injector DODGE RAM 2002 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1213 of 2255

INSPECTION

The cylinder head cover gasket and isolators

are reusable.However, should cracks be present in

the rubber/silicone construction, the defective compo-

nents should be replaced.

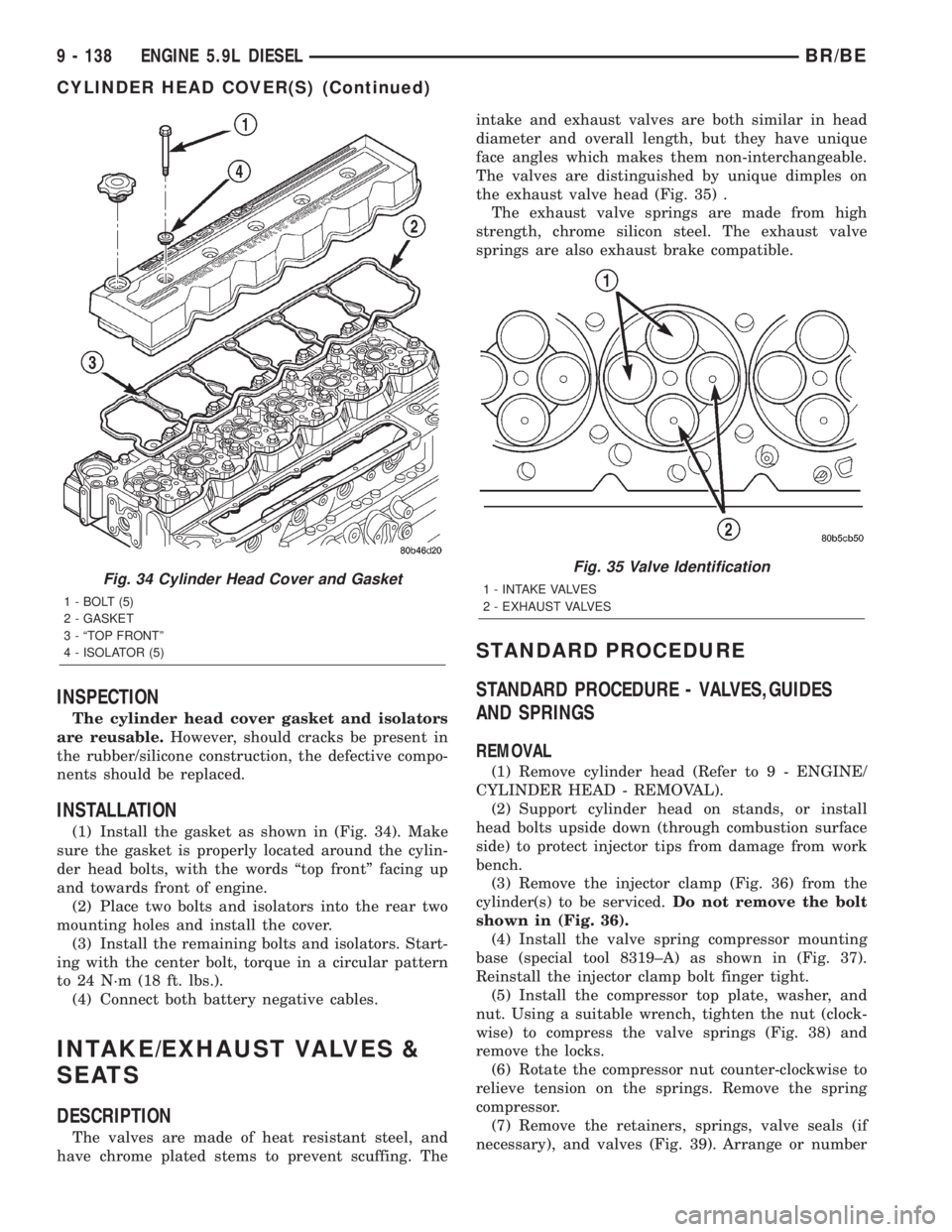

INSTALLATION

(1) Install the gasket as shown in (Fig. 34). Make

sure the gasket is properly located around the cylin-

der head bolts, with the words ªtop frontº facing up

and towards front of engine.

(2) Place two bolts and isolators into the rear two

mounting holes and install the cover.

(3) Install the remaining bolts and isolators. Start-

ing with the center bolt, torque in a circular pattern

to 24 N´m (18 ft. lbs.).

(4) Connect both battery negative cables.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

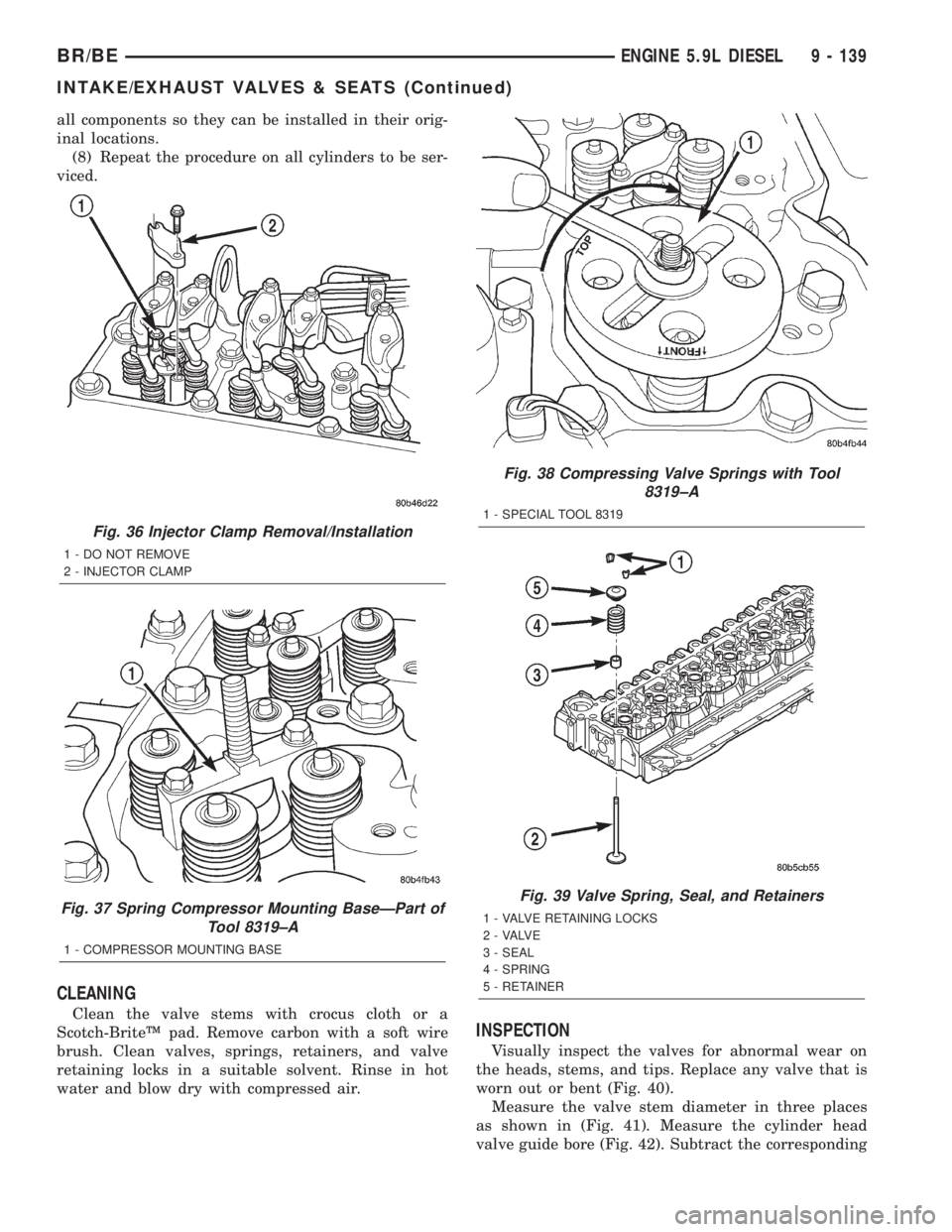

The valves are made of heat resistant steel, and

have chrome plated stems to prevent scuffing. Theintake and exhaust valves are both similar in head

diameter and overall length, but they have unique

face angles which makes them non-interchangeable.

