child restraint DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 676 of 2889

RESTRAINTS

TABLE OF CONTENTS

page page

RESTRAINTS

DESCRIPTION............................1

OPERATION.............................2

WARNING...............................3

DIAGNOSIS AND TESTING..................4

AIRBAG SYSTEM........................4

STANDARD PROCEDURE...................4

HANDLING NON-DEPLOYED AIRBAGS.......4

SERVICE AFTER AN AIRBAG

DEPLOYMENT..........................4

VERIFICATION TEST.....................5

SPECIAL TOOLS..........................6

AIRBAG CONTROL MODULE

DESCRIPTION............................6

OPERATION.............................6

REMOVAL...............................7

INSTALLATION............................8

CHILD TETHER

REMOVAL...............................9

INSTALLATION............................9

CLOCKSPRING

DESCRIPTION...........................10

OPERATION.............................10

STANDARD PROCEDURE..................11

CLOCKSPRING CENTERING..............11

REMOVAL..............................11

INSTALLATION...........................13

DRIVER AIRBAG

DESCRIPTION...........................14

OPERATION.............................14

REMOVAL..............................14

DISASSEMBLY...........................15

ASSEMBLY.............................17

INSTALLATION...........................18FRONT SEAT BELT & RETRACTOR

REMOVAL..............................18

INSTALLATION...........................19

FRONT SEAT BELT BUCKLE

REMOVAL..............................20

INSTALLATION...........................20

PASSENGER AIRBAG

DESCRIPTION...........................21

OPERATION.............................21

REMOVAL..............................21

INSTALLATION...........................23

PASSENGER AIRBAG ON/OFF SWITCH

DESCRIPTION...........................23

OPERATION.............................24

REMOVAL..............................24

INSTALLATION...........................25

REAR SEAT BELT & RETRACTOR

REMOVAL..............................26

INSTALLATION...........................26

REAR SEAT BELT BUCKLE

REMOVAL..............................27

INSTALLATION...........................27

SEAT BELT SWITCH

DESCRIPTION...........................28

OPERATION.............................28

DIAGNOSIS AND TESTING.................28

SEAT BELT SWITCH....................28

SEAT BELT TURNING LOOP ADJUSTER

REMOVAL..............................29

INSTALLATION...........................29

TURNING LOOP HEIGHT ADJUSTER KNOB

REMOVAL..............................30

INSTALLATION...........................30

RESTRAINTS

DESCRIPTION

A dual front airbag system is standard factory-in-

stalled safety equipment on this model. The airbag

system is a passive, inflatable, Supplemental

Restraint System (SRS) and vehicles with this equip-

ment can be readily identified by the ªSRS - AIR-

BAGº logo molded into the driver airbag trim cover

in the center of the steering wheel and also into the

passenger airbag door on the instrument panel above

the glove box (Fig. 1). Vehicles with the airbag sys-

tem can also be identified by the airbag indicator,which will illuminate in the instrument cluster for

about seven seconds as a bulb test each time the

ignition switch is turned to the On position.

The dual front airbag system consists of the follow-

ing major components, which are described in further

detail elsewhere in this service manual:

²Airbag Control Module- The Airbag Control

Module (ACM) is located on a mount on the floor

panel transmission tunnel, below the center of the

instrument panel.

²Airbag Indicator- The airbag indicator is inte-

gral to the ElectroMechanical Instrument Cluster

(EMIC), which is located on the instrument panel in

front of the driver.

BR/BERESTRAINTS 8O - 1

Page 677 of 2889

²Clockspring- The clockspring is located near

the top of the steering column, directly beneath the

steering wheel.

²Driver Airbag- The driver airbag is located in

the center of the steering wheel, beneath the driver

airbag trim cover.

²Driver Knee Blocker- The driver knee blocker

is a molded plastic structural unit secured to the

back side of and integral to the instrument panel

steering column opening cover.

²Passenger Airbag- The passenger airbag is

located on the instrument panel, beneath the passen-

ger airbag door on the instrument panel above the

glove box on the passenger side of the vehicle.

