injector DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1354 of 2255

FUEL DELIVERY - DIESEL

DESCRIPTION

DESCRIPTION - DIESEL FUEL DELIVERY

SYSTEM

The fuel system on the Cummins 24 valveÐTurbo

Diesel Engine uses anelectronically controlled

fuel injection pump with three control modules.

Also refer to the Powertrain Control Module (PCM)

or Engine Control Module sections.

Some fuel system components are shown in (Fig.

1).

The fuel delivery system consists of the:

²Accelerator pedal

²Air cleaner housing/element

²Fuel drain manifold (passage)

²Fuel filter/water separator

²Fuel heater

²Fuel heater relay

²Fuel transfer (lift) pump

²Fuel injection pump

²Fuel injectors

²Fuel heater temperature sensor

²Fuel tank

²Fuel tank filler/vent tube assembly²Fuel tank filler tube cap

²Fuel tank module containing the rollover valve,

fuel gauge sending unit (fuel level sensor) and a sep-

arate fuel filter located at bottom of tank module

²Fuel tubes/lines/hoses

²High-pressure fuel injector lines

²In-tank fuel filter (at bottom of fuel tank mod-

ule)

²Low-pressure fuel supply lines

²Low-pressure fuel return line

²Overflow valve

²Quick-connect fittings

²Throttle cable

²Water draining

OPERATION

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 120,000 KPA (17,405

PSI). USE EXTREME CAUTION WHEN INSPECTING

FOR HIGH-PRESSURE FUEL LEAKS. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

BR/BEFUEL DELIVERY - DIESEL 14 - 55

Page 1355 of 2255

Fig. 1 FUEL SYSTEM COMPONENTS - DIESEL

1 - ENGINE COOLANT TEMPERATURE (ECT) SENSOR 14 - FUEL SUPPLY LINE (LOW-PRESSURE, TO ENGINE)

2 - THROTTLE LEVER BELLCRANK AND APPS (ACCELERATOR

PEDAL POSITION SENSOR)15 - FUEL TRANSFER (LIFT) PUMP

3 - INTAKE MANIFOLD AIR HEATER/ELEMENTS 16 - OIL PRESSURE SENSOR

4 - HIGH-PRESSURE FUEL LINES 17 - FUEL FILTER/WATER SEPARATOR

5 - FUEL HEATER 18 - DRAIN TUBE

6 - FUEL PRESSURE TEST PORT 19 - WATER-IN-FUEL (WIF) SENSOR

7 - MAP (BOOST) SENSOR 20 - ENGINE CONTROL MODULE (ECM)

8 - FUEL INJECTORS 21 - FUEL PRESSURE TEST PORT

9 - FUEL INJECTOR CONNECTOR 22 - CAMSHAFT POSITION SENSOR (CMP)

10 - INTAKE AIR TEMPERATURE (IAT) SENSOR 23 - OVERFLOW VALVE

11 - FUEL DRAIN MANIFOLD 24 - FUEL INJECTION PUMP

12 - DRAIN VALVE 25 - FUEL HEATER TEMPERATURE SENSOR (THERMOSTAT)

13 - FUEL RETURN LINE (TO FUEL TANK)

14 - 56 FUEL DELIVERY - DIESELBR/BE

FUEL DELIVERY - DIESEL (Continued)

Page 1358 of 2255

(b) Remove all high-pressure fuel lines at injec-

tor high-pressure connectors. Examine all injector

connector o-rings. If any damage to o-ring exists,

replace connector.

(c) If no damage is found at connectors, remove

all 6 fuel injectors to inspect o-rings and sealing

washers. Also inspect cylinder head bores where

these sealing washers make contact. The bore con-

tact area should be smooth and uniform.

(7) Vacuum holds ? Proceed.

