Cooling system DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 2178 of 2255

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 added to an R-134a refrigerant

system will cause compressor failure, refrigerant oil

sludge or poor air conditioning system performance.

In addition, the PolyAlkylene Glycol (PAG) synthetic

refrigerant oils used in an R-134a refrigerant system

are not compatible with the mineral-based refriger-

ant oils used in an R-12 refrigerant system.

R-134a refrigerant system service ports, service

tool couplers and refrigerant dispensing bottles have

all been designed with unique fittings to ensure that

an R-134a system is not accidentally contaminated

with the wrong refrigerant (R-12). There are also

labels posted in the engine compartment of the vehi-

cle and on the compressor identifying to service tech-

nicians that the air conditioning system is equipped

with R-134a.

REFRIGERANT OIL

DESCRIPTION

The refrigerant oil used in R-134a refrigerant sys-

tems is a synthetic-based, PolyAlkylene Glycol (PAG),

wax-free lubricant. Mineral-based R-12 refrigerant

oils are not compatible with PAG oils, and should

never be introduced to an R-134a refrigerant system.

There are different PAG oils available, and each

contains a different additive package. The SD7H15

compressor used in this vehicle is designed to use an

SP-20 PAG refrigerant oil. Use only refrigerant oil of

this same type to service the refrigerant system.

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.

PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system has

been charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The accumulator, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrica-

tion of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a compo-

nent, or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.

Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when a accumulator,

evaporator coil, or condenser are replaced. See the

Refrigerant Oil Capacities chart. When a compressor

is replaced, the refrigerant oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of refrigerant

oil that was drained out of the old compressor.

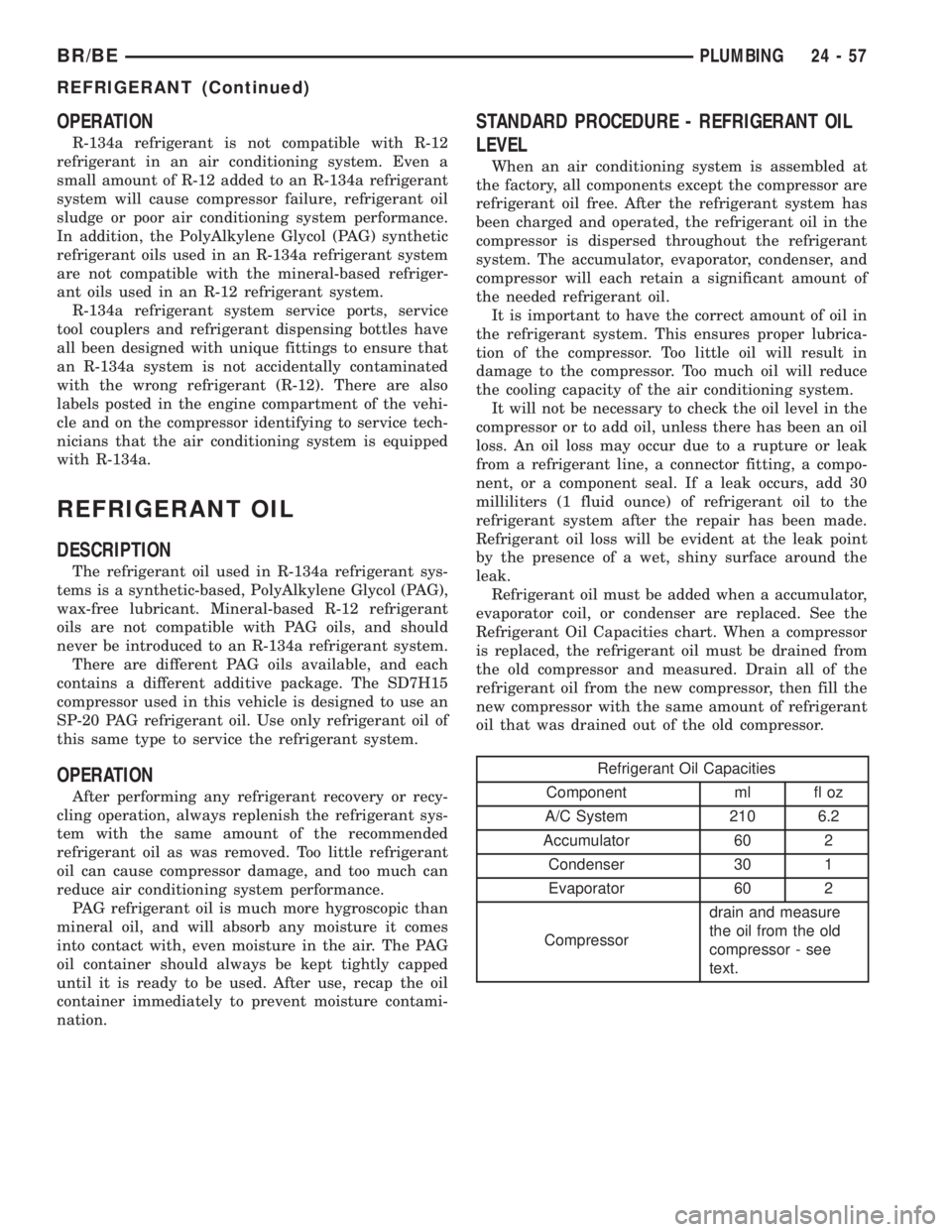

Refrigerant Oil Capacities

Component ml fl oz

A/C System 210 6.2

Accumulator 60 2

Condenser 30 1

Evaporator 60 2

Compressordrain and measure

the oil from the old

compressor - see

text.

BR/BEPLUMBING 24 - 57

REFRIGERANT (Continued)

Page 2193 of 2255

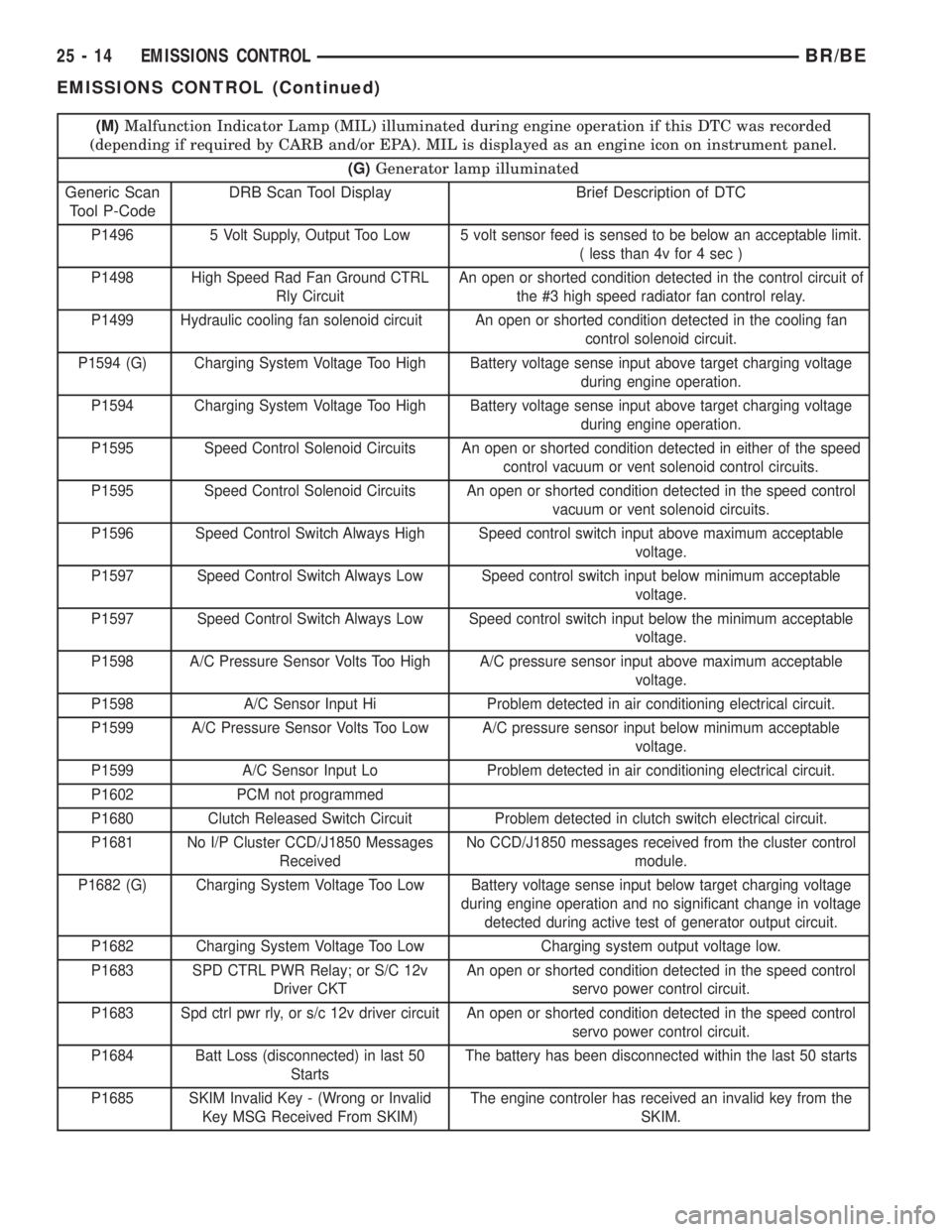

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1496 5 Volt Supply, Output Too Low 5 volt sensor feed is sensed to be below an acceptable limit.

( less than 4v for 4 sec )

P1498 High Speed Rad Fan Ground CTRL

Rly CircuitAn open or shorted condition detected in the control circuit of

the #3 high speed radiator fan control relay.

P1499 Hydraulic cooling fan solenoid circuit An open or shorted condition detected in the cooling fan

control solenoid circuit.

P1594 (G) Charging System Voltage Too High Battery voltage sense input above target charging voltage

during engine operation.

P1594 Charging System Voltage Too High Battery voltage sense input above target charging voltage

during engine operation.

P1595 Speed Control Solenoid Circuits An open or shorted condition detected in either of the speed

control vacuum or vent solenoid control circuits.

P1595 Speed Control Solenoid Circuits An open or shorted condition detected in the speed control

vacuum or vent solenoid circuits.

P1596 Speed Control Switch Always High Speed control switch input above maximum acceptable

voltage.

P1597 Speed Control Switch Always Low Speed control switch input below minimum acceptable

voltage.

P1597 Speed Control Switch Always Low Speed control switch input below the minimum acceptable

voltage.

P1598 A/C Pressure Sensor Volts Too High A/C pressure sensor input above maximum acceptable

voltage.

P1598 A/C Sensor Input Hi Problem detected in air conditioning electrical circuit.

P1599 A/C Pressure Sensor Volts Too Low A/C pressure sensor input below minimum acceptable

voltage.

P1599 A/C Sensor Input Lo Problem detected in air conditioning electrical circuit.

P1602 PCM not programmed

P1680 Clutch Released Switch Circuit Problem detected in clutch switch electrical circuit.

P1681 No I/P Cluster CCD/J1850 Messages

ReceivedNo CCD/J1850 messages received from the cluster control

module.

P1682 (G) Charging System Voltage Too Low Battery voltage sense input below target charging voltage

during engine operation and no significant change in voltage

detected during active test of generator output circuit.

P1682 Charging System Voltage Too Low Charging system output voltage low.

P1683 SPD CTRL PWR Relay; or S/C 12v

Driver CKTAn open or shorted condition detected in the speed control

servo power control circuit.

P1683 Spd ctrl pwr rly, or s/c 12v driver circuit An open or shorted condition detected in the speed control

servo power control circuit.

