oil capacities DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 19 of 2889

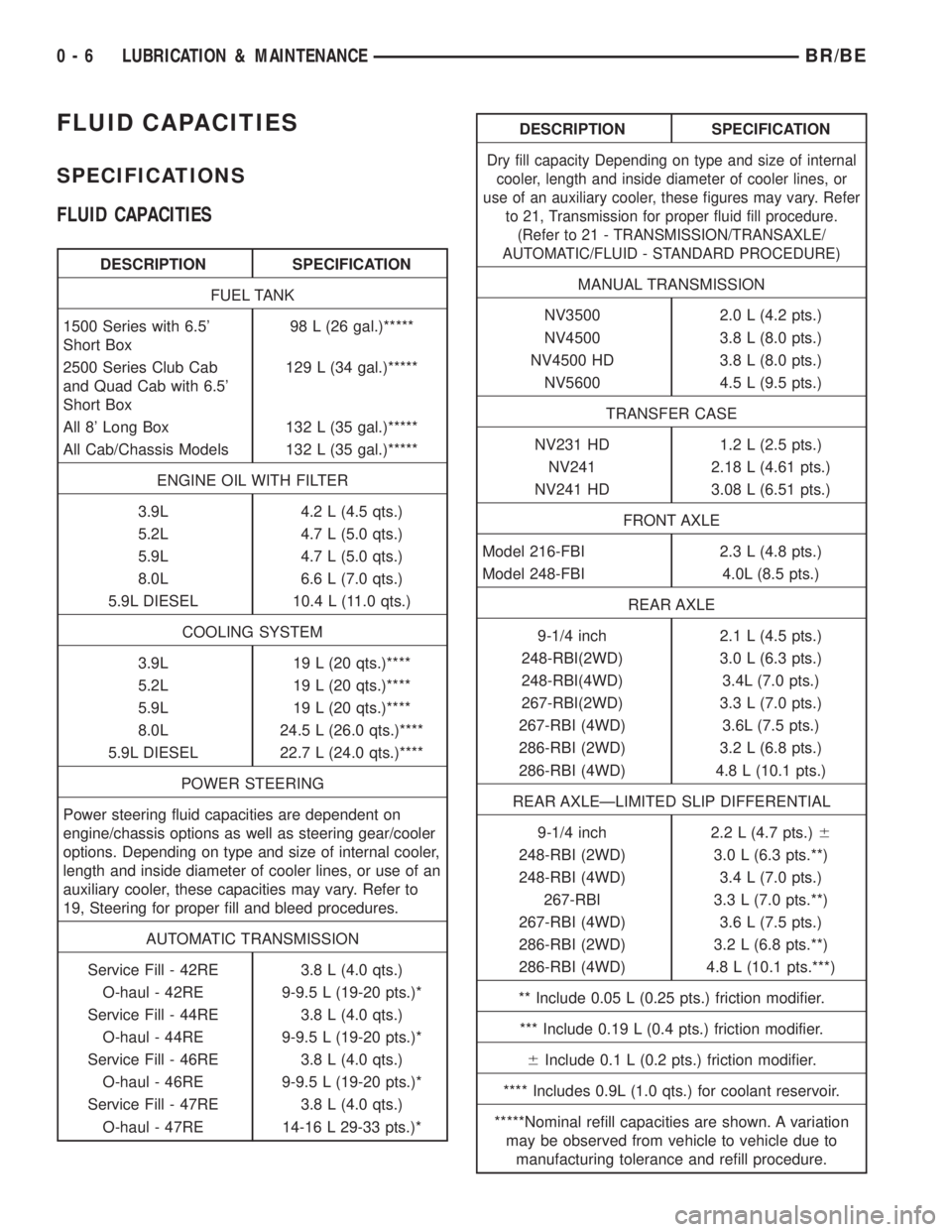

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

DESCRIPTION SPECIFICATION

FUEL TANK

1500 Series with 6.5'

Short Box98 L (26 gal.)*****

2500 Series Club Cab

and Quad Cab with 6.5'

Short Box129 L (34 gal.)*****

All 8' Long Box 132 L (35 gal.)*****

All Cab/Chassis Models 132 L (35 gal.)*****

ENGINE OIL WITH FILTER

3.9L 4.2 L (4.5 qts.)

5.2L 4.7 L (5.0 qts.)

5.9L 4.7 L (5.0 qts.)

8.0L 6.6 L (7.0 qts.)

5.9L DIESEL 10.4 L (11.0 qts.)

COOLING SYSTEM

3.9L 19 L (20 qts.)****

5.2L 19 L (20 qts.)****

5.9L 19 L (20 qts.)****

8.0L 24.5 L (26.0 qts.)****

5.9L DIESEL 22.7 L (24.0 qts.)****

POWER STEERING

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cooler

options. Depending on type and size of internal cooler,

length and inside diameter of cooler lines, or use of an

auxiliary cooler, these capacities may vary. Refer to

19, Steering for proper fill and bleed procedures.

AUTOMATIC TRANSMISSION

Service Fill - 42RE 3.8 L (4.0 qts.)

O-haul - 42RE 9-9.5 L (19-20 pts.)*

Service Fill - 44RE 3.8 L (4.0 qts.)

O-haul - 44RE 9-9.5 L (19-20 pts.)*

Service Fill - 46RE 3.8 L (4.0 qts.)

O-haul - 46RE 9-9.5 L (19-20 pts.)*

Service Fill - 47RE 3.8 L (4.0 qts.)

O-haul - 47RE 14-16 L 29-33 pts.)*

DESCRIPTION SPECIFICATION

Dry fill capacity Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these figures may vary. Refer

to 21, Transmission for proper fluid fill procedure.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC/FLUID - STANDARD PROCEDURE)

MANUAL TRANSMISSION

NV3500 2.0 L (4.2 pts.)

NV4500 3.8 L (8.0 pts.)

NV4500 HD 3.8 L (8.0 pts.)

NV5600 4.5 L (9.5 pts.)

TRANSFER CASE

NV231 HD 1.2 L (2.5 pts.)

NV241 2.18 L (4.61 pts.)

NV241 HD 3.08 L (6.51 pts.)

FRONT AXLE

Model 216-FBI 2.3 L (4.8 pts.)

Model 248-FBI 4.0L (8.5 pts.)

REAR AXLE

9-1/4 inch 2.1 L (4.5 pts.)

248-RBI(2WD) 3.0 L (6.3 pts.)

248-RBI(4WD) 3.4L (7.0 pts.)

267-RBI(2WD) 3.3 L (7.0 pts.)

267-RBI (4WD) 3.6L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.)

286-RBI (4WD) 4.8 L (10.1 pts.)

REAR AXLEÐLIMITED SLIP DIFFERENTIAL

9-1/4 inch 2.2 L (4.7 pts.)6

248-RBI (2WD) 3.0 L (6.3 pts.**)

248-RBI (4WD) 3.4 L (7.0 pts.)

267-RBI 3.3 L (7.0 pts.**)

267-RBI (4WD) 3.6 L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.**)

286-RBI (4WD) 4.8 L (10.1 pts.***)

** Include 0.05 L (0.25 pts.) friction modifier.

*** Include 0.19 L (0.4 pts.) friction modifier.

6Include 0.1 L (0.2 pts.) friction modifier.

**** Includes 0.9L (1.0 qts.) for coolant reservoir.

*****Nominal refill capacities are shown. A variation

may be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure.

0 - 6 LUBRICATION & MAINTENANCEBR/BE

Page 513 of 2889

5.9L DIESEL ENGINE

(1) If equipped, position aluminum spacer to rear

of starter.

(2) Position starter motor to engine.

(3) Support starter and loosely install three

mounting bolts.

(4) Tighten 3 bolts to 43.4 N´m (32 ft. lbs.).

(5) Position wiring eyelets to starter studs and

install nuts. Tighten small nut to 6.2 N´m (55 in.

lbs.). Tighten large nut to 13.6 N´m (120 in. lbs.).

(6) Install protective rubber boot over stud.

(7) Lower vehicle.

(8) Connect battery cables to both batteries.