Testing VP-44 Pump and its Return Line

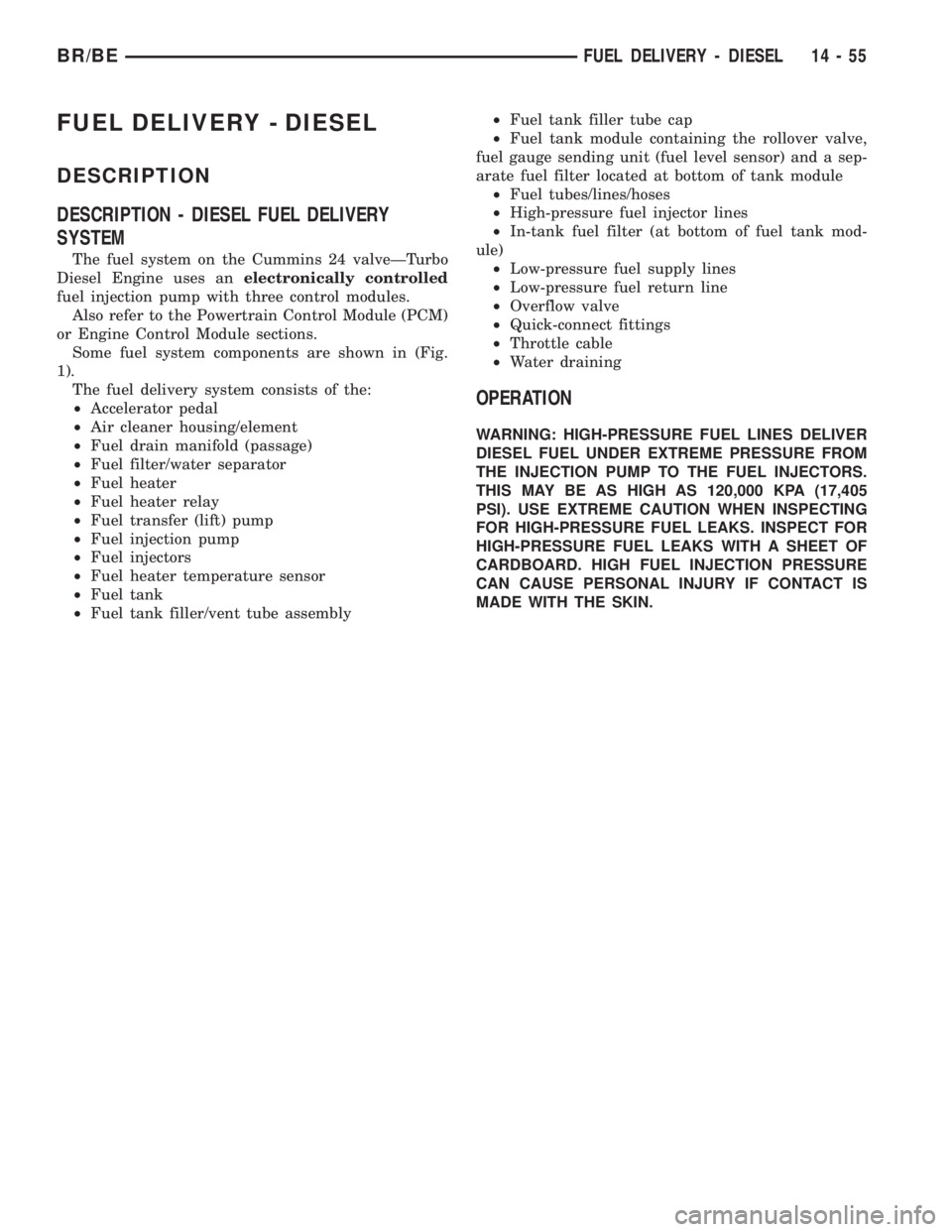

(1) Remove rubber 3/8º sealing cap and reconnect /

tighten fuel drain line to top of ªTº fitting (Fig. 8).

(2) Disconnect and separate VP-44 drain line at

front of ªTº fitting (Fig. 9). To plug / seal system,

install 3/8º rubber cap to this disconnected line (Fig.

9).

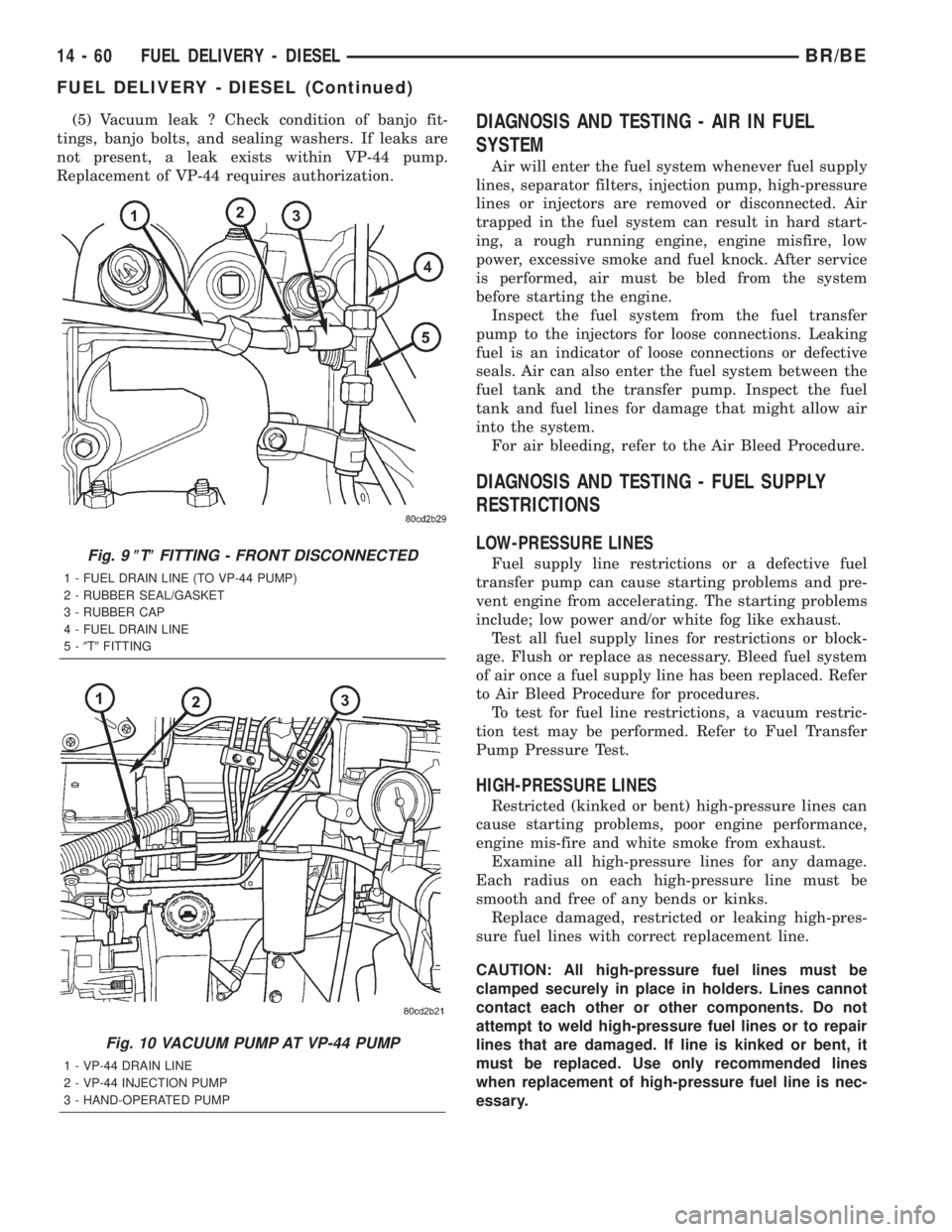

(3) Disconnect rubber fuel hose at VP-44 inlet (Fig.

10). Connect your hand-operated vacuum pump at

this inlet point.

(4) Perform vacuum test. Be careful not to allow

liquid fuel to get into your hand-operated vacuum

pump.

