service DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 34 of 2255

SPECIAL TOOLS

INDEPENDENT FRONT SUSPENSION

HUB / BEARING

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the caliper adapter bolts from the

steering knuckle and remove caliper adapter assem-

bly (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/DISC BRAKE CALIPERS - REMOVAL).

NOTE: Do not allow brake hose to support caliper

adapter assembly.

(4) Remove the rotor from the hub/bearing wheel

studs.

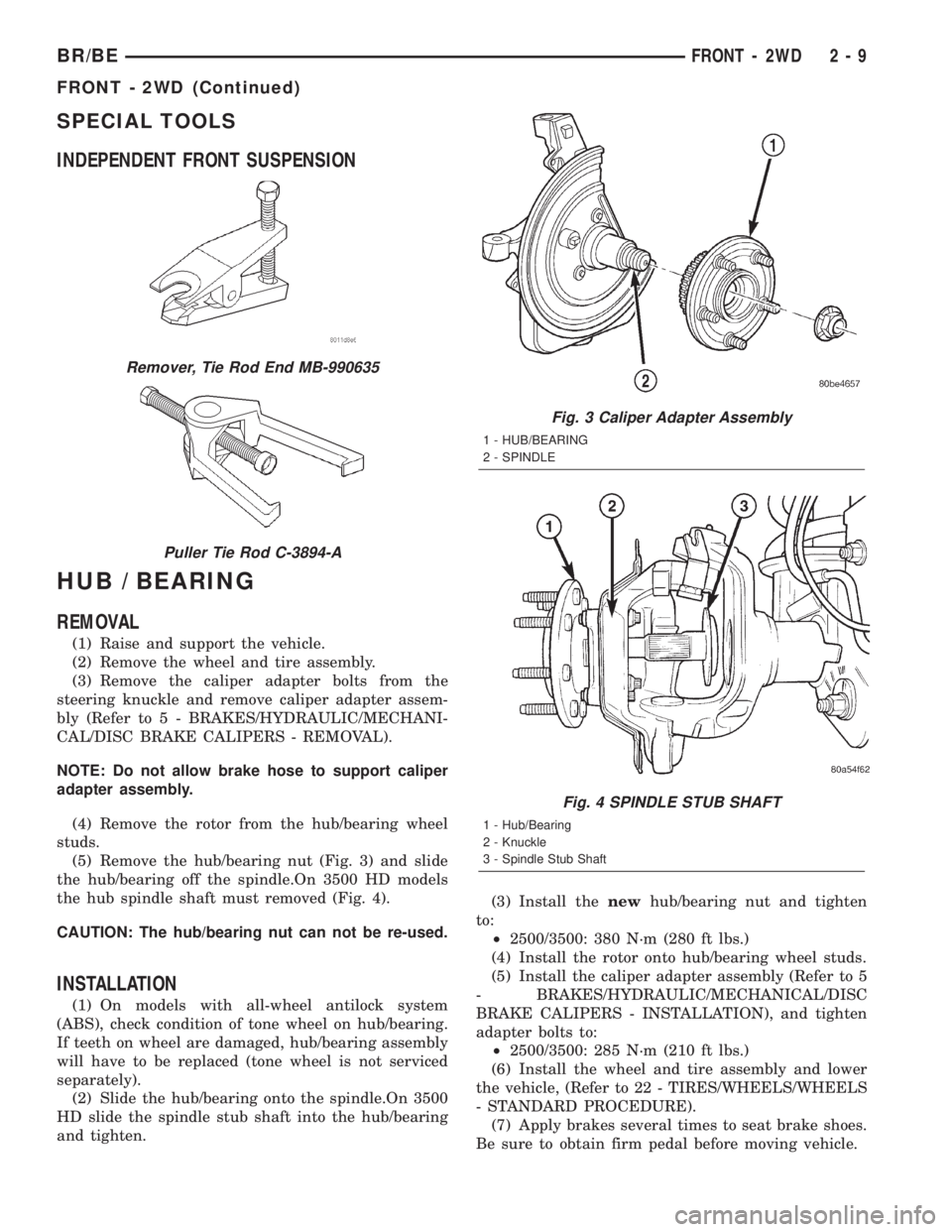

(5) Remove the hub/bearing nut (Fig. 3) and slide

the hub/bearing off the spindle.On 3500 HD models

the hub spindle shaft must removed (Fig. 4).

CAUTION: The hub/bearing nut can not be re-used.

INSTALLATION

(1) On models with all-wheel antilock system

(ABS), check condition of tone wheel on hub/bearing.

If teeth on wheel are damaged, hub/bearing assembly

will have to be replaced (tone wheel is not serviced

separately).

(2) Slide the hub/bearing onto the spindle.On 3500

HD slide the spindle stub shaft into the hub/bearing

and tighten.(3) Install thenewhub/bearing nut and tighten

to:

²2500/3500: 380 N´m (280 ft lbs.)

(4) Install the rotor onto hub/bearing wheel studs.

(5) Install the caliper adapter assembly (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION), and tighten

adapter bolts to:

²2500/3500: 285 N´m (210 ft lbs.)

(6) Install the wheel and tire assembly and lower

the vehicle, (Refer to 22 - TIRES/WHEELS/WHEELS

- STANDARD PROCEDURE).

(7) Apply brakes several times to seat brake shoes.

Be sure to obtain firm pedal before moving vehicle.

Remover, Tie Rod End MB-990635

Puller Tie Rod C-3894-A

Fig. 3 Caliper Adapter Assembly

1 - HUB/BEARING

2 - SPINDLE

Fig. 4 SPINDLE STUB SHAFT

1 - Hub/Bearing

2 - Knuckle

3 - Spindle Stub Shaft

BR/BEFRONT - 2WD 2 - 9

FRONT - 2WD (Continued)

Page 63 of 2255

CENTER BEARING

REMOVAL

(1) Remove rear propeller shaft.

(2) Remove slip joint boot clamp and separate the

two half-shafts.

(3) Use hammer and punch to tap slinger away

from shaft to provide room for bearing splitter.

(4) Position Bearing Splitter Tool 1130 between

slinger and shaft.

CAUTION: Do not damage shaft spline during

removal of center bearing.

(5)

Set shaft in press and press bearing off the shaft.