²Passenger Airbag On/Off Switch- The pas-

senger airbag on/off switch is located in a dedicated

opening in the upper right corner of the instrument

panel cluster bezel, to the right of the center panel

outlets of the climate control system.

²Passenger Knee Blocker- The passenger knee

blocker is a structural reinforcement that is integral

to and concealed within the glove box door.

The ACM and the EMIC each contain a central

processing unit and programming that allow them to

communicate with each other using the Chrysler Col-

lision Detection (CCD) data bus network. This

method of communication is used for control of the

airbag indicator on all models. (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

COMMUNICATION - DESCRIPTION).

Hard wired circuitry connects the airbag system

components to each other through the electrical sys-

tem of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system, and to the air-

bag system components through the use of a combi-

nation of soldered splices, splice block connectors,and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

OPERATION

The airbag system is referred to as a supplemental

restraint system because it was designed and is

intended to enhance the protection for the front seat

occupants of the vehicleonlywhen used in conjunc-

tion with the seat belts. It is referred to as a passive

system because the vehicle occupants are not

required to do anything to make it work. The pri-

mary passenger restraints in this or any other vehi-

cle are the standard equipment factory-installed seat

belts. Seat belts are referred to as an active restraint

because the vehicle occupants are required to physi-

cally fasten and properly adjust these restraints in

order to benefit from them. The vehicle occupants

must be wearing their seat belts in order to obtain

the maximum safety benefit from the factory-in-

stalled airbag system.

The airbag system electrical circuits are continu-

ously monitored and controlled by a microprocessor

and software contained within the Airbag Control

Module (ACM). An airbag indicator in the ElectroMe-

chanical Instrument Cluster (EMIC) lights for about

seven seconds as a bulb test each time the ignition

switch is turned to the On or Start positions. Follow-

ing the bulb test, the airbag indicator is turned on or

off by the ACM to indicate the status of the airbag

system. If the airbag indicator comes on at any time

other than during the bulb test, it indicates that

there is a problem in the airbag system electrical cir-

cuits. Such a problem may cause the airbags not to

deploy when required, or to deploy when not

required.

The clockspring on the top of the steering column

allows a continuous electrical circuit to be main-

tained between the stationary steering column and

the driver airbag inflator, which rotates with the

steering wheel. The passenger airbag on/off switch

allows the passenger side airbag to be disabled when

circumstances necessitate that a child, or an adult

with certain medical conditions be placed in the front

passenger seating position. Refer to the owner's man-

ual in the vehicle glove box for specific recommenda-

tions concerning the specific circumstances where the

passenger airbag on/off switch should be used to dis-

able the passenger airbag.

Fig. 1 SRS Logo

8O - 2 RESTRAINTSBR/BE

RESTRAINTS (Continued)

