set clock DODGE RAM 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1717 of 2255

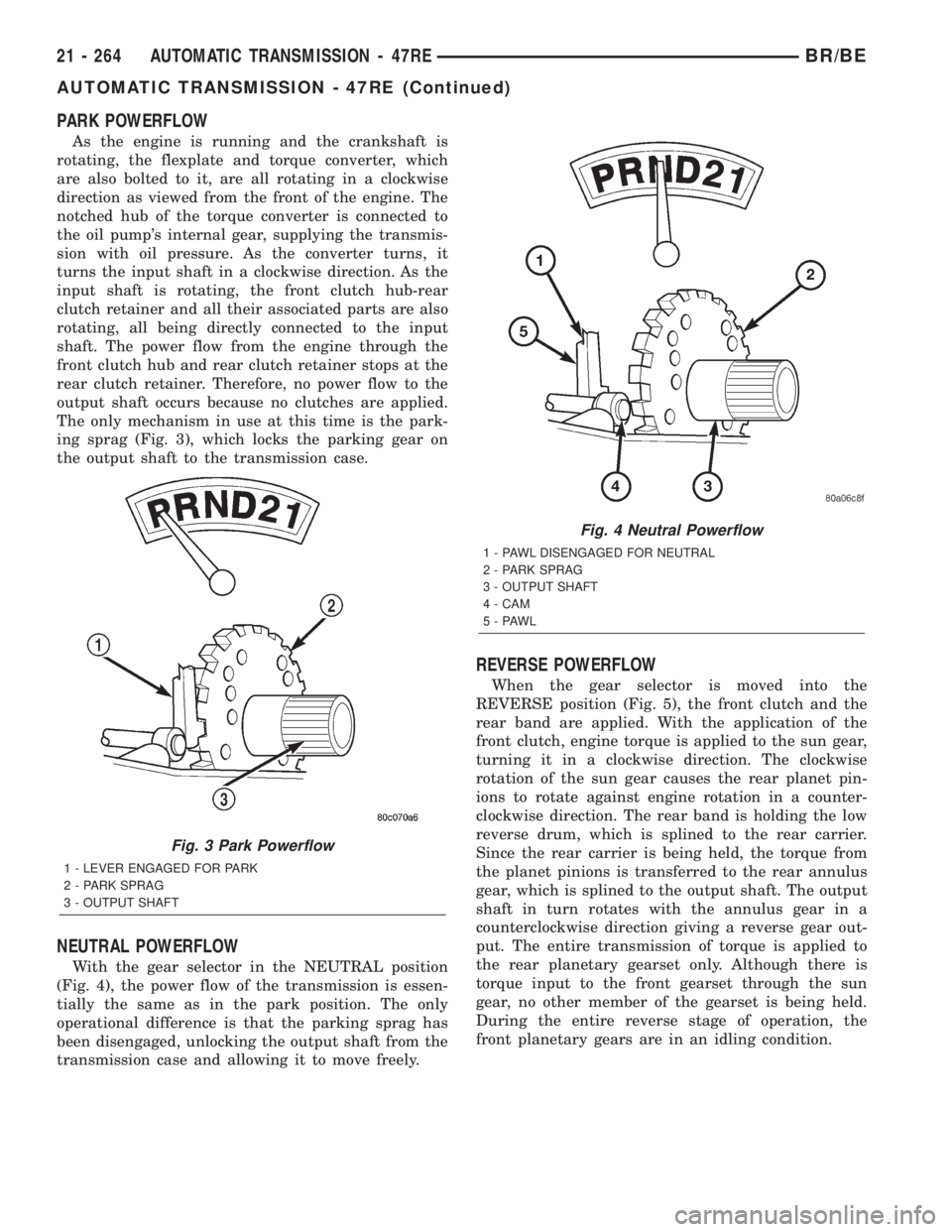

PARK POWERFLOW

As the engine is running and the crankshaft is

rotating, the flexplate and torque converter, which

are also bolted to it, are all rotating in a clockwise

direction as viewed from the front of the engine. The

notched hub of the torque converter is connected to

the oil pump's internal gear, supplying the transmis-

sion with oil pressure. As the converter turns, it

turns the input shaft in a clockwise direction. As the

input shaft is rotating, the front clutch hub-rear

clutch retainer and all their associated parts are also

rotating, all being directly connected to the input

shaft. The power flow from the engine through the

front clutch hub and rear clutch retainer stops at the

rear clutch retainer. Therefore, no power flow to the

output shaft occurs because no clutches are applied.