The valves are distinguished by unique dimples on

the exhaust valve head (Fig. 35) .

The exhaust valve springs are made from high

strength, chrome silicon steel. The exhaust valve

springs are also exhaust brake compatible.

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVES,GUIDES

AND SPRINGS

REMOVAL

(1) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(2) Support cylinder head on stands, or install

head bolts upside down (through combustion surface

side) to protect injector tips from damage from work

bench.

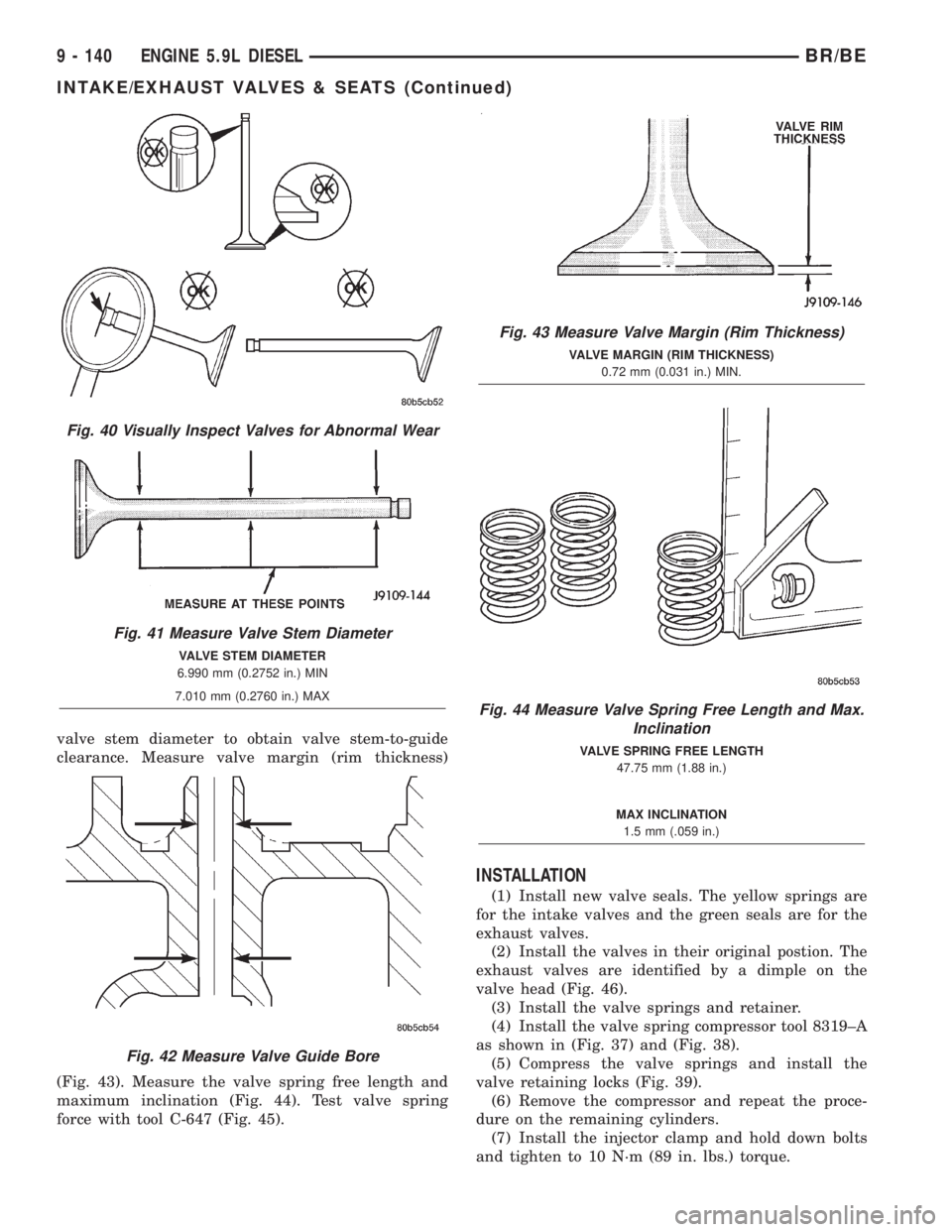

(3) Remove the injector clamp (Fig. 36) from the

cylinder(s) to be serviced.Do not remove the bolt

shown in (Fig. 36).

(4) Install the valve spring compressor mounting

base (special tool 8319±A) as shown in (Fig. 37).

Reinstall the injector clamp bolt finger tight.

(5) Install the compressor top plate, washer, and

nut. Using a suitable wrench, tighten the nut (clock-

wise) to compress the valve springs (Fig. 38) and

remove the locks.

(6) Rotate the compressor nut counter-clockwise to

relieve tension on the springs. Remove the spring

compressor.

