engine coolant DODGE RAM 2002 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1201 of 2255

(8) Connect the engine harness connector and

ground cable to the PDC.

(9) Connect the vacuum pump supply hose.

(10) Connect the APPS connector (Fig. 5).

(11) Install the APPS assembly bracket to the cyl-

inder head bracket.

(12) Install the throttle linkage cover.

(13) Connect the power steering pressure and

return lines.

(14) Connect the passenger battery ground cable to

the engine block. Tighten the bolt to 77 N´m (57 ft.

lbs.) torque.

(15) Connect the engine block heater connector.

(16) Connect the a/c compressor electrical connec-

tors.

(17) Install the charge air cooler and a/c condenser

(if a/c equipped). Install and tighten the charge air

cooler mounting bolts to 2 N´m (17 in. lbs.) torque.

(18) Connect the charge air cooler piping. Torque

all clamps to 8 N´m (72 in. lbs.) torque.

(19) Connect the a/c refrigerant lines to the a/c

condenser (if equipped).

(20) Install the front bumper (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT

BUMPER - INSTALLATION).(21) Install the radiator upper support panel.

(22) Install the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION).

(23) Connect the transmission quick-connect oil

cooler lines to the radiator. Push together until an

audible ªclickº is heard. Verify connection by pulling

apart.

(24) Raise vehicle.

(25) Connect a/c compressor suction/discharge hose

(if a/c equipped).

(26) Install the radiator lower hose and clamps.

(27) Install the starter motor (Refer to 8 - ELEC-

TRICAL/STARTING/STARTER MOTOR - INSTAL-

LATION).

(28) Install the transmission and transfer case (if

equipped).

(29) Connect the exhaust pipe to the turbocharger

elbow (Fig. 3). Torque the bolts to 34 N´m (25 ft. lbs.)

torque.

(30) Connect the transmission auxiliary oil cooler

lines (if equipped).

(31) Lower the vehicle

(32) Connect the heater core supply and return

hoses.

(33) Install the cooling fan and shroud at the same

time (Refer to 7 - COOLING/ENGINE/RADIATOR

FAN - INSTALLATION).

(34) Install the coolant recovery bottle to the fan

shroud (Fig. 2) and connect the hose to the radiator

filler neck.

(35) Install the windshield washer bottle to the fan

shroud and connect the pump supply hose and elec-

trical connections.

(36) Install the radiator upper hose and clamps.

(37) Change oil filter and install new engine oil.

(38) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(39) Connect battery negative cables.

(40) Perform the fuel line air bleed procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(41) Start engine and inspect for engine oil, cool-

ant, and fuel leaks.

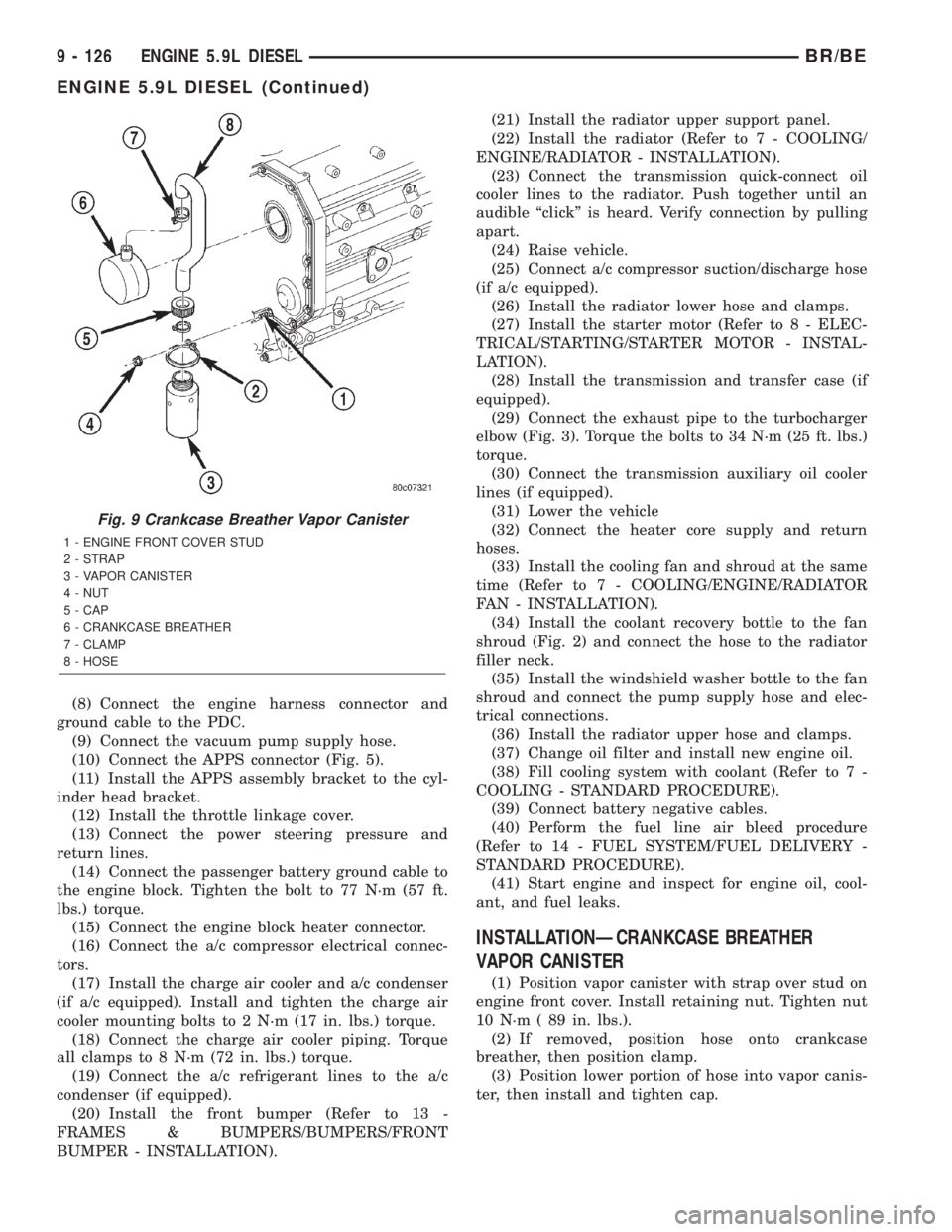

INSTALLATIONÐCRANKCASE BREATHER

VAPOR CANISTER

(1) Position vapor canister with strap over stud on

engine front cover. Install retaining nut. Tighten nut

10 N´m ( 89 in. lbs.).

(2) If removed, position hose onto crankcase

breather, then position clamp.

(3) Position lower portion of hose into vapor canis-

ter, then install and tighten cap.

Fig. 9 Crankcase Breather Vapor Canister

1 - ENGINE FRONT COVER STUD

2 - STRAP

3 - VAPOR CANISTER

4 - NUT

5 - CAP

6 - CRANKCASE BREATHER

7 - CLAMP

8 - HOSE

9 - 126 ENGINE 5.9L DIESELBR/BE

ENGINE 5.9L DIESEL (Continued)

