height DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 162 of 2255

REAR AXLE - 286RBI

TABLE OF CONTENTS

page page

REAR AXLE - 286RBI

DESCRIPTION........................107

OPERATION..........................108

DIAGNOSIS AND TESTING - AXLE.........108

REMOVAL............................112

INSTALLATION........................112

ADJUSTMENTS.......................112

SPECIFICATIONS

REAR AXLE - 286RBI.................120

SPECIAL TOOLS

REAR AXLE - 286 RBI.................120

AXLE SHAFTS

REMOVAL............................123

INSTALLATION........................123

AXLE BEARINGS

REMOVAL............................123

INSTALLATION........................123

PINION SEAL

REMOVAL............................123INSTALLATION........................124

DIFFERENTIAL

REMOVAL............................125

DISASSEMBLY........................126

ASSEMBLY...........................126

INSTALLATION........................126

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT....128

DISASSEMBLY........................128

ASSEMBLY...........................129

DIFFERENTIAL CASE BEARINGS

REMOVAL............................129

INSTALLATION........................129

PINION GEAR/RING GEAR/TONE RING

REMOVAL............................131

INSTALLATION........................132

REAR AXLE - 286RBI

DESCRIPTION

The Rear Beam-design Iron (RBI) axle housings

consist of an iron center casting (differential housing)

with axle shaft tubes extending from either side. The

tubes are pressed into the differential housing and

welded. The axles are full-floating axle shafts, that

are supported by the axle housing tubes. The full-

float axle shafts are retained by bolts attached to the

hub.

The differential case for the standard differential is

a one-piece design. Differential bearing preload and

ring gear backlash are adjusted by the use of shims

located between the differential bearing cones andcase. Outboard protective spacers are located

between the differential bearing cup and housing.

Pinion bearing preload is set and maintained by the

use of shims. Pinion height is controlled by a shim

pack located under the inner pinion bearing cup. The

differential cover provides a means for inspection and

service.

Axles equipped with a Trac-Loktdifferential are

optional. The differential contains two clutch packs,

four pinion gears, and a one-piece pinion mate cross

shaft to provide increased torque to the non-slipping

wheel in addition to the standard differential compo-

nents. A Trac-loktdifferential for the has a two-piece

differential case.

BR/BEREAR AXLE - 286RBI 3 - 107

Page 168 of 2255

thousands of an inch deviation from the standard. If the

number is negative, add that value to the required

thickness of the depth shim(s). If the number is posi-tive, subtract that value from the thickness of the depth

shim(s). If the number is 0 no change is necessary. Refer

to the Pinion Gear Depth Variance Chart.