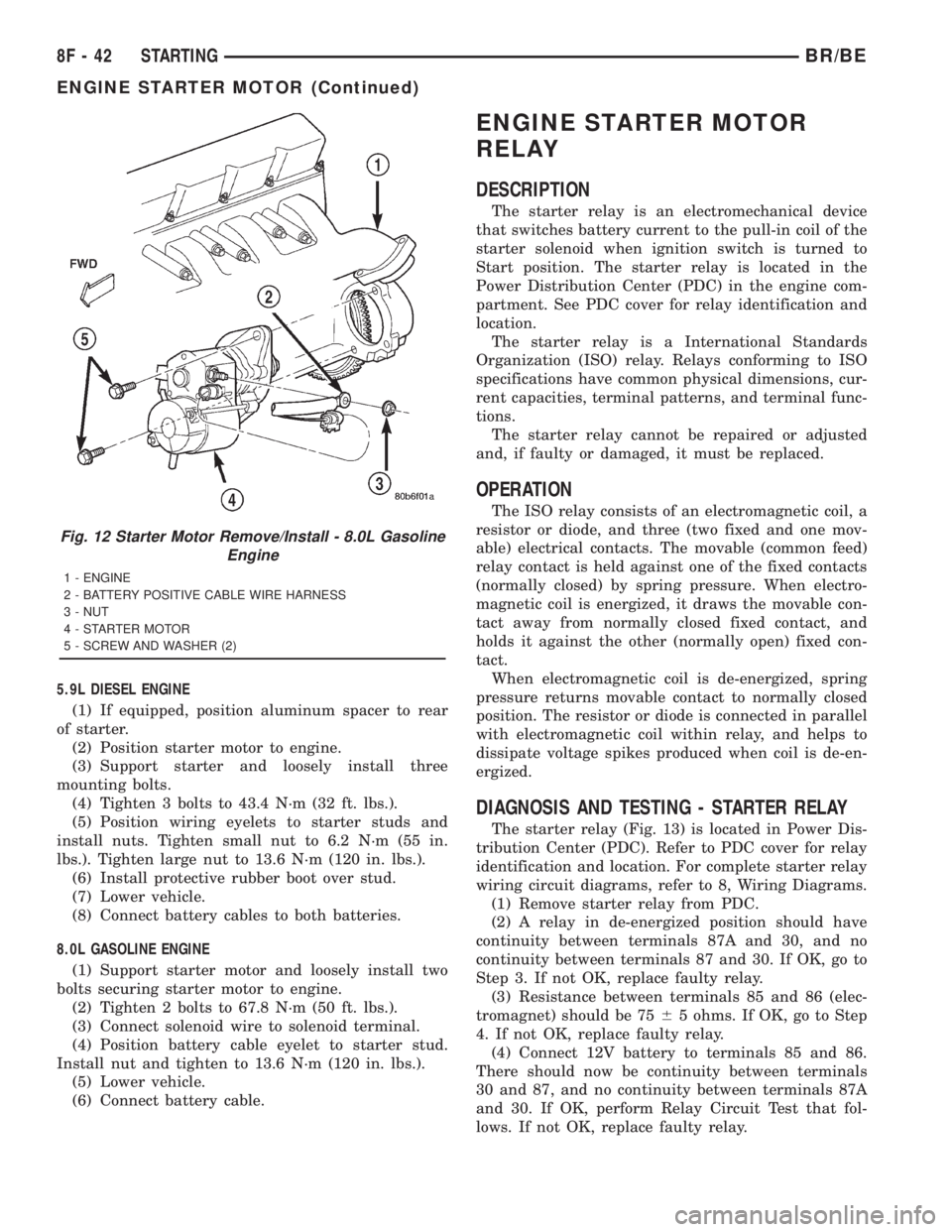

8.0L GASOLINE ENGINE

(1) Support starter motor and loosely install two

bolts securing starter motor to engine.

(2) Tighten 2 bolts to 67.8 N´m (50 ft. lbs.).

(3) Connect solenoid wire to solenoid terminal.

(4) Position battery cable eyelet to starter stud.

Install nut and tighten to 13.6 N´m (120 in. lbs.).

(5) Lower vehicle.

(6) Connect battery cable.

ENGINE STARTER MOTOR

RELAY

DESCRIPTION

The starter relay is an electromechanical device

that switches battery current to the pull-in coil of the

starter solenoid when ignition switch is turned to

Start position. The starter relay is located in the

Power Distribution Center (PDC) in the engine com-

partment. See PDC cover for relay identification and

location.

The starter relay is a International Standards

Organization (ISO) relay. Relays conforming to ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions.

The starter relay cannot be repaired or adjusted

and, if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When electro-

magnetic coil is energized, it draws the movable con-

tact away from normally closed fixed contact, and

holds it against the other (normally open) fixed con-

tact.

When electromagnetic coil is de-energized, spring

pressure returns movable contact to normally closed

position. The resistor or diode is connected in parallel

with electromagnetic coil within relay, and helps to

dissipate voltage spikes produced when coil is de-en-

ergized.

DIAGNOSIS AND TESTING - STARTER RELAY

The starter relay (Fig. 13) is located in Power Dis-

tribution Center (PDC). Refer to PDC cover for relay

identification and location. For complete starter relay

wiring circuit diagrams, refer to 8, Wiring Diagrams.

(1) Remove starter relay from PDC.

(2) A relay in de-energized position should have

continuity between terminals 87A and 30, and no

continuity between terminals 87 and 30. If OK, go to

Step 3. If not OK, replace faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

4. If not OK, replace faulty relay.

(4) Connect 12V battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform Relay Circuit Test that fol-

lows. If not OK, replace faulty relay.

Fig. 12 Starter Motor Remove/Install - 8.0L Gasoline

Engine

1 - ENGINE

2 - BATTERY POSITIVE CABLE WIRE HARNESS

3 - NUT

4 - STARTER MOTOR

5 - SCREW AND WASHER (2)

8F - 42 STARTINGBR/BE

ENGINE STARTER MOTOR (Continued)

Page 527 of 2889

ifications have common physical dimensions, current

capacities, terminal patterns, and terminal functions.

The ISO micro-relay terminal functions are the same

as a conventional ISO relay. However, the ISO micro-

relay terminal pattern (or footprint) is different, the

current capacity is lower, and the physical dimen-

sions are smaller than those of the conventional ISO

relay.

The heated seat relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact. When the electromagnetic coil is de-ener-

gized, spring pressure returns the movable contact to

the normally closed position. The resistor or diode is

connected in parallel with the electromagnetic coil in

the relay, and helps to dissipate voltage spikes that

are produced when the coil is de-energized.

The heated seat relay is controlled by the premium

version of the Central Timer Module (CTM), which

controls the ground feed to the coil ground terminal

of the relay to energize and de-energize the electro-

magnetic coil of the relay. The CTM monitors engine

operation through messages it receives from the Pow-

ertrain Control Module (PCM) over the Chrysler Col-

lision Detection (CCD) data bus network. The CTM is

programmed to energize the relay only when the

engine is running, and to de-energize the relay when

the engine is not running. Refer toCentral Timer

Modulein the index of this service manual for the

location of more information on the premium CTM.

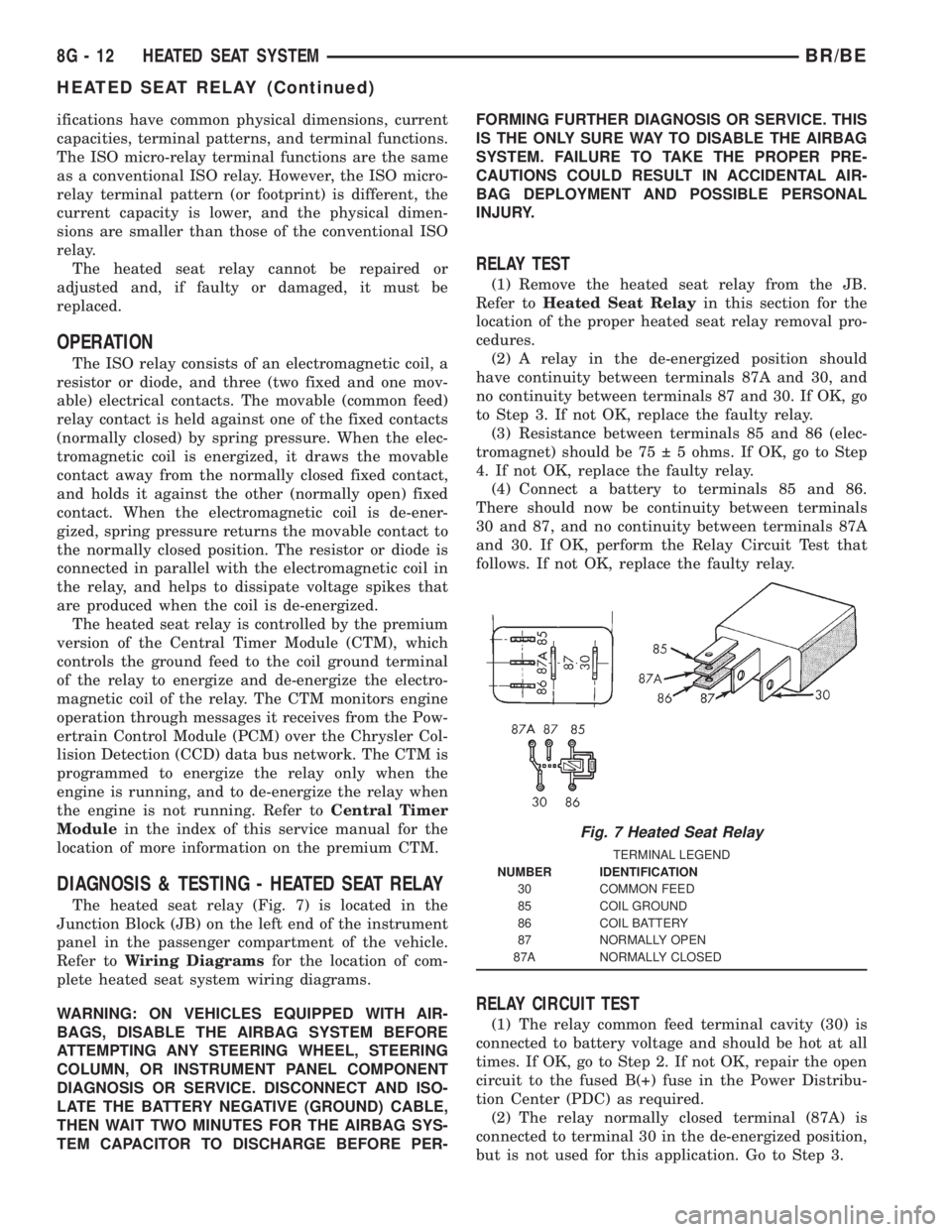

DIAGNOSIS & TESTING - HEATED SEAT RELAY

The heated seat relay (Fig. 7) is located in the

Junction Block (JB) on the left end of the instrument

panel in the passenger compartment of the vehicle.

Refer toWiring Diagramsfor the location of com-

plete heated seat system wiring diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

RELAY TEST

(1) Remove the heated seat relay from the JB.

