height DODGE RAM 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 623 of 2255

TURNING LOOP HGT

ADJUSTER KNOB

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

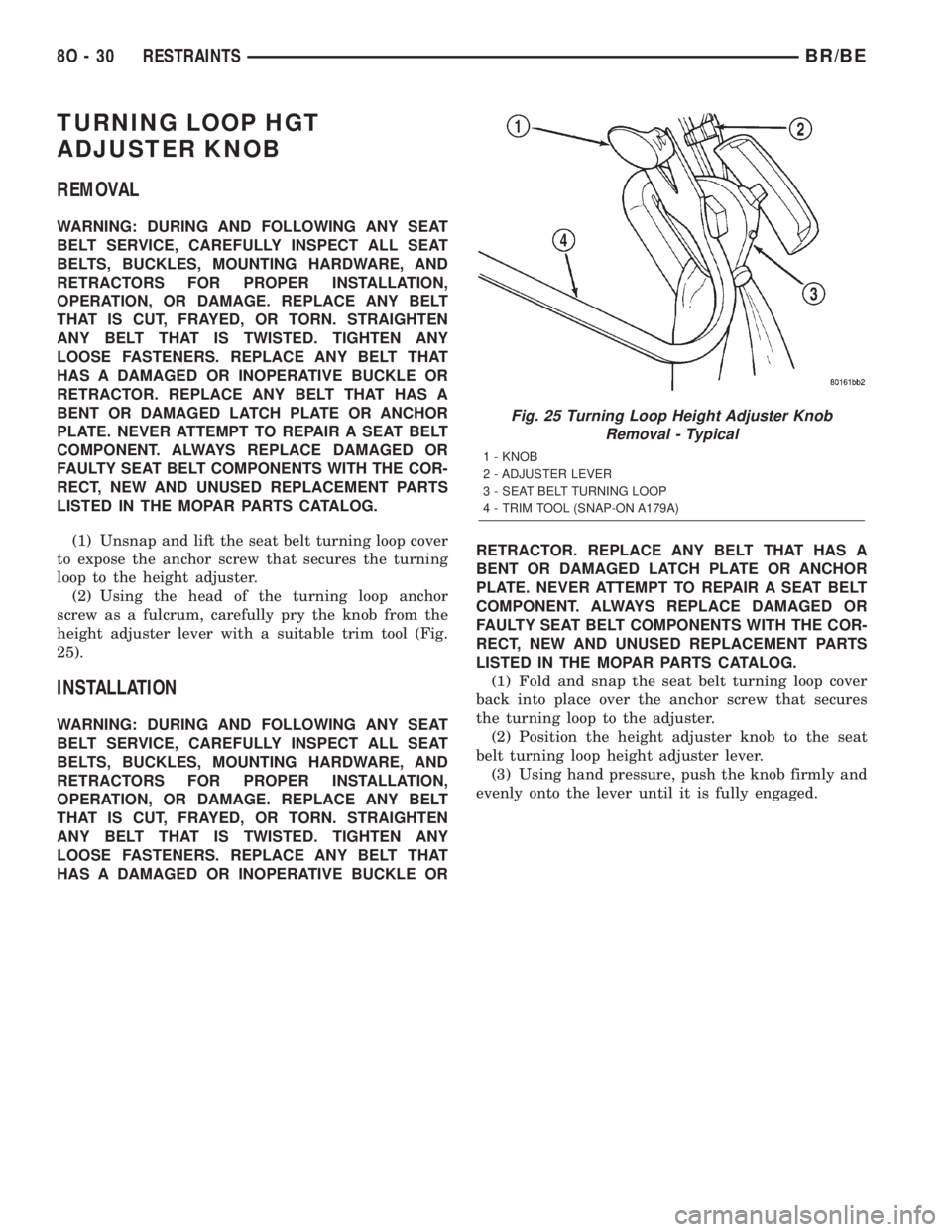

(1) Unsnap and lift the seat belt turning loop cover

to expose the anchor screw that secures the turning

loop to the height adjuster.

(2) Using the head of the turning loop anchor

screw as a fulcrum, carefully pry the knob from the

height adjuster lever with a suitable trim tool (Fig.

25).

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE ORRETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Fold and snap the seat belt turning loop cover

back into place over the anchor screw that secures

the turning loop to the adjuster.

(2) Position the height adjuster knob to the seat

belt turning loop height adjuster lever.

(3) Using hand pressure, push the knob firmly and

evenly onto the lever until it is fully engaged.

Fig. 25 Turning Loop Height Adjuster Knob

Removal - Typical

1 - KNOB

2 - ADJUSTER LEVER

3 - SEAT BELT TURNING LOOP

4 - TRIM TOOL (SNAP-ON A179A)

8O - 30 RESTRAINTSBR/BE

Page 1090 of 2255

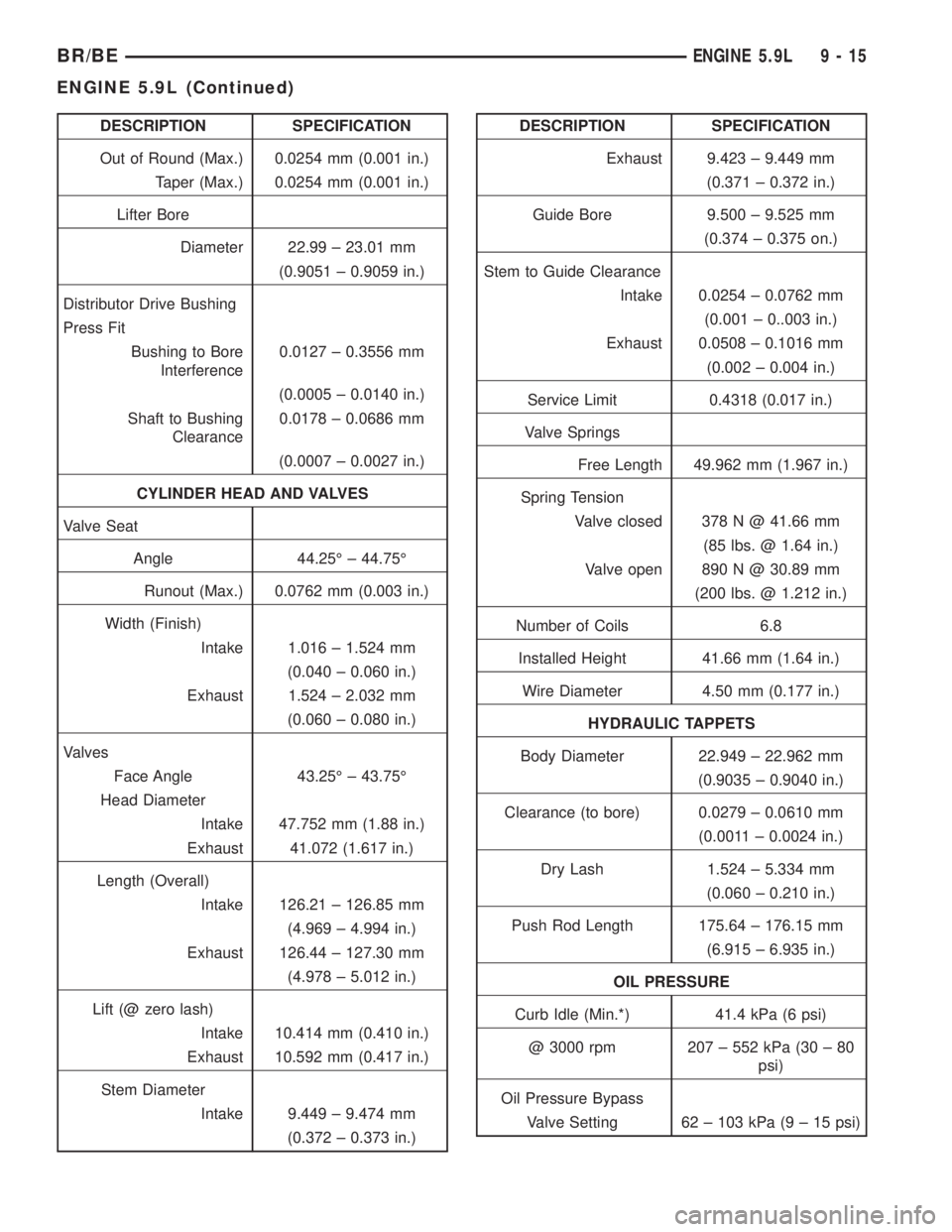

DESCRIPTION SPECIFICATION

Out of Round (Max.) 0.0254 mm (0.001 in.)