PINION GEAR DEPTH VARIANCE

Original

Pinion

Gear

Depth

VarianceReplacement Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

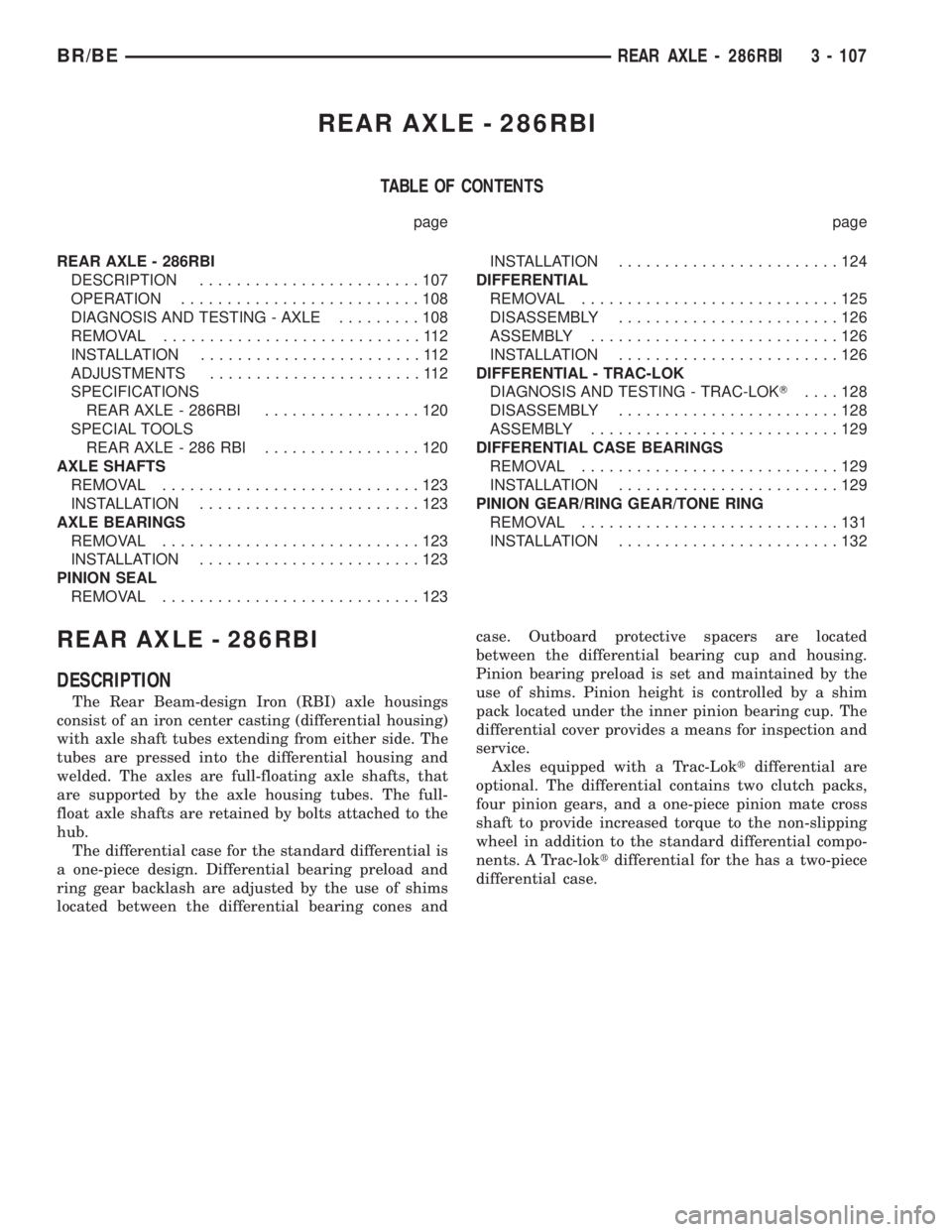

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion cups and pin-

ion bearings installed in housing. Take measure-

ments with a Pinion Gauge Set 6730 and Dial

Indicator C-3339 (Fig. 6).

(1) Assemble Pinion Height Block 6739, Pinion

Block 6738 and rear pinion bearing onto Screw 6741

(Fig. 6).

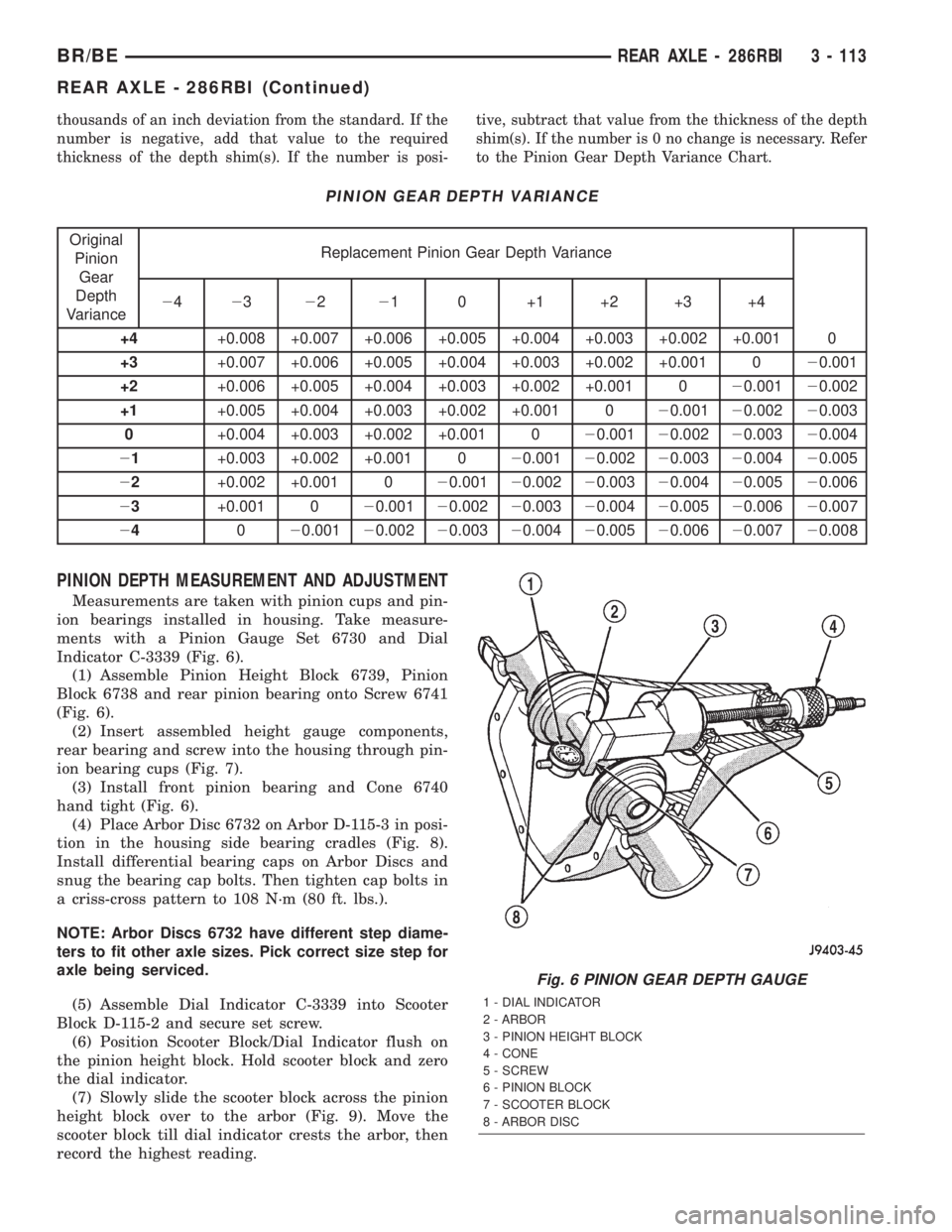

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 7).

(3) Install front pinion bearing and Cone 6740

hand tight (Fig. 6).

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 8).