Refer toHeated Seat Relayin this section for the

location of the proper heated seat relay removal pro-

cedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fused B(+) fuse in the Power Distribu-

tion Center (PDC) as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

Fig. 7 Heated Seat Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8G - 12 HEATED SEAT SYSTEMBR/BE

HEATED SEAT RELAY (Continued)

Page 534 of 2889

INSTALLATION

(1) Position the horn and mounting bracket unit(s)

onto the right fender wheel house front extension.

(2) Install and tighten the screw that secures the

horn and mounting bracket unit(s) to the right

fender wheel house front extension. Tighten the

screw to 11 N´m (95 in. lbs.).

(3) Reconnect the wire harness connector(s) to the

horn connector receptacle(s).

(4) Reconnect the battery negative cable.

HORN RELAY

DESCRIPTION

The horn relay is a electromechanical device that

switches battery current to the horn when the horn

switch grounds the relay coil. The horn relay is

located in the Power Distribution Center (PDC) in

the engine compartment. If a problem is encountered

with a continuously sounding horn, it can usually be

quickly resolved by removing the horn relay from the

PDC until further diagnosis is completed. See the

fuse and relay layout label affixed to the inside sur-

face of the PDC cover for horn relay identification

and location.

The horn relay is a International Standards Orga-

nization (ISO) micro-relay. Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The ISO micro-relay terminal functions

are the same as a conventional ISO relay. However,

the ISO micro-relay terminal pattern (or footprint) is

different, the current capacity is lower, and the phys-

ical dimensions are smaller than those of the conven-

tional ISO relay.

The horn relay cannot be repaired or adjusted and,

if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HORN RELAY

The horn relay (Fig. 2) is located in the Power Dis-

tribution Center (PDC) behind the battery on the

driver side of the engine compartment. If a problem

is encountered with a continuously sounding horn, it

can usually be quickly resolved by removing the horn

relay from the PDC until further diagnosis is com-

pleted. See the fuse and relay layout label affixed to

the inside surface of the PDC cover for horn relay

identification and location. For complete circuit dia-

grams, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Remove the horn relay from the PDC. (Refer to

8 - ELECTRICAL/HORN/HORN RELAY -

REMOVAL) for the procedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

BR/BEHORN 8H - 3

HORN (Continued)

Page 613 of 2889

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMP SWITCH ON

(HIGH BEAMS ON), ONE

HIGH BEAM ON AND

BOTH LOW BEAMS DIM.1. Headlamp feed circuit shorted to

ground.1. Check wiring circuit from right headlamp

fuse to headlamp. Repeat for left side.

Trace short circuit in wiring and repair.

HEADLAMP SWITCH ON,

ONE HEADLAMP

FILAMENT WILL BE AT

FULL INTENSITY AND ALL

OTHER FILAMENTS ARE

ON AND DIM.1. Blown headlamp fuse. 1. Trace short circuit and replace fuse.

2. Open circuit from headlamp fuse

to headlamp.2. Repair open headlamp circuit.

1. HEADLAMPS STAY ON

WITH KEY OUT (DRLM

EQUIPPED VEHICLES).1. Failed DRLM 1. Replace DRLM.

*Canada vehicles must have lamps ON.

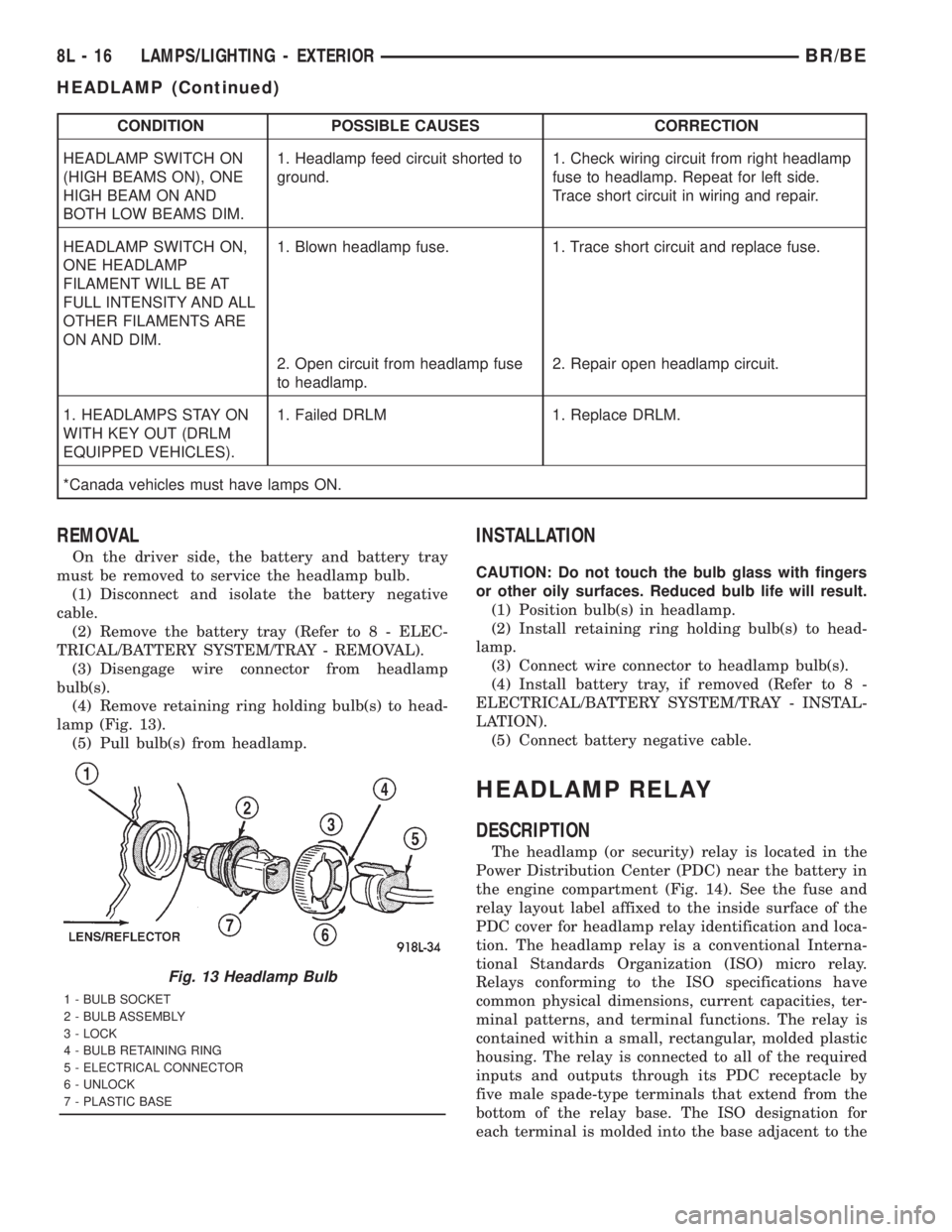

REMOVAL

On the driver side, the battery and battery tray

must be removed to service the headlamp bulb.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(3) Disengage wire connector from headlamp

bulb(s).

(4) Remove retaining ring holding bulb(s) to head-

lamp (Fig. 13).

(5) Pull bulb(s) from headlamp.

INSTALLATION

CAUTION: Do not touch the bulb glass with fingers

or other oily surfaces. Reduced bulb life will result.

(1) Position bulb(s) in headlamp.

(2) Install retaining ring holding bulb(s) to head-

lamp.

(3) Connect wire connector to headlamp bulb(s).

(4) Install battery tray, if removed (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/TRAY - INSTAL-

LATION).

(5) Connect battery negative cable.

HEADLAMP RELAY

DESCRIPTION

The headlamp (or security) relay is located in the

Power Distribution Center (PDC) near the battery in

the engine compartment (Fig. 14). See the fuse and

relay layout label affixed to the inside surface of the

PDC cover for headlamp relay identification and loca-

tion. The headlamp relay is a conventional Interna-

tional Standards Organization (ISO) micro relay.

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The relay is

contained within a small, rectangular, molded plastic

housing. The relay is connected to all of the required

inputs and outputs through its PDC receptacle by

five male spade-type terminals that extend from the

bottom of the relay base. The ISO designation for

each terminal is molded into the base adjacent to the

Fig. 13 Headlamp Bulb

1 - BULB SOCKET

2 - BULB ASSEMBLY

3 - LOCK

4 - BULB RETAINING RING

5 - ELECTRICAL CONNECTOR

6 - UNLOCK

7 - PLASTIC BASE

8L - 16 LAMPS/LIGHTING - EXTERIORBR/BE

HEADLAMP (Continued)

