injector DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1378 of 2255

CAUTION: The high-pressure fuel lines must be

clamped securely in place in the holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high-pressure

fuel line is necessary.

REMOVAL

High-pressure lines are used between the fuel

injection pump and the fuel injectors only. All high-

pressure fuel lines are of the same length and inside

diameter. Correct high-pressure fuel line usage and

installation is critical to smooth engine operation.

CAUTION: Refer to Cleaning Fuel System Parts.

(1) Disconnect both negative battery cables from

both batteries. Cover and isolate ends of cables.

(2) Thoroughly clean fuel lines at cylinder head

and injection pump ends.

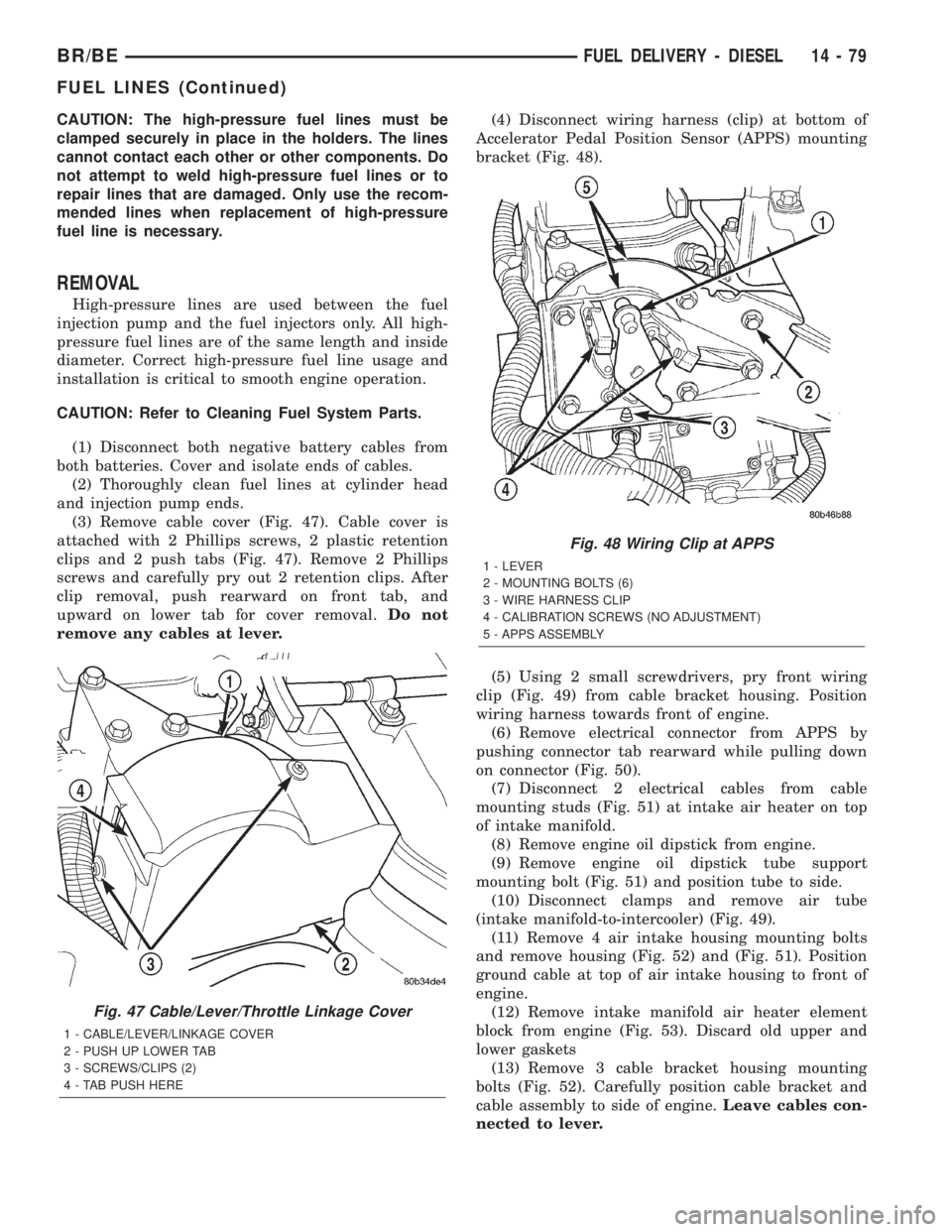

