4WD DODGE RAM 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 936 of 2255

8W-80 CONNECTOR PIN-OUTS

Component Page

4WD Switch........................ 8W-80-4

A/C Compressor Clutch................ 8W-80-4

A/C Heater Control................... 8W-80-4

A/C Heater Temperature Select......... 8W-80-4

A/C High Pressure Switch............. 8W-80-4

A/C Low Pressure Switch.............. 8W-80-5

Accelerator Pedal Position Sensor

(Diesel).......................... 8W-80-5

Aftermarket Trailer Tow Connector...... 8W-80-5

Airbag Control Module................ 8W-80-5

Ambient Temperature Sensor........... 8W-80-6

Ash Receiver Lamp................... 8W-80-6

Automatic Day/Night Mirror............ 8W-80-6

Back-Up Lamp Switch (M/T)........... 8W-80-6

Battery Temperature Sensor............ 8W-80-7

Blend Door Actuator.................. 8W-80-7

Blower Motor....................... 8W-80-7

Blower Motor Resistor Block............ 8W-80-7

Brake Lamp Switch.................. 8W-80-7

Brake Pressure Switch................ 8W-80-8

Bypass Jumper (A/T)................. 8W-80-8

C105.............................. 8W-80-8

C105.............................. 8W-80-8

C106.............................. 8W-80-8

C106.............................. 8W-80-8

C114 .............................. 8W-80-9

C114 .............................. 8W-80-9

C125 (Diesel)....................... 8W-80-9

C125 (Diesel)....................... 8W-80-9

C126 (Diesel)....................... 8W-80-10

C126 (Diesel)....................... 8W-80-10

C129............................. 8W-80-10

C129............................. 8W-80-11

C130 (Diesel)....................... 8W-80-11

C130 (Diesel) (In PDC)............... 8W-80-12

C130 (Gas)........................ 8W-80-13

C130 (Gas) (In PDC)................. 8W-80-14

C134............................. 8W-80-15

C134............................. 8W-80-17

C203............................. 8W-80-18

C203............................. 8W-80-19

C205............................. 8W-80-20

C205............................. 8W-80-20

C206 (Heated Seats)................. 8W-80-20

C206 (Heated Seats)................. 8W-80-21

C237............................. 8W-80-21

C237............................. 8W-80-21

C303............................. 8W-80-22

C303............................. 8W-80-22

C308............................. 8W-80-22

C308............................. 8W-80-22

C329 (Club Cab).................... 8W-80-22Component Page

C329 (Club Cab).................... 8W-80-23

C329 (Standard Cab)................ 8W-80-23

C329 (Standard Cab)................ 8W-80-23

C333 (Club Cab).................... 8W-80-23

C333 (Club Cab).................... 8W-80-23

C333 (Standard Cab)................ 8W-80-24

C333 (Standard Cab)................ 8W-80-24

C342............................. 8W-80-24

C342............................. 8W-80-24

C343............................. 8W-80-24

C343............................. 8W-80-24

C344 (Dual Rear Wheels)............. 8W-80-25

C344 (Dual Rear Wheels)............. 8W-80-25