P1684 Batt Loss (disconnected) in last 50

StartsThe battery has been disconnected within the last 50 starts

P1685 SKIM Invalid Key - (Wrong or Invalid

Key MSG Received From SKIM)The engine controler has received an invalid key from the

SKIM.

25 - 14 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2209 of 2255

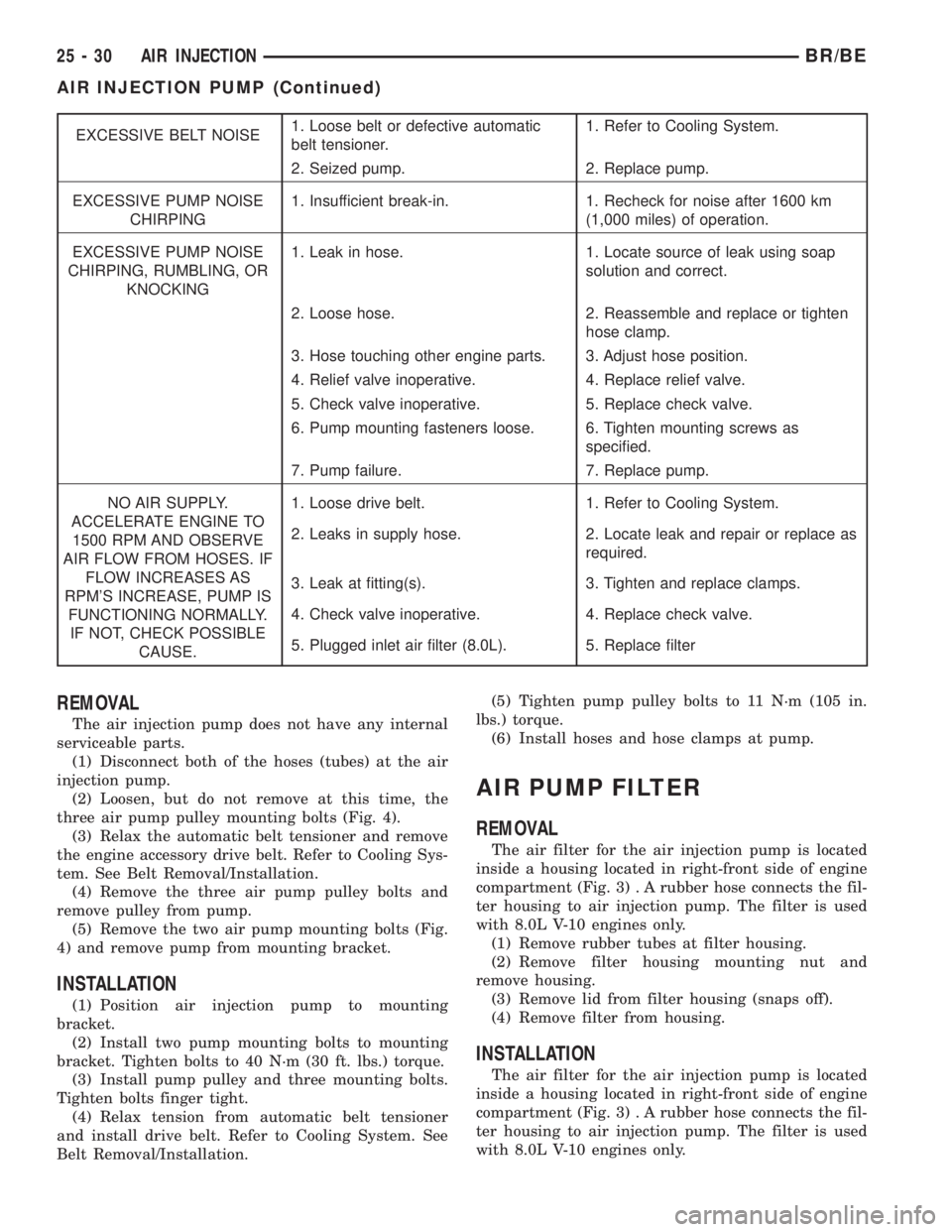

EXCESSIVE BELT NOISE1. Loose belt or defective automatic

belt tensioner.1. Refer to Cooling System.

2. Seized pump. 2. Replace pump.

EXCESSIVE PUMP NOISE

CHIRPING1. Insufficient break-in. 1. Recheck for noise after 1600 km

(1,000 miles) of operation.

EXCESSIVE PUMP NOISE

CHIRPING, RUMBLING, OR

KNOCKING1. Leak in hose. 1. Locate source of leak using soap

solution and correct.

2. Loose hose. 2. Reassemble and replace or tighten

hose clamp.

3. Hose touching other engine parts. 3. Adjust hose position.

4. Relief valve inoperative. 4. Replace relief valve.

5. Check valve inoperative. 5. Replace check valve.

6. Pump mounting fasteners loose. 6. Tighten mounting screws as

specified.

7. Pump failure. 7. Replace pump.

NO AIR SUPPLY.

ACCELERATE ENGINE TO

1500 RPM AND OBSERVE

AIR FLOW FROM HOSES. IF

FLOW INCREASES AS

RPM'S INCREASE, PUMP IS

FUNCTIONING NORMALLY.

IF NOT, CHECK POSSIBLE

CAUSE.1. Loose drive belt. 1. Refer to Cooling System.

2. Leaks in supply hose. 2. Locate leak and repair or replace as

required.

3. Leak at fitting(s). 3. Tighten and replace clamps.

4. Check valve inoperative. 4. Replace check valve.

5. Plugged inlet air filter (8.0L). 5. Replace filter

REMOVAL

The air injection pump does not have any internal

serviceable parts.

(1) Disconnect both of the hoses (tubes) at the air

injection pump.

(2) Loosen, but do not remove at this time, the

three air pump pulley mounting bolts (Fig. 4).

(3) Relax the automatic belt tensioner and remove

the engine accessory drive belt. Refer to Cooling Sys-

tem. See Belt Removal/Installation.

(4) Remove the three air pump pulley bolts and

remove pulley from pump.

(5) Remove the two air pump mounting bolts (Fig.

4) and remove pump from mounting bracket.

INSTALLATION

(1) Position air injection pump to mounting

bracket.

(2) Install two pump mounting bolts to mounting

bracket. Tighten bolts to 40 N´m (30 ft. lbs.) torque.

(3) Install pump pulley and three mounting bolts.

Tighten bolts finger tight.

(4) Relax tension from automatic belt tensioner

and install drive belt. Refer to Cooling System. See

Belt Removal/Installation.(5) Tighten pump pulley bolts to 11 N´m (105 in.

lbs.) torque.

(6) Install hoses and hose clamps at pump.

AIR PUMP FILTER

REMOVAL

The air filter for the air injection pump is located

inside a housing located in right-front side of engine

compartment (Fig. 3) . A rubber hose connects the fil-

ter housing to air injection pump. The filter is used

with 8.0L V-10 engines only.

(1) Remove rubber tubes at filter housing.

(2) Remove filter housing mounting nut and

remove housing.

(3) Remove lid from filter housing (snaps off).

(4) Remove filter from housing.

INSTALLATION

The air filter for the air injection pump is located

inside a housing located in right-front side of engine

compartment (Fig. 3) . A rubber hose connects the fil-

ter housing to air injection pump. The filter is used

with 8.0L V-10 engines only.

25 - 30 AIR INJECTIONBR/BE

AIR INJECTION PUMP (Continued)

Page 2223 of 2255

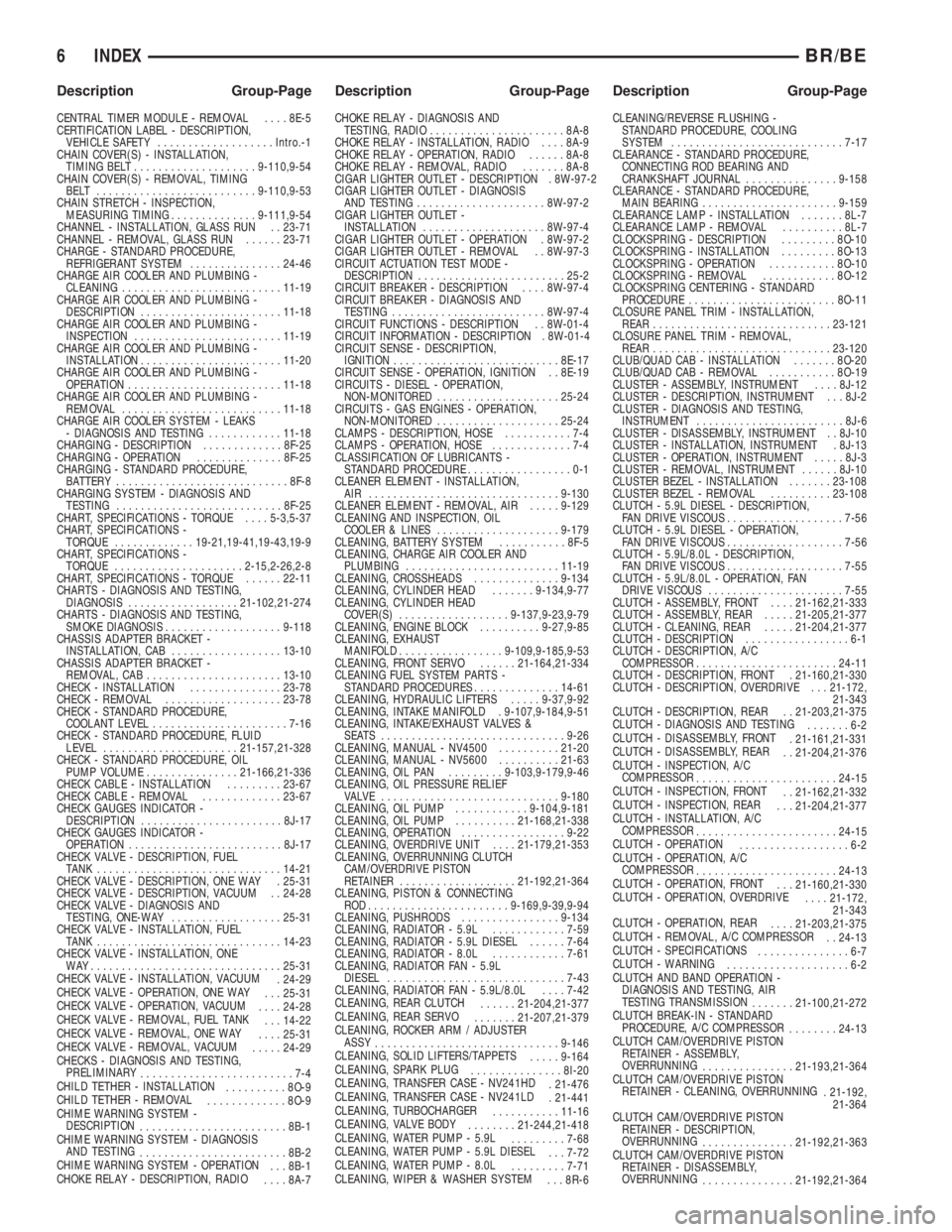

CENTRAL TIMER MODULE - REMOVAL....8E-5

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY...................Intro.-1