Page 738 of 2889

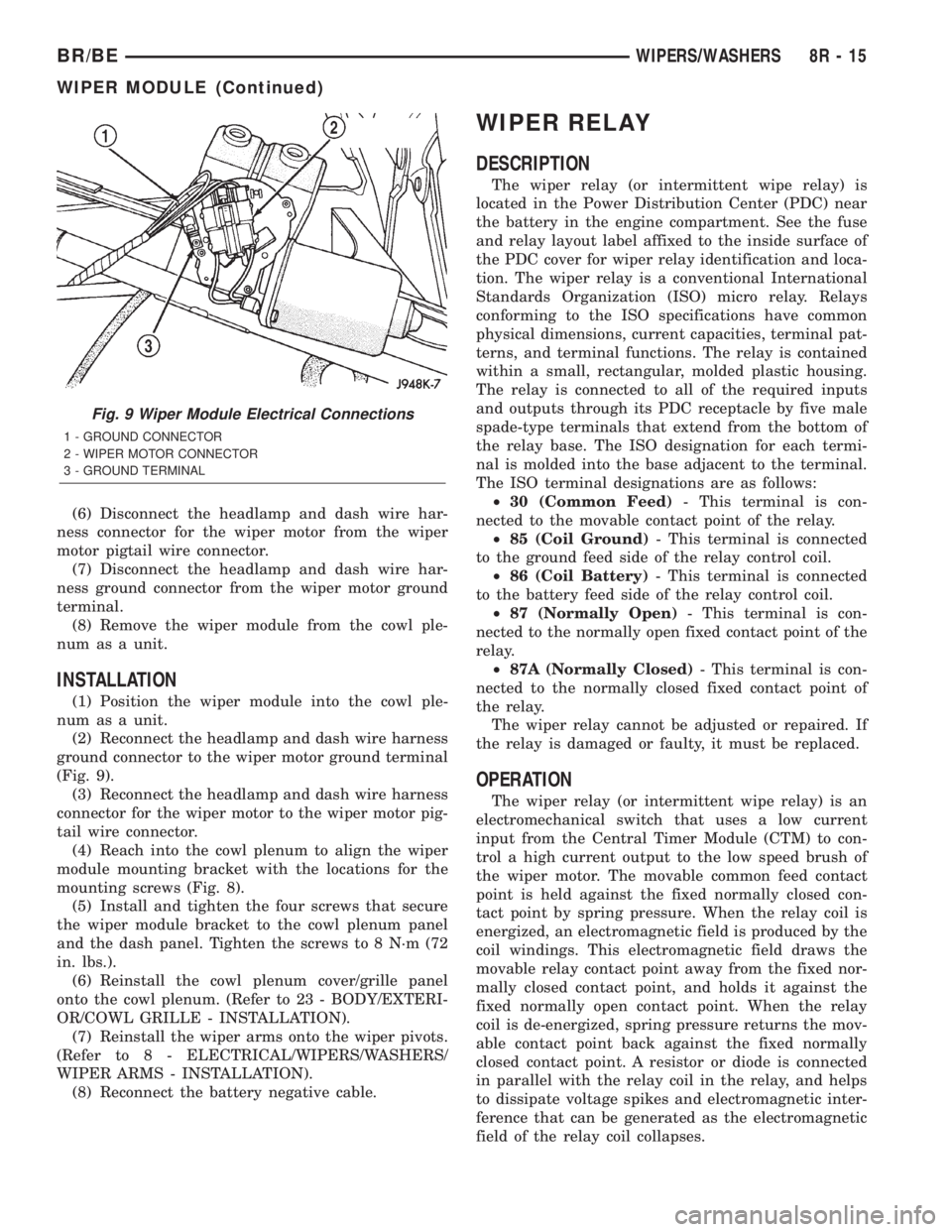

(6) Disconnect the headlamp and dash wire har-

ness connector for the wiper motor from the wiper

motor pigtail wire connector.

(7) Disconnect the headlamp and dash wire har-

ness ground connector from the wiper motor ground

terminal.

(8) Remove the wiper module from the cowl ple-

num as a unit.

INSTALLATION

(1) Position the wiper module into the cowl ple-

num as a unit.

(2) Reconnect the headlamp and dash wire harness

ground connector to the wiper motor ground terminal

(Fig. 9).

(3) Reconnect the headlamp and dash wire harness

connector for the wiper motor to the wiper motor pig-

tail wire connector.

(4) Reach into the cowl plenum to align the wiper

module mounting bracket with the locations for the

mounting screws (Fig. 8).

(5) Install and tighten the four screws that secure

the wiper module bracket to the cowl plenum panel

and the dash panel. Tighten the screws to 8 N´m (72

in. lbs.).

(6) Reinstall the cowl plenum cover/grille panel

onto the cowl plenum. (Refer to 23 - BODY/EXTERI-

OR/COWL GRILLE - INSTALLATION).

(7) Reinstall the wiper arms onto the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARMS - INSTALLATION).

(8) Reconnect the battery negative cable.

WIPER RELAY

DESCRIPTION

The wiper relay (or intermittent wipe relay) is

located in the Power Distribution Center (PDC) near

the battery in the engine compartment. See the fuse

and relay layout label affixed to the inside surface of

the PDC cover for wiper relay identification and loca-

tion. The wiper relay is a conventional International

Standards Organization (ISO) micro relay. Relays

conforming to the ISO specifications have common

physical dimensions, current capacities, terminal pat-

terns, and terminal functions. The relay is contained

within a small, rectangular, molded plastic housing.

The relay is connected to all of the required inputs

and outputs through its PDC receptacle by five male

spade-type terminals that extend from the bottom of

the relay base. The ISO designation for each termi-

nal is molded into the base adjacent to the terminal.

The ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The wiper relay cannot be adjusted or repaired. If

the relay is damaged or faulty, it must be replaced.

OPERATION

The wiper relay (or intermittent wipe relay) is an

electromechanical switch that uses a low current

input from the Central Timer Module (CTM) to con-

trol a high current output to the low speed brush of

the wiper motor. The movable common feed contact

point is held against the fixed normally closed con-

tact point by spring pressure. When the relay coil is

energized, an electromagnetic field is produced by the

coil windings. This electromagnetic field draws the

movable relay contact point away from the fixed nor-

mally closed contact point, and holds it against the

fixed normally open contact point. When the relay

coil is de-energized, spring pressure returns the mov-

able contact point back against the fixed normally

closed contact point. A resistor or diode is connected

in parallel with the relay coil in the relay, and helps

to dissipate voltage spikes and electromagnetic inter-

ference that can be generated as the electromagnetic

field of the relay coil collapses.

Fig. 9 Wiper Module Electrical Connections

1 - GROUND CONNECTOR

2 - WIPER MOTOR CONNECTOR

3 - GROUND TERMINAL

BR/BEWIPERS/WASHERS 8R - 15

WIPER MODULE (Continued)

Page 1443 of 2889

²Milky discoloration indicates coolant dilution.

(4) Clean the area around the oil filter head.

Remove the filter (Refer to 9 - ENGINE/LUBRICA-

TION/OIL FILTER - REMOVAL).

(5) Install new oil filter (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION).

(6) Clean the drain plug and the sealing surface of

the pan. Check the condition of the threads and seal-

ing surface on the oil pan and drain plug.

(7) Install the drain plug. Tighten the plug to 60

N´m (44 ft. lbs.) torque.

(8) Use only High-Quality Multi-Viscosity lubricat-

ing oil in the Cummins Turbo Diesel engine. Choose

the correct oil for the operating conditions (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

(9) Fill the engine with the correct grade of new oil

(Refer to LUBRICATION & MAINTENANCE/FLUID

CAPACITIES - SPECIFICATIONS).

(10) Start the engine and operate it at idle for sev-

eral minutes. Check for leaks at the filter and drain

plug.

(11) Stop engine. Wait several minutes to allow the

oil to drain back to the pan and check the level

again.

USED ENGINE OIL DISPOSAL Care should be

exercised when disposing of used engine oil after

it has been drained from a vehicle's engine.

OIL COOLER & LINES

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter using a 90-95 mm filter wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional ó turn.

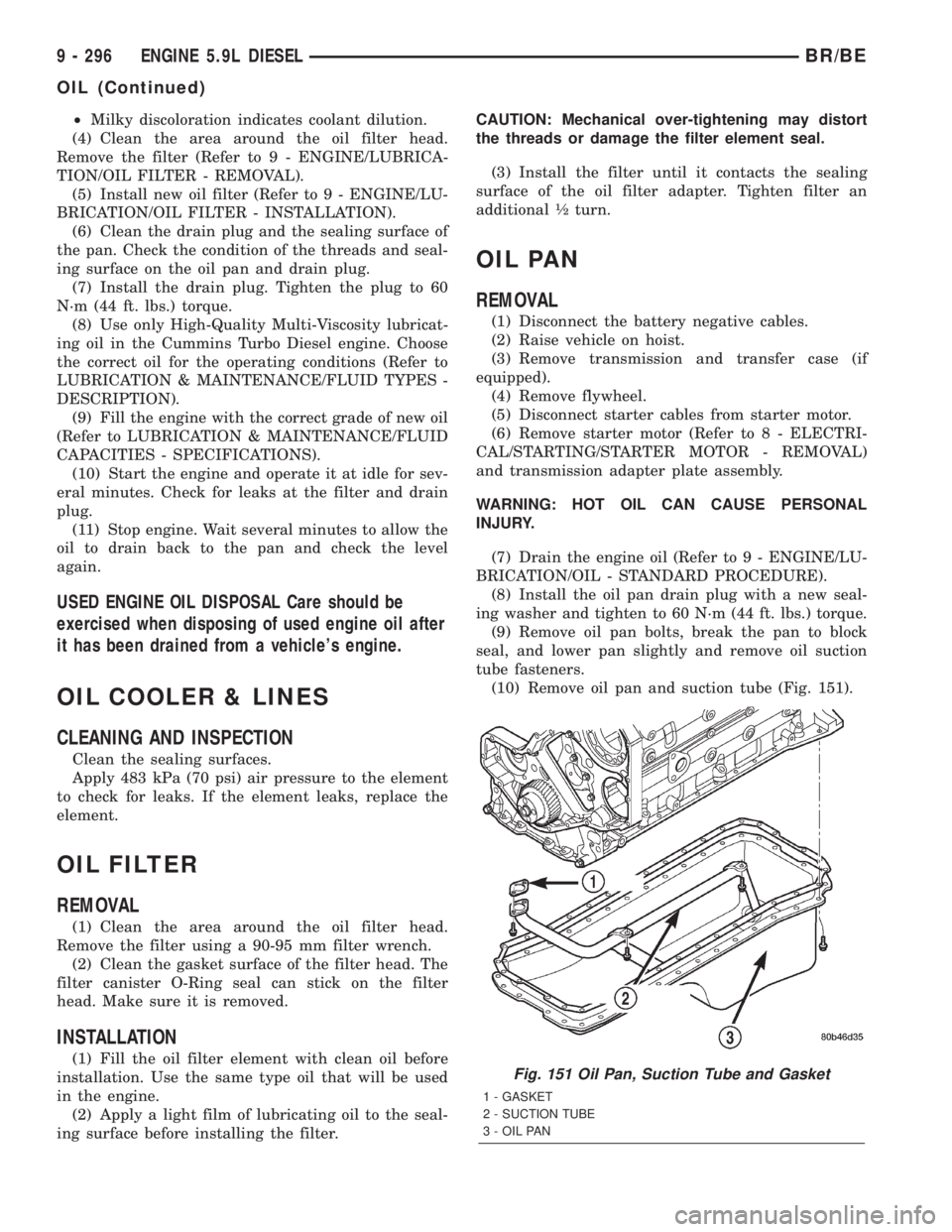

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Remove transmission and transfer case (if

equipped).