C345............................. 8W-80-25

C345............................. 8W-80-25

C346............................. 8W-80-26

C346............................. 8W-80-26

C347............................. 8W-80-26

C347............................. 8W-80-27

C348............................. 8W-80-27

C348............................. 8W-80-28

C352............................. 8W-80-28

C352............................. 8W-80-28

C353............................. 8W-80-28

C353............................. 8W-80-28

C358............................. 8W-80-29

C358............................. 8W-80-29

C359 (Heated Seat).................. 8W-80-29

C359 (Heated Seat).................. 8W-80-29

C360 (Club Cab).................... 8W-80-30

C360 (Club Cab).................... 8W-80-30

C361............................. 8W-80-30

C361............................. 8W-80-30

C364............................. 8W-80-31

C364............................. 8W-80-31

C365 (Heated Seat).................. 8W-80-31

C365 (Heated Seat).................. 8W-80-31

Camshaft Position Sensor (8.0L Gas).... 8W-80-32

Camshaft Position Sensor (Diesel)...... 8W-80-32

Camshaft Position Sensor

(Gas Except 8.0L)................. 8W-80-32

Cargo Lamp No. 1................... 8W-80-32

Cargo Lamp No. 2................... 8W-80-32

Center High Mounted Stop Lamp No. 1 . . 8W-80-33

Center High Mounted Stop Lamp No. 2 . . 8W-80-33

Center Identification Lamp............ 8W-80-33

Central Timer Module C1............. 8W-80-33

Central Timer Module C2............. 8W-80-34

Cigar Lighter...................... 8W-80-34

Clockspring C1..................... 8W-80-34

Clockspring C2..................... 8W-80-34

Clockspring C3..................... 8W-80-35

BR/BE8W-80 CONNECTOR PIN-OUTS 8W - 80 - 1

Page 939 of 2255

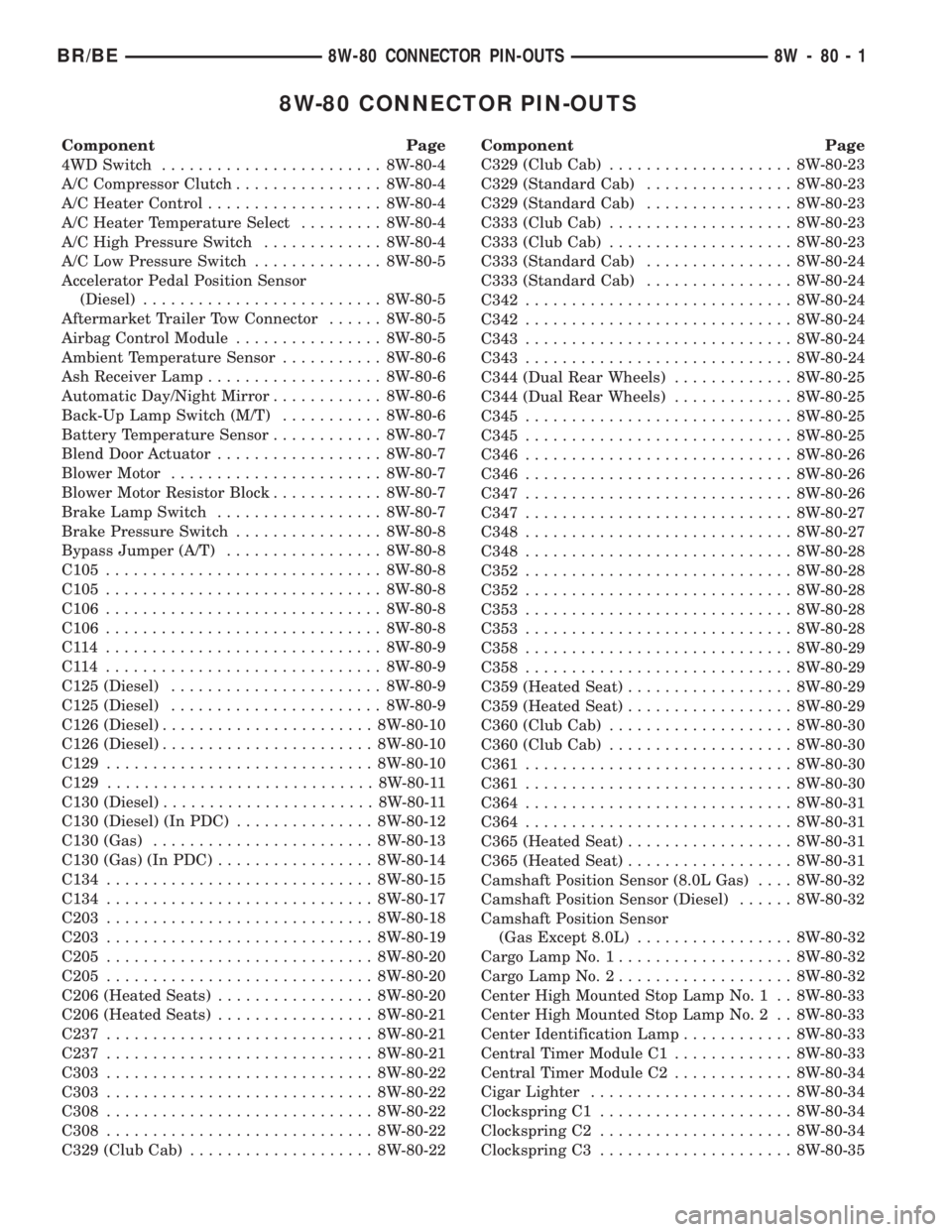

4WD SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 G107 18BK/GY 4WD SWITCH SENSE

2 Z1 18BK GROUND

A/C COMPRESSOR CLUTCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 C3 18DB/BK A/C COMPRESSOR CLUTCH RELAY OUTPUT

2 Z11 18BK/WT GROUND

A/C-HEATER CONTROL - BLACK 7 WAY

CAV CIRCUIT FUNCTION

1 Z3 12BK/OR GROUND

2 C7 12BK/TN HIGH SPEED BLOWER MOTOR CONTROL

3 C6 14LB M2 SPEED BLOWER MOTOR CONTROL

4 C5 16LG M1 SPEED BLOWER MOTOR CONTROL

5 C4 16TN LOW SPEED BLOWER MOTOR CONTROL

6 C90 22LG/WT A/C SELECT INPUT

7 E2 22OR PANEL LAMPS FEED

A/C HEATER TEMPERATURE SELECT-5WAY

CAV CIRCUIT FUNCTION

1- -

2 Z2 22BK/LG GROUND

3 C82 22YL/OR TEMPERATURE SELECT

4 F15 22DB FUSED IGNITION SWITCH OUTPUT (RUN)

5- -

A/C HIGH PRESSURE SWITCH-2WAY

CAV CIRCUIT FUNCTION

1 C90 18LG/WT A/C SELECT INPUT

2 C22 18DB A/C SWITCH SENSE

8W - 80 - 4 8W-80 CONNECTOR PIN-OUTSBR/BE

Page 970 of 2255

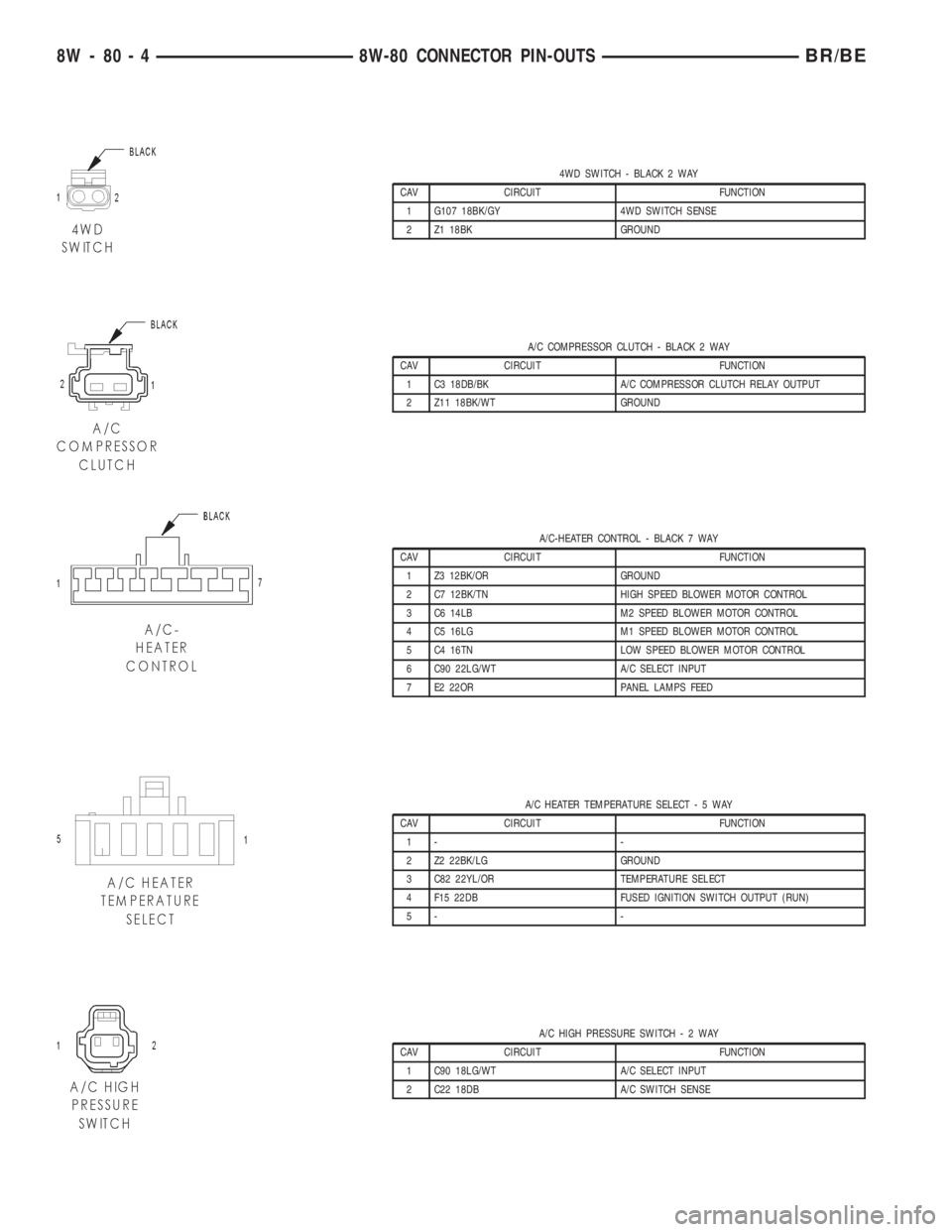

CLOCKSPRING C3-4WAY

CAV CIRCUIT FUNCTION

A V37 22DG/RD SPEED CONTROL SWITCH SIGNAL

B Z2 22BK/LG GROUND

D X20 22RD/BK RADIO CONTROL MUX

C K4 22WT SENSOR GROUND

CLUTCH PEDAL POSITION SWITCH (M/T) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 A41 14YL FUSED IGNITION SWITCH OUTPUT (START)

