light DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 93 of 2255

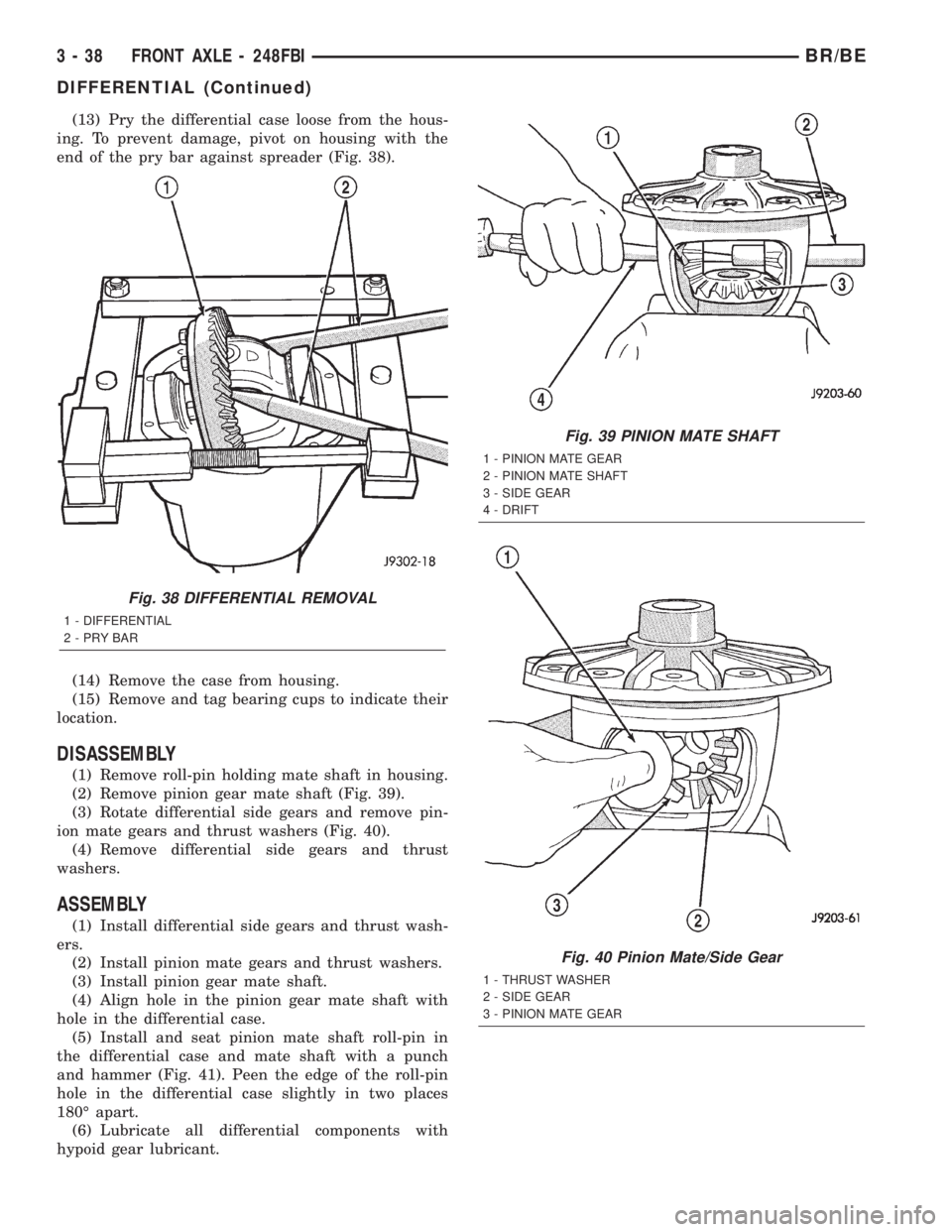

(13) Pry the differential case loose from the hous-

ing. To prevent damage, pivot on housing with the

end of the pry bar against spreader (Fig. 38).

(14) Remove the case from housing.

(15) Remove and tag bearing cups to indicate their

location.

DISASSEMBLY

(1) Remove roll-pin holding mate shaft in housing.

(2) Remove pinion gear mate shaft (Fig. 39).

(3) Rotate differential side gears and remove pin-

ion mate gears and thrust washers (Fig. 40).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install pinion mate gears and thrust washers.

(3) Install pinion gear mate shaft.

(4) Align hole in the pinion gear mate shaft with

hole in the differential case.

(5) Install and seat pinion mate shaft roll-pin in

the differential case and mate shaft with a punch

and hammer (Fig. 41). Peen the edge of the roll-pin

hole in the differential case slightly in two places

180É apart.

(6) Lubricate all differential components with

hypoid gear lubricant.

Fig. 38 DIFFERENTIAL REMOVAL

1 - DIFFERENTIAL

2-PRYBAR

Fig. 39 PINION MATE SHAFT

1 - PINION MATE GEAR

2 - PINION MATE SHAFT

3 - SIDE GEAR

4 - DRIFT

Fig. 40 Pinion Mate/Side Gear

1 - THRUST WASHER

2 - SIDE GEAR

3 - PINION MATE GEAR

3 - 38 FRONT AXLE - 248FBIBR/BE

DIFFERENTIAL (Continued)