Taper (Max.) 0.0254 mm (0.001 in.)

Lifter Bore

Diameter 22.99 ± 23.01 mm

(0.9051 ± 0.9059 in.)

Distributor Drive Bushing

Press Fit

Bushing to Bore

Interference0.0127 ± 0.3556 mm

(0.0005 ± 0.0140 in.)

Shaft to Bushing

Clearance0.0178 ± 0.0686 mm

(0.0007 ± 0.0027 in.)

CYLINDER HEAD AND VALVES

Valve Seat

Angle 44.25É ± 44.75É

Runout (Max.) 0.0762 mm (0.003 in.)

Width (Finish)

Intake 1.016 ± 1.524 mm

(0.040 ± 0.060 in.)

Exhaust 1.524 ± 2.032 mm

(0.060 ± 0.080 in.)

Valves

Face Angle 43.25É ± 43.75É

Head Diameter

Intake 47.752 mm (1.88 in.)

Exhaust 41.072 (1.617 in.)

Length (Overall)

Intake 126.21 ± 126.85 mm

(4.969 ± 4.994 in.)

Exhaust 126.44 ± 127.30 mm

(4.978 ± 5.012 in.)

Lift (@ zero lash)

Intake 10.414 mm (0.410 in.)

Exhaust 10.592 mm (0.417 in.)

Stem Diameter

Intake 9.449 ± 9.474 mm

(0.372 ± 0.373 in.)DESCRIPTION SPECIFICATION

Exhaust 9.423 ± 9.449 mm

(0.371 ± 0.372 in.)

Guide Bore 9.500 ± 9.525 mm

(0.374 ± 0.375 on.)

Stem to Guide Clearance

Intake 0.0254 ± 0.0762 mm

(0.001 ± 0..003 in.)

Exhaust 0.0508 ± 0.1016 mm

(0.002 ± 0.004 in.)

Service Limit 0.4318 (0.017 in.)

Valve Springs

Free Length 49.962 mm (1.967 in.)

Spring Tension

Valve closed 378 N @ 41.66 mm

(85 lbs. @ 1.64 in.)

Valve open 890 N @ 30.89 mm

(200 lbs. @ 1.212 in.)

Number of Coils 6.8

Installed Height 41.66 mm (1.64 in.)

Wire Diameter 4.50 mm (0.177 in.)

HYDRAULIC TAPPETS

Body Diameter 22.949 ± 22.962 mm

(0.9035 ± 0.9040 in.)

Clearance (to bore) 0.0279 ± 0.0610 mm

(0.0011 ± 0.0024 in.)

Dry Lash 1.524 ± 5.334 mm

(0.060 ± 0.210 in.)

Push Rod Length 175.64 ± 176.15 mm

(6.915 ± 6.935 in.)

OIL PRESSURE

Curb Idle (Min.*) 41.4 kPa (6 psi)

@ 3000 rpm 207 ± 552 kPa (30 ± 80

psi)

Oil Pressure Bypass

Valve Setting 62 ± 103 kPa (9 ± 15 psi)

BR/BEENGINE 5.9L 9 - 15

ENGINE 5.9L (Continued)

Page 1098 of 2255

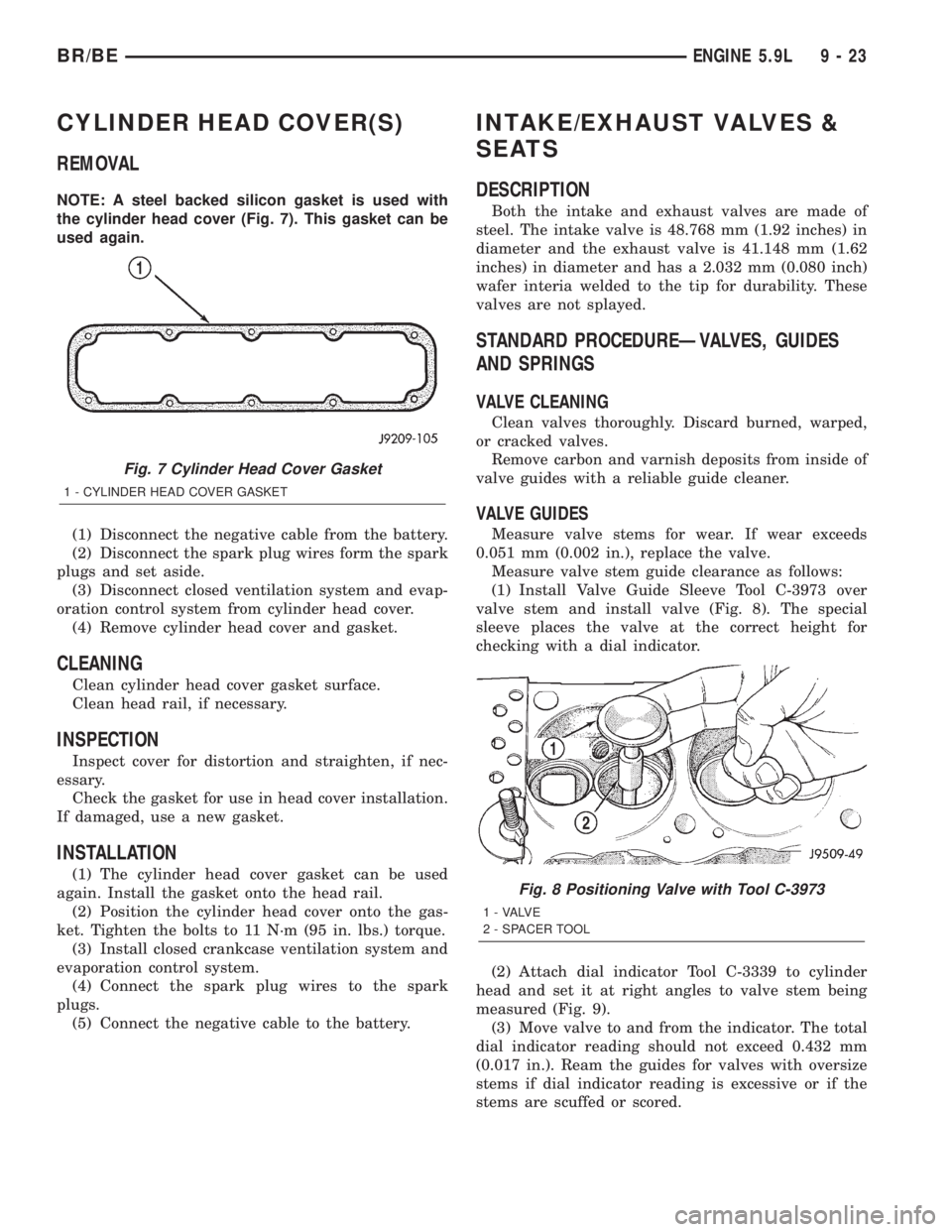

CYLINDER HEAD COVER(S)

REMOVAL

NOTE: A steel backed silicon gasket is used with

the cylinder head cover (Fig. 7). This gasket can be

used again.