CHAIN COVER(S) - INSTALLATION,

TIMING BELT....................9-110,9-54

CHAIN COVER(S) - REMOVAL, TIMING

BELT ..........................9-110,9-53

CHAIN STRETCH - INSPECTION,

MEASURING TIMING..............9-111,9-54

CHANNEL - INSTALLATION, GLASS RUN . . 23-71

CHANNEL - REMOVAL, GLASS RUN......23-71

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-46

CHARGE AIR COOLER AND PLUMBING -

CLEANING..........................11-19

CHARGE AIR COOLER AND PLUMBING -

DESCRIPTION.......................11-18

CHARGE AIR COOLER AND PLUMBING -

INSPECTION........................11-19

CHARGE AIR COOLER AND PLUMBING -

INSTALLATION.......................11-20

CHARGE AIR COOLER AND PLUMBING -

OPERATION.........................11-18

CHARGE AIR COOLER AND PLUMBING -

REMOVAL..........................11-18

CHARGE AIR COOLER SYSTEM - LEAKS

- DIAGNOSIS AND TESTING............11-18

CHARGING - DESCRIPTION.............8F-25

CHARGING - OPERATION..............8F-25

CHARGING - STANDARD PROCEDURE,

BATTERY............................8F-8

CHARGING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-25

CHART, SPECIFICATIONS - TORQUE....5-3,5-37

CHART, SPECIFICATIONS -

TORQUE.............19-21,19-41,19-43,19-9

CHART, SPECIFICATIONS -

TORQUE.....................2-15,2-26,2-8

CHART, SPECIFICATIONS - TORQUE......22-11

CHARTS - DIAGNOSIS AND TESTING,

DIAGNOSIS..................21-102,21-274

CHARTS - DIAGNOSIS AND TESTING,

SMOKE DIAGNOSIS...................9-118

CHASSIS ADAPTER BRACKET -

INSTALLATION, CAB..................13-10

CHASSIS ADAPTER BRACKET -

REMOVAL, CAB......................13-10

CHECK - INSTALLATION...............23-78

CHECK - REMOVAL...................23-78

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL......................7-16

CHECK - STANDARD PROCEDURE, FLUID

LEVEL......................21-157,21-328

CHECK - STANDARD PROCEDURE, OIL

PUMP VOLUME...............21-166,21-336

CHECK CABLE - INSTALLATION.........23-67

CHECK CABLE - REMOVAL.............23-67

CHECK GAUGES INDICATOR -

DESCRIPTION.......................8J-17

CHECK GAUGES INDICATOR -

OPERATION.........................8J-17

CHECK VALVE - DESCRIPTION, FUEL

TANK ..............................14-21

CHECK VALVE - DESCRIPTION, ONE WAY . 25-31

CHECK VALVE - DESCRIPTION, VACUUM . . 24-28

CHECK VALVE - DIAGNOSIS AND

TESTING, ONE-WAY..................25-31

CHECK VALVE - INSTALLATION, FUEL

TANK ..............................14-23

CHECK VALVE - INSTALLATION, ONE

WAY...............................25-31

CHECK VALVE - INSTALLATION, VACUUM

. 24-29

CHECK VALVE - OPERATION, ONE WAY

. . . 25-31

CHECK VALVE - OPERATION, VACUUM

....24-28

CHECK VALVE - REMOVAL, FUEL TANK

. . . 14-22

CHECK VALVE - REMOVAL, ONE WAY

....25-31

CHECK VALVE - REMOVAL, VACUUM

.....24-29

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY

.........................7-4

CHILD TETHER - INSTALLATION

..........8O-9

CHILD TETHER - REMOVAL

.............8O-9

CHIME WARNING SYSTEM -

DESCRIPTION

........................8B-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING

........................8B-2

CHIME WARNING SYSTEM - OPERATION

. . . 8B-1

CHOKE RELAY - DESCRIPTION, RADIO

....8A-7CHOKE RELAY - DIAGNOSIS AND

TESTING, RADIO......................8A-8

CHOKE RELAY - INSTALLATION, RADIO....8A-9

CHOKE RELAY - OPERATION, RADIO......8A-8

CHOKE RELAY - REMOVAL, RADIO.......8A-8

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET -

INSTALLATION....................8W-97-4

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIGAR LIGHTER OUTLET - REMOVAL . . 8W-97-3

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-2

CIRCUIT BREAKER - DESCRIPTION....8W-97-4

CIRCUIT BREAKER - DIAGNOSIS AND

TESTING.........................8W-97-4

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-4

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-4

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-17

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-19

CIRCUITS - DIESEL - OPERATION,

NON-MONITORED....................25-24

CIRCUITS - GAS ENGINES - OPERATION,

NON-MONITORED....................25-24

CLAMPS - DESCRIPTION, HOSE...........7-4

CLAMPS - OPERATION, HOSE.............7-4

CLASSIFICATION OF LUBRICANTS -

STANDARD PROCEDURE..................0-1

CLEANER ELEMENT - INSTALLATION,

AIR ...............................9-130

CLEANER ELEMENT - REMOVAL, AIR.....9-129

CLEANING AND INSPECTION, OIL

COOLER & LINES....................9-179

CLEANING, BATTERY SYSTEM...........8F-5

CLEANING, CHARGE AIR COOLER AND

PLUMBING.........................11-19

CLEANING, CROSSHEADS..............9-134

CLEANING, CYLINDER HEAD.......9-134,9-77

CLEANING, CYLINDER HEAD

COVER(S)..................9-137,9-23,9-79

CLEANING, ENGINE BLOCK..........9-27,9-85

CLEANING, EXHAUST

MANIFOLD.................9-109,9-185,9-53

CLEANING, FRONT SERVO......21-164,21-334

CLEANING FUEL SYSTEM PARTS -

STANDARD PROCEDURES..............14-61

CLEANING, HYDRAULIC LIFTERS.....9-37,9-92

CLEANING, INTAKE MANIFOLD . 9-107,9-184,9-51

CLEANING, INTAKE/EXHAUST VALVES &

SEATS ..............................9-26

CLEANING, MANUAL - NV4500..........21-20

CLEANING, MANUAL - NV5600..........21-63

CLEANING, OIL PAN.........9-103,9-179,9-46

CLEANING, OIL PRESSURE RELIEF

VALVE .............................9-180

CLEANING, OIL PUMP............9-104,9-181

CLEANING, OIL PUMP..........21-168,21-338

CLEANING, OPERATION.................9-22

CLEANING, OVERDRIVE UNIT....21-179,21-353

CLEANING, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER...................21-192,21-364

CLEANING, PISTON & CONNECTING

ROD.......................9-169,9-39,9-94

CLEANING, PUSHRODS................9-134

CLEANING, RADIATOR - 5.9L............7-59

CLEANING, RADIATOR - 5.9L DIESEL......7-64

CLEANING, RADIATOR - 8.0L............7-61

CLEANING, RADIATOR FAN - 5.9L

DIESEL.............................7-43

CLEANING, RADIATOR FAN - 5.9L/8.0L....7-42

CLEANING, REAR CLUTCH

......21-204,21-377

CLEANING, REAR SERVO

.......21-207,21-379

CLEANING, ROCKER ARM / ADJUSTER

ASSY

..............................9-146

CLEANING, SOLID LIFTERS/TAPPETS

.....9-164

CLEANING, SPARK PLUG

...............8I-20

CLEANING, TRANSFER CASE - NV241HD

. 21-476

CLEANING, TRANSFER CASE - NV241LD

. 21-441

CLEANING, TURBOCHARGER

...........11-16

CLEANING, VALVE BODY

........21-244,21-418

CLEANING, WATER PUMP - 5.9L

.........7-68

CLEANING, WATER PUMP - 5.9L DIESEL

. . . 7-72

CLEANING, WATER PUMP - 8.0L

.........7-71

CLEANING, WIPER & WASHER SYSTEM

. . . 8R-6CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-158

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-159

CLEARANCE LAMP - INSTALLATION.......8L-7

CLEARANCE LAMP - REMOVAL..........8L-7

CLOCKSPRING - DESCRIPTION.........8O-10

CLOCKSPRING - INSTALLATION.........8O-13

CLOCKSPRING - OPERATION...........8O-10

CLOCKSPRING - REMOVAL............8O-12

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-11

CLOSURE PANEL TRIM - INSTALLATION,

REAR.............................23-121

CLOSURE PANEL TRIM - REMOVAL,

REAR.............................23-120

CLUB/QUAD CAB - INSTALLATION.......8O-20

CLUB/QUAD CAB - REMOVAL...........8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-12

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-6

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-10

CLUSTER - INSTALLATION, INSTRUMENT . 8J-13

CLUSTER - OPERATION, INSTRUMENT.....8J-3

CLUSTER - REMOVAL, INSTRUMENT......8J-10

CLUSTER BEZEL - INSTALLATION.......23-108

CLUSTER BEZEL - REMOVAL..........23-108

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L/8.0L - DESCRIPTION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - 5.9L/8.0L - OPERATION, FAN

DRIVE VISCOUS......................7-55

CLUTCH - ASSEMBLY, FRONT....21-162,21-333

CLUTCH - ASSEMBLY, REAR.....21-205,21-377

CLUTCH - CLEANING, REAR.....21-204,21-377

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR.......................24-11

CLUTCH - DESCRIPTION, FRONT . 21-160,21-330

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-172,

21-343

CLUTCH - DESCRIPTION, REAR . . 21-203,21-375

CLUTCH - DIAGNOSIS AND TESTING

.......6-2

CLUTCH - DISASSEMBLY, FRONT

. 21-161,21-331

CLUTCH - DISASSEMBLY, REAR

. . 21-204,21-376

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-15

CLUTCH - INSPECTION, FRONT

. . 21-162,21-332

CLUTCH - INSPECTION, REAR

. . . 21-204,21-377

CLUTCH - INSTALLATION, A/C

COMPRESSOR

.......................24-15

CLUTCH - OPERATION

..................6-2

CLUTCH - OPERATION, A/C

COMPRESSOR

.......................24-13

CLUTCH - OPERATION, FRONT

. . . 21-160,21-330

CLUTCH - OPERATION, OVERDRIVE

....21-172,

21-343

CLUTCH - OPERATION, REAR

....21-203,21-375

CLUTCH - REMOVAL, A/C COMPRESSOR

. . 24-13

CLUTCH - SPECIFICATIONS

...............6-7

CLUTCH - WARNING

....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION

.......21-100,21-272

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR

........24-13

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING

...............21-193,21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING

. 21-192,

21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING

...............21-192,21-363

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING

...............21-192,21-364

6 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2225 of 2255

CONTROLS - DIAGNOSIS AND TESTING,

OVERDRIVE ELECTRICAL.......21-191,21-344

CONVERTER - 3.9L/5.2L/5.9L -

DESCRIPTION, CATALYTIC...............11-5

CONVERTER - 3.9L/5.2L/5.9L -

INSPECTION, CATALYTIC................11-6

CONVERTER - 3.9L/5.2L/5.9L -

INSTALLATION, CATALYTIC..............11-6

CONVERTER - 3.9L/5.2L/5.9L -

OPERATION, CATALYTIC................11-5

CONVERTER - 3.9L/5.2L/5.9L -

REMOVAL, CATALYTIC..................11-5

CONVERTER - 5.9L HD/8.0L -

DESCRIPTION, CATALYTIC...............11-6

CONVERTER - 5.9L HD/8.0L -

INSPECTION, CATALYTIC................11-6

CONVERTER - 5.9L HD/8.0L -

INSTALLATION, CATALYTIC..............11-7

CONVERTER - 5.9L HD/8.0L -

OPERATION, CATALYTIC................11-6

CONVERTER - 5.9L HD/8.0L - REMOVAL,

CATALYTIC...........................11-6

CONVERTER - DESCRIPTION,

TORQUE.....................21-212,21-384

CONVERTER - INSTALLATION,

TORQUE.....................21-217,21-389

CONVERTER - OPERATION,

TORQUE.....................21-215,21-388

CONVERTER - REMOVAL,

TORQUE.....................21-216,21-389

CONVERTER DRAINBACK VALVE -

DESCRIPTION, TORQUE........21-217,21-390

CONVERTER DRAINBACK VALVE -

OPERATION, TORQUE............21-217,21-390

CONVERTER DRAINBACK VALVE -

STANDARD PROCEDURE,

TORQUE.....................21-217,21-390

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND TESTING......21-101,21-273

