light DODGE RAM 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 151 of 2255

DIFFERENTIAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove fill hole plug from the differential

housing cover.

(3) Remove differential housing cover and drain

lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove axle shafts.

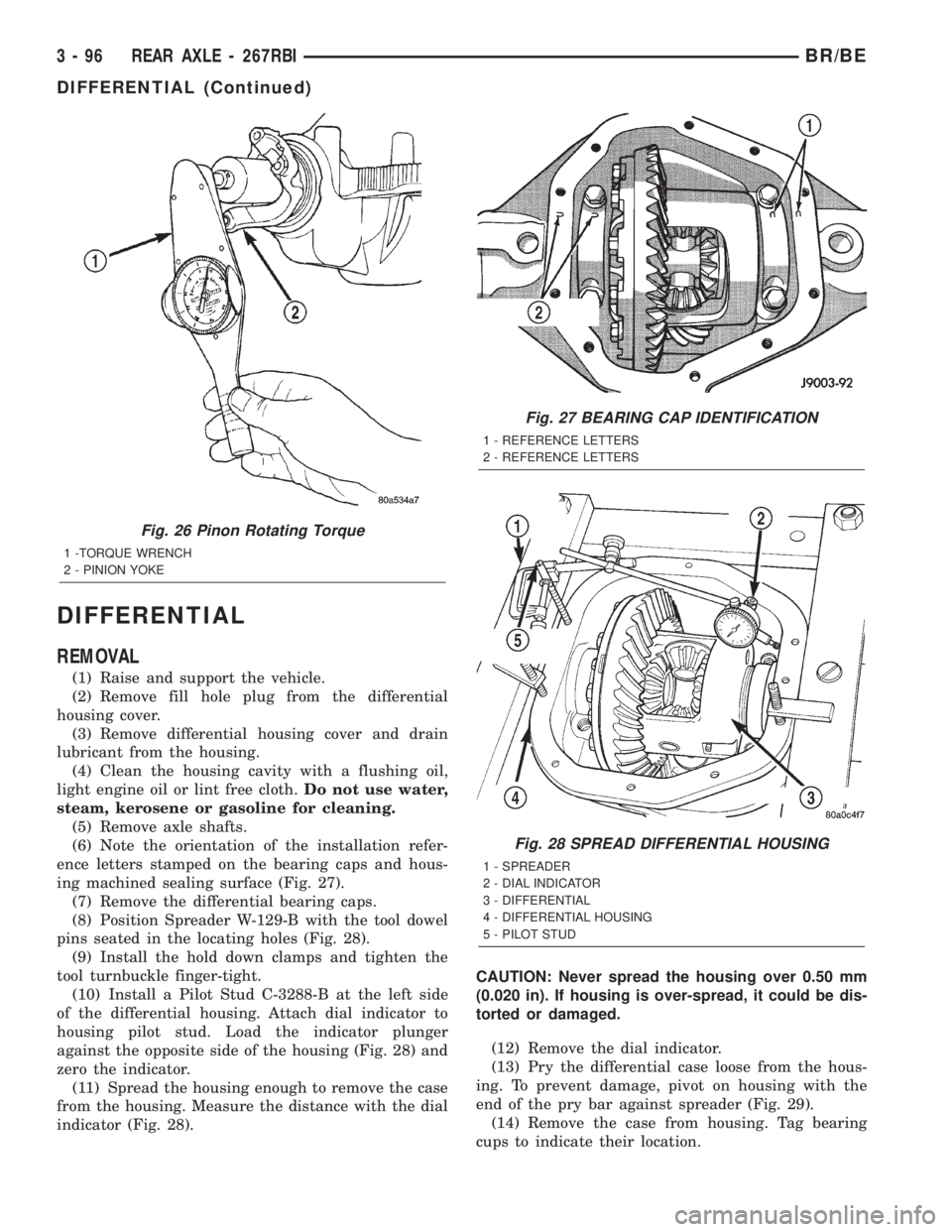

(6) Note the orientation of the installation refer-

ence letters stamped on the bearing caps and hous-

ing machined sealing surface (Fig. 27).

(7) Remove the differential bearing caps.

(8) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 28).

(9) Install the hold down clamps and tighten the

tool turnbuckle finger-tight.

(10) Install a Pilot Stud C-3288-B at the left side

of the differential housing. Attach dial indicator to

housing pilot stud. Load the indicator plunger

against the opposite side of the housing (Fig. 28) and

zero the indicator.

(11) Spread the housing enough to remove the case

from the housing. Measure the distance with the dial

indicator (Fig. 28).CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If housing is over-spread, it could be dis-

torted or damaged.

(12) Remove the dial indicator.

(13) Pry the differential case loose from the hous-

ing. To prevent damage, pivot on housing with the

end of the pry bar against spreader (Fig. 29).

(14) Remove the case from housing. Tag bearing

cups to indicate their location.

Fig. 26 Pinon Rotating Torque

1 -TORQUE WRENCH

2 - PINION YOKE

Fig. 27 BEARING CAP IDENTIFICATION

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 28 SPREAD DIFFERENTIAL HOUSING

1 - SPREADER

2 - DIAL INDICATOR

3 - DIFFERENTIAL

4 - DIFFERENTIAL HOUSING

5 - PILOT STUD

3 - 96 REAR AXLE - 267RBIBR/BE

DIFFERENTIAL (Continued)