(1) Disconnect the negative cable from the battery.

(2) Disconnect the spark plug wires form the spark

plugs and set aside.

(3) Disconnect closed ventilation system and evap-

oration control system from cylinder head cover.

(4) Remove cylinder head cover and gasket.

CLEANING

Clean cylinder head cover gasket surface.

Clean head rail, if necessary.

INSPECTION

Inspect cover for distortion and straighten, if nec-

essary.

Check the gasket for use in head cover installation.

If damaged, use a new gasket.

INSTALLATION

(1) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.

(2) Position the cylinder head cover onto the gas-

ket. Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(3) Install closed crankcase ventilation system and

evaporation control system.

(4) Connect the spark plug wires to the spark

plugs.

(5) Connect the negative cable to the battery.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

Both the intake and exhaust valves are made of

steel. The intake valve is 48.768 mm (1.92 inches) in

diameter and the exhaust valve is 41.148 mm (1.62

inches) in diameter and has a 2.032 mm (0.080 inch)

wafer interia welded to the tip for durability. These

valves are not splayed.

STANDARD PROCEDUREÐVALVES, GUIDES

AND SPRINGS

VALVE CLEANING

Clean valves thoroughly. Discard burned, warped,

or cracked valves.

Remove carbon and varnish deposits from inside of

valve guides with a reliable guide cleaner.

VALVE GUIDES

Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 in.), replace the valve.

Measure valve stem guide clearance as follows:

(1) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 8). The special

sleeve places the valve at the correct height for

checking with a dial indicator.

(2) Attach dial indicator Tool C-3339 to cylinder

head and set it at right angles to valve stem being

measured (Fig. 9).

(3) Move valve to and from the indicator. The total

dial indicator reading should not exceed 0.432 mm

(0.017 in.). Ream the guides for valves with oversize

stems if dial indicator reading is excessive or if the

stems are scuffed or scored.

Fig. 7 Cylinder Head Cover Gasket

1 - CYLINDER HEAD COVER GASKET

Fig. 8 Positioning Valve with Tool C-3973

1 - VALVE

2 - SPACER TOOL

BR/BEENGINE 5.9L 9 - 23

Page 1100 of 2255

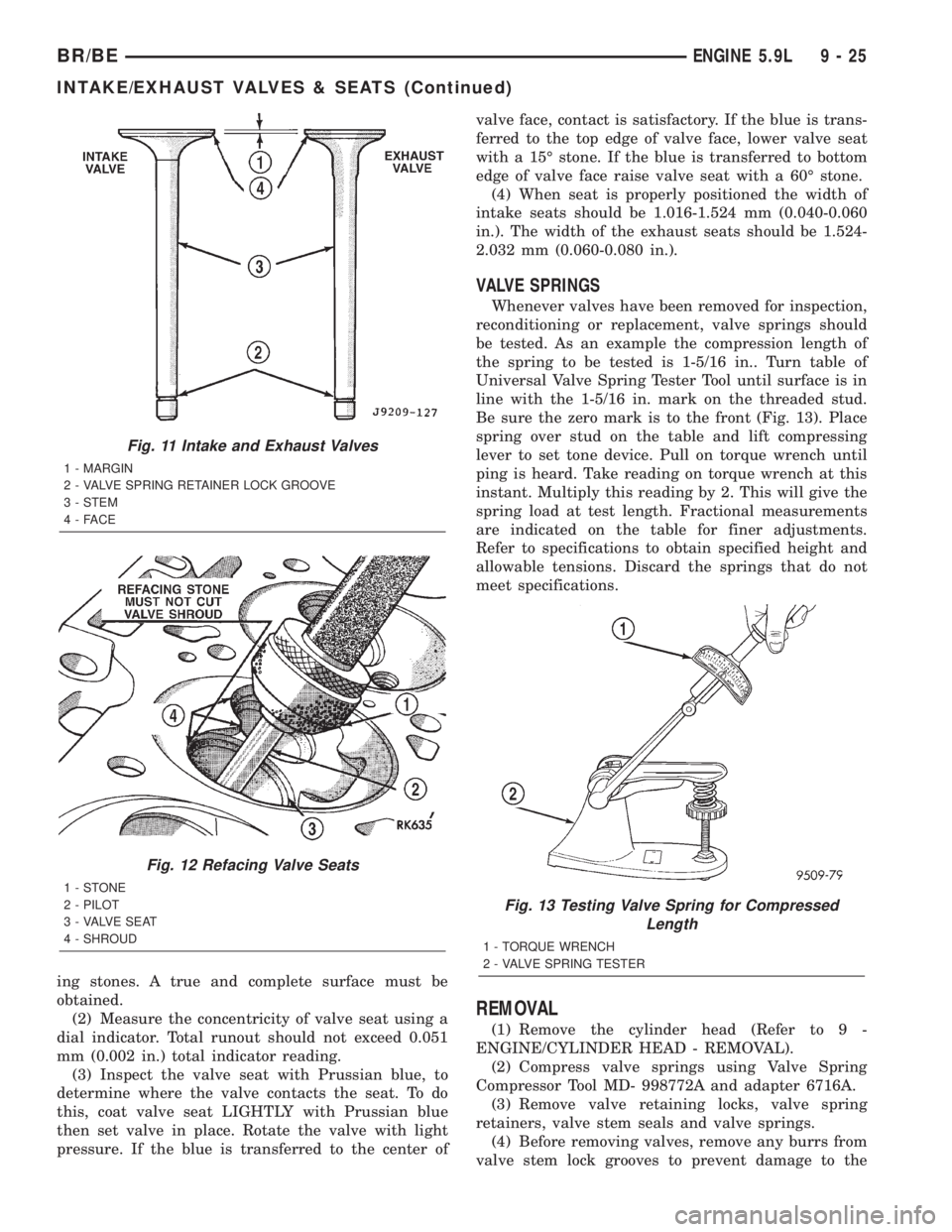

ing stones. A true and complete surface must be

obtained.

(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 in.) total indicator reading.

(3) Inspect the valve seat with Prussian blue, to

determine where the valve contacts the seat. To do

this, coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center ofvalve face, contact is satisfactory. If the blue is trans-

ferred to the top edge of valve face, lower valve seat

with a 15É stone. If the blue is transferred to bottom

edge of valve face raise valve seat with a 60É stone.

(4) When seat is properly positioned the width of

intake seats should be 1.016-1.524 mm (0.040-0.060

in.). The width of the exhaust seats should be 1.524-

2.032 mm (0.060-0.080 in.).

VALVE SPRINGS

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested. As an example the compression length of

the spring to be tested is 1-5/16 in.. Turn table of

Universal Valve Spring Tester Tool until surface is in

line with the 1-5/16 in. mark on the threaded stud.

Be sure the zero mark is to the front (Fig. 13). Place

spring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by 2. This will give the

spring load at test length. Fractional measurements

are indicated on the table for finer adjustments.

Refer to specifications to obtain specified height and

allowable tensions. Discard the springs that do not

meet specifications.