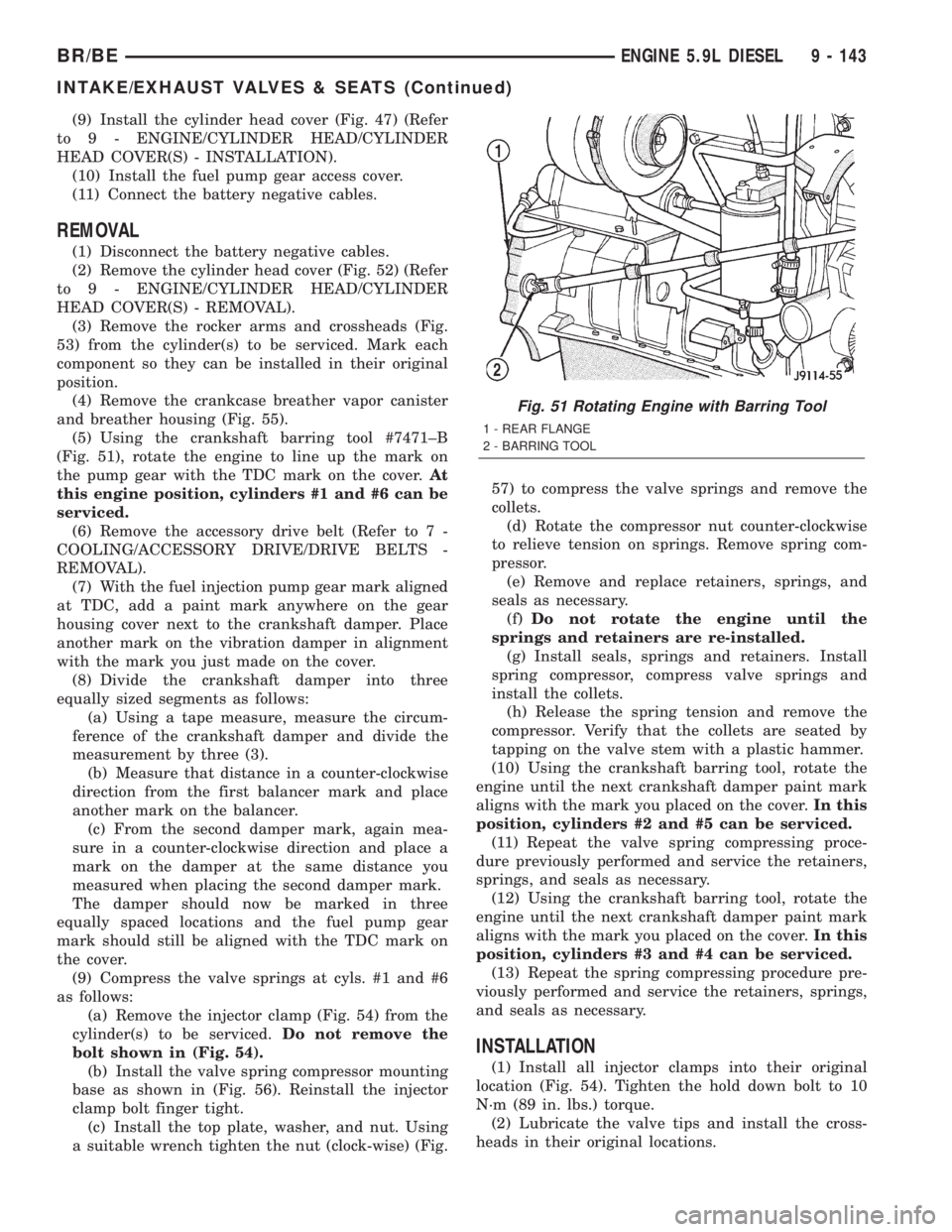

(7) Remove the retainers, springs, valve seals (if

necessary), and valves (Fig. 39). Arrange or number

Fig. 34 Cylinder Head Cover and Gasket

1 - BOLT (5)

2 - GASKET

3 - ªTOP FRONTº

4 - ISOLATOR (5)

Fig. 35 Valve Identification

1 - INTAKE VALVES

2 - EXHAUST VALVES

9 - 138 ENGINE 5.9L DIESELBR/BE

CYLINDER HEAD COVER(S) (Continued)

Page 1214 of 2255

all components so they can be installed in their orig-

inal locations.

(8) Repeat the procedure on all cylinders to be ser-

viced.

CLEANING

Clean the valve stems with crocus cloth or a

Scotch-BriteŸ pad. Remove carbon with a soft wire

brush. Clean valves, springs, retainers, and valve

retaining locks in a suitable solvent. Rinse in hot

water and blow dry with compressed air.

INSPECTION

Visually inspect the valves for abnormal wear on

the heads, stems, and tips. Replace any valve that is

worn out or bent (Fig. 40).

Measure the valve stem diameter in three places

as shown in (Fig. 41). Measure the cylinder head

valve guide bore (Fig. 42). Subtract the corresponding

Fig. 36 Injector Clamp Removal/Installation

1 - DO NOT REMOVE

2 - INJECTOR CLAMP

Fig. 37 Spring Compressor Mounting BaseÐPart of

Tool 8319±A

1 - COMPRESSOR MOUNTING BASE

Fig. 38 Compressing Valve Springs with Tool

8319±A

1 - SPECIAL TOOL 8319

Fig. 39 Valve Spring, Seal, and Retainers

1 - VALVE RETAINING LOCKS

2 - VALVE

3 - SEAL

4 - SPRING

5 - RETAINER

BR/BEENGINE 5.9L DIESEL 9 - 139

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1215 of 2255

valve stem diameter to obtain valve stem-to-guide

clearance. Measure valve margin (rim thickness)

(Fig. 43). Measure the valve spring free length and

maximum inclination (Fig. 44). Test valve spring

force with tool C-647 (Fig. 45).

INSTALLATION

(1) Install new valve seals. The yellow springs are

for the intake valves and the green seals are for the

exhaust valves.

(2) Install the valves in their original postion. The

exhaust valves are identified by a dimple on the

valve head (Fig. 46).

(3) Install the valve springs and retainer.

(4) Install the valve spring compressor tool 8319±A

as shown in (Fig. 37) and (Fig. 38).

(5) Compress the valve springs and install the

valve retaining locks (Fig. 39).

(6) Remove the compressor and repeat the proce-

dure on the remaining cylinders.

(7) Install the injector clamp and hold down bolts

and tighten to 10 N´m (89 in. lbs.) torque.

Fig. 40 Visually Inspect Valves for Abnormal Wear

Fig. 41 Measure Valve Stem Diameter

VALVE STEM DIAMETER

6.990 mm (0.2752 in.) MIN

7.010 mm (0.2760 in.) MAX

Fig. 42 Measure Valve Guide Bore

Fig. 43 Measure Valve Margin (Rim Thickness)

VALVE MARGIN (RIM THICKNESS)

0.72 mm (0.031 in.) MIN.

Fig. 44 Measure Valve Spring Free Length and Max.

Inclination

VALVE SPRING FREE LENGTH

47.75 mm (1.88 in.)

MAX INCLINATION

1.5 mm (.059 in.)

9 - 140 ENGINE 5.9L DIESELBR/BE

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1218 of 2255

(9) Install the cylinder head cover (Fig. 47) (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - INSTALLATION).

(10) Install the fuel pump gear access cover.

(11) Connect the battery negative cables.

REMOVAL

(1) Disconnect the battery negative cables.