Page 152 of 2255

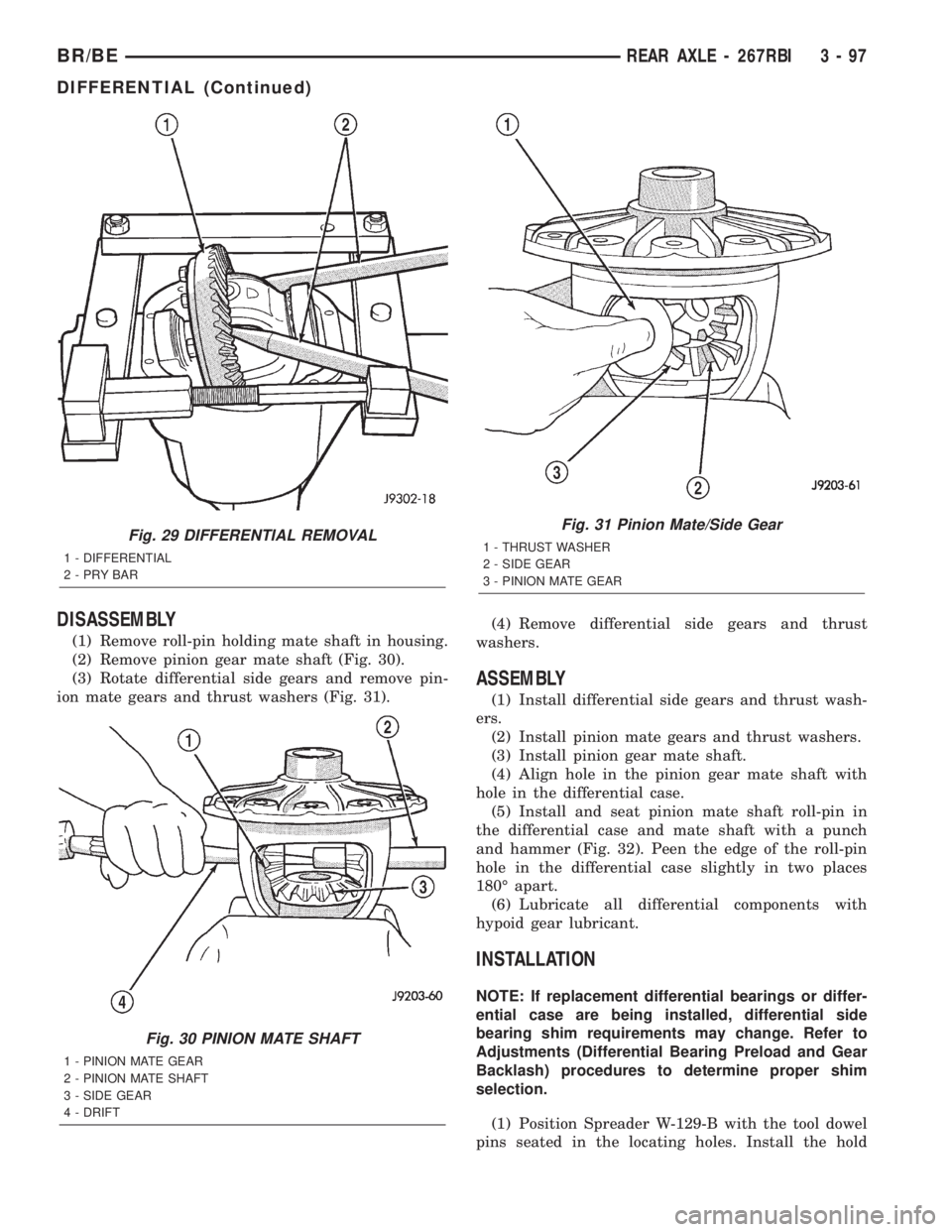

DISASSEMBLY

(1) Remove roll-pin holding mate shaft in housing.

(2) Remove pinion gear mate shaft (Fig. 30).

(3) Rotate differential side gears and remove pin-

ion mate gears and thrust washers (Fig. 31).(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install pinion mate gears and thrust washers.

(3) Install pinion gear mate shaft.

(4) Align hole in the pinion gear mate shaft with

hole in the differential case.

(5) Install and seat pinion mate shaft roll-pin in

the differential case and mate shaft with a punch

and hammer (Fig. 32). Peen the edge of the roll-pin

hole in the differential case slightly in two places

180É apart.

(6) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer to

Adjustments (Differential Bearing Preload and Gear

Backlash) procedures to determine proper shim

selection.

(1) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes. Install the hold

Fig. 29 DIFFERENTIAL REMOVAL

1 - DIFFERENTIAL

2-PRYBAR

Fig. 30 PINION MATE SHAFT

1 - PINION MATE GEAR

2 - PINION MATE SHAFT

3 - SIDE GEAR

4 - DRIFT

Fig. 31 Pinion Mate/Side Gear

1 - THRUST WASHER

2 - SIDE GEAR

3 - PINION MATE GEAR

BR/BEREAR AXLE - 267RBI 3 - 97

DIFFERENTIAL (Continued)

