER BELT

WEATHERSTRIP - INSTALLATION.......23-154

FRONT DOOR OUTER BELT

WEATHERSTRIP - REMOVAL...........23-154

FRONT DOOR SECOND WEATHERSTRIP -

INSTALLATION......................23-155

FRONT DOOR SECOND WEATHERSTRIP -

REMOVAL.........................23-154

FRONT DOOR SPEAKER - INSTALLATION . . 8A-20

FRONT DOOR SPEAKER - REMOVAL.....8A-20

FRONT DOOR UP/DOWN - ADJUSTMENT . . 23-69

FRONT DOOR UPPER CORNER SEAL -

INSTALLATION......................23-154

FRONT DOOR UPPER CORNER SEAL -

REMOVAL.........................23-154

FRONT END SPLASH SHIELDS -

INSTALLATION.......................23-92

FRONT END SPLASH SHIELDS -

REMOVAL..........................23-92

FRONT FASCIA - ADJUSTMENT..........13-2

FRONT FASCIA - INSTALLATION..........13-2

FRONT FASCIA - REMOVAL..............13-2

FRONT FASCIA-SPORT - INSTALLATION....13-3

FRONT FASCIA-SPORT - REMOVAL.......13-3

FRONT FENDER - INSTALLATION, LEFT . . . 23-93

FRONT FENDER - INSTALLATION, RIGHT . . 23-94

FRONT FENDER - REMOVAL, LEFT.......23-92

FRONT FENDER - REMOVAL, RIGHT......23-94

FRONT LOWER FASCIA - INSTALLATION . . . 13-3

FRONT LOWER FASCIA - REMOVAL.......13-3

FRONT MOUNT - INSTALLATION . . . 9-100,9-156,

9-213,9-290,9-43

FRONT MOUNT - REMOVAL . . 9-100,9-156,9-213,

9-290,9-43

FRONT OIL SEAL - FRONT COVER

INSTALLED - INSTALLATION............9-205

FRONT OIL SEAL - FRONT COVER

INSTALLED - REMOVAL

...............9-204

FRONT OIL SEAL - FRONT COVER

REMOVED - INSTALLATION

.............9-205

FRONT OIL SEAL - FRONT COVER

REMOVED - REMOVAL

................9-204

FRONT OUTPUT SHAFT SEAL -

INSTALLATION

..........21-852,21-886,21-922

FRONT OUTPUT SHAFT SEAL -

REMOVAL

.............21-851,21-886,21-922FRONT PARKING BRAKE CABLE -

INSTALLATION........................5-39

FRONT PARKING BRAKE CABLE -

REMOVAL...........................5-37

FRONT SEAT BELT BUCKLE -

INSTALLATION......................8O-20

FRONT SEAT BELT BUCKLE - REMOVAL . . 8O-20

FRONT SERVO - ASSEMBLY.....21-208,21-379,

21-553,21-723

FRONT SERVO - CLEANING.....21-207,21-378,

21-552,21-723

FRONT SERVO - DESCRIPTION . . 21-206,21-377,

21-551,21-722

FRONT SERVO - DISASSEMBLY . . 21-207,21-378,

21-552,21-723

FRONT SERVO - INSPECTION . . . 21-207,21-378,

21-553,21-723

FRONT SERVO - OPERATION....21-207,21-377,

21-552,21-723

FRONT SUSPENSION, SPECIAL TOOLS -

INDEPENDENT.........................2-9

FRONT TOW HOOK - INSTALLATION......13-10

FRONT TOW HOOK - REMOVAL..........13-9

FUEL - INSPECTION..................30-15

FUEL DELIVERY - DIESEL - OPERATION . . . 14-56

FUEL DELIVERY - SPECIFICATIONS,

TORQUE............................14-4

FUEL DELIVERY SYSTEM -

DESCRIPTION........................14-2

FUEL DELIVERY SYSTEM -

DESCRIPTION, DIESEL................14-54

FUEL DELIVERY SYSTEM - OPERATION.....14-2

FUEL DRAIN MANIFOLD - DESCRIPTION . . 14-86

FUEL DRAIN MANIFOLD - INSTALLATION . . 14-86

FUEL DRAIN MANIFOLD - OPERATION....14-86

FUEL DRAIN MANIFOLD - REMOVAL.....14-86

FUEL FILL DOOR - INSTALLATION.......23-95

FUEL FILL DOOR - REMOVAL...........23-95

FUEL FILLER CAP - DESCRIPTION.......25-33

FUEL FILLER CAP - OPERATION.........25-33

FUEL FILLER CAP - REMOVAL/

INSTALLATION.......................25-33

FUEL FILTER - STANDARD

PROCEDURES, WATER DRAINING AT.....14-56

FUEL FILTER / WATER SEPARATOR -

DESCRIPTION.......................14-59

FUEL FILTER / WATER SEPARATOR -

INSTALLATION.......................14-61

FUEL FILTER / WATER SEPARATOR -

OPERATION.........................14-59

FUEL FILTER / WATER SEPARATOR -

REMOVAL..........................14-60

FUEL FILTER/PRESSURE REGULATOR -

DESCRIPTION........................14-5

FUEL FILTER/PRESSURE REGULATOR -

INSTALLATION........................14-6

FUEL FILTER/PRESSURE REGULATOR -

OPERATION..........................14-5

FUEL FILTER/PRESSURE REGULATOR -

REMOVAL...........................14-5

FUEL GAUGE - DESCRIPTION...........8J-20

FUEL GAUGE - OPERATION.............8J-20

FUEL GAUGE SENDING UNIT -

DIAGNOSIS AND TESTING..............14-8

FUEL HEATER - DESCRIPTION..........14-62

FUEL HEATER - DIAGNOSIS AND

TESTING...........................14-62

FUEL HEATER - OPERATION............14-62

FUEL HEATER - REMOVAL/INSTALLATION . 14-63

FUEL HEATER RELAY - DESCRIPTION....14-63

FUEL HEATER RELAY - DIAGNOSIS AND

TESTING...........................14-64

FUEL HEATER RELAY - INSTALLATION....14-65

FUEL HEATER RELAY - OPERATION......14-63

FUEL HEATER RELAY - REMOVAL........14-65

FUEL INDICATOR - DESCRIPTION, LOW . . . 8J-23

FUEL INDICATOR - OPERATION, LOW.....8J-23

FUEL INJECTION - SPECIFICATIONS,

TORQUE - GAS......................14-35

FUEL INJECTION PUMP - INSTALLATION . . 14-71

FUEL INJECTION PUMP - OPERATION

....14-66

FUEL INJECTION PUMP - REMOVAL

......14-68

FUEL INJECTION PUMP DATA PLATE,

SPECIFICATIONS

.....................14-73

FUEL INJECTION PUMP RELAY -

DESCRIPTION

.......................14-99

FUEL INJECTION PUMP RELAY -

OPERATION

.........................14-99FUEL INJECTION PUMP TIMING -

DIAGNOSIS AND TESTING.............14-66

FUEL INJECTION SYSTEM -

DESCRIPTION, DIESEL................14-87

FUEL INJECTOR - DESCRIPTION....14-53,14-93

FUEL INJECTOR - INSTALLATION . . . 14-53,14-98

FUEL INJECTOR - OPERATION.....14-53,14-94

FUEL INJECTOR - REMOVAL.......14-53,14-96

FUEL INJECTOR FIRING ORDER, DIESEL . . 14-58

FUEL INJECTOR TEST - DIAGNOSIS AND

TESTING......................14-53,14-95

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION...................14-7,14-73

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-9

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION.....................14-7,14-73