REMOVAL

(1) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(2) Compress valve springs using Valve Spring

Compressor Tool MD- 998772A and adapter 6716A.

(3) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(4) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

Fig. 11 Intake and Exhaust Valves

1 - MARGIN

2 - VALVE SPRING RETAINER LOCK GROOVE

3 - STEM

4-FACE

Fig. 12 Refacing Valve Seats

1-STONE

2 - PILOT

3 - VALVE SEAT

4 - SHROUD

Fig. 13 Testing Valve Spring for Compressed

Length

1 - TORQUE WRENCH

2 - VALVE SPRING TESTER

BR/BEENGINE 5.9L 9 - 25

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1101 of 2255

valve guides. Identify valves to ensure installation in

original location.

CLEANING

Clean valves thoroughly. Discard burned, warped,

or cracked valves.

Remove carbon and varnish deposits from inside of

valve guides with a reliable guide cleaner.

INSPECTION

Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 in.), replace the valve.

Measure valve stem guide clearance as follows:

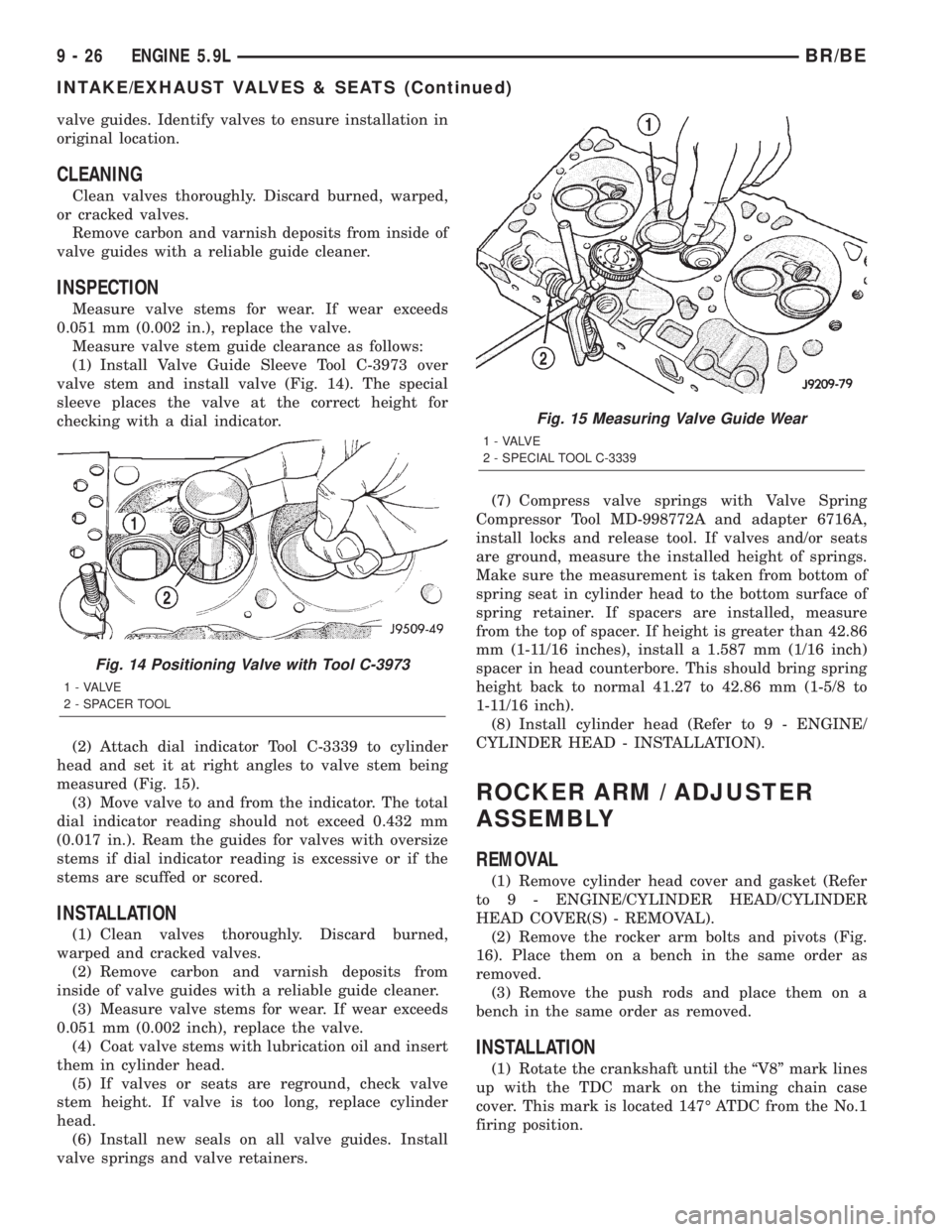

(1) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 14). The special

sleeve places the valve at the correct height for

checking with a dial indicator.