Page 160 of 2255

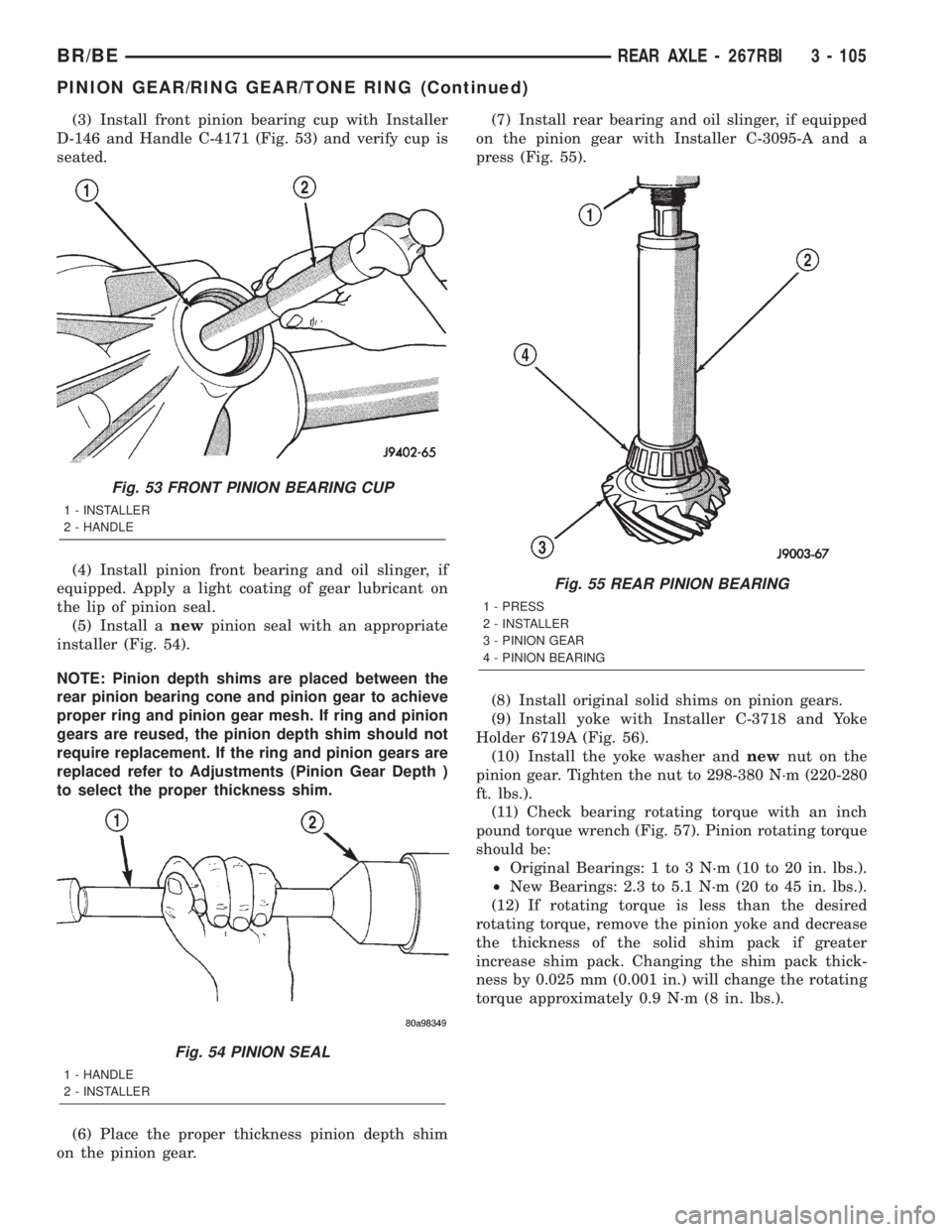

(3) Install front pinion bearing cup with Installer

D-146 and Handle C-4171 (Fig. 53) and verify cup is

seated.

(4) Install pinion front bearing and oil slinger, if

equipped. Apply a light coating of gear lubricant on

the lip of pinion seal.

(5) Install anewpinion seal with an appropriate

installer (Fig. 54).

NOTE: Pinion depth shims are placed between the

rear pinion bearing cone and pinion gear to achieve

proper ring and pinion gear mesh. If ring and pinion

gears are reused, the pinion depth shim should not

require replacement. If the ring and pinion gears are

replaced refer to Adjustments (Pinion Gear Depth )

to select the proper thickness shim.

(6) Place the proper thickness pinion depth shim

on the pinion gear.(7) Install rear bearing and oil slinger, if equipped

on the pinion gear with Installer C-3095-A and a

press (Fig. 55).

(8) Install original solid shims on pinion gears.

(9) Install yoke with Installer C-3718 and Yoke

Holder 6719A (Fig. 56).

(10) Install the yoke washer andnewnut on the

pinion gear. Tighten the nut to 298-380 N´m (220-280

ft. lbs.).

(11) Check bearing rotating torque with an inch

pound torque wrench (Fig. 57). Pinion rotating torque

should be:

²Original Bearings: 1 to 3 N´m (10 to 20 in. lbs.).

²New Bearings: 2.3 to 5.1 N´m (20 to 45 in. lbs.).

(12) If rotating torque is less than the desired

rotating torque, remove the pinion yoke and decrease

the thickness of the solid shim pack if greater

increase shim pack. Changing the shim pack thick-

ness by 0.025 mm (0.001 in.) will change the rotating

torque approximately 0.9 N´m (8 in. lbs.).

Fig. 53 FRONT PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 54 PINION SEAL