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-8

FUEL LINE LEAKS - DIAGNOSIS AND

TESTING, HIGH-PRESSURE.............14-74

FUEL LINES - DESCRIPTION........14-73,14-9

FUEL LINES - DESCRIPTION, HIGH

PRESSURE.........................14-74

FUEL LINES - INSTALLATION...........14-77

FUEL LINES - OPERATION, HIGH

PRESSURE.........................14-74

FUEL LINES - REMOVAL...............14-75

FUEL PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING..............14-2

FUEL PUMP - DESCRIPTION..............14-9

FUEL PUMP - OPERATION..............14-9

FUEL PUMP 235 H.P. - DESCRIPTION....14-66

FUEL PUMP 245 H.P. - DESCRIPTION....14-65

FUEL PUMP AMPERAGE TEST -

DIAGNOSIS AND TESTING.............14-10

FUEL PUMP CAPACITY TEST -

DIAGNOSIS AND TESTING..............14-9

FUEL PUMP MODULE - DESCRIPTION....14-12

FUEL PUMP MODULE - INSTALLATION . . . 14-13

FUEL PUMP MODULE - OPERATION......14-13

FUEL PUMP MODULE - REMOVAL.......14-13

FUEL PUMP PRESSURE TEST -

DIAGNOSIS AND TESTING.............14-10

FUEL PUMP RELAY - DESCRIPTION......14-41

FUEL PUMP RELAY - INSTALLATION.....14-41

FUEL PUMP RELAY - OPERATION........14-41

FUEL PUMP RELAY - REMOVAL.........14-41

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-3

FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-2

FUEL REQUIREMENTS - GAS ENGINES -

DESCRIPTION.........................0-1

FUEL SENSOR - DESCRIPTION, WATER

IN ................................14-85

FUEL SENSOR - OPERATION, WATER IN . . 14-85

FUEL SENSOR - REMOVAL, WATER IN....14-85

FUEL SUPPLY RESTRICTIONS -

DIAGNOSIS AND TESTING.............14-56

FUEL SYSTEM - DIAGNOSIS AND

TESTING, AIR IN.....................14-56

FUEL SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING..............14-57