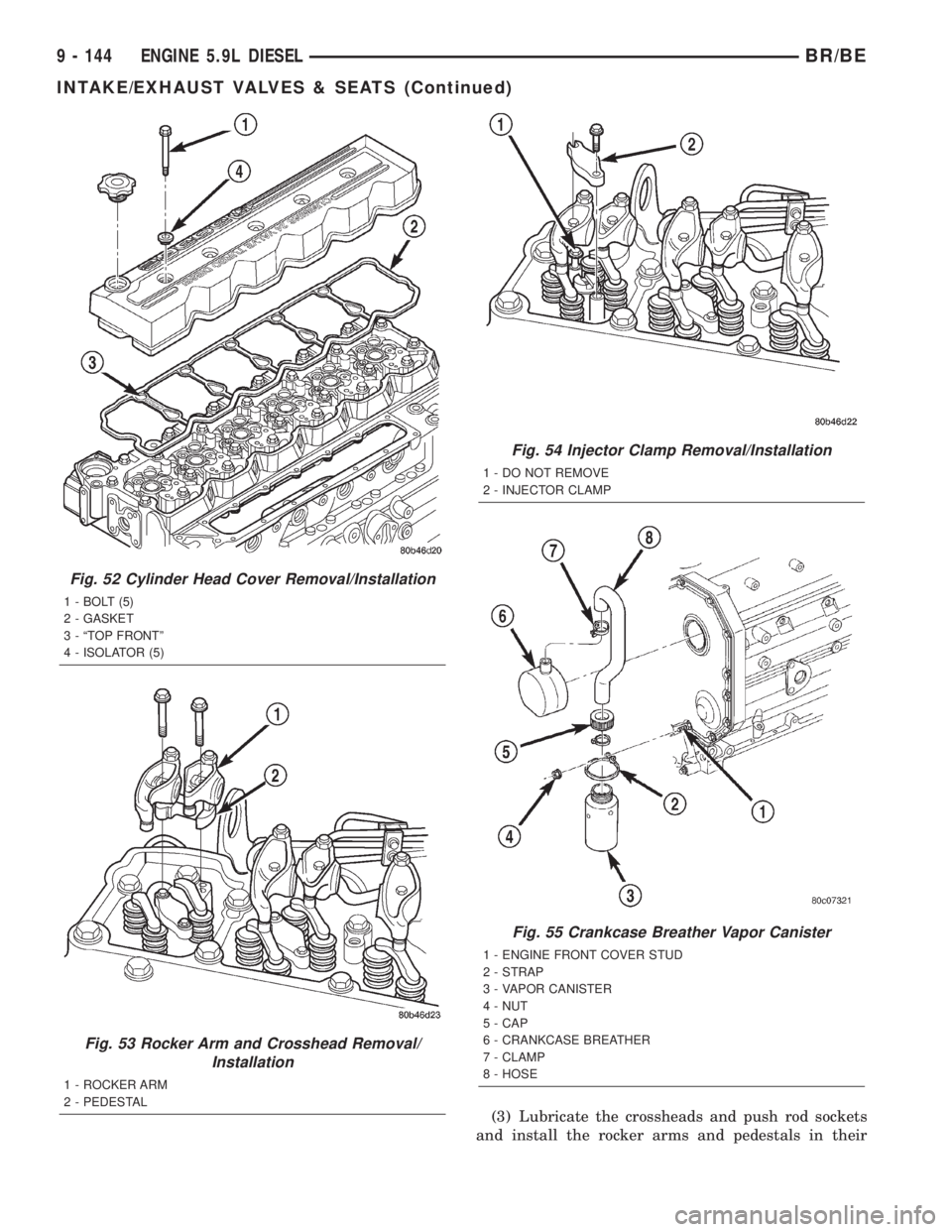

(2) Remove the cylinder head cover (Fig. 52) (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

(3) Remove the rocker arms and crossheads (Fig.

53) from the cylinder(s) to be serviced. Mark each

component so they can be installed in their original

position.

(4) Remove the crankcase breather vapor canister

and breather housing (Fig. 55).

(5) Using the crankshaft barring tool #7471±B

(Fig. 51), rotate the engine to line up the mark on

the pump gear with the TDC mark on the cover.At

this engine position, cylinders #1 and #6 can be

serviced.

(6) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) With the fuel injection pump gear mark aligned

at TDC, add a paint mark anywhere on the gear

housing cover next to the crankshaft damper. Place

another mark on the vibration damper in alignment

with the mark you just made on the cover.

(8) Divide the crankshaft damper into three

equally sized segments as follows:

(a) Using a tape measure, measure the circum-

ference of the crankshaft damper and divide the

measurement by three (3).

(b) Measure that distance in a counter-clockwise

direction from the first balancer mark and place

another mark on the balancer.

(c) From the second damper mark, again mea-

sure in a counter-clockwise direction and place a

mark on the damper at the same distance you

measured when placing the second damper mark.

The damper should now be marked in three

equally spaced locations and the fuel pump gear

mark should still be aligned with the TDC mark on

the cover.

(9) Compress the valve springs at cyls. #1 and #6

as follows:

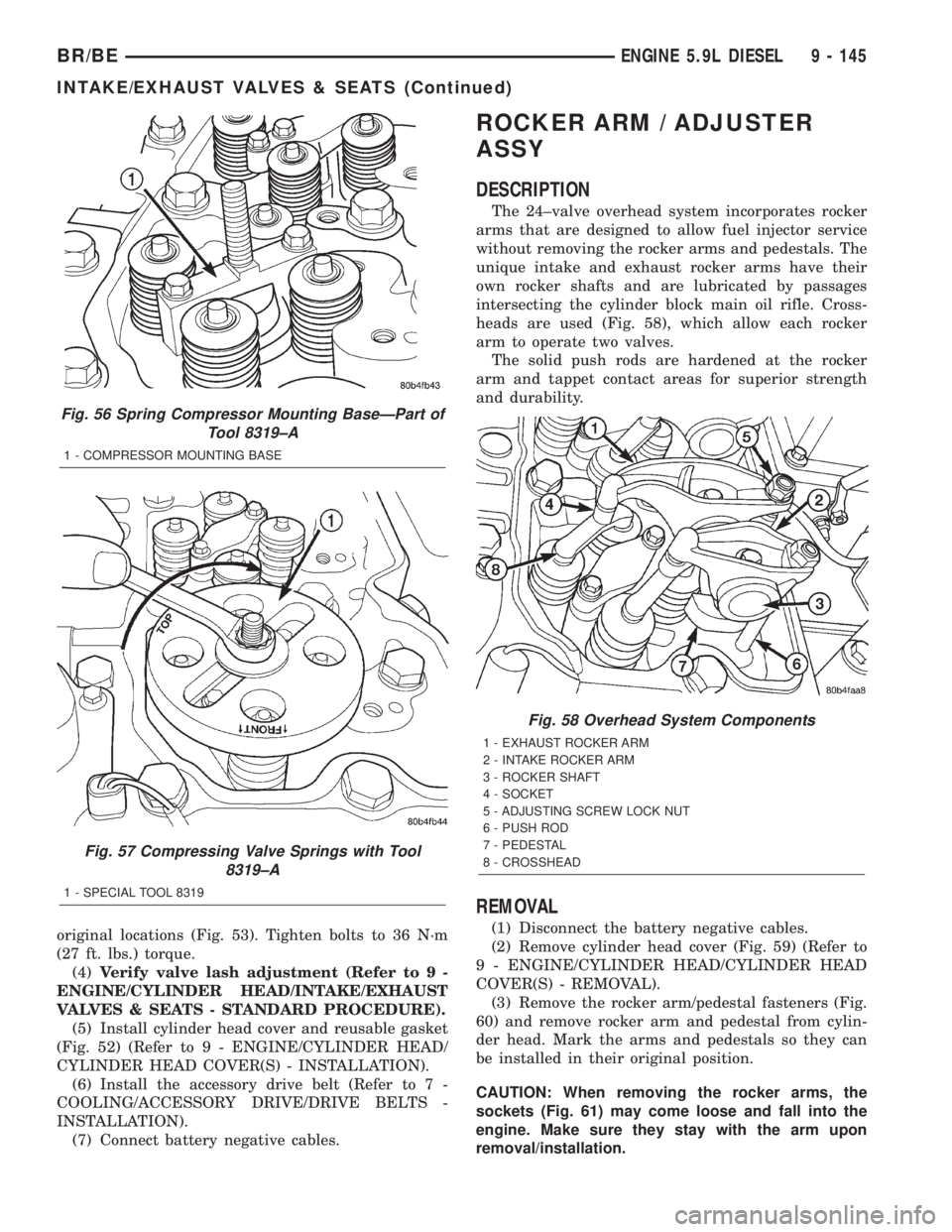

(a) Remove the injector clamp (Fig. 54) from the

cylinder(s) to be serviced.Do not remove the

bolt shown in (Fig. 54).

(b) Install the valve spring compressor mounting

base as shown in (Fig. 56). Reinstall the injector

clamp bolt finger tight.

(c) Install the top plate, washer, and nut. Using

a suitable wrench tighten the nut (clock-wise) (Fig.57) to compress the valve springs and remove the

collets.

(d) Rotate the compressor nut counter-clockwise

to relieve tension on springs. Remove spring com-

pressor.

(e) Remove and replace retainers, springs, and

seals as necessary.

(f)Do not rotate the engine until the

springs and retainers are re-installed.

(g) Install seals, springs and retainers. Install

spring compressor, compress valve springs and

install the collets.

(h) Release the spring tension and remove the

compressor. Verify that the collets are seated by

tapping on the valve stem with a plastic hammer.

(10) Using the crankshaft barring tool, rotate the

engine until the next crankshaft damper paint mark

aligns with the mark you placed on the cover.In this

position, cylinders #2 and #5 can be serviced.