(4) Remove flywheel.

(5) Disconnect starter cables from starter motor.

(6) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(7) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).

(8) Install the oil pan drain plug with a new seal-

ing washer and tighten to 60 N´m (44 ft. lbs.) torque.

(9) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(10) Remove oil pan and suction tube (Fig. 151).

Fig. 151 Oil Pan, Suction Tube and Gasket

1 - GASKET

2 - SUCTION TUBE

3 - OIL PAN

9 - 296 ENGINE 5.9L DIESELBR/BE

OIL (Continued)

Page 2786 of 2889

container immediately to prevent moisture contami-

nation.

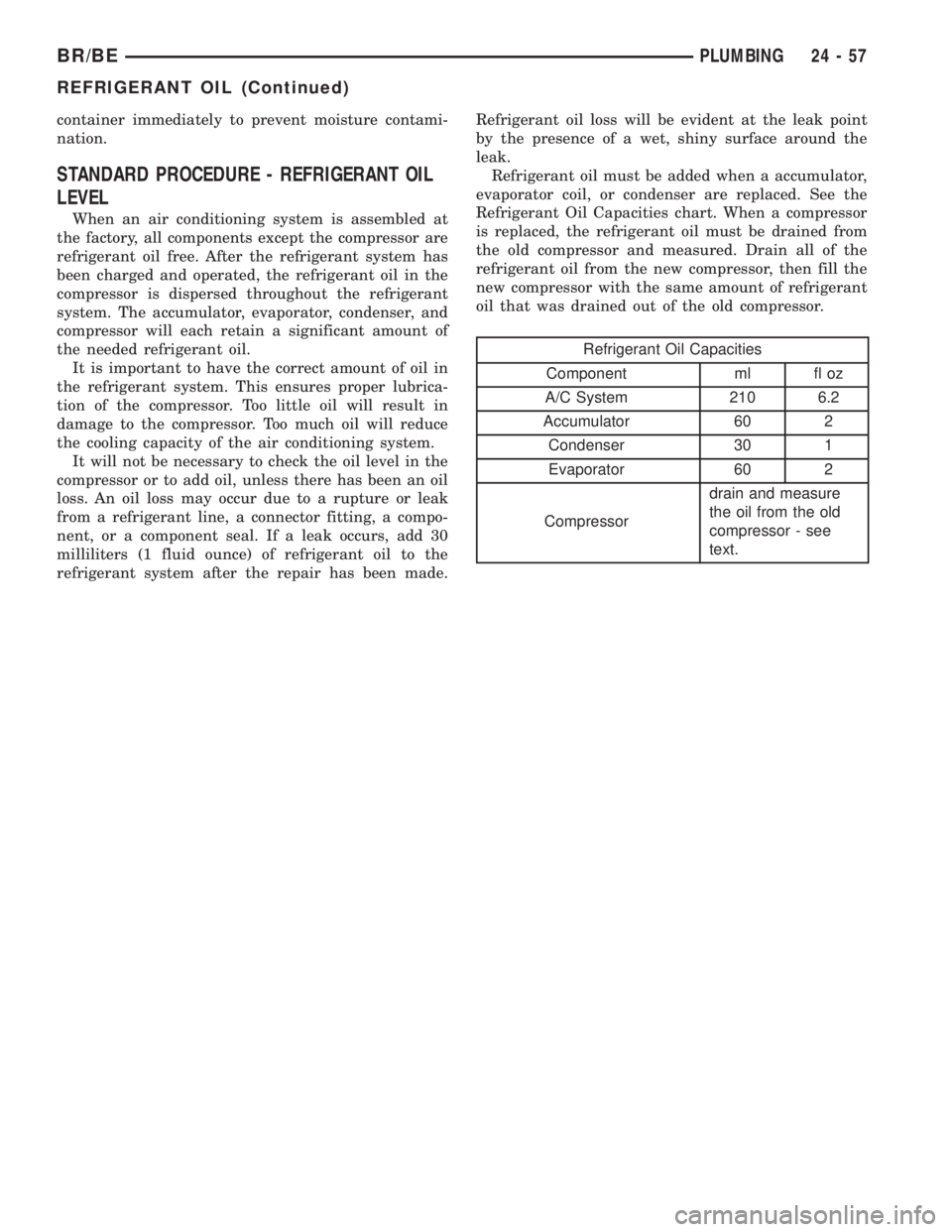

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system has

been charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The accumulator, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrica-

tion of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a compo-

nent, or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when a accumulator,

evaporator coil, or condenser are replaced. See the

Refrigerant Oil Capacities chart. When a compressor

is replaced, the refrigerant oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of refrigerant

oil that was drained out of the old compressor.

Refrigerant Oil Capacities

Component ml fl oz

A/C System 210 6.2

Accumulator 60 2

Condenser 30 1

Evaporator 60 2

Compressordrain and measure

the oil from the old

compressor - see

text.

BR/BEPLUMBING 24 - 57

REFRIGERANT OIL (Continued)

Page 2861 of 2889

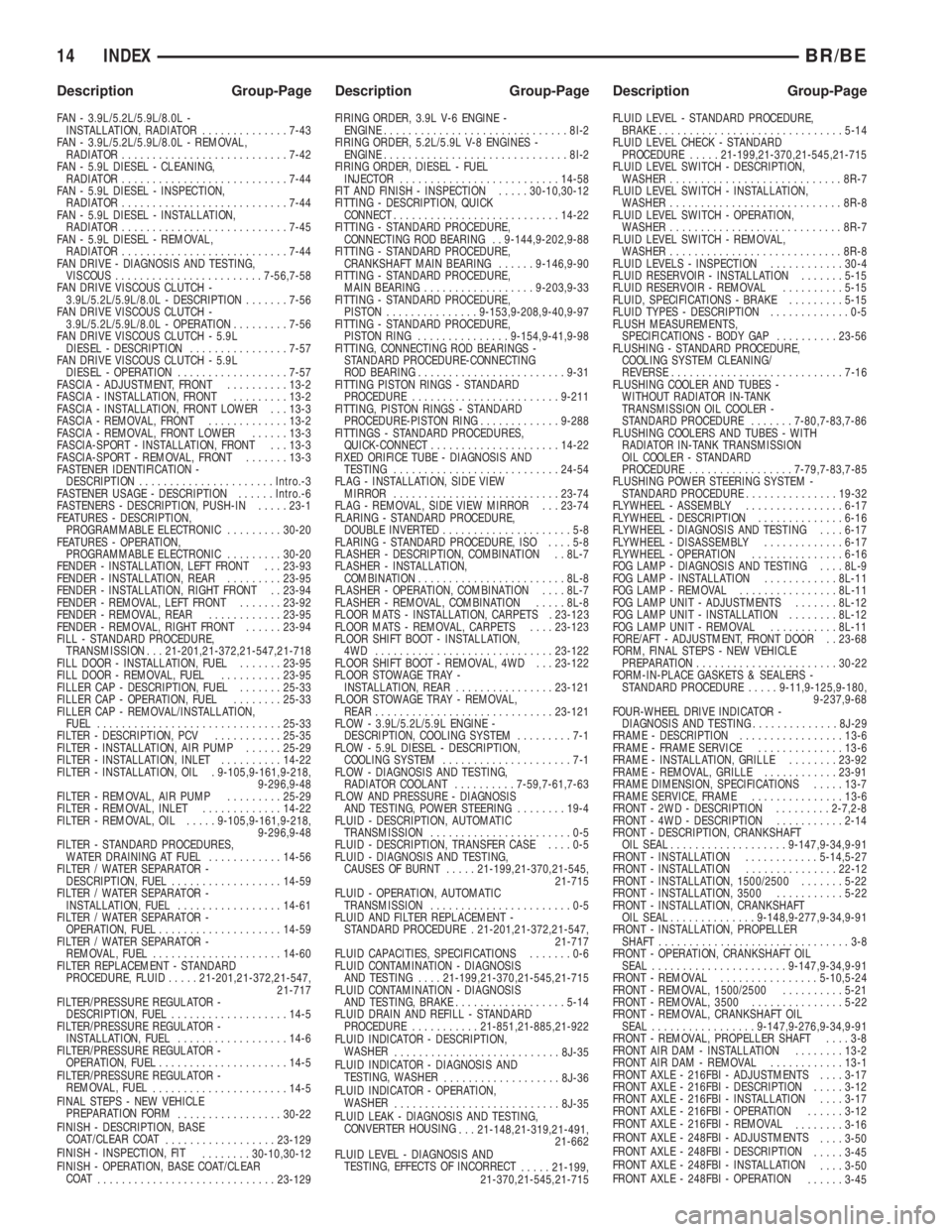

FAN - 3.9L/5.2L/5.9L/8.0L -

INSTALLATION, RADIATOR..............7-43

FAN - 3.9L/5.2L/5.9L/8.0L - REMOVAL,

RADIATOR...........................7-42

FAN - 5.9L DIESEL - CLEANING,

RADIATOR...........................7-44

FAN - 5.9L DIESEL - INSPECTION,

RADIATOR...........................7-44

FAN - 5.9L DIESEL - INSTALLATION,

RADIATOR...........................7-45

FAN - 5.9L DIESEL - REMOVAL,

RADIATOR...........................7-44

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS........................7-56,7-58