Page 98 of 2255

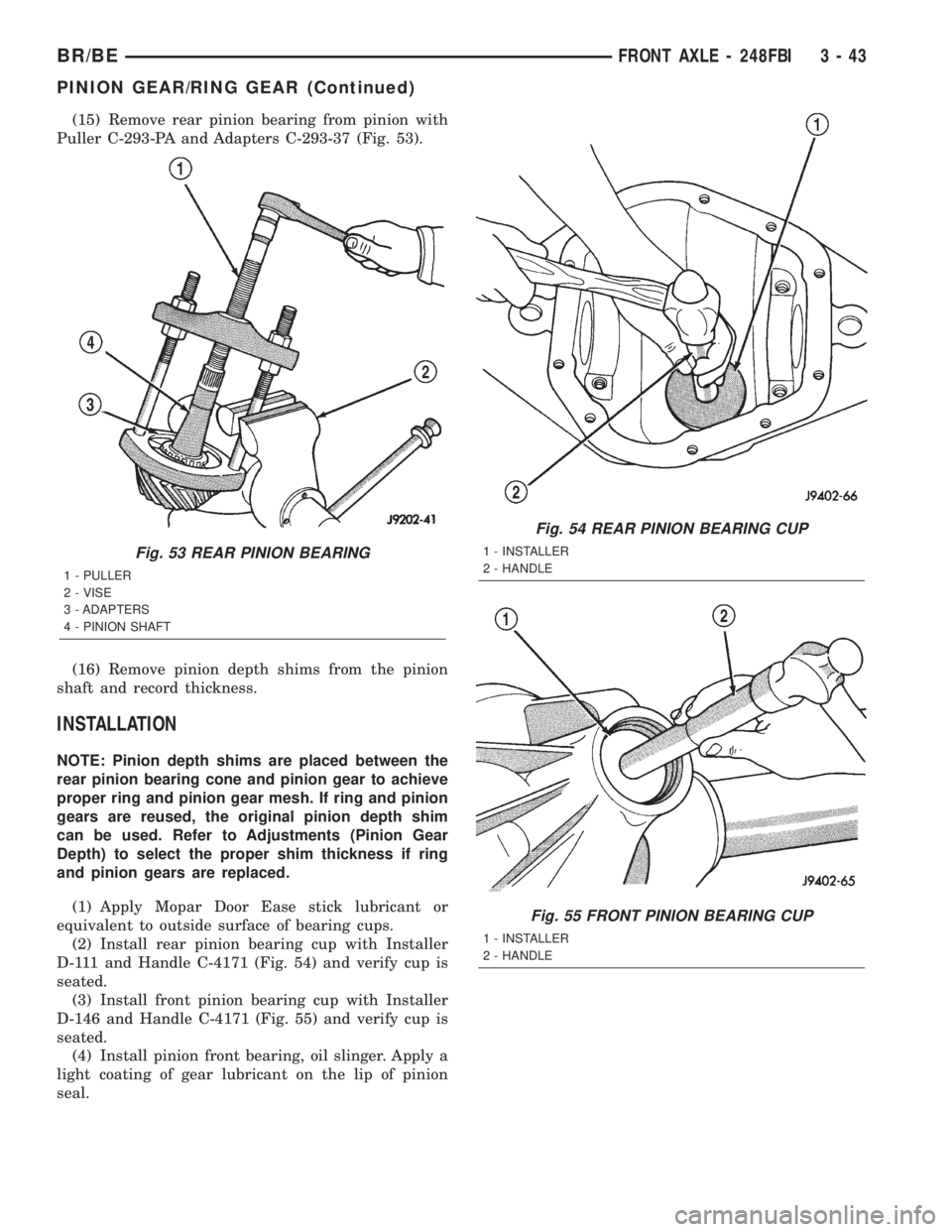

(15) Remove rear pinion bearing from pinion with

Puller C-293-PA and Adapters C-293-37 (Fig. 53).

(16) Remove pinion depth shims from the pinion

shaft and record thickness.

INSTALLATION

NOTE: Pinion depth shims are placed between the

rear pinion bearing cone and pinion gear to achieve

proper ring and pinion gear mesh. If ring and pinion

gears are reused, the original pinion depth shim

can be used. Refer to Adjustments (Pinion Gear

Depth) to select the proper shim thickness if ring

and pinion gears are replaced.

(1) Apply Mopar Door Ease stick lubricant or

equivalent to outside surface of bearing cups.

(2) Install rear pinion bearing cup with Installer

D-111 and Handle C-4171 (Fig. 54) and verify cup is

seated.

(3) Install front pinion bearing cup with Installer

D-146 and Handle C-4171 (Fig. 55) and verify cup is

seated.

(4) Install pinion front bearing, oil slinger. Apply a

light coating of gear lubricant on the lip of pinion

seal.

Fig. 53 REAR PINION BEARING

1 - PULLER

2 - VISE

3 - ADAPTERS

4 - PINION SHAFT

Fig. 54 REAR PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 55 FRONT PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

BR/BEFRONT AXLE - 248FBI 3 - 43

PINION GEAR/RING GEAR (Continued)

Page 103 of 2255

cle turns. A worn pinion shaft can also cause a snap-

ping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side±gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

3 - 48 REAR AXLE - 248RBIBR/BE

REAR AXLE - 248RBI (Continued)