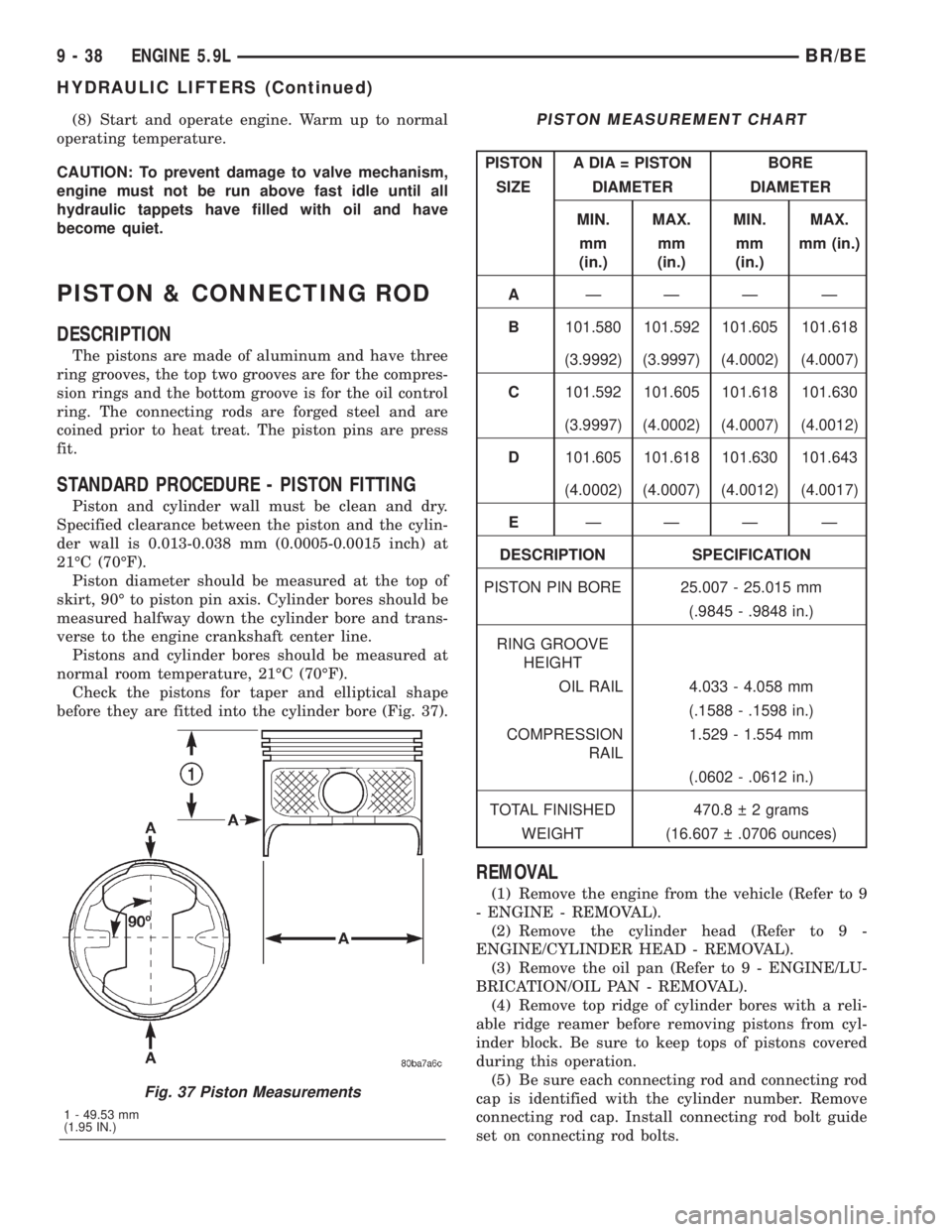

(2) Attach dial indicator Tool C-3339 to cylinder

head and set it at right angles to valve stem being

measured (Fig. 15).

(3) Move valve to and from the indicator. The total

dial indicator reading should not exceed 0.432 mm

(0.017 in.). Ream the guides for valves with oversize

stems if dial indicator reading is excessive or if the

stems are scuffed or scored.

INSTALLATION

(1) Clean valves thoroughly. Discard burned,

warped and cracked valves.

(2) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(3) Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 inch), replace the valve.

(4) Coat valve stems with lubrication oil and insert

them in cylinder head.

(5) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(6) Install new seals on all valve guides. Install

valve springs and valve retainers.(7) Compress valve springs with Valve Spring

Compressor Tool MD-998772A and adapter 6716A,

install locks and release tool. If valves and/or seats

are ground, measure the installed height of springs.

Make sure the measurement is taken from bottom of

spring seat in cylinder head to the bottom surface of

spring retainer. If spacers are installed, measure

from the top of spacer. If height is greater than 42.86

mm (1-11/16 inches), install a 1.587 mm (1/16 inch)

spacer in head counterbore. This should bring spring

height back to normal 41.27 to 42.86 mm (1-5/8 to

1-11/16 inch).

(8) Install cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

ROCKER ARM / ADJUSTER

ASSEMBLY

REMOVAL

(1) Remove cylinder head cover and gasket (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

(2) Remove the rocker arm bolts and pivots (Fig.

16). Place them on a bench in the same order as

removed.

(3) Remove the push rods and place them on a

bench in the same order as removed.

INSTALLATION

(1) Rotate the crankshaft until the ªV8º mark lines

up with the TDC mark on the timing chain case

cover. This mark is located 147É ATDC from the No.1

firing position.

Fig. 14 Positioning Valve with Tool C-3973

1 - VALVE

2 - SPACER TOOL

Fig. 15 Measuring Valve Guide Wear

1 - VALVE

2 - SPECIAL TOOL C-3339

9 - 26 ENGINE 5.9LBR/BE

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1113 of 2255

(8) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

PISTON & CONNECTING ROD

DESCRIPTION

The pistons are made of aluminum and have three

ring grooves, the top two grooves are for the compres-

sion rings and the bottom groove is for the oil control

ring. The connecting rods are forged steel and are

coined prior to heat treat. The piston pins are press

fit.

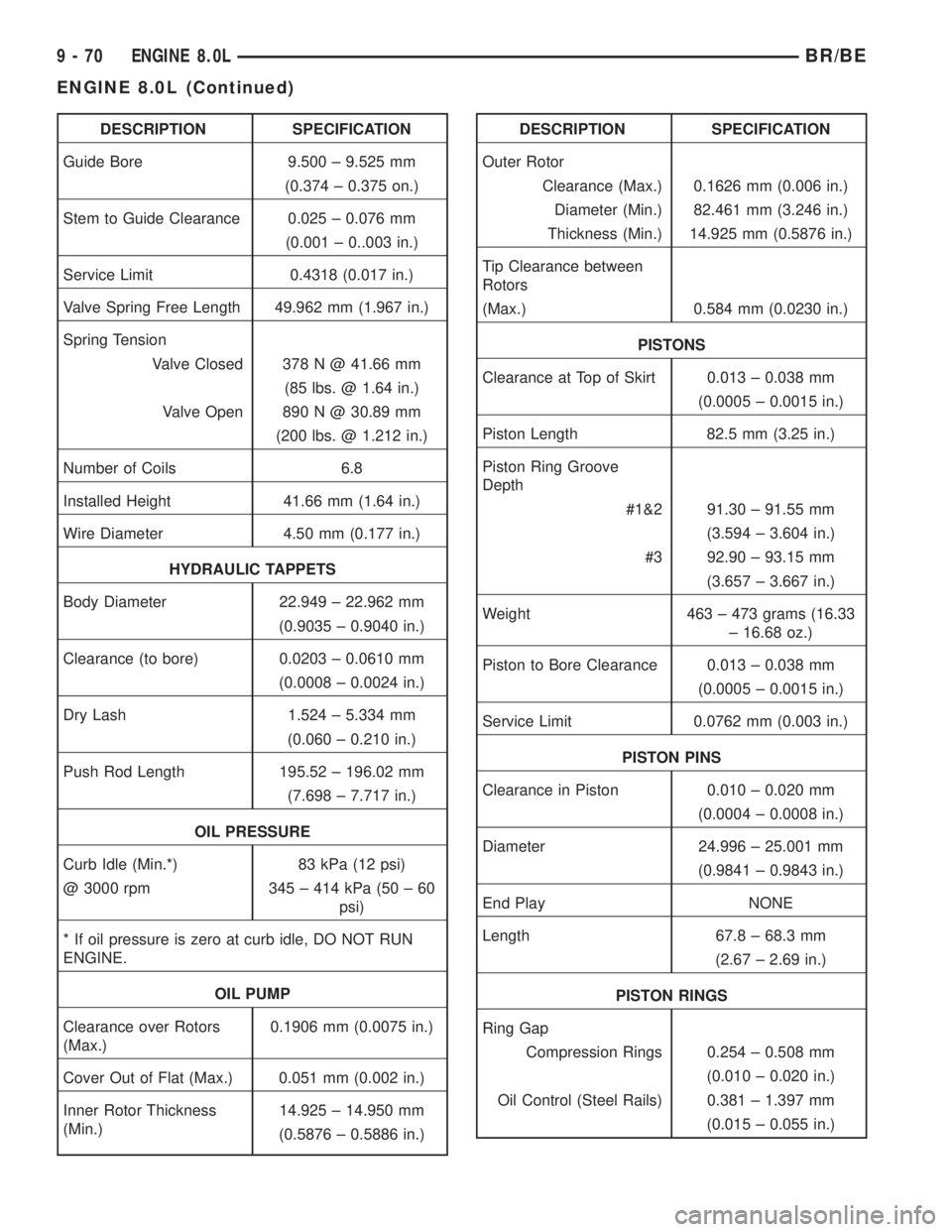

STANDARD PROCEDURE - PISTON FITTING

Piston and cylinder wall must be clean and dry.

Specified clearance between the piston and the cylin-

der wall is 0.013-0.038 mm (0.0005-0.0015 inch) at

21ÉC (70ÉF).

Piston diameter should be measured at the top of

skirt, 90É to piston pin axis. Cylinder bores should be

measured halfway down the cylinder bore and trans-

verse to the engine crankshaft center line.