INSTALLATION

NOTE: Two types of center bearings are used and

are not interchangeable. Install the same type as

the vehicle was built with.

(1) Install new slinger on shaft and drive into posi-

tion with appropriate installer tool.

(2) Install new center bearing on shaft with Bear-

ing Installer Tool 6052. Drive on shaft with hammer

until bearing is seated.

(3) Clean shaft splines and apply a coat of multi-

purpose grease.

(4) Align master splines and slide front and rear

half-shafts together. Reposition slip yoke boot and

install new clamp.

(5) Install propeller shaft in vehicle.

ADJUSTMENTS

ADJUSTMENT - CENTER BEARING

Launch shudder is a vibration that occurs at first

acceleration from a stop. Shudder vibration usually

peaks at the engines highest torque output. Shudder is

a symptom associated with vehicles using a two-piece

propeller shaft. To decrease shudder, lower the center

bearing in 1/8 inch increments. Use shim stock or fab-

ricated plates. Plate stock must be used to maintain

compression of the rubber insulator around the bearing.

Do not use washers. Replace the original bolts with the

appropriate increased length bolts.

SINGLE CARDAN UNIVERSAL

JOINTS

DISASSEMBLY

Individual components of cardan universal joints

are not serviceable. If worn or leaking, they must be

replaced as an assembly.

(1) Remove the propeller shaft.

(2) With a soft drift, tap the outside of the bearing

cap assembly to loosen snap ring.

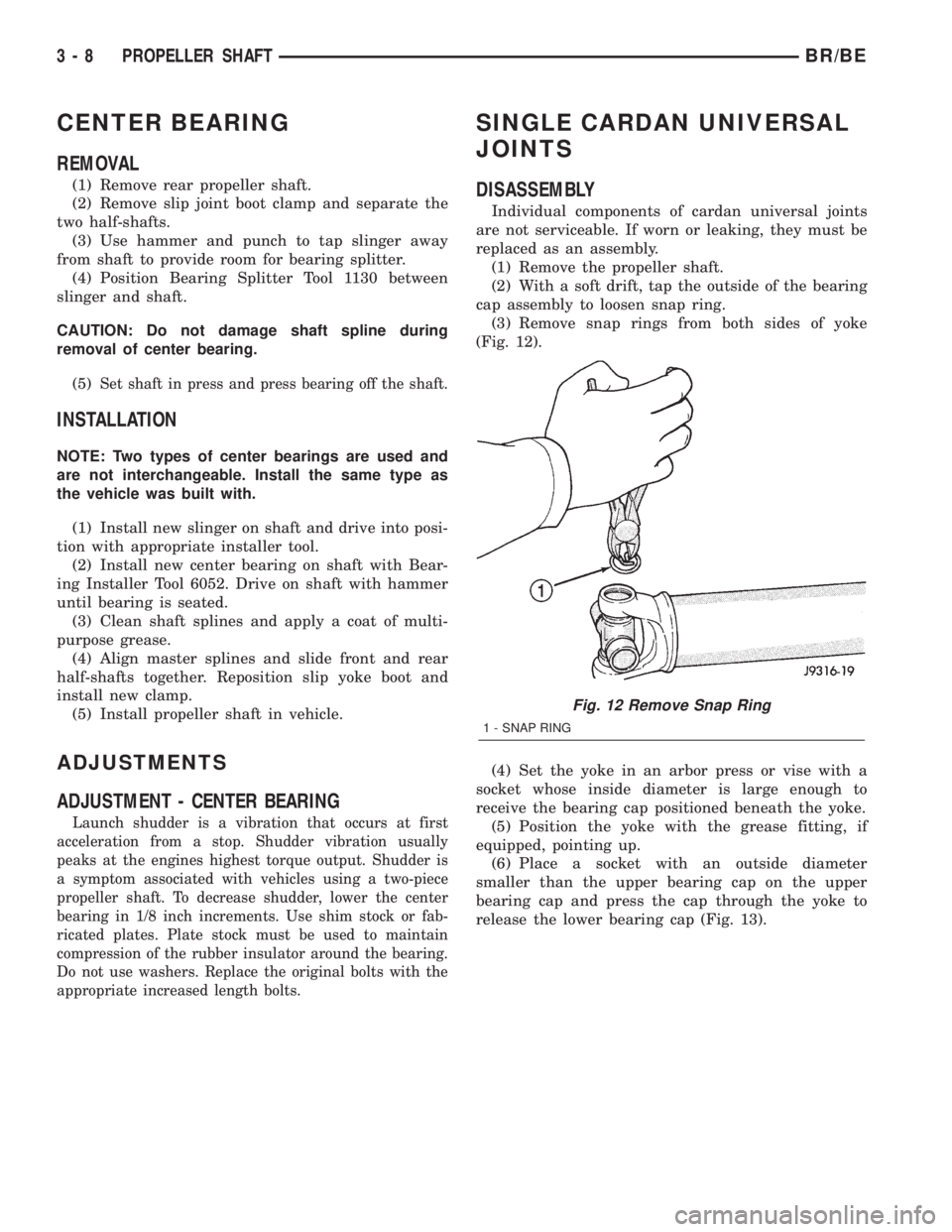

(3) Remove snap rings from both sides of yoke

(Fig. 12).

(4) Set the yoke in an arbor press or vise with a

socket whose inside diameter is large enough to

receive the bearing cap positioned beneath the yoke.

(5) Position the yoke with the grease fitting, if

equipped, pointing up.

(6) Place a socket with an outside diameter

smaller than the upper bearing cap on the upper

bearing cap and press the cap through the yoke to

release the lower bearing cap (Fig. 13).

Fig. 12 Remove Snap Ring

1 - SNAP RING

3 - 8 PROPELLER SHAFTBR/BE

Page 65 of 2255

(3) Place a bearing cap over the trunnion and

align the cap with the yoke bore (Fig. 16). Keep the

needle bearings upright in the bearing assembly.

(4) Press the bearing cap into the yoke bore

enough to install a snap ring.

(5) Install a snap ring.

(6) Repeat Step 3 and Step 4to install the opposite

bearing cap. If the joint is stiff or binding, strike the

yoke with a soft hammer to seat the needle bearings.

(7) Add grease to lube fitting, if equipped.

