refrigerant type DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 2169 of 2255

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the serpentine drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL), (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - REMOVAL) or (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Unplug the compressor clutch coil wire harness

connector.

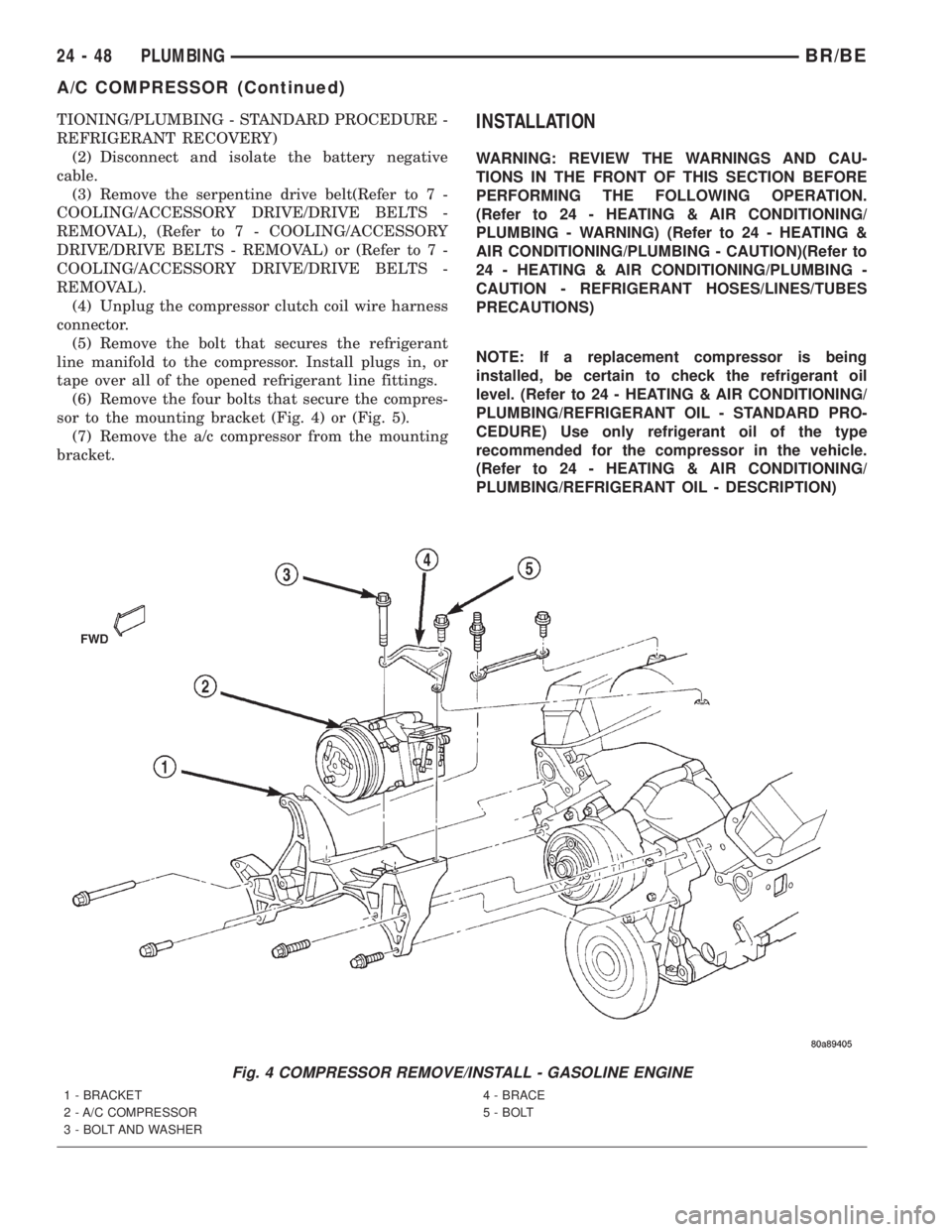

(5) Remove the bolt that secures the refrigerant

line manifold to the compressor. Install plugs in, or

tape over all of the opened refrigerant line fittings.

(6) Remove the four bolts that secure the compres-

sor to the mounting bracket (Fig. 4) or (Fig. 5).