Page 1205 of 2255

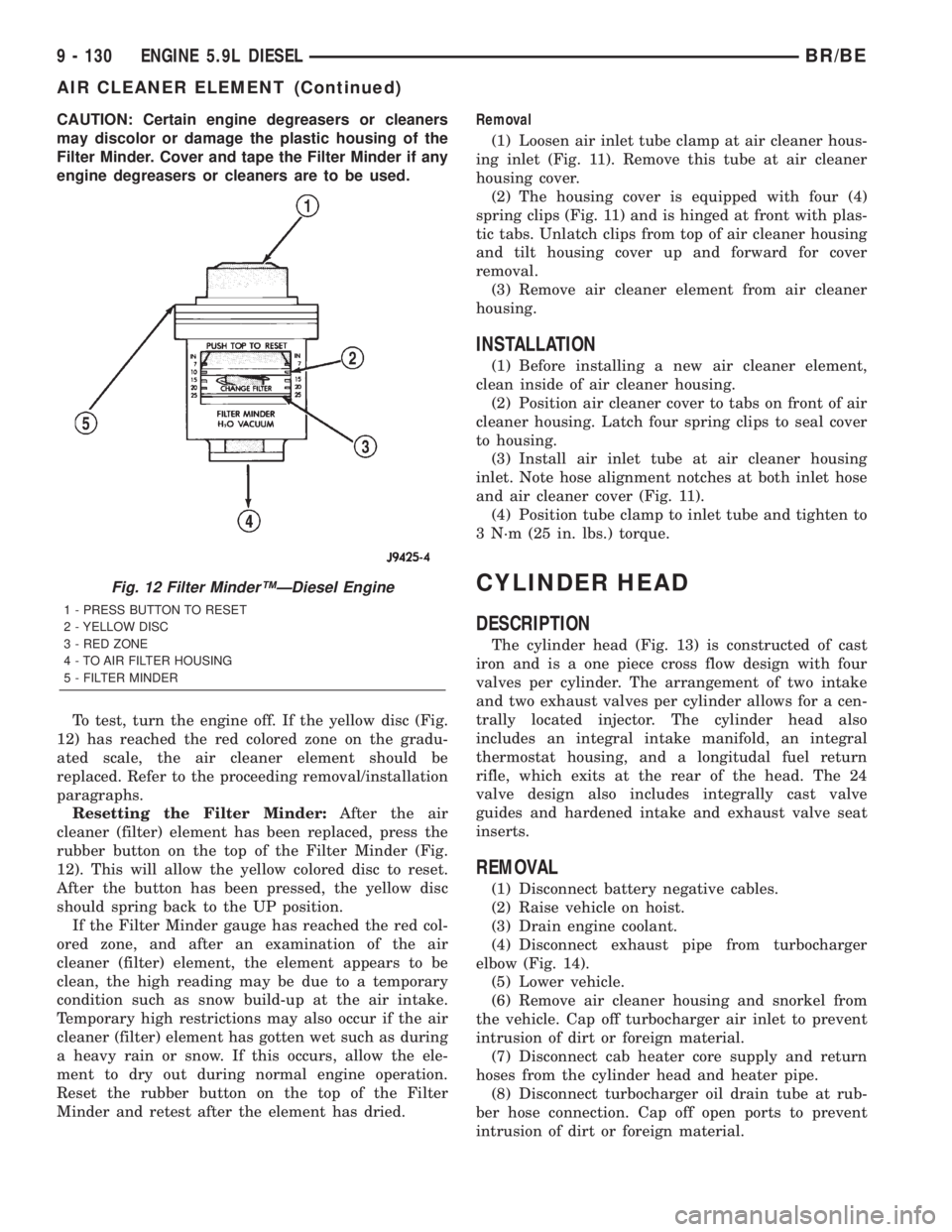

CAUTION: Certain engine degreasers or cleaners

may discolor or damage the plastic housing of the

Filter Minder. Cover and tape the Filter Minder if any

engine degreasers or cleaners are to be used.

To test, turn the engine off. If the yellow disc (Fig.

12) has reached the red colored zone on the gradu-

ated scale, the air cleaner element should be

replaced. Refer to the proceeding removal/installation

paragraphs.

Resetting the Filter Minder:After the air

cleaner (filter) element has been replaced, press the

rubber button on the top of the Filter Minder (Fig.

12). This will allow the yellow colored disc to reset.

After the button has been pressed, the yellow disc

should spring back to the UP position.

If the Filter Minder gauge has reached the red col-

ored zone, and after an examination of the air

cleaner (filter) element, the element appears to be

clean, the high reading may be due to a temporary

condition such as snow build-up at the air intake.

Temporary high restrictions may also occur if the air

cleaner (filter) element has gotten wet such as during

a heavy rain or snow. If this occurs, allow the ele-

ment to dry out during normal engine operation.

Reset the rubber button on the top of the Filter

Minder and retest after the element has dried.Removal

(1) Loosen air inlet tube clamp at air cleaner hous-

ing inlet (Fig. 11). Remove this tube at air cleaner

housing cover.

(2) The housing cover is equipped with four (4)

spring clips (Fig. 11) and is hinged at front with plas-

tic tabs. Unlatch clips from top of air cleaner housing

and tilt housing cover up and forward for cover

removal.

(3) Remove air cleaner element from air cleaner

housing.

INSTALLATION

(1) Before installing a new air cleaner element,

clean inside of air cleaner housing.

(2) Position air cleaner cover to tabs on front of air

cleaner housing. Latch four spring clips to seal cover

to housing.

(3) Install air inlet tube at air cleaner housing

inlet. Note hose alignment notches at both inlet hose

and air cleaner cover (Fig. 11).

(4) Position tube clamp to inlet tube and tighten to

3 N´m (25 in. lbs.) torque.

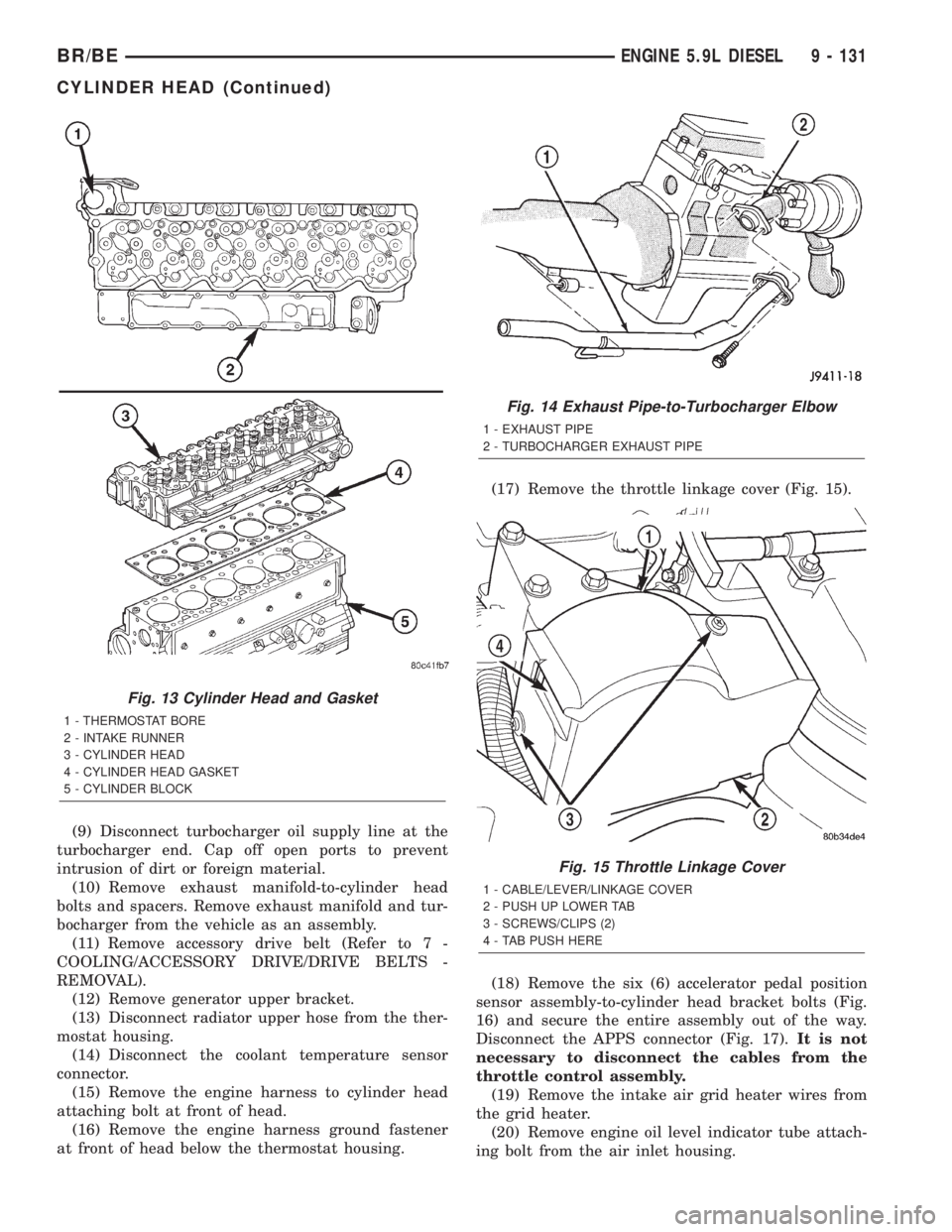

CYLINDER HEAD

DESCRIPTION

The cylinder head (Fig. 13) is constructed of cast

iron and is a one piece cross flow design with four

valves per cylinder. The arrangement of two intake

and two exhaust valves per cylinder allows for a cen-

trally located injector. The cylinder head also

includes an integral intake manifold, an integral

thermostat housing, and a longitudal fuel return

rifle, which exits at the rear of the head. The 24

valve design also includes integrally cast valve

guides and hardened intake and exhaust valve seat

inserts.