(8) Install the propeller shaft.

DOUBLE CARDAN UNIVERSAL

JOINTS

DISASSEMBLY

NOTE: Individual components of cardan universal

joints are not serviceable they must be replaced as

an assembly.

(1) Remove the propeller shaft.

(2) Mark the propeller shaft, link yoke and flange

yoke for assembly reference.

(3) Tap the outside of the bearing cap assembly

with drift to loosen snap rings.

(4) Remove all the bearing cap snap rings (Fig.

17).

(5) Remove any grease fittings if equipped.(6) Position a socket on the press with an inside

diameter large enough to receive the bearing cap

under the link yoke.

(7) Place another socket with an outside diameter

smaller than the bearing cap on the upper bearing

cap.

(8) Press one bearing cap from the outboard side of

the link yoke enough to grasp the cap with vise jaws

(Fig. 18).

Fig. 16 Install Bearing On Trunnion

1 - BEARING CAP

2 - TRUNNION

Fig. 17 SNAP RINGS

Fig. 18 PRESS OUT BEARING

3 - 10 PROPELLER SHAFTBR/BE

SINGLE CARDAN UNIVERSAL JOINTS (Continued)

Page 72 of 2255

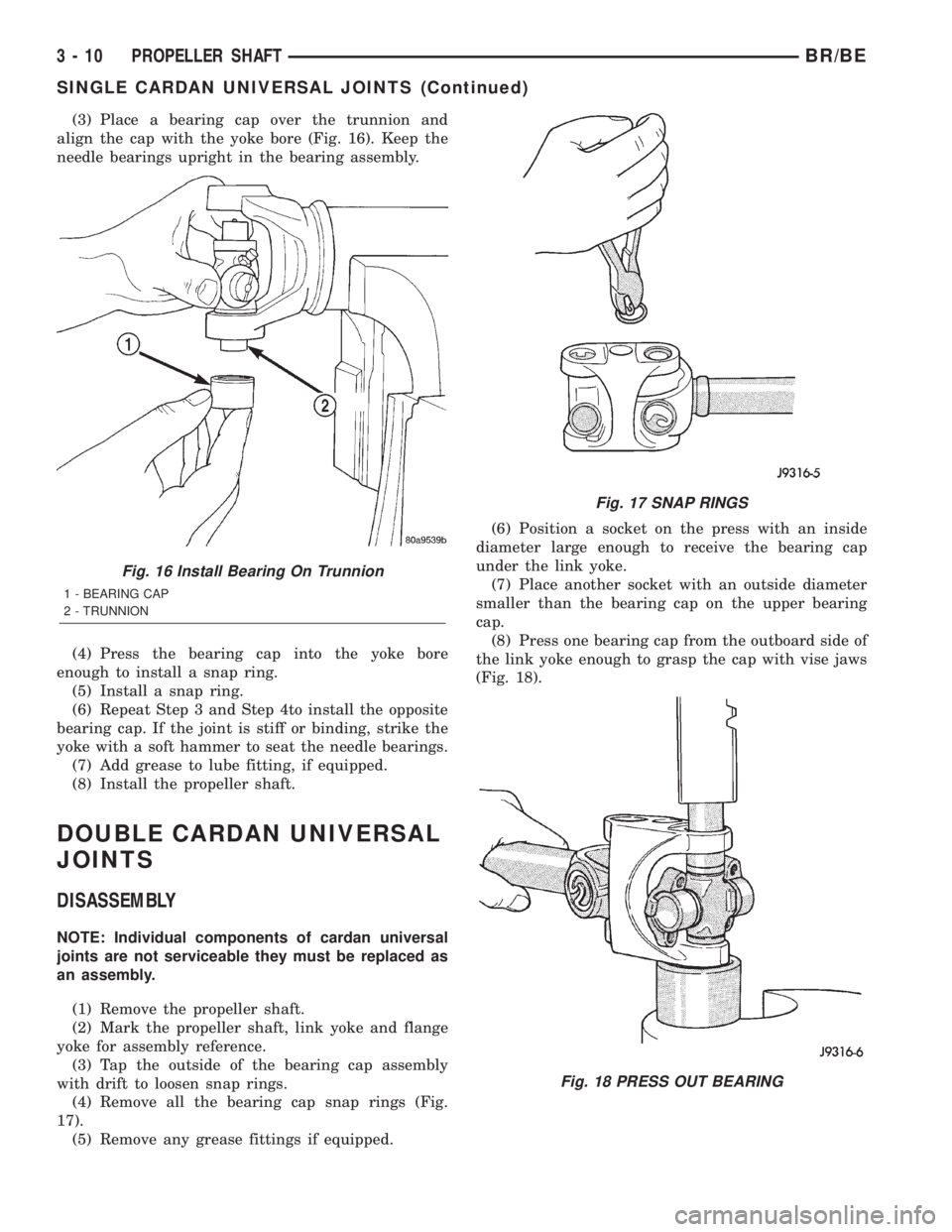

Condition Possible Causes Correction

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

Differential Cracked 1. Improper adjustment of the

differential bearings.1. Replace case and inspect gears

and bearings for further damage.

Set differential bearing pre-load

properly.

2. Excessive ring gear backlash. 2. Replace case and inspect gears

and bearings for further damage.

Set ring gear backlash properly.

3. Vehicle overloaded. 3. Replace case and inspect gears

and bearings for further damage.

Avoid excessive vehicle weight.

4. Erratic clutch operation. 4. Replace case and inspect gears

and bearings for further damage.

Avoid erratic use of clutch.

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

3. Excessive spinning of one

wheel/tire.3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct

level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal

cover.