Page 684 of 2889

CHILD TETHER

REMOVAL

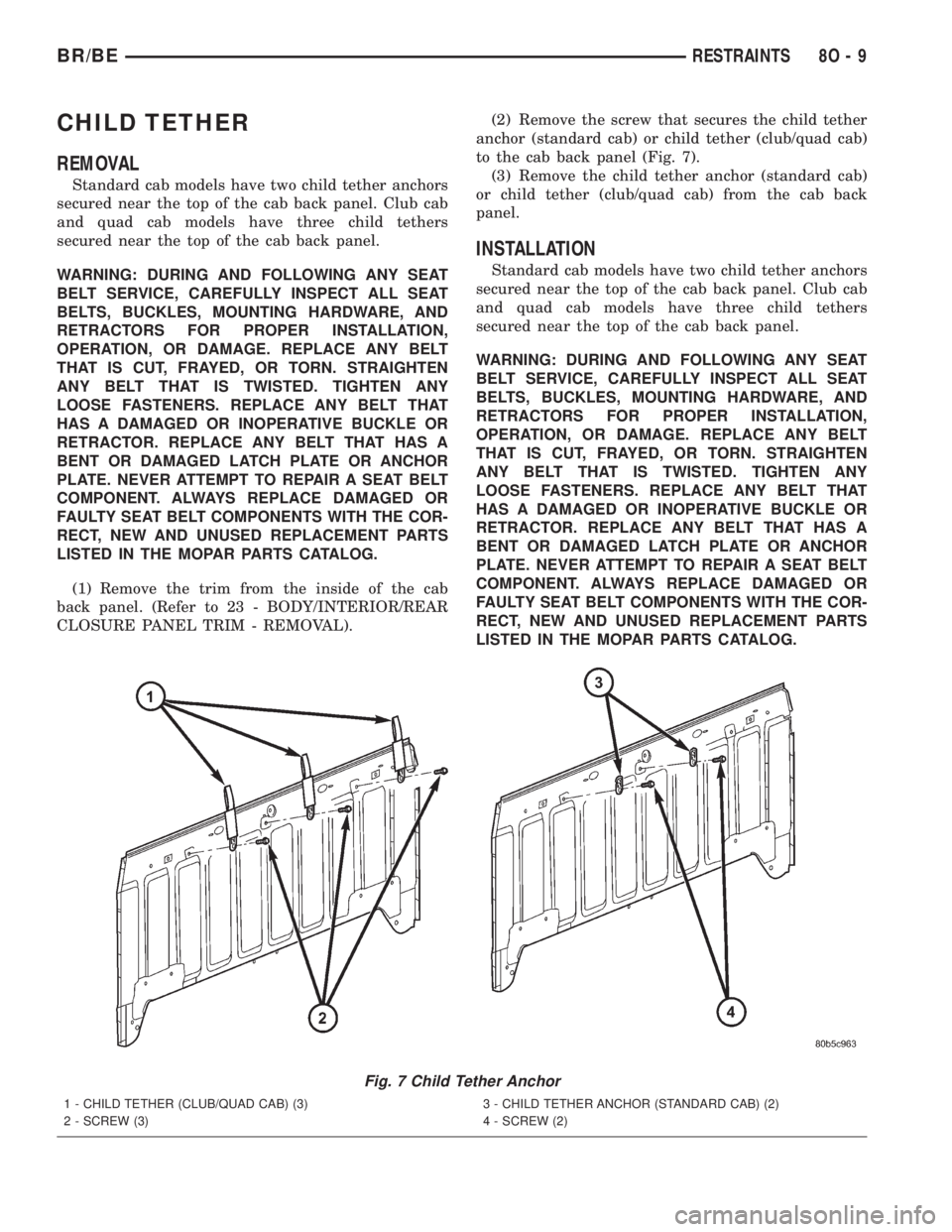

Standard cab models have two child tether anchors

secured near the top of the cab back panel. Club cab

and quad cab models have three child tethers

secured near the top of the cab back panel.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Remove the trim from the inside of the cab

back panel. (Refer to 23 - BODY/INTERIOR/REAR

CLOSURE PANEL TRIM - REMOVAL).(2) Remove the screw that secures the child tether

anchor (standard cab) or child tether (club/quad cab)

to the cab back panel (Fig. 7).

(3) Remove the child tether anchor (standard cab)

or child tether (club/quad cab) from the cab back

panel.

INSTALLATION

Standard cab models have two child tether anchors

secured near the top of the cab back panel. Club cab

and quad cab models have three child tethers

secured near the top of the cab back panel.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

Fig. 7 Child Tether Anchor

1 - CHILD TETHER (CLUB/QUAD CAB) (3)

2 - SCREW (3)3 - CHILD TETHER ANCHOR (STANDARD CAB) (2)

4 - SCREW (2)

BR/BERESTRAINTS 8O - 9

Page 685 of 2889

(1) Position the child tether anchor (standard cab)

or child tether (club/quad cab) onto the cab back

panel (Fig. 7).

(2) Install and tighten the screw that secures the

child tether anchor (standard cab) or child tether

(club/quad cab) onto the cab back panel. Tighten the

screw to 13.5 N´m (120 in. lbs.).