(7) Remove the a/c compressor from the mounting

bracket.INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

NOTE: If a replacement compressor is being

installed, be certain to check the refrigerant oil

level. (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - STANDARD PRO-

CEDURE) Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - DESCRIPTION)

Fig. 4 COMPRESSOR REMOVE/INSTALL - GASOLINE ENGINE

1 - BRACKET

2 - A/C COMPRESSOR

3 - BOLT AND WASHER4 - BRACE

5 - BOLT

24 - 48 PLUMBINGBR/BE

A/C COMPRESSOR (Continued)

Page 2172 of 2255

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

NOTE: If the condenser is replaced, add 30 millili-

ters (1 fluid ounce) of refrigerant oil to the refriger-

ant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - DESCRIPTION)

SUCTION AND DISCHARGE

LINE

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

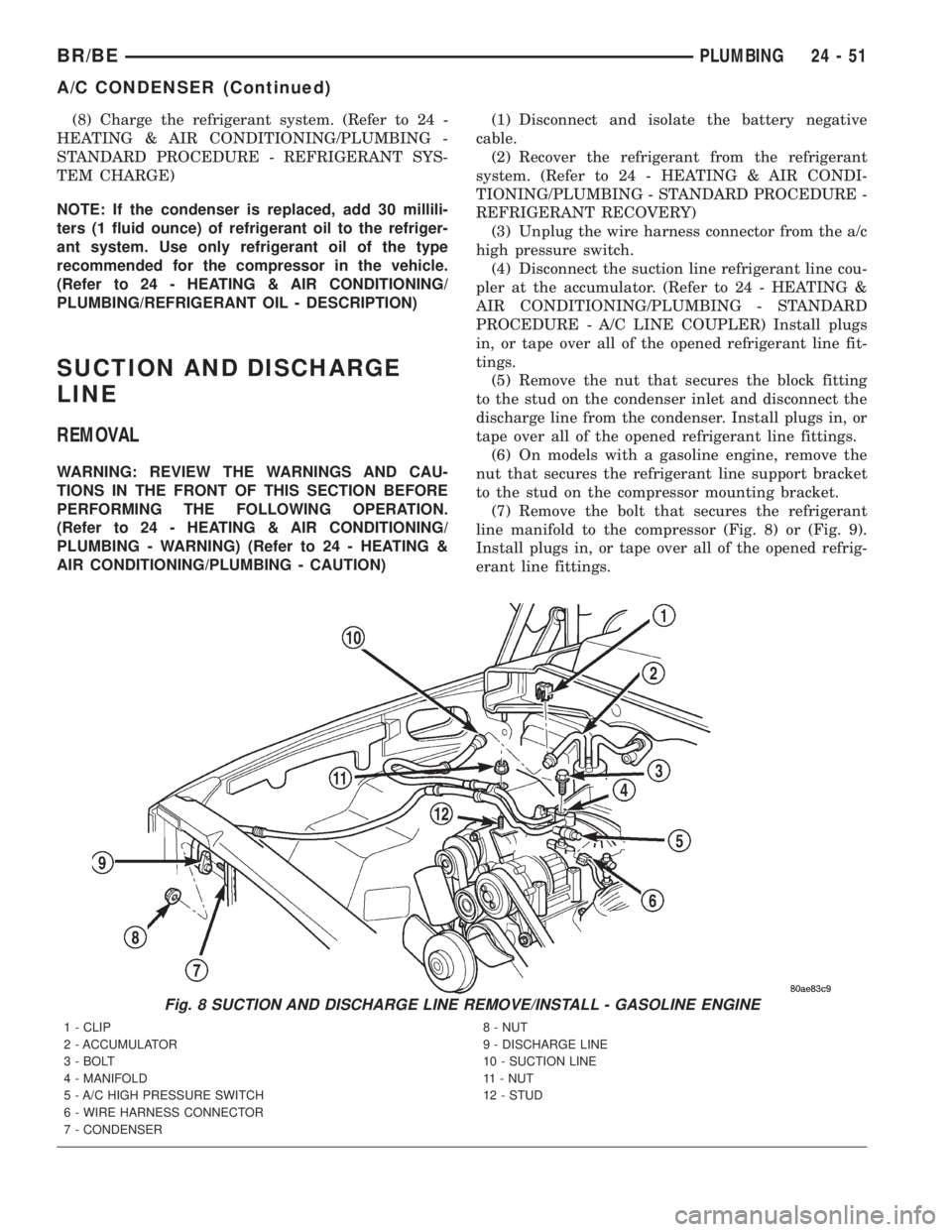

(3) Unplug the wire harness connector from the a/c

high pressure switch.