Install differential bearing caps on Arbor Discs and

snug the bearing cap bolts. Then tighten cap bolts in

a criss-cross pattern to 108 N´m (80 ft. lbs.).

NOTE: Arbor Discs 6732 have different step diame-

ters to fit other axle sizes. Pick correct size step for

axle being serviced.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(7) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 9). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

Fig. 6 PINION GEAR DEPTH GAUGE

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

BR/BEREAR AXLE - 286RBI 3 - 113

REAR AXLE - 286RBI (Continued)

Page 169 of 2255

(8) Select a shim equal to the dial indicator read-

ing plus the drive pinion gear depth variance number

etched in the face of the pinion gear (Fig. 4) using

the opposite sign on the variance number. For exam-

ple, if the depth variance is ±2, add +0.002 in. to the

dial indicator reading.

(9) Remove the pinion depth gauge components

from the axle housing

DIFFERENTIAL BEARING PRELOAD AND GEAR

BACKLASH

Differential side bearing preload and gear backlash

is achieved by selective shims positioned behind thedifferential side bearing cones. The proper shim

thickness can be determined using slip-fit dummy

bearings D-346 in place of the differential side bear-

ings and a dial indicator C-3339. Before proceeding

with the differential bearing preload and gear back-

lash measurements, measure the pinion gear depth

and prepare the pinion gear for installation. Estab-

lishing proper pinion gear depth is essential to estab-

lishing gear backlash and tooth contact patterns.

After the overall shim thickness to take up differen-

tial side play is measured, the pinion gear is

installed, and the gear backlash shim thickness is

measured. The overall shim thickness is the total of

the dial indicator reading and the preload specifica-

tion added together. The gear backlash measurement

determines the thickness of the shim used on the

ring gear side of the differential case. Subtract the

gear backlash shim thickness from the total overall

shim thickness and select that amount for the pinion

gear side of the differential (Fig. 10). Differential

shim measurements are performed with axle

spreader W-129-B removed.

SHIM SELECTION

NOTE: It is difficult to salvage the differential side

bearings during the removal procedure. Install

replacement bearings if necessary.

(1) Remove differential side bearings from differ-

ential case.

(2) Remove factory installed shims from differen-

tial case.

(3) Install ring gear on differential case and

tighten bolts to specification, if necessary.

Fig. 7 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

Fig. 8 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 9 PINION DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

3 - 114 REAR AXLE - 286RBIBR/BE

REAR AXLE - 286RBI (Continued)

Page 194 of 2255

CAUTION: Never use gasoline, kerosene, alcohol,

motor oil, transmission fluid, or any fluid containing

mineral oil to clean the system components. These

fluids damage rubber cups and seals. Use only

fresh brake fluid or Mopar brake cleaner to clean or

flush brake system components. These are the only

cleaning materials recommended. If system contam-

ination is suspected, check the fluid for dirt, discol-

oration, or separation into distinct layers. Also

check the reservoir cap seal for distortion. Drain

and flush the system with new brake fluid if con-

tamination is suspected.

CAUTION: Use Mopar brake fluid, or an equivalent

quality fluid meeting SAE/DOT standards J1703 and

DOT 3. Brake fluid must be clean and free of con-

taminants. Use fresh fluid from sealed containers

only to ensure proper antilock component opera-

tion.

CAUTION: Use Mopar multi-mileage or high temper-

ature grease to lubricate caliper slide surfaces,

drum brake pivot pins, and shoe contact points on

the backing plates. Use multi-mileage grease or GE

661 or Dow 111 silicone grease on caliper slide pins

to ensure proper operation.

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake shoes,

calipers, wheel cylinders, brake drums, rotors, brake

lines, master cylinder, booster, and parking brake

components.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, wheel cylinders, brake

lines, and master cylinder.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals

and cups will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and pedal. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper/wheel cylinder. If leakage is severe, fluid will

be evident at or around the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action is

to inspect and replace all worn component and make

the proper adjustments.

BR/BEBRAKES - BASE 5 - 5

HYDRAULIC/MECHANICAL (Continued)

Page 462 of 2255

²Terminal number 30 is connected to battery volt-

age. For both the ASD and fuel pump relays, termi-

nal 30 is connected to battery voltage at all times.

²The PCM grounds the coil side of the relay

through terminal number 85.

²Terminal number 86 supplies voltage to the coil

side of the relay.

²When the PCM de-energizes the ASD and fuel

pump relays, terminal number 87A connects to termi-

nal 30. This is the Off position. In the off position,

voltage is not supplied to the rest of the circuit. Ter-

minal 87A is the center terminal on the relay.

²When the PCM energizes the ASD and fuel

pump relays, terminal 87 connects to terminal 30.

This is the On position. Terminal 87 supplies voltage

to the rest of the circuit.

The following procedure applies to the ASD and

fuel pump relays.

(1) Remove relay from connector before testing.

(2) With the relay removed from the vehicle, use

an ohmmeter to check the resistance between termi-

nals 85 and 86. The resistance should be 75 ohms +/-

5 ohms.

(3) Connect the ohmmeter between terminals 30

and 87A. The ohmmeter should show continuity

between terminals 30 and 87A.

(4) Connect the ohmmeter between terminals 87

and 30. The ohmmeter should not show continuity at

this time.

(5) Connect one end of a jumper wire (16 gauge or

smaller) to relay terminal 85. Connect the other end

of the jumper wire to the ground side of a 12 volt

power source.