2 T141 14YL/RD CLUTCH PEDAL POSITION SWITCH OUTPUT

CONTROLLER ANTILOCK BRAKE C1 - BLACK 14 WAY

CAV CIRCUIT FUNCTION

1 B113 20RD/VT REAR WHEEL SPEED SENSOR (+)

2 G107 20GY 4WD SWITCH SENSE

3 D1 20VT/BR CCD BUS (+)

4 A20 20RD/DB FUSED IGNITION SWITCH OUTPUT (RUN)

5- -

6 Z8 14BK/VT GROUND

7 A10 14RD/DG FUSED B(+)

8 B114 20WT/VT REAR WHEEL SPEED SENSOR (-)

9 V40 20WT/PK BRAKE SWITCH SENSE

10 D2 20WT/BK CCD BUS (-)

11 G9 20GY/BK BRAKE PRESSURE SWITCH SENSE

12 G7 20WT/OR VEHICLE SPEED SENSOR SIGNAL

13 Z8 14BK/VT GROUND

14 A10 14RD/DG FUSED B(+)

CONTROLLER ANTILOCK BRAKE C2 (ABS) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 B9 20RD LEFT FRONT WHEEL SPEED SENSOR (+)

2 B8 20RD/GY LEFT FRONT WHEEL SPEED SENSOR (-)

3 B6 20WT/DB RIGHT FRONT WHEEL SPEED SENSOR (-)

4 B7 20WT RIGHT FRONT WHEEL SPEED SENSOR (+)

BR/BE8W-80 CONNECTOR PIN-OUTS 8W - 80 - 35

Page 985 of 2255

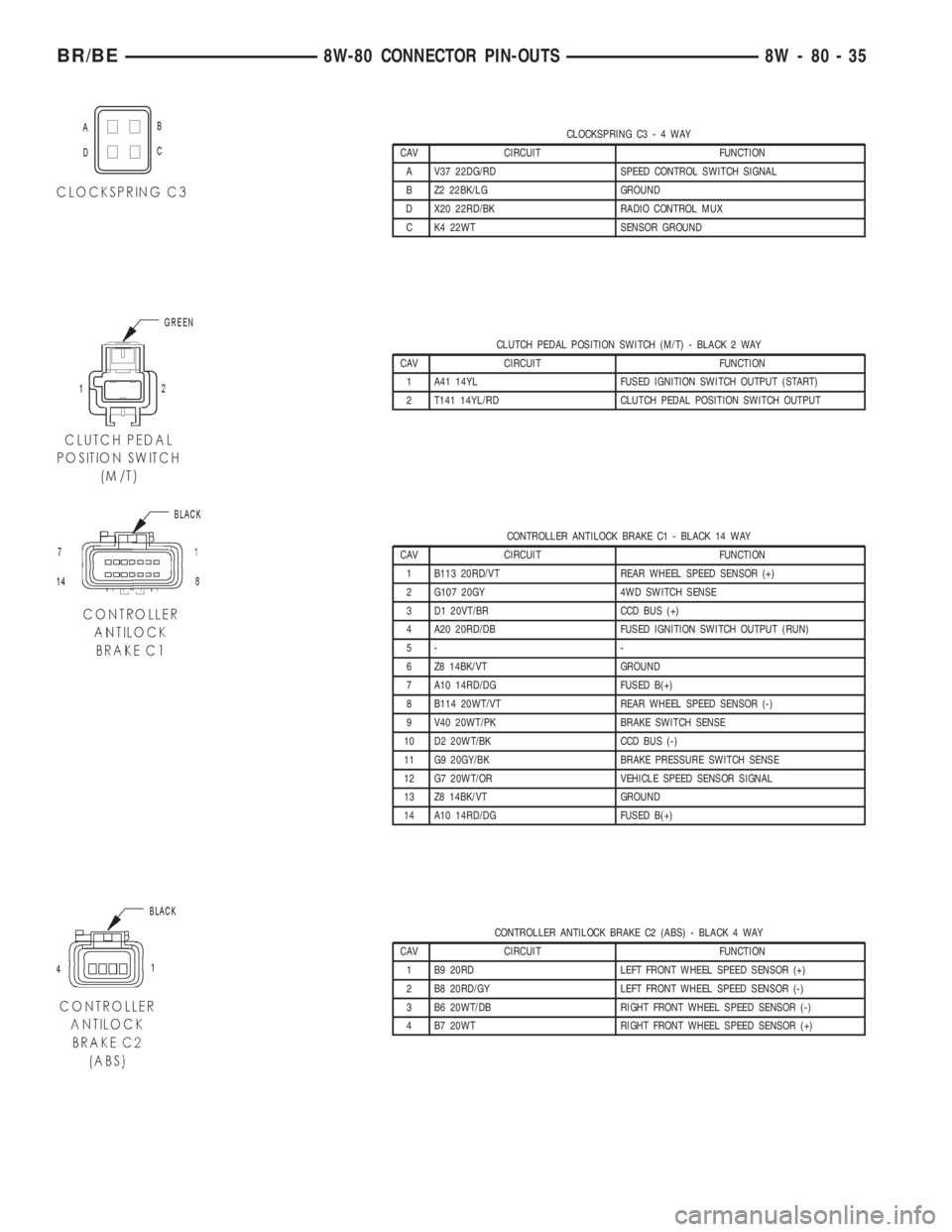

INSTRUMENT CLUSTER C2 - 10 WAY

CAV CIRCUIT FUNCTION

1 E2 22OR PANEL LAMPS FEED

2 G29 22BK/WT WASHER FLUID SWITCH SENSE

3 G10 22LG/RD SEAT BELT SWITCH SENSE

4- -

5 E17 18YL/BK DAY BRIGHTNESS SENSE

6 L61 18LG LEFT TURN SIGNAL

7 G13 22DB/RD CHIME REQUEST SIGNAL

8 L60 18TN RIGHT TURN SIGNAL

9 G34 16RD/GY HIGH BEAM INDICATOR DRIVER

10 G107 22GY 4WD SWITCH SENSE

INTAKE AIR HEATER RELAYS (DIESEL)-4WAY

CAV CIRCUIT FUNCTION

1 S22 18OR/BK AIR INTAKE HEATER RELAY CONTROL NO. 2