FAN DRIVE VISCOUS CLUTCH -

3.9L/5.2L/5.9L/8.0L - DESCRIPTION.......7-56

FAN DRIVE VISCOUS CLUTCH -

3.9L/5.2L/5.9L/8.0L - OPERATION.........7-56

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION................7-57

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION..................7-57

FASCIA - ADJUSTMENT, FRONT..........13-2

FASCIA - INSTALLATION, FRONT.........13-2

FASCIA - INSTALLATION, FRONT LOWER . . . 13-3

FASCIA - REMOVAL, FRONT.............13-2

FASCIA - REMOVAL, FRONT LOWER......13-3

FASCIA-SPORT - INSTALLATION, FRONT . . . 13-3

FASCIA-SPORT - REMOVAL, FRONT.......13-3

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-3

FASTENER USAGE - DESCRIPTION......Intro.-6

FASTENERS - DESCRIPTION, PUSH-IN.....23-1

FEATURES - DESCRIPTION,

PROGRAMMABLE ELECTRONIC.........30-20

FEATURES - OPERATION,

PROGRAMMABLE ELECTRONIC.........30-20

FENDER - INSTALLATION, LEFT FRONT . . . 23-93

FENDER - INSTALLATION, REAR.........23-95

FENDER - INSTALLATION, RIGHT FRONT . . 23-94

FENDER - REMOVAL, LEFT FRONT.......23-92

FENDER - REMOVAL, REAR............23-95

FENDER - REMOVAL, RIGHT FRONT......23-94

FILL - STANDARD PROCEDURE,

TRANSMISSION . . . 21-201,21-372,21-547,21-718

FILL DOOR - INSTALLATION, FUEL.......23-95

FILL DOOR - REMOVAL, FUEL..........23-95

FILLER CAP - DESCRIPTION, FUEL.......25-33

FILLER CAP - OPERATION, FUEL........25-33

FILLER CAP - REMOVAL/INSTALLATION,

FUEL..............................25-33

FILTER - DESCRIPTION, PCV...........25-35

FILTER - INSTALLATION, AIR PUMP......25-29

FILTER - INSTALLATION, INLET..........14-22

FILTER - INSTALLATION, OIL . 9-105,9-161,9-218,

9-296,9-48

FILTER - REMOVAL, AIR PUMP.........25-29

FILTER - REMOVAL, INLET.............14-22

FILTER - REMOVAL, OIL.....9-105,9-161,9-218,

9-296,9-48

FILTER - STANDARD PROCEDURES,

WATER DRAINING AT FUEL............14-56

FILTER / WATER SEPARATOR -

DESCRIPTION, FUEL..................14-59

FILTER / WATER SEPARATOR -

INSTALLATION, FUEL.................14-61

FILTER / WATER SEPARATOR -

OPERATION, FUEL....................14-59

FILTER / WATER SEPARATOR -

REMOVAL, FUEL.....................14-60

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID.....21-201,21-372,21-547,

21-717

FILTER/PRESSURE REGULATOR -

DESCRIPTION, FUEL...................14-5

FILTER/PRESSURE REGULATOR -

INSTALLATION, FUEL..................14-6

FILTER/PRESSURE REGULATOR -

OPERATION, FUEL.....................14-5

FILTER/PRESSURE REGULATOR -

REMOVAL, FUEL

......................14-5

FINAL STEPS - NEW VEHICLE

PREPARATION FORM

.................30-22

FINISH - DESCRIPTION, BASE

COAT/CLEAR COAT

..................23-129

FINISH - INSPECTION, FIT

........30-10,30-12

FINISH - OPERATION, BASE COAT/CLEAR

COAT

.............................23-129FIRING ORDER, 3.9L V-6 ENGINE -

ENGINE..............................8I-2

FIRING ORDER, 5.2L/5.9L V-8 ENGINES -

ENGINE..............................8I-2

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-58

FIT AND FINISH - INSPECTION.....30-10,30-12

FITTING - DESCRIPTION, QUICK

CONNECT...........................14-22

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING . . 9-144,9-202,9-88

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING......9-146,9-90

FITTING - STANDARD PROCEDURE,

MAIN BEARING..................9-203,9-33

FITTING - STANDARD PROCEDURE,

PISTON...............9-153,9-208,9-40,9-97

FITTING - STANDARD PROCEDURE,

PISTON RING...............9-154,9-41,9-98

FITTING, CONNECTING ROD BEARINGS -

STANDARD PROCEDURE-CONNECTING

ROD BEARING........................9-31

FITTING PISTON RINGS - STANDARD

PROCEDURE........................9-211

FITTING, PISTON RINGS - STANDARD

PROCEDURE-PISTON RING.............9-288

FITTINGS - STANDARD PROCEDURES,

QUICK-CONNECT.....................14-22

FIXED ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-54

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-74

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-74

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED.....................5-8

FLARING - STANDARD PROCEDURE, ISO....5-8

FLASHER - DESCRIPTION, COMBINATION . . 8L-7

FLASHER - INSTALLATION,

COMBINATION........................8L-8

FLASHER - OPERATION, COMBINATION....8L-7

FLASHER - REMOVAL, COMBINATION.....8L-8

FLOOR MATS - INSTALLATION, CARPETS . 23-123

FLOOR MATS - REMOVAL, CARPETS....23-123

FLOOR SHIFT BOOT - INSTALLATION,

4WD .............................23-122

FLOOR SHIFT BOOT - REMOVAL, 4WD . . . 23-122

FLOOR STOWAGE TRAY -

INSTALLATION, REAR................23-121

FLOOR STOWAGE TRAY - REMOVAL,

REAR.............................23-121

FLOW - 3.9L/5.2L/5.9L ENGINE -

DESCRIPTION, COOLING SYSTEM.........7-1

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-1

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..........7-59,7-61,7-63

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID - DESCRIPTION, TRANSFER CASE....0-5

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT.....21-199,21-370,21-545,

21-715

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE . 21-201,21-372,21-547,

21-717

FLUID CAPACITIES, SPECIFICATIONS.......0-6

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING....21-199,21-370,21-545,21-715

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-14

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE...........21-851,21-885,21-922

FLUID INDICATOR - DESCRIPTION,

WASHER

...........................8J-35

FLUID INDICATOR - DIAGNOSIS AND

TESTING, WASHER

...................8J-36

FLUID INDICATOR - OPERATION,

WASHER

...........................8J-35

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING

. . . 21-148,21-319,21-491,

21-662

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT

.....21-199,

21-370,21-545,21-715FLUID LEVEL - STANDARD PROCEDURE,

BRAKE..............................5-14

FLUID LEVEL CHECK - STANDARD

PROCEDURE.....21-199,21-370,21-545,21-715

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER............................8R-7

FLUID LEVEL SWITCH - INSTALLATION,

WASHER............................8R-8

FLUID LEVEL SWITCH - OPERATION,

WASHER............................8R-7

FLUID LEVEL SWITCH - REMOVAL,

WASHER............................8R-8

FLUID LEVELS - INSPECTION............30-4

FLUID RESERVOIR - INSTALLATION.......5-15

FLUID RESERVOIR - REMOVAL..........5-15

FLUID, SPECIFICATIONS - BRAKE.........5-15

FLUID TYPES - DESCRIPTION.............0-5

FLUSH MEASUREMENTS,

SPECIFICATIONS - BODY GAP..........23-56

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM CLEANING/

REVERSE............................7-16

FLUSHING COOLER AND TUBES -

WITHOUT RADIATOR IN-TANK

TRANSMISSION OIL COOLER -

STANDARD PROCEDURE.......7-80,7-83,7-86

FLUSHING COOLERS AND TUBES - WITH

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE.................7-79,7-83,7-85

FLUSHING POWER STEERING SYSTEM -

STANDARD PROCEDURE...............19-32

FLYWHEEL - ASSEMBLY................6-17

FLYWHEEL - DESCRIPTION..............6-16

FLYWHEEL - DIAGNOSIS AND TESTING....6-17

FLYWHEEL - DISASSEMBLY.............6-17

FLYWHEEL - OPERATION...............6-16

FOG LAMP - DIAGNOSIS AND TESTING....8L-9

FOG LAMP - INSTALLATION............8L-11

FOG LAMP - REMOVAL................8L-11

FOG LAMP UNIT - ADJUSTMENTS.......8L-12

FOG LAMP UNIT - INSTALLATION........8L-12

FOG LAMP UNIT - REMOVAL...........8L-11

FORE/AFT - ADJUSTMENT, FRONT DOOR . . 23-68

FORM, FINAL STEPS - NEW VEHICLE

PREPARATION.......................30-22

FORM-IN-PLACE GASKETS & SEALERS -

STANDARD PROCEDURE.....9-11,9-125,9-180,

9-237,9-68

FOUR-WHEEL DRIVE INDICATOR -

DIAGNOSIS AND TESTING..............8J-29

FRAME - DESCRIPTION.................13-6

FRAME - FRAME SERVICE..............13-6

FRAME - INSTALLATION, GRILLE........23-92

FRAME - REMOVAL, GRILLE............23-91

FRAME DIMENSION, SPECIFICATIONS.....13-7

FRAME SERVICE, FRAME...............13-6

FRONT - 2WD - DESCRIPTION.........2-7,2-8

FRONT - 4WD - DESCRIPTION...........2-14

FRONT - DESCRIPTION, CRANKSHAFT

OIL SEAL...................9-147,9-34,9-91

FRONT - INSTALLATION............5-14,5-27

FRONT - INSTALLATION...............22-12

FRONT - INSTALLATION, 1500/2500.......5-22

FRONT - INSTALLATION, 3500...........5-22

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL..............9-148,9-277,9-34,9-91