REMOVAL

(1) Disconnect battery negative cables.

(2) Raise vehicle on hoist.

(3) Drain engine coolant.

(4) Disconnect exhaust pipe from turbocharger

elbow (Fig. 14).

(5) Lower vehicle.

(6) Remove air cleaner housing and snorkel from

the vehicle. Cap off turbocharger air inlet to prevent

intrusion of dirt or foreign material.

(7) Disconnect cab heater core supply and return

hoses from the cylinder head and heater pipe.

(8) Disconnect turbocharger oil drain tube at rub-

ber hose connection. Cap off open ports to prevent

intrusion of dirt or foreign material.

Fig. 12 Filter MinderŸÐDiesel Engine

1 - PRESS BUTTON TO RESET

2 - YELLOW DISC

3 - RED ZONE

4 - TO AIR FILTER HOUSING

5 - FILTER MINDER

9 - 130 ENGINE 5.9L DIESELBR/BE

AIR CLEANER ELEMENT (Continued)

Page 1206 of 2255

(9) Disconnect turbocharger oil supply line at the

turbocharger end. Cap off open ports to prevent

intrusion of dirt or foreign material.

(10) Remove exhaust manifold-to-cylinder head

bolts and spacers. Remove exhaust manifold and tur-

bocharger from the vehicle as an assembly.

(11) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(12) Remove generator upper bracket.

(13) Disconnect radiator upper hose from the ther-

mostat housing.

(14) Disconnect the coolant temperature sensor

connector.

(15) Remove the engine harness to cylinder head

attaching bolt at front of head.

(16) Remove the engine harness ground fastener

at front of head below the thermostat housing.(17) Remove the throttle linkage cover (Fig. 15).

(18) Remove the six (6) accelerator pedal position

sensor assembly-to-cylinder head bracket bolts (Fig.

16) and secure the entire assembly out of the way.

Disconnect the APPS connector (Fig. 17).It is not

necessary to disconnect the cables from the

throttle control assembly.

(19) Remove the intake air grid heater wires from

the grid heater.

(20) Remove engine oil level indicator tube attach-

ing bolt from the air inlet housing.

Fig. 13 Cylinder Head and Gasket

1 - THERMOSTAT BORE

2 - INTAKE RUNNER

3 - CYLINDER HEAD

4 - CYLINDER HEAD GASKET

5 - CYLINDER BLOCK

Fig. 14 Exhaust Pipe-to-Turbocharger Elbow

1 - EXHAUST PIPE

2 - TURBOCHARGER EXHAUST PIPE

Fig. 15 Throttle Linkage Cover

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

BR/BEENGINE 5.9L DIESEL 9 - 131

CYLINDER HEAD (Continued)

Page 1212 of 2255

(b) Install the rear line bundle (cyls. #3, 5, and

6), and tighten the threads at the head and pump

by hand.

(c) Torque the connections at the cylinder head

first. Torque connections to 38 N´m (28 ft. lbs.).

(d) Torque the line connections at the injection

pump to 24 N´m (18 ft. lbs.).

(e) Install the front line bundle (cyls. #1, 2, and

4) following the same procedure used for the rear

line bundle.

(f) Torque the connections at the cylinder head

first. Torque connections to 38 N´m (28 ft. lbs.).

(g) Torque the line connections at the injection

pump to 24 N´m (18 ft. lbs.).

(h) Install the injection line support bracket to

intake cover/cylinder head bolts and torque to 24

N´m (18 ft. lbs.).

(16) Install the engine lift bracket at the rear of

cylinder head. Torque to 77 N´m (57 ft. lbs.).

(17) Install the fuel filter to injection pump low

pressure line. Inspect and replace sealing washers if

necessary. Torque banjo bolts to 24 N´m (18 ft. lbs.).

(18) Using new gaskets, install the intake grid

heater and air inlet housing. Torque bolts to 24 N´m

(18 ft. lbs.).(19) Connect the APPS connector (Fig. 17).

(20) Install the APPS assembly. to the cylinder

head bracket and torque bolts to 12 N´m (105 in.

lbs.).

(21) Install the throttle linkage cover (Fig. 15).

(22) Install the charge air cooler-to-air inlet hous-

ing duct assembly. Torque all clamps to 11 N´m (100

in. lbs.).

(23) Connect intake grid heater wires.

(24) Fasten engine harness to front of cylinder

head with bolt.

(25) Install engine harness ground wire and torque

bolt to 24 N´m (18 ft. lbs.).

(26) Connect engine coolant temperature sensor

connector.

(27) Connect radiator upper hose to thermostat

housing.

(28) Install generator upper bracket and torque

bolts to 41 N´m (31 ft. lbs.).

(29) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(30) Install exhaust manifold/turbocharger assem-

bly. and start all bolts/spacers by hand. Torque bolts

to 43 N´m (32 ft. lbs.).

(31) Connect turbocharger oil drain tube.

(32) Perform the turbocharger pre-lube procedure.

Refer to Group 11, Exhaust System and Turbo-

charger for the correct procedure.

(33) Connect the turbocharger oil supply line.

(34) Install air cleaner housing and duct.

(35) Raise vehicle on hoist.

(36) Install exhaust pipe to turbocharger elbow

(Fig. 14). Torque bolts to 34 N´m (25 ft. lbs.).

(37) Lower vehicle.

(38) Fill engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(39) Start engine and check for leaks.