2 Z12 18BK/TN GROUND

3 S21 18YL/BK AIR INTAKE HEATER RELAY CONTROL NO. 1

4 Z12 18BK/TN GROUND

INTAKE AIR TEMPERATURE SENSOR (DIESEL)-2WAY

CAV CIRCUIT FUNCTION

A K104 18BK/LB SENSOR GROUND

B K21 18BK/RD INTAKE AIR TEMPERATURE SENSOR SIGNAL

INTAKE AIR TEMPERATURE SENSOR (GAS) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 K4 18BK/LB SENSOR GROUND

2 K21 18BK/RD INTAKE AIR TEMPERATURE SENSOR SIGNAL

JOINT CONNECTOR NO. 1 (IN PDC) - 28 WAY

CAV CIRCUIT FUNCTION

1 V40 20WT/PK BRAKE SWITCH SENSE

2 V40 22WT/PK BRAKE SWITCH SENSE

3 V40 22WT/PK BRAKE SWITCH SENSE

4 L4 18VT/WT DIMMER SWITCH LOW BEAM OUTPUT

5 L4 16VT/WT DIMMER SWITCH LOW BEAM OUTPUT

5 L4 16VT/WT(QUAD) DIMMER SWITCH LOW BEAM OUTPUT

8W - 80 - 50 8W-80 CONNECTOR PIN-OUTSBR/BE

Page 1018 of 2255

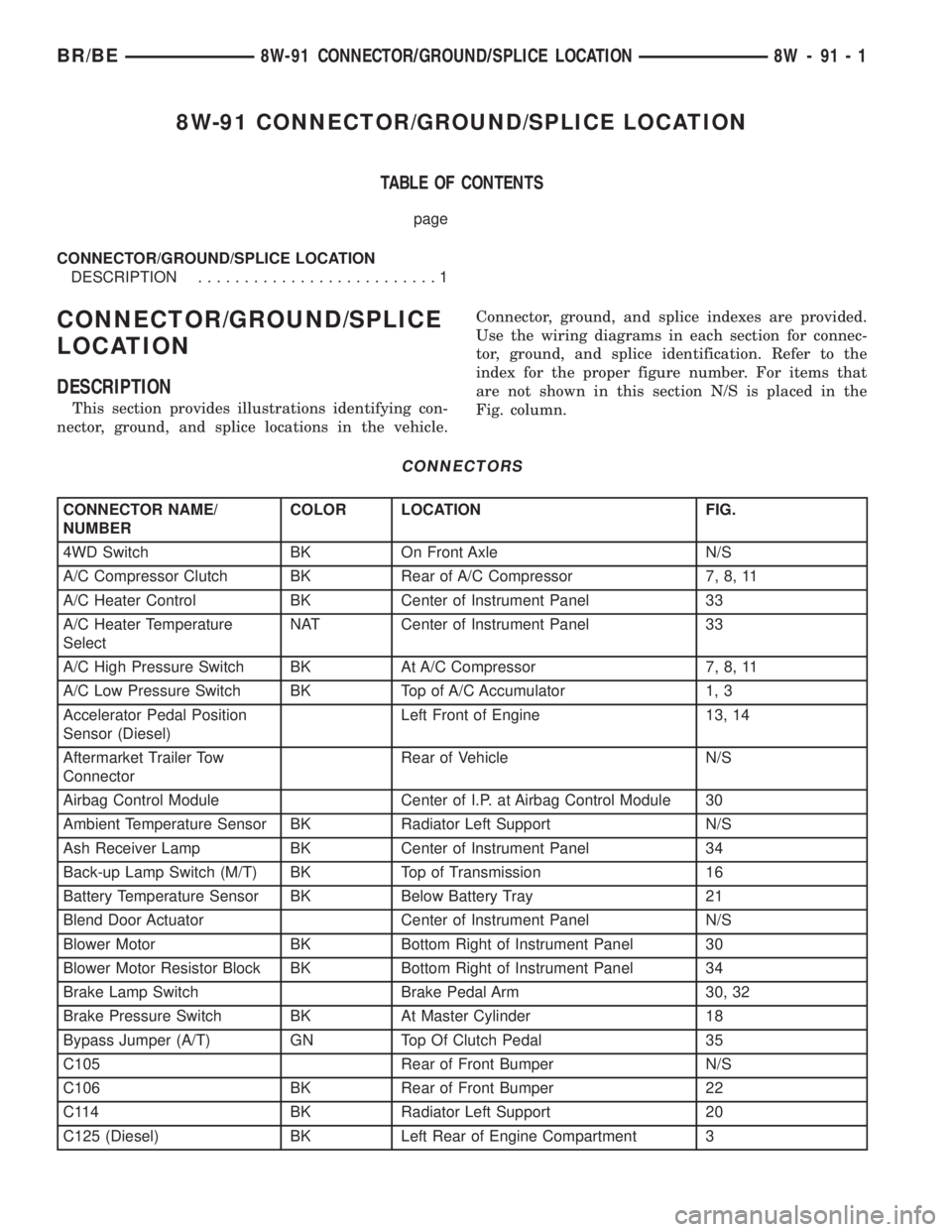

8W-91 CONNECTOR/GROUND/SPLICE LOCATION

TABLE OF CONTENTS

page

CONNECTOR/GROUND/SPLICE LOCATION

DESCRIPTION..........................1

CONNECTOR/GROUND/SPLICE

LOCATION

DESCRIPTION

This section provides illustrations identifying con-

nector, ground, and splice locations in the vehicle.Connector, ground, and splice indexes are provided.

Use the wiring diagrams in each section for connec-

tor, ground, and splice identification. Refer to the

index for the proper figure number. For items that

are not shown in this section N/S is placed in the

Fig. column.