(3) Remove cable cover (Fig. 47). Cable cover is

attached with 2 Phillips screws, 2 plastic retention

clips and 2 push tabs (Fig. 47). Remove 2 Phillips

screws and carefully pry out 2 retention clips. After

clip removal, push rearward on front tab, and

upward on lower tab for cover removal.Do not

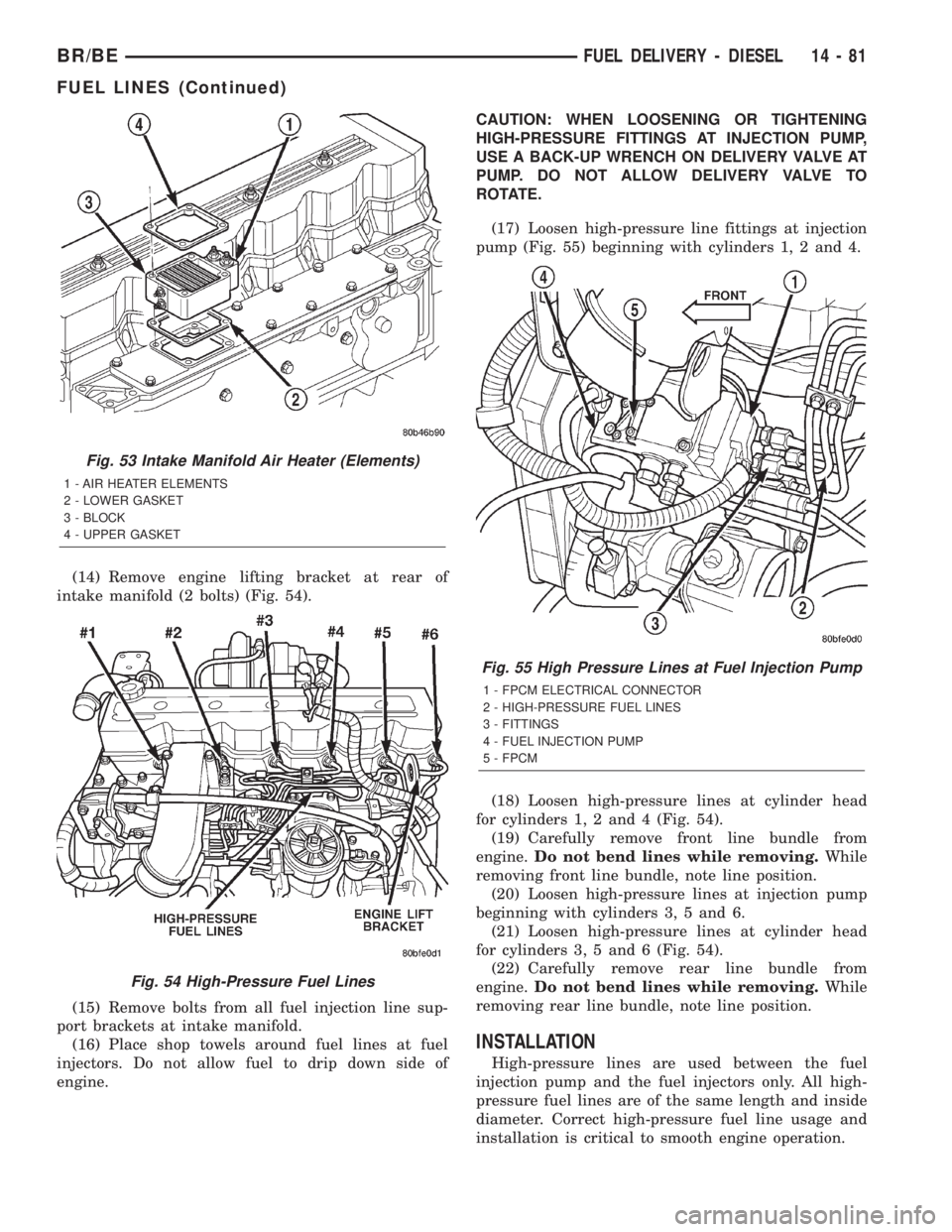

remove any cables at lever.(4) Disconnect wiring harness (clip) at bottom of

Accelerator Pedal Position Sensor (APPS) mounting

bracket (Fig. 48).

(5) Using 2 small screwdrivers, pry front wiring

clip (Fig. 49) from cable bracket housing. Position

wiring harness towards front of engine.

(6) Remove electrical connector from APPS by

pushing connector tab rearward while pulling down

on connector (Fig. 50).