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct

fluid type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

BR/BEFRONT AXLE - 248FBI 3 - 17

FRONT AXLE - 248FBI (Continued)

Page 76 of 2255

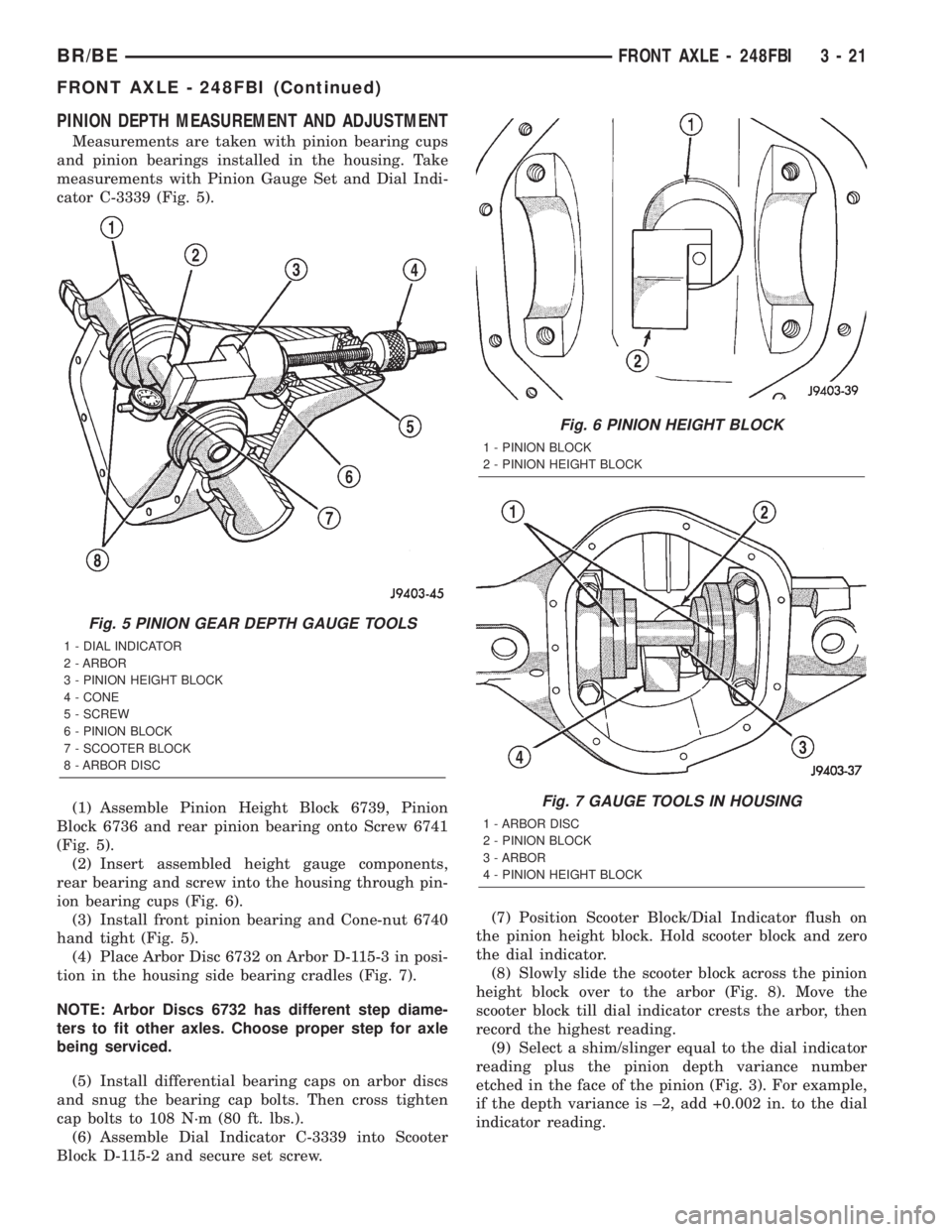

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 5).

(1) Assemble Pinion Height Block 6739, Pinion

Block 6736 and rear pinion bearing onto Screw 6741

(Fig. 5).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 6).

(3) Install front pinion bearing and Cone-nut 6740

hand tight (Fig. 5).

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 7).

NOTE: Arbor Discs 6732 has different step diame-

ters to fit other axles. Choose proper step for axle

being serviced.

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 108 N´m (80 ft. lbs.).

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 8). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

(9) Select a shim/slinger equal to the dial indicator

reading plus the pinion depth variance number

etched in the face of the pinion (Fig. 3). For example,

if the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

Fig. 5 PINION GEAR DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 6 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

Fig. 7 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

BR/BEFRONT AXLE - 248FBI 3 - 21

FRONT AXLE - 248FBI (Continued)