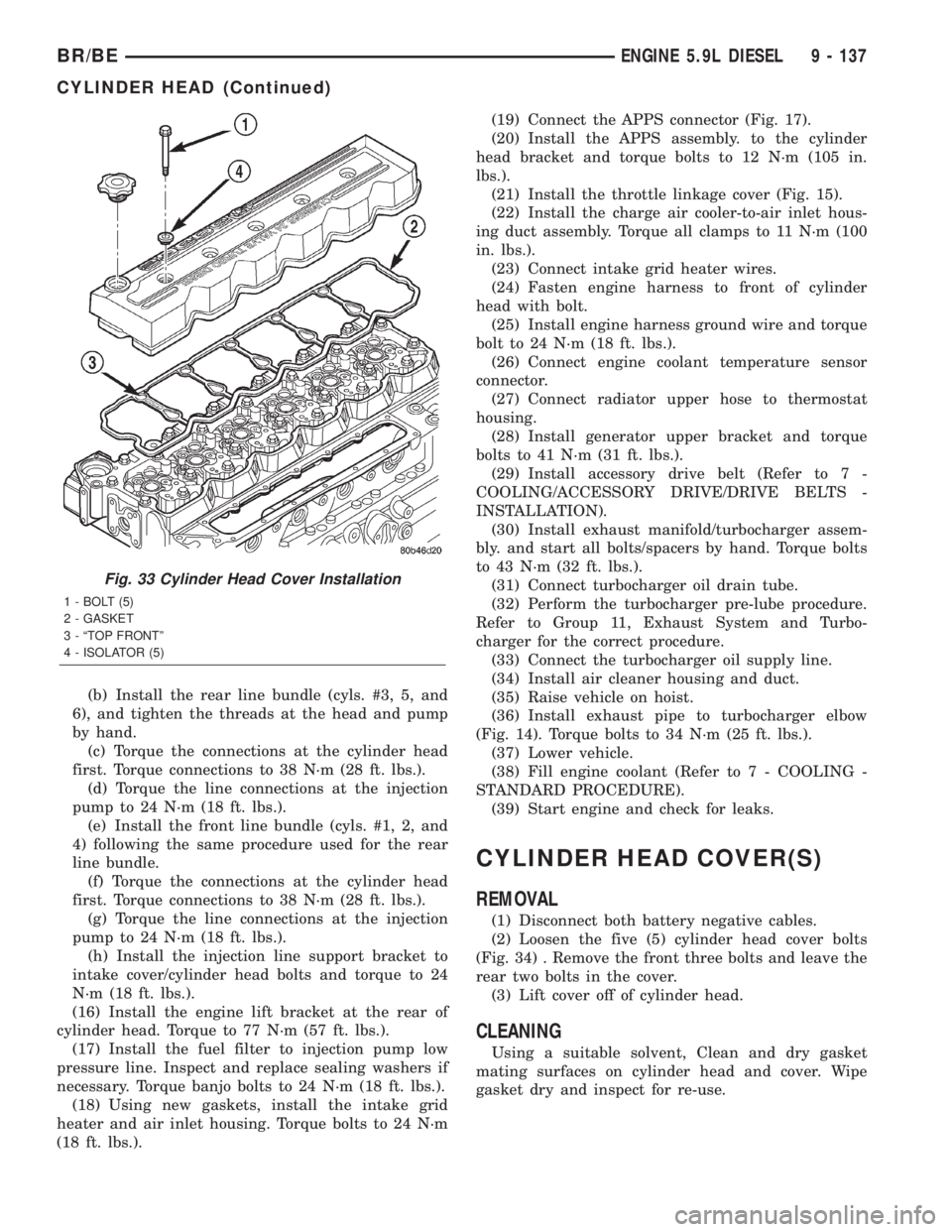

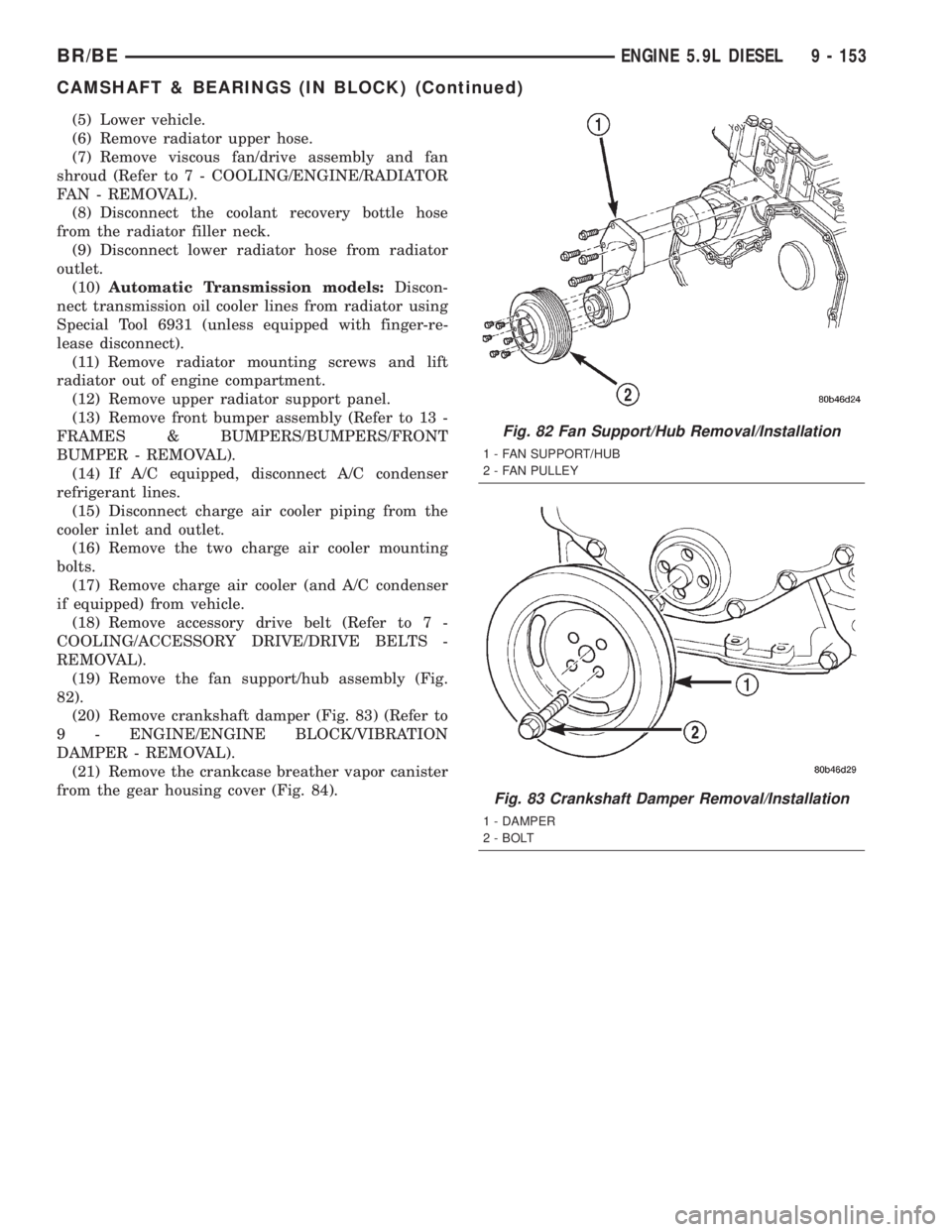

CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect both battery negative cables.

(2) Loosen the five (5) cylinder head cover bolts

(Fig. 34) . Remove the front three bolts and leave the

rear two bolts in the cover.

(3) Lift cover off of cylinder head.

CLEANING

Using a suitable solvent, Clean and dry gasket

mating surfaces on cylinder head and cover. Wipe

gasket dry and inspect for re-use.

Fig. 33 Cylinder Head Cover Installation

1 - BOLT (5)

2 - GASKET

3 - ªTOP FRONTº

4 - ISOLATOR (5)

BR/BEENGINE 5.9L DIESEL 9 - 137

CYLINDER HEAD (Continued)