Fig. 6 FUEL HOSE AT FUEL FILTER

1 - TEST PORT FITTING

2 - VP-44 FUEL INLET LINE

3 - RUBBER FUEL HOSE

4 - FUEL FILTER OUTLET LINE

5 - HOSE CLAMPS (2)

6 - VP-44 INJECTION PUMP

Fig. 7 CAPPING OFF FUEL FILTER OUTLET LINE

1 - FUEL FILTER / WATER SEPARATOR

2 - OUTLET LINE

3 - RUBBER CAP

Fig. 8(T(FITTING - TOP DISCONNECTED

1 - RUBBER SEAL/GASKET

2 - FUEL DRAIN LINE AT TOP OF9T9FITTING (FROM REAR OF

CYLINDER HEAD)

3 - RUBBER CAP

4-9T9FITTING

5 - LEFT REAR CORNER OF ENGINE

6 - SUPPORT BRACKET BOLT

BR/BEFUEL DELIVERY - DIESEL 14 - 59

FUEL DELIVERY - DIESEL (Continued)

Page 1359 of 2255

(5) Vacuum leak ? Check condition of banjo fit-

tings, banjo bolts, and sealing washers. If leaks are

not present, a leak exists within VP-44 pump.

Replacement of VP-44 requires authorization.DIAGNOSIS AND TESTING - AIR IN FUEL

SYSTEM

Air will enter the fuel system whenever fuel supply

lines, separator filters, injection pump, high-pressure

lines or injectors are removed or disconnected. Air

trapped in the fuel system can result in hard start-

ing, a rough running engine, engine misfire, low

power, excessive smoke and fuel knock. After service

is performed, air must be bled from the system

before starting the engine.

Inspect the fuel system from the fuel transfer

pump to the injectors for loose connections. Leaking

fuel is an indicator of loose connections or defective

seals. Air can also enter the fuel system between the

fuel tank and the transfer pump. Inspect the fuel

tank and fuel lines for damage that might allow air

into the system.

For air bleeding, refer to the Air Bleed Procedure.

DIAGNOSIS AND TESTING - FUEL SUPPLY

RESTRICTIONS

LOW-PRESSURE LINES

Fuel supply line restrictions or a defective fuel

transfer pump can cause starting problems and pre-

vent engine from accelerating. The starting problems

include; low power and/or white fog like exhaust.

Test all fuel supply lines for restrictions or block-

age. Flush or replace as necessary. Bleed fuel system

of air once a fuel supply line has been replaced. Refer

to Air Bleed Procedure for procedures.

To test for fuel line restrictions, a vacuum restric-

tion test may be performed. Refer to Fuel Transfer

Pump Pressure Test.

HIGH-PRESSURE LINES

Restricted (kinked or bent) high-pressure lines can

cause starting problems, poor engine performance,

engine mis-fire and white smoke from exhaust.

Examine all high-pressure lines for any damage.

Each radius on each high-pressure line must be

smooth and free of any bends or kinks.

Replace damaged, restricted or leaking high-pres-

sure fuel lines with correct replacement line.

CAUTION: All high-pressure fuel lines must be

clamped securely in place in holders. Lines cannot

contact each other or other components. Do not

attempt to weld high-pressure fuel lines or to repair

lines that are damaged. If line is kinked or bent, it

must be replaced. Use only recommended lines

when replacement of high-pressure fuel line is nec-

essary.

Fig. 9(T(FITTING - FRONT DISCONNECTED

1 - FUEL DRAIN LINE (TO VP-44 PUMP)

2 - RUBBER SEAL/GASKET

3 - RUBBER CAP

4 - FUEL DRAIN LINE

5-9T9FITTING

Fig. 10 VACUUM PUMP AT VP-44 PUMP

1 - VP-44 DRAIN LINE

2 - VP-44 INJECTION PUMP

3 - HAND-OPERATED PUMP

14 - 60 FUEL DELIVERY - DIESELBR/BE

FUEL DELIVERY - DIESEL (Continued)

Page 1360 of 2255

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER DRAINING

AT FUEL FILTER

Refer to Fuel Filter/Water Separator removal/in-

stallation for procedures.

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM PARTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

STANDARD PROCEDURE - AIR BLEED

A certain amount of air becomes trapped in the

fuel system when fuel system components on the

supply and/or high-pressure side are serviced or

replaced. Primary air bleeding is accomplished using

the electric fuel transfer (lift) pump. If the vehicle

has been allowed to run completely out of fuel, the

fuel injectors must also be bled as the fuel injection

pumpis notself-bleeding (priming).

Servicing or replacing components on the fuel

return side will not require air bleeding.

WARNING: DO NOT BLEED AIR FROM THE FUEL

SYSTEM OF A HOT ENGINE.