Pistons and cylinder bores should be measured at

normal room temperature, 21ÉC (70ÉF).

Check the pistons for taper and elliptical shape

before they are fitted into the cylinder bore (Fig. 37).

PISTON MEASUREMENT CHART

PISTON A DIA = PISTON BORE

SIZE DIAMETER DIAMETER

MIN. MAX. MIN. MAX.

mm

(in.)mm

(in.)mm

(in.)mm (in.)

AÐÐÐ Ð

B101.580 101.592 101.605 101.618

(3.9992) (3.9997) (4.0002) (4.0007)

C101.592 101.605 101.618 101.630

(3.9997) (4.0002) (4.0007) (4.0012)

D101.605 101.618 101.630 101.643

(4.0002) (4.0007) (4.0012) (4.0017)

EÐÐÐ Ð

DESCRIPTION SPECIFICATION

PISTON PIN BORE 25.007 - 25.015 mm

(.9845 - .9848 in.)

RING GROOVE

HEIGHT

OIL RAIL 4.033 - 4.058 mm

(.1588 - .1598 in.)

COMPRESSION

RAIL1.529 - 1.554 mm

(.0602 - .0612 in.)

TOTAL FINISHED 470.8 2 grams

WEIGHT (16.607 .0706 ounces)

REMOVAL

(1) Remove the engine from the vehicle (Refer to 9

- ENGINE - REMOVAL).

(2) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(3) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block. Be sure to keep tops of pistons covered

during this operation.

(5) Be sure each connecting rod and connecting rod

cap is identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.

Fig. 37 Piston Measurements

1 - 49.53 mm

(1.95 IN.)

9 - 38 ENGINE 5.9LBR/BE

HYDRAULIC LIFTERS (Continued)

Page 1145 of 2255

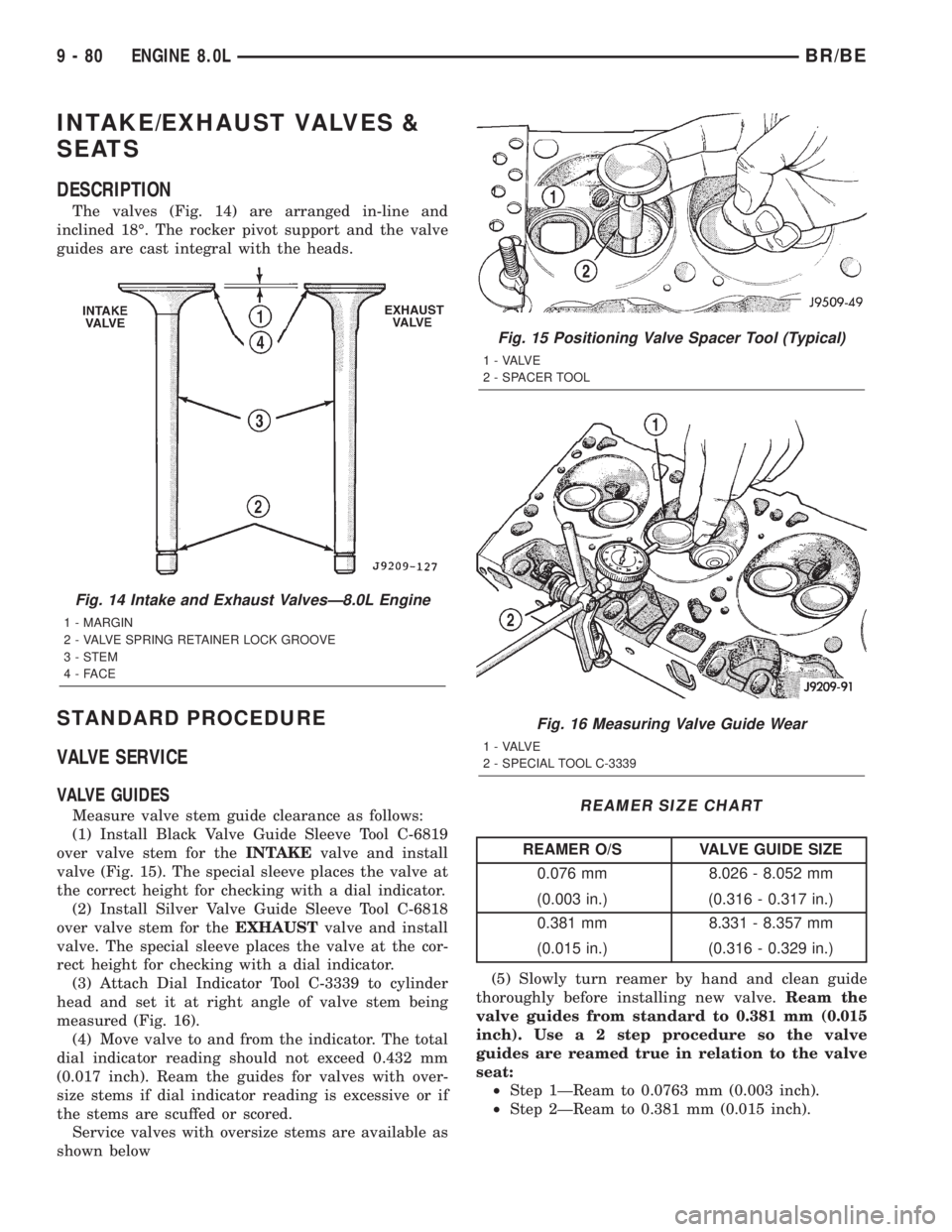

DESCRIPTION SPECIFICATION

Guide Bore 9.500 ± 9.525 mm

(0.374 ± 0.375 on.)

Stem to Guide Clearance 0.025 ± 0.076 mm

(0.001 ± 0..003 in.)

Service Limit 0.4318 (0.017 in.)

Valve Spring Free Length 49.962 mm (1.967 in.)

Spring Tension

Valve Closed 378 N @ 41.66 mm

(85 lbs. @ 1.64 in.)

Valve Open 890 N @ 30.89 mm

(200 lbs. @ 1.212 in.)

Number of Coils 6.8

Installed Height 41.66 mm (1.64 in.)

Wire Diameter 4.50 mm (0.177 in.)

HYDRAULIC TAPPETS

Body Diameter 22.949 ± 22.962 mm

(0.9035 ± 0.9040 in.)

Clearance (to bore) 0.0203 ± 0.0610 mm

(0.0008 ± 0.0024 in.)

Dry Lash 1.524 ± 5.334 mm

(0.060 ± 0.210 in.)

Push Rod Length 195.52 ± 196.02 mm

(7.698 ± 7.717 in.)

OIL PRESSURE

Curb Idle (Min.*) 83 kPa (12 psi)

@ 3000 rpm 345 ± 414 kPa (50 ± 60

psi)

* If oil pressure is zero at curb idle, DO NOT RUN

ENGINE.

OIL PUMP

Clearance over Rotors

(Max.)0.1906 mm (0.0075 in.)

Cover Out of Flat (Max.) 0.051 mm (0.002 in.)

Inner Rotor Thickness

(Min.)14.925 ± 14.950 mm

(0.5876 ± 0.5886 in.)DESCRIPTION SPECIFICATION

Outer Rotor

Clearance (Max.) 0.1626 mm (0.006 in.)

Diameter (Min.) 82.461 mm (3.246 in.)

Thickness (Min.) 14.925 mm (0.5876 in.)

Tip Clearance between

Rotors

(Max.) 0.584 mm (0.0230 in.)