1 - HANDLE

2 - INSTALLER

Fig. 55 REAR PINION BEARING

1 - PRESS

2 - INSTALLER

3 - PINION GEAR

4 - PINION BEARING

BR/BEREAR AXLE - 267RBI 3 - 105

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 164 of 2255

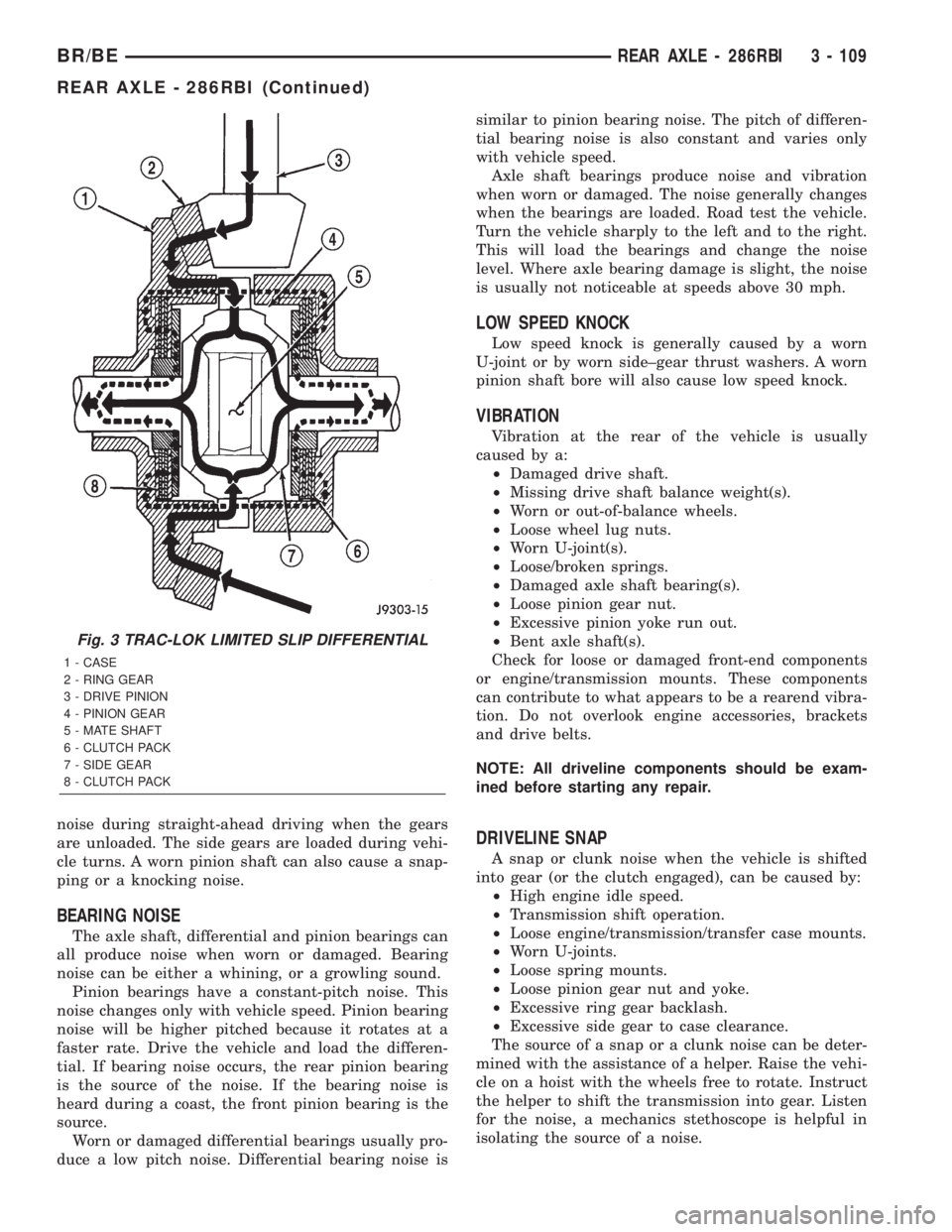

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion shaft can also cause a snap-

ping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise issimilar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side±gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

Fig. 3 TRAC-LOK LIMITED SLIP DIFFERENTIAL

1 - CASE

2 - RING GEAR

3 - DRIVE PINION

4 - PINION GEAR

5 - MATE SHAFT

6 - CLUTCH PACK

7 - SIDE GEAR

8 - CLUTCH PACK

BR/BEREAR AXLE - 286RBI 3 - 109

REAR AXLE - 286RBI (Continued)

Page 179 of 2255

INSTALLATION

(1) Clean the seal contact surface in the housing

bore.

(2) Apply a light coating of gear lubricant on the

lip of pinion seal.

(3) Installnewpinion shaft seal with an appropri-

ate Installer.

(4) Position pinion yoke on the end of the shaft

with the reference marks aligned.

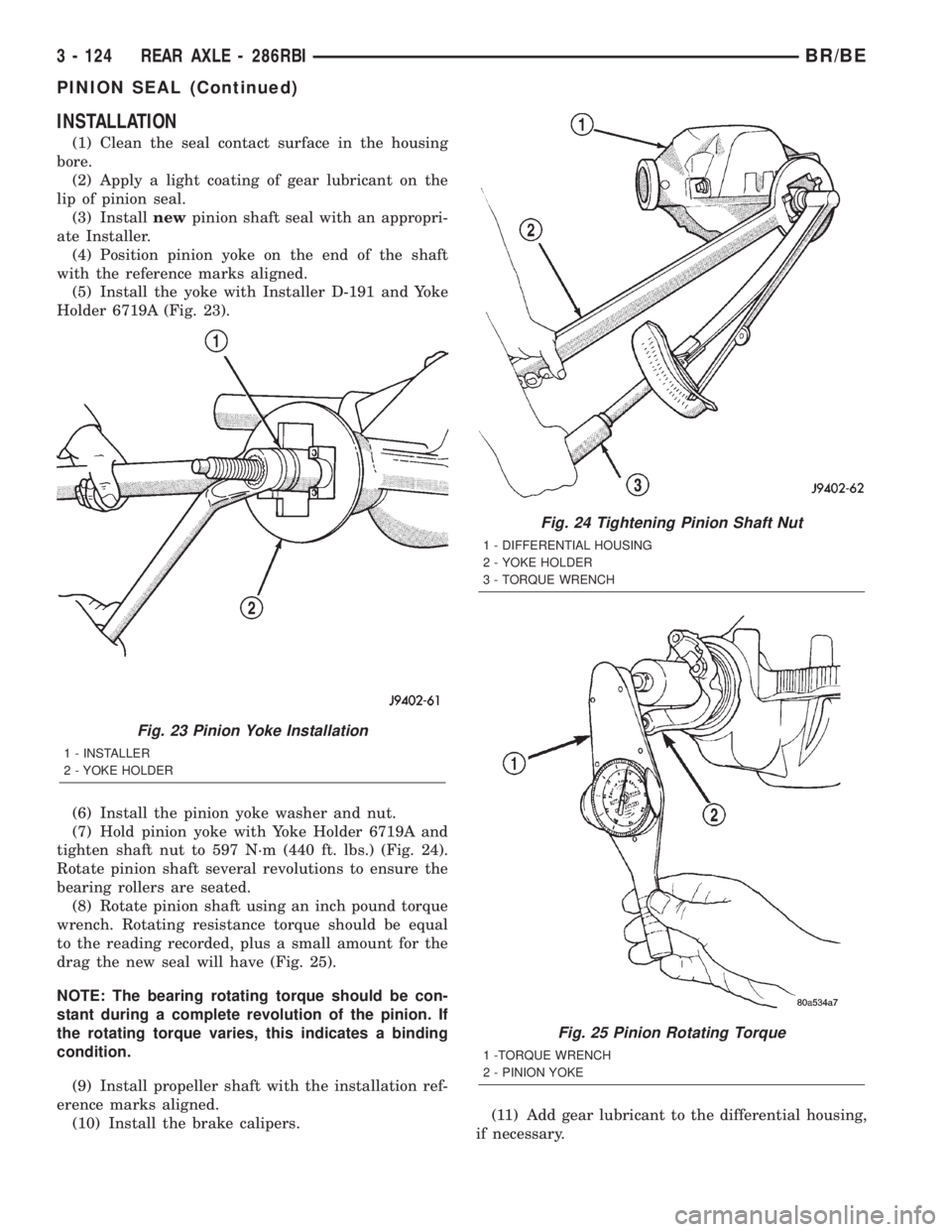

(5) Install the yoke with Installer D-191 and Yoke

Holder 6719A (Fig. 23).

(6) Install the pinion yoke washer and nut.