(6) Connect one end of another jumper wire (16

gauge or smaller) to the power side of the 12 volt

power source.Do not attach the other end of the

jumper wire to the relay at this time.

WARNING: DO NOT ALLOW OHMMETER TO CON-

TACT TERMINALS 85 OR 86 DURING THIS TEST.

DAMAGE TO OHMMETER MAY RESULT.

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohm-

meter should now show continuity between relay ter-

minals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.(9) Replace the relay if it did not pass the continu-

ity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the ASD

and fuel pump relay circuits. Refer to 8, Wiring Dia-

grams.

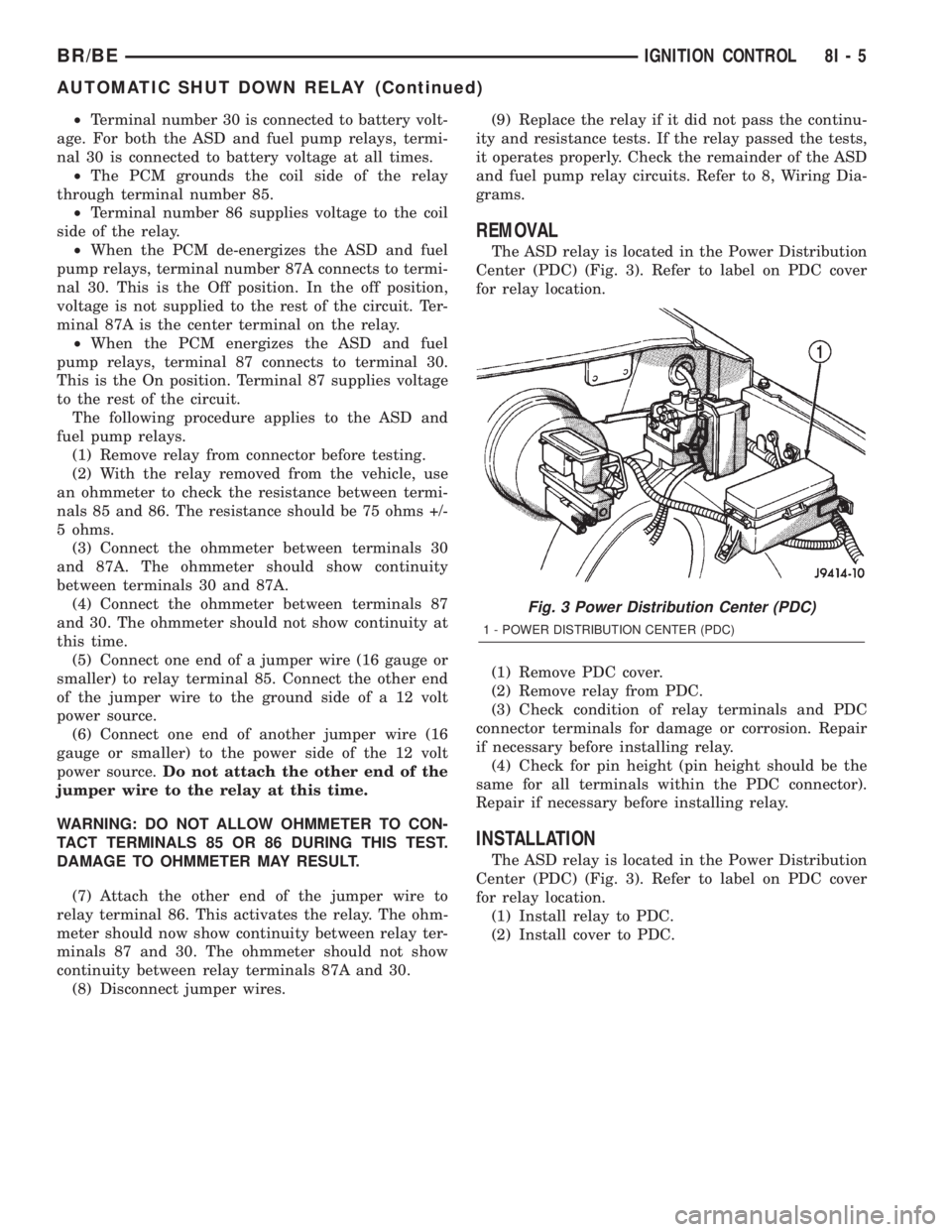

REMOVAL

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 3). Refer to label on PDC cover

for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 3). Refer to label on PDC cover

for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

Fig. 3 Power Distribution Center (PDC)

1 - POWER DISTRIBUTION CENTER (PDC)

BR/BEIGNITION CONTROL 8I - 5

AUTOMATIC SHUT DOWN RELAY (Continued)

Page 528 of 2255

SPORT

(1) Position fog lamp in fascia.

(2) Install screws attaching fog lamp to fascia.

(3) Connect wire connector to fog lamp.

(4) Connect the battery negative cable.

(5) Check for proper operation and beam align-

ment.