Page 1216 of 2255

(8) Install the cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

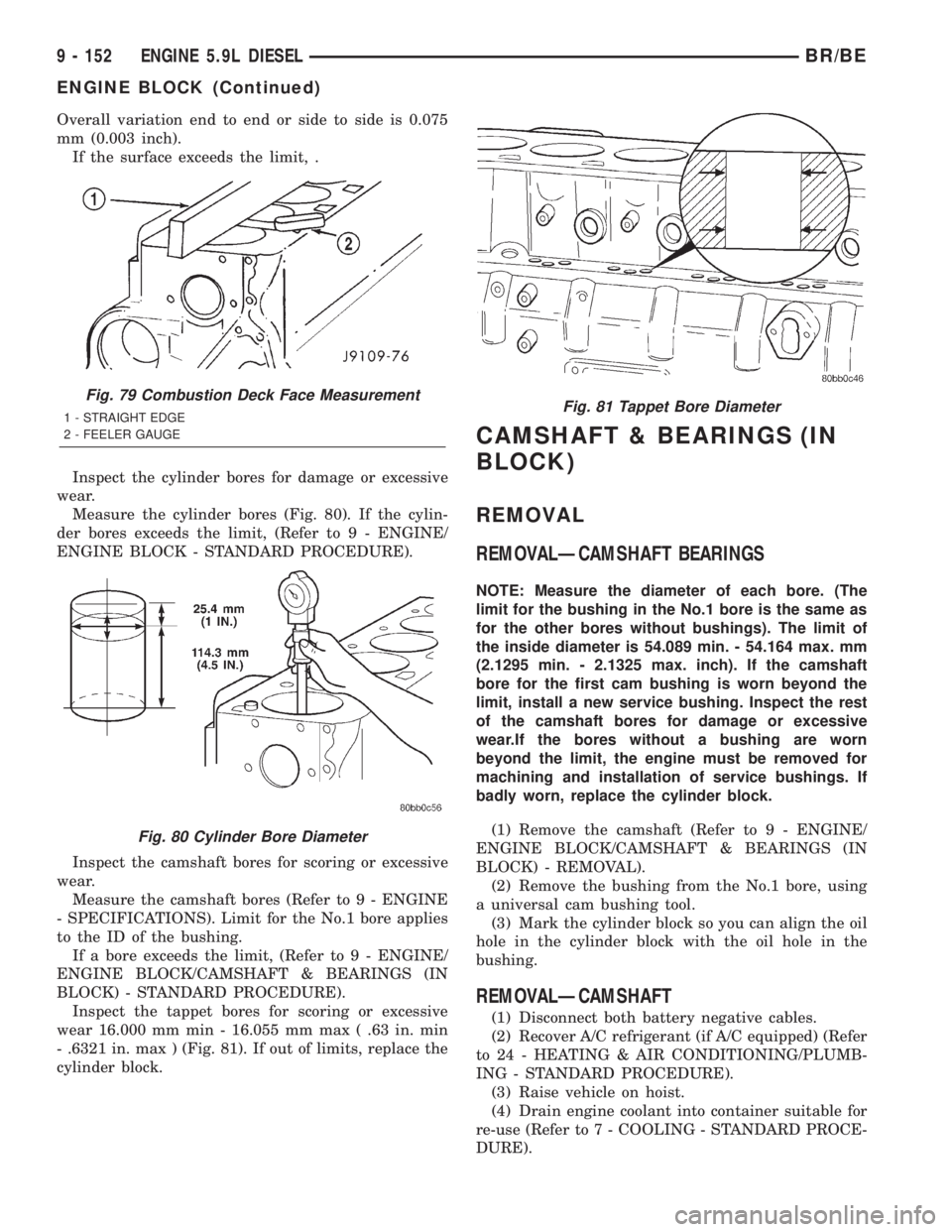

STANDARD PROCEDUREÐVALVE LASH

ADJUSTMENT AND VERIFICATION

NOTE: To obtain accurate readings, valve lash mea-

surements AND adjustments should only be per-

formed when the engine coolant temperature is less

than 60É C (140É F).

The 24±valve overhead system is a ªlow-mainte-

nanceº design. Routine adjustments are no longer

necessary, however, measurement should still take

place when trouble-shooting performance problems,or upon completion of a repair that includes removal

and installation of the valve train components.

(1) Disconnect battery negative cables.

(2) Remove cylinder head cover (Fig. 47) (Refer to

9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(3) Remove the crankcase breather and vapor can-

ister (Fig. 48).

(4) Using the crankshaft barring tool #7471±B,

rotate the engine and align the pump gear mark with

the top dead center (TDC) mark on the gear housing

cover (Fig. 49).

(5) With the engine in this position (pump gear

mark at 12 o'clock), valve lash can be measured at

the following rocker arms:INTAKE 1±2±4 /

EXHAUST 1±3±5. Measure the valve lash by insert-

ing a feeler gauge between the rocker arm socket and

crosshead (Fig. 50). Refer to VALVE LASH LIMIT

CHART for the correct specifications. If the measure-

ment fallswithinthe limits, adjustment/resettingis

notnecessary. If measurement finds the lashout-

sideof the limits, adjustment/resettingisrequired.

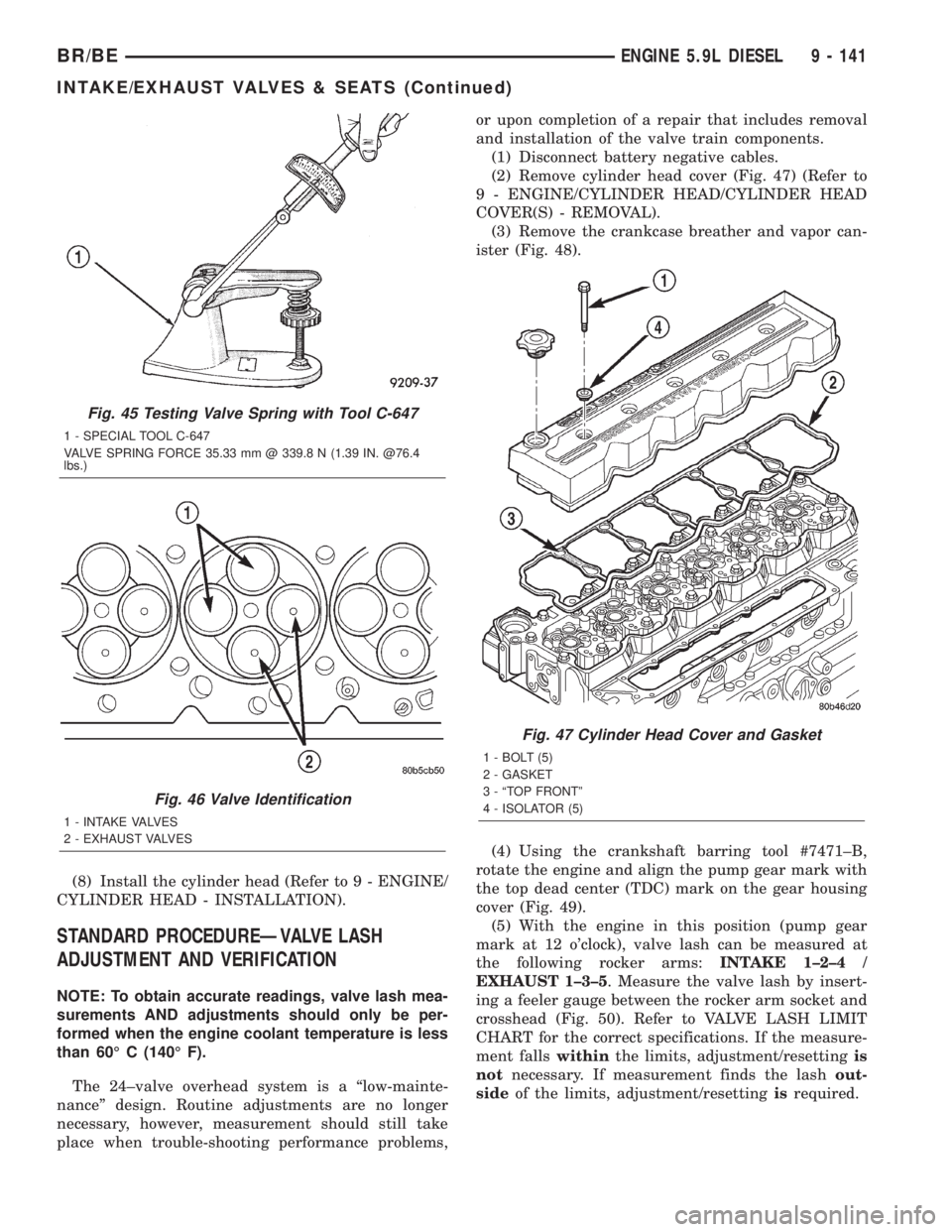

Fig. 45 Testing Valve Spring with Tool C-647

1 - SPECIAL TOOL C-647

VALVE SPRING FORCE 35.33 mm @ 339.8 N (1.39 IN. @76.4

lbs.)