FUEL SYSTEM PRESSURE - GAS

ENGINES - SPECIFICATIONS.............14-4

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-3

FUEL SYSTEM PRESSURES, DIESEL

ENGINES...........................14-58

FUEL SYSTEM, SPECIAL TOOLS.....14-36,14-4

FUEL SYSTEM, SPECIAL TOOLS -

DIESEL............................14-59

FUEL TANK - DESCRIPTION............14-19

FUEL TANK - DESCRIPTION, DIESEL.....14-78

FUEL TANK - INSTALLATION............14-20

FUEL TANK - OPERATION..............14-19

FUEL TANK - REMOVAL...............14-19

FUEL TANK MODULE - DESCRIPTION.....14-78

FUEL TANK MODULE - INSTALLATION....14-79

FUEL TANK MODULE - OPERATION......14-78

FUEL TANK MODULE - REMOVAL

........14-78

FUEL TEMPERATURE SENSOR -

DESCRIPTION

.......................14-99

FUEL TEMPERATURE SENSOR -

OPERATION

........................14-100

FUEL TRANSFER PUMP - DESCRIPTION

. . 14-79

FUEL TRANSFER PUMP - INSTALLATION

. . 14-83

BR/BEINDEX 15

Description Group-Page Description Group-Page Description Group-Page

Page 2874 of 2889

PROPELLER SHAFT - FRONT -

INSTALLATION.........................3-8

PROPELLER SHAFT - FRONT - REMOVAL . . . 3-8

PROPELLER SHAFT - OPERATION.........3-1

PROPELLER SHAFT - REAR -

INSTALLATION.........................3-9

PROPELLER SHAFT - REAR - REMOVAL....3-9

PROPELLER SHAFT - STANDARD

PROCEDURES.........................3-5

PROPELLER SHAFT, SPECIAL TOOLS.......3-8

PROPELLER SHAFT, SPECIFICATIONS.......3-8

PTO SWITCH - DESCRIPTION...........14-48

PTO SWITCH - OPERATION.......14-104,14-48

PULLEY - INSTALLATION..............19-36

PULLEY - REMOVAL..................19-36

PUMP - 3.9L/5.2L/5.9L - CLEANING,

WATER .............................7-69

PUMP - 3.9L/5.2L/5.9L - DESCRIPTION,

WATER .............................7-67

PUMP - 3.9L/5.2L/5.9L - INSPECTION,

WATER .............................7-69

PUMP - 3.9L/5.2L/5.9L - INSTALLATION,

WATER .............................7-70

PUMP - 3.9L/5.2L/5.9L - OPERATION,

WATER .............................7-67

PUMP - 3.9L/5.2L/5.9L - REMOVAL,

WATER .............................7-67

PUMP - 5.9L DIESEL - CLEANING,

WATER .............................7-73

PUMP - 5.9L DIESEL - DESCRIPTION,

VACUUM..............................7-34

PUMP - 5.9L DIESEL - DESCRIPTION,

WATER .............................7-73

PUMP - 5.9L DIESEL - INSPECTION,

WATER .............................7-73

PUMP - 5.9L DIESEL - INSTALLATION,

VACUUM............................7-37

PUMP - 5.9L DIESEL - INSTALLATION,

WATER .............................7-74

PUMP - 5.9L DIESEL - OPERATION,

VACUUM............................7-35

PUMP - 5.9L DIESEL - OPERATION,

WATER .............................7-73

PUMP - 5.9L DIESEL - REMOVAL,

VACUUM............................7-35

PUMP - 5.9L DIESEL - REMOVAL,

WATER .............................7-73

PUMP - 8.0L - CLEANING, WATER........7-72

PUMP - 8.0L - INSPECTION, WATER......7-72

PUMP - 8.0L - INSTALLATION, WATER.....7-72

PUMP - 8.0L - REMOVAL, WATER........7-70

PUMP - ASSEMBLE, OIL..........9-109,9-165

PUMP - ASSEMBLY, OIL................9-51

PUMP - ASSEMBLY, OIL . . 21-212,21-382,21-558,

21-729

PUMP - CLEANING, OIL......9-220,9-299,9-50