The only mechanism in use at this time is the park-

ing sprag (Fig. 3), which locks the parking gear on

the output shaft to the transmission case.

NEUTRAL POWERFLOW

With the gear selector in the NEUTRAL position

(Fig. 4), the power flow of the transmission is essen-

tially the same as in the park position. The only

operational difference is that the parking sprag has

been disengaged, unlocking the output shaft from the

transmission case and allowing it to move freely.

REVERSE POWERFLOW

When the gear selector is moved into the

REVERSE position (Fig. 5), the front clutch and the

rear band are applied. With the application of the

front clutch, engine torque is applied to the sun gear,

turning it in a clockwise direction. The clockwise

rotation of the sun gear causes the rear planet pin-

ions to rotate against engine rotation in a counter-

clockwise direction. The rear band is holding the low

reverse drum, which is splined to the rear carrier.

Since the rear carrier is being held, the torque from

the planet pinions is transferred to the rear annulus

gear, which is splined to the output shaft. The output

shaft in turn rotates with the annulus gear in a

counterclockwise direction giving a reverse gear out-

put. The entire transmission of torque is applied to

the rear planetary gearset only. Although there is

torque input to the front gearset through the sun

gear, no other member of the gearset is being held.

During the entire reverse stage of operation, the

front planetary gears are in an idling condition.