(4) Disconnect the suction line refrigerant line cou-

pler at the accumulator. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - A/C LINE COUPLER) Install plugs

in, or tape over all of the opened refrigerant line fit-

tings.

(5) Remove the nut that secures the block fitting

to the stud on the condenser inlet and disconnect the

discharge line from the condenser. Install plugs in, or

tape over all of the opened refrigerant line fittings.

(6) On models with a gasoline engine, remove the

nut that secures the refrigerant line support bracket

to the stud on the compressor mounting bracket.

(7) Remove the bolt that secures the refrigerant

line manifold to the compressor (Fig. 8) or (Fig. 9).

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

Fig. 8 SUCTION AND DISCHARGE LINE REMOVE/INSTALL - GASOLINE ENGINE

1 - CLIP

2 - ACCUMULATOR

3 - BOLT

4 - MANIFOLD

5 - A/C HIGH PRESSURE SWITCH

6 - WIRE HARNESS CONNECTOR

7 - CONDENSER8 - NUT

9 - DISCHARGE LINE

10 - SUCTION LINE

11 - NUT

12 - STUD

BR/BEPLUMBING 24 - 51

A/C CONDENSER (Continued)

Page 2177 of 2255

(3) Tighten the accumulator retaining band screw

to 4.5 N´m (40 in. lbs.).

(4) Remove the tape or plugs from the refrigerant

line fittings on the suction line and the accumulator

outlet. Connect the suction line refrigerant line cou-

pler to the accumulator outlet. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(5) Reinstall the a/c low pressure switch on the

accumulator. (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/A/C LOW PRESSURE

SWITCH - INSTALLATION)

(6) Connect the battery negative cable.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

NOTE: If the accumulator is replaced, add 60 milli-

liters (2 fluid ounces) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

HEATER CORE

DESCRIPTION

The heater core is located in the HVAC housing,

under the instrument panel. It is a heat exchanger

made of rows of tubes and fins.

The heater core is not repairable and if damaged it

must be replaced.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The blend door