Page 89 of 2255

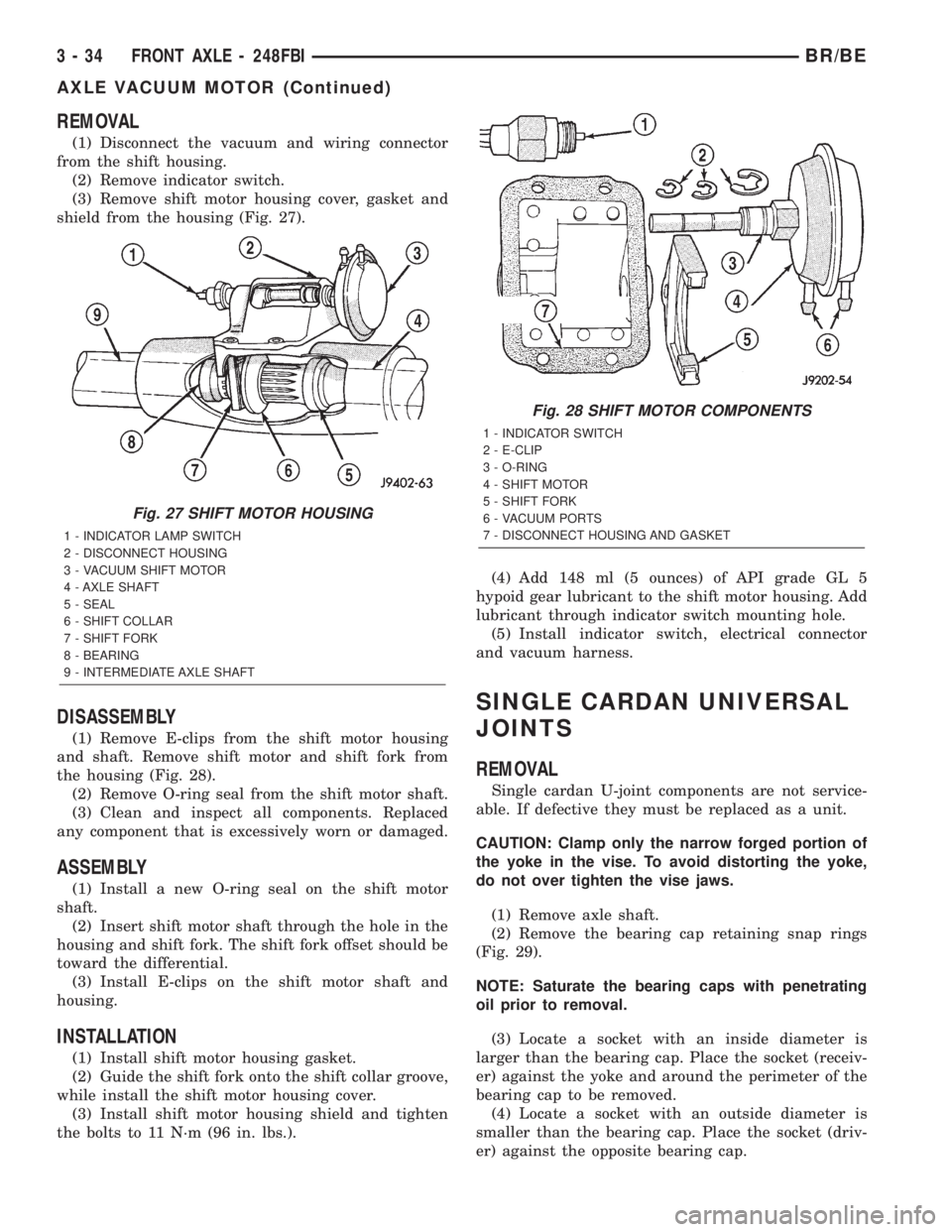

REMOVAL

(1) Disconnect the vacuum and wiring connector

from the shift housing.

(2) Remove indicator switch.

(3) Remove shift motor housing cover, gasket and

shield from the housing (Fig. 27).

DISASSEMBLY

(1) Remove E-clips from the shift motor housing

and shaft. Remove shift motor and shift fork from

the housing (Fig. 28).

(2) Remove O-ring seal from the shift motor shaft.

(3) Clean and inspect all components. Replaced

any component that is excessively worn or damaged.

ASSEMBLY

(1) Install a new O-ring seal on the shift motor

shaft.

(2) Insert shift motor shaft through the hole in the

housing and shift fork. The shift fork offset should be

toward the differential.

(3) Install E-clips on the shift motor shaft and

housing.

INSTALLATION

(1) Install shift motor housing gasket.

(2) Guide the shift fork onto the shift collar groove,

while install the shift motor housing cover.

(3) Install shift motor housing shield and tighten

the bolts to 11 N´m (96 in. lbs.).(4) Add 148 ml (5 ounces) of API grade GL 5

hypoid gear lubricant to the shift motor housing. Add

lubricant through indicator switch mounting hole.

(5) Install indicator switch, electrical connector

and vacuum harness.

SINGLE CARDAN UNIVERSAL

JOINTS

REMOVAL

Single cardan U-joint components are not service-

able. If defective they must be replaced as a unit.

CAUTION: Clamp only the narrow forged portion of

the yoke in the vise. To avoid distorting the yoke,

do not over tighten the vise jaws.

(1) Remove axle shaft.

(2) Remove the bearing cap retaining snap rings

(Fig. 29).

NOTE: Saturate the bearing caps with penetrating

oil prior to removal.

(3) Locate a socket with an inside diameter is

larger than the bearing cap. Place the socket (receiv-

er) against the yoke and around the perimeter of the

bearing cap to be removed.

(4) Locate a socket with an outside diameter is

smaller than the bearing cap. Place the socket (driv-

er) against the opposite bearing cap.

Fig. 27 SHIFT MOTOR HOUSING

1 - INDICATOR LAMP SWITCH

2 - DISCONNECT HOUSING

3 - VACUUM SHIFT MOTOR

4 - AXLE SHAFT

5 - SEAL

6 - SHIFT COLLAR

7 - SHIFT FORK

8 - BEARING

9 - INTERMEDIATE AXLE SHAFT

Fig. 28 SHIFT MOTOR COMPONENTS

1 - INDICATOR SWITCH

2 - E-CLIP

3 - O-RING

4 - SHIFT MOTOR

5 - SHIFT FORK

6 - VACUUM PORTS

7 - DISCONNECT HOUSING AND GASKET

3 - 34 FRONT AXLE - 248FBIBR/BE

AXLE VACUUM MOTOR (Continued)