Page 118 of 2255

PINION SEAL

REMOVAL

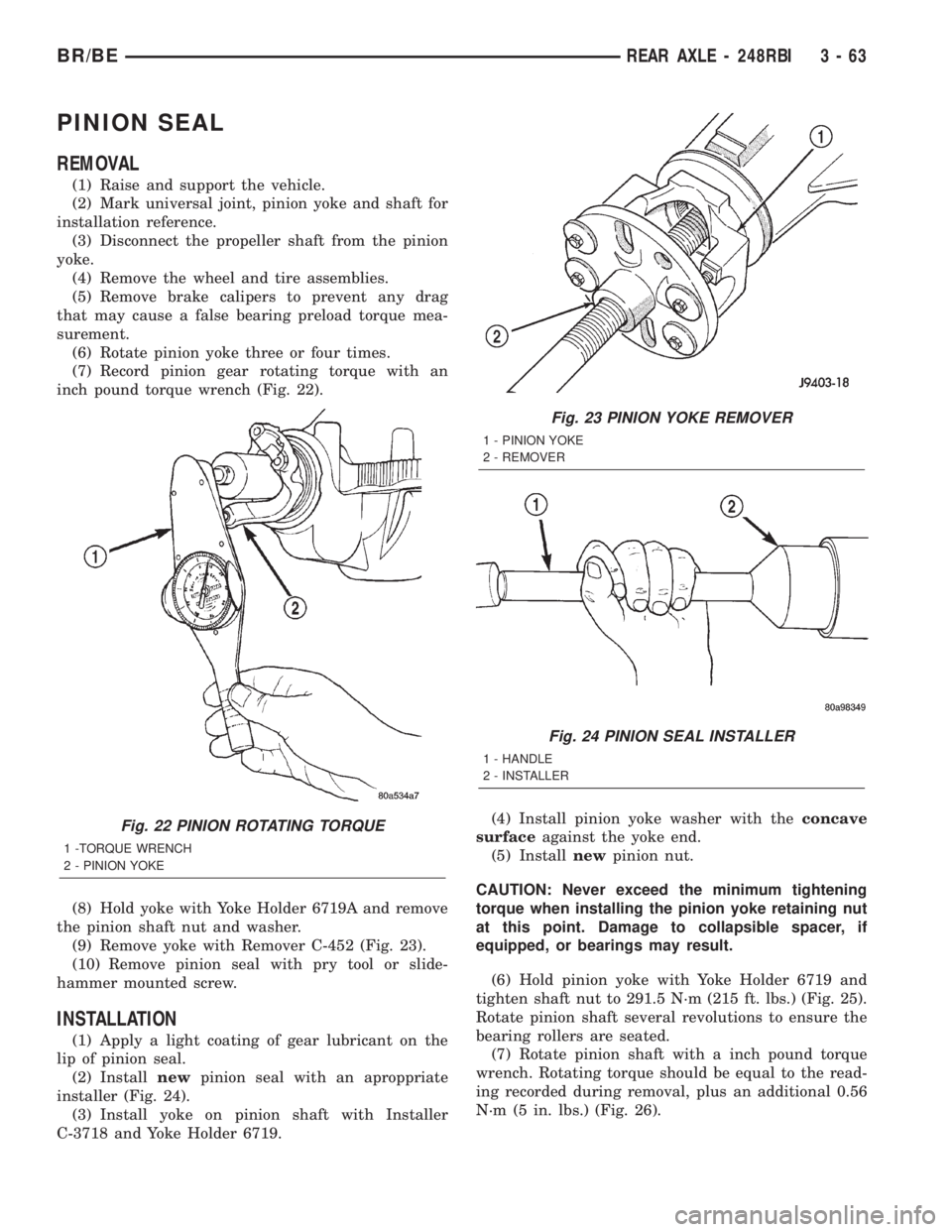

(1) Raise and support the vehicle.

(2) Mark universal joint, pinion yoke and shaft for

installation reference.

(3) Disconnect the propeller shaft from the pinion

yoke.

(4) Remove the wheel and tire assemblies.

(5) Remove brake calipers to prevent any drag

that may cause a false bearing preload torque mea-

surement.

(6) Rotate pinion yoke three or four times.

(7) Record pinion gear rotating torque with an

inch pound torque wrench (Fig. 22).

(8) Hold yoke with Yoke Holder 6719A and remove

the pinion shaft nut and washer.

(9) Remove yoke with Remover C-452 (Fig. 23).

(10) Remove pinion seal with pry tool or slide-

hammer mounted screw.

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal.

(2) Installnewpinion seal with an aproppriate

installer (Fig. 24).

(3) Install yoke on pinion shaft with Installer

C-3718 and Yoke Holder 6719.(4) Install pinion yoke washer with theconcave

surfaceagainst the yoke end.

(5) Installnewpinion nut.

CAUTION: Never exceed the minimum tightening

torque when installing the pinion yoke retaining nut

at this point. Damage to collapsible spacer, if

equipped, or bearings may result.