(11) Repeat the valve spring compressing proce-

dure previously performed and service the retainers,

springs, and seals as necessary.

(12) Using the crankshaft barring tool, rotate the

engine until the next crankshaft damper paint mark

aligns with the mark you placed on the cover.In this

position, cylinders #3 and #4 can be serviced.

(13) Repeat the spring compressing procedure pre-

viously performed and service the retainers, springs,

and seals as necessary.

INSTALLATION

(1) Install all injector clamps into their original

location (Fig. 54). Tighten the hold down bolt to 10

N´m (89 in. lbs.) torque.

(2) Lubricate the valve tips and install the cross-

heads in their original locations.

Fig. 51 Rotating Engine with Barring Tool

1 - REAR FLANGE

2 - BARRING TOOL

BR/BEENGINE 5.9L DIESEL 9 - 143

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1219 of 2255

(3) Lubricate the crossheads and push rod sockets

and install the rocker arms and pedestals in their

Fig. 52 Cylinder Head Cover Removal/Installation

1 - BOLT (5)

2 - GASKET

3 - ªTOP FRONTº

4 - ISOLATOR (5)

Fig. 53 Rocker Arm and Crosshead Removal/

Installation

1 - ROCKER ARM

2 - PEDESTAL

Fig. 54 Injector Clamp Removal/Installation

1 - DO NOT REMOVE

2 - INJECTOR CLAMP

Fig. 55 Crankcase Breather Vapor Canister

1 - ENGINE FRONT COVER STUD

2 - STRAP

3 - VAPOR CANISTER

4 - NUT

5 - CAP

6 - CRANKCASE BREATHER

7 - CLAMP

8 - HOSE

9 - 144 ENGINE 5.9L DIESELBR/BE

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1220 of 2255

original locations (Fig. 53). Tighten bolts to 36 N´m

(27 ft. lbs.) torque.

(4)Verify valve lash adjustment (Refer to 9 -

ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE).

(5) Install cylinder head cover and reusable gasket

(Fig. 52) (Refer to 9 - ENGINE/CYLINDER HEAD/

CYLINDER HEAD COVER(S) - INSTALLATION).

(6) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(7) Connect battery negative cables.

ROCKER ARM / ADJUSTER

ASSY

DESCRIPTION

The 24±valve overhead system incorporates rocker

arms that are designed to allow fuel injector service

without removing the rocker arms and pedestals. The

unique intake and exhaust rocker arms have their

own rocker shafts and are lubricated by passages

intersecting the cylinder block main oil rifle. Cross-

heads are used (Fig. 58), which allow each rocker

arm to operate two valves.

The solid push rods are hardened at the rocker

arm and tappet contact areas for superior strength

and durability.

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove cylinder head cover (Fig. 59) (Refer to

9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(3) Remove the rocker arm/pedestal fasteners (Fig.

60) and remove rocker arm and pedestal from cylin-

der head. Mark the arms and pedestals so they can

be installed in their original position.

CAUTION: When removing the rocker arms, the

sockets (Fig. 61) may come loose and fall into the

engine. Make sure they stay with the arm upon

removal/installation.

Fig. 56 Spring Compressor Mounting BaseÐPart of

Tool 8319±A

1 - COMPRESSOR MOUNTING BASE

Fig. 57 Compressing Valve Springs with Tool

8319±A

1 - SPECIAL TOOL 8319

Fig. 58 Overhead System Components

1 - EXHAUST ROCKER ARM

2 - INTAKE ROCKER ARM

3 - ROCKER SHAFT

4 - SOCKET

5 - ADJUSTING SCREW LOCK NUT

6 - PUSH ROD

7 - PEDESTAL

8 - CROSSHEAD

BR/BEENGINE 5.9L DIESEL 9 - 145

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1262 of 2255

(7) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 8 N´m (72 in. lbs.) torque.

(8) Position the air inlet hose to the turbocharger

(Fig. 170). Tighten the clamp to 8 N´m (72 in. lbs.)

torque.

(9) Raise vehicle on hoist.

(10) Connect the exhaust pipe to the turbocharger

(Fig. 169) and tighten the bolts to 34 N´m (25 ft. lbs.)

torque.

(11) Lower the vehicle.

(12) Connect the battery negative cables.

(13) Start the engine to check for leaks.

VALVE TIMING

STANDARD PROCEDURE - TIMING

VERIFICATION

(1) Remove the cylinder head cover.

(2) Remove fuel injector from cylinder number 1.

(3) Remove the crankcase breather from the gear

housing cover.

(4) Using Special Tool 7471B rotate the engine

until the timing mark on the fuel pump gear is

aligned with the TDC mark on the gear housing

cover.

(5) Using a 8 in.x 1/4 in. dowel rod inserted into

cylinder number 1, rock the crankshaft back and

forth to verify piston number 1 is at TDC.

(6) With piston number 1 at TDC the timing mark

on the fuel pump gear should be aligned with the

TDC mark on the gear housing cover. If marks do not

line up, remove the gear housing cover.

(7) With cylinder number still at TDC, inspect the

keyway on the crankshaft gear for proper alignment

(12 o'clock position).

(8) If the keyway is not at 12 o'clock position

replace the crankshaft gear assembly.

(9) If the keyway is at 12 o'clock position, verify

timing mark alignment between the camshaft gear,

crankshaft gear and the fuel pump gear, if not

aligned inspect keyway on camshaft gear.

(10) Inspect keyway on camshaft gear for proper

alignment with the key in the camshaft, if alignment

is off replace the camshaft/gear assembly.

(11) If timing marks alignment is off and no dam-

age is found at either the crankshaft or camshaft

gear keyways, realign timing marks as necessary.

GEAR HOUSING

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove the fan shroud-to-radiator mounting

bolts.

(9) Remove viscous fan/drive assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(10) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