CONNECTORS

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

4WD Switch BK On Front Axle N/S

A/C Compressor Clutch BK Rear of A/C Compressor 7, 8, 11

A/C Heater Control BK Center of Instrument Panel 33

A/C Heater Temperature

SelectNAT Center of Instrument Panel 33

A/C High Pressure Switch BK At A/C Compressor 7, 8, 11

A/C Low Pressure Switch BK Top of A/C Accumulator 1, 3

Accelerator Pedal Position

Sensor (Diesel)Left Front of Engine 13, 14

Aftermarket Trailer Tow

ConnectorRear of Vehicle N/S

Airbag Control Module Center of I.P. at Airbag Control Module 30

Ambient Temperature Sensor BK Radiator Left Support N/S

Ash Receiver Lamp BK Center of Instrument Panel 34

Back-up Lamp Switch (M/T) BK Top of Transmission 16

Battery Temperature Sensor BK Below Battery Tray 21

Blend Door Actuator Center of Instrument Panel N/S

Blower Motor BK Bottom Right of Instrument Panel 30

Blower Motor Resistor Block BK Bottom Right of Instrument Panel 34

Brake Lamp Switch Brake Pedal Arm 30, 32

Brake Pressure Switch BK At Master Cylinder 18

Bypass Jumper (A/T) GN Top Of Clutch Pedal 35

C105 Rear of Front Bumper N/S

C106 BK Rear of Front Bumper 22

C114 BK Radiator Left Support 20

C125 (Diesel) BK Left Rear of Engine Compartment 3

BR/BE8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 1

Page 1092 of 2255

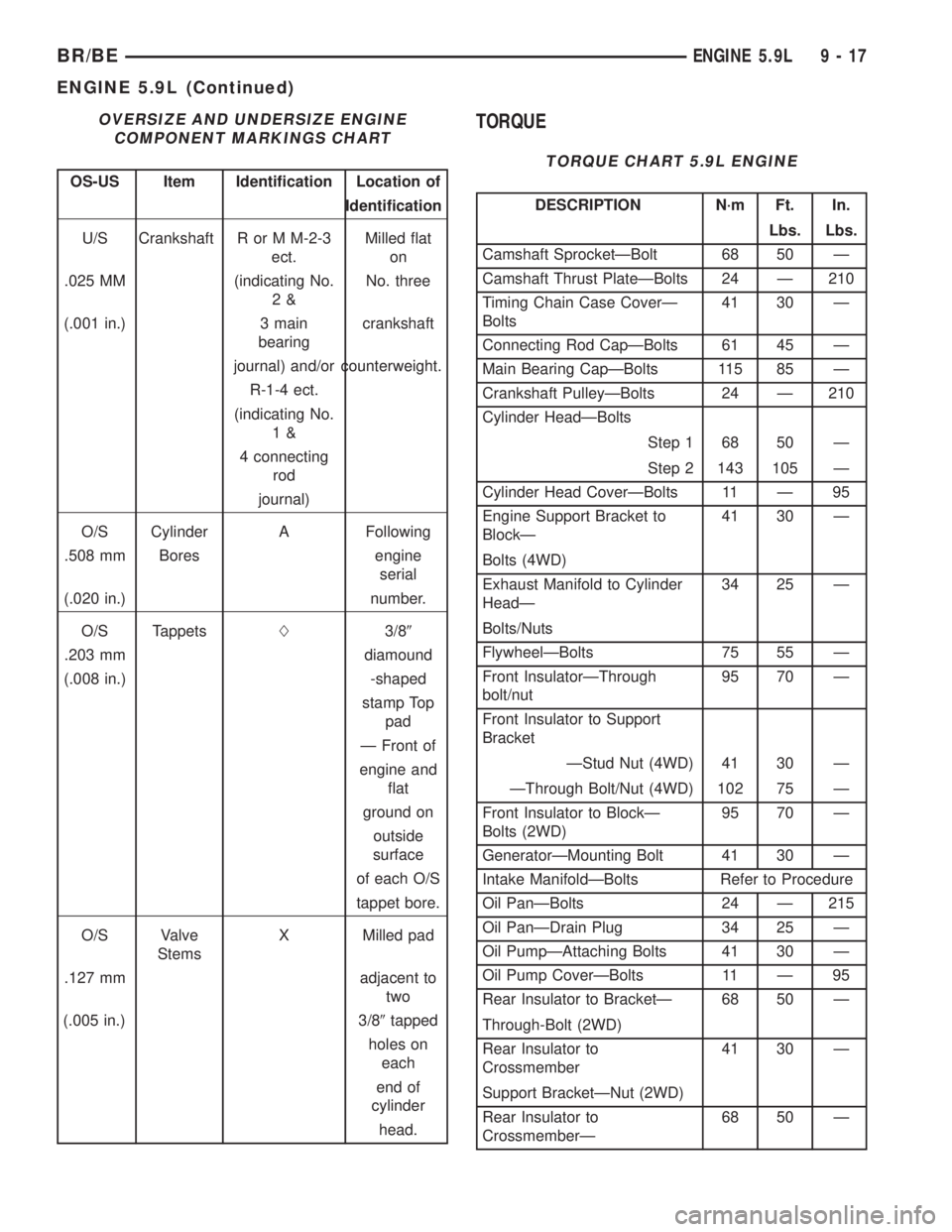

OVERSIZE AND UNDERSIZE ENGINE

COMPONENT MARKINGS CHART

OS-US Item Identification Location of

Identification

U/S Crankshaft R or M M-2-3

ect.Milled flat

on

.025 MM (indicating No.

2&No. three

(.001 in.) 3 main

bearingcrankshaft

journal) and/or counterweight.

R-1-4 ect.

(indicating No.

1&

4 connecting

rod

journal)

O/S Cylinder A Following

.508 mm Bores engine

serial

(.020 in.) number.

O/S TappetsL3/89

.203 mm diamound

(.008 in.) -shaped

stamp Top

pad

Ð Front of

engine and

flat

ground on

outside

surface

of each O/S

tappet bore.

O/S Valve

StemsX Milled pad

.127 mm adjacent to

two

(.005 in.) 3/89tapped

holes on

each

end of

cylinder

head.

TORQUE

TORQUE CHART 5.9L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Camshaft SprocketÐBolt 68 50 Ð

Camshaft Thrust PlateÐBolts 24 Ð 210

Timing Chain Case CoverÐ

Bolts41 30 Ð

Connecting Rod CapÐBolts 61 45 Ð

Main Bearing CapÐBolts 115 85 Ð

Crankshaft PulleyÐBolts 24 Ð 210

Cylinder HeadÐBolts

Step 1 68 50 Ð

Step 2 143 105 Ð

Cylinder Head CoverÐBolts 11 Ð 95

Engine Support Bracket to

BlockÐ41 30 Ð

Bolts (4WD)

Exhaust Manifold to Cylinder

HeadÐ34 25 Ð

Bolts/Nuts

FlywheelÐBolts 75 55 Ð

Front InsulatorÐThrough

bolt/nut95 70 Ð

Front Insulator to Support

Bracket

ÐStud Nut (4WD) 41 30 Ð

ÐThrough Bolt/Nut (4WD) 102 75 Ð

Front Insulator to BlockÐ

Bolts (2WD)95 70 Ð

GeneratorÐMounting Bolt 41 30 Ð

Intake ManifoldÐBolts Refer to Procedure

Oil PanÐBolts 24 Ð 215

Oil PanÐDrain Plug 34 25 Ð

Oil PumpÐAttaching Bolts 41 30 Ð

Oil Pump CoverÐBolts 11 Ð 95

Rear Insulator to BracketÐ 68 50 Ð

Through-Bolt (2WD)

Rear Insulator to

Crossmember41 30 Ð

Support BracketÐNut (2WD)

Rear Insulator to

CrossmemberÐ68 50 Ð

BR/BEENGINE 5.9L 9 - 17

ENGINE 5.9L (Continued)

Page 1093 of 2255

DESCRIPTION N´m Ft. In.