PISTONS

Clearance at Top of Skirt 0.013 ± 0.038 mm

(0.0005 ± 0.0015 in.)

Piston Length 82.5 mm (3.25 in.)

Piston Ring Groove

Depth

#1&2 91.30 ± 91.55 mm

(3.594 ± 3.604 in.)

#3 92.90 ± 93.15 mm

(3.657 ± 3.667 in.)

Weight 463 ± 473 grams (16.33

± 16.68 oz.)

Piston to Bore Clearance 0.013 ± 0.038 mm

(0.0005 ± 0.0015 in.)

Service Limit 0.0762 mm (0.003 in.)

PISTON PINS

Clearance in Piston 0.010 ± 0.020 mm

(0.0004 ± 0.0008 in.)

Diameter 24.996 ± 25.001 mm

(0.9841 ± 0.9843 in.)

End Play NONE

Length 67.8 ± 68.3 mm

(2.67 ± 2.69 in.)

PISTON RINGS

Ring Gap

Compression Rings 0.254 ± 0.508 mm

(0.010 ± 0.020 in.)

Oil Control (Steel Rails) 0.381 ± 1.397 mm

(0.015 ± 0.055 in.)

9 - 70 ENGINE 8.0LBR/BE

ENGINE 8.0L (Continued)

Page 1155 of 2255

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves (Fig. 14) are arranged in-line and

inclined 18É. The rocker pivot support and the valve

guides are cast integral with the heads.

STANDARD PROCEDURE

VALVE SERVICE

VALVE GUIDES

Measure valve stem guide clearance as follows:

(1) Install Black Valve Guide Sleeve Tool C-6819

over valve stem for theINTAKEvalve and install

valve (Fig. 15). The special sleeve places the valve at

the correct height for checking with a dial indicator.

(2) Install Silver Valve Guide Sleeve Tool C-6818

over valve stem for theEXHAUSTvalve and install

valve. The special sleeve places the valve at the cor-

rect height for checking with a dial indicator.

(3) Attach Dial Indicator Tool C-3339 to cylinder

head and set it at right angle of valve stem being

measured (Fig. 16).

(4) Move valve to and from the indicator. The total

dial indicator reading should not exceed 0.432 mm

(0.017 inch). Ream the guides for valves with over-

size stems if dial indicator reading is excessive or if

the stems are scuffed or scored.

Service valves with oversize stems are available as

shown belowREAMER SIZE CHART

REAMER O/S VALVE GUIDE SIZE

0.076 mm 8.026 - 8.052 mm

(0.003 in.) (0.316 - 0.317 in.)

0.381 mm 8.331 - 8.357 mm

(0.015 in.) (0.316 - 0.329 in.)

(5) Slowly turn reamer by hand and clean guide

thoroughly before installing new valve.Ream the

valve guides from standard to 0.381 mm (0.015

inch). Use a 2 step procedure so the valve

guides are reamed true in relation to the valve

seat:

²Step 1ÐReam to 0.0763 mm (0.003 inch).

²Step 2ÐReam to 0.381 mm (0.015 inch).

Fig. 14 Intake and Exhaust ValvesÐ8.0L Engine

1 - MARGIN

2 - VALVE SPRING RETAINER LOCK GROOVE

3 - STEM

4-FACE

Fig. 15 Positioning Valve Spacer Tool (Typical)

1 - VALVE

2 - SPACER TOOL

Fig. 16 Measuring Valve Guide Wear

1 - VALVE

2 - SPECIAL TOOL C-3339

9 - 80 ENGINE 8.0LBR/BE

Page 1156 of 2255

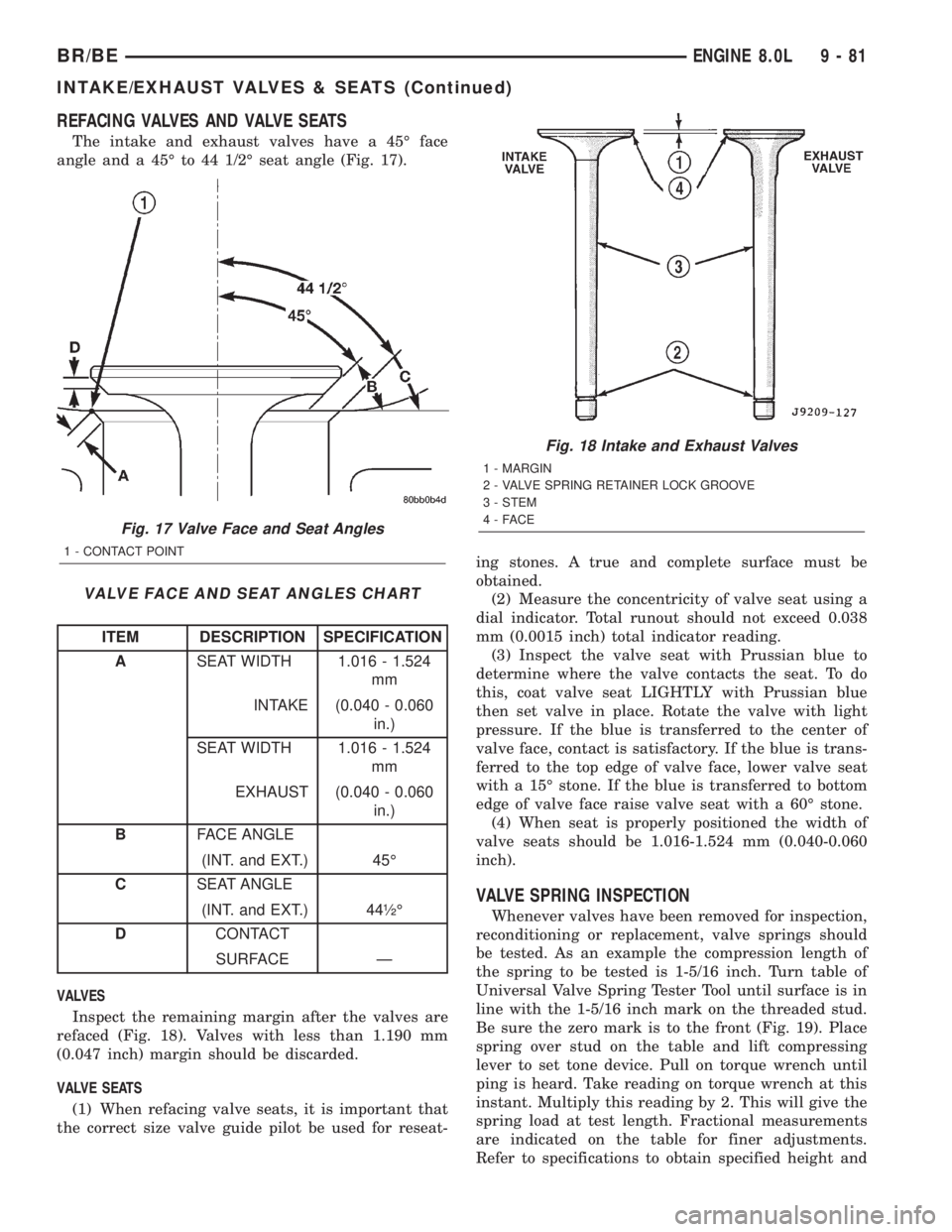

REFACING VALVES AND VALVE SEATS

The intake and exhaust valves have a 45É face

angle and a 45É to 44 1/2É seat angle (Fig. 17).