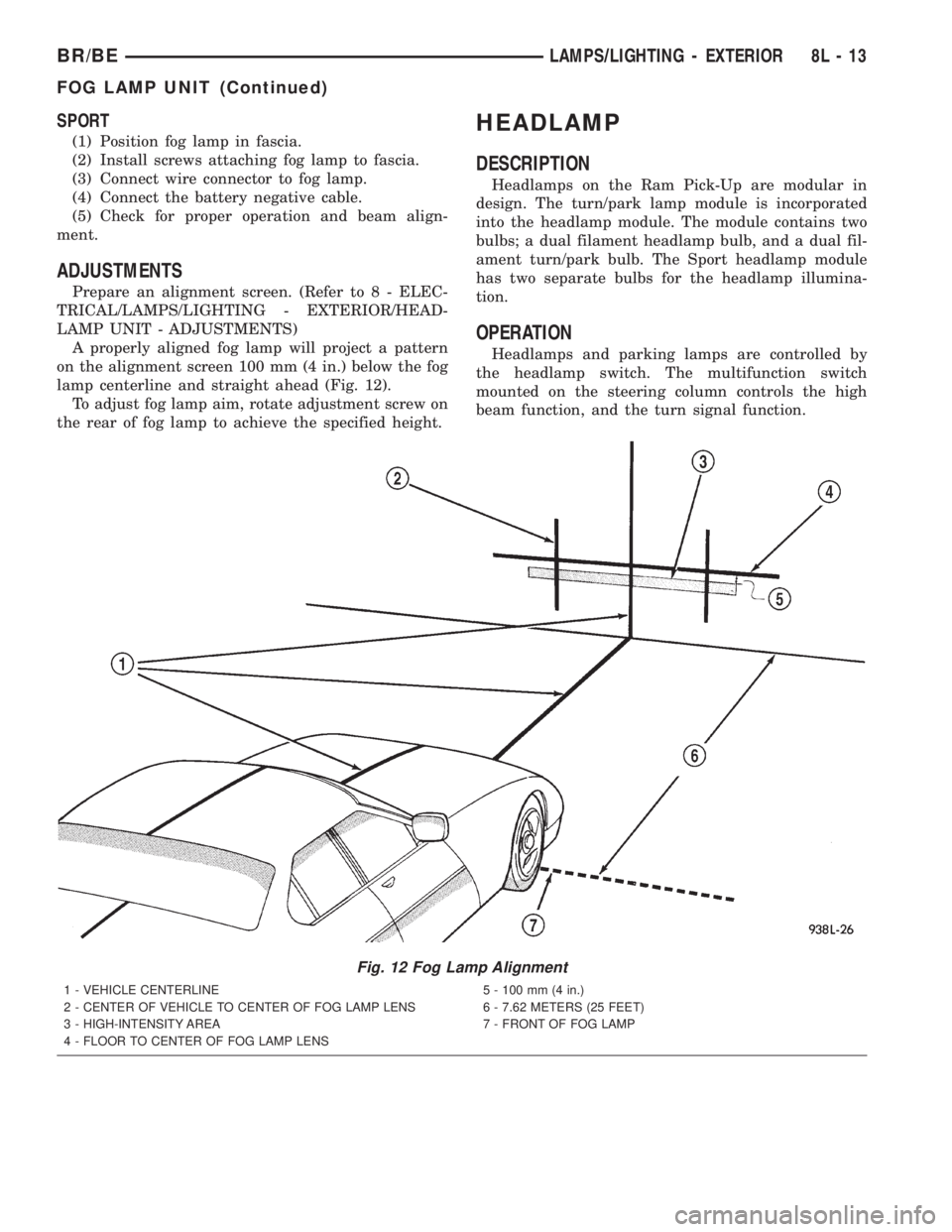

ADJUSTMENTS

Prepare an alignment screen. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - ADJUSTMENTS)

A properly aligned fog lamp will project a pattern

on the alignment screen 100 mm (4 in.) below the fog

lamp centerline and straight ahead (Fig. 12).

To adjust fog lamp aim, rotate adjustment screw on

the rear of fog lamp to achieve the specified height.

HEADLAMP

DESCRIPTION

Headlamps on the Ram Pick-Up are modular in

design. The turn/park lamp module is incorporated

into the headlamp module. The module contains two

bulbs; a dual filament headlamp bulb, and a dual fil-

ament turn/park bulb. The Sport headlamp module

has two separate bulbs for the headlamp illumina-

tion.

OPERATION

Headlamps and parking lamps are controlled by

the headlamp switch. The multifunction switch

mounted on the steering column controls the high

beam function, and the turn signal function.

Fig. 12 Fog Lamp Alignment

1 - VEHICLE CENTERLINE

2 - CENTER OF VEHICLE TO CENTER OF FOG LAMP LENS

3 - HIGH-INTENSITY AREA

4 - FLOOR TO CENTER OF FOG LAMP LENS5 - 100 mm (4 in.)

6 - 7.62 METERS (25 FEET)

7 - FRONT OF FOG LAMP

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 13

FOG LAMP UNIT (Continued)

Page 611 of 2255

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

REMOVAL) and (Refer to 19 - STEERING/COLUMN

- REMOVAL).

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

WARNING: USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE DRIVER

AIRBAG, OR BECOMING ENTRAPPED BETWEEN

THE DRIVER AIRBAG CUSHION AND THE DRIVER

AIRBAG TRIM COVER. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN OCCUPANT INJURIES

UPON AIRBAG DEPLOYMENT.

WARNING: THE DRIVER AIRBAG TRIM COVER

MUST NEVER BE PAINTED. REPLACEMENT TRIM

COVERS ARE SERVICED IN THE ORIGINAL COL-

ORS. PAINT MAY CHANGE THE WAY IN WHICH THE

MATERIAL OF THE TRIM COVER RESPONDS TO AN

AIRBAG DEPLOYMENT. FAILURE TO OBSERVE

THIS WARNING COULD RESULT IN OCCUPANT

INJURIES UPON AIRBAG DEPLOYMENT.