Fig. 3 Park Powerflow

1 - LEVER ENGAGED FOR PARK

2 - PARK SPRAG

3 - OUTPUT SHAFT

Fig. 4 Neutral Powerflow

1 - PAWL DISENGAGED FOR NEUTRAL

2 - PARK SPRAG

3 - OUTPUT SHAFT

4 - CAM

5-PAWL

21 - 264 AUTOMATIC TRANSMISSION - 47REBR/BE

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 1719 of 2255

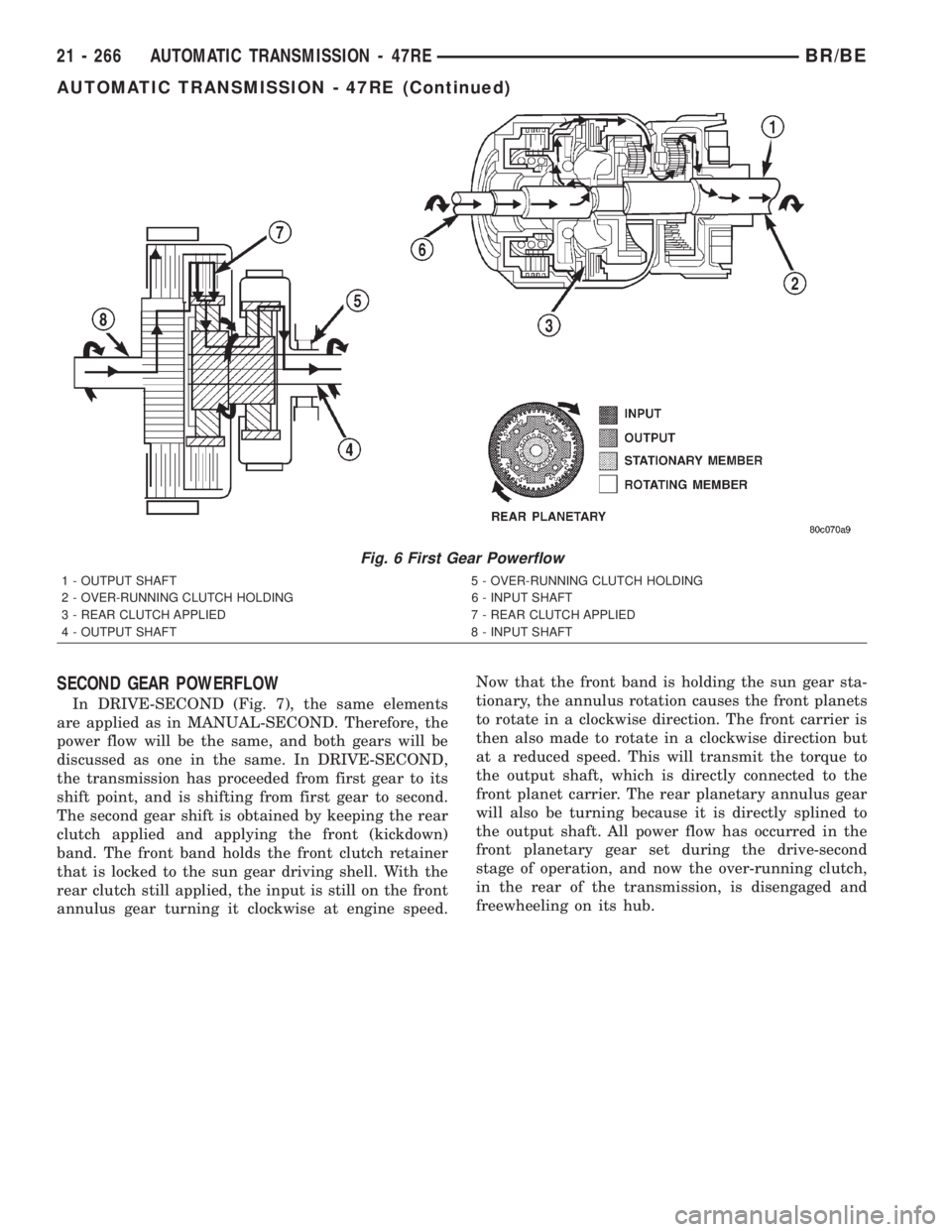

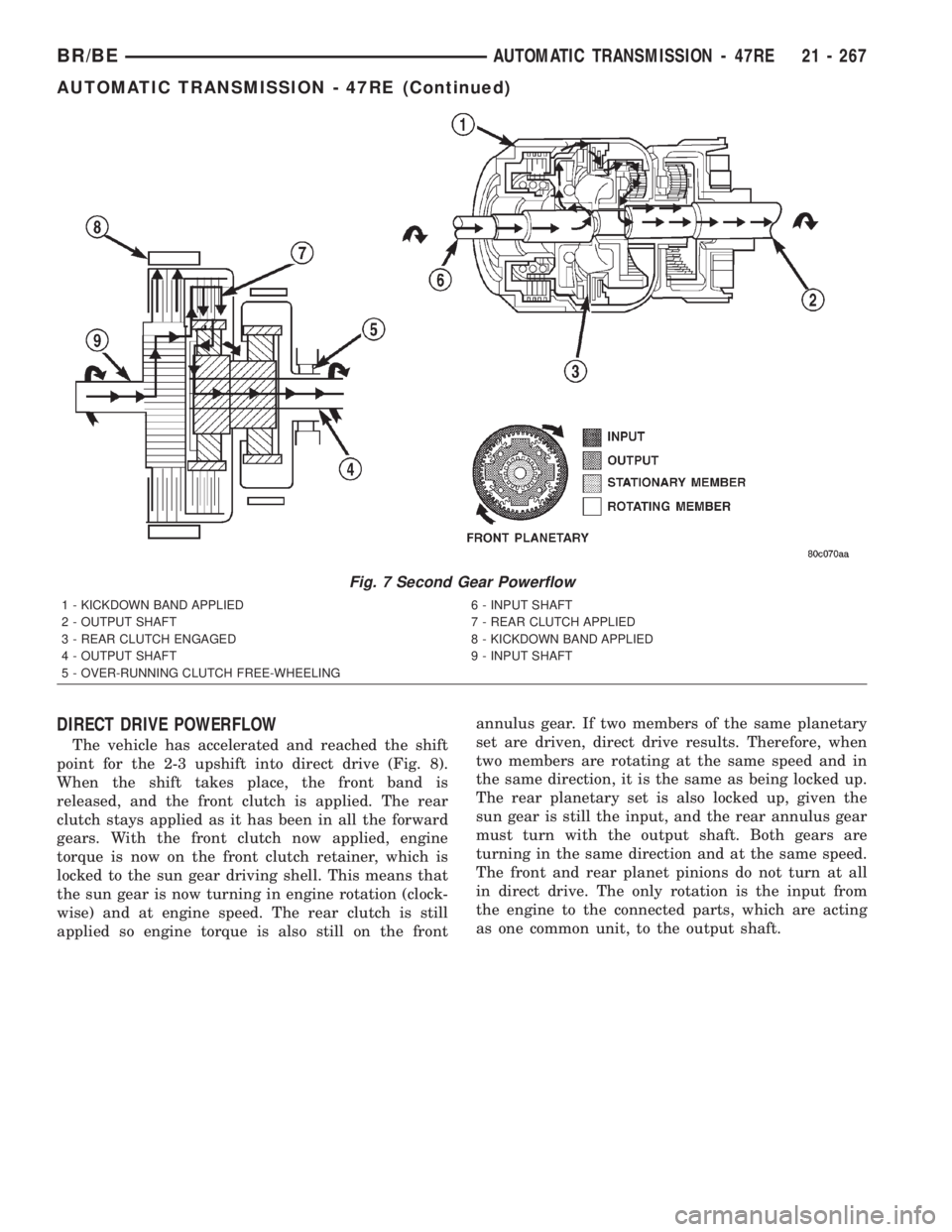

SECOND GEAR POWERFLOW

In DRIVE-SECOND (Fig. 7), the same elements

are applied as in MANUAL-SECOND. Therefore, the

power flow will be the same, and both gears will be

discussed as one in the same. In DRIVE-SECOND,

the transmission has proceeded from first gear to its

shift point, and is shifting from first gear to second.

The second gear shift is obtained by keeping the rear

clutch applied and applying the front (kickdown)

band. The front band holds the front clutch retainer

that is locked to the sun gear driving shell. With the

rear clutch still applied, the input is still on the front

annulus gear turning it clockwise at engine speed.Now that the front band is holding the sun gear sta-

tionary, the annulus rotation causes the front planets

to rotate in a clockwise direction. The front carrier is

then also made to rotate in a clockwise direction but

at a reduced speed. This will transmit the torque to

the output shaft, which is directly connected to the

front planet carrier. The rear planetary annulus gear

will also be turning because it is directly splined to

the output shaft. All power flow has occurred in the

front planetary gear set during the drive-second

stage of operation, and now the over-running clutch,