Nuts (4WD)

Rear Insulator to

TransmissionÐ68 50 Ð

Bolts (4WD)

Rear Insulator BracketÐBolts 68 50 Ð

(4WD Automatic)

Rear Support Bracket to 41 30 Ð

Crossmember FlangeÐNuts

Rear Support Plate to

Transfer41 30 Ð

CaseÐBolts

Rocker ArmÐBolts 28 21 Ð

Spark Plugs 41 30 Ð

Starter MotorÐMounting Bolts 68 50 Ð

Thermostat HousingÐBolts 25 Ð 225

Throttle BodyÐBolts 23 Ð 200

Torque Converter Drive

PlateÐBolts31 Ð 270

Transfer Case to Insulator 204 105 Ð

Mounting PlateÐNuts

Transmission Support

BracketÐ68 50 Ð

Bolts (2WD)

Vibration DamperÐBolt 244 180 Ð

Water Pump to Timing Chain 41 30 Ð

Case CoverÐBolts

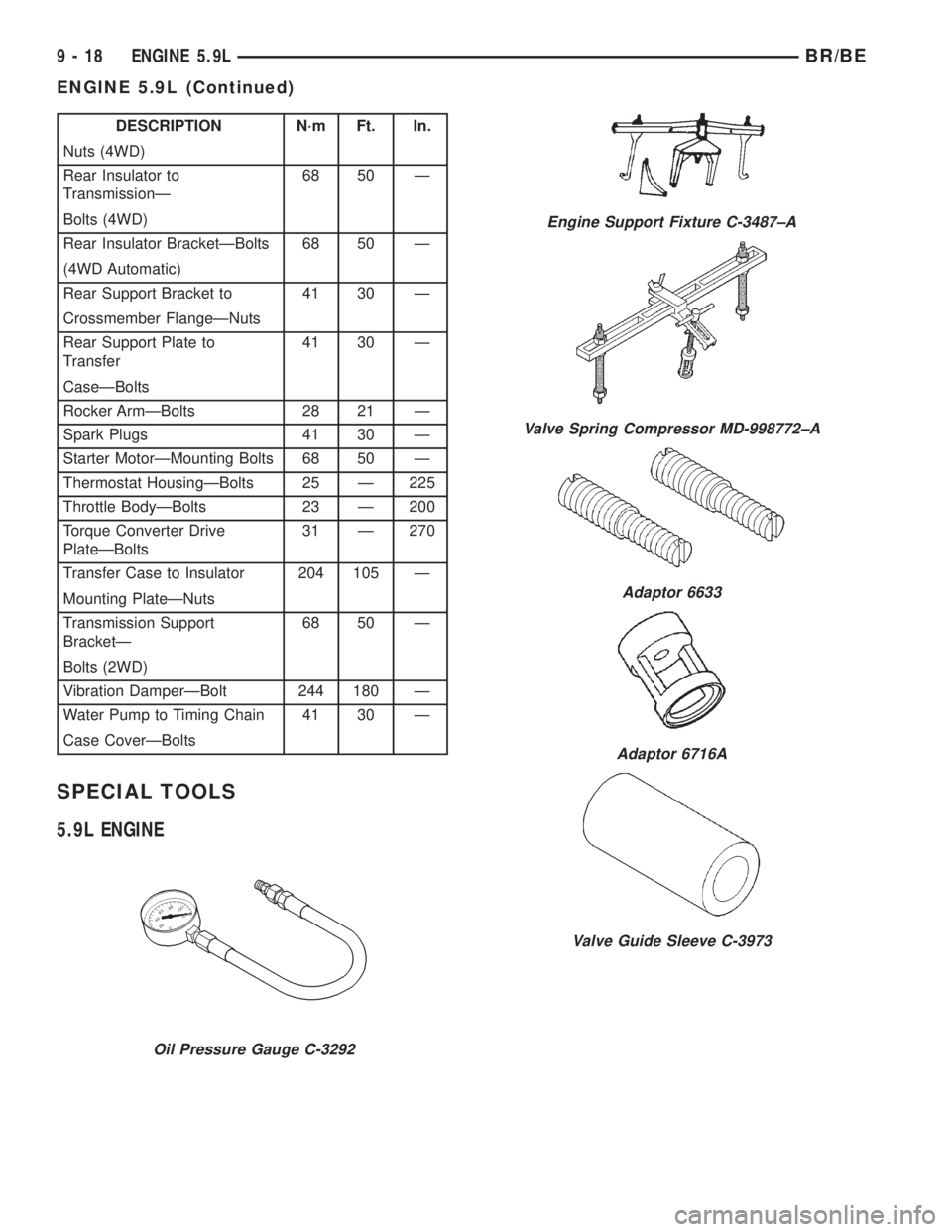

SPECIAL TOOLS

5.9L ENGINE

Oil Pressure Gauge C-3292

Engine Support Fixture C-3487±A

Valve Spring Compressor MD-998772±A

Adaptor 6633

Adaptor 6716A

Valve Guide Sleeve C-3973

9 - 18 ENGINE 5.9LBR/BE

ENGINE 5.9L (Continued)