PUMP - CLEANING, OIL . . 21-211,21-381,21-557,

21-728

PUMP - DESCRIPTION................19-31

PUMP - DESCRIPTION, AIR INJECTION . . . 25-28

PUMP - DESCRIPTION, FUEL............14-9

PUMP - DESCRIPTION, FUEL TRANSFER . . 14-79

PUMP - DESCRIPTION, LEAK DETECTION . 25-33

PUMP - DESCRIPTION, OIL.....21-208,21-379,

21-554,21-724

PUMP - DIAGNOSIS AND TESTING, AIR

INJECTION..........................25-28

PUMP - DIAGNOSIS AND TESTING,

WATER .....................7-67,7-70,7-73

PUMP - DISASSEMBLE, OIL . . . 9-107,9-163,9-50

PUMP - DISASSEMBLY, OIL.....21-209,21-380,

21-555,21-726

PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER

STEERING..........................19-31

PUMP - INSPECTION, OIL . . . 9-107,9-163,9-220,

9-299,9-50

PUMP - INSPECTION, OIL......21-211,21-382,

21-557,21-728

PUMP - INSTALLATION, AIR INJECTION . . . 25-29

PUMP - INSTALLATION, FUEL INJECTION . 14-71

PUMP - INSTALLATION, FUEL TRANSFER

. 14-83

PUMP - INSTALLATION, LEAK

DETECTION

.........................25-34

PUMP - INSTALLATION, OIL

. 9-109,9-165,9-221,

9-300,9-52

PUMP - OPERATION

..................19-31

PUMP - OPERATION, AIR INJECTION

.....25-28PUMP - OPERATION, FUEL..............14-9

PUMP - OPERATION, FUEL INJECTION....14-66

PUMP - OPERATION, FUEL TRANSFER....14-79

PUMP - OPERATION, OIL . 21-208,21-379,21-554,

21-724

PUMP - REMOVAL, AIR INJECTION......25-29

PUMP - REMOVAL, FUEL INJECTION.....14-68

PUMP - REMOVAL, FUEL TRANSFER.....14-83

PUMP - REMOVAL, LEAK DETECTION....25-34

PUMP - REMOVAL, OIL.....9-107,9-162,9-219,

9-299,9-50

PUMP 235 H.P. - DESCRIPTION, FUEL....14-66

PUMP 245 H.P. - DESCRIPTION, FUEL....14-65

PUMP AMPERAGE TEST - DIAGNOSIS

AND TESTING, FUEL..................14-10

PUMP BYPASS HOSE WITH AIR

CONDITIONING - INSTALLATION,

WATER .............................7-77

PUMP BYPASS HOSE WITH AIR

CONDITIONING - REMOVAL, WATER......7-74

PUMP BYPASS HOSE WITHOUT AIR

CONDITIONING - INSTALLATION,

WATER .............................7-78

PUMP BYPASS HOSE WITHOUT AIR

CONDITIONING - REMOVAL, WATER......7-77

PUMP CAPACITY TEST - DIAGNOSIS

AND TESTING, FUEL...................14-9

PUMP DATA PLATE, SPECIFICATIONS -

FUEL INJECTION.....................14-73

PUMP FILTER - INSTALLATION, AIR......25-29

PUMP FILTER - REMOVAL, AIR...........25-29

PUMP LEAKAGE - DIAGNOSIS AND

TESTING...........................19-31

PUMP MODULE - DESCRIPTION, FUEL....14-12

PUMP MODULE - INSTALLATION, FUEL . . . 14-13

PUMP MODULE - OPERATION, FUEL.....14-13

PUMP MODULE - REMOVAL, FUEL.......14-13

PUMP OUTPUT - DIAGNOSIS AND

TESTING, VACUUM....................7-35

PUMP PRESSURE - DIAGNOSIS AND

TESTING, FUEL TRANSFER.............14-80

PUMP PRESSURE TEST - DIAGNOSIS

AND TESTING, FUEL..................14-10

PUMP RELAY - DESCRIPTION, FUEL.....14-41

PUMP RELAY - DESCRIPTION, FUEL

INJECTION..........................14-99

PUMP RELAY - INSTALLATION, FUEL.....14-41

PUMP RELAY - OPERATION, FUEL.......14-41

PUMP RELAY - OPERATION, FUEL

INJECTION..........................14-99

PUMP RELAY - REMOVAL, FUEL........14-41

PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD AND FUEL...............8I-3