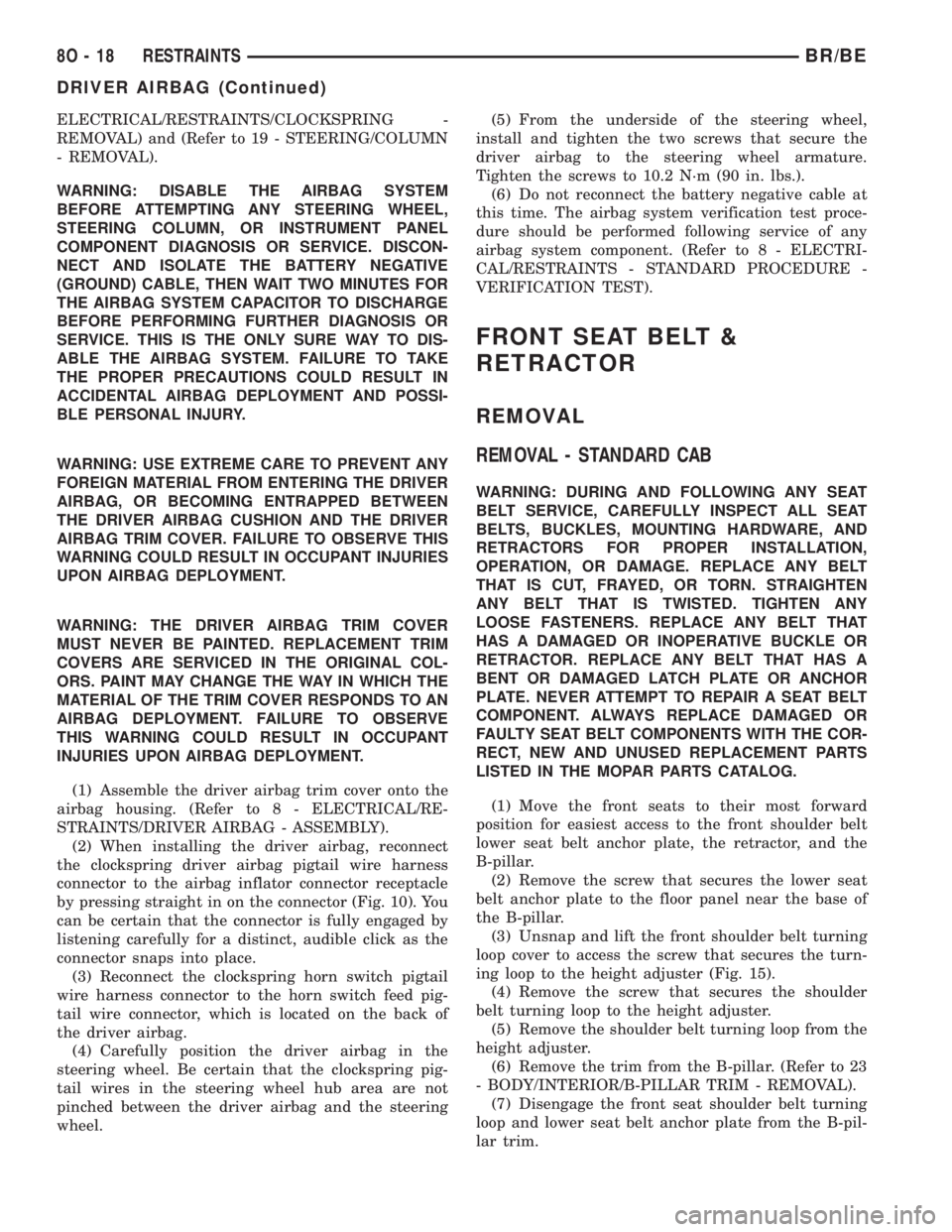

(1) Assemble the driver airbag trim cover onto the

airbag housing. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - ASSEMBLY).

(2) When installing the driver airbag, reconnect

the clockspring driver airbag pigtail wire harness

connector to the airbag inflator connector receptacle

by pressing straight in on the connector (Fig. 10). You

can be certain that the connector is fully engaged by

listening carefully for a distinct, audible click as the

connector snaps into place.

(3) Reconnect the clockspring horn switch pigtail

wire harness connector to the horn switch feed pig-

tail wire connector, which is located on the back of

the driver airbag.

(4) Carefully position the driver airbag in the

steering wheel. Be certain that the clockspring pig-

tail wires in the steering wheel hub area are not

pinched between the driver airbag and the steering

wheel.(5) From the underside of the steering wheel,

install and tighten the two screws that secure the

driver airbag to the steering wheel armature.

Tighten the screws to 10.2 N´m (90 in. lbs.).

(6) Do not reconnect the battery negative cable at

this time. The airbag system verification test proce-

dure should be performed following service of any

airbag system component. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

VERIFICATION TEST).