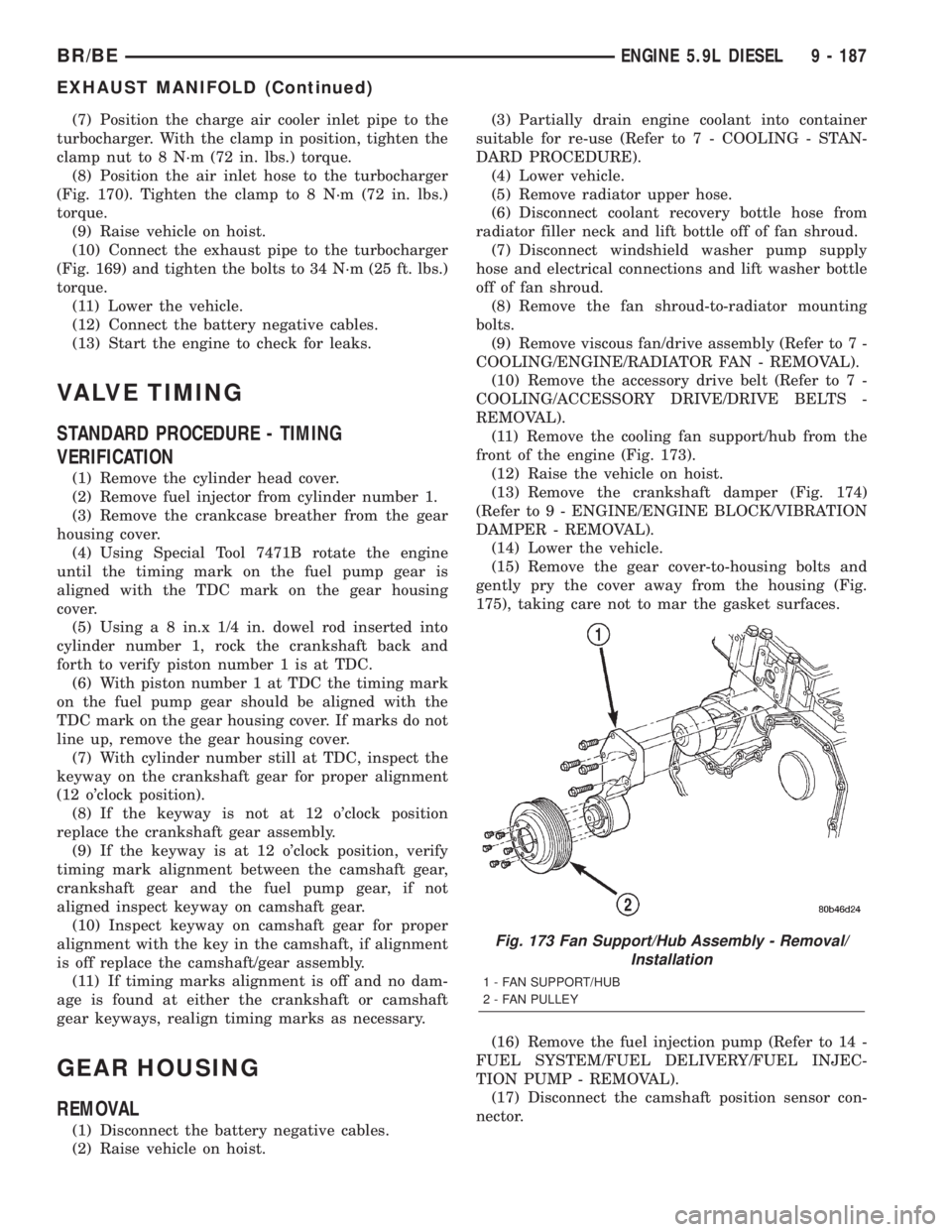

(11) Remove the cooling fan support/hub from the

front of the engine (Fig. 173).

(12) Raise the vehicle on hoist.

(13) Remove the crankshaft damper (Fig. 174)

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(14) Lower the vehicle.

(15) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing (Fig.

175), taking care not to mar the gasket surfaces.

(16) Remove the fuel injection pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(17) Disconnect the camshaft position sensor con-

nector.

Fig. 173 Fan Support/Hub Assembly - Removal/

Installation

1 - FAN SUPPORT/HUB

2 - FAN PULLEY

BR/BEENGINE 5.9L DIESEL 9 - 187

EXHAUST MANIFOLD (Continued)

Page 1301 of 2255

FUEL DELIVERY - GASOLINE

DESCRIPTION - FUEL DELIVERY SYSTEM

The fuel delivery system consists of:

²the fuel pump module containing the electric

fuel pump, fuel filter/fuel pressure regulator, rollover

valve (certain modules), fuel gauge sending unit (fuel

level sensor) and a separate fuel filter located at bot-

tom of pump module

²fuel tubes/lines/hoses

²quick-connect fittings

²fuel injector rail

²fuel injectors

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

OPERATION - FUEL DELIVERY SYSTEM

Fuel is returned through the fuel pump module

and back into the fuel tank through the fuel filter/

fuel pressure regulator. A separate fuel return line

from the engine to the tank is not used with any gas-

oline powered engine.

The fuel tank assembly consists of: the fuel tank,

fuel pump module assembly, fuel pump module lock-

nut/gasket and fuel tank check valve(s) (refer to 25,

Emission Control System for Fuel Tank Check Valve

information).

A fuel filler/vent tube assembly using a pressure/

vacuum, 1/4 turn fuel filler cap is used. The fuel

filler tube contains a flap door located below the fuel

fill cap.

Also to be considered part of the fuel system is the

evaporation control system. This is designed to

reduce the emission of fuel vapors into the atmo-

sphere. The description and function of the Evapora-

tive Control System is found in 25, Emission Control

Systems.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

DIAGNOSIS AND TESTING - FUEL PRESSURE

LEAK DOWN TEST

Use this test in conjunction with the Fuel Pump

Pressure Test and Fuel Pump Capacity Test.

Check Valve Operation:The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply linefull of gasoline when pump is not operational. After

the vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline will

remain in fuel supply line between the check valve

and fuel injectors.Fuel pressure that has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition.When the elec-

tric fuel pump is activated, fuel pressure should

immediately(1±2 seconds) rise to specification.

Abnormally long periods of cranking to restart a

hotengine that has been shut down for a short

period of time may be caused by:

²Fuel pressure bleeding past a fuel injector(s).

²Fuel pressure bleeding past the check valve in

the fuel pump module.

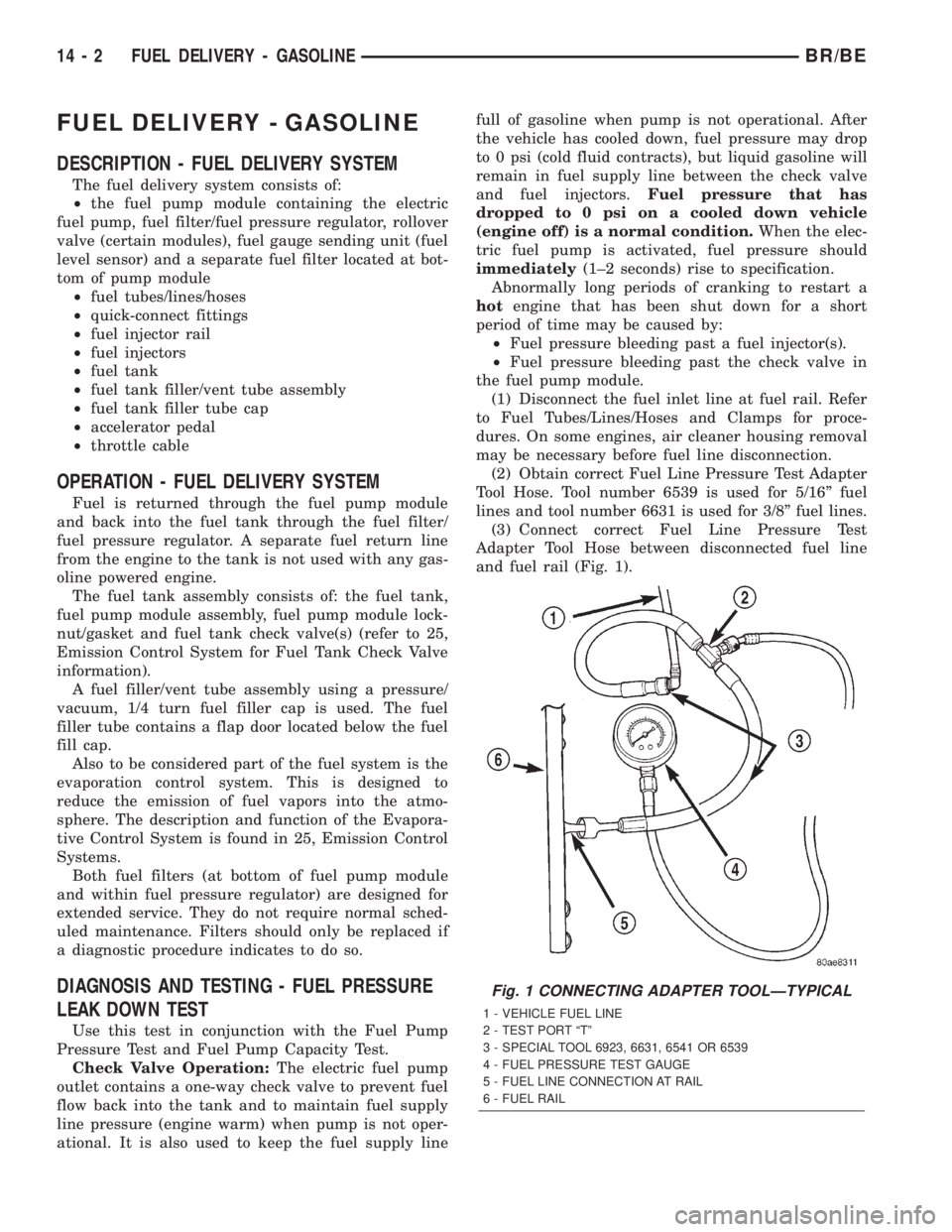

(1) Disconnect the fuel inlet line at fuel rail. Refer

to Fuel Tubes/Lines/Hoses and Clamps for proce-

dures. On some engines, air cleaner housing removal

may be necessary before fuel line disconnection.