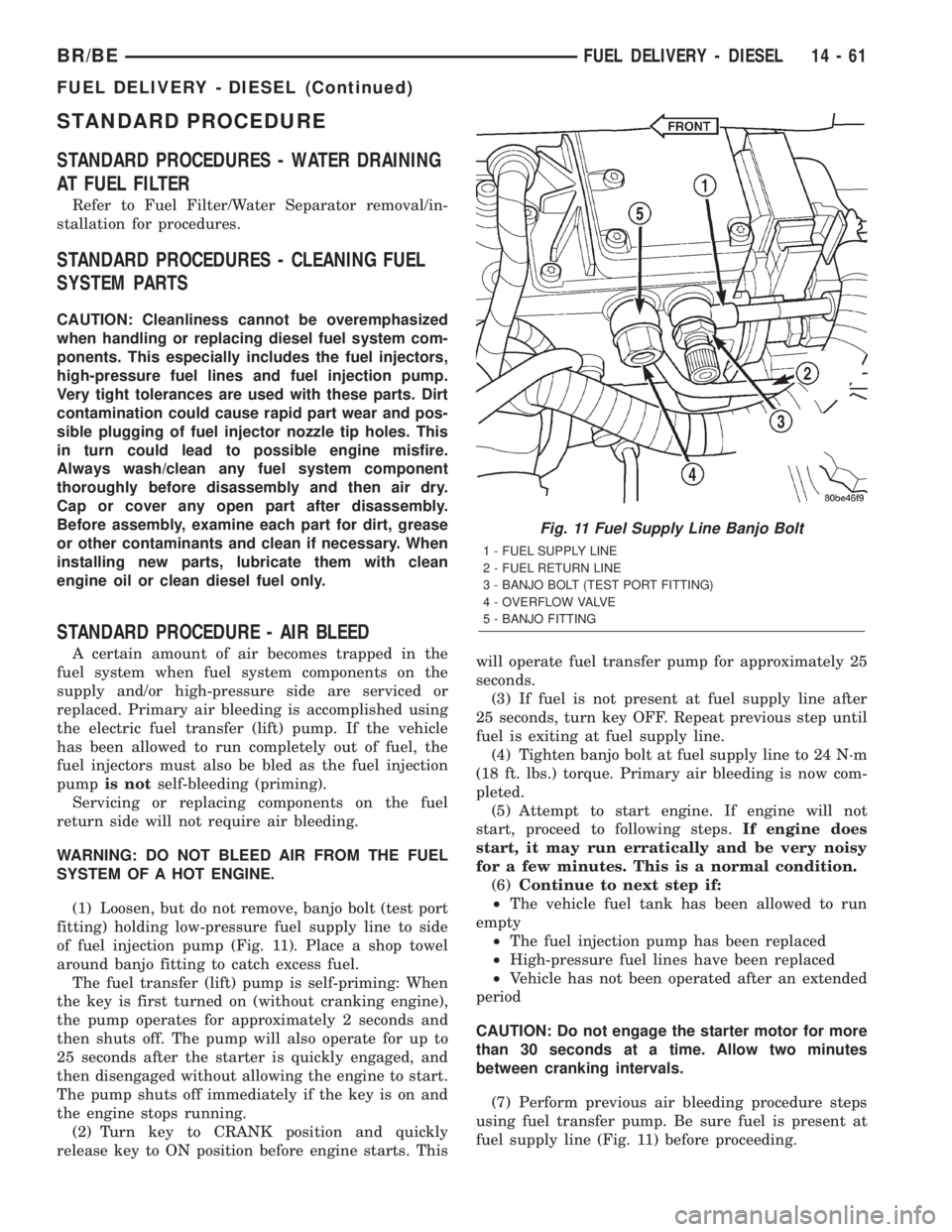

(1) Loosen, but do not remove, banjo bolt (test port

fitting) holding low-pressure fuel supply line to side

of fuel injection pump (Fig. 11). Place a shop towel

around banjo fitting to catch excess fuel.

The fuel transfer (lift) pump is self-priming: When

the key is first turned on (without cranking engine),

the pump operates for approximately 2 seconds and

then shuts off. The pump will also operate for up to

25 seconds after the starter is quickly engaged, and

then disengaged without allowing the engine to start.

The pump shuts off immediately if the key is on and

the engine stops running.

(2) Turn key to CRANK position and quickly

release key to ON position before engine starts. Thiswill operate fuel transfer pump for approximately 25

seconds.

(3) If fuel is not present at fuel supply line after

25 seconds, turn key OFF. Repeat previous step until

fuel is exiting at fuel supply line.

(4) Tighten banjo bolt at fuel supply line to 24 N´m

(18 ft. lbs.) torque. Primary air bleeding is now com-

pleted.

(5) Attempt to start engine. If engine will not

start, proceed to following steps.If engine does

start, it may run erratically and be very noisy

for a few minutes. This is a normal condition.

(6)Continue to next step if:

²The vehicle fuel tank has been allowed to run

empty

²The fuel injection pump has been replaced

²High-pressure fuel lines have been replaced

²Vehicle has not been operated after an extended

period

CAUTION: Do not engage the starter motor for more

than 30 seconds at a time. Allow two minutes

between cranking intervals.

(7) Perform previous air bleeding procedure steps

using fuel transfer pump. Be sure fuel is present at

fuel supply line (Fig. 11) before proceeding.

Fig. 11 Fuel Supply Line Banjo Bolt

1 - FUEL SUPPLY LINE

2 - FUEL RETURN LINE

3 - BANJO BOLT (TEST PORT FITTING)

4 - OVERFLOW VALVE

5 - BANJO FITTING

BR/BEFUEL DELIVERY - DIESEL 14 - 61

FUEL DELIVERY - DIESEL (Continued)

Page 1361 of 2255

(8) Crank the engine for 30 seconds at a time to

allow air trapped in the injection pump to vent out

the drain manifold.

WARNING: THE FUEL INJECTION PUMP SUPPLIES

EXTREMELY HIGH FUEL PRESSURE TO EACH INDI-

VIDUAL INJECTOR THROUGH THE HIGH-PRES-

SURE LINES. FUEL UNDER THIS AMOUNT OF

PRESSURE CAN PENETRATE THE SKIN AND

CAUSE PERSONAL INJURY. WEAR SAFETY GOG-

GLES AND ADEQUATE PROTECTIVE CLOTHING

AND AVOID CONTACT WITH FUEL SPRAY WHEN

BLEEDING HIGH-PRESSURE FUEL LINES.

WARNING: ENGINE MAY START WHILE CRANKING

STARTER MOTOR.

Engine may start, may run erratically and be

very noisy for a few minutes. This is a normal

condition.