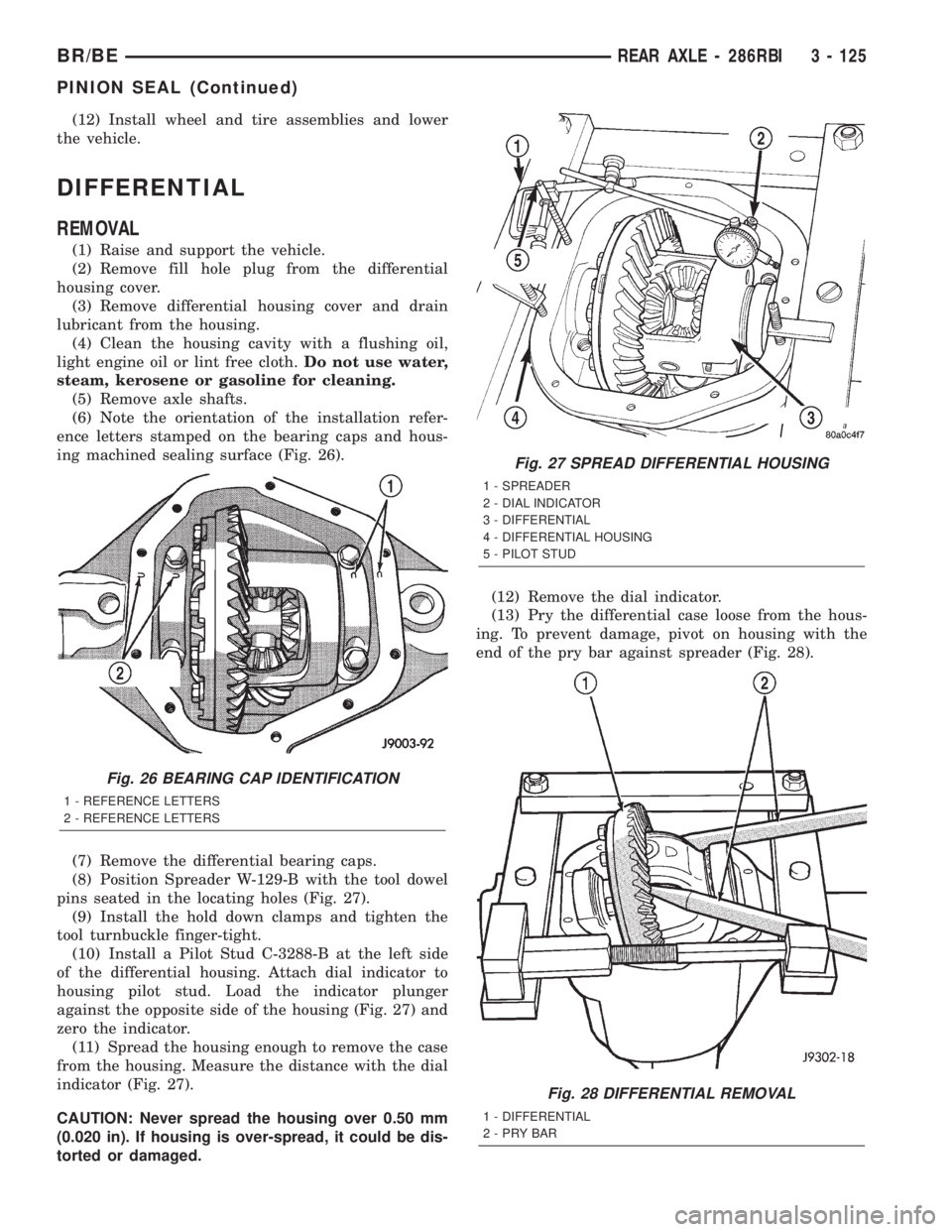

(7) Hold pinion yoke with Yoke Holder 6719A and

tighten shaft nut to 597 N´m (440 ft. lbs.) (Fig. 24).

Rotate pinion shaft several revolutions to ensure the

bearing rollers are seated.

(8) Rotate pinion shaft using an inch pound torque

wrench. Rotating resistance torque should be equal

to the reading recorded, plus a small amount for the

drag the new seal will have (Fig. 25).

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

(9) Install propeller shaft with the installation ref-

erence marks aligned.

(10) Install the brake calipers.(11) Add gear lubricant to the differential housing,

if necessary.

Fig. 23 Pinion Yoke Installation

1 - INSTALLER

2 - YOKE HOLDER

Fig. 24 Tightening Pinion Shaft Nut

1 - DIFFERENTIAL HOUSING

2 - YOKE HOLDER

3 - TORQUE WRENCH

Fig. 25 Pinion Rotating Torque

1 -TORQUE WRENCH

2 - PINION YOKE

3 - 124 REAR AXLE - 286RBIBR/BE

PINION SEAL (Continued)

Page 180 of 2255

(12) Install wheel and tire assemblies and lower

the vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove fill hole plug from the differential

housing cover.

(3) Remove differential housing cover and drain

lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove axle shafts.

(6) Note the orientation of the installation refer-

ence letters stamped on the bearing caps and hous-

ing machined sealing surface (Fig. 26).

(7) Remove the differential bearing caps.