(2) Obtain correct Fuel Line Pressure Test Adapter

Tool Hose. Tool number 6539 is used for 5/16º fuel

lines and tool number 6631 is used for 3/8º fuel lines.

(3) Connect correct Fuel Line Pressure Test

Adapter Tool Hose between disconnected fuel line

and fuel rail (Fig. 1).

Fig. 1 CONNECTING ADAPTER TOOLÐTYPICAL

1 - VEHICLE FUEL LINE

2 - TEST PORT ªTº

3 - SPECIAL TOOL 6923, 6631, 6541 OR 6539

4 - FUEL PRESSURE TEST GAUGE

5 - FUEL LINE CONNECTION AT RAIL

6 - FUEL RAIL

14 - 2 FUEL DELIVERY - GASOLINEBR/BE

Page 1302 of 2255

(4) Connect the 0-414 kPa (0-60 psi) fuel pressure

test gauge (from Gauge Set 5069) to the test port on

the appropriate Adaptor Tool.The DRBtIII Scan

Tool along with the PEP module, the 500 psi

pressure transducer, and the transducer-to-test

port adapter may also be used in place of the

fuel pressure gauge.

The fittings on both tools must be in good

condition and free from any small leaks before

performing the proceeding test.

(5) Start engine and bring to normal operating

temperature.

(6) Observe test gauge. Normal operating pressure

should be 339 kPa +/±34 kPa (49.2 psi +/±5 psi).

(7) Shut engine off.

(8) Pressure should not fall below30 psi for five

minutes.

(9) If pressure falls below 30 psi, it must be deter-

mined if a fuel injector, the check valve within the

fuel pump module, or a fuel tube/line is leaking.

(10) Again, start engine and bring to normal oper-

ating temperature.

(11) Shut engine off.

(12)Testing for fuel injector or fuel rail leak-

age:Clamp off the rubber hose portion of Adaptor

Tool between the fuel rail and the test port ªTº on

Adapter Tool. If pressure now holds at or above 30

psi, a fuel injector or the fuel rail is leaking.

(13)Testing for fuel pump check valve, filter/

regulator check valve or fuel tube/line leakage:

Clamp off the rubber hose portion of Adaptor Tool

between the vehicle fuel line and test port ªTº on

Adapter Tool. If pressure now holds at or above 30

psi, a leak may be found at a fuel tube/line. If no

leaks are found at fuel tubes or lines, one of the

check valves in either the electric fuel pump or filter/

regulator may be leaking.

Note: A quick loss of pressure usually indicates a

defective check valve in the filter/regulator. A slow

loss of pressure usually indicates a defective check

valve in the electric fuel pump.

The electric fuel pump is not serviced separately.

Replace the fuel pump module assembly. The filter/

regulator may be replaced separately on certain

applications. Refer to Fuel Filter/Fuel Pressure Reg-

ulator Removal/Installation for additional informa-

tion.

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE

Use following procedure if the fuel injector

rail is, or is not equipped with a fuel pressure

test port.

(1) Remove fuel fill cap.(2) Remove fuel pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(3) Start and run engine until it stalls.

(4) Attempt restarting engine until it will no

longer run.

(5) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(6) Unplug connector from any fuel injector.

(7) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.

(8) Connect other end of jumper wire to positive

side of battery.

(9) Connect one end of a second jumper wire to

remaining injector terminal.

CAUTION: Powering an injector for more than a few

seconds will permanently damage the injector.

(10) Momentarily touch other end of jumper wire

to negative terminal of battery for no more than a

few seconds.

(11) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(12) Disconnect quick-connect fitting at fuel rail.

Refer to Quick-Connect Fittings.

(13) Return fuel pump relay to PDC.

(14) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRBtscan tool must be

used to erase a DTC.

SPECIFICATIONS

SPECIFICATIONS - FUEL SYSTEM PRESSURE -

GAS ENGINES

All Gasoline Powered Engines:339 kPa 34

kPa (49.2 psi 5 psi)

BR/BEFUEL DELIVERY - GASOLINE 14 - 3

FUEL DELIVERY - GASOLINE (Continued)