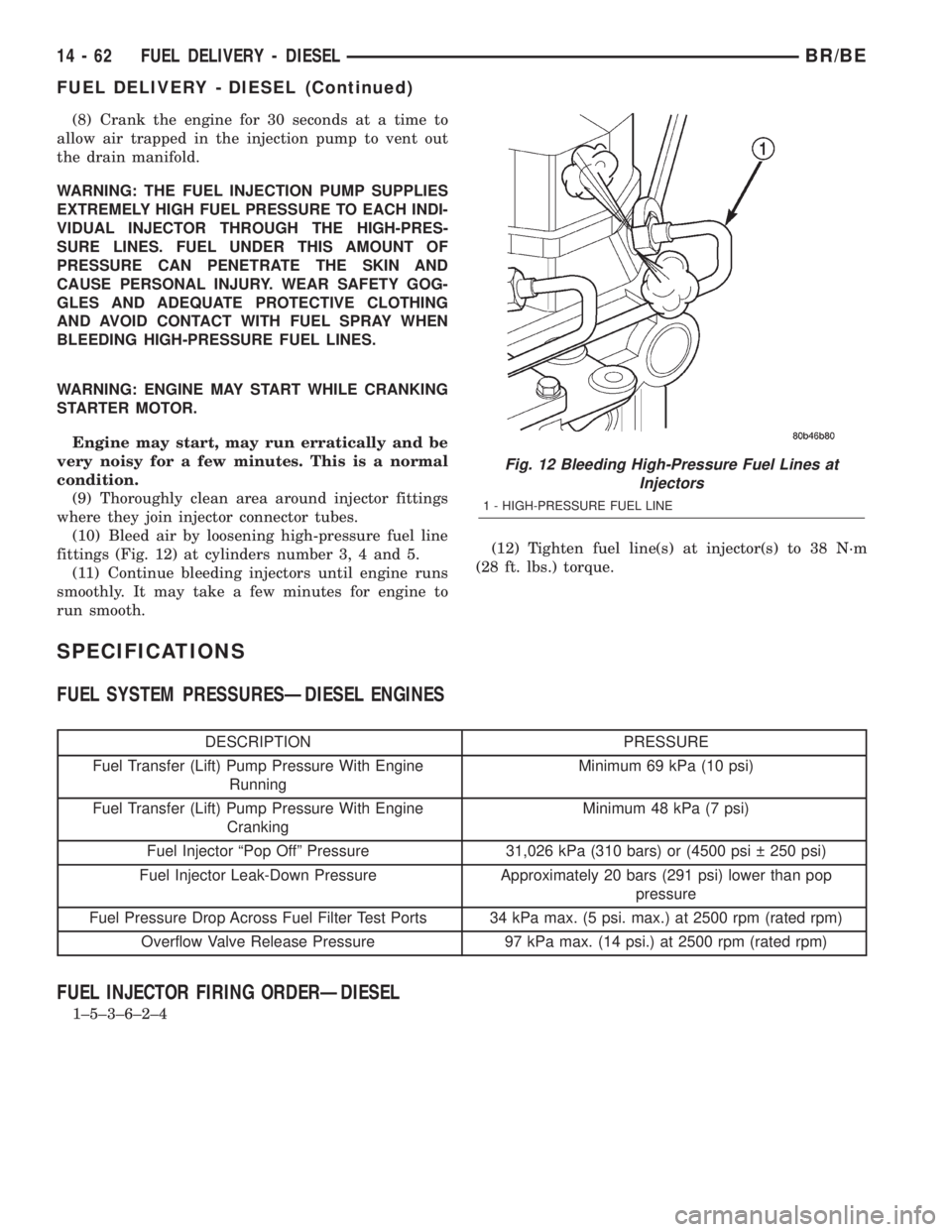

(9) Thoroughly clean area around injector fittings

where they join injector connector tubes.

(10) Bleed air by loosening high-pressure fuel line

fittings (Fig. 12) at cylinders number 3, 4 and 5.

(11) Continue bleeding injectors until engine runs

smoothly. It may take a few minutes for engine to

run smooth.(12) Tighten fuel line(s) at injector(s) to 38 N´m

(28 ft. lbs.) torque.

SPECIFICATIONS

FUEL SYSTEM PRESSURESÐDIESEL ENGINES

DESCRIPTION PRESSURE

Fuel Transfer (Lift) Pump Pressure With Engine

RunningMinimum 69 kPa (10 psi)

Fuel Transfer (Lift) Pump Pressure With Engine

CrankingMinimum 48 kPa (7 psi)

Fuel Injector ªPop Offº Pressure 31,026 kPa (310 bars) or (4500 psi 250 psi)

Fuel Injector Leak-Down Pressure Approximately 20 bars (291 psi) lower than pop

pressure

Fuel Pressure Drop Across Fuel Filter Test Ports 34 kPa max. (5 psi. max.) at 2500 rpm (rated rpm)

Overflow Valve Release Pressure 97 kPa max. (14 psi.) at 2500 rpm (rated rpm)

FUEL INJECTOR FIRING ORDERÐDIESEL

1±5±3±6±2±4

Fig. 12 Bleeding High-Pressure Fuel Lines at

Injectors

1 - HIGH-PRESSURE FUEL LINE

14 - 62 FUEL DELIVERY - DIESELBR/BE

FUEL DELIVERY - DIESEL (Continued)

Page 1362 of 2255

SPECIAL TOOLS

DIESEL FUEL SYSTEMFUEL FILTER / WATER

SEPARATOR

DESCRIPTION

The fuel filter/water separator assembly is located

on left side of engine above starter motor (Fig. 13).

The assembly also includes the fuel heater and

Water-In-Fuel (WIF) sensor.

OPERATION

The fuel filter/water separator protects the fuel

injection pump by removing water and contaminants

from the fuel. The construction of the filter/separator

allows fuel to pass through it, but helps prevent

moisture (water) from doing so. Moisture collects at

the bottom of the canister.

Refer to the maintenance schedules for the recom-

mended fuel filter replacement intervals.

For draining of water from canister, refer to Fuel

Filter/Water Separator Removal/Installation section.

A Water-In-Fuel (WIF) sensor is attached to side of

canister. Refer to Water-In-Fuel Sensor Description/

Operation.

The fuel heater is installed into the top of the fil-

ter/separator housing. Refer to Fuel Heater Descrip-

tion/Operation.