Fig. 46 Valve Identification

1 - INTAKE VALVES

2 - EXHAUST VALVES

Fig. 47 Cylinder Head Cover and Gasket

1 - BOLT (5)

2 - GASKET

3 - ªTOP FRONTº

4 - ISOLATOR (5)

BR/BEENGINE 5.9L DIESEL 9 - 141

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1227 of 2255

Overall variation end to end or side to side is 0.075

mm (0.003 inch).

If the surface exceeds the limit, .

Inspect the cylinder bores for damage or excessive

wear.

Measure the cylinder bores (Fig. 80). If the cylin-

der bores exceeds the limit, (Refer to 9 - ENGINE/

ENGINE BLOCK - STANDARD PROCEDURE).

Inspect the camshaft bores for scoring or excessive

wear.

Measure the camshaft bores (Refer to 9 - ENGINE

- SPECIFICATIONS). Limit for the No.1 bore applies

to the ID of the bushing.

If a bore exceeds the limit, (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - STANDARD PROCEDURE).

Inspect the tappet bores for scoring or excessive

wear 16.000 mm min - 16.055 mm max ( .63 in. min

- .6321 in. max ) (Fig. 81). If out of limits, replace the

cylinder block.

CAMSHAFT & BEARINGS (IN

BLOCK)

REMOVAL

REMOVALÐCAMSHAFT BEARINGS

NOTE: Measure the diameter of each bore. (The

limit for the bushing in the No.1 bore is the same as

for the other bores without bushings). The limit of

the inside diameter is 54.089 min. - 54.164 max. mm

(2.1295 min. - 2.1325 max. inch). If the camshaft

bore for the first cam bushing is worn beyond the

limit, install a new service bushing. Inspect the rest

of the camshaft bores for damage or excessive

wear.If the bores without a bushing are worn

beyond the limit, the engine must be removed for

machining and installation of service bushings. If

badly worn, replace the cylinder block.

(1) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(2) Remove the bushing from the No.1 bore, using

a universal cam bushing tool.

(3) Mark the cylinder block so you can align the oil

hole in the cylinder block with the oil hole in the

bushing.

REMOVALÐCAMSHAFT

(1) Disconnect both battery negative cables.

(2) Recover A/C refrigerant (if A/C equipped) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE).

(3) Raise vehicle on hoist.

(4) Drain engine coolant into container suitable for

re-use (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

Fig. 79 Combustion Deck Face Measurement

1 - STRAIGHT EDGE

2 - FEELER GAUGE

Fig. 80 Cylinder Bore Diameter

Fig. 81 Tappet Bore Diameter

9 - 152 ENGINE 5.9L DIESELBR/BE

ENGINE BLOCK (Continued)

Page 1228 of 2255

(5) Lower vehicle.

(6) Remove radiator upper hose.

(7) Remove viscous fan/drive assembly and fan

shroud (Refer to 7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL).

(8) Disconnect the coolant recovery bottle hose

from the radiator filler neck.

(9) Disconnect lower radiator hose from radiator

outlet.

(10)Automatic Transmission models:Discon-

nect transmission oil cooler lines from radiator using

Special Tool 6931 (unless equipped with finger-re-

lease disconnect).

(11) Remove radiator mounting screws and lift

radiator out of engine compartment.

(12) Remove upper radiator support panel.

(13) Remove front bumper assembly (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT

BUMPER - REMOVAL).

(14) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(15) Disconnect charge air cooler piping from the

cooler inlet and outlet.

(16) Remove the two charge air cooler mounting

bolts.

(17) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(18) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(19) Remove the fan support/hub assembly (Fig.

82).

(20) Remove crankshaft damper (Fig. 83) (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(21) Remove the crankcase breather vapor canister

from the gear housing cover (Fig. 84).

Fig. 82 Fan Support/Hub Removal/Installation

1 - FAN SUPPORT/HUB

2 - FAN PULLEY

Fig. 83 Crankshaft Damper Removal/Installation

1 - DAMPER

2 - BOLT

BR/BEENGINE 5.9L DIESEL 9 - 153

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1233 of 2255

(11) Install the cylinder head cover and reusable

gasket (Fig. 85) (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

(12) Install gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- INSTALLATION).

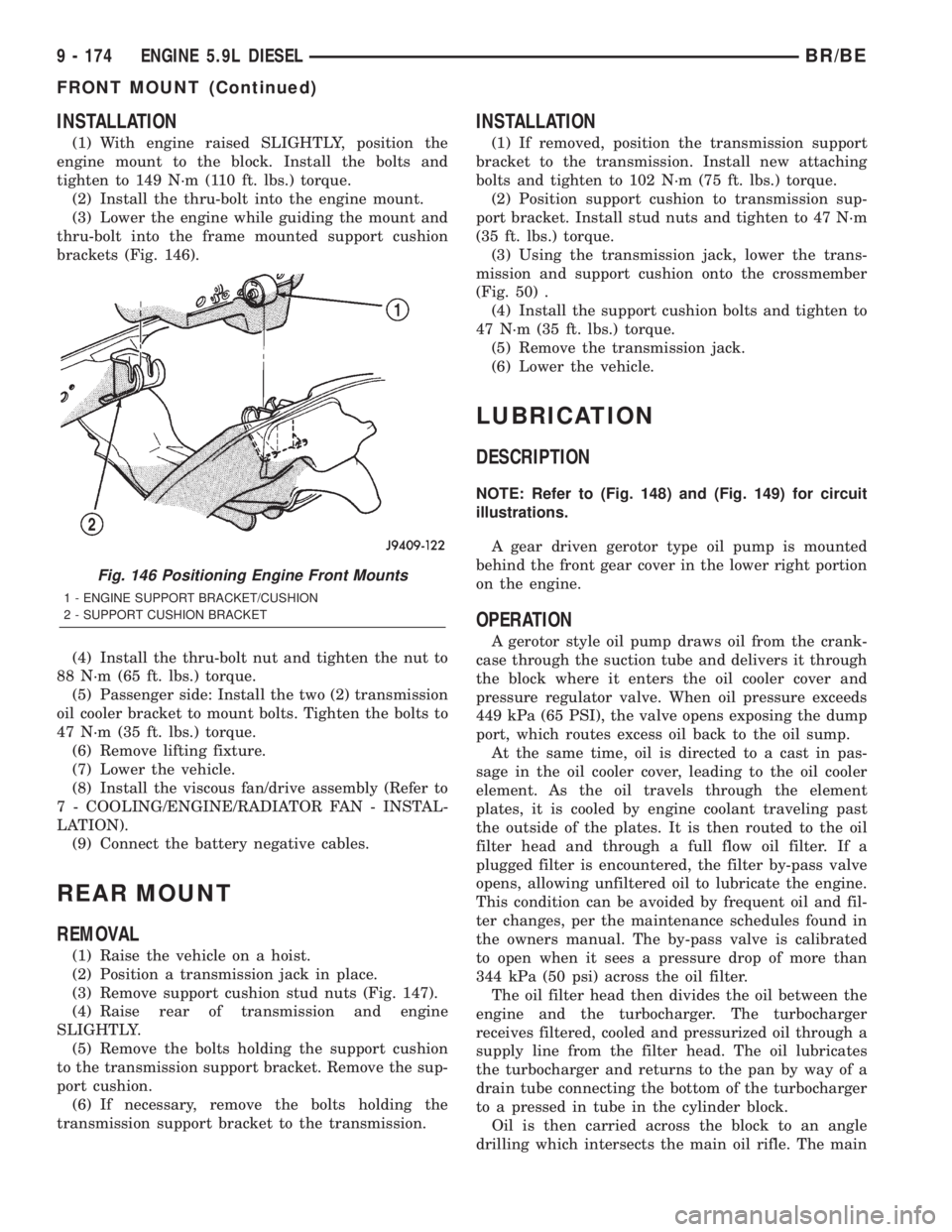

(13) Install the crankshaft damper (Fig. 83) (Refer

to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

(14) Install the fan support/hub assembly (Fig. 82)

and tighten bolts to 24 N´m (18 ft. lbs.) torque.

(15) Install the crankcase breather housing (Refer

to 9 - ENGINE - INSTALLATION).