in the rear of the transmission, is disengaged and

freewheeling on its hub.

Fig. 6 First Gear Powerflow

1 - OUTPUT SHAFT 5 - OVER-RUNNING CLUTCH HOLDING

2 - OVER-RUNNING CLUTCH HOLDING 6 - INPUT SHAFT

3 - REAR CLUTCH APPLIED 7 - REAR CLUTCH APPLIED

4 - OUTPUT SHAFT 8 - INPUT SHAFT

21 - 266 AUTOMATIC TRANSMISSION - 47REBR/BE

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 1720 of 2255

DIRECT DRIVE POWERFLOW

The vehicle has accelerated and reached the shift

point for the 2-3 upshift into direct drive (Fig. 8).

When the shift takes place, the front band is

released, and the front clutch is applied. The rear

clutch stays applied as it has been in all the forward

gears. With the front clutch now applied, engine

torque is now on the front clutch retainer, which is

locked to the sun gear driving shell. This means that

the sun gear is now turning in engine rotation (clock-

wise) and at engine speed. The rear clutch is still

applied so engine torque is also still on the frontannulus gear. If two members of the same planetary

set are driven, direct drive results. Therefore, when

two members are rotating at the same speed and in

the same direction, it is the same as being locked up.

The rear planetary set is also locked up, given the

sun gear is still the input, and the rear annulus gear

must turn with the output shaft. Both gears are

turning in the same direction and at the same speed.

The front and rear planet pinions do not turn at all

in direct drive. The only rotation is the input from

the engine to the connected parts, which are acting

as one common unit, to the output shaft.