PUMP, SPECIAL TOOLS - POWER

STEERING..........................19-36

PUMP TIMING - DIAGNOSIS AND

TESTING, FUEL INJECTION.............14-66

PUMP VOLUME CHECK - STANDARD

PROCEDURE, OIL . 21-209,21-379,21-554,21-724

PUMP/MOTOR - DESCRIPTION, WASHER . . 8R-9

PUMP/MOTOR - INSTALLATION,

WASHER...........................8R-10

PUMP/MOTOR - OPERATION, WASHER....8R-9

PUMP/MOTOR - REMOVAL, WASHER....8R-10

PUSH-IN FASTENERS - DESCRIPTION.....23-1

PUSHRODS - CLEANING...............9-249

PUSHRODS - INSPECTION.............9-250

QUARTER TRIM PANEL - INSTALLATION . 23-128

QUARTER TRIM PANEL - REMOVAL.....23-127

QUARTER WINDOW - INSTALLATION....23-151

QUARTER WINDOW - REMOVAL........23-151

QUICK CONNECT FITTING -

DESCRIPTION.......................14-22

QUICK-CONNECT FITTINGS - STANDARD

PROCEDURES.......................14-22

RADIATOR - 3.9L/5.2L/5.9L - CLEANING . . . 7-60

RADIATOR - 3.9L/5.2L/5.9L -

DESCRIPTION........................7-59

RADIATOR - 3.9L/5.2L/5.9L -

INSPECTION.........................7-61

RADIATOR - 3.9L/5.2L/5.9L -

INSTALLATION........................7-61

RADIATOR - 3.9L/5.2L/5.9L - OPERATION

. . 7-59

RADIATOR - 3.9L/5.2L/5.9L - REMOVAL

....7-59

RADIATOR - 5.9L DIESEL - CLEANING

.....7-65

RADIATOR - 5.9L DIESEL -

DESCRIPTION

........................7-63

RADIATOR - 5.9L DIESEL - INSPECTION

. . . 7-65RADIATOR - 5.9L DIESEL -

INSTALLATION........................7-65

RADIATOR - 5.9L DIESEL - OPERATION....7-63

RADIATOR - 5.9L DIESEL - REMOVAL.....7-63

RADIATOR - 8.0L - CLEANING...........7-62

RADIATOR - 8.0L - DESCRIPTION........7-61

RADIATOR - 8.0L - INSPECTION..........7-62

RADIATOR - 8.0L - INSTALLATION........7-63

RADIATOR - 8.0L - OPERATION..........7-61

RADIATOR - 8.0L - REMOVAL............7-62

RADIATOR CAP - DIAGNOSIS AND

TESTING............................7-66

RADIATOR CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING..............7-66