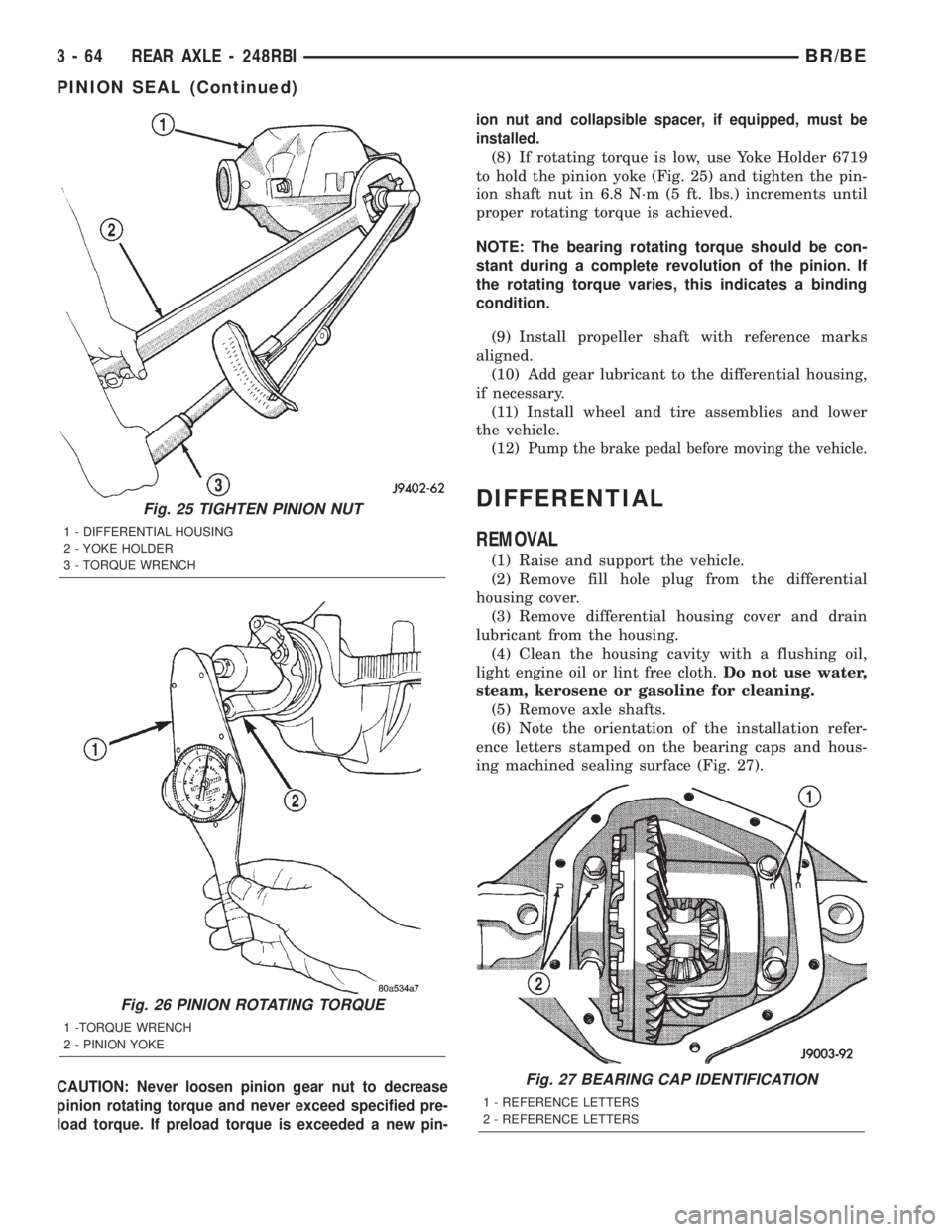

(6) Hold pinion yoke with Yoke Holder 6719 and

tighten shaft nut to 291.5 N´m (215 ft. lbs.) (Fig. 25).

Rotate pinion shaft several revolutions to ensure the

bearing rollers are seated.

(7) Rotate pinion shaft with a inch pound torque

wrench. Rotating torque should be equal to the read-

ing recorded during removal, plus an additional 0.56

N´m (5 in. lbs.) (Fig. 26).

Fig. 22 PINION ROTATING TORQUE

1 -TORQUE WRENCH

2 - PINION YOKE

Fig. 23 PINION YOKE REMOVER

1 - PINION YOKE

2 - REMOVER

Fig. 24 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

BR/BEREAR AXLE - 248RBI 3 - 63

Page 119 of 2255

CAUTION: Never loosen pinion gear nut to decrease

pinion rotating torque and never exceed specified pre-

load torque. If preload torque is exceeded a new pin-ion nut and collapsible spacer, if equipped, must be

installed.

(8) If rotating torque is low, use Yoke Holder 6719

to hold the pinion yoke (Fig. 25) and tighten the pin-

ion shaft nut in 6.8 N´m (5 ft. lbs.) increments until

proper rotating torque is achieved.

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

(9) Install propeller shaft with reference marks

aligned.

(10) Add gear lubricant to the differential housing,

if necessary.

(11) Install wheel and tire assemblies and lower

the vehicle.

(12)

Pump the brake pedal before moving the vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove fill hole plug from the differential

housing cover.

(3) Remove differential housing cover and drain

lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove axle shafts.

(6) Note the orientation of the installation refer-

ence letters stamped on the bearing caps and hous-

ing machined sealing surface (Fig. 27).

Fig. 25 TIGHTEN PINION NUT

1 - DIFFERENTIAL HOUSING

2 - YOKE HOLDER

3 - TORQUE WRENCH

Fig. 26 PINION ROTATING TORQUE

1 -TORQUE WRENCH

2 - PINION YOKE

Fig. 27 BEARING CAP IDENTIFICATION

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

3 - 64 REAR AXLE - 248RBIBR/BE

PINION SEAL (Continued)