FRONT SEAT BELT &

RETRACTOR

REMOVAL

REMOVAL - STANDARD CAB

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

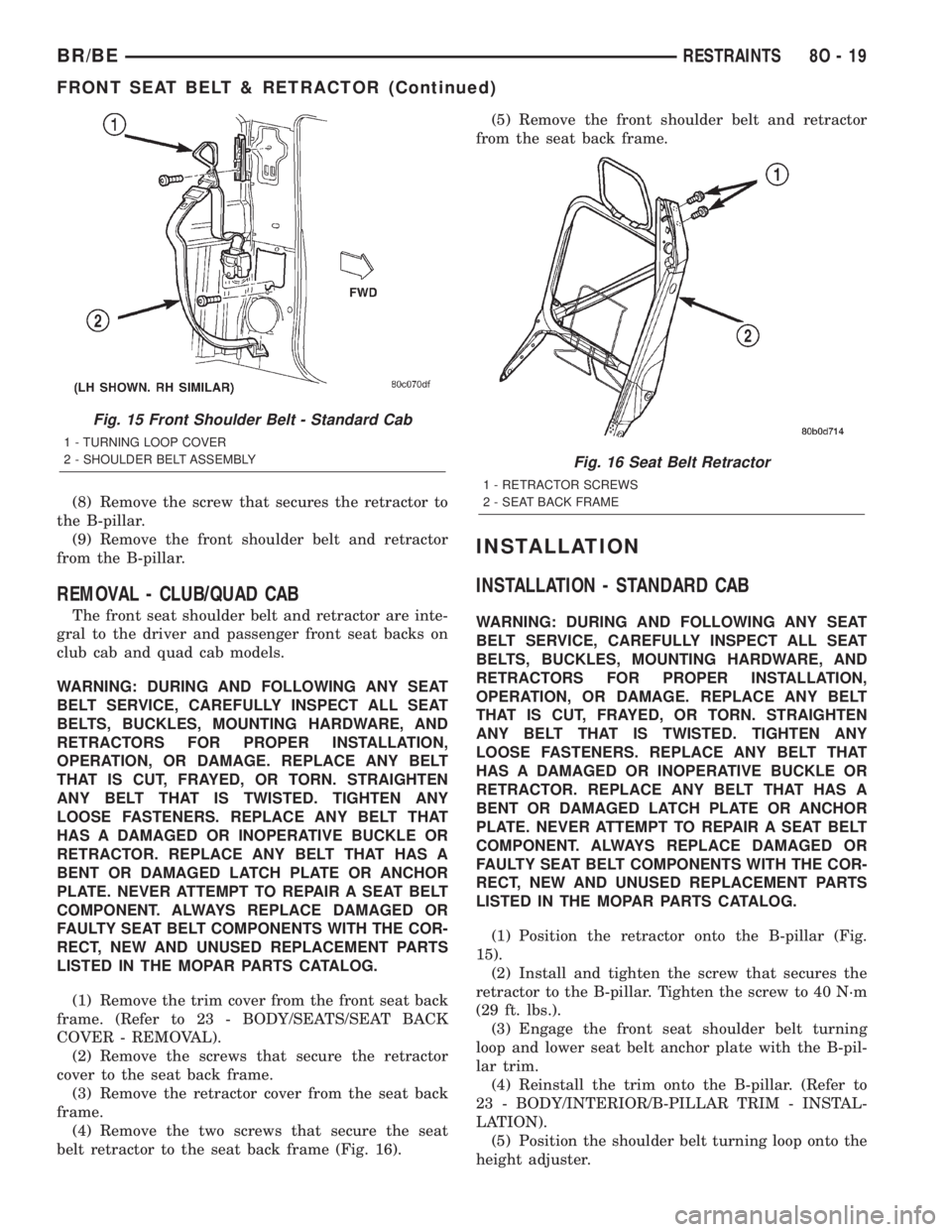

(1) Move the front seats to their most forward

position for easiest access to the front shoulder belt

lower seat belt anchor plate, the retractor, and the

B-pillar.

(2) Remove the screw that secures the lower seat

belt anchor plate to the floor panel near the base of

the B-pillar.

(3) Unsnap and lift the front shoulder belt turning

loop cover to access the screw that secures the turn-

ing loop to the height adjuster (Fig. 15).

(4) Remove the screw that secures the shoulder

belt turning loop to the height adjuster.

(5) Remove the shoulder belt turning loop from the

height adjuster.

(6) Remove the trim from the B-pillar. (Refer to 23

- BODY/INTERIOR/B-PILLAR TRIM - REMOVAL).

(7) Disengage the front seat shoulder belt turning

loop and lower seat belt anchor plate from the B-pil-

lar trim.

8O - 18 RESTRAINTSBR/BE

DRIVER AIRBAG (Continued)

Page 612 of 2255

(8) Remove the screw that secures the retractor to

the B-pillar.

(9) Remove the front shoulder belt and retractor

from the B-pillar.

REMOVAL - CLUB/QUAD CAB

The front seat shoulder belt and retractor are inte-

gral to the driver and passenger front seat backs on

club cab and quad cab models.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Remove the trim cover from the front seat back

frame. (Refer to 23 - BODY/SEATS/SEAT BACK

COVER - REMOVAL).

(2) Remove the screws that secure the retractor

cover to the seat back frame.

(3) Remove the retractor cover from the seat back

frame.

(4) Remove the two screws that secure the seat

belt retractor to the seat back frame (Fig. 16).(5) Remove the front shoulder belt and retractor

from the seat back frame.

INSTALLATION

INSTALLATION - STANDARD CAB

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the retractor onto the B-pillar (Fig.