(7) Disconnect 2 electrical cables from cable

mounting studs (Fig. 51) at intake air heater on top

of intake manifold.

(8) Remove engine oil dipstick from engine.

(9) Remove engine oil dipstick tube support

mounting bolt (Fig. 51) and position tube to side.

(10) Disconnect clamps and remove air tube

(intake manifold-to-intercooler) (Fig. 49).

(11) Remove 4 air intake housing mounting bolts

and remove housing (Fig. 52) and (Fig. 51). Position

ground cable at top of air intake housing to front of

engine.

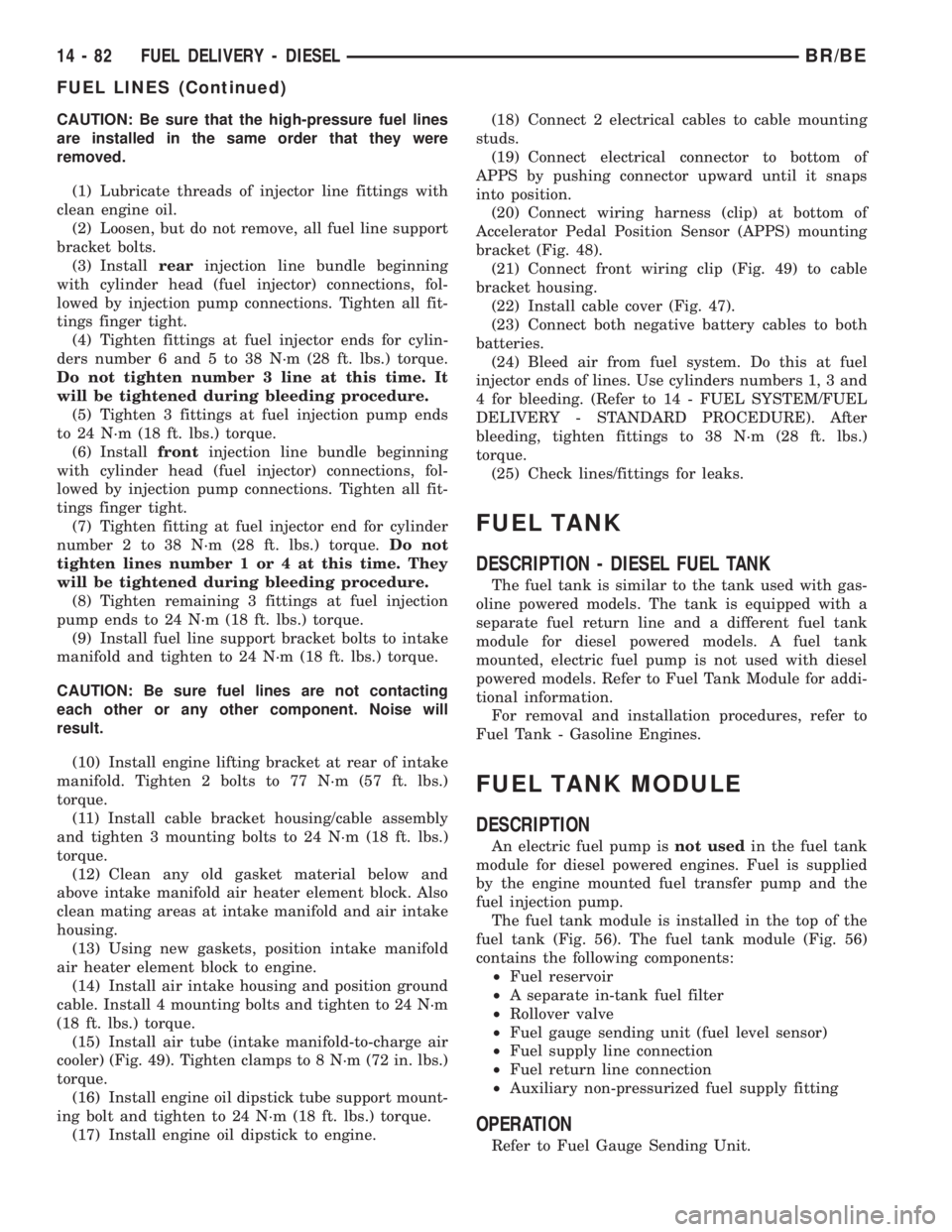

(12) Remove intake manifold air heater element

block from engine (Fig. 53). Discard old upper and

lower gaskets

(13) Remove 3 cable bracket housing mounting

bolts (Fig. 52). Carefully position cable bracket and

cable assembly to side of engine.Leave cables con-

nected to lever.