FRONT - INSTALLATION, PROPELLER

SHAFT...............................3-8

FRONT - OPERATION, CRANKSHAFT OIL

SEAL......................9-147,9-34,9-91

FRONT - REMOVAL................5-10,5-24

FRONT - REMOVAL, 1500/2500..........5-21

FRONT - REMOVAL, 3500...............5-22

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL.................9-147,9-276,9-34,9-91

FRONT - REMOVAL, PROPELLER SHAFT....3-8

FRONT AIR DAM - INSTALLATION........13-2

FRONT AIR DAM - REMOVAL............13-1

FRONT AXLE - 216FBI - ADJUSTMENTS....3-17

FRONT AXLE - 216FBI - DESCRIPTION.....3-12

FRONT AXLE - 216FBI - INSTALLATION....3-17

FRONT AXLE - 216FBI - OPERATION......3-12

FRONT AXLE - 216FBI - REMOVAL

........3-16

FRONT AXLE - 248FBI - ADJUSTMENTS

....3-50

FRONT AXLE - 248FBI - DESCRIPTION

.....3-45

FRONT AXLE - 248FBI - INSTALLATION

....3-50

FRONT AXLE - 248FBI - OPERATION

......3-45

14 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2879 of 2889

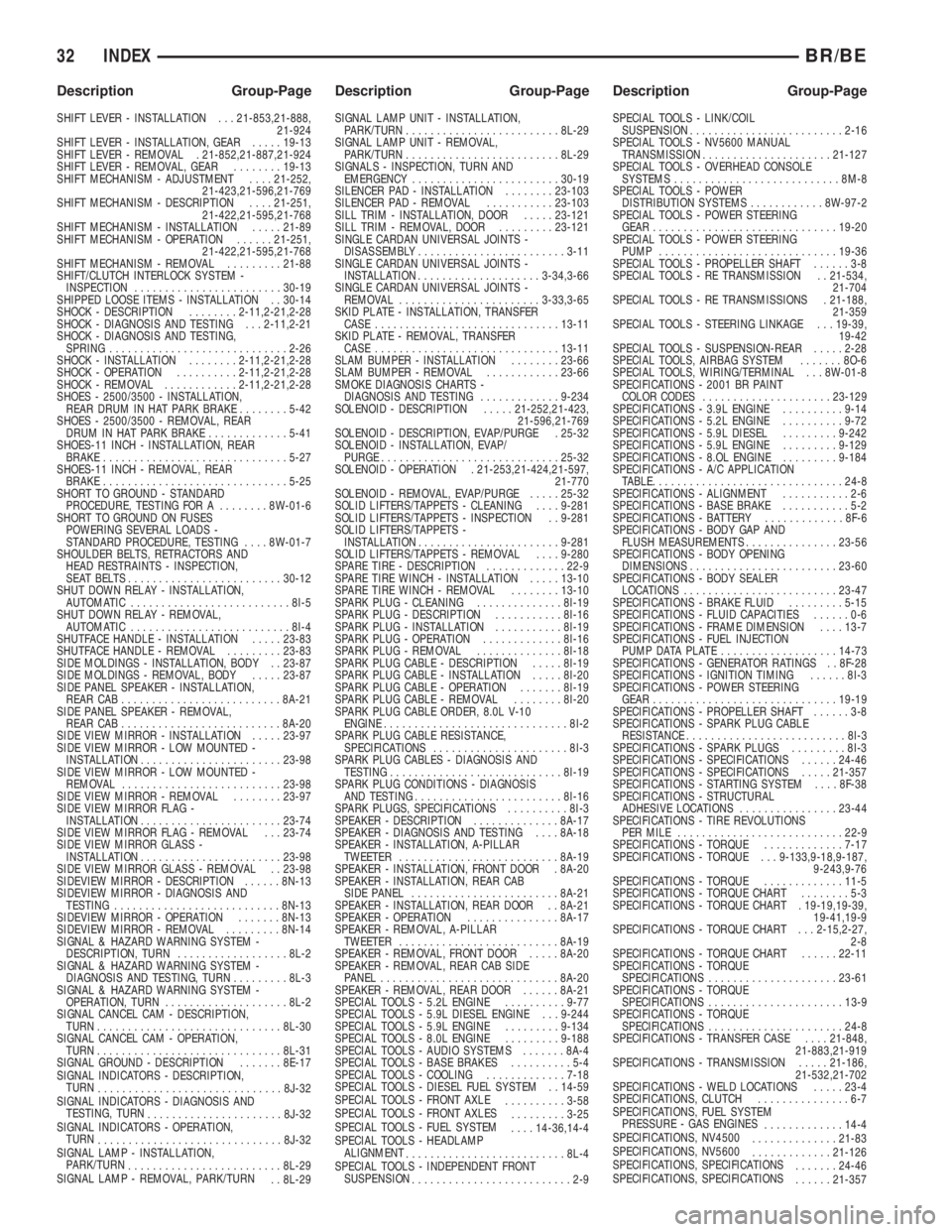

SHIFT LEVER - INSTALLATION . . . 21-853,21-888,

21-924

SHIFT LEVER - INSTALLATION, GEAR.....19-13

SHIFT LEVER - REMOVAL . 21-852,21-887,21-924

SHIFT LEVER - REMOVAL, GEAR........19-13

SHIFT MECHANISM - ADJUSTMENT....21-252,

21-423,21-596,21-769

SHIFT MECHANISM - DESCRIPTION....21-251,

21-422,21-595,21-768

SHIFT MECHANISM - INSTALLATION.....21-89

SHIFT MECHANISM - OPERATION......21-251,

21-422,21-595,21-768

SHIFT MECHANISM - REMOVAL.........21-88

SHIFT/CLUTCH INTERLOCK SYSTEM -

INSPECTION........................30-19

SHIPPED LOOSE ITEMS - INSTALLATION . . 30-14

SHOCK - DESCRIPTION........2-11,2-21,2-28

SHOCK - DIAGNOSIS AND TESTING . . . 2-11,2-21

SHOCK - DIAGNOSIS AND TESTING,

SPRING.............................2-26

SHOCK - INSTALLATION........2-11,2-21,2-28

SHOCK - OPERATION..........2-11,2-21,2-28

SHOCK - REMOVAL............2-11,2-21,2-28

SHOES - 2500/3500 - INSTALLATION,

REAR DRUM IN HAT PARK BRAKE........5-42

SHOES - 2500/3500 - REMOVAL, REAR

DRUM IN HAT PARK BRAKE.............5-41

SHOES-11 INCH - INSTALLATION, REAR

BRAKE..............................5-27

SHOES-11 INCH - REMOVAL, REAR

BRAKE..............................5-25

SHORT TO GROUND - STANDARD

PROCEDURE, TESTING FOR A........8W-01-6

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING....8W-01-7

SHOULDER BELTS, RETRACTORS AND

HEAD RESTRAINTS - INSPECTION,

SEAT BELTS.........................30-12

SHUT DOWN RELAY - INSTALLATION,

AUTOMATIC..........................8I-5

SHUT DOWN RELAY - REMOVAL,

AUTOMATIC..........................8I-4

SHUTFACE HANDLE - INSTALLATION.....23-83

SHUTFACE HANDLE - REMOVAL.........23-83

SIDE MOLDINGS - INSTALLATION, BODY . . 23-87

SIDE MOLDINGS - REMOVAL, BODY.....23-87

SIDE PANEL SPEAKER - INSTALLATION,

REAR CAB..........................8A-21

SIDE PANEL SPEAKER - REMOVAL,

REAR CAB..........................8A-20

SIDE VIEW MIRROR - INSTALLATION.....23-97

SIDE VIEW MIRROR - LOW MOUNTED -

INSTALLATION.......................23-98

SIDE VIEW MIRROR - LOW MOUNTED -

REMOVAL..........................23-98

SIDE VIEW MIRROR - REMOVAL........23-97

SIDE VIEW MIRROR FLAG -

INSTALLATION.......................23-74

SIDE VIEW MIRROR FLAG - REMOVAL . . . 23-74

SIDE VIEW MIRROR GLASS -

INSTALLATION.......................23-98

SIDE VIEW MIRROR GLASS - REMOVAL . . 23-98

SIDEVIEW MIRROR - DESCRIPTION......8N-13

SIDEVIEW MIRROR - DIAGNOSIS AND

TESTING...........................8N-13

SIDEVIEW MIRROR - OPERATION.......8N-13

SIDEVIEW MIRROR - REMOVAL.........8N-14

SIGNAL & HAZARD WARNING SYSTEM -

DESCRIPTION, TURN..................8L-2

SIGNAL & HAZARD WARNING SYSTEM -

DIAGNOSIS AND TESTING, TURN.........8L-3

SIGNAL & HAZARD WARNING SYSTEM -

OPERATION, TURN....................8L-2

SIGNAL CANCEL CAM - DESCRIPTION,

TURN..............................8L-30

SIGNAL CANCEL CAM - OPERATION,

TURN..............................8L-31

SIGNAL GROUND - DESCRIPTION.......8E-17

SIGNAL INDICATORS - DESCRIPTION,

TURN

..............................8J-32

SIGNAL INDICATORS - DIAGNOSIS AND

TESTING, TURN

......................8J-32

SIGNAL INDICATORS - OPERATION,

TURN

..............................8J-32

SIGNAL LAMP - INSTALLATION,

PARK/TURN

.........................8L-29

SIGNAL LAMP - REMOVAL, PARK/TURN

. . 8L-29SIGNAL LAMP UNIT - INSTALLATION,

PARK/TURN.........................8L-29

SIGNAL LAMP UNIT - REMOVAL,

PARK/TURN.........................8L-29

SIGNALS - INSPECTION, TURN AND

EMERGENCY........................30-19

SILENCER PAD - INSTALLATION........23-103

SILENCER PAD - REMOVAL...........23-103

SILL TRIM - INSTALLATION, DOOR.....23-121

SILL TRIM - REMOVAL, DOOR.........23-121

SINGLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY........................3-11