Page 1410 of 2255

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM....................2

DIAGNOSIS AND TESTING - POWER

STEERING FLOW AND PRESSURE........4COLUMN...............................6

GEAR.................................16

PUMP.................................33

LINKAGE - 2WD.........................40

LINKAGE - 4WD.........................42

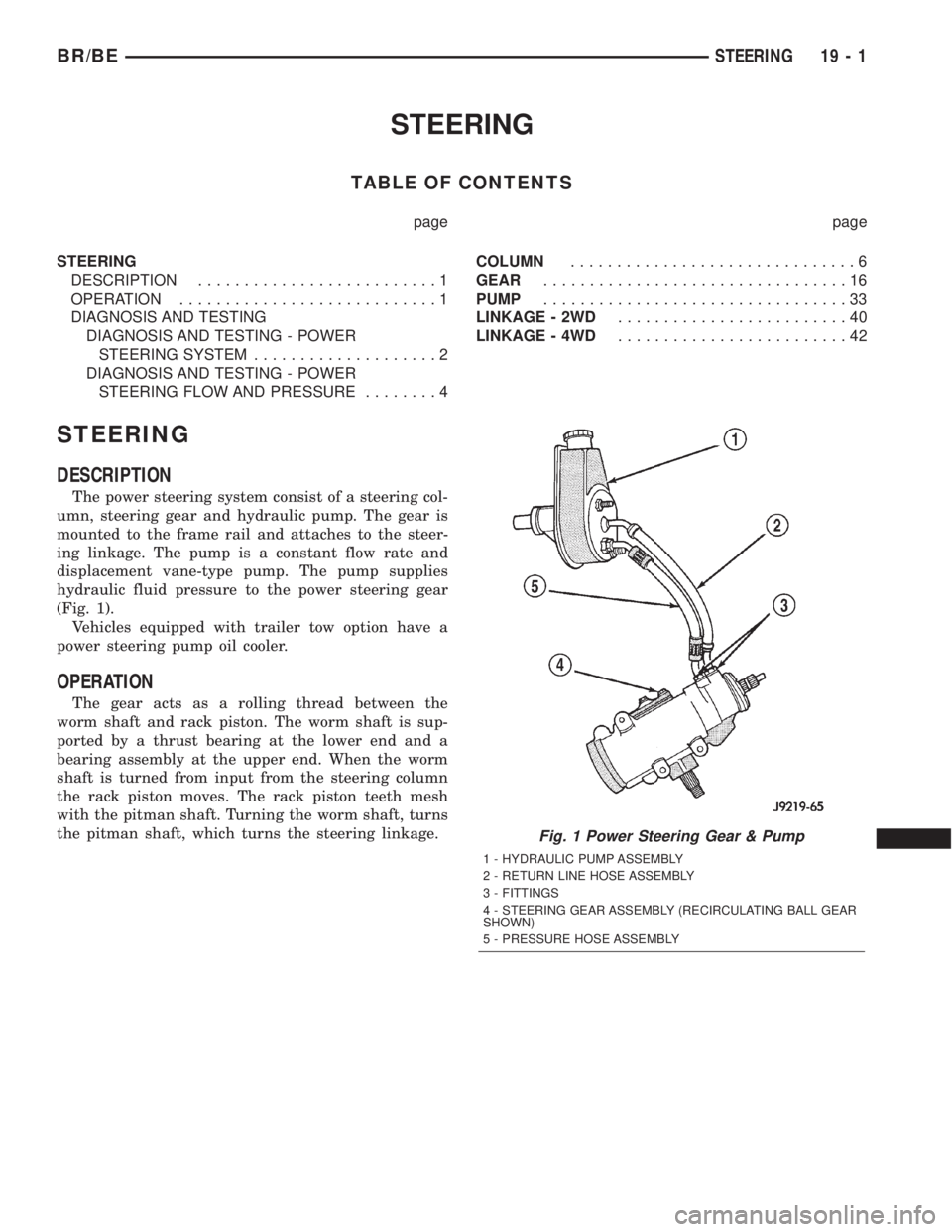

STEERING

DESCRIPTION

The power steering system consist of a steering col-

umn, steering gear and hydraulic pump. The gear is

mounted to the frame rail and attaches to the steer-

ing linkage. The pump is a constant flow rate and

displacement vane-type pump. The pump supplies

hydraulic fluid pressure to the power steering gear

(Fig. 1).

Vehicles equipped with trailer tow option have a

power steering pump oil cooler.

OPERATION

The gear acts as a rolling thread between the

worm shaft and rack piston. The worm shaft is sup-

ported by a thrust bearing at the lower end and a

bearing assembly at the upper end. When the worm

shaft is turned from input from the steering column

the rack piston moves. The rack piston teeth mesh

with the pitman shaft. Turning the worm shaft, turns

the pitman shaft, which turns the steering linkage.

Fig. 1 Power Steering Gear & Pump

1 - HYDRAULIC PUMP ASSEMBLY

2 - RETURN LINE HOSE ASSEMBLY

3 - FITTINGS

4 - STEERING GEAR ASSEMBLY (RECIRCULATING BALL GEAR

SHOWN)

5 - PRESSURE HOSE ASSEMBLY

BR/BESTEERING 19 - 1

Page 1451 of 2255

LINKAGE - 4WD

TABLE OF CONTENTS

page page

LINKAGE - 4WD

DESCRIPTION.........................42

STANDARD PROCEDURE - LUBRICATION....42

REMOVAL.............................42

INSTALLATION.........................43SPECIFICATIONS

TORQUE CHART......................43

SPECIAL TOOLS

STEERING LINKAGE...................44

LINKAGE - 4WD

DESCRIPTION

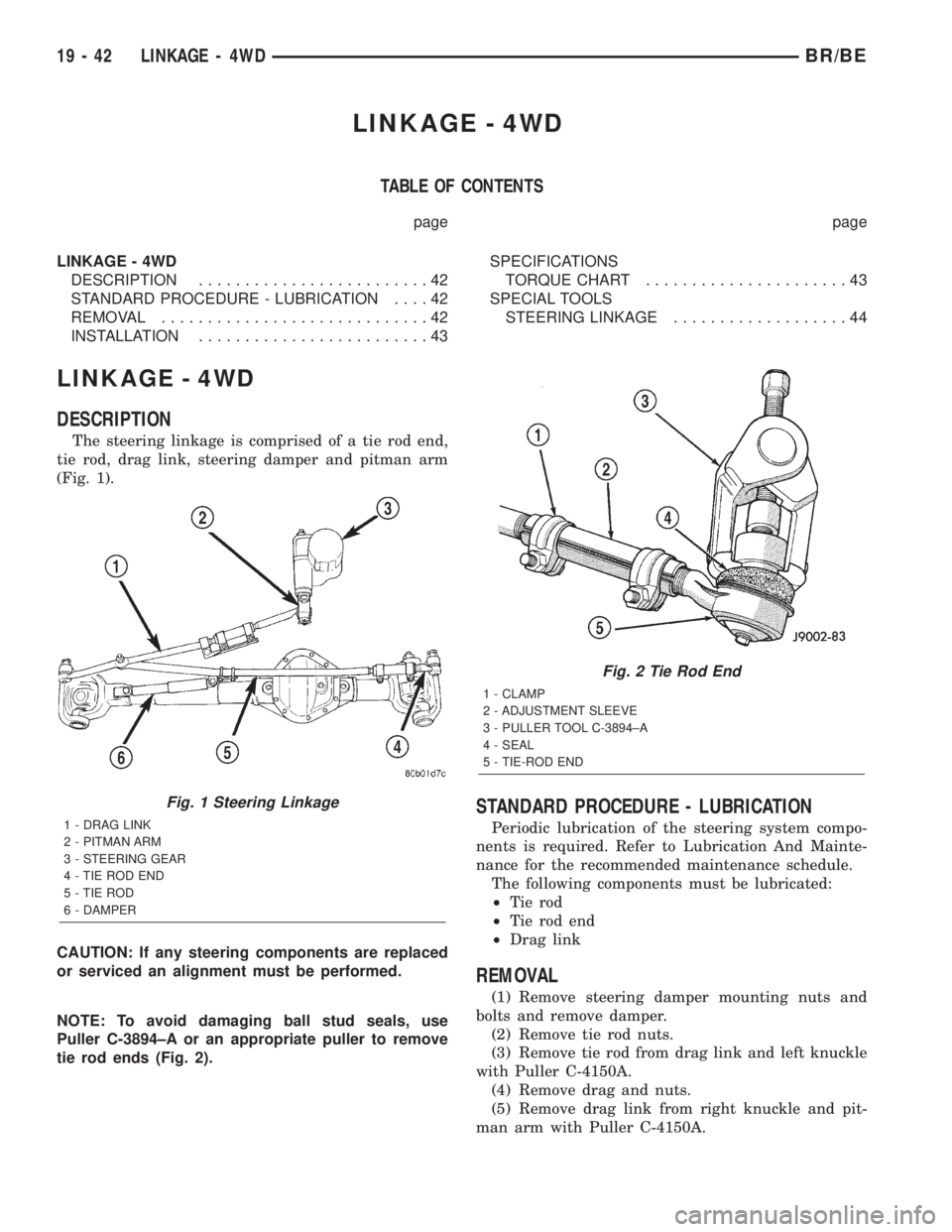

The steering linkage is comprised of a tie rod end,

tie rod, drag link, steering damper and pitman arm

(Fig. 1).