Spanner Wrench (Fuel Tank Module Removal/

Installation)Ð6856

Engine Barring (Rotating ) ToolÐ7471B (also part of

Kit #6860)

Fuel Injector Pop Pressure AdaptorÐ8301

Fuel Injector RemoverÐ8318

Fuel Injector Tube (Connector) RemoverÐ8324

Fig. 13 FUEL HEATER LOCATION

1 - FUEL HEATER AND TEMP. SENSOR

2 - FUEL FILTER/WATER SEPARATOR

3 - FUEL HEATER ELECTRICAL CONNECTOR

BR/BEFUEL DELIVERY - DIESEL 14 - 63

FUEL DELIVERY - DIESEL (Continued)

Page 1369 of 2255

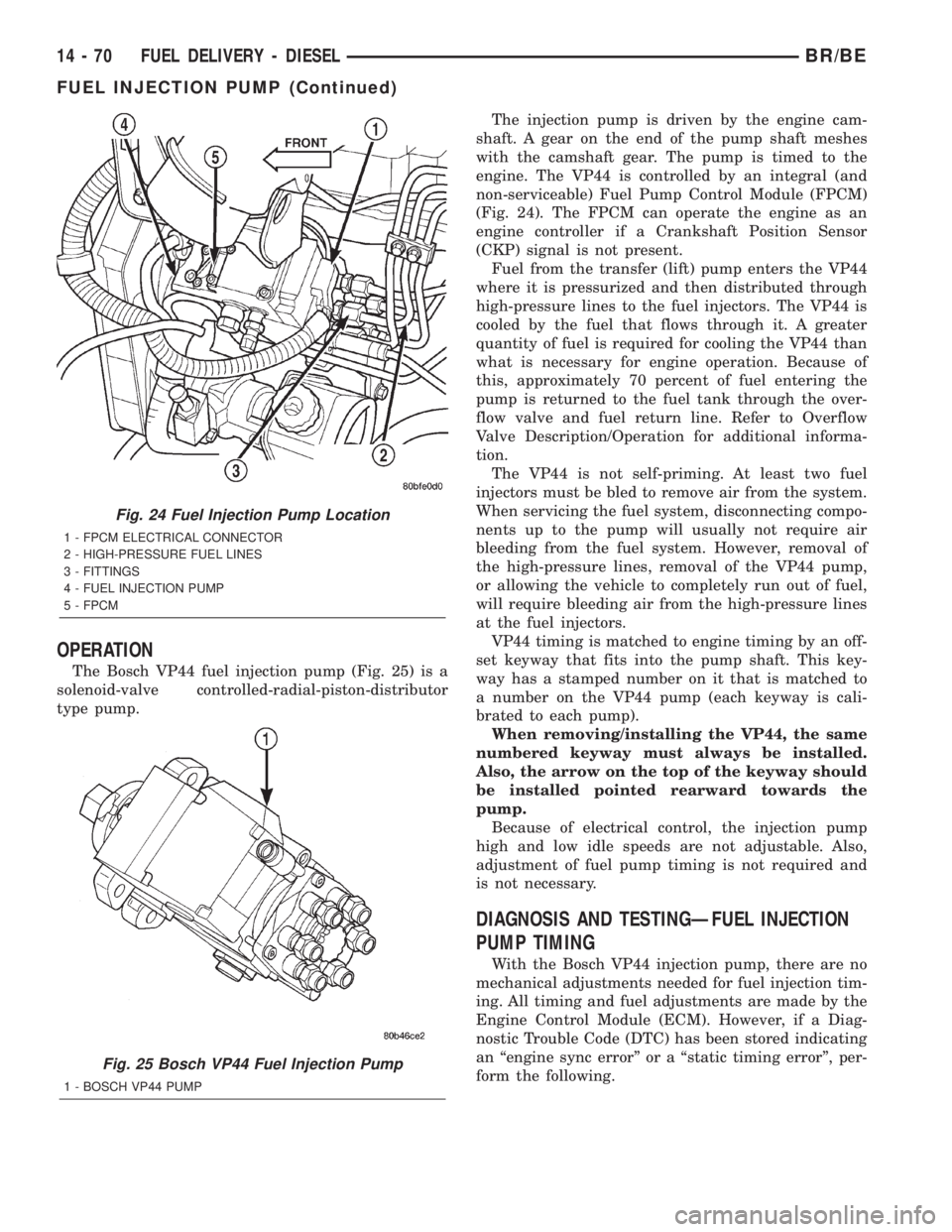

OPERATION

The Bosch VP44 fuel injection pump (Fig. 25) is a

solenoid-valve controlled-radial-piston-distributor

type pump.The injection pump is driven by the engine cam-

shaft. A gear on the end of the pump shaft meshes

with the camshaft gear. The pump is timed to the

engine. The VP44 is controlled by an integral (and

non-serviceable) Fuel Pump Control Module (FPCM)

(Fig. 24). The FPCM can operate the engine as an

engine controller if a Crankshaft Position Sensor

(CKP) signal is not present.

Fuel from the transfer (lift) pump enters the VP44

where it is pressurized and then distributed through

high-pressure lines to the fuel injectors. The VP44 is

cooled by the fuel that flows through it. A greater

quantity of fuel is required for cooling the VP44 than

what is necessary for engine operation. Because of

this, approximately 70 percent of fuel entering the

pump is returned to the fuel tank through the over-

flow valve and fuel return line. Refer to Overflow

Valve Description/Operation for additional informa-

tion.

The VP44 is not self-priming. At least two fuel

injectors must be bled to remove air from the system.

When servicing the fuel system, disconnecting compo-

nents up to the pump will usually not require air

bleeding from the fuel system. However, removal of

the high-pressure lines, removal of the VP44 pump,

or allowing the vehicle to completely run out of fuel,

will require bleeding air from the high-pressure lines

at the fuel injectors.

VP44 timing is matched to engine timing by an off-

set keyway that fits into the pump shaft. This key-

way has a stamped number on it that is matched to

a number on the VP44 pump (each keyway is cali-

brated to each pump).

When removing/installing the VP44, the same

numbered keyway must always be installed.

Also, the arrow on the top of the keyway should

be installed pointed rearward towards the

pump.

Because of electrical control, the injection pump

high and low idle speeds are not adjustable. Also,

adjustment of fuel pump timing is not required and

is not necessary.

DIAGNOSIS AND TESTINGÐFUEL INJECTION

PUMP TIMING

With the Bosch VP44 injection pump, there are no

mechanical adjustments needed for fuel injection tim-

ing. All timing and fuel adjustments are made by the

Engine Control Module (ECM). However, if a Diag-

nostic Trouble Code (DTC) has been stored indicating

an ªengine sync errorº or a ªstatic timing errorº, per-

form the following.