SINGLE CARDAN UNIVERSAL JOINTS -

INSTALLATION....................3-34,3-66

SINGLE CARDAN UNIVERSAL JOINTS -

REMOVAL.......................3-33,3-65

SKID PLATE - INSTALLATION, TRANSFER

CASE..............................13-11

SKID PLATE - REMOVAL, TRANSFER

CASE..............................13-11

SLAM BUMPER - INSTALLATION........23-66

SLAM BUMPER - REMOVAL............23-66

SMOKE DIAGNOSIS CHARTS -

DIAGNOSIS AND TESTING.............9-234

SOLENOID - DESCRIPTION.....21-252,21-423,

21-596,21-769

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-32

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-32

SOLENOID - OPERATION . 21-253,21-424,21-597,

21-770

SOLENOID - REMOVAL, EVAP/PURGE.....25-32

SOLID LIFTERS/TAPPETS - CLEANING....9-281

SOLID LIFTERS/TAPPETS - INSPECTION . . 9-281

SOLID LIFTERS/TAPPETS -

INSTALLATION.......................9-281

SOLID LIFTERS/TAPPETS - REMOVAL....9-280

SPARE TIRE - DESCRIPTION.............22-9

SPARE TIRE WINCH - INSTALLATION.....13-10

SPARE TIRE WINCH - REMOVAL........13-10

SPARK PLUG - CLEANING..............8I-19

SPARK PLUG - DESCRIPTION...........8I-16

SPARK PLUG - INSTALLATION...........8I-19

SPARK PLUG - OPERATION.............8I-16

SPARK PLUG - REMOVAL..............8I-18

SPARK PLUG CABLE - DESCRIPTION.....8I-19

SPARK PLUG CABLE - INSTALLATION.....8I-20

SPARK PLUG CABLE - OPERATION.......8I-19

SPARK PLUG CABLE - REMOVAL........8I-20

SPARK PLUG CABLE ORDER, 8.0L V-10

ENGINE..............................8I-2

SPARK PLUG CABLE RESISTANCE,

SPECIFICATIONS......................8I-3

SPARK PLUG CABLES - DIAGNOSIS AND

TESTING............................8I-19

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-16

SPARK PLUGS, SPECIFICATIONS..........8I-3

SPEAKER - DESCRIPTION..............8A-17

SPEAKER - DIAGNOSIS AND TESTING....8A-18

SPEAKER - INSTALLATION, A-PILLAR

TWEETER..........................8A-19

SPEAKER - INSTALLATION, FRONT DOOR . 8A-20

SPEAKER - INSTALLATION, REAR CAB

SIDE PANEL........................8A-21

SPEAKER - INSTALLATION, REAR DOOR . . 8A-21

SPEAKER - OPERATION...............8A-17

SPEAKER - REMOVAL, A-PILLAR

TWEETER..........................8A-19

SPEAKER - REMOVAL, FRONT DOOR.....8A-20

SPEAKER - REMOVAL, REAR CAB SIDE

PANEL.............................8A-20

SPEAKER - REMOVAL, REAR DOOR......8A-21

SPECIAL TOOLS - 5.2L ENGINE..........9-77

SPECIAL TOOLS - 5.9L DIESEL ENGINE . . . 9-244

SPECIAL TOOLS - 5.9L ENGINE.........9-134

SPECIAL TOOLS - 8.0L ENGINE.........9-188

SPECIAL TOOLS - AUDIO SYSTEMS.......8A-4

SPECIAL TOOLS - BASE BRAKES..........5-4

SPECIAL TOOLS - COOLING.............7-18

SPECIAL TOOLS - DIESEL FUEL SYSTEM . . 14-59

SPECIAL TOOLS - FRONT AXLE

..........3-58

SPECIAL TOOLS - FRONT AXLES

.........3-25

SPECIAL TOOLS - FUEL SYSTEM

....14-36,14-4

SPECIAL TOOLS - HEADLAMP

ALIGNMENT

..........................8L-4

SPECIAL TOOLS - INDEPENDENT FRONT

SUSPENSION

..........................2-9SPECIAL TOOLS - LINK/COIL

SUSPENSION.........................2-16

SPECIAL TOOLS - NV5600 MANUAL

TRANSMISSION.....................21-127

SPECIAL TOOLS - OVERHEAD CONSOLE

SYSTEMS...........................8M-8

SPECIAL TOOLS - POWER

DISTRIBUTION SYSTEMS............8W-97-2

SPECIAL TOOLS - POWER STEERING

GEAR..............................19-20

SPECIAL TOOLS - POWER STEERING

PUMP.............................19-36

SPECIAL TOOLS - PROPELLER SHAFT......3-8

SPECIAL TOOLS - RE TRANSMISSION . . 21-534,

21-704

SPECIAL TOOLS - RE TRANSMISSIONS . 21-188,

21-359

SPECIAL TOOLS - STEERING LINKAGE . . . 19-39,

19-42

SPECIAL TOOLS - SUSPENSION-REAR.....2-28

SPECIAL TOOLS, AIRBAG SYSTEM.......8O-6

SPECIAL TOOLS, WIRING/TERMINAL . . . 8W-01-8

SPECIFICATIONS - 2001 BR PAINT

COLOR CODES.....................23-129

SPECIFICATIONS - 3.9L ENGINE..........9-14

SPECIFICATIONS - 5.2L ENGINE..........9-72

SPECIFICATIONS - 5.9L DIESEL.........9-242

SPECIFICATIONS - 5.9L ENGINE.........9-129

SPECIFICATIONS - 8.OL ENGINE.........9-184

SPECIFICATIONS - A/C APPLICATION

TABLE................................24-8

SPECIFICATIONS - ALIGNMENT...........2-6

SPECIFICATIONS - BASE BRAKE...........5-2

SPECIFICATIONS - BATTERY.............8F-6

SPECIFICATIONS - BODY GAP AND

FLUSH MEASUREMENTS...............23-56

SPECIFICATIONS - BODY OPENING

DIMENSIONS........................23-60

SPECIFICATIONS - BODY SEALER

LOCATIONS.........................23-47

SPECIFICATIONS - BRAKE FLUID.........5-15

SPECIFICATIONS - FLUID CAPACITIES......0-6

SPECIFICATIONS - FRAME DIMENSION....13-7

SPECIFICATIONS - FUEL INJECTION

PUMP DATA PLATE...................14-73

SPECIFICATIONS - GENERATOR RATINGS . . 8F-28

SPECIFICATIONS - IGNITION TIMING......8I-3

SPECIFICATIONS - POWER STEERING

GEAR..............................19-19

SPECIFICATIONS - PROPELLER SHAFT......3-8

SPECIFICATIONS - SPARK PLUG CABLE

RESISTANCE..........................8I-3

SPECIFICATIONS - SPARK PLUGS.........8I-3

SPECIFICATIONS - SPECIFICATIONS......24-46

SPECIFICATIONS - SPECIFICATIONS.....21-357

SPECIFICATIONS - STARTING SYSTEM....8F-38

SPECIFICATIONS - STRUCTURAL

ADHESIVE LOCATIONS................23-44

SPECIFICATIONS - TIRE REVOLUTIONS

PER MILE...........................22-9

SPECIFICATIONS - TORQUE.............7-17

SPECIFICATIONS - TORQUE . . . 9-133,9-18,9-187,

9-243,9-76

SPECIFICATIONS - TORQUE.............11-5

SPECIFICATIONS - TORQUE CHART........5-3

SPECIFICATIONS - TORQUE CHART . 19-19,19-39,

19-41,19-9

SPECIFICATIONS - TORQUE CHART . . . 2-15,2-27,

2-8

SPECIFICATIONS - TORQUE CHART......22-11

SPECIFICATIONS - TORQUE

SPECIFICATIONS.....................23-61

SPECIFICATIONS - TORQUE

SPECIFICATIONS......................13-9

SPECIFICATIONS - TORQUE

SPECIFICATIONS......................24-8

SPECIFICATIONS - TRANSFER CASE....21-848,

21-883,21-919

SPECIFICATIONS - TRANSMISSION.....21-186,

21-532,21-702

SPECIFICATIONS - WELD LOCATIONS.....23-4

SPECIFICATIONS, CLUTCH...............6-7

SPECIFICATIONS, FUEL SYSTEM

PRESSURE - GAS ENGINES

.............14-4

SPECIFICATIONS, NV4500

..............21-83

SPECIFICATIONS, NV5600

.............21-126

SPECIFICATIONS, SPECIFICATIONS

.......24-46

SPECIFICATIONS, SPECIFICATIONS

......21-357

32 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page