COOLANT - DESCRIPTION, ENGINE.......7-39

COOLANT - DESCRIPTION, ENGINE........0-3

COOLANT - OPERATION................7-40

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL..................7-16

COOLANT FLOW - DIAGNOSIS AND

TESTING, RADIATOR...........7-58,7-60,7-62

COOLANT LEVEL CHECK - STANDARD

PROCEDURE.........................7-16

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

DESCRIPTION........................7-40

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

INSTALLATION........................7-41

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

OPERATION..........................7-40

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

REMOVAL...........................7-40

COOLANT RECOVERY CONTAINER - 8.0L

- DESCRIPTION.......................7-41

COOLANT RECOVERY CONTAINER - 8.0L

- OPERATION.........................7-41

COOLANT SELECTION - ADDITIVES -

STANDARD PROCEDURE................7-17

COOLANT TEMP SENSOR - 5.9L -

DESCRIPTION, ENGINE.................7-47

COOLANT TEMP SENSOR - 5.9L -

INSTALLATION, ENGINE................7-47

COOLANT TEMP SENSOR - 5.9L -

OPERATION, ENGINE...................7-47

COOLANT TEMP SENSOR - 5.9L -

REMOVAL, ENGINE....................7-47

COOLANT THERMOSTAT - 5.9L -

DESCRIPTION, ENGINE.................7-48

COOLANT THERMOSTAT - 5.9L -

INSTALLATION, ENGINE................7-49

COOLANT THERMOSTAT - 5.9L -

OPERATION, ENGINE

...................7-48

COOLANT THERMOSTAT - 5.9L -

REMOVAL, ENGINE

....................7-48

COOLANT THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE

.................7-53

COOLANT THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE

................7-54

COOLANT THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE

...................7-53COOLANT THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE....................7-54

COOLANT THERMOSTAT - 8.0L -

DESCRIPTION, ENGINE.................7-51

COOLANT THERMOSTAT - 8.0L -

INSTALLATION, ENGINE................7-52

COOLANT THERMOSTAT - 8.0L -

OPERATION, ENGINE...................7-51

COOLANT THERMOSTAT - 8.0L -

REMOVAL, ENGINE....................7-51

COOLER - 5.9L - DESCRIPTION, TRANS....7-78

COOLER - 5.9L - OPERATION, TRANS.....7-78

COOLER - 5.9L DIESEL - DESCRIPTION,

TRANS..............................7-84

COOLER - 5.9L DIESEL - OPERATION,

TRANS..............................7-84

COOLER - 8.0L - DESCRIPTION, TRANS....7-81

COOLER - 8.0L - OPERATION, TRANS.....7-81

COOLER - INSTALLATION, AIR TO OIL.....7-87

COOLER & LINES - CLEANING AND

INSPECTION, OIL.....................9-179

COOLER - REMOVAL, AIR TO OIL.........7-86

COOLER - REMOVAL, WATER TO OIL......7-86

COOLER - STANDARD PROCEDURE,

FLUSHING COOLERS AND TUBES -

WITH RADIATOR IN-TANK

TRANSMISSION OIL...........7-78,7-82,7-84

COOLER - STANDARD PROCEDURE,

FLUSHING COOLERS AND TUBES -

WITHOUT RADIATOR IN-TANK

TRANSMISSION OIL...........7-79,7-82,7-85

COOLER AND PLUMBING - CLEANING,

CHARGE AIR..........................11-19

COOLER AND PLUMBING -

DESCRIPTION, CHARGE AIR............11-18

COOLER AND PLUMBING - INSPECTION,

CHARGE AIR........................11-19

COOLER AND PLUMBING -

INSTALLATION, CHARGE AIR...........11-20

COOLER AND PLUMBING - OPERATION,

CHARGE AIR........................11-18

COOLER AND PLUMBING - REMOVAL,

CHARGE AIR........................11-18

COOLER SYSTEM - LEAKS - DIAGNOSIS

AND TESTING, CHARGE AIR............11-18

COOLERS AND TUBES - WITH

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE, FLUSHING........7-78,7-82,7-84

COOLERS AND TUBES - WITHOUT

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE, FLUSHING........7-79,7-82,7-85

COOLING, SPECIAL TOOLS..............7-18

COOLING SYSTEM - OPERATION..........7-4

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, DRAINING.....7-15

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, REFILLING.....7-16

COOLING SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, DRAINING......7-15

COOLING SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, REFILLING......7-16

COOLING SYSTEM CLEANING/REVERSE

FLUSHING - STANDARD PROCEDURE.....7-17

COOLING SYSTEM DIESEL ENGINE -

DIAGNOSIS AND TESTING

..............7-13

COOLING SYSTEM FLOW - 5.9L DIESEL

- DESCRIPTION

........................7-2

COOLING SYSTEM FLOW - 5.9L ENGINE

- DESCRIPTION

........................7-1

COOLING SYSTEM GAS ENGINE -

DIAGNOSIS AND TESTING

...............7-7

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING

.........................7-5

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION

........................24-1

CORE - DESCRIPTION, HEATER

.........24-56

CORE - INSTALLATION, HEATER

.........24-56

CORE - OPERATION, HEATER

...........24-56

CORE - REMOVAL, HEATER

............24-56

CORE GROUND STRAP - INSTALLATION,

HEATER

............................8A-14

CORE GROUND STRAP - REMOVAL,

HEATER

............................8A-14

CORNER SEAL - INSTALLATION, FRONT

DOOR UPPER

......................23-154CORNER SEAL - REMOVAL, FRONT

DOOR UPPER......................23-153

COUPLERS - DESCRIPTION, A/C LINE....24-40

COUPLERS - OPERATION, A/C LINE......24-41

COUPLERS - STANDARD PROCEDURE,

A/C LINE...........................24-44

COVER - INSTALLATION, CENTER SEAT

ARMREST/LATCH...................23-132

COVER - INSTALLATION, COWL TRIM . . . 23-120

COVER - INSTALLATION, GEAR HOUSING . 9-190

COVER - INSTALLATION, INSTRUMENT

PANEL TOP........................23-113

COVER - INSTALLATION, SEAT BACK....23-137

COVER - INSTALLATION, SEAT CUSHION . 23-139

COVER - INSTALLATION, STANCHION....23-143

COVER - INSTALLATION, STEERING

COLUMN OPENING..................23-114

COVER - NV4500 - INSTALLATION, SHIFT . 21-45

COVER - NV4500 - REMOVAL, SHIFT.....21-45

COVER - NV5600 - INSTALLATION, SHIFT . 21-86

COVER - NV5600 - REMOVAL, SHIFT.....21-86

COVER - REMOVAL, CENTER SEAT

ARMREST/LATCH...................23-132

COVER - REMOVAL, COWL TRIM.......23-119

COVER - REMOVAL, GEAR HOUSING.....9-189

COVER - REMOVAL, INSTRUMENT

PANEL TOP........................23-113

COVER - REMOVAL, SEAT BACK........23-137

COVER - REMOVAL, SEAT CUSHION......23-139

COVER - REMOVAL, STANCHION.......23-143

COVER - REMOVAL, STEERING COLUMN

OPENING..........................23-113

COVER - REMOVAL, WHEEL............22-12

COVER - SPLIT BENCH - INSTALLATION,

SEAT BACK........................23-137

COVER - SPLIT BENCH - INSTALLATION,

SEAT CUSHION.....................23-140

COVER - SPLIT BENCH - REMOVAL,

SEAT BACK........................23-137

COVER - SPLIT BENCH - REMOVAL,

SEAT CUSHION.....................23-139

COVER GASKET - DESCRIPTION,

CYLINDER HEAD......................9-20

COVER GASKET - OPERATION,

CYLINDER HEAD......................9-21

COVER INSTALLED - INSTALLATION,

FRONT OIL SEAL - FRONT..............9-89

COVER INSTALLED - REMOVAL, FRONT

OIL SEAL - FRONT....................9-89

COVER REMOVED - INSTALLATION,

FRONT OIL SEAL - FRONT..............9-90

COVER REMOVED - REMOVAL, FRONT

OIL SEAL - FRONT....................9-89

COVER(S) - CLEANING, CYLINDER HEAD . 9-137,

9-23,9-79

COVER(S) - DESCRIPTION, CYLINDER

HEAD...............................9-78

COVER(S) - INSPECTION, CYLINDER

HEAD......................9-138,9-23,9-79

COVER(S) - INSTALLATION, CYLINDER

HEAD......................9-138,9-23,9-79

COVER(S) - INSTALLATION, TIMING

BELT / CHAIN...................9-110,9-54

COVER(S) - REMOVAL, CYLINDER HEAD . 9-137,

9-23,9-78

COVER(S) - REMOVAL, TIMING BELT /

CHAIN.........................9-110,9-53

COWL GRILLE - INSTALLATION.........23-90

COWL GRILLE - REMOVAL.............23-90

COWL TRIM COVER - INSTALLATION....23-120

COWL TRIM COVER - REMOVAL.......23-119

COWL WEATHERSTRIP - INSTALLATION . 23-152

COWL WEATHERSTRIP - REMOVAL.....23-152

C-PILLAR TRIM - INSTALLATION.......23-128

C-PILLAR TRIM - REMOVAL...........23-128

CRANKCASE BREATHER VAPOR

CANISTER - INSTALLATION.............9-126

CRANKCASE BREATHER VAPOR

CANISTER - REMOVAL................9-125

CRANKSHAFT - DESCRIPTION......9-159,9-29

CRANKSHAFT - INSTALLATION

.......9-30,9-88

CRANKSHAFT - OPERATION

.............9-29

CRANKSHAFT - REMOVAL

..........9-30,9-87

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE, CONNECTING

ROD BEARING

.......................9-158

CRANKSHAFT MAIN BEARING FITTING -

STANDARD PROCEDURE

................9-31

8 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2226 of 2255

CRANKSHAFT MAIN BEARINGS -

DESCRIPTION........................9-31

CRANKSHAFT MAIN BEARINGS -

INSTALLATION....................9-32,9-88

CRANKSHAFT MAIN BEARINGS -

OPERATION..........................9-31

CRANKSHAFT MAIN BEARINGS -

REMOVAL.......................9-31,9-88

CRANKSHAFT MAIN BEARINGS -

STANDARD PROCEDURE, FITTING........9-88

CRANKSHAFT OIL SEAL - FRONT -

DESCRIPTION........................9-32

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION...................9-160,9-32

CRANKSHAFT OIL SEAL - FRONT -

OPERATION..........................9-32

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL......................9-160,9-32

CRANKSHAFT OIL SEAL - REAR -

DESCRIPTION........................9-33

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION...............9-162,9-34,9-90