Page 96 of 2255

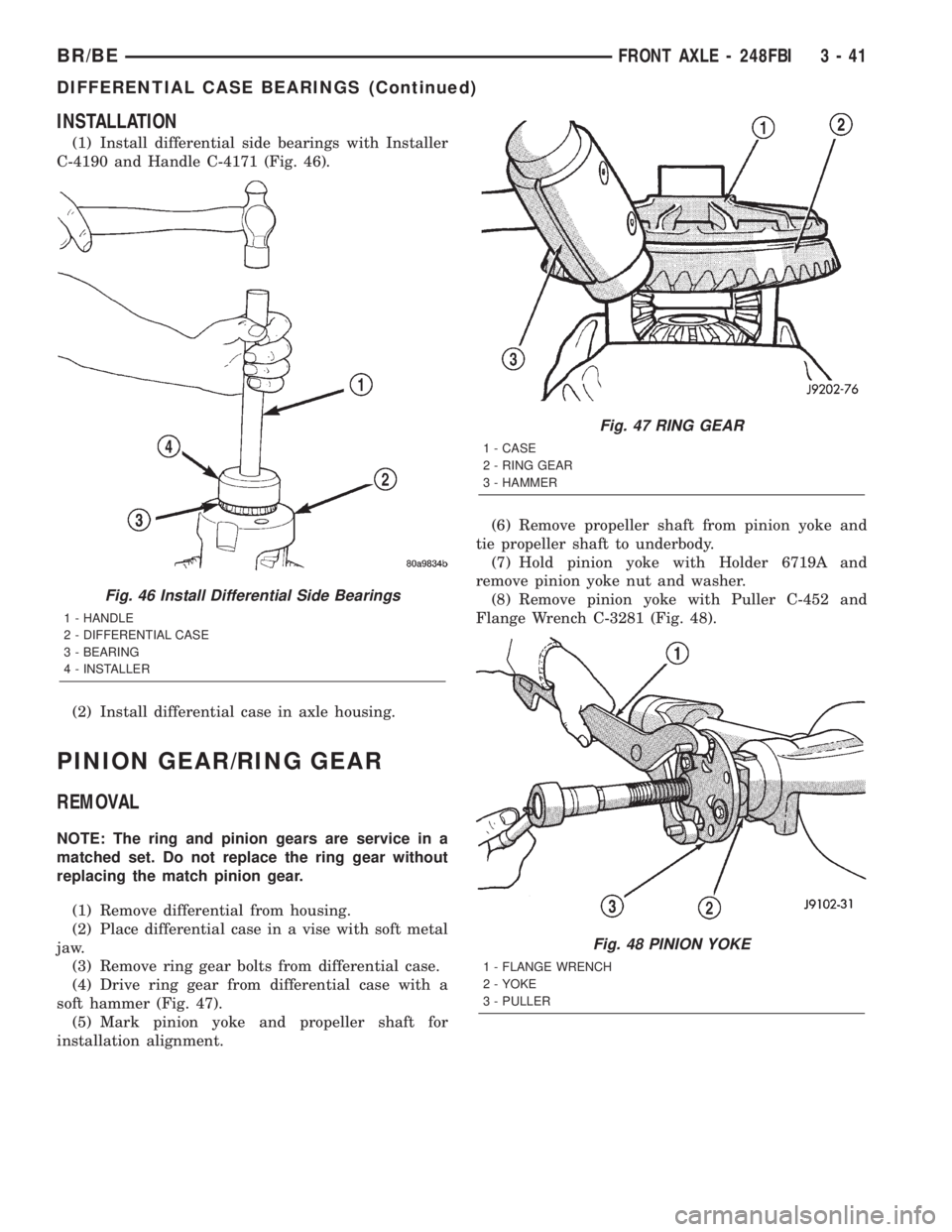

INSTALLATION

(1) Install differential side bearings with Installer

C-4190 and Handle C-4171 (Fig. 46).

(2) Install differential case in axle housing.

PINION GEAR/RING GEAR

REMOVAL

NOTE: The ring and pinion gears are service in a

matched set. Do not replace the ring gear without

replacing the match pinion gear.

(1) Remove differential from housing.

(2) Place differential case in a vise with soft metal

jaw.

(3) Remove ring gear bolts from differential case.

(4) Drive ring gear from differential case with a

soft hammer (Fig. 47).

(5) Mark pinion yoke and propeller shaft for

installation alignment.(6) Remove propeller shaft from pinion yoke and

tie propeller shaft to underbody.

(7) Hold pinion yoke with Holder 6719A and

remove pinion yoke nut and washer.

(8) Remove pinion yoke with Puller C-452 and

Flange Wrench C-3281 (Fig. 48).

Fig. 46 Install Differential Side Bearings

1 - HANDLE

2 - DIFFERENTIAL CASE

3 - BEARING

4 - INSTALLER

Fig. 47 RING GEAR

1 - CASE

2 - RING GEAR

3 - HAMMER

Fig. 48 PINION YOKE

1 - FLANGE WRENCH

2 - YOKE

3 - PULLER

BR/BEFRONT AXLE - 248FBI 3 - 41

DIFFERENTIAL CASE BEARINGS (Continued)

Page 101 of 2255

REAR AXLE - 248RBI

TABLE OF CONTENTS

page page

REAR AXLE - 248RBI

DESCRIPTION.........................46

OPERATION...........................46

DIAGNOSIS AND TESTING - AXLE..........47

REMOVAL.............................51

INSTALLATION.........................51

ADJUSTMENTS........................51

SPECIFICATIONS

REAR AXLE - 248RBI..................59

SPECIAL TOOLS

REAR AXLE - 248RBI..................59

AXLE SHAFTS

REMOVAL.............................62

INSTALLATION.........................62

AXLE BEARINGS

REMOVAL.............................62

INSTALLATION.........................62

PINION SEAL

REMOVAL.............................63INSTALLATION.........................63

DIFFERENTIAL

REMOVAL.............................64

DISASSEMBLY.........................65

ASSEMBLY............................66

INSTALLATION.........................66

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT.....67

DISASSEMBLY.........................68

ASSEMBLY............................70

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................72

INSTALLATION.........................72

PINION GEAR/RING GEAR/TONE RING

REMOVAL.............................73

INSTALLATION.........................75

REAR AXLE - 248RBI

DESCRIPTION

The Rear Beam-design Iron (RBI) axle housings consist

of an iron center casting (differential housing) with axle

shaft tubes extending from either side. The tubes are

pressed into the differential housing and welded. The

axles are equipped with full-floating axle shafts, meaning

that loads are supported by the axle housing tubes.

The differential case for the standard differentials

and the Trac-loktdifferential are a one-piece design.

Differential bearing preload and ring gear backlash

are adjusted by the use of shims located between the

differential bearing cones and case. Pinion bearing

preload is set and maintained by the use of a collaps-

ible spacer. The removable, stamped steel cover pro-

vides a means for inspection and service.