allows control of the heater output air temperature

by controlling how much of the air flowing through

the HVAC housing is directed through the heater

core. The blower motor speed controls the volume of

air flowing through the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

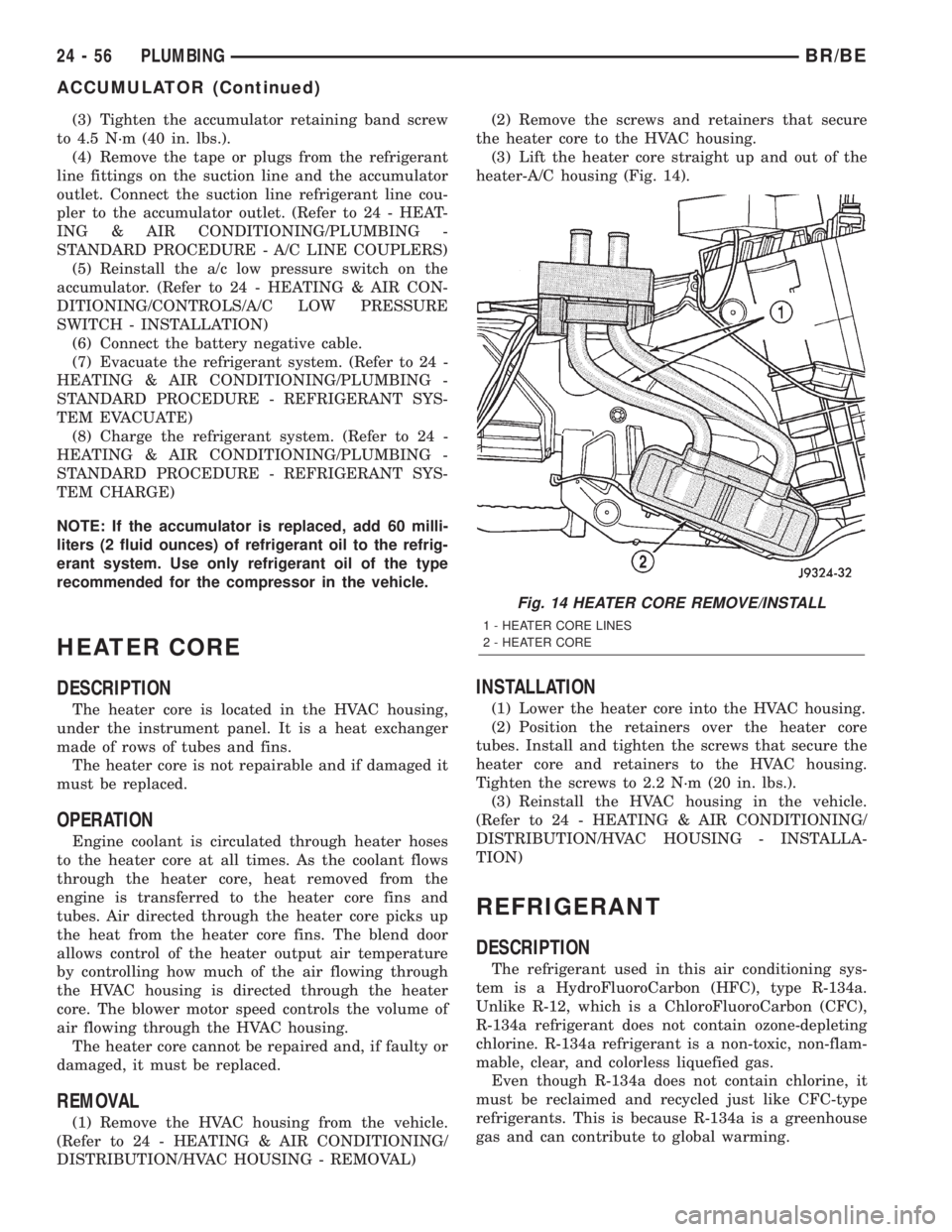

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)(2) Remove the screws and retainers that secure

the heater core to the HVAC housing.

(3) Lift the heater core straight up and out of the

heater-A/C housing (Fig. 14).

INSTALLATION

(1) Lower the heater core into the HVAC housing.

(2) Position the retainers over the heater core

tubes. Install and tighten the screws that secure the

heater core and retainers to the HVAC housing.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Reinstall the HVAC housing in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - INSTALLA-

TION)

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas.

Even though R-134a does not contain chlorine, it

must be reclaimed and recycled just like CFC-type

refrigerants. This is because R-134a is a greenhouse

gas and can contribute to global warming.

Fig. 14 HEATER CORE REMOVE/INSTALL

1 - HEATER CORE LINES

2 - HEATER CORE

24 - 56 PLUMBINGBR/BE

ACCUMULATOR (Continued)

Page 2178 of 2255

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 added to an R-134a refrigerant

system will cause compressor failure, refrigerant oil

sludge or poor air conditioning system performance.

In addition, the PolyAlkylene Glycol (PAG) synthetic

refrigerant oils used in an R-134a refrigerant system

are not compatible with the mineral-based refriger-

ant oils used in an R-12 refrigerant system.

R-134a refrigerant system service ports, service

tool couplers and refrigerant dispensing bottles have

all been designed with unique fittings to ensure that

an R-134a system is not accidentally contaminated

with the wrong refrigerant (R-12). There are also

labels posted in the engine compartment of the vehi-

cle and on the compressor identifying to service tech-

nicians that the air conditioning system is equipped

with R-134a.

REFRIGERANT OIL

DESCRIPTION

The refrigerant oil used in R-134a refrigerant sys-

tems is a synthetic-based, PolyAlkylene Glycol (PAG),

wax-free lubricant. Mineral-based R-12 refrigerant

oils are not compatible with PAG oils, and should

never be introduced to an R-134a refrigerant system.

There are different PAG oils available, and each

contains a different additive package. The SD7H15

compressor used in this vehicle is designed to use an

SP-20 PAG refrigerant oil. Use only refrigerant oil of

this same type to service the refrigerant system.

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.

PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

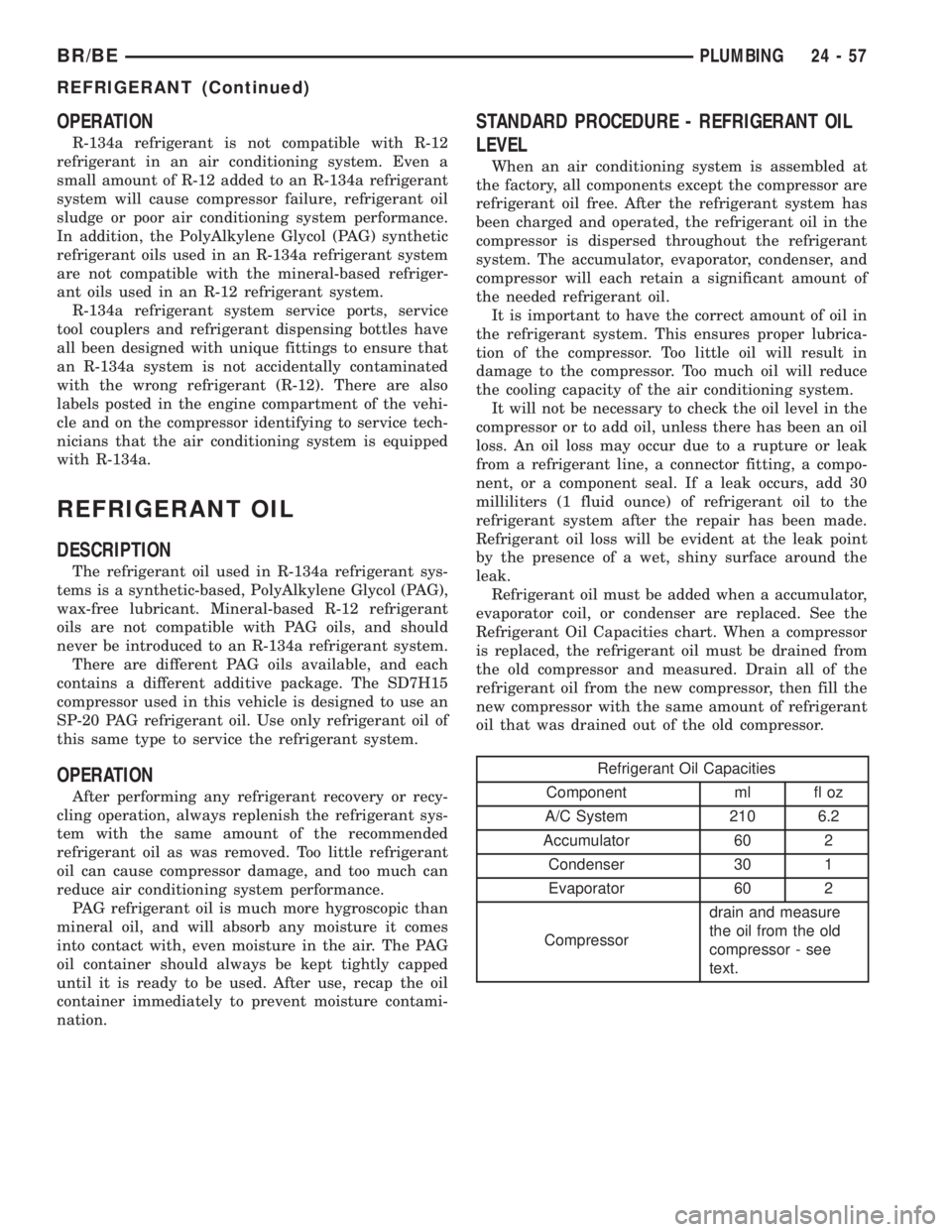

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system has

been charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The accumulator, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrica-

tion of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a compo-

nent, or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.

Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when a accumulator,

evaporator coil, or condenser are replaced. See the

Refrigerant Oil Capacities chart. When a compressor

is replaced, the refrigerant oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of refrigerant

oil that was drained out of the old compressor.

Refrigerant Oil Capacities

Component ml fl oz

A/C System 210 6.2

Accumulator 60 2

Condenser 30 1

Evaporator 60 2

Compressordrain and measure

the oil from the old

compressor - see

text.

BR/BEPLUMBING 24 - 57

REFRIGERANT (Continued)