Page 1304 of 2255

FUEL FILTER/PRESSURE

REGULATOR

DESCRIPTION

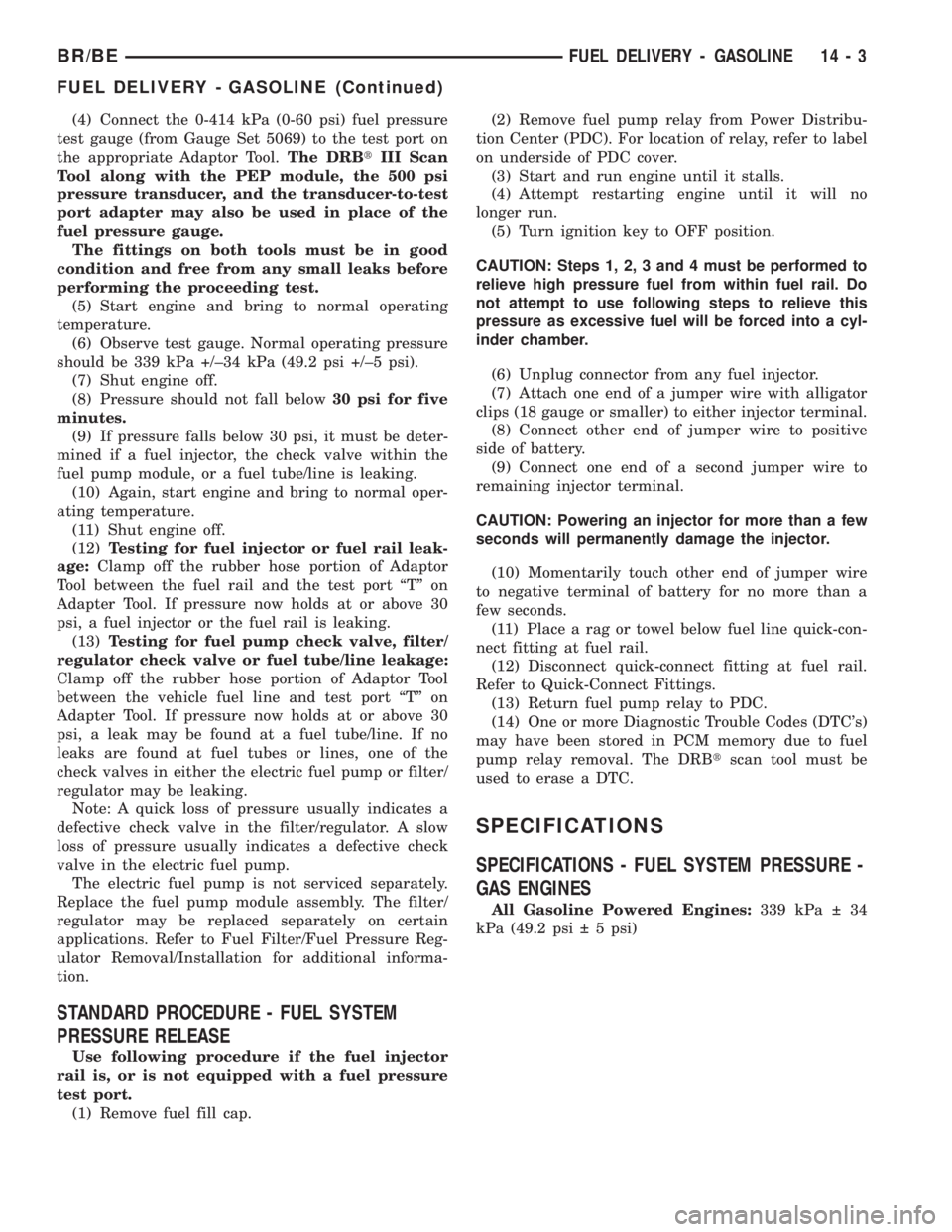

A combination fuel filter and fuel pressure regula-

tor (Fig. 2) is used on all engines. It is located on the

top of the fuel pump module. A separate frame

mounted fuel filter is not used with any engine.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

OPERATION

Fuel Pressure Regulator Operation:The pres-

sure regulator is a mechanical device that is not con-

trolled by engine vacuum or the powertrain control

module (PCM).

The regulator is calibrated to maintain fuel system

operating pressure of approximately 339 kPa 34

kPa (49.2 psi 5 psi) at the fuel injectors. It contains

a diaphragm, calibrated springs and a fuel return

valve. The internal fuel filter (Fig. 2) is also part of

the assembly.

Fuel is supplied to the filter/regulator by the elec-

tric fuel pump through an opening tube at the bot-

tom of filter/regulator (Fig. 2) .

The regulator acts as a check valve to maintain

some fuel pressure when the engine is not operating.

This will help to start the engine. A second checkvalve is located at the outlet end of the electric fuel

pump.Refer to Fuel PumpÐDescription and

Operation for more information. Also refer to

the Fuel Pressure Leak Down Test and the Fuel

Pump Pressure Tests.

If fuel pressure at the pressure regulator exceeds

approximately 49.2 psi, an internal diaphragm opens

and excess fuel pressure is routed back into the tank

through the bottom of pressure regulator.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE, EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL FILTER/FUEL PRES-

SURE REGULATOR, FUEL SYSTEM PRESSURE

MUST BE RELEASED.

Refer to Fuel System Pressure Release in Fuel

Delivery System section of this group.

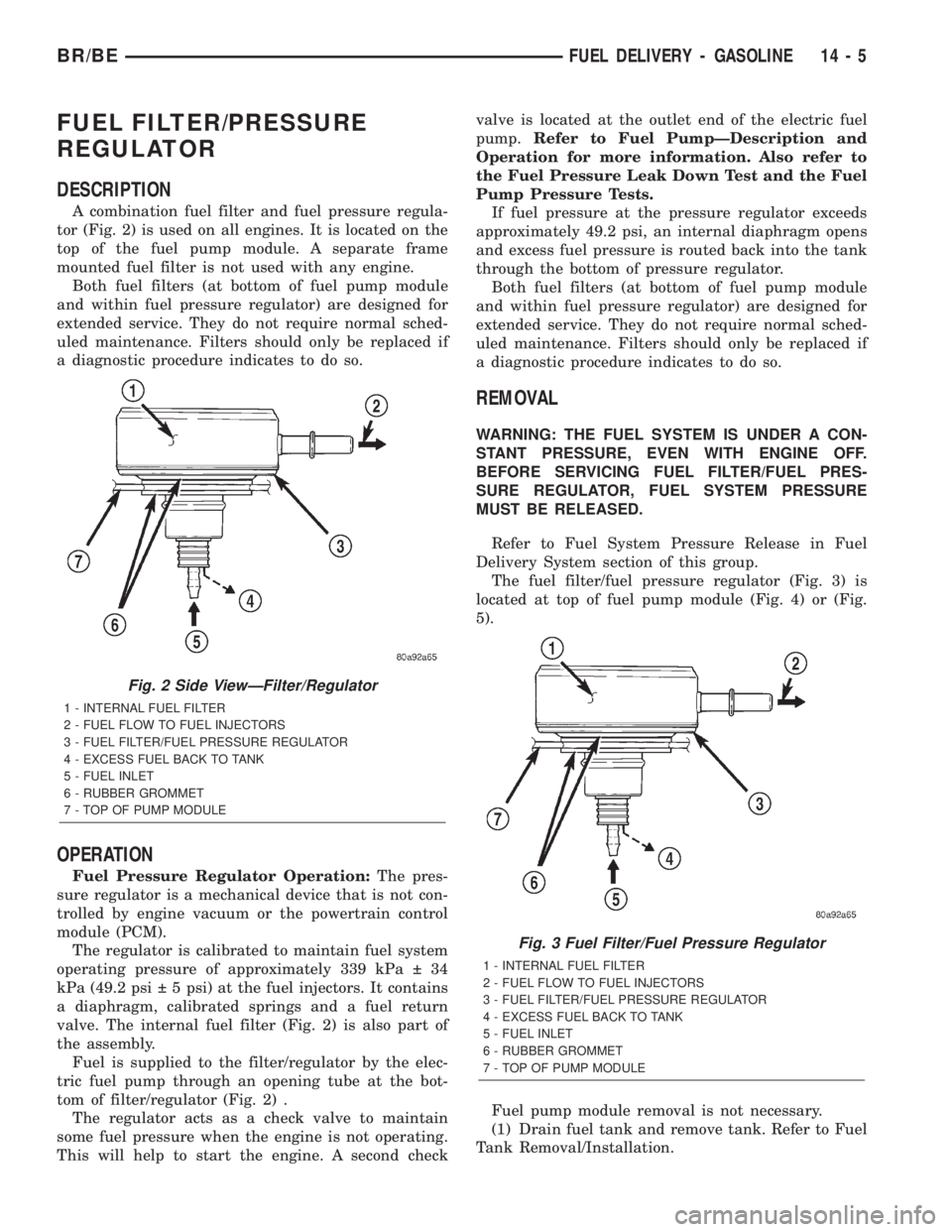

The fuel filter/fuel pressure regulator (Fig. 3) is

located at top of fuel pump module (Fig. 4) or (Fig.

5).

Fuel pump module removal is not necessary.

(1) Drain fuel tank and remove tank. Refer to Fuel

Tank Removal/Installation.

Fig. 2 Side ViewÐFilter/Regulator

1 - INTERNAL FUEL FILTER

2 - FUEL FLOW TO FUEL INJECTORS

3 - FUEL FILTER/FUEL PRESSURE REGULATOR

4 - EXCESS FUEL BACK TO TANK

5 - FUEL INLET

6 - RUBBER GROMMET

7 - TOP OF PUMP MODULE

Fig. 3 Fuel Filter/Fuel Pressure Regulator

1 - INTERNAL FUEL FILTER

2 - FUEL FLOW TO FUEL INJECTORS

3 - FUEL FILTER/FUEL PRESSURE REGULATOR

4 - EXCESS FUEL BACK TO TANK

5 - FUEL INLET

6 - RUBBER GROMMET

7 - TOP OF PUMP MODULE

BR/BEFUEL DELIVERY - GASOLINE 14 - 5