CAUTION: If any steering components are replaced

or serviced an alignment must be performed.

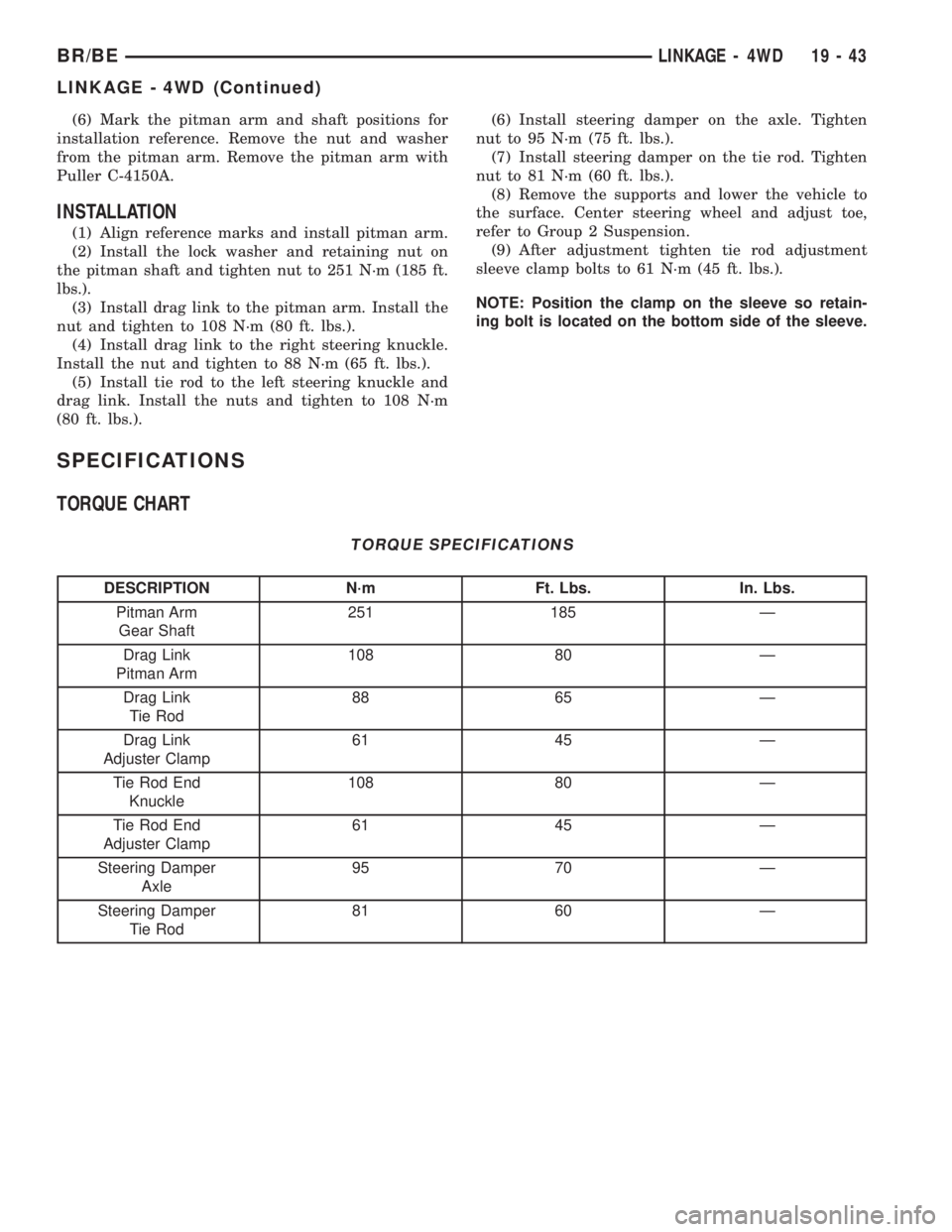

NOTE: To avoid damaging ball stud seals, use

Puller C-3894±A or an appropriate puller to remove

tie rod ends (Fig. 2).

STANDARD PROCEDURE - LUBRICATION

Periodic lubrication of the steering system compo-

nents is required. Refer to Lubrication And Mainte-

nance for the recommended maintenance schedule.

The following components must be lubricated:

²Tie rod

²Tie rod end

²Drag link

REMOVAL

(1) Remove steering damper mounting nuts and

bolts and remove damper.

(2) Remove tie rod nuts.

(3) Remove tie rod from drag link and left knuckle

with Puller C-4150A.

(4) Remove drag and nuts.

(5) Remove drag link from right knuckle and pit-

man arm with Puller C-4150A.

Fig. 1 Steering Linkage

1 - DRAG LINK

2 - PITMAN ARM

3 - STEERING GEAR

4 - TIE ROD END

5 - TIE ROD

6 - DAMPER

Fig. 2 Tie Rod End

1 - CLAMP

2 - ADJUSTMENT SLEEVE

3 - PULLER TOOL C-3894±A

4 - SEAL

5 - TIE-ROD END

19 - 42 LINKAGE - 4WDBR/BE

Page 1452 of 2255

(6) Mark the pitman arm and shaft positions for

installation reference. Remove the nut and washer

from the pitman arm. Remove the pitman arm with

Puller C-4150A.

INSTALLATION

(1) Align reference marks and install pitman arm.

(2) Install the lock washer and retaining nut on

the pitman shaft and tighten nut to 251 N´m (185 ft.

lbs.).

(3) Install drag link to the pitman arm. Install the

nut and tighten to 108 N´m (80 ft. lbs.).

(4) Install drag link to the right steering knuckle.

Install the nut and tighten to 88 N´m (65 ft. lbs.).

(5) Install tie rod to the left steering knuckle and

drag link. Install the nuts and tighten to 108 N´m

(80 ft. lbs.).(6) Install steering damper on the axle. Tighten

nut to 95 N´m (75 ft. lbs.).

(7) Install steering damper on the tie rod. Tighten

nut to 81 N´m (60 ft. lbs.).

(8) Remove the supports and lower the vehicle to

the surface. Center steering wheel and adjust toe,

refer to Group 2 Suspension.

(9) After adjustment tighten tie rod adjustment

sleeve clamp bolts to 61 N´m (45 ft. lbs.).

NOTE: Position the clamp on the sleeve so retain-

ing bolt is located on the bottom side of the sleeve.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Pitman Arm

Gear Shaft251 185 Ð

Drag Link

Pitman Arm108 80 Ð

Drag Link

Tie Rod88 65 Ð

Drag Link

Adjuster Clamp61 45 Ð

Tie Rod End

Knuckle108 80 Ð

Tie Rod End

Adjuster Clamp61 45 Ð

Steering Damper

Axle95 70 Ð

Steering Damper

Tie Rod81 60 Ð

BR/BELINKAGE - 4WD 19 - 43

LINKAGE - 4WD (Continued)