RADIATOR COOLANT FLOW -

DIAGNOSIS AND TESTING......7-59,7-61,7-63

RADIATOR FAN - 3.9L/5.2L/5.9L/8.0L -

CLEANING...........................7-43

RADIATOR FAN - 3.9L/5.2L/5.9L/8.0L -

INSPECTION.........................7-43

RADIATOR FAN - 3.9L/5.2L/5.9L/8.0L -

INSTALLATION........................7-43

RADIATOR FAN - 3.9L/5.2L/5.9L/8.0L -

REMOVAL...........................7-42

RADIATOR FAN - 5.9L DIESEL -

CLEANING...........................7-44

RADIATOR FAN - 5.9L DIESEL -

INSPECTION.........................7-44

RADIATOR FAN - 5.9L DIESEL -

INSTALLATION........................7-45

RADIATOR FAN - 5.9L DIESEL -

REMOVAL...........................7-44

RADIATOR IN-TANK TRANSMISSION OIL

COOLER - STANDARD PROCEDURE,

FLUSHING COOLER AND TUBES -

WITHOUT...................7-80,7-83,7-86

RADIATOR IN-TANK TRANSMISSION OIL

COOLER - STANDARD PROCEDURE,

FLUSHING COOLERS AND TUBES -

WITH.......................7-79,7-83,7-85

RADIATOR PRESSURE CAP - CLEANING . . . 7-66

RADIATOR PRESSURE CAP -

DESCRIPTION........................7-65

RADIATOR PRESSURE CAP -

INSPECTION.........................7-66

RADIATOR PRESSURE CAP - OPERATION . . 7-65

RADIO - DESCRIPTION................8A-10

RADIO - DIAGNOSIS AND TESTING......8A-10

RADIO - INSPECTION.................30-17

RADIO - OPERATION..................8A-10

RADIO CHOKE RELAY - DESCRIPTION.....8A-8

RADIO CHOKE RELAY - DIAGNOSIS AND

TESTING............................8A-8

RADIO CHOKE RELAY - INSTALLATION....8A-9

RADIO CHOKE RELAY - OPERATION.......8A-8

RADIO CHOKE RELAY - REMOVAL........8A-9

RADIO NOISE SUPPRESSION

COMPONENTS - DESCRIPTION..........8A-12

RADIO NOISE SUPPRESSION

COMPONENTS - DIAGNOSIS AND

TESTING...........................8A-12

RATINGS, SPECIFICATIONS -

GENERATOR........................8F-28

RATTLES AND WIND NOISE -

INSPECTION, SQUEAKS................30-15

RBI - REAR AXLE, 286................3-182

RE TRANSMISSION, SPECIAL TOOLS . . . 21-534,

21-704

RE TRANSMISSIONS, SPECIAL TOOLS . . 21-188,

21-359

READING LAMP - DESCRIPTION.........8L-36

READING LAMP - INSTALLATION........8L-36

READING LAMP - OPERATION..........8L-36

READING LAMP - REMOVAL............8L-36

REAR - 2500/3500 - INSTALLATION.......5-22

REAR - 2500/3500 - REMOVAL...........5-21

REAR - DESCRIPTION..................2-26

REAR - DESCRIPTION, CRANKSHAFT OIL

SEAL......................9-148,9-34,9-91

REAR - INSTALLATION.............5-13,5-26

REAR - INSTALLATION

................22-12

REAR - INSTALLATION, CRANKSHAFT

OIL SEAL

.........9-149,9-206,9-278,9-35,9-92

REAR - INSTALLATION, PROPELLER

SHAFT

...............................3-9

REAR - OPERATION, CRANKSHAFT OIL

SEAL

......................9-148,9-34,9-92

REAR - REMOVAL

.................5-10,5-23

BR/BEINDEX 27

Description Group-Page Description Group-Page Description Group-Page

Page 2882 of 2889

TANK MODULE - DESCRIPTION, FUEL....14-78

TANK MODULE - INSTALLATION, FUEL....14-79

TANK MODULE - OPERATION, FUEL......14-78

TANK MODULE - REMOVAL, FUEL.......14-78

TAPE STRIPE - INSTALLATION..........23-88

TAPE STRIPE - REMOVAL..............23-88

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC............9-151,9-206,9-38,9-95

TASK MANAGER - DESCRIPTION........25-15

TASK MANAGER - OPERATION..........25-19

TEMP SENSOR - 3.9L/5.2L/5.9L -

DESCRIPTION, ENGINE COOLANT.........7-48

TEMP SENSOR - 3.9L/5.2L/5.9L -

INSTALLATION, ENGINE COOLANT........7-48

TEMP SENSOR - 3.9L/5.2L/5.9L -

OPERATION, ENGINE COOLANT..........7-48

TEMP SENSOR - 3.9L/5.2L/5.9L -

REMOVAL, ENGINE COOLANT............7-48

TEMP SENSOR - DESCRIPTION,

AMBIENT..........................8M-11

TEMP SENSOR - INSTALLATION,

AMBIENT..........................8M-13

TEMP SENSOR - OPERATION, AMBIENT . . 8M-11

TEMP SENSOR - REMOVAL, AMBIENT . . . 8M-12

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE............................8J-19

TEMPERATURE GAUGE - OPERATION,

ENGINE............................8J-19

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY...........................8F-29

TEMPERATURE SENSOR - DESCRIPTION,

FUEL..............................14-99

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION . . . 21-262,21-433,21-606,21-779

TEMPERATURE SENSOR - DIAGNOSIS &

TESTING, AMBIENT..................8M-12

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-29

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-29

TEMPERATURE SENSOR - OPERATION,

FUEL.............................14-100

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION . . . 21-262,21-433,21-606,21-779