Fig. 47 Cable/Lever/Throttle Linkage Cover

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

Fig. 48 Wiring Clip at APPS

1 - LEVER

2 - MOUNTING BOLTS (6)

3 - WIRE HARNESS CLIP

4 - CALIBRATION SCREWS (NO ADJUSTMENT)

5 - APPS ASSEMBLY

BR/BEFUEL DELIVERY - DIESEL 14 - 79

FUEL LINES (Continued)

Page 1380 of 2255

(14) Remove engine lifting bracket at rear of

intake manifold (2 bolts) (Fig. 54).

(15) Remove bolts from all fuel injection line sup-

port brackets at intake manifold.

(16) Place shop towels around fuel lines at fuel

injectors. Do not allow fuel to drip down side of

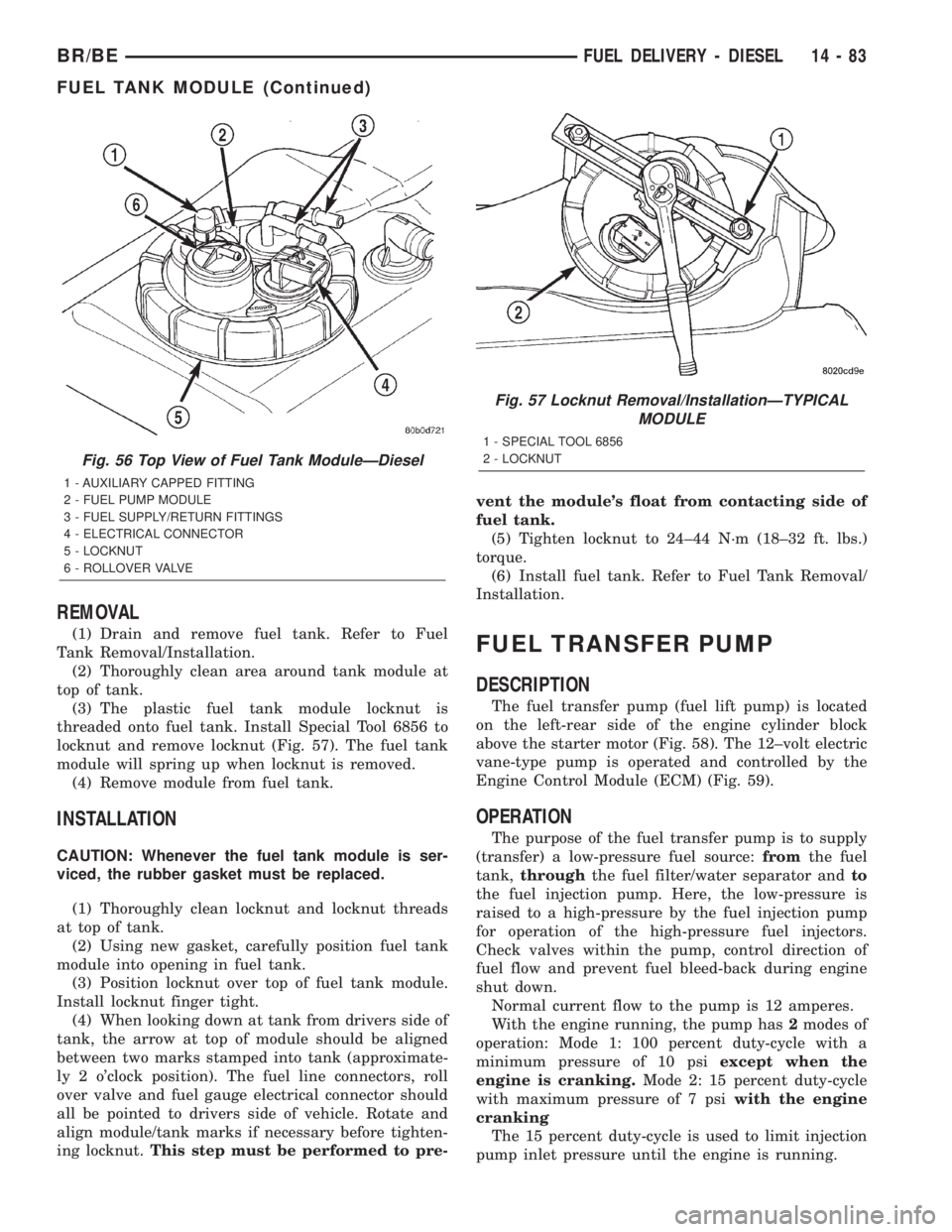

engine.CAUTION: WHEN LOOSENING OR TIGHTENING

HIGH-PRESSURE FITTINGS AT INJECTION PUMP,

USE A BACK-UP WRENCH ON DELIVERY VALVE AT

PUMP. DO NOT ALLOW DELIVERY VALVE TO

ROTATE.