(16) Install the charge air cooler (with a/c con-

denser and auxiliary transmission oil cooler, if

equipped) and tighten the mounting bolts to 2 N´m

(17 in. lbs.) torque.

(17) Connect charge air cooler inlet and outlet

pipes. Tighten clamps to 10 N´m (100 in. lbs.) torque.

(18) Install the radiator upper support panel.

(19) Close radiator petcock and lower the radiator

into the engine compartment. Tighten the mounting

bolts to 11 N´m (95 in. lbs.) torque.

(20) Raise vehicle on hoist.

(21) Connect radiator lower hose and install

clamp.

(22) Connect transmission auxiliary oil cooler lines

(if equipped).

(23) Lower vehicle.

(24) Install the fan shroud and tighten the mount-

ing screws to 6 N´m (50 in. lbs.) torque.

(25) Install the viscous fan/drive assembly (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(26) Install the coolant recovery and windshield

washer fluid reservoirs to the fan shroud.

(27) Connect the coolant recovery hose to the radi-

ator filler neck.

(28) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(29) Install the front bumper assembly (Refer to 13

- FRAMES & BUMPERS/BUMPERS/FRONT

BUMPER - INSTALLATION).

(30) Add engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(31) Charge A/C system with refrigerant (if A/C

equipped) (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(32) Connect the battery negative cables.

(33) Start engine and check for engine oil and cool-

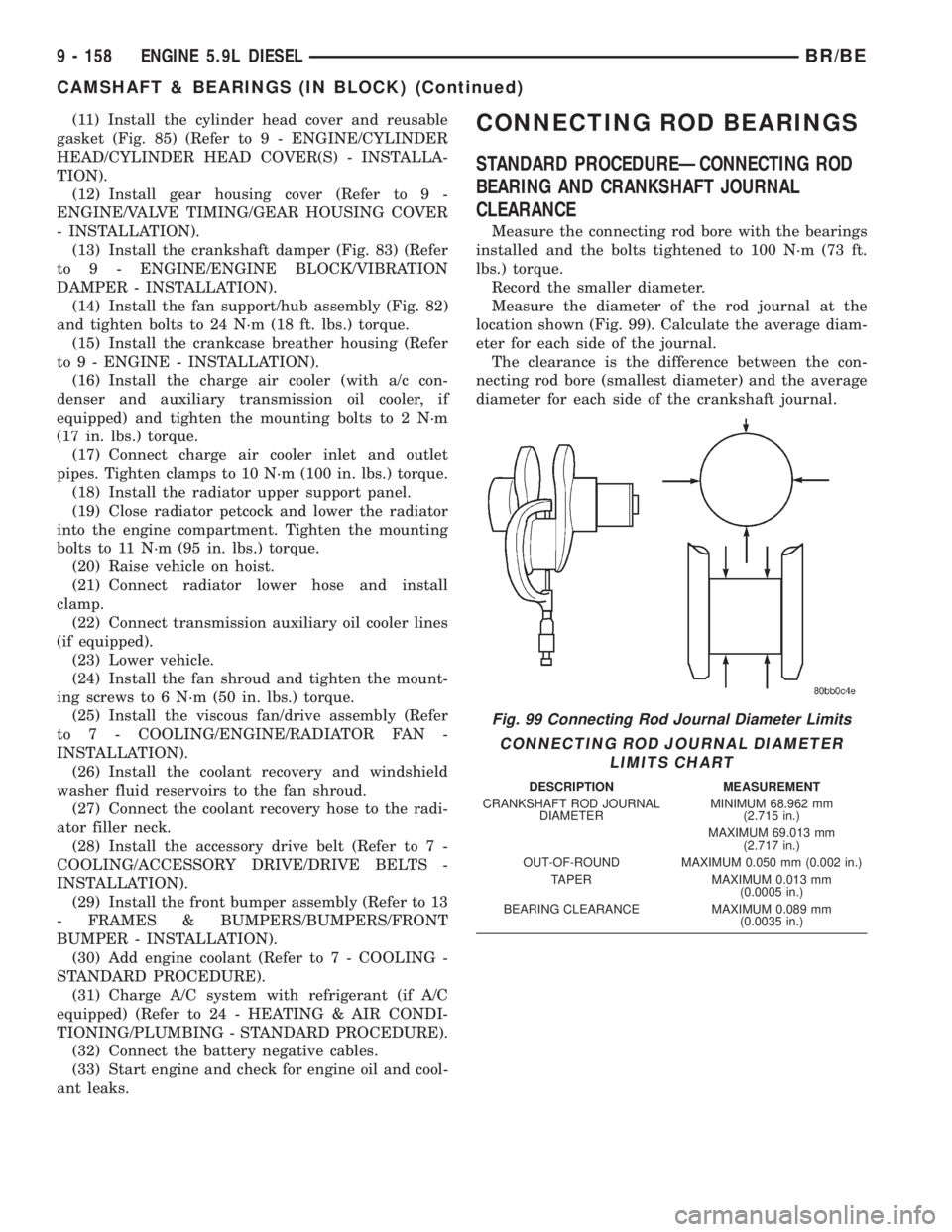

ant leaks.CONNECTING ROD BEARINGS

STANDARD PROCEDUREÐCONNECTING ROD

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE

Measure the connecting rod bore with the bearings

installed and the bolts tightened to 100 N´m (73 ft.

lbs.) torque.

Record the smaller diameter.

Measure the diameter of the rod journal at the

location shown (Fig. 99). Calculate the average diam-

eter for each side of the journal.

The clearance is the difference between the con-

necting rod bore (smallest diameter) and the average

diameter for each side of the crankshaft journal.

Fig. 99 Connecting Rod Journal Diameter Limits

CONNECTING ROD JOURNAL DIAMETER

LIMITS CHART

DESCRIPTION MEASUREMENT

CRANKSHAFT ROD JOURNAL

DIAMETERMINIMUM 68.962 mm

(2.715 in.)

MAXIMUM 69.013 mm

(2.717 in.)

OUT-OF-ROUND MAXIMUM 0.050 mm (0.002 in.)

TAPER MAXIMUM 0.013 mm

(0.0005 in.)

BEARING CLEARANCE MAXIMUM 0.089 mm

(0.0035 in.)

9 - 158 ENGINE 5.9L DIESELBR/BE

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1235 of 2255

CRANKSHAFT MAIN JOURNAL DIAMETER

CHART

ITEM SPECIFICATION

MINIMUM DIAMETER 82.962 mm (3.2662 in.)

MAXIMUM DIAMETER 83.013 mm (3.2682 in.)

Calculate the main bearing journal to bearing

clearance. the clearance specifications are 0.119 mm

(0.00475 inch). If the crankshaft journal is within

limits, replace the main bearings. If not within spec-

ifications, grind the crankshaft to next size and use

oversize bearings.

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect both battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle from radia-

tor filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove the fan shroud-to-radiator mounting

bolts.

(9) Remove viscous fan/drive assembly.The fan

drive nut has left handed threads.(Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(10) Remove cooling fan shroud and fan assembly

from the vehicle.