Fig. 24 Fuel Injection Pump Location

1 - FPCM ELECTRICAL CONNECTOR

2 - HIGH-PRESSURE FUEL LINES

3 - FITTINGS

4 - FUEL INJECTION PUMP

5 - FPCM

Fig. 25 Bosch VP44 Fuel Injection Pump

1 - BOSCH VP44 PUMP

14 - 70 FUEL DELIVERY - DIESELBR/BE

FUEL INJECTION PUMP (Continued)

Page 1376 of 2255

FUEL INJECTION PUMP DATA

PLATE

SPECIFICATIONS

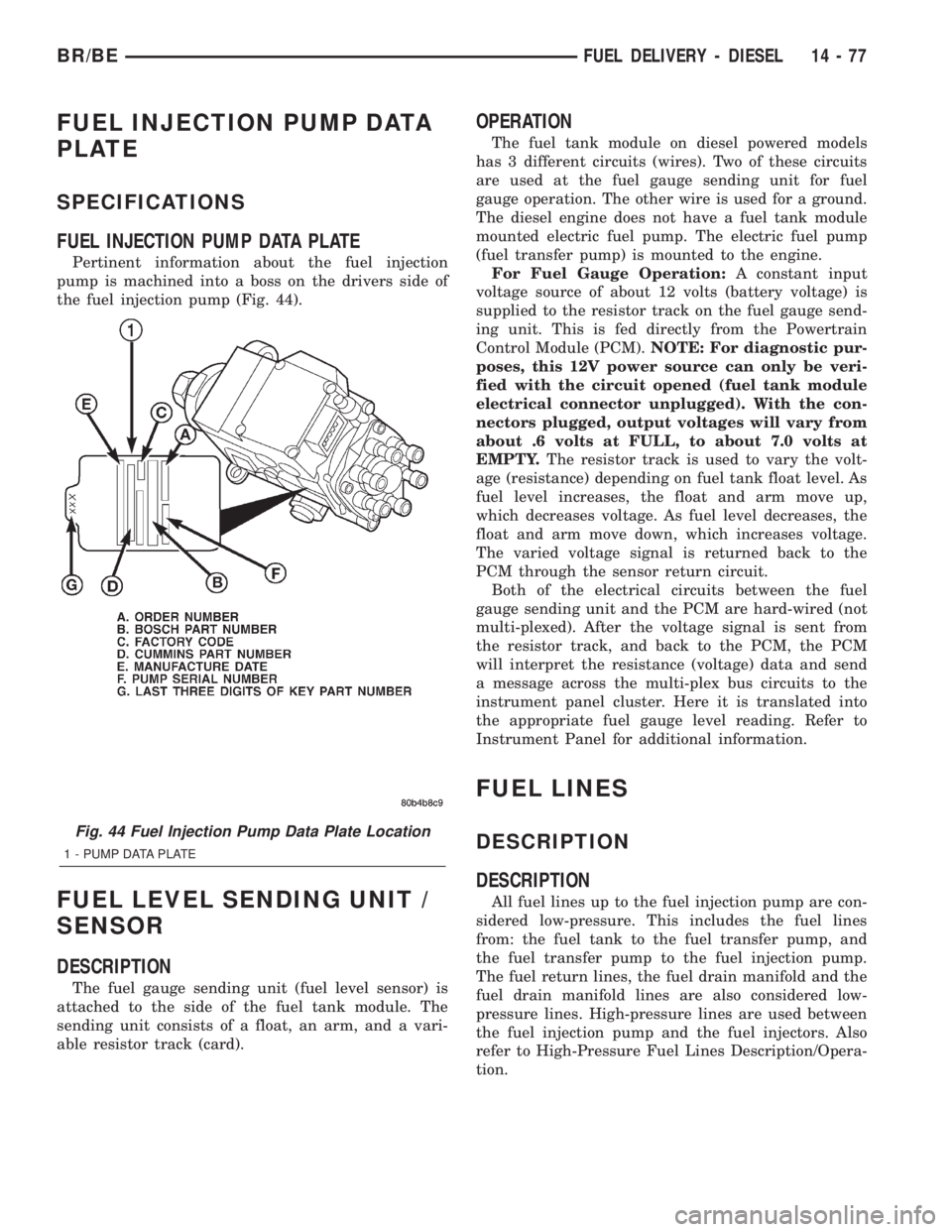

FUEL INJECTION PUMP DATA PLATE

Pertinent information about the fuel injection

pump is machined into a boss on the drivers side of

the fuel injection pump (Fig. 44).

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel tank module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel tank module on diesel powered models

has 3 different circuits (wires). Two of these circuits

are used at the fuel gauge sending unit for fuel

gauge operation. The other wire is used for a ground.

The diesel engine does not have a fuel tank module

mounted electric fuel pump. The electric fuel pump

(fuel transfer pump) is mounted to the engine.

For Fuel Gauge Operation:A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Powertrain

Control Module (PCM).NOTE: For diagnostic pur-

poses, this 12V power source can only be veri-

fied with the circuit opened (fuel tank module

electrical connector unplugged). With the con-

nectors plugged, output voltages will vary from

about .6 volts at FULL, to about 7.0 volts at

EMPTY.The resistor track is used to vary the volt-

age (resistance) depending on fuel tank float level. As

fuel level increases, the float and arm move up,

which decreases voltage. As fuel level decreases, the

float and arm move down, which increases voltage.

The varied voltage signal is returned back to the

PCM through the sensor return circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

FUEL LINES

DESCRIPTION

DESCRIPTION

All fuel lines up to the fuel injection pump are con-

sidered low-pressure. This includes the fuel lines

from: the fuel tank to the fuel transfer pump, and

the fuel transfer pump to the fuel injection pump.

The fuel return lines, the fuel drain manifold and the

fuel drain manifold lines are also considered low-

pressure lines. High-pressure lines are used between

the fuel injection pump and the fuel injectors. Also

refer to High-Pressure Fuel Lines Description/Opera-

tion.