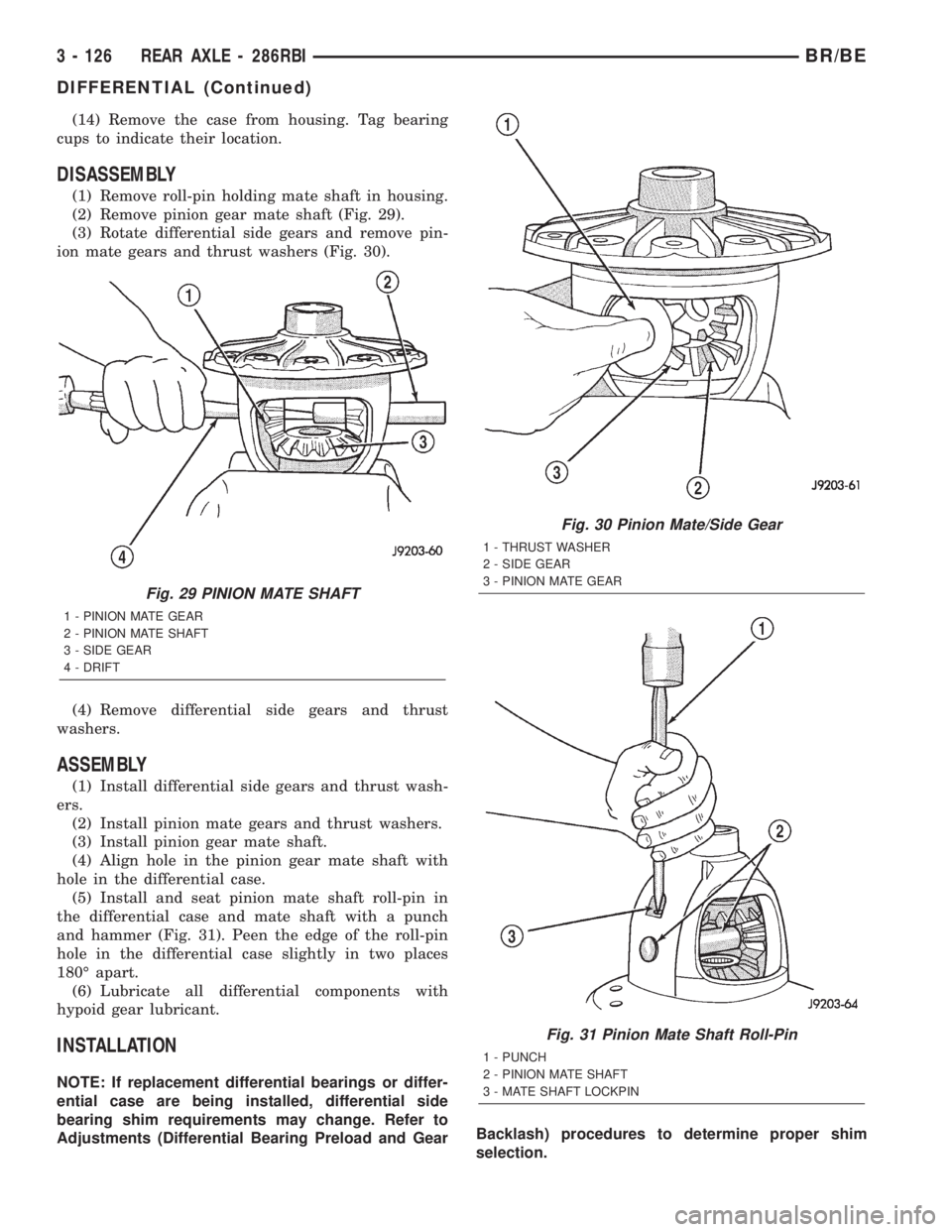

(8) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 27).

(9) Install the hold down clamps and tighten the

tool turnbuckle finger-tight.

(10) Install a Pilot Stud C-3288-B at the left side

of the differential housing. Attach dial indicator to

housing pilot stud. Load the indicator plunger

against the opposite side of the housing (Fig. 27) and

zero the indicator.

(11) Spread the housing enough to remove the case

from the housing. Measure the distance with the dial

indicator (Fig. 27).

CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If housing is over-spread, it could be dis-

torted or damaged.(12) Remove the dial indicator.

(13) Pry the differential case loose from the hous-

ing. To prevent damage, pivot on housing with the

end of the pry bar against spreader (Fig. 28).

Fig. 26 BEARING CAP IDENTIFICATION

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 27 SPREAD DIFFERENTIAL HOUSING

1 - SPREADER

2 - DIAL INDICATOR

3 - DIFFERENTIAL

4 - DIFFERENTIAL HOUSING

5 - PILOT STUD

Fig. 28 DIFFERENTIAL REMOVAL

1 - DIFFERENTIAL

2-PRYBAR

BR/BEREAR AXLE - 286RBI 3 - 125

PINION SEAL (Continued)

Page 181 of 2255

(14) Remove the case from housing. Tag bearing

cups to indicate their location.

DISASSEMBLY

(1) Remove roll-pin holding mate shaft in housing.

(2) Remove pinion gear mate shaft (Fig. 29).

(3) Rotate differential side gears and remove pin-

ion mate gears and thrust washers (Fig. 30).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install pinion mate gears and thrust washers.

(3) Install pinion gear mate shaft.

(4) Align hole in the pinion gear mate shaft with

hole in the differential case.

(5) Install and seat pinion mate shaft roll-pin in

the differential case and mate shaft with a punch

and hammer (Fig. 31). Peen the edge of the roll-pin

hole in the differential case slightly in two places

180É apart.

(6) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer to

Adjustments (Differential Bearing Preload and GearBacklash) procedures to determine proper shim

selection.

Fig. 29 PINION MATE SHAFT

1 - PINION MATE GEAR

2 - PINION MATE SHAFT

3 - SIDE GEAR

4 - DRIFT

Fig. 30 Pinion Mate/Side Gear

1 - THRUST WASHER

2 - SIDE GEAR

3 - PINION MATE GEAR

Fig. 31 Pinion Mate Shaft Roll-Pin

1 - PUNCH

2 - PINION MATE SHAFT

3 - MATE SHAFT LOCKPIN

3 - 126 REAR AXLE - 286RBIBR/BE

DIFFERENTIAL (Continued)