Page 121 of 2255

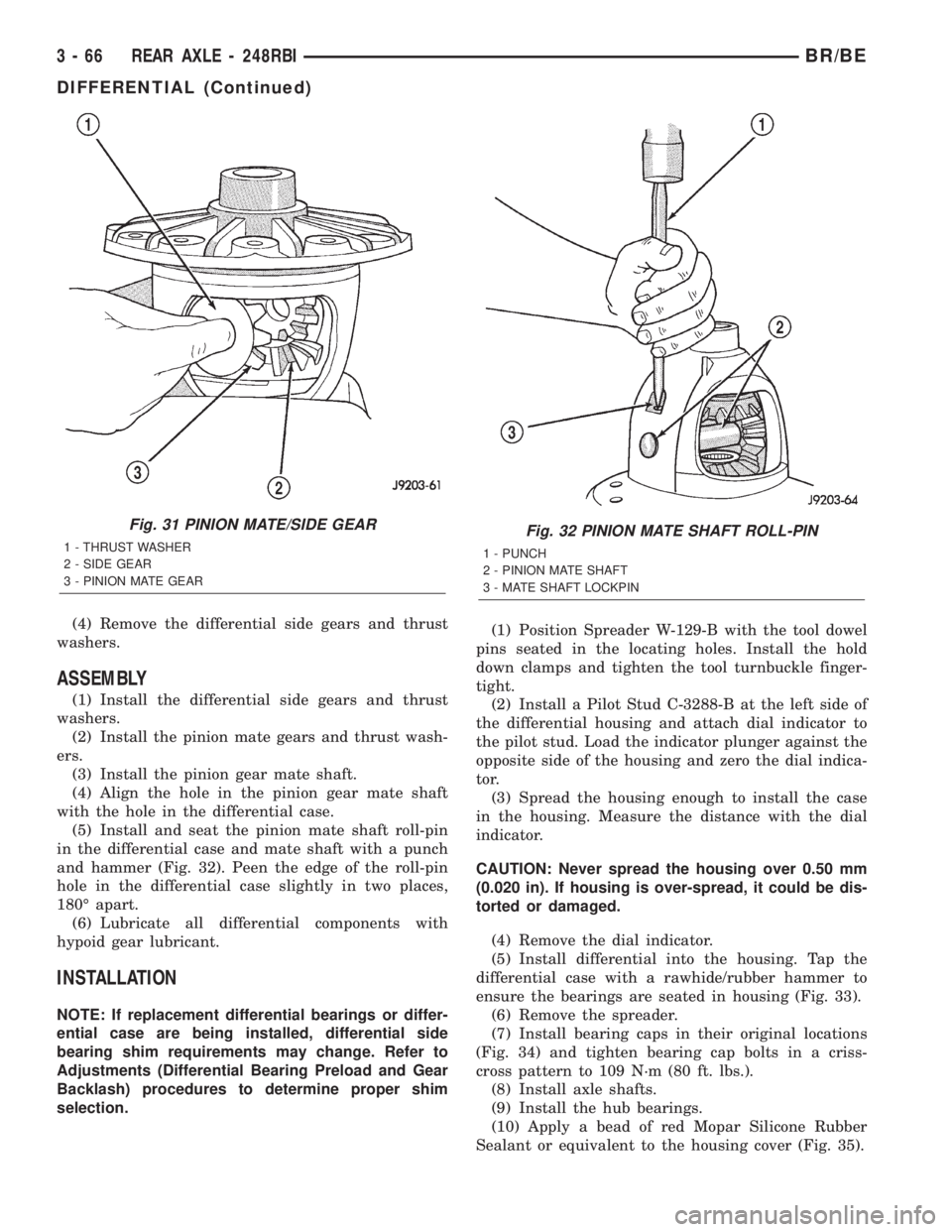

(4) Remove the differential side gears and thrust

washers.

ASSEMBLY

(1) Install the differential side gears and thrust

washers.

(2) Install the pinion mate gears and thrust wash-

ers.

(3) Install the pinion gear mate shaft.

(4) Align the hole in the pinion gear mate shaft

with the hole in the differential case.

(5) Install and seat the pinion mate shaft roll-pin

in the differential case and mate shaft with a punch

and hammer (Fig. 32). Peen the edge of the roll-pin

hole in the differential case slightly in two places,

180É apart.

(6) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer to

Adjustments (Differential Bearing Preload and Gear

Backlash) procedures to determine proper shim

selection.(1) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes. Install the hold

down clamps and tighten the tool turnbuckle finger-

tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing and attach dial indicator to

the pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the dial indica-

tor.

(3) Spread the housing enough to install the case

in the housing. Measure the distance with the dial

indicator.

CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If housing is over-spread, it could be dis-

torted or damaged.

(4) Remove the dial indicator.

(5) Install differential into the housing. Tap the

differential case with a rawhide/rubber hammer to

ensure the bearings are seated in housing (Fig. 33).

(6) Remove the spreader.

(7) Install bearing caps in their original locations

(Fig. 34) and tighten bearing cap bolts in a criss-

cross pattern to 109 N´m (80 ft. lbs.).

(8) Install axle shafts.

(9) Install the hub bearings.

(10) Apply a bead of red Mopar Silicone Rubber

Sealant or equivalent to the housing cover (Fig. 35).

Fig. 31 PINION MATE/SIDE GEAR

1 - THRUST WASHER

2 - SIDE GEAR

3 - PINION MATE GEARFig. 32 PINION MATE SHAFT ROLL-PIN

1 - PUNCH

2 - PINION MATE SHAFT

3 - MATE SHAFT LOCKPIN

3 - 66 REAR AXLE - 248RBIBR/BE

DIFFERENTIAL (Continued)