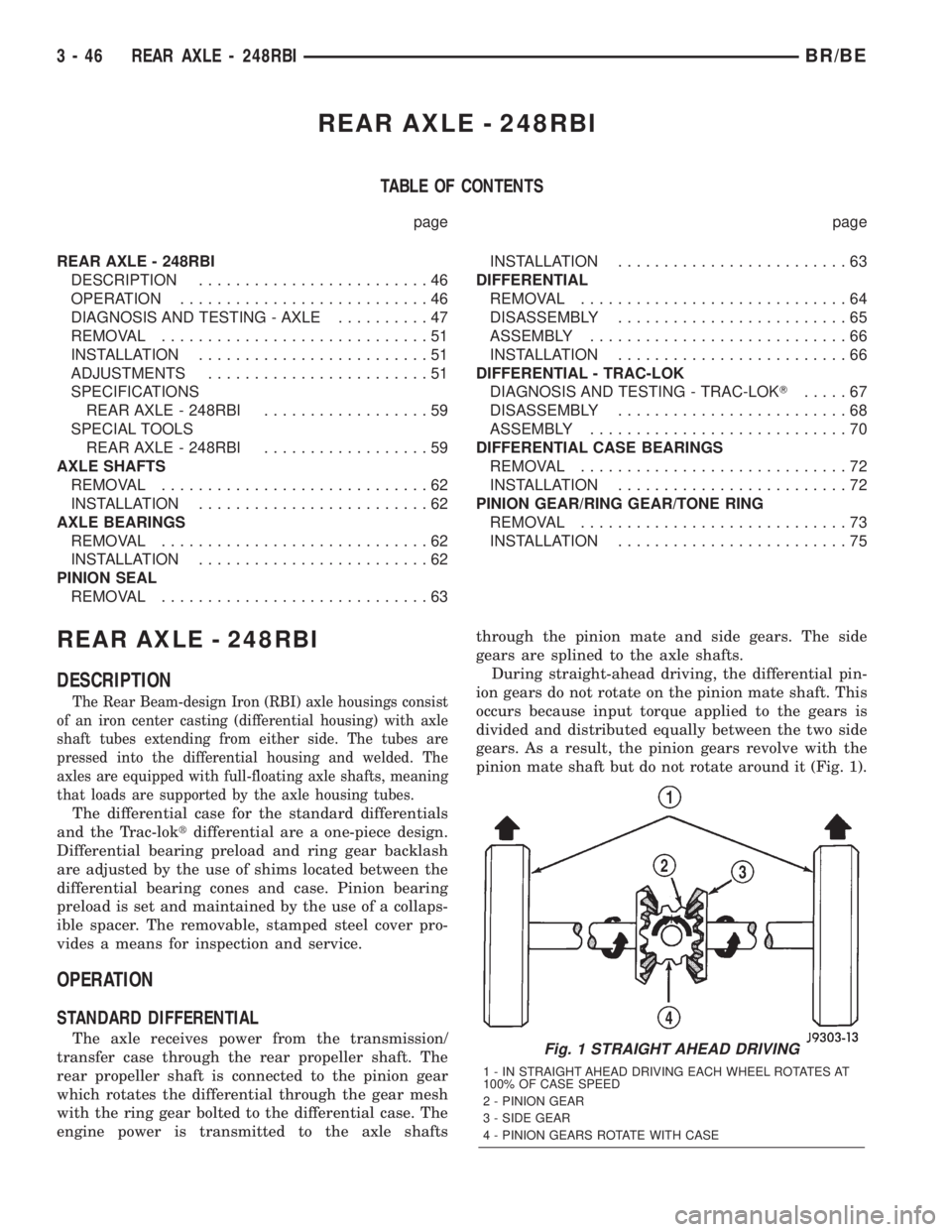

OPERATION

STANDARD DIFFERENTIAL

The axle receives power from the transmission/

transfer case through the rear propeller shaft. The

rear propeller shaft is connected to the pinion gear

which rotates the differential through the gear mesh

with the ring gear bolted to the differential case. The

engine power is transmitted to the axle shaftsthrough the pinion mate and side gears. The side

gears are splined to the axle shafts.

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig. 1).Fig. 1 STRAIGHT AHEAD DRIVING

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

3 - 46 REAR AXLE - 248RBIBR/BE

Page 104 of 2255

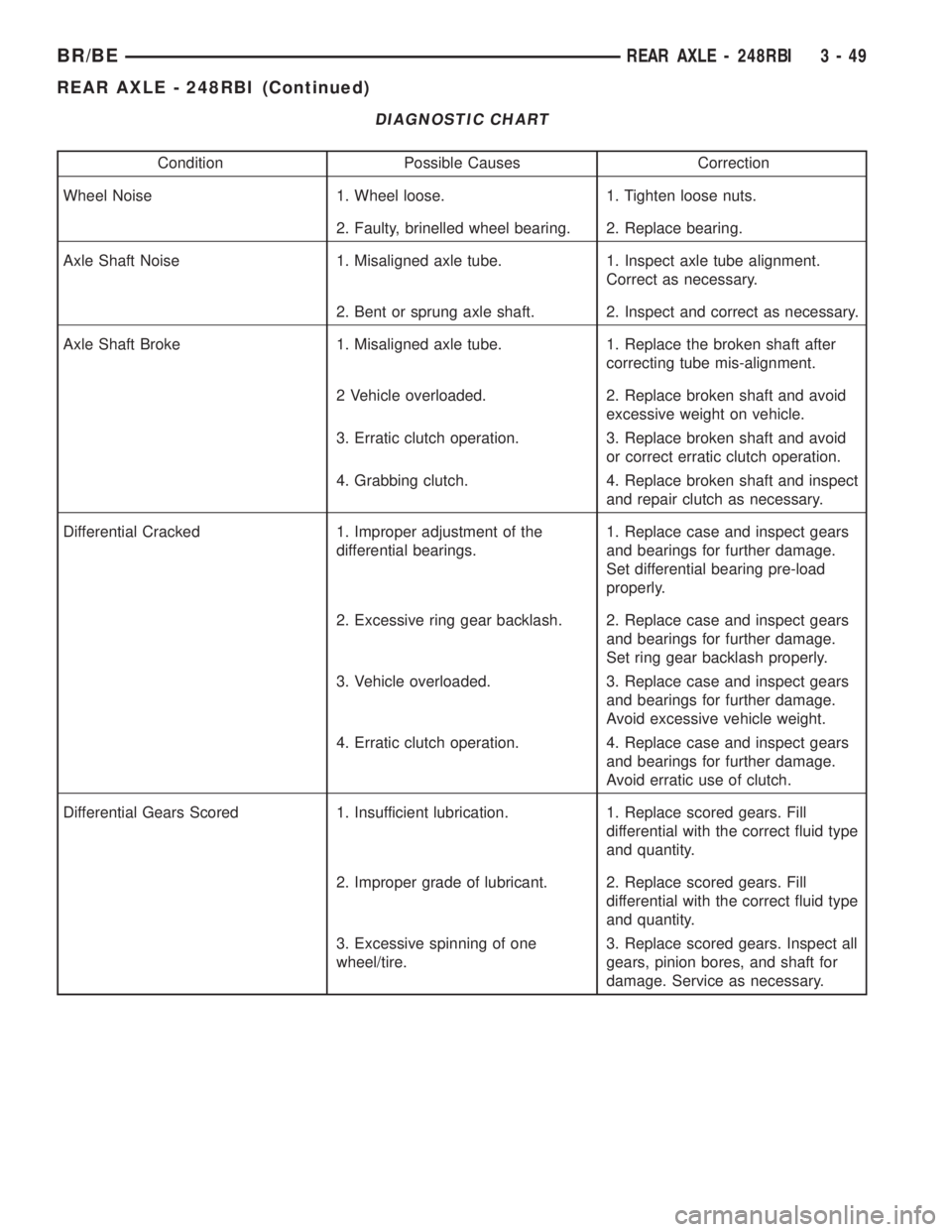

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

Differential Cracked 1. Improper adjustment of the

differential bearings.1. Replace case and inspect gears

and bearings for further damage.