(3) Reinstall the trim onto the inside of the cab

back panel. (Refer to 23 - BODY/INTERIOR/REAR

CLOSURE PANEL TRIM - INSTALLATION).

CLOCKSPRING

DESCRIPTION

The clockspring assembly is secured with two inte-

gral plastic latches onto the steering column lock

housing near the top of the steering column, behind

the steering wheel. The clockspring consists of a flat,

round molded plastic case with a stubby tail that

hangs below the steering column and contains a con-

nector receptacle and a long pigtail wire with connec-

tor that face toward the instrument panel. Within

the plastic housing is a spool-like molded plastic

rotor with a large exposed hub. The upper surface of

the rotor hub has a large center hole, two large flats,

two auto-locking tabs, and three short pigtail wires

with connectors that face toward the steering wheel.

The lower surface of the rotor hub has two integral

turn signal cancelling cam lobes. Within the plastic

case and wound around the rotor spool is a long rib-

bon-like tape that consists of several thin copper wire

leads sandwiched between two thin plastic mem-

branes. The outer end of the tape terminates at the

connector receptacle and pigtail wire that face the

instrument panel, while the inner end of the tape

terminates at the pigtail wires on the hub of the

clockspring rotor that face the steering wheel.

Service replacement clocksprings are shipped pre-

centered and with a piece of tape covering the

engaged auto-locking tabs. The auto-locking tabs

secure the centered clockspring rotor to the clock-

spring case during shipment, but these tabs are auto-

matically disengaged once the clockspring is installed

on the steering column. (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - STANDARD PRO-

CEDURE - CLOCKSPRING CENTERING).

The clockspring cannot be repaired. If the clock-

spring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electri-

cal continuity between the fixed instrument panel

wire harness and the electrical components mountedon or in the rotating steering wheel. On this model

the rotating electrical components include the driver

airbag, the horn switch, the speed control switches,

and the remote radio switches if the vehicle is so

equipped. The clockspring case is positioned and

secured to the upper steering column lock housing by

two integral plastic latches. The connector receptacle

on the tail of the fixed clockspring housing connect

the clockspring to the vehicle electrical system

through a take out with connector from the instru-

ment panel wire harness. The lower clockspring pig-

tail on the tail of the clockspring housing connect the

clockspring driver airbag circuits to a separate take

out and connector of the instrument panel wire har-

ness located near the lower instrument panel rein-

forcement, below the steering column. The

clockspring rotor is movable and is keyed to the hub

of the steering wheel by two large flats that are

molded into the rotor hub. The two lobes on the

lower surface of the clockspring rotor hub contact a

turn signal cancel actuator of the multi-function

switch to provide automatic turn signal cancellation.

The pigtail wires on the upper surface of the clock-

spring connect the clockspring to the horn switch, the

two speed control switches, and the remote radio

switches on vehicles that are so equipped.

Like the clockspring in a timepiece, the clockspring

tape has travel limits and can be damaged by being

wound too tightly during full stop-to-stop steering

wheel rotation. To prevent this from occurring, the

clockspring must be centered when it is installed on

the steering column. Centering the clockspring

indexes the clockspring spool to the movable steering

components so that the tape can operate within its

designed travel limits. However, if the clockspring is

removed from the steering column or if the steering

shaft is disconnected from the steering gear, the

clockspring spool can change position relative to the

movable steering components and must be re-cen-

tered following completion of the service or the tape

may be damaged. Service replacement clocksprings

are shipped pre-centered and with the auto-locking

tabs engaged. A piece of tape covers the auto-locking

tabs to discourage tampering. These auto-locking

tabs should not be disengaged until the clockspring

has been installed on the steering column. If this

shipping tape is removed or damaged, or if the auto-

locking tabs are disengaged before the clockspring is

installed on a steering column, the clockspring cen-

tering procedure must be performed. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING).

8O - 10 RESTRAINTSBR/BE

CHILD TETHER (Continued)