Page 126 of 2255

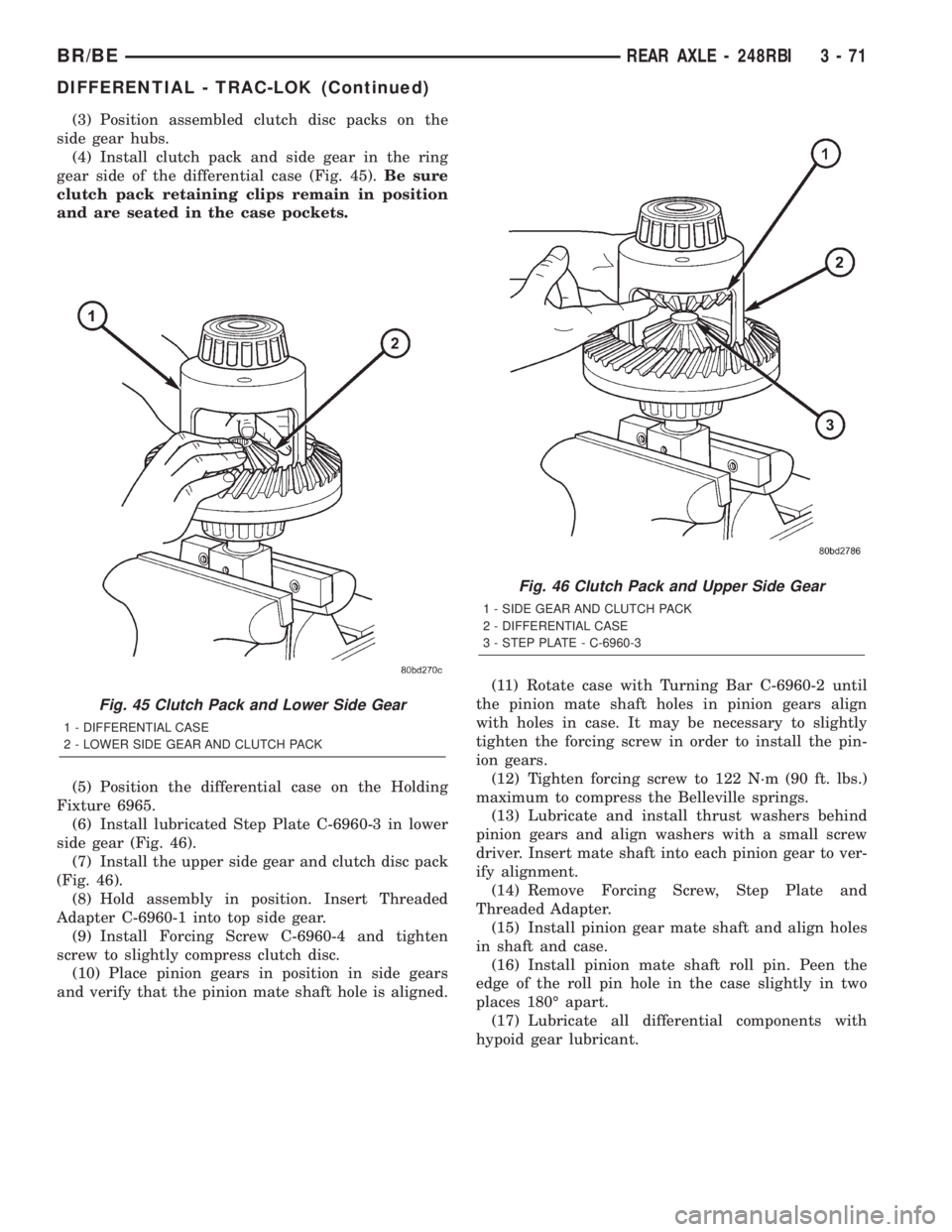

(3) Position assembled clutch disc packs on the

side gear hubs.

(4) Install clutch pack and side gear in the ring

gear side of the differential case (Fig. 45).Be sure

clutch pack retaining clips remain in position

and are seated in the case pockets.

(5) Position the differential case on the Holding

Fixture 6965.

(6) Install lubricated Step Plate C-6960-3 in lower

side gear (Fig. 46).

(7) Install the upper side gear and clutch disc pack

(Fig. 46).

(8) Hold assembly in position. Insert Threaded

Adapter C-6960-1 into top side gear.

(9) Install Forcing Screw C-6960-4 and tighten

screw to slightly compress clutch disc.

(10) Place pinion gears in position in side gears

and verify that the pinion mate shaft hole is aligned.(11) Rotate case with Turning Bar C-6960-2 until

the pinion mate shaft holes in pinion gears align

with holes in case. It may be necessary to slightly

tighten the forcing screw in order to install the pin-

ion gears.

(12) Tighten forcing screw to 122 N´m (90 ft. lbs.)

maximum to compress the Belleville springs.

(13) Lubricate and install thrust washers behind

pinion gears and align washers with a small screw

driver. Insert mate shaft into each pinion gear to ver-

ify alignment.

(14) Remove Forcing Screw, Step Plate and

Threaded Adapter.

(15) Install pinion gear mate shaft and align holes

in shaft and case.

(16) Install pinion mate shaft roll pin. Peen the

edge of the roll pin hole in the case slightly in two

places 180É apart.

(17) Lubricate all differential components with

hypoid gear lubricant.