(17) Loosen high-pressure line fittings at injection

pump (Fig. 55) beginning with cylinders 1, 2 and 4.

(18) Loosen high-pressure lines at cylinder head

for cylinders 1, 2 and 4 (Fig. 54).

(19) Carefully remove front line bundle from

engine.Do not bend lines while removing.While

removing front line bundle, note line position.

(20) Loosen high-pressure lines at injection pump

beginning with cylinders 3, 5 and 6.

(21) Loosen high-pressure lines at cylinder head

for cylinders 3, 5 and 6 (Fig. 54).

(22) Carefully remove rear line bundle from

engine.Do not bend lines while removing.While

removing rear line bundle, note line position.

INSTALLATION

High-pressure lines are used between the fuel

injection pump and the fuel injectors only. All high-

pressure fuel lines are of the same length and inside

diameter. Correct high-pressure fuel line usage and

installation is critical to smooth engine operation.

Fig. 53 Intake Manifold Air Heater (Elements)

1 - AIR HEATER ELEMENTS

2 - LOWER GASKET

3 - BLOCK

4 - UPPER GASKET

Fig. 54 High-Pressure Fuel Lines

Fig. 55 High Pressure Lines at Fuel Injection Pump

1 - FPCM ELECTRICAL CONNECTOR

2 - HIGH-PRESSURE FUEL LINES

3 - FITTINGS

4 - FUEL INJECTION PUMP

5 - FPCM

BR/BEFUEL DELIVERY - DIESEL 14 - 81

FUEL LINES (Continued)

Page 1381 of 2255

CAUTION: Be sure that the high-pressure fuel lines

are installed in the same order that they were

removed.

(1) Lubricate threads of injector line fittings with

clean engine oil.

(2) Loosen, but do not remove, all fuel line support

bracket bolts.

(3) Installrearinjection line bundle beginning

with cylinder head (fuel injector) connections, fol-

lowed by injection pump connections. Tighten all fit-

tings finger tight.

(4) Tighten fittings at fuel injector ends for cylin-

ders number 6 and 5 to 38 N´m (28 ft. lbs.) torque.

Do not tighten number 3 line at this time. It

will be tightened during bleeding procedure.

(5) Tighten 3 fittings at fuel injection pump ends

to 24 N´m (18 ft. lbs.) torque.

(6) Installfrontinjection line bundle beginning

with cylinder head (fuel injector) connections, fol-

lowed by injection pump connections. Tighten all fit-

tings finger tight.

(7) Tighten fitting at fuel injector end for cylinder

number 2 to 38 N´m (28 ft. lbs.) torque.Do not

tighten lines number 1 or 4 at this time. They

will be tightened during bleeding procedure.

(8) Tighten remaining 3 fittings at fuel injection

pump ends to 24 N´m (18 ft. lbs.) torque.

(9) Install fuel line support bracket bolts to intake

manifold and tighten to 24 N´m (18 ft. lbs.) torque.

CAUTION: Be sure fuel lines are not contacting

each other or any other component. Noise will

result.

(10) Install engine lifting bracket at rear of intake

manifold. Tighten 2 bolts to 77 N´m (57 ft. lbs.)

torque.

(11) Install cable bracket housing/cable assembly

and tighten 3 mounting bolts to 24 N´m (18 ft. lbs.)

torque.

(12) Clean any old gasket material below and

above intake manifold air heater element block. Also

clean mating areas at intake manifold and air intake

housing.

(13) Using new gaskets, position intake manifold

air heater element block to engine.

(14) Install air intake housing and position ground

cable. Install 4 mounting bolts and tighten to 24 N´m

(18 ft. lbs.) torque.

(15) Install air tube (intake manifold-to-charge air

cooler) (Fig. 49). Tighten clamps to 8 N´m (72 in. lbs.)

torque.

(16) Install engine oil dipstick tube support mount-

ing bolt and tighten to 24 N´m (18 ft. lbs.) torque.

(17) Install engine oil dipstick to engine.(18) Connect 2 electrical cables to cable mounting

studs.

(19) Connect electrical connector to bottom of

APPS by pushing connector upward until it snaps

into position.