Page 188 of 2255

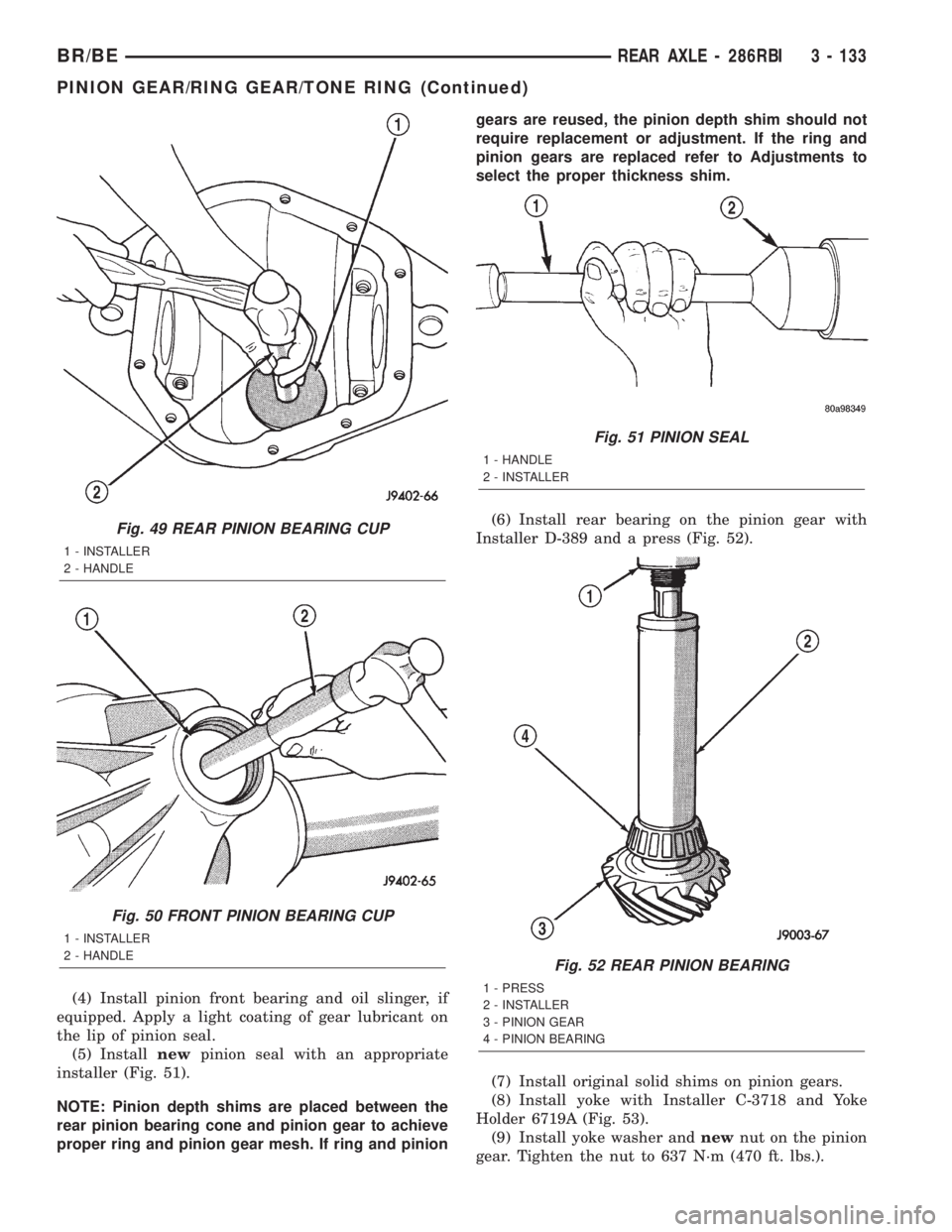

(4) Install pinion front bearing and oil slinger, if

equipped. Apply a light coating of gear lubricant on

the lip of pinion seal.

(5) Installnewpinion seal with an appropriate

installer (Fig. 51).

NOTE: Pinion depth shims are placed between the

rear pinion bearing cone and pinion gear to achieve

proper ring and pinion gear mesh. If ring and piniongears are reused, the pinion depth shim should not

require replacement or adjustment. If the ring and

pinion gears are replaced refer to Adjustments to

select the proper thickness shim.

(6) Install rear bearing on the pinion gear with

Installer D-389 and a press (Fig. 52).

(7) Install original solid shims on pinion gears.

(8) Install yoke with Installer C-3718 and Yoke

Holder 6719A (Fig. 53).

(9) Install yoke washer andnewnut on the pinion

gear. Tighten the nut to 637 N´m (470 ft. lbs.).

Fig. 49 REAR PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 50 FRONT PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 51 PINION SEAL

1 - HANDLE

2 - INSTALLER

Fig. 52 REAR PINION BEARING

1 - PRESS

2 - INSTALLER

3 - PINION GEAR

4 - PINION BEARING

BR/BEREAR AXLE - 286RBI 3 - 133

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 195 of 2255

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However, thin brake drums or substandard

brake lines and hoses can also cause a spongy pedal.

The proper course of action is to bleed the system,

and replace thin drums and substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could

also be faulty.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation, or out of round brake drums. Other causes are

loose wheel bearings or calipers and worn or dam-

aged tires.

NOTE: Some pedal pulsation may be felt during

ABS/EBD activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake shoe release.

Drag can be minor or severe enough to overheat the

linings, rotors and drums.

Minor drag will usually cause slight surface char-

ring of the lining. It can also generate hard spots in

rotors and drums from the overheat-cool down pro-

cess. In most cases, the rotors, drums, wheels and

tires are quite warm to the touch after the vehicle is

stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and

drums to the point of replacement. The wheels, tires

and brake components will be extremely hot. In

severe cases, the lining may generate smoke as it

chars from overheating.

Common causes of brake drag are:

²Seized or improperly adjusted parking brake

cables

²Loose/worn wheel bearing

²Seized caliper or wheel cylinder piston

²Caliper binding on damaged or missing anti-rat-

tle clips or bushings

²Loose caliper mounting

²Drum brake shoes binding on worn/damaged

support plates

²Mis-assembled components²Long booster output rod

If brake drag occurs at all wheels, the problem

may be related to a blocked master cylinder return

port, or faulty power booster (binds-does not release).

BRAKE FADE

Brake fade is usually a product of overheating

caused by brake drag. However, brake overheating

and resulting fade can also be caused by riding the

brake pedal, making repeated high deceleration stops

in a short time span, or constant braking on steep

mountain roads. Refer to the Brake Drag information

in this section for causes.

BRAKE PULL

Front brake pull condition could result from:

²Contaminated lining in one caliper

²Seized caliper piston

²Binding caliper

²Loose caliper

²Damaged anti-rattle clips

²Improper brake shoes

²Damaged rotor

A worn, damaged wheel bearing or suspension

component are further causes of pull. A damaged

front tire (bruised, ply separation) can also cause

pull.

A common and frequently misdiagnosed pull condi-

tion is where direction of pull changes after a few

stops. The cause is a combination of brake drag fol-

lowed by fade at one of the brake units.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in

favor of the normally functioning brake unit.

An additional point when diagnosing a change in

pull condition concerns brake cool down. Remember

that pull will return to the original direction, if the

dragging brake unit is allowed to cool down (and is

not seriously damaged).