Fig. 45 Clutch Pack and Lower Side Gear

1 - DIFFERENTIAL CASE

2 - LOWER SIDE GEAR AND CLUTCH PACK

Fig. 46 Clutch Pack and Upper Side Gear

1 - SIDE GEAR AND CLUTCH PACK

2 - DIFFERENTIAL CASE

3 - STEP PLATE - C-6960-3

BR/BEREAR AXLE - 248RBI 3 - 71

DIFFERENTIAL - TRAC-LOK (Continued)

Page 130 of 2255

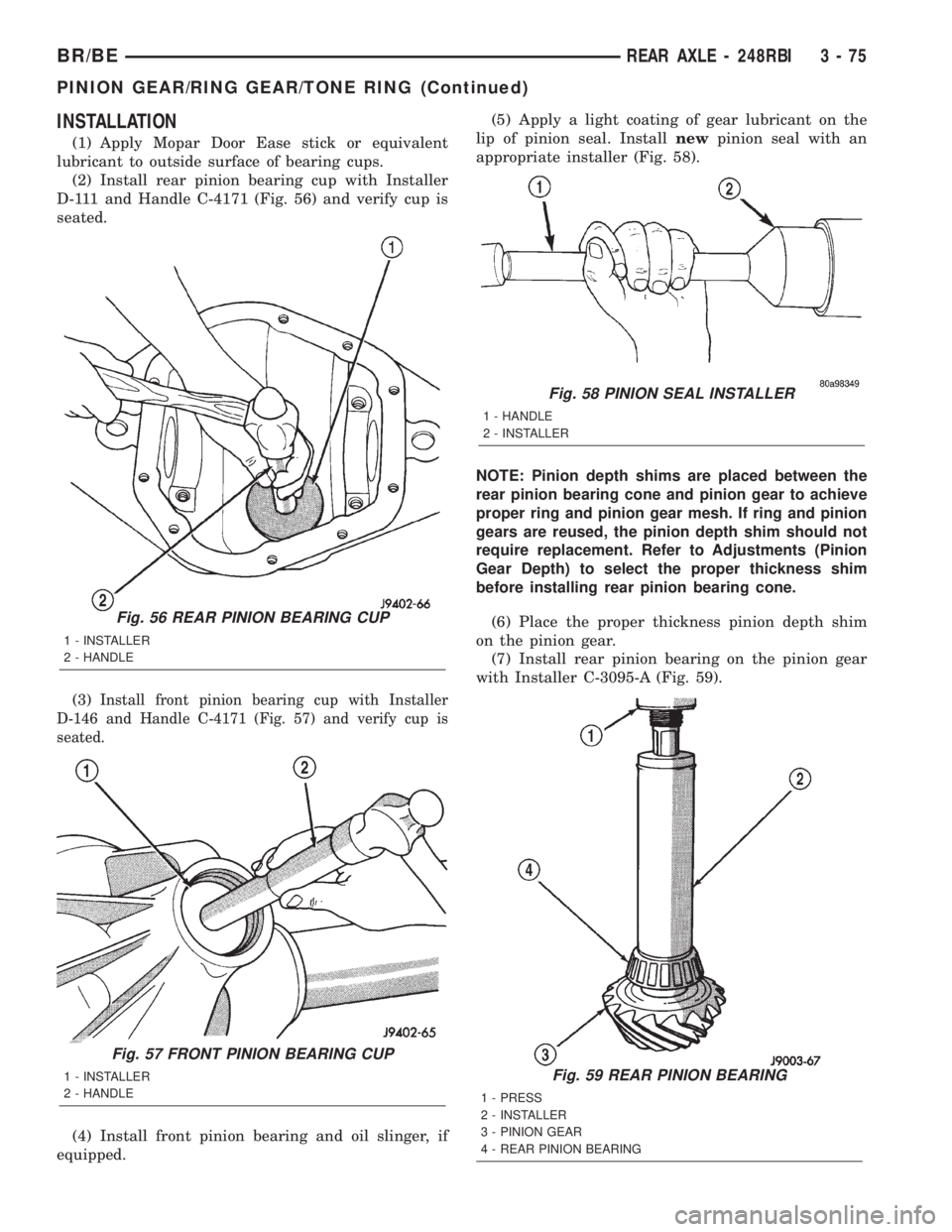

INSTALLATION

(1) Apply Mopar Door Ease stick or equivalent

lubricant to outside surface of bearing cups.

(2) Install rear pinion bearing cup with Installer

D-111 and Handle C-4171 (Fig. 56) and verify cup is

seated.

(3)

Install front pinion bearing cup with Installer

D-146 and Handle C-4171 (Fig. 57) and verify cup is

seated.

(4) Install front pinion bearing and oil slinger, if

equipped.(5) Apply a light coating of gear lubricant on the

lip of pinion seal. Installnewpinion seal with an

appropriate installer (Fig. 58).

NOTE: Pinion depth shims are placed between the

rear pinion bearing cone and pinion gear to achieve

proper ring and pinion gear mesh. If ring and pinion

gears are reused, the pinion depth shim should not

require replacement. Refer to Adjustments (Pinion

Gear Depth) to select the proper thickness shim

before installing rear pinion bearing cone.

(6) Place the proper thickness pinion depth shim

on the pinion gear.

(7) Install rear pinion bearing on the pinion gear

with Installer C-3095-A (Fig. 59).

Fig. 59 REAR PINION BEARING

1 - PRESS

2 - INSTALLER

3 - PINION GEAR

4 - REAR PINION BEARING

Fig. 56 REAR PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 57 FRONT PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 58 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

BR/BEREAR AXLE - 248RBI 3 - 75

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 135 of 2255

torque supplied to the non-slipping wheel. The differ-

ential resist wheel spin on bumpy roads and provide

more pulling power when one wheel looses traction.

Pulling power is provided continuously until both

wheels loose traction. If both wheels slip due to

unequal traction, operation is normal. In extreme

cases of differences of traction, the wheel with the

least traction may spin.