Fig. 7 Second Gear Powerflow

1 - KICKDOWN BAND APPLIED 6 - INPUT SHAFT

2 - OUTPUT SHAFT 7 - REAR CLUTCH APPLIED

3 - REAR CLUTCH ENGAGED 8 - KICKDOWN BAND APPLIED

4 - OUTPUT SHAFT 9 - INPUT SHAFT

5 - OVER-RUNNING CLUTCH FREE-WHEELING

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 267

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 1882 of 2255

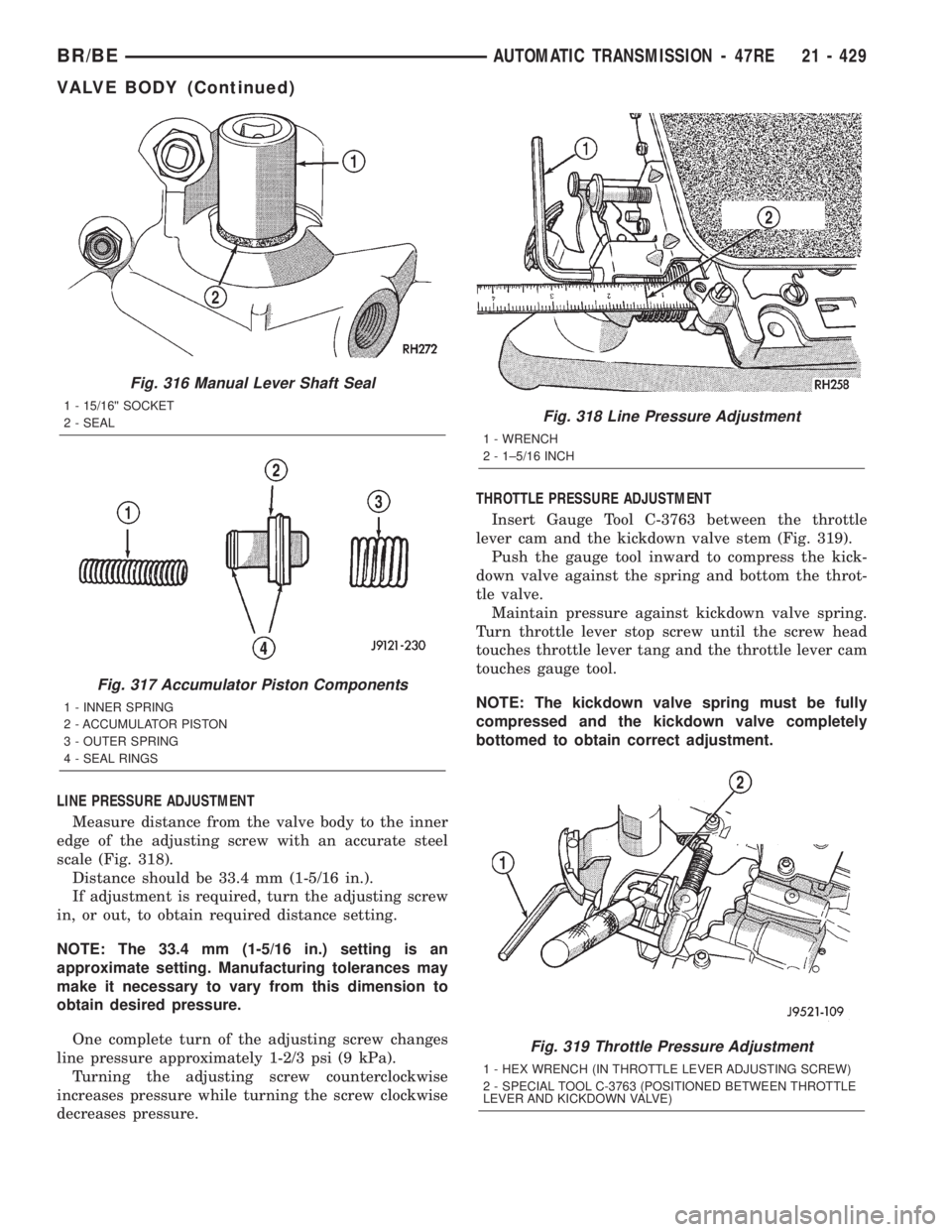

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 318).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 319).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 316 Manual Lever Shaft Seal

1 - 15/16©© SOCKET

2 - SEAL

Fig. 317 Accumulator Piston Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 318 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 319 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 429

VALVE BODY (Continued)

Page 2140 of 2255

(3) On vehicles with air conditioning, turn the

temperature control knob to the extreme counter

clockwise (Cool) position, and set the mode control

switch knob to the Bi-Level (A/C) position. The out-

side (recirculation) air door should be open to outside

air. If not OK, (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS - DIAGNOSIS AND TEST-

ING - VACUUM SYSTEM).