(20) Connect wiring harness (clip) at bottom of

Accelerator Pedal Position Sensor (APPS) mounting

bracket (Fig. 48).

(21) Connect front wiring clip (Fig. 49) to cable

bracket housing.

(22) Install cable cover (Fig. 47).

(23) Connect both negative battery cables to both

batteries.

(24) Bleed air from fuel system. Do this at fuel

injector ends of lines. Use cylinders numbers 1, 3 and

4 for bleeding. (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE). After

bleeding, tighten fittings to 38 N´m (28 ft. lbs.)

torque.

(25) Check lines/fittings for leaks.

FUEL TANK

DESCRIPTION - DIESEL FUEL TANK

The fuel tank is similar to the tank used with gas-

oline powered models. The tank is equipped with a

separate fuel return line and a different fuel tank

module for diesel powered models. A fuel tank

mounted, electric fuel pump is not used with diesel

powered models. Refer to Fuel Tank Module for addi-

tional information.

For removal and installation procedures, refer to

Fuel Tank - Gasoline Engines.

FUEL TANK MODULE

DESCRIPTION

An electric fuel pump isnot usedin the fuel tank

module for diesel powered engines. Fuel is supplied

by the engine mounted fuel transfer pump and the

fuel injection pump.

The fuel tank module is installed in the top of the

fuel tank (Fig. 56). The fuel tank module (Fig. 56)

contains the following components:

²Fuel reservoir

²A separate in-tank fuel filter

²Rollover valve

²Fuel gauge sending unit (fuel level sensor)

²Fuel supply line connection

²Fuel return line connection

²Auxiliary non-pressurized fuel supply fitting

OPERATION

Refer to Fuel Gauge Sending Unit.

14 - 82 FUEL DELIVERY - DIESELBR/BE

FUEL LINES (Continued)

Page 1382 of 2255

REMOVAL

(1) Drain and remove fuel tank. Refer to Fuel

Tank Removal/Installation.

(2) Thoroughly clean area around tank module at

top of tank.

(3) The plastic fuel tank module locknut is

threaded onto fuel tank. Install Special Tool 6856 to

locknut and remove locknut (Fig. 57). The fuel tank

module will spring up when locknut is removed.

(4) Remove module from fuel tank.

INSTALLATION

CAUTION: Whenever the fuel tank module is ser-

viced, the rubber gasket must be replaced.

(1) Thoroughly clean locknut and locknut threads

at top of tank.

(2) Using new gasket, carefully position fuel tank

module into opening in fuel tank.

(3) Position locknut over top of fuel tank module.

Install locknut finger tight.

(4) When looking down at tank from drivers side of

tank, the arrow at top of module should be aligned

between two marks stamped into tank (approximate-

ly 2 o'clock position). The fuel line connectors, roll

over valve and fuel gauge electrical connector should

all be pointed to drivers side of vehicle. Rotate and

align module/tank marks if necessary before tighten-

ing locknut.This step must be performed to pre-vent the module's float from contacting side of

fuel tank.

(5) Tighten locknut to 24±44 N´m (18±32 ft. lbs.)

torque.

(6) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

FUEL TRANSFER PUMP

DESCRIPTION

The fuel transfer pump (fuel lift pump) is located

on the left-rear side of the engine cylinder block

above the starter motor (Fig. 58). The 12±volt electric

vane-type pump is operated and controlled by the

Engine Control Module (ECM) (Fig. 59).

OPERATION

The purpose of the fuel transfer pump is to supply

(transfer) a low-pressure fuel source:fromthe fuel

tank,throughthe fuel filter/water separator andto

the fuel injection pump. Here, the low-pressure is

raised to a high-pressure by the fuel injection pump

for operation of the high-pressure fuel injectors.

Check valves within the pump, control direction of

fuel flow and prevent fuel bleed-back during engine

shut down.

Normal current flow to the pump is 12 amperes.

With the engine running, the pump has2modes of

operation: Mode 1: 100 percent duty-cycle with a

minimum pressure of 10 psiexcept when the

engine is cranking.Mode 2: 15 percent duty-cycle

with maximum pressure of 7 psiwith the engine

cranking

The 15 percent duty-cycle is used to limit injection

pump inlet pressure until the engine is running.

Fig. 56 Top View of Fuel Tank ModuleÐDiesel

1 - AUXILIARY CAPPED FITTING

2 - FUEL PUMP MODULE

3 - FUEL SUPPLY/RETURN FITTINGS