DIAGNOSIS AND TESTING - AXLE

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, incorrect pinion depth, tooth

contact, worn/damaged gears, or the carrier housing

not having the proper offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion shaft can also cause a snap-

ping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side±gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

3 - 80 REAR AXLE - 267RBIBR/BE

REAR AXLE - 267RBI (Continued)

Page 150 of 2255

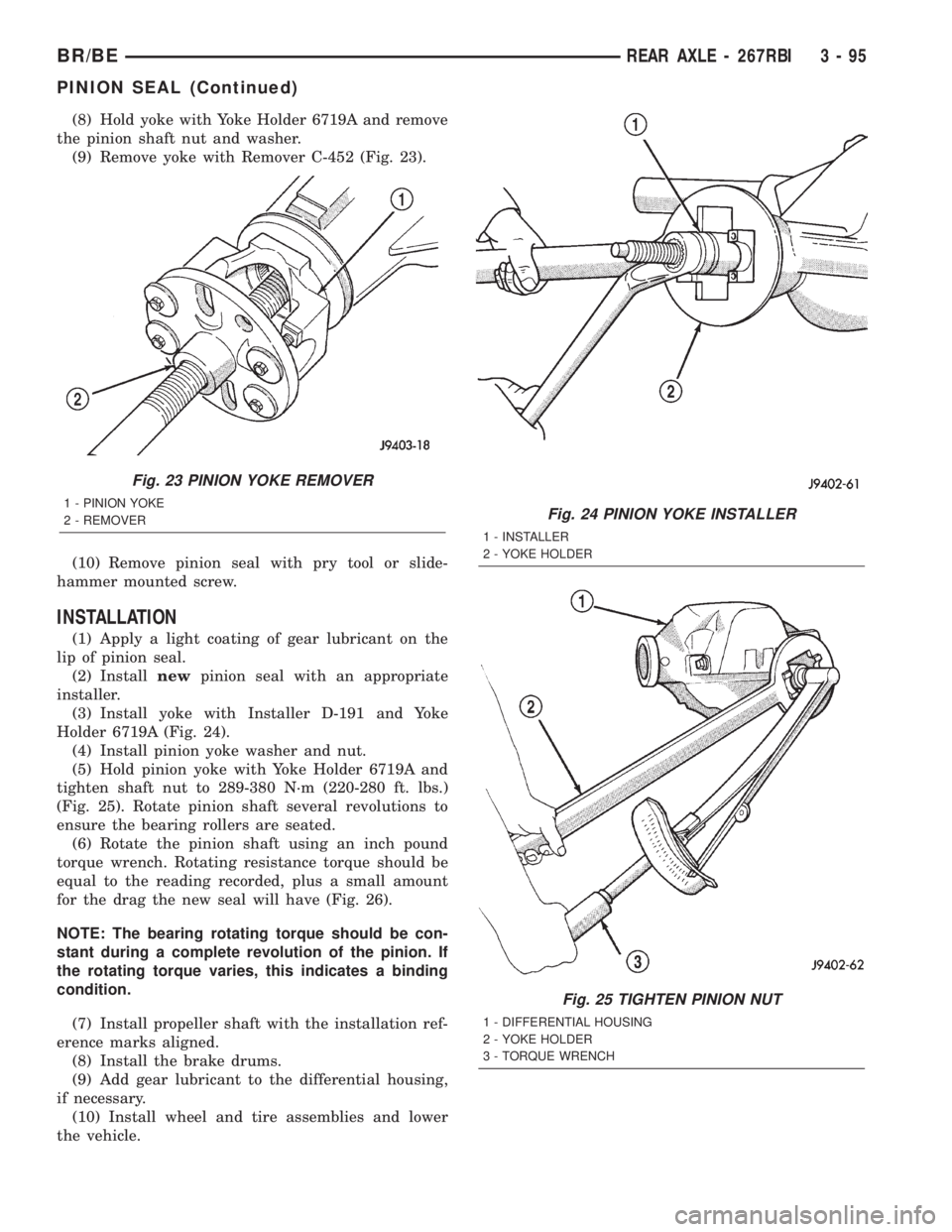

(8) Hold yoke with Yoke Holder 6719A and remove

the pinion shaft nut and washer.

(9) Remove yoke with Remover C-452 (Fig. 23).

(10) Remove pinion seal with pry tool or slide-

hammer mounted screw.

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal.

(2) Installnewpinion seal with an appropriate

installer.

(3) Install yoke with Installer D-191 and Yoke

Holder 6719A (Fig. 24).

(4) Install pinion yoke washer and nut.

(5) Hold pinion yoke with Yoke Holder 6719A and

tighten shaft nut to 289-380 N´m (220-280 ft. lbs.)

(Fig. 25). Rotate pinion shaft several revolutions to

ensure the bearing rollers are seated.

(6) Rotate the pinion shaft using an inch pound

torque wrench. Rotating resistance torque should be

equal to the reading recorded, plus a small amount

for the drag the new seal will have (Fig. 26).

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

(7) Install propeller shaft with the installation ref-

erence marks aligned.

(8) Install the brake drums.

(9) Add gear lubricant to the differential housing,

if necessary.

(10) Install wheel and tire assemblies and lower

the vehicle.

Fig. 23 PINION YOKE REMOVER

1 - PINION YOKE

2 - REMOVERFig. 24 PINION YOKE INSTALLER

1 - INSTALLER

2 - YOKE HOLDER

Fig. 25 TIGHTEN PINION NUT

1 - DIFFERENTIAL HOUSING

2 - YOKE HOLDER

3 - TORQUE WRENCH

BR/BEREAR AXLE - 267RBI 3 - 95

PINION SEAL (Continued)