CRANKSHAFT OIL SEAL - REAR -

OPERATION..........................9-33

CRANKSHAFT OIL SEAL - REAR -

REMOVAL..................9-161,9-33,9-90

CRANKSHAFT REAR OIL SEAL RETAINER

- INSTALLATION.................9-163,9-90

CRANKSHAFT REAR OIL SEAL RETAINER

- REMOVAL.....................9-162,9-90

CROSSHEADS - CLEANING.............9-134

CROSSHEADS - INSPECTION...........9-135

CRUISE INDICATOR - DESCRIPTION.......8J-18

CRUISE INDICATOR - OPERATION.......8J-18

CUBBY BIN - INSTALLATION...........23-109

CUBBY BIN - REMOVAL..............23-108

CUP HOLDER - INSTALLATION.........23-110

CUP HOLDER - REMOVAL.............23-109

CUSHION - INSTALLATION, SEAT.......23-138

CUSHION - REMOVAL, SEAT...........23-138

CUSHION COVER - INSTALLATION, SEAT . 23-139

CUSHION COVER - REMOVAL, SEAT.....23-139

CUSHION COVER - SPLIT BENCH -

INSTALLATION, SEAT.................23-140

CUSHION COVER - SPLIT BENCH -

REMOVAL, SEAT....................23-139

CYLINDER - DESCRIPTION, MASTER......5-26

CYLINDER - DIAGNOSIS AND TESTING,

IGNITION SWITCH AND KEY LOCK........19-9

CYLINDER - INSTALLATION, LOCK.......23-74

CYLINDER - INSTALLATION, LOCK.......19-10

CYLINDER - INSTALLATION, MASTER.....5-28

CYLINDER - OPERATION, MASTER........5-26

CYLINDER - REMOVAL, LOCK...........23-74

CYLINDER - REMOVAL, LOCK...........19-10

CYLINDER - REMOVAL, MASTER.........5-27

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-27

CYLINDER BLOCK REFACING -

STANDARD PROCEDURE...............9-148

CYLINDER BORE - DE-GLAZE -

STANDARD PROCEDURE...............9-148

CYLINDER BORE HONING - STANDARD

PROCEDURE.....................9-11,9-65

CYLINDER BORE REPAIR - STANDARD

PROCEDURE........................9-149

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING

. . 9-64,9-9

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING

...........9-64,9-9

CYLINDER HEAD - CLEANING

.......9-134,9-77

CYLINDER HEAD - DESCRIPTION

. . . 9-130,9-20,

9-76

CYLINDER HEAD - INSPECTION

.....9-134,9-77

CYLINDER HEAD - INSTALLATION

........9-77

CYLINDER HEAD - OPERATION

...........9-21

CYLINDER HEAD - REMOVAL

.......9-130,9-76

CYLINDER HEAD COVER GASKET -

DESCRIPTION

........................9-20

CYLINDER HEAD COVER GASKET -

OPERATION

..........................9-21

CYLINDER HEAD COVER(S) - CLEANING

. . 9-137,

9-23,9-79

CYLINDER HEAD COVER(S) -

DESCRIPTION

........................9-78

CYLINDER HEAD COVER(S) -

INSPECTION

................9-138,9-23,9-79CYLINDER HEAD COVER(S) -

INSTALLATION...............9-138,9-23,9-79

CYLINDER HEAD COVER(S) - REMOVAL . . 9-137,

9-23,9-78

CYLINDER HEAD GASKET FAILURE -

DIAGNOSIS AND TESTING..........9-21,9-76

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR..................8N-5

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR..................8N-6

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR.................8N-6

CYLINDER LOCK SWITCH - OPERATION,

DOOR..............................8N-5

CYLINDER LOCK SWITCH - REMOVAL,

DOOR..............................8N-6

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER......5-26

DAM - INSTALLATION, FRONT AIR........13-2

DAM - REMOVAL, FRONT AIR...........13-2

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE,

REPAIR ....................9-11,9-122,9-66

DAMPER - INSPECTION, VIBRATION.....9-172

DAMPER - INSTALLATION,

VIBRATION.................9-173,9-40,9-97

DAMPER - REMOVAL, VIBRATION . . . 9-172,9-40,

9-96

DANA 44 & 60 - REMOVAL..............2-19

DANA 44 AXLE - INSTALLATION......2-20,2-21

DANA 44 AXLE - REMOVAL.............2-21

DANA 60 AXLE - INSTALLATION.......2-20,2-22

DANA 60 AXLE - REMOVAL.............2-21

DATA BUS - DESCRIPTION, CCD..........8E-6

DATA BUS - DIAGNOSIS AND TESTING,

CCD ...............................8E-11

DATA BUS - OPERATION, CCD...........8E-7

DATA LINK CONNECTOR - DESCRIPTION . . 8E-12

DATA LINK CONNECTOR - OPERATION....8E-12

DATA PLATE - DESCRIPTION, ENGINE....9-129

DATA PLATE, SPECIFICATIONS - FUEL

INJECTION PUMP....................14-77

DAY / NIGHT MIRROR - DESCRIPTION,

AUTOMATIC........................8N-11

DAY / NIGHT MIRROR - INSTALLATION,

AUTOMATIC........................8N-13

DAY / NIGHT MIRROR - OPERATION,

AUTOMATIC........................8N-12

DAY / NIGHT MIRROR - REMOVAL,

AUTOMATIC........................8N-13

DAY/NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC................8N-12

DAYTIME RUNNING LAMP MODULE -

DESCRIPTION........................8L-9

DAYTIME RUNNING LAMP MODULE -

INSTALLATION........................8L-9

DAYTIME RUNNING LAMP MODULE -

OPERATION..........................8L-9

DAYTIME RUNNING LAMP MODULE -

REMOVAL...........................8L-9

DECALS - INSTALLATION..............23-64

DECALS - INSTALLATION, BODY

STRIPES...........................23-87

DECALS - REMOVAL..................23-64

DECALS - REMOVAL, BODY STRIPES

.....23-87

DEFINITION - DESCRIPTION, TRIP

.......25-19

DEFROSTER AND DEMISTER DUCT

ADAPTER - INSTALLATION

.............24-33

DEFROSTER AND DEMISTER DUCT

ADAPTER - REMOVAL

.................24-33

DEFROSTER AND DEMISTER DUCTS -

INSTALLATION

.......................24-33

DEFROSTER AND DEMISTER DUCTS -

REMOVAL

..........................24-33

DE-GLAZE - STANDARD PROCEDURE,

CYLINDER BORE

.....................9-148

DELIVERY - SPECIFICATIONS, TORQUE -

FUEL

...............................14-4

DELIVERY SYSTEM - DESCRIPTION,

DIESEL FUEL

........................14-55

DELIVERY SYSTEM - DESCRIPTION,

FUEL

...............................14-2

DELIVERY SYSTEM - OPERATION, FUEL

. . . 14-2

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS

...............8M-5

DEMISTER DUCT ADAPTER -

INSTALLATION, DEFROSTER

............24-33DEMISTER DUCT ADAPTER - REMOVAL,

DEFROSTER.........................24-33

DEMISTER DUCTS - INSTALLATION,

DEFROSTER.........................24-33

DEMISTER DUCTS - INSTALLATION,

INSTRUMENT PANEL..................24-36

DEMISTER DUCTS - REMOVAL,

DEFROSTER.........................24-33

DEMISTER DUCTS - REMOVAL,

INSTRUMENT PANEL..................24-36

DEMISTER GRILLES - INSTALLATION.....24-31

DEMISTER GRILLES - REMOVAL........24-31

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN

AIRBAG.............................8O-4

DETECTION PUMP - DESCRIPTION, LEAK . 25-34

DETECTION PUMP - INSTALLATION,

LEAK..............................25-34

DETECTION PUMP - OPERATION, LEAK . . . 25-34

DETECTION PUMP - REMOVAL, LEAK....25-34

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS.................21-132,21-302

DIESEL - CLEANING, RADIATOR - 5.9L....7-64

DIESEL - CLEANING, RADIATOR FAN -

5.9L................................7-43

DIESEL - CLEANING, WATER PUMP -

5.9L................................7-72

DIESEL - DESCRIPTION................25-1

DIESEL - DESCRIPTION........14-106,14-108

DIESEL - DESCRIPTION.................8I-6

DIESEL - DESCRIPTION, 5.9L............11-3

DIESEL - DESCRIPTION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - DESCRIPTION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-40

DIESEL - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L...................7-2

DIESEL - DESCRIPTION, ENGINE 5.9L....9-115

DIESEL - DESCRIPTION, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - DESCRIPTION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-53

DIESEL - DESCRIPTION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-56

DIESEL - DESCRIPTION, RADIATOR -

5.9L................................7-62

DIESEL - DESCRIPTION, TRANS COOLER

- 5.9L..............................7-84

DIESEL - DESCRIPTION, VACUUM PUMP

- 5.9L..............................7-33

DIESEL - DESCRIPTION, WATER PUMP -

5.9L................................7-72

DIESEL - FUEL INJECTOR FIRING ORDER . 14-62

DIESEL - INSPECTION, EXHAUST PIPE -

5.9L................................11-9

DIESEL - INSPECTION, RADIATOR - 5.9L . . . 7-64

DIESEL - INSPECTION, RADIATOR FAN -

5.9L................................7-43

DIESEL - INSPECTION, TAILPIPE - 5.9L . . . 11-12

DIESEL - INSPECTION, WATER PUMP -

5.9L................................7-72

DIESEL - INSTALLATION..............14-107

DIESEL - INSTALLATION................8I-9

DIESEL - INSTALLATION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - INSTALLATION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-41

DIESEL - INSTALLATION, DRIVE BELTS -

5.9L................................7-32

DIESEL - INSTALLATION, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - INSTALLATION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-54

DIESEL - INSTALLATION, EXHAUST PIPE

- 5.9L..............................11-9

DIESEL - INSTALLATION, MUFFLER -

5.9L

...............................11-11

DIESEL - INSTALLATION, RADIATOR -

5.9L

................................7-64

DIESEL - INSTALLATION, RADIATOR FAN

- 5.9L

..............................7-44

DIESEL - INSTALLATION, TAILPIPE - 5.9L

. 11-13

DIESEL - INSTALLATION, VACUUM

PUMP - 5.9L

.........................7-36

BR/BEINDEX 9

Description Group-Page Description Group-Page Description Group-Page

Page 2227 of 2255

DIESEL - INSTALLATION, WATER PUMP -

5.9L................................7-72

DIESEL - OPERATION.................8E-18

DIESEL - OPERATION.................25-20

DIESEL - OPERATION..........14-106,14-108

DIESEL - OPERATION...................8I-6

DIESEL - OPERATION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - OPERATION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-40

DIESEL - OPERATION, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - OPERATION, ENGINE COOLANT

THERMOSTAT - 5.9L...................7-53

DIESEL - OPERATION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-56

DIESEL - OPERATION, NON-MONITORED

CIRCUITS...........................25-24

DIESEL - OPERATION, RADIATOR - 5.9L . . . 7-62

DIESEL - OPERATION, TRANS COOLER -

5.9L................................7-84

DIESEL - OPERATION, VACUUM PUMP -

5.9L................................7-34

DIESEL - OPERATION, WATER PUMP -

5.9L................................7-72

DIESEL - REMOVAL............14-107,14-108

DIESEL - REMOVAL....................8I-7

DIESEL - REMOVAL, BELT TENSIONERS -

5.9L................................7-23

DIESEL - REMOVAL, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-40

DIESEL - REMOVAL, DRIVE BELTS - 5.9L . . 7-32

DIESEL - REMOVAL, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - REMOVAL, ENGINE COOLANT