Fig. 44 Fuel Injection Pump Data Plate Location

1 - PUMP DATA PLATE

BR/BEFUEL DELIVERY - DIESEL 14 - 77

Page 1377 of 2255

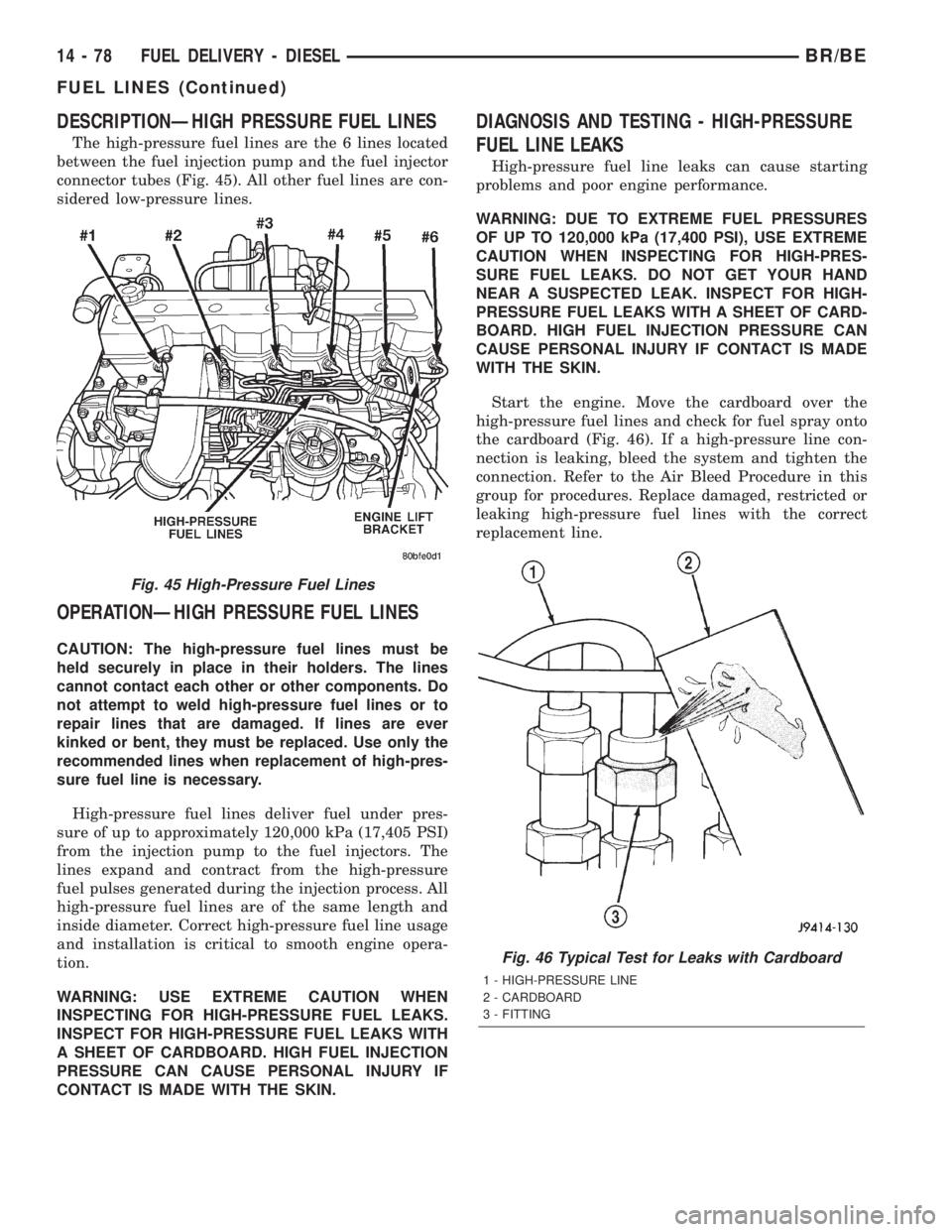

DESCRIPTIONÐHIGH PRESSURE FUEL LINES

The high-pressure fuel lines are the 6 lines located

between the fuel injection pump and the fuel injector

connector tubes (Fig. 45). All other fuel lines are con-

sidered low-pressure lines.

OPERATIONÐHIGH PRESSURE FUEL LINES

CAUTION: The high-pressure fuel lines must be

held securely in place in their holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. If lines are ever

kinked or bent, they must be replaced. Use only the

recommended lines when replacement of high-pres-

sure fuel line is necessary.

High-pressure fuel lines deliver fuel under pres-

sure of up to approximately 120,000 kPa (17,405 PSI)

from the injection pump to the fuel injectors. The

lines expand and contract from the high-pressure

fuel pulses generated during the injection process. All

high-pressure fuel lines are of the same length and

inside diameter. Correct high-pressure fuel line usage

and installation is critical to smooth engine opera-

tion.

WARNING: USE EXTREME CAUTION WHEN

INSPECTING FOR HIGH-PRESSURE FUEL LEAKS.

INSPECT FOR HIGH-PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

DIAGNOSIS AND TESTING - HIGH-PRESSURE

FUEL LINE LEAKS

High-pressure fuel line leaks can cause starting

problems and poor engine performance.

WARNING: DUE TO EXTREME FUEL PRESSURES

OF UP TO 120,000 kPa (17,400 PSI), USE EXTREME

CAUTION WHEN INSPECTING FOR HIGH-PRES-

SURE FUEL LEAKS. DO NOT GET YOUR HAND

NEAR A SUSPECTED LEAK. INSPECT FOR HIGH-

PRESSURE FUEL LEAKS WITH A SHEET OF CARD-

BOARD. HIGH FUEL INJECTION PRESSURE CAN

CAUSE PERSONAL INJURY IF CONTACT IS MADE

WITH THE SKIN.

Start the engine. Move the cardboard over the

high-pressure fuel lines and check for fuel spray onto

the cardboard (Fig. 46). If a high-pressure line con-

nection is leaking, bleed the system and tighten the

connection. Refer to the Air Bleed Procedure in this

group for procedures. Replace damaged, restricted or

leaking high-pressure fuel lines with the correct

replacement line.

Fig. 45 High-Pressure Fuel Lines

Fig. 46 Typical Test for Leaks with Cardboard

1 - HIGH-PRESSURE LINE

2 - CARDBOARD

3 - FITTING

14 - 78 FUEL DELIVERY - DIESELBR/BE

FUEL LINES (Continued)