REAR BRAKE GRAB OR PULL

Rear grab or pull is usually caused by improperly

adjusted or seized parking brake cables, contami-

nated lining, bent or binding shoes and support

plates, or improperly assembled components. This is

particularly true when only one rear wheel is

involved. However, when both rear wheels are

affected, the master cylinder or proportioning valve

could be at fault.

BRAKES DO NOT HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes very lightly applied for a

5 - 6 BRAKES - BASEBR/BE

HYDRAULIC/MECHANICAL (Continued)

Page 196 of 2255

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and/or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or wheel cylinders, worn seals, driv-

ing through deep water puddles, or lining that has

become covered with grease and grit during repair.

Contaminated lining should be replaced to avoid fur-

ther brake problems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibra-

tion and generate shudder during brake operation. A

tire with internal damage such as a severe bruise,

cut, or ply separation can cause pull and vibration.

BRAKE NOISES

Some brake noise is common with rear drum

brakes and on some disc brakes during the first few

stops after a vehicle has been parked overnight or

stored. This is primarily due to the formation of trace

corrosion (light rust) on metal surfaces. This light

corrosion is typically cleared from the metal surfaces

after a few brake applications causing the noise to

subside.

BRAKE SQUEAK/SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake shoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors and drums can become so scored that replace-

ment is necessary.

BRAKE CHATTER

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional causes

of chatter are out-of-tolerance rotors, brake lining not

securely attached to the shoes, loose wheel bearings

and contaminated brake lining.THUMP/CLUNK NOISE

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. However,

calipers that bind on the slide surfaces can generate

a thump or clunk noise. In addition, worn out,

improperly adjusted, or improperly assembled rear

brake shoes can also produce a thump noise.

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

(1) Remove reservoir filler caps and fill reservoir.

(2) If calipers, or wheel cylinders were overhauled,

open all caliper and wheel cylinder bleed screws.

Then close each bleed screw as fluid starts to drip

from it. Top off master cylinder reservoir once more

before proceeding.

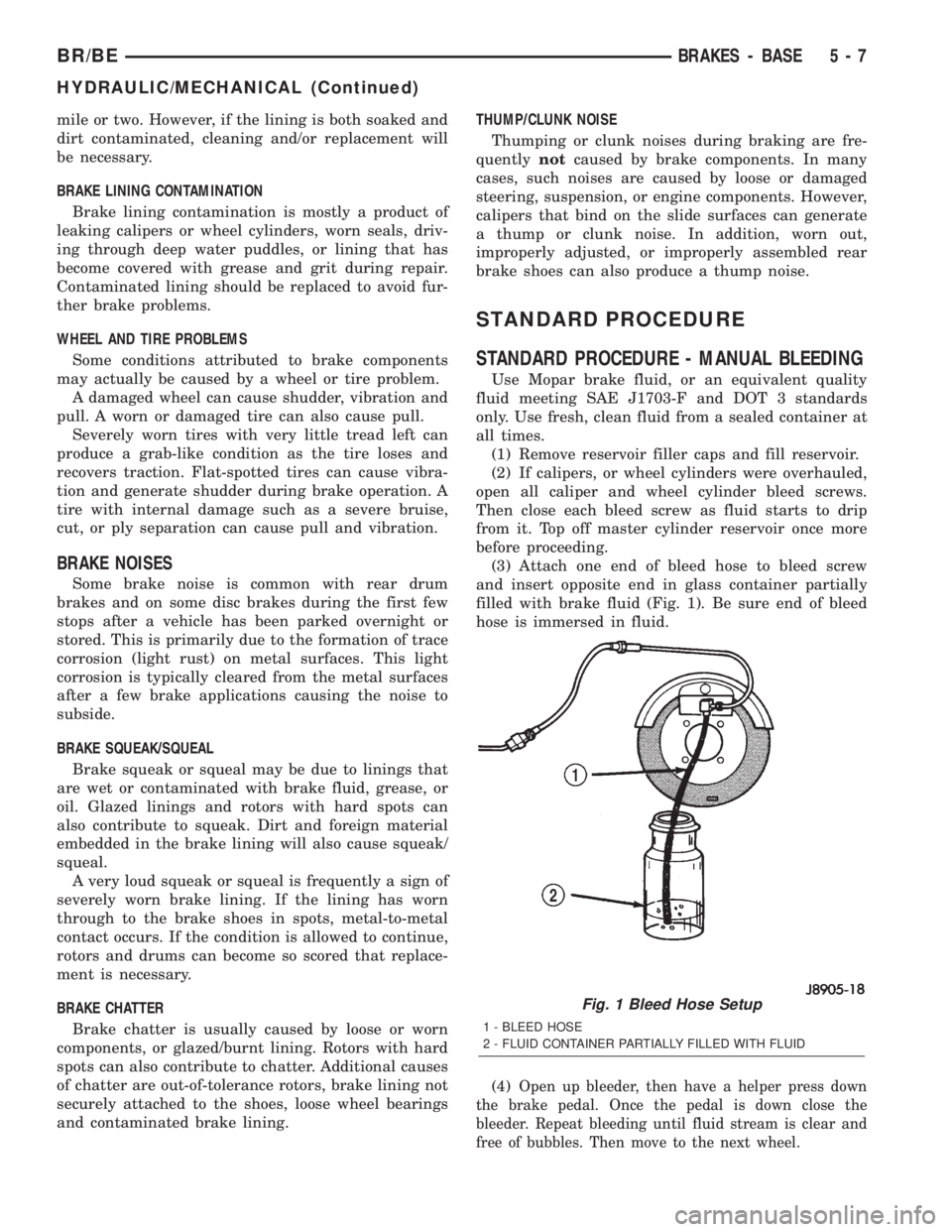

(3) Attach one end of bleed hose to bleed screw

and insert opposite end in glass container partially

filled with brake fluid (Fig. 1). Be sure end of bleed

hose is immersed in fluid.

(4)

Open up bleeder, then have a helper press down

the brake pedal. Once the pedal is down close the

bleeder. Repeat bleeding until fluid stream is clear and

free of bubbles. Then move to the next wheel.

Fig. 1 Bleed Hose Setup

1 - BLEED HOSE

2 - FLUID CONTAINER PARTIALLY FILLED WITH FLUID

BR/BEBRAKES - BASE 5 - 7

HYDRAULIC/MECHANICAL (Continued)