(4) Open the vehicle windows. Test the blower

motor operation in all speeds. If not OK, (Refer to 24

- HEATING & AIR CONDITIONING/DISTRIBU-

TION/BLOWER MOTOR - DIAGNOSIS AND TEST-

ING).

(5) On vehicles with air conditioning, the compres-

sor should be running and the air conditioning sys-

tem in operation unless the ambient air temperature

is below about -1É C (30É F). If not OK, (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE).

(6) Check the mode control switch operation. The

heater and air conditioner systems should respond as

described in the owner's manual in the vehicle glove

box to each mode selected. Reduce the engine speed

to normal idle. The vacuum will be high at low idle

and the vacuum actuators should respond quickly. If

not OK, (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - DIAGNOSIS AND TEST-

ING - VACUUM SYSTEM).

(7) If the vacuum tests, and the electrical compo-

nent and circuit tests reveal no problems, disassem-

ble the HVAC housing to inspect for mechanical

misalignment or binding of the mode doors (Refer to

24 - HEATING & AIR CONDITIONING/DISTRIBU-

TION/HVAC HOUSING - DISASSEMBLY)

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

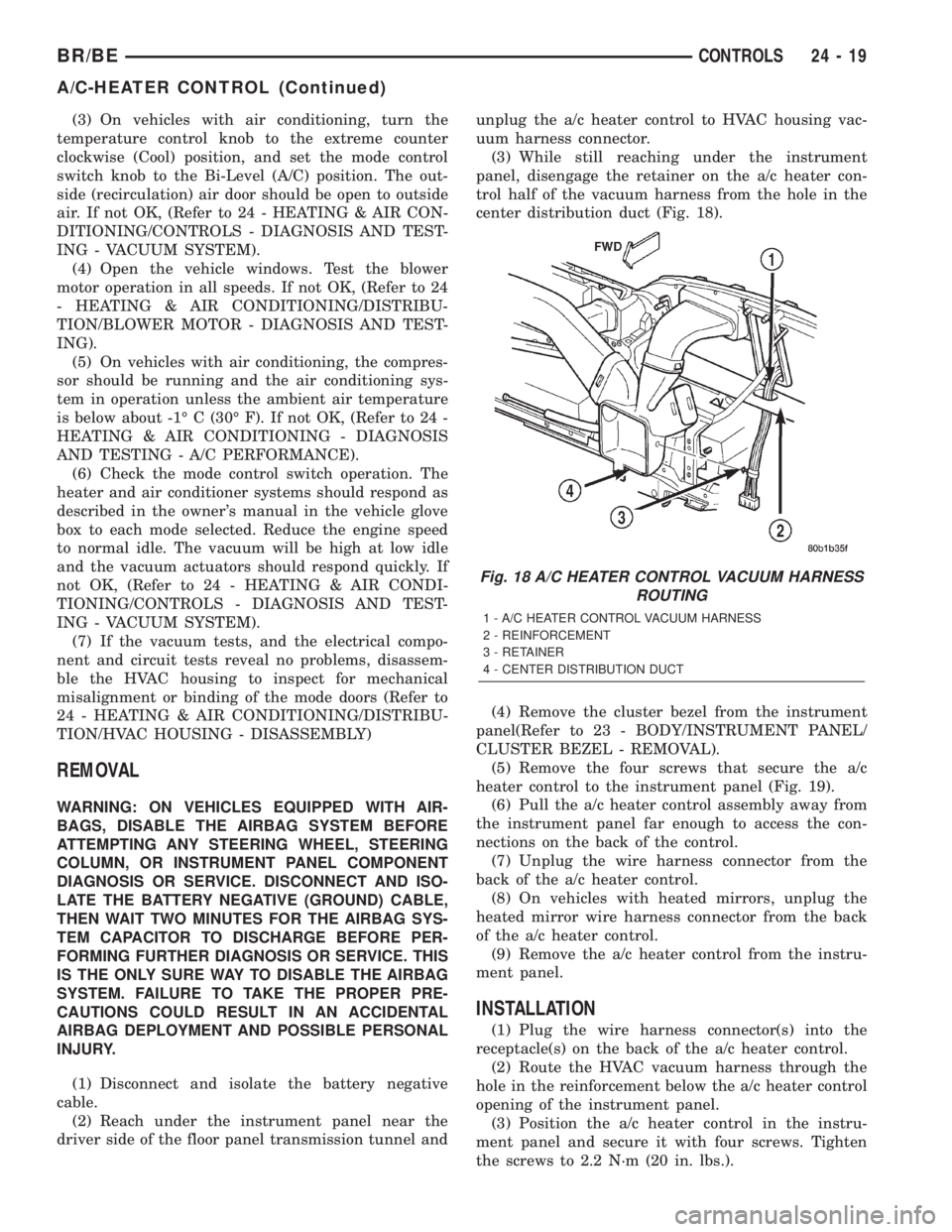

(2) Reach under the instrument panel near the

driver side of the floor panel transmission tunnel andunplug the a/c heater control to HVAC housing vac-

uum harness connector.

(3) While still reaching under the instrument

panel, disengage the retainer on the a/c heater con-

trol half of the vacuum harness from the hole in the

center distribution duct (Fig. 18).

(4) Remove the cluster bezel from the instrument

panel(Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(5) Remove the four screws that secure the a/c

heater control to the instrument panel (Fig. 19).

(6) Pull the a/c heater control assembly away from

the instrument panel far enough to access the con-

nections on the back of the control.

(7) Unplug the wire harness connector from the

back of the a/c heater control.

(8) On vehicles with heated mirrors, unplug the

heated mirror wire harness connector from the back

of the a/c heater control.

(9) Remove the a/c heater control from the instru-

ment panel.

INSTALLATION

(1) Plug the wire harness connector(s) into the

receptacle(s) on the back of the a/c heater control.

(2) Route the HVAC vacuum harness through the

hole in the reinforcement below the a/c heater control

opening of the instrument panel.

(3) Position the a/c heater control in the instru-

ment panel and secure it with four screws. Tighten

the screws to 2.2 N´m (20 in. lbs.).

Fig. 18 A/C HEATER CONTROL VACUUM HARNESS

ROUTING