15).

(2) Install and tighten the screw that secures the

retractor to the B-pillar. Tighten the screw to 40 N´m

(29 ft. lbs.).

(3) Engage the front seat shoulder belt turning

loop and lower seat belt anchor plate with the B-pil-

lar trim.

(4) Reinstall the trim onto the B-pillar. (Refer to

23 - BODY/INTERIOR/B-PILLAR TRIM - INSTAL-

LATION).

(5) Position the shoulder belt turning loop onto the

height adjuster.

Fig. 15 Front Shoulder Belt - Standard Cab

1 - TURNING LOOP COVER

2 - SHOULDER BELT ASSEMBLY

Fig. 16 Seat Belt Retractor

1 - RETRACTOR SCREWS

2 - SEAT BACK FRAME

BR/BERESTRAINTS 8O - 19

FRONT SEAT BELT & RETRACTOR (Continued)

Page 613 of 2255

(6) Install and tighten the screw that secures the

shoulder belt turning loop to the height adjuster.

Tighten the screw to 30 N´m (22 ft. lbs.).

(7) Fold and snap the cover over the front shoulder

belt turning loop to conceal the screw that secures

the turning loop to the height adjuster.

(8) Install and tighten the screw that secures the

lower seat belt anchor plate to the floor panel near

the base of the B-pillar. Tighten the screw to 40 N´m

(29 ft. lbs.).

INSTALLATION - CLUB/QUAD CAB

The front seat shoulder belt and retractor are inte-

gral to the driver and passenger front seat backs on

club cab and quad cab models.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the front shoulder belt and retractor

onto the seat back frame.

(2) Install and tighten the two screws that secure

the seat belt retractor to the seat back frame (Fig.

16). Tighten the screws to 16 N´m (12 ft. lbs.).

(3) Position the retractor cover onto the seat back

frame.

(4) Install and tighten the screws that secure the

retractor cover to the seat back frame. Tighten the

screws to 2 N´m (17 in. lbs.).

(5) Reinstall the trim cover onto the front seat

back frame. (Refer to 23 - BODY/SEATS/SEAT BACK

COVER - INSTALLATION).

FRONT SEAT BELT BUCKLE

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELTTHAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Move the front seat to its most forward position

for easiest access to the front seat belt buckle

anchors.

(2) Tilt both front seat backs forward far enough to

access the seat belt buckle anchor screws.

(3) On the driver's side only, disconnect the body

wire harness connector for the seat belt switch from

the seat belt switch pigtail wire connector on the seat

belt buckle.

(4) Remove the screw that secures the seat belt

buckle to the anchor on the seat cushion frame.

(5) Remove the front seat belt buckle from the seat

cushion frame.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the front seat belt buckle onto the seat

cushion frame.

(2) On the driver's side only, reconnect the body

wire harness connector for the seat belt switch to the

seat belt switch pigtail wire connector on the seat

belt buckle.

(3) Install and tighten the screw that secures the

seat belt buckle to the anchor on the seat cushion

frame. Tighten the screw to 40 N´m (29 ft. lbs.).

8O - 20 RESTRAINTSBR/BE

FRONT SEAT BELT & RETRACTOR (Continued)

Page 622 of 2255

between the seat belt switch and the instrument

cluster as required.

(4) Check for continuity between the seat belt

switch sense circuit cavities in the body wire harness

connector for the seat belt switch and the instrument

panel wire harness connector (Connector C2) for the

instrument cluster. There should be continuity. If

OK, proceed to the diagnosis for the instrument clus-

ter. (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). If not OK,

repair the open seat belt switch sense circuit between

the seat belt switch and the instrument cluster as

required.

SEAT BELT TURNING LOOP

ADJUSTER

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Remove the knob from the lever of the seat belt

turning loop adjuster. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/TURNING LOOP HEIGHT ADJUSTER

KNOB - REMOVAL).

(2) Remove the screw that secures the shoulder

belt turning loop to the height adjuster.

(3) Remove the trim from the B-pillar. (Refer to 23

- BODY/INTERIOR/B-PILLAR TRIM - REMOVAL).

(4) Remove the screw that secures the upper end

of the height adjuster to the B-pillar.(5) Pull the upper end of the height adjuster away

from the B-pillar far enough to disengage the hooks

on the lower end of the adjuster from the slots in the

pillar.

(6) Remove the adjuster from the B-pillar.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the height adjuster to the B-pillar

with the hook formations oriented toward the lower

end of the adjuster.

(2) Engage the hooks on the lower end of the

adjuster into the slots in the B-pillar.

(3) Tilt the upper end of the height adjuster up

into position against the B-pillar.

(4) Install and tighten the screw that secures the

upper end of the height adjuster to the B-pillar.

Tighten the screw to 41 N´m (30 ft. lbs.).

(5) Reinstall the trim onto the B-pillar. (Refer to

23 - BODY/INTERIOR/B-PILLAR TRIM - INSTAL-

LATION).

(6) Install and tighten the anchor screw that

secures the seat belt turning loop to the adjuster.

Tighten the screw to 30 N´m (22 ft. lbs.).

(7) Reinstall the knob onto the lever of the seat

belt turning loop adjuster. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/TURNING LOOP HEIGHT

ADJUSTER KNOB - INSTALLATION).

BR/BERESTRAINTS 8O - 29

SEAT BELT SWITCH (Continued)