Set differential bearing pre-load

properly.

2. Excessive ring gear backlash. 2. Replace case and inspect gears

and bearings for further damage.

Set ring gear backlash properly.

3. Vehicle overloaded. 3. Replace case and inspect gears

and bearings for further damage.

Avoid excessive vehicle weight.

4. Erratic clutch operation. 4. Replace case and inspect gears

and bearings for further damage.

Avoid erratic use of clutch.

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

3. Excessive spinning of one

wheel/tire.3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

BR/BEREAR AXLE - 248RBI 3 - 49

REAR AXLE - 248RBI (Continued)

Page 107 of 2255

Note the etched number on the face of the pinion

gear head (±1, ±2, 0, +1, +2, etc.). The numbers rep-

resent thousands of an inch deviation from the stan-

dard. If the number is negative, add that value to therequired thickness of the depth shims. If the number

is positive, subtract that value from the thickness of

the depth shim. If the number is 0 no change is nec-

essary.

PINION GEAR DEPTH VARIANCE

Original Pinion

Gear Depth

VarianceReplacement Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

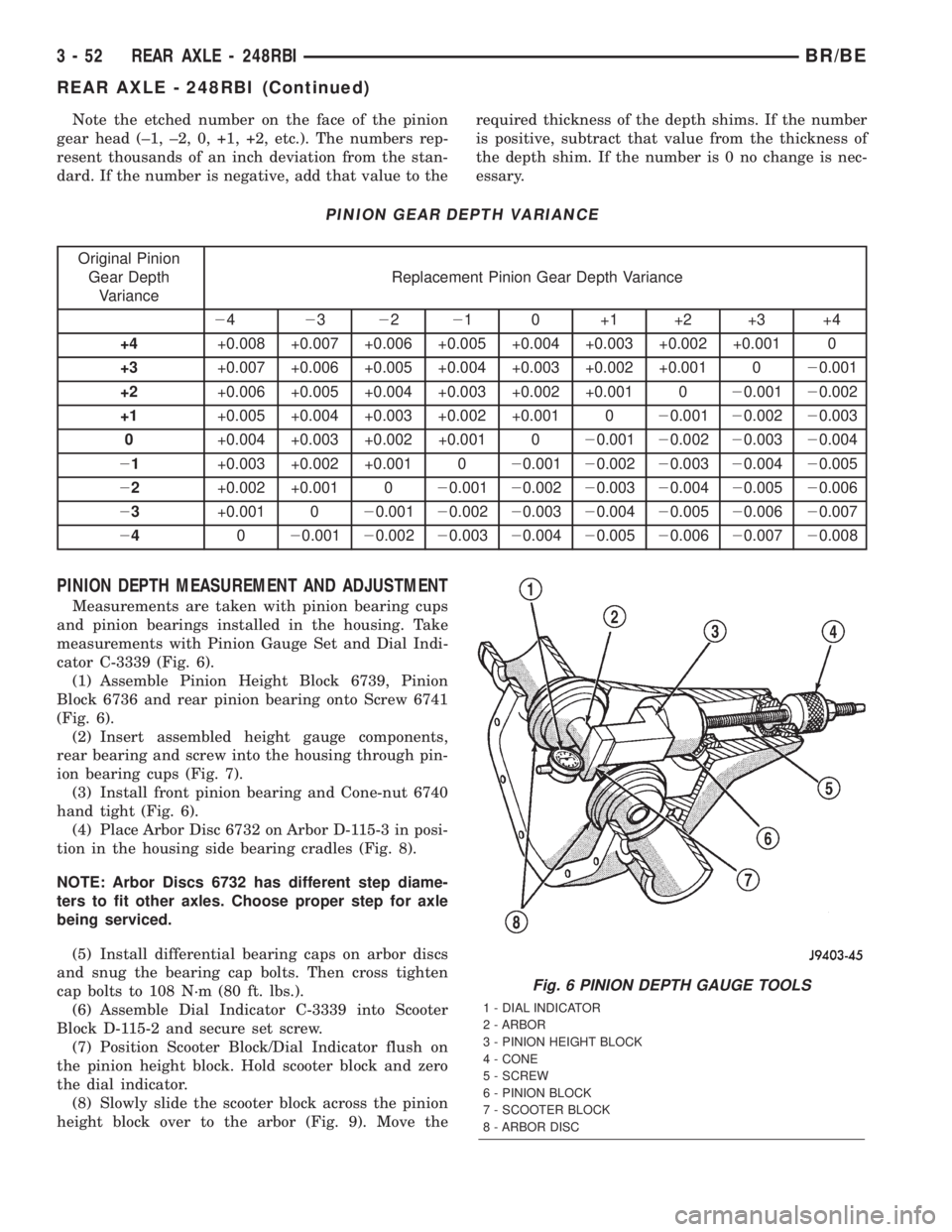

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 6).

(1) Assemble Pinion Height Block 6739, Pinion

Block 6736 and rear pinion bearing onto Screw 6741

(Fig. 6).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 7).

(3) Install front pinion bearing and Cone-nut 6740

hand tight (Fig. 6).

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 8).

NOTE: Arbor Discs 6732 has different step diame-

ters to fit other axles. Choose proper step for axle

being serviced.

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 108 N´m (80 ft. lbs.).

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 9). Move the

Fig. 6 PINION DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

3 - 52 REAR AXLE - 248RBIBR/BE

REAR AXLE - 248RBI (Continued)