VALVE FACE AND SEAT ANGLES CHART

ITEM DESCRIPTION SPECIFICATION

ASEAT WIDTH 1.016 - 1.524

mm

INTAKE (0.040 - 0.060

in.)

SEAT WIDTH 1.016 - 1.524

mm

EXHAUST (0.040 - 0.060

in.)

BFACE ANGLE

(INT. and EXT.) 45É

CSEAT ANGLE

(INT. and EXT.) 44óÉ

DCONTACT

SURFACE Ð

VALVES

Inspect the remaining margin after the valves are

refaced (Fig. 18). Valves with less than 1.190 mm

(0.047 inch) margin should be discarded.

VALVE SEATS

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-ing stones. A true and complete surface must be

obtained.

(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.038

mm (0.0015 inch) total indicator reading.

(3) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to the top edge of valve face, lower valve seat

with a 15É stone. If the blue is transferred to bottom

edge of valve face raise valve seat with a 60É stone.

(4) When seat is properly positioned the width of

valve seats should be 1.016-1.524 mm (0.040-0.060

inch).

VALVE SPRING INSPECTION

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested. As an example the compression length of

the spring to be tested is 1-5/16 inch. Turn table of

Universal Valve Spring Tester Tool until surface is in

line with the 1-5/16 inch mark on the threaded stud.

Be sure the zero mark is to the front (Fig. 19). Place

spring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by 2. This will give the

spring load at test length. Fractional measurements

are indicated on the table for finer adjustments.

Refer to specifications to obtain specified height and

Fig. 17 Valve Face and Seat Angles

1 - CONTACT POINT

Fig. 18 Intake and Exhaust Valves

1 - MARGIN

2 - VALVE SPRING RETAINER LOCK GROOVE

3 - STEM

4-FACE

BR/BEENGINE 8.0L 9 - 81

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1158 of 2255

(4) Remove valve retaining locks, valve spring

retainers and valve springs. Check for abnormal

wear, replace as required.

(5) Remove the valve stem seals.

(6) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

valve guides. Identify valves to ensure installation in

original location.

CLEANING

Clean valves thoroughly. Discard burned, warped,

or cracked valves.

Remove carbon and varnish deposits from inside of

valve guides with a reliable guide cleaner.

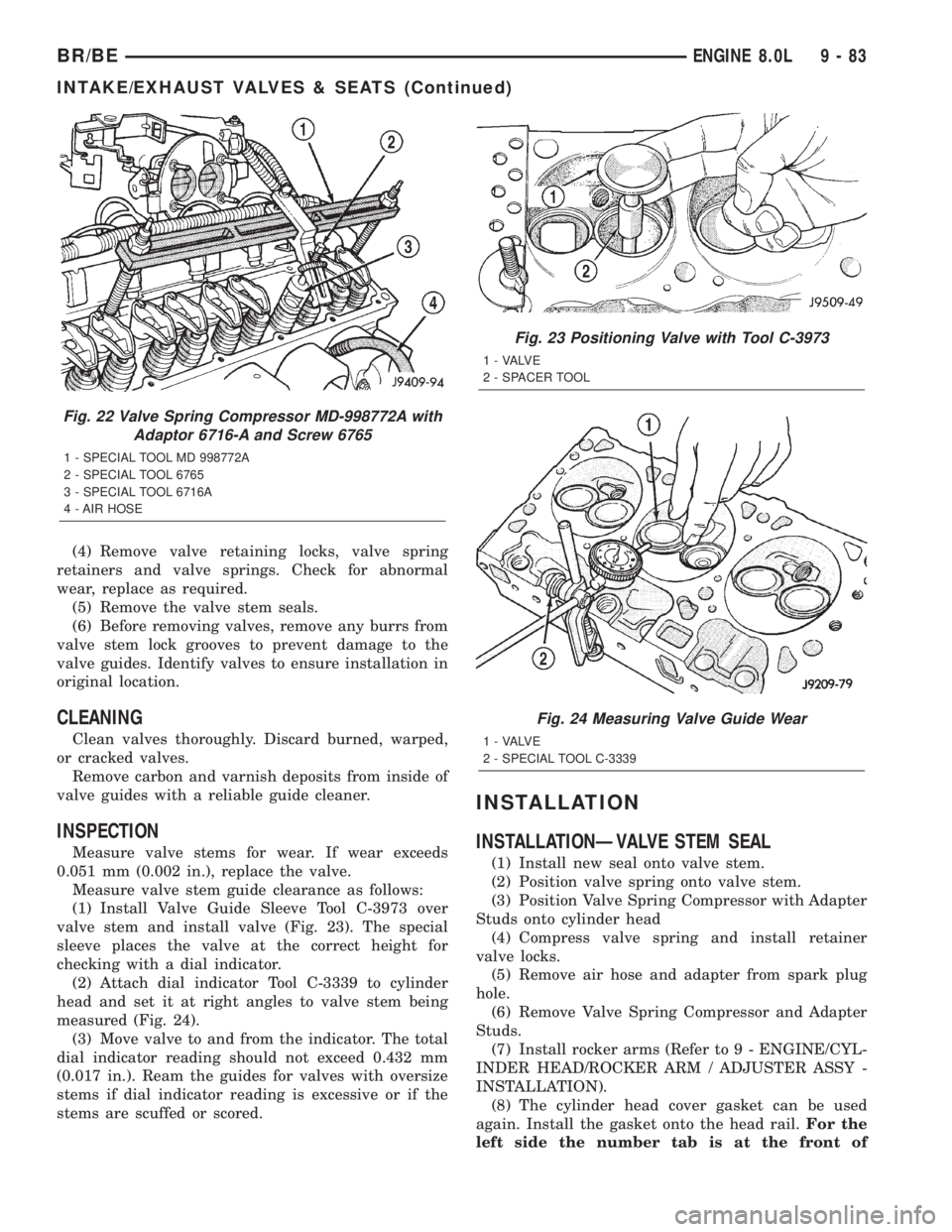

INSPECTION

Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 in.), replace the valve.

Measure valve stem guide clearance as follows:

(1) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 23). The special

sleeve places the valve at the correct height for

checking with a dial indicator.

(2) Attach dial indicator Tool C-3339 to cylinder

head and set it at right angles to valve stem being

measured (Fig. 24).

(3) Move valve to and from the indicator. The total

dial indicator reading should not exceed 0.432 mm

(0.017 in.). Ream the guides for valves with oversize

stems if dial indicator reading is excessive or if the

stems are scuffed or scored.

INSTALLATION

INSTALLATIONÐVALVE STEM SEAL

(1) Install new seal onto valve stem.

(2) Position valve spring onto valve stem.

(3) Position Valve Spring Compressor with Adapter

Studs onto cylinder head

(4) Compress valve spring and install retainer

valve locks.

(5) Remove air hose and adapter from spark plug

hole.

(6) Remove Valve Spring Compressor and Adapter

Studs.

(7) Install rocker arms (Refer to 9 - ENGINE/CYL-

INDER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

(8) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

Fig. 22 Valve Spring Compressor MD-998772A with

Adaptor 6716-A and Screw 6765

1 - SPECIAL TOOL MD 998772A

2 - SPECIAL TOOL 6765

3 - SPECIAL TOOL 6716A

4 - AIR HOSE

Fig. 23 Positioning Valve with Tool C-3973

1 - VALVE

2 - SPACER TOOL

Fig. 24 Measuring Valve Guide Wear

1 - VALVE

2 - SPECIAL TOOL C-3339

BR/BEENGINE 8.0L 9 - 83

INTAKE/EXHAUST VALVES & SEATS (Continued)