(11) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

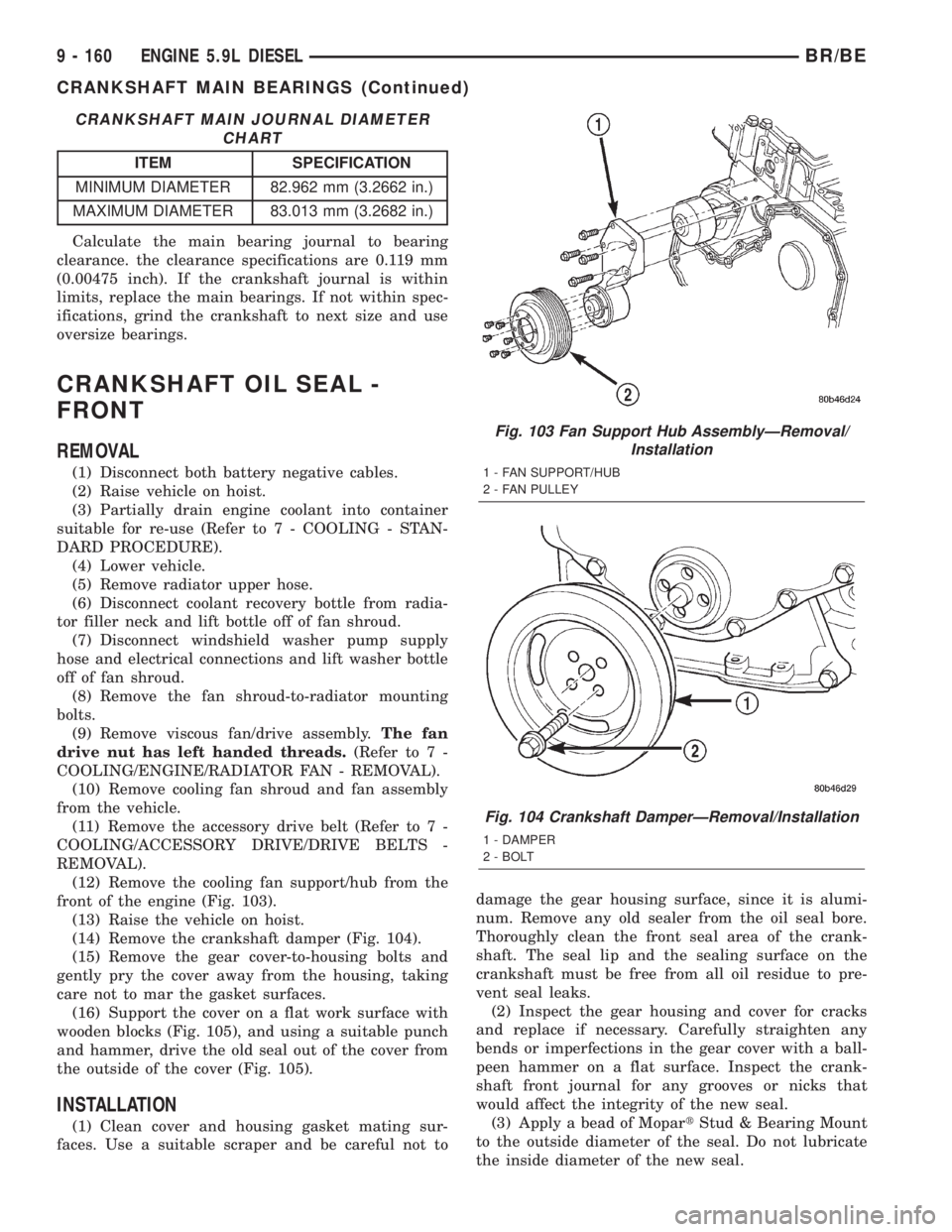

(12) Remove the cooling fan support/hub from the

front of the engine (Fig. 103).

(13) Raise the vehicle on hoist.

(14) Remove the crankshaft damper (Fig. 104).

(15) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

(16) Support the cover on a flat work surface with

wooden blocks (Fig. 105), and using a suitable punch

and hammer, drive the old seal out of the cover from

the outside of the cover (Fig. 105).

INSTALLATION

(1) Clean cover and housing gasket mating sur-

faces. Use a suitable scraper and be careful not todamage the gear housing surface, since it is alumi-

num. Remove any old sealer from the oil seal bore.

Thoroughly clean the front seal area of the crank-

shaft. The seal lip and the sealing surface on the

crankshaft must be free from all oil residue to pre-

vent seal leaks.

(2) Inspect the gear housing and cover for cracks

and replace if necessary. Carefully straighten any

bends or imperfections in the gear cover with a ball-

peen hammer on a flat surface. Inspect the crank-

shaft front journal for any grooves or nicks that

would affect the integrity of the new seal.

(3) Apply a bead of MopartStud & Bearing Mount

to the outside diameter of the seal. Do not lubricate

the inside diameter of the new seal.

Fig. 103 Fan Support Hub AssemblyÐRemoval/

Installation

1 - FAN SUPPORT/HUB

2 - FAN PULLEY

Fig. 104 Crankshaft DamperÐRemoval/Installation

1 - DAMPER

2 - BOLT

9 - 160 ENGINE 5.9L DIESELBR/BE

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1249 of 2255

INSTALLATION

(1) With engine raised SLIGHTLY, position the

engine mount to the block. Install the bolts and

tighten to 149 N´m (110 ft. lbs.) torque.

(2) Install the thru-bolt into the engine mount.

(3) Lower the engine while guiding the mount and

thru-bolt into the frame mounted support cushion

brackets (Fig. 146).

(4) Install the thru-bolt nut and tighten the nut to

88 N´m (65 ft. lbs.) torque.

(5) Passenger side: Install the two (2) transmission

oil cooler bracket to mount bolts. Tighten the bolts to

47 N´m (35 ft. lbs.) torque.

(6) Remove lifting fixture.

(7) Lower the vehicle.

(8) Install the viscous fan/drive assembly (Refer to

7 - COOLING/ENGINE/RADIATOR FAN - INSTAL-

LATION).

(9) Connect the battery negative cables.

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Position a transmission jack in place.

(3) Remove support cushion stud nuts (Fig. 147).

(4) Raise rear of transmission and engine

SLIGHTLY.

(5) Remove the bolts holding the support cushion

to the transmission support bracket. Remove the sup-

port cushion.

(6) If necessary, remove the bolts holding the

transmission support bracket to the transmission.

INSTALLATION

(1) If removed, position the transmission support

bracket to the transmission. Install new attaching

bolts and tighten to 102 N´m (75 ft. lbs.) torque.

(2) Position support cushion to transmission sup-

port bracket. Install stud nuts and tighten to 47 N´m

(35 ft. lbs.) torque.

(3) Using the transmission jack, lower the trans-

mission and support cushion onto the crossmember

(Fig. 50) .

(4) Install the support cushion bolts and tighten to

47 N´m (35 ft. lbs.) torque.

(5) Remove the transmission jack.

(6) Lower the vehicle.

LUBRICATION

DESCRIPTION

NOTE: Refer to (Fig. 148) and (Fig. 149) for circuit

illustrations.

A gear driven gerotor type oil pump is mounted

behind the front gear cover in the lower right portion

on the engine.

OPERATION

A gerotor style oil pump draws oil from the crank-

case through the suction tube and delivers it through

the block where it enters the oil cooler cover and

pressure regulator valve. When oil pressure exceeds

449 kPa (65 PSI), the valve opens exposing the dump

port, which routes excess oil back to the oil sump.

At the same time, oil is directed to a cast in pas-

sage in the oil cooler cover, leading to the oil cooler

element. As the oil travels through the element

plates, it is cooled by engine coolant traveling past

the outside of the plates. It is then routed to the oil

filter head and through a full flow oil filter. If a

plugged filter is encountered, the filter by-pass valve

opens, allowing unfiltered oil to lubricate the engine.

This condition can be avoided by frequent oil and fil-

ter changes, per the maintenance schedules found in

the owners manual. The by-pass valve is calibrated

to open when it sees a pressure drop of more than

344 kPa (50 psi) across the oil filter.

The oil filter head then divides the oil between the

engine and the turbocharger. The turbocharger

receives filtered, cooled and pressurized oil through a

supply line from the filter head. The oil lubricates

the turbocharger and returns to the pan by way of a

drain tube connecting the bottom of the turbocharger

to a pressed in tube in the cylinder block.

Oil is then carried across the block to an angle

drilling which intersects the main oil rifle. The main

Fig. 146 Positioning Engine Front Mounts

1 - ENGINE SUPPORT BRACKET/CUSHION

2 - SUPPORT CUSHION BRACKET

9 - 174 ENGINE 5.9L DIESELBR/BE

FRONT MOUNT (Continued)