THERMOSTAT - 5.9L...................7-54

DIESEL - REMOVAL, EXHAUST PIPE -

5.9L................................11-9

DIESEL - REMOVAL, MUFFLER - 5.9L.....11-11

DIESEL - REMOVAL, RADIATOR - 5.9L.....7-62

DIESEL - REMOVAL, RADIATOR FAN -

5.9L................................7-43

DIESEL - REMOVAL, TAILPIPE - 5.9L.....11-12

DIESEL - REMOVAL, VACUUM PUMP -

5.9L................................7-34

DIESEL - REMOVAL, WATER PUMP -

5.9L................................7-72

DIESEL ENGINE - DESCRIPTION, FUEL

REQUIREMENTS.......................0-3

DIESEL ENGINE - DIAGNOSIS AND

TESTING............................11-4

DIESEL ENGINE - DIAGNOSIS AND

TESTING, COOLING SYSTEM............7-13

DIESEL ENGINE - INSTALLATION........19-37

DIESEL ENGINE - REMOVAL............19-36

DIESEL ENGINE - STANDARD

PROCEDURE, DRAINING COOLING

SYSTEM 5.9L........................7-15

DIESEL ENGINE - STANDARD

PROCEDURE, REFILLING COOLING

SYSTEM 5.9L........................7-16

DIESEL ENGINE - TORQUE.............14-94

DIESEL ENGINE, SPECIAL TOOLS - 5.9L . . 9-128

DIESEL ENGINES - DESCRIPTION,

COMPONENT MONITORS

..............25-20

DIESEL ENGINES - FUEL SYSTEM

PRESSURES

........................14-62

DIESEL FUEL DELIVERY SYSTEM -

DESCRIPTION

.......................14-55

DIESEL FUEL INJECTION SYSTEM -

DESCRIPTION

.......................14-91

DIESEL FUEL SYSTEM, SPECIAL TOOLS

. . 14-63

DIESEL FUEL TANK - DESCRIPTION

......14-82

DIESEL, SPECIFICATIONS - 5.9L

.........9-127

DIESEL WITH AUTO. TRANS. -

INSTALLATION

..................8P-12,8P-6

DIESEL WITH AUTO. TRANS. -

REMOVAL

.......................8P-5,8P-9

DIFFERENTIAL - ASSEMBLY

....3-126,3-38,3-66,

3-97

DIFFERENTIAL - DISASSEMBLY

. 3-126,3-38,3-65,

3-97

DIFFERENTIAL - INSTALLATION

. 3-126,3-39,3-66,

3-97

DIFFERENTIAL - POWR-LOK - ASSEMBLY

. . 3-99DIFFERENTIAL - POWR-LOK -

DISASSEMBLY........................3-99

DIFFERENTIAL - REMOVAL . 3-125,3-37,3-64,3-96

DIFFERENTIAL - TRAC-LOK - ASSEMBLY . . 3-129,

3-70

DIFFERENTIAL - TRAC-LOK -

DISASSEMBLY...................3-128,3-68

DIFFERENTIAL CASE BEARINGS -

INSTALLATION.........3-102,3-129,3-41,3-72

DIFFERENTIAL CASE BEARINGS -

REMOVAL.............3-102,3-129,3-40,3-72

DIMENSION, SPECIFICATIONS - FRAME....13-8

DIMENSIONS, SPECIFICATIONS - BODY

OPENING...........................23-60

DIODE - INSTALLATION............8W-01-13

DIODE - REMOVAL................8W-01-13

DIODE REPLACEMENT - STANDARD

PROCEDURE.........................24-7

DISASSEMBLY - OVERHEAD CONSOLE

DISASSEMBLY.......................8M-7

DISASSEMBLY, AXLE VACUUM MOTOR....3-34

DISASSEMBLY, DIAGNOSIS AND

TESTING....................21-115,21-287

DISASSEMBLY, DIFFERENTIAL . . 3-126,3-38,3-65,

3-97

DISASSEMBLY, DIFFERENTIAL -

POWR-LOK..........................3-99

DISASSEMBLY, DIFFERENTIAL -

TRAC-LOK......................3-128,3-68

DISASSEMBLY, DISASSEMBLY -

OVERHEAD CONSOLE.................8M-7

DISASSEMBLY, DOUBLE CARDAN

UNIVERSAL JOINTS...................3-10

DISASSEMBLY, DRIVER AIRBAG.........8O-15

DISASSEMBLY, FLYWHEEL..............6-13

DISASSEMBLY, FRONT CLUTCH . . 21-161,21-331

DISASSEMBLY, FRONT SERVO . . . 21-164,21-334

DISASSEMBLY, GLOVE BOX...........23-110

DISASSEMBLY, HVAC HOUSING.........24-35

DISASSEMBLY, INSTRUMENT CLUSTER . . . 8J-10

DISASSEMBLY, MANUAL - NV4500........21-5

DISASSEMBLY, MANUAL - NV5600.......21-49

DISASSEMBLY, OIL PUMP...............9-47

DISASSEMBLY, OIL PUMP.......21-167,21-337

DISASSEMBLY, OVERDRIVE UNIT . 21-173,21-346

DISASSEMBLY, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON RETAINER....21-192,

21-364

DISASSEMBLY, PLANETARY GEARTRAIN/

OUTPUT SHAFT...............21-198,21-369

DISASSEMBLY, REAR CLUTCH . . . 21-204,21-376

DISASSEMBLY, REAR SERVO....21-207,21-378

DISASSEMBLY, REMOVAL...............5-11

DISASSEMBLY, SINGLE CARDAN

UNIVERSAL JOINTS....................3-8

DISASSEMBLY, STANDARD PROCEDURE . . . 7-80

DISASSEMBLY, TRANSFER CASE -

NV241HD..........................21-469

DISASSEMBLY, TRANSFER CASE -

NV241LD..........................21-432

DISASSEMBLY, VALVE BODY.....21-237,21-409

DISC - INSTALLATION, CLUTCH...........6-8

DISC - REMOVAL, CLUTCH...............6-7

DISC BRAKE CALIPERS - DESCRIPTION....5-10

DISC BRAKE CALIPERS - OPERATION.....5-10

DISC BRAKE ROTOR, DIAGNOSIS AND

TESTING............................5-20

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-8

DISCHARGE LINE - INSTALLATION,

SUCTION...........................24-52

DISCHARGE LINE - REMOVAL, SUCTION . . 24-51

DISPLAY TEST MODE - DESCRIPTION,

STATE ..............................25-1

DISTRIBUTION - DESCRIPTION, POWER . 8W-97-1

DISTRIBUTION - OPERATION, POWER . . 8W-97-1

DISTRIBUTION CENTER - DESCRIPTION,

POWER..........................8W-97-8

DISTRIBUTION CENTER - INSTALLATION,

POWER

.........................8W-97-10

DISTRIBUTION CENTER - OPERATION,

POWER

..........................8W-97-8

DISTRIBUTION CENTER - REMOVAL,

POWER

..........................8W-97-8

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER

...................8W-97-2

DISTRIBUTOR - DESCRIPTION

..........8I-11DISTRIBUTOR - INSTALLATION..........8I-13

DISTRIBUTOR - OPERATION............8I-12

DISTRIBUTOR - REMOVAL..............8I-12

DISTRIBUTOR BUSHING - INSTALLATION . . 9-35

DISTRIBUTOR BUSHING - REMOVAL......9-35

DISTRIBUTOR CAP - DIAGNOSIS AND

TESTING............................8I-14

DISTRIBUTOR ROTOR - DIAGNOSIS AND

TESTING............................8I-14

DOME LAMP - INSTALLATION..........8L-34

DOME LAMP - REMOVAL..............8L-34

DOOR - ADJUSTMENT, CARGO..........23-78

DOOR - INSTALLATION...........23-69,23-78

DOOR - INSTALLATION, BLEND.........24-37

DOOR - INSTALLATION, FUEL FILL.......23-95

DOOR - INSTALLATION, HEAT/DEFROST . . . 24-38

DOOR - INSTALLATION, PANEL/DEFROST . . 24-38

DOOR - INSTALLATION, RECIRCULATION . . 24-39

DOOR - REMOVAL...............23-69,23-78

DOOR - REMOVAL, BLEND.............24-37

DOOR - REMOVAL, FUEL FILL..........23-95

DOOR - REMOVAL, HEAT/DEFROST......24-37

DOOR - REMOVAL, PANEL/DEFROST.....24-38

DOOR - REMOVAL, RECIRCULATION.....24-38

DOOR ACTUATOR - INSTALLATION,

BLEND.............................24-25

DOOR ACTUATOR - INSTALLATION,

HEAT/DEFROST......................24-27

DOOR ACTUATOR - INSTALLATION,

PANEL/DEFROST.....................24-27

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION.....................24-28

DOOR ACTUATOR - REMOVAL, BLEND....24-25

DOOR ACTUATOR - REMOVAL,

HEAT/DEFROST......................24-26

DOOR ACTUATOR - REMOVAL,

PANEL/DEFROST.....................24-26

DOOR ACTUATOR - REMOVAL,

RECIRCULATION.....................24-27

DOOR AJAR SWITCH - DESCRIPTION....8L-34

DOOR AJAR SWITCH - DIAGNOSIS AND

TESTING...........................8L-34

DOOR AJAR SWITCH - INSTALLATION....8L-35

DOOR AJAR SWITCH - REMOVAL........8L-35

DOOR CYLINDER LOCK SWITCH -

DESCRIPTION........................8N-5

DOOR CYLINDER LOCK SWITCH -

DIAGNOSIS AND TESTING..............8N-6

DOOR CYLINDER LOCK SWITCH -

INSTALLATION.......................8N-6

DOOR CYLINDER LOCK SWITCH -

OPERATION..........................8N-5

DOOR CYLINDER LOCK SWITCH -

REMOVAL...........................8N-6

DOOR FORE/AFT - ADJUSTMENT, FRONT . . 23-69

DOOR GLASS - INSTALLATION..........23-70

DOOR GLASS - REMOVAL.............23-70

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT...............23-153

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT...................23-152

DOOR INNER BELT WEATHERSTRIP -

INSTALLATION, FRONT...............23-153

DOOR INNER BELT WEATHERSTRIP -

REMOVAL, FRONT...................23-153

DOOR IN/OUT - ADJUSTMENT, FRONT....23-70

DOOR LATCH - ADJUSTMENT, FRONT....23-73

DOOR OPENING SEAL - INSTALLATION . . 23-152

DOOR OPENING SEAL - REMOVAL......23-152

DOOR OUTER BELT WEATHERSTRIP -

INSTALLATION, FRONT...............23-153

DOOR OUTER BELT WEATHERSTRIP -

REMOVAL, FRONT...................23-153

DOOR SEAL - INSTALLATION, B-PILLAR . 23-151

DOOR SEAL - REMOVAL, B-PILLAR.....23-151

DOOR SECOND WEATHERSTRIP -

INSTALLATION, FRONT...............23-154

DOOR SECOND WEATHERSTRIP -

REMOVAL, FRONT...................23-154

DOOR SILL TRIM - INSTALLATION......23-121

DOOR SILL TRIM - REMOVAL.........23-121

DOOR SPEAKER - INSTALLATION, FRONT . 8A-19

DOOR SPEAKER - INSTALLATION, REAR

. . 8A-21

DOOR SPEAKER - REMOVAL, FRONT

.....8A-19

DOOR SPEAKER - REMOVAL, REAR

......8A-20

DOOR UP/DOWN - ADJUSTMENT, FRONT

. 23-70

DOOR UPPER CORNER SEAL -

INSTALLATION, FRONT

...............23-154

10 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2228 of 2255

DOOR UPPER CORNER SEAL -

REMOVAL, FRONT...................23-153

DOUBLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY..........................3-11

DOUBLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY........................3-10

DOUBLE INVERTED FLARING -

STANDARD PROCEDURE.................5-8

DRAIN AND REFILL - STANDARD

PROCEDURE, FLUID.................21-460

DRAIN MANIFOLD - DESCRIPTION, FUEL . . 14-89

DRAIN MANIFOLD - INSTALLATION,

FUEL..............................14-90

DRAIN MANIFOLD - OPERATION, FUEL . . . 14-89

DRAIN MANIFOLD - REMOVAL, FUEL.....14-90

DRAINBACK VALVE - DESCRIPTION,

TORQUE CONVERTER..........21-217,21-390

DRAINBACK VALVE - OPERATION,

TORQUE CONVERTER..........21-217,21-390

DRAINBACK VALVE - STANDARD

PROCEDURE, TORQUE CONVERTER....21-217,

21-390

DRAINING AT FUEL FILTER - STANDARD

PROCEDURES, WATER................14-61

DRAINING COOLING SYSTEM 5.9L

DIESEL ENGINE - STANDARD

PROCEDURE.........................7-15

DRAINING COOLING SYSTEM 5.9L/8.0L

ENGINES - STANDARD PROCEDURE......7-15

DRAIN/REFILL - STANDARD

PROCEDURE, FLUID.................21-497

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-13

DRIVE - DIAGNOSIS AND TESTING,

VISCOUS FAN....................7-55,7-57

DRIVE BELT - DIAGNOSIS AND TESTING,

ACCESSORY.................7-24,7-27,7-30

DRIVE BELTS - 5.9L - INSTALLATION......7-26

DRIVE BELTS - 5.9L - REMOVAL.........7-26

DRIVE BELTS - 5.9L DIESEL -

INSTALLATION........................7-32

DRIVE BELTS - 5.9L DIESEL - REMOVAL . . . 7-32

DRIVE BELTS - 8.0L - INSTALLATION......7-29

DRIVE BELTS - 8.0L - REMOVAL.........7-29

DRIVE INDICATOR - DIAGNOSIS AND

TESTING, FOUR-WHEEL...............8J-29

DRIVE VISCOUS CLUTCH - 5.9L DIESEL

- DESCRIPTION, FAN...................7-56

DRIVE VISCOUS CLUTCH - 5.9L DIESEL

- OPERATION, FAN....................7-56

DRIVE VISCOUS CLUTCH - 5.9L/8.0L -

DESCRIPTION, FAN....................7-55

DRIVE VISCOUS CLUTCH - 5.9L/8.0L -

OPERATION, FAN......................7-55

DRIVER AIRBAG - ASSEMBLY..........8O-16

DRIVER AIRBAG - DESCRIPTION........8O-14

DRIVER AIRBAG - DISASSEMBLY........8O-15

DRIVER AIRBAG - INSTALLATION.......8O-17

DRIVER AIRBAG - OPERATION..........8O-14

DRIVER AIRBAG - REMOVAL...........8O-14

DRIVER POWER SEAT SWITCH -

DESCRIPTION.......................8N-17

DRIVER POWER SEAT SWITCH -

DIAGNOSIS AND TESTING.............8N-17

DRIVER POWER SEAT SWITCH -

INSTALLATION......................8N-18

DRIVER POWER SEAT SWITCH -

OPERATION.........................8N-17

DRIVER POWER SEAT SWITCH -

REMOVAL..........................8N-18

DRIVER SEAT HEATER SWITCH -

DESCRIPTION........................8G-7

DRIVER SEAT HEATER SWITCH -

INSTALLATION......................8G-10

DRIVER SEAT HEATER SWITCH -

OPERATION..........................8G-8

DRIVER SEAT HEATER SWITCH -

REMOVAL...........................8G-9

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE

............8W-01-9

DUAL REAR WHEEL INSTALLATION -

STANDARD PROCEDURE

...............22-11

DUCT ADAPTER - INSTALLATION,

DEFROSTER AND DEMISTER

...........24-33

DUCT ADAPTER - REMOVAL,

DEFROSTER AND DEMISTER

...........24-33

DUCTS - INSTALLATION, DEFROSTER

AND DEMISTER

......................24-33DUCTS - INSTALLATION, INSTRUMENT

PANEL.............................24-37

DUCTS - INSTALLATION, INSTRUMENT

PANEL DEMISTER....................24-36

DUCTS - REMOVAL, DEFROSTER AND

DEMISTER..........................24-33

DUCTS - REMOVAL, INSTRUMENT

PANEL.............................24-37

DUCTS - REMOVAL, INSTRUMENT

PANEL DEMISTER....................24-36

EASY ENTRY SEAT TRACK -

INSTALLATION......................23-143

EASY ENTRY SEAT TRACK - REMOVAL . . 23-143

ECM - DESCRIPTION..................8E-13

ECM - OPERATION...................8E-13

EFFECTS OF INCORRECT FLUID LEVEL -

DIAGNOSIS AND TESTING......21-157,21-327

ELECTRICAL CONTROLS - DIAGNOSIS

AND TESTING, OVERDRIVE......21-191,21-344

ELECTRICAL TESTER - STANDARD

PROCEDURE, USING MIDTRONICS.......8F-15

ELECTRONIC GOVERNOR -

DESCRIPTION................21-152,21-322

ELECTRONIC GOVERNOR -

INSTALLATION................21-154,21-324

ELECTRONIC GOVERNOR - OPERATION . 21-153,

21-323

ELECTRONIC GOVERNOR - REMOVAL . . . 21-154,

21-324

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES - STANDARD

PROCEDURE......................8W-01-8

ELEMENT - DESCRIPTION, HEATED SEAT . . . 8G-10

ELEMENT - INSTALLATION, AIR

CLEANER...........................9-130

ELEMENT - INSTALLATION, HEATED

SEAT ..............................8G-13

ELEMENT - OPERATION, HEATED SEAT . . . 8G-11

ELEMENT - REMOVAL, AIR CLEANER.....9-129

ELEMENT - REMOVAL, HEATED SEAT....8G-13

ELEMENT AND SENSOR - DIAGNOSIS

AND TESTING, HEATED SEAT...........8G-11

EMISSION CONTROL INFORMATION

(VECI) - DESCRIPTION, VEHICLE.......Intro.-3

END SPLASH SHIELDS - INSTALLATION,

FRONT.............................23-92

END SPLASH SHIELDS - REMOVAL,

FRONT.............................23-92

ENGINE - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L...................7-1

ENGINE - DESCRIPTION, FUEL

REQUIREMENTS - DIESEL...............0-3

ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIESEL..............7-13

ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM GAS.................7-7

ENGINE - DIAGNOSIS AND TESTING,

DIESEL.............................11-4

ENGINE - DIAGNOSIS AND TESTING,

GAS................................11-4

ENGINE - IGNITION COIL RESISTANCE,

8.0L V-10............................8I-4

ENGINE - INSTALLATION...............9-125

ENGINE - INSTALLATION, DIESEL........19-37

ENGINE - INSTALLATION, GASOLINE.....19-37

ENGINE - NEGATIVE CABLE

INSTALLATION, GASOLINE.............8F-22

ENGINE - NEGATIVE CABLE REMOVAL,

GASOLINE..........................8F-22

ENGINE - POSITIVE CABLE

INSTALLATION, GASOLINE.............8F-22

ENGINE - POSITIVE CABLE REMOVAL,

GASOLINE..........................8F-21

ENGINE - REMOVAL..................9-123

ENGINE - REMOVAL, DIESEL...........19-36

ENGINE - REMOVAL, GASOLINE.........19-35

ENGINE - SPARK PLUG CABLE ORDER,

8.0L V-10............................8I-3

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM 5.9L

DIESEL.............................7-15

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM 5.9L

DIESEL

.............................7-16

ENGINE - TORQUE, DIESEL

.............14-94

ENGINE - VISUAL INSPECTION, 8.0L

.....14-32

ENGINE 5.9L - DESCRIPTION

.............9-3

ENGINE 5.9L DIESEL - DESCRIPTION

.....9-115ENGINE 8.0L - DESCRIPTION............9-58

ENGINE BLOCK - CLEANING.........9-27,9-85

ENGINE BLOCK - INSPECTION.......9-27,9-85

ENGINE BLOCK HEATER - 5.9L -

DESCRIPTION........................7-44

ENGINE BLOCK HEATER - 5.9L -

INSTALLATION........................7-44

ENGINE BLOCK HEATER - 5.9L -

OPERATION..........................7-44

ENGINE BLOCK HEATER - 5.9L -

REMOVAL...........................7-44

ENGINE BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION........................7-46

ENGINE BLOCK HEATER - 5.9L DIESEL -

INSTALLATION........................7-46

ENGINE BLOCK HEATER - 5.9L DIESEL -

OPERATION..........................7-46

ENGINE BLOCK HEATER - 5.9L DIESEL -

REMOVAL...........................7-46

ENGINE BLOCK HEATER - 8.0L -

DESCRIPTION........................7-45

ENGINE BLOCK HEATER - 8.0L -

INSTALLATION........................7-45

ENGINE BLOCK HEATER - 8.0L -

OPERATION..........................7-45

ENGINE BLOCK HEATER - 8.0L -

REMOVAL...........................7-45

ENGINE CONTROL MODULE -

INSTALLATION.......................8E-14

ENGINE CONTROL MODULE - REMOVAL . . 8E-14

ENGINE COOLANT - DESCRIPTION........7-39

ENGINE COOLANT - DESCRIPTION..........0-3

ENGINE COOLANT TEMP SENSOR - 5.9L

- DESCRIPTION.......................7-47

ENGINE COOLANT TEMP SENSOR - 5.9L

- INSTALLATION......................7-47

ENGINE COOLANT TEMP SENSOR - 5.9L

- OPERATION.........................7-47

ENGINE COOLANT TEMP SENSOR - 5.9L

- REMOVAL..........................7-47

ENGINE COOLANT THERMOSTAT - 5.9L -

DESCRIPTION........................7-48

ENGINE COOLANT THERMOSTAT - 5.9L -

INSTALLATION........................7-49

ENGINE COOLANT THERMOSTAT - 5.9L -

OPERATION..........................7-48

ENGINE COOLANT THERMOSTAT - 5.9L -

REMOVAL...........................7-48

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - DESCRIPTION................7-53

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - INSTALLATION................7-54

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - OPERATION..................7-53

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - REMOVAL....................7-54

ENGINE COOLANT THERMOSTAT - 8.0L -

DESCRIPTION........................7-51

ENGINE COOLANT THERMOSTAT - 8.0L -

INSTALLATION........................7-52

ENGINE COOLANT THERMOSTAT - 8.0L -

OPERATION..........................7-51

ENGINE COOLANT THERMOSTAT - 8.0L -

REMOVAL...........................7-51

ENGINE DATA PLATE - DESCRIPTION.....9-129

ENGINE DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING...........9-3,9-58