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-29

TENSIONER - ADJUSTMENT, CABLE.......5-40

TENSIONER - DESCRIPTION, TIMING

BELT/CHAIN..........................9-57

TENSIONER - OPERATION, TIMING

BELT/CHAIN..........................9-57

TENSIONERS - 3.9L/5.2L/5.9L -

DESCRIPTION, BELT...................7-19

TENSIONERS - 3.9L/5.2L/5.9L -

INSTALLATION, BELT...................7-20

TENSIONERS - 3.9L/5.2L/5.9L -

OPERATION, BELT.....................7-19

TENSIONERS - 3.9L/5.2L/5.9L -

REMOVAL, BELT......................7-20

TENSIONERS - 5.9L DIESEL -

DESCRIPTION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

INSTALLATION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

OPERATION, BELT.....................7-23

TENSIONERS - 5.9L DIESEL - REMOVAL,

BELT ...............................7-23

TENSIONERS - 8.0L - DESCRIPTION,

BELT ...............................7-20

TENSIONERS - 8.0L - INSTALLATION,

BELT ...............................7-22

TENSIONERS - 8.0L - OPERATION, BELT . . . 7-20

TENSIONERS - 8.0L - REMOVAL, BELT.....7-21

TERMINAL - INSTALLATION.........8W-01-11

TERMINAL - REMOVAL.............8W-01-11

TEST - DIAGNOSIS AND TESTING, FUEL

INJECTOR.....................14-53,14-95

TEST - DIAGNOSIS AND TESTING, FUEL

PRESSURE LEAK DOWN

................14-2

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP AMPERAGE

....................14-10

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP CAPACITY

......................14-9

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP PRESSURE

....................14-10

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE

. . 21-144,21-315,21-487,

21-658TEST - DIAGNOSIS AND TESTING,

POWR-LOKY........................3-161

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-3

TEST - INSPECTION WINDSHIELD

WIPERS/WASHERS, ROAD.............30-18

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-11

TEST - STANDARD PROCEDURE,

HYDROMETER.......................8F-12

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-15

TEST - STANDARD PROCEDURE, LOAD . . . 8F-14

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE...............8F-13

TEST - STANDARD PROCEDURE,

VERIFICATION........................8O-5

TEST INSPECTION - DESCRIPTION,

ROAD..............................30-15

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION..........................25-1