1 - A/C HEATER CONTROL VACUUM HARNESS

2 - REINFORCEMENT

3 - RETAINER

4 - CENTER DISTRIBUTION DUCT

BR/BECONTROLS 24 - 19

A/C-HEATER CONTROL (Continued)

Page 2197 of 2255

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode: The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode: The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º H20.

The cycle rate of pump strokes is quite rapid as the

system begins to pump up to this pressure. As the

pressure increases, the cycle rate starts to drop off. If

there is no leak in the system, the pump would even-

tually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at .040º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

After passing the leak detection phase of the test,

system pressure is maintained by turning on the

LDP's solenoid until the purge system is activated.

Purge activation in effect creates a leak. The cycle

rate is again interrogated and when it increases due

to the flow through the purge system, the leak check

portion of the diagnostic is complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.Evaporative system functionality will be verified by

using the stricter evap purge flow monitor. At an

appropriate warm idle the LDP will be energized to

seal the canister vent. The purge flow will be clocked

up from some small value in an attempt to see a

shift in the 02 control system. If fuel vapor, indicated

by a shift in the 02 control, is present the test is

passed. If not, it is assumed that the purge system is

not functioning in some respect. The LDP is again

turned off and the test is ended.

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

FUEL SYSTEM MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide. The catalyst works best

when the Air Fuel (A/F) ratio is at or near the opti-

mum of 14.7 to 1.

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S sensor output. The programmed

memory acts as a self calibration tool that the engine

controller uses to compensate for variations in engine

specifications, sensor tolerances and engine fatigue

over the life span of the engine. By monitoring the

actual fuel-air ratio with the O2S sensor (short term)

and multiplying that with the program long-term

(adaptive) memory and comparing that to the limit,

it can be determined whether it will pass an emis-

sions test. If a malfunction occurs such that the PCM

cannot maintain the optimum A/F ratio, then the

MIL will be illuminated.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. This can increase vehicle emissions

and deteriorate engine performance, driveability and

fuel economy.

25 - 18 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)