ENGINE DIAGNOSIS - LUBRICATION -

DIAGNOSIS AND TESTING...........9-63,9-8

ENGINE DIAGNOSIS - MECHANICAL -

DIAGNOSIS AND TESTING......9-116,9-6,9-61

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING...........9-4,9-59

ENGINE FIRING ORDER, 5.9L V-8

ENGINES............................8I-3

ENGINE OIL - DESCRIPTION...........0-4,0-5

ENGINE OIL - STANDARD PROCEDURE . . . 9-101,

9-45

ENGINE OIL LEAKS - DIAGNOSIS AND

TESTING........................9-43,9-99

ENGINE OIL LEVEL - STANDARD

PROCEDURE

........................9-178

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING

..............9-101,9-178,9-45

ENGINE OIL SERVICE - STANDARD

PROCEDURE

........................9-178

ENGINE, SPECIAL TOOLS - 5.9L

..........9-18

ENGINE, SPECIAL TOOLS - 5.9L DIESEL

. . 9-128

BR/BEINDEX 11

Description Group-Page Description Group-Page Description Group-Page

Page 2229 of 2255

ENGINE, SPECIAL TOOLS - 8.0L..........9-72

ENGINE, SPECIFICATIONS - 5.9L.........9-13

ENGINE, SPECIFICATIONS - 8.OL.........9-68

ENGINE TEMPERATURE GAUGE -

DESCRIPTION.......................8J-18

ENGINE TEMPERATURE GAUGE -

OPERATION.........................8J-19

ENGINES - DESCRIPTION, COMPONENT

MONITORS - DIESEL..................25-20

ENGINES - DESCRIPTION, COMPONENT

MONITORS - GAS....................25-19

ENGINES - DESCRIPTION, FUEL

REQUIREMENTS - GAS..................0-2

ENGINES - DESCRIPTION, V-8..........25-35

ENGINES - ENGINE FIRING ORDER, 5.9L

V-8 .................................8I-3

ENGINES - FUEL SYSTEM PRESSURES,

DIESEL............................14-62

ENGINES - IGNITION COIL RESISTANCE,

5.9L................................8I-3

ENGINES - INSTALLATION, GAS..........8P-5

ENGINES - OPERATION, GAS...........25-20

ENGINES - OPERATION, NON-

MONITORED CIRCUITS - GAS...........25-24

ENGINES - OPERATION, PCM - GAS......8E-18

ENGINES - OPERATION, V-8............25-35

ENGINES - REMOVAL, GAS..............8P-4

ENGINES - SPECIFICATIONS, FUEL

SYSTEM PRESSURE - GAS..............14-3

ENGINES - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM

5.9L/8.0L............................7-15

ENGINES - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM

5.9L/8.0L............................7-16

ENGINES - VISUAL INSPECTION, 5.9L....14-29

ENGINE-TO-BODY GROUND STRAP -

INSTALLATION.......................8A-13

ENGINE-TO-BODY GROUND STRAP -

REMOVAL..........................8A-12

ENTRY SEAT TRACK - INSTALLATION,

EASY.............................23-143

ENTRY SEAT TRACK - REMOVAL, EASY . . 23-143

ENTRY SYSTEM - DESCRIPTION,

REMOTE KEYLESS....................8N-2

ENTRY SYSTEM - DIAGNOSIS AND

TESTING, POWER LOCK & REMOTE

KEYLESS............................8N-5

ENTRY SYSTEM - OPERATION, REMOTE

KEYLESS............................8N-4

ENTRY TRANSMITTER - DESCRIPTION,

REMOTE KEYLESS....................8N-7

ENTRY TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS............8N-8

ENTRY TRANSMITTER - OPERATION,

REMOTE KEYLESS....................8N-8

ENTRY TRANSMITTER BATTERIES -

STANDARD PROCEDURE, REMOTE

KEYLESS............................8N-8

EQUIPMENT - STANDARD PROCEDURE,

REFRIGERANT SYSTEM SERVICE........24-45

EQUIPMENT IDENTIFICATION PLATE -

DESCRIPTION......................Intro.-3

ESCUTCHEON - INSTALLATION, HANDLE . . 23-64

ESCUTCHEON - REMOVAL, HANDLE......23-64

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-46

EVAP SYSTEM - DESCRIPTION..........25-32

EVAP SYSTEM - TORQUE..............25-32

EVAPORATOR - DESCRIPTION, A/C.......24-53

EVAPORATOR - INSTALLATION, A/C......24-53

EVAPORATOR - OPERATION, A/C........24-53

EVAPORATOR - REMOVAL, A/C..........24-53

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-33

EVAP/PURGE SOLENOID - INSTALLATION . 25-34

EVAP/PURGE SOLENOID - OPERATION....25-33

EVAP/PURGE SOLENOID - REMOVAL.....25-33

EXHAUST MANIFOLD - CLEANING . . 9-109,9-185,

9-53

EXHAUST MANIFOLD - DESCRIPTION

....9-109,

9-53

EXHAUST MANIFOLD - INSPECTION

.....9-109,

9-186,9-53

EXHAUST MANIFOLD - INSTALLATION

. . . 9-109,

9-186,9-53

EXHAUST MANIFOLD - OPERATION

. . 9-109,9-53

EXHAUST MANIFOLD - REMOVAL

. . 9-109,9-185,

9-53EXHAUST PIPE - 3.9L/5.2L/5.9L -

INSPECTION.........................11-7

EXHAUST PIPE - 3.9L/5.2L/5.9L -

INSTALLATION........................11-7

EXHAUST PIPE - 3.9L/5.2L/5.9L -

REMOVAL...........................11-7

EXHAUST PIPE - 5.9L DIESEL -

INSPECTION.........................11-9

EXHAUST PIPE - 5.9L DIESEL -

INSTALLATION........................11-9

EXHAUST PIPE - 5.9L DIESEL -

REMOVAL...........................11-9

EXHAUST PIPE - 5.9L HD/8.0L -

INSPECTION.........................11-8

EXHAUST PIPE - 5.9L HD/8.0L -

INSTALLATION........................11-8

EXHAUST PIPE - 5.9L HD/8.0L -

REMOVAL...........................11-7

EXHAUST VENT - INSTALLATION........23-79

EXHAUST VENT - REMOVAL............23-79

EXHAUSTER - INSTALLATION, AIR.......23-77

EXHAUSTER - REMOVAL, AIR...........23-77

EXTENSION HOUSING BUSHING -

INSTALLATION................21-156,21-326

EXTENSION HOUSING BUSHING -

REMOVAL...................21-156,21-326

EXTENSION HOUSING BUSHING AND

SEAL - INSTALLATION..........21-460,21-497

EXTENSION HOUSING BUSHING AND

SEAL - REMOVAL.............21-460,21-497

EXTENSION HOUSING SEAL -

INSTALLATION................21-156,21-327

EXTENSION HOUSING SEAL - NV4500 -

INSTALLATION.......................21-42

EXTENSION HOUSING SEAL - NV4500 -

REMOVAL..........................21-42

EXTENSION HOUSING SEAL - NV5600 -

INSTALLATION.......................21-85

EXTENSION HOUSING SEAL - NV5600 -

REMOVAL..........................21-85

EXTENSION HOUSING SEAL - REMOVAL . 21-156,

21-326

EXTERIOR - DESCRIPTION.............23-86

EXTERIOR - OPERATION...............23-86

EXTERIOR HANDLE - INSTALLATION.....23-71

EXTERIOR HANDLE - REMOVAL.........23-71

EXTERIOR LAMPS, SPECIFICATIONS......8L-4

EXTERIOR NAME PLATES -

INSTALLATION.......................23-89

EXTERIOR NAME PLATES - REMOVAL....23-89

FAILURE - DIAGNOSIS AND TESTING,

CYLINDER HEAD GASKET...........9-21,9-76

FAN - 5.9L DIESEL - CLEANING,

RADIATOR...........................7-43

FAN - 5.9L DIESEL - INSPECTION,

RADIATOR...........................7-43

FAN - 5.9L DIESEL - INSTALLATION,

RADIATOR...........................7-44

FAN - 5.9L DIESEL - REMOVAL,

RADIATOR...........................7-43

FAN - 5.9L/8.0L - CLEANING, RADIATOR . . . 7-42

FAN - 5.9L/8.0L - INSPECTION,

RADIATOR...........................7-42

FAN - 5.9L/8.0L - INSTALLATION,

RADIATOR...........................7-42

FAN - 5.9L/8.0L - REMOVAL, RADIATOR . . . 7-41

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS........................7-55,7-57

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION................7-56

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION..................7-56

FAN DRIVE VISCOUS CLUTCH -

5.9L/8.0L - DESCRIPTION...............7-55

FAN DRIVE VISCOUS CLUTCH -

5.9L/8.0L - OPERATION.................7-55

FASCIA - INSTALLATION, FRONT.........13-2

FASCIA - INSTALLATION, FRONT LOWER . . . 13-3

FASCIA - REMOVAL, FRONT.............13-2

FASCIA - REMOVAL, FRONT LOWER......13-3

FASCIA - SPORT - INSTALLATION,

FRONT..............................13-3

FASCIA - SPORT - REMOVAL, FRONT

......13-3

FASTENER IDENTIFICATION -

DESCRIPTION

......................Intro.-6

FASTENER USAGE - DESCRIPTION

......Intro.-9

FENDER - INSTALLATION, LEFT FRONT

. . . 23-93

FENDER - INSTALLATION, REAR

.........23-95FENDER - INSTALLATION, RIGHT FRONT . . 23-94

FENDER - REMOVAL, LEFT FRONT.......23-93

FENDER - REMOVAL, REAR............23-95

FENDER - REMOVAL, RIGHT FRONT......23-94

FILL - STANDARD PROCEDURE,

TRANSMISSION...............21-160,21-330

FILL DOOR - INSTALLATION, FUEL.......23-95

FILL DOOR - REMOVAL, FUEL..........23-95

FILLER CAP - DESCRIPTION, FUEL.......25-34

FILLER CAP - OPERATION, FUEL........25-34

FILLER CAP - REMOVAL/INSTALLATION,

FUEL..............................25-34

FILTER - INSTALLATION, AIR PUMP......25-30

FILTER - INSTALLATION, INLET..........14-23

FILTER - INSTALLATION, OIL . . 9-102,9-179,9-46

FILTER - REMOVAL, AIR PUMP.........25-30

FILTER - REMOVAL, INLET.............14-23

FILTER - REMOVAL, OIL......9-102,9-179,9-46

FILTER - STANDARD PROCEDURES,

WATER DRAINING AT FUEL............14-61

FILTER / WATER SEPARATOR -

DESCRIPTION, FUEL..................14-63

FILTER / WATER SEPARATOR -

INSTALLATION, FUEL.................14-65

FILTER / WATER SEPARATOR -

OPERATION, FUEL....................14-63

FILTER / WATER SEPARATOR -

REMOVAL, FUEL.....................14-64

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID...........21-158,21-329

FILTER/PRESSURE REGULATOR -

DESCRIPTION, FUEL...................14-5

FILTER/PRESSURE REGULATOR -

INSTALLATION, FUEL..................14-7

FILTER/PRESSURE REGULATOR -

OPERATION, FUEL.....................14-5

FILTER/PRESSURE REGULATOR -

REMOVAL, FUEL......................14-5

FINISH - DESCRIPTION, BASE

COAT/CLEAR COAT..................23-129

FINISH - OPERATION, BASE COAT/CLEAR

COAT .............................23-129

FIRING ORDER, 5.9L V-8 ENGINES -

ENGINE..............................8I-3

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-62

FITTING - DESCRIPTION, QUICK

CONNECT...........................14-24

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING........9-29,9-87

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING...........9-31

FITTING - STANDARD PROCEDURE,

PISTON.........................9-38,9-93

FITTING - STANDARD PROCEDURE,

PISTON RING...................9-171,9-39

FITTING CRANKSHAFT MAIN BEARINGS

- STANDARD PROCEDURE..............9-88

FITTING PISTON RINGS - STANDARD

PROCEDURE.........................9-95

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT.....................14-24

FIXED ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-54

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-75

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-74