TEST MODE - DESCRIPTION, STATE

DISPLAY............................25-1

TETHER - INSTALLATION, CHILD.........8O-9

TETHER - REMOVAL, CHILD.............8O-9

THEFT SECURITY - DESCRIPTION,

VEHICLE............................8Q-1

THEFT SECURITY - OPERATION, VEHICLE . . 8Q-2

THEFT SECURITY SYSTEM - DIAGNOSIS

AND TESTING, VEHICLE................8Q-3

THERMOSTAT - 3.9L/5.2L/5.9L -

DESCRIPTION, ENGINE COOLANT.........7-49

THERMOSTAT - 3.9L/5.2L/5.9L -

INSTALLATION, ENGINE COOLANT........7-50

THERMOSTAT - 3.9L/5.2L/5.9L -

OPERATION, ENGINE COOLANT..........7-49

THERMOSTAT - 3.9L/5.2L/5.9L -

REMOVAL, ENGINE COOLANT............7-49

THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE COOLANT.........7-54

THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE COOLANT........7-55

THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE COOLANT..........7-54

THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE COOLANT............7-55

THERMOSTAT - 8.0L - DESCRIPTION,

ENGINE COOLANT.....................7-52

THERMOSTAT - 8.0L - INSTALLATION,

ENGINE COOLANT.....................7-53

THERMOSTAT - 8.0L - OPERATION,

ENGINE COOLANT.....................7-52

THERMOSTAT - 8.0L - REMOVAL,

ENGINE COOLANT.....................7-52

THERMOSTAT - DIAGNOSIS AND

TESTING....................7-49,7-52,7-54

THOMAS AND BETTS - INSTALLATION,

CONNECTOR.....................8W-01-10

THOMAS AND BETTS - REMOVAL,

CONNECTOR......................8W-01-9

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM......21-159,21-330,

21-502,21-673

THREADED HOLE REPAIR -

DESCRIPTION......................Intro.-6

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN . 9-11,9-125,9-181,

9-238,9-68

THROTTLE BODY - DESCRIPTION........14-48

THROTTLE BODY - OPERATION.........14-48

THROTTLE CONTROL CABLE -

INSTALLATION.................14-105,14-50

THROTTLE CONTROL CABLE -

REMOVAL....................14-104,14-50

THROTTLE POSITION SENSOR -

DESCRIPTION.......................14-51

THROTTLE POSITION SENSOR -

OPERATION.........................14-51

THROTTLE VALVE CABLE -

ADJUSTMENTS, TRANSMISSION

. 21-254,21-425,

21-598,21-771

THROTTLE VALVE CABLE -

DESCRIPTION

....21-253,21-424,21-597,21-770

TIMER MODULE - DESCRIPTION, BODY

CONTROL/CENTRAL

...................8E-1

TIMER MODULE - DIAGNOSIS AND

TESTING, CENTRAL

....................8E-4

TIMER MODULE - INSTALLATION, BODY

CONTROL/CENTRAL

...................8E-6TIMER MODULE - OPERATION, BODY

CONTROL/CENTRAL...................8E-3

TIMER MODULE - REMOVAL, BODY

CONTROL/CENTRAL...................8E-5

TIMING - DIAGNOSIS AND TESTING,

FUEL INJECTION PUMP...............14-66

TIMING BELT / CHAIN COVER(S) -

INSTALLATION........9-113,9-169,9-226,9-56

TIMING BELT / CHAIN COVER(S) -

REMOVAL............9-113,9-169,9-225,9-56

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION........9-115,9-170,9-227,9-58

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL............9-114,9-170,9-226,9-57

TIMING BELT/CHAIN TENSIONER -

DESCRIPTION........................9-57

TIMING BELT/CHAIN TENSIONER -

OPERATION..........................9-57

TIMING CHAIN STRETCH - INSPECTION,

MEASURING..........9-114,9-170,9-227,9-58

TIMING, SPECIFICATIONS - IGNITION......8I-3

TIPS - CLEANING, APPEARANCE........30-21

TIRE - DESCRIPTION, SPARE............22-9

TIRE AND WHEEL BALANCE -

STANDARD PROCEDURES...............22-4

TIRE AND WHEEL RUNOUT - DIAGNOSIS

AND TESTING........................22-1

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING........................22-8

TIRE PRESSURES - INSPECTION.........30-8

TIRE REVOLUTIONS PER MILE,

SPECIFICATIONS......................22-9

TIRE ROTATION - STANDARD

PROCEDURES........................22-2

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING........................22-7

TIRE WINCH - INSTALLATION, SPARE....13-10

TIRE WINCH - REMOVAL, SPARE........13-10

TIRES - DESCRIPTION.............22-5,22-6

TO GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT.............8W-01-6

TO GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR SHORT....8W-01-7

TO OIL COOLER - INSTALLATION, AIR.....7-88

TO OIL COOLER - REMOVAL, AIR.........7-87

TO OIL COOLER - REMOVAL, WATER......7-87

TO USE WIRING DIAGRAMS -

DESCRIPTION, HOW................8W-01-1

TOOLS - 5.2L ENGINE, SPECIAL..........9-77

TOOLS - 5.9L DIESEL ENGINE, SPECIAL . . 9-244

TOOLS - 5.9L ENGINE, SPECIAL.........9-134

TOOLS - 8.0L ENGINE, SPECIAL.........9-188

TOOLS - AUDIO SYSTEMS, SPECIAL......8A-4

TOOLS - BASE BRAKES, SPECIAL.........5-4

TOOLS - COOLING, SPECIAL.............7-18

TOOLS - DIESEL FUEL SYSTEM,

SPECIAL...........................14-59

TOOLS - FRONT AXLE, SPECIAL..........3-58

TOOLS - FRONT AXLES, SPECIAL.........3-25

TOOLS - FUEL SYSTEM, SPECIAL . . . 14-36,14-4

TOOLS - HEADLAMP ALIGNMENT,

SPECIAL............................8L-4

TOOLS - INDEPENDENT FRONT

SUSPENSION, SPECIAL..................2-9

TOOLS - LINK/COIL SUSPENSION,

SPECIAL

............................2-16

TOOLS - NV5600 MANUAL

TRANSMISSION, SPECIAL

.............21-127

TOOLS - OVERHEAD CONSOLE

SYSTEMS, SPECIAL

...................8M-8

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL

................8W-97-2

TOOLS - POWER STEERING GEAR,

SPECIAL

...........................19-20

TOOLS - POWER STEERING PUMP,

SPECIAL

...........................19-36

TOOLS - PROPELLER SHAFT, SPECIAL

......3-8

TOOLS - RE TRANSMISSION, SPECIAL

. . 21-534,

21-704

TOOLS - RE TRANSMISSIONS, SPECIAL

. 21-188,

21-359

TOOLS - STEERING LINKAGE, SPECIAL

. . . 19-39,

19-42

TOOLS - SUSPENSION-REAR, SPECIAL

....2-28

TOOLS, AIRBAG SYSTEM - SPECIAL

......8O-6

TOOLS, WIRING/TERMINAL - SPECIAL

. 8W-01-8

BR/BEINDEX 35

Description Group-Page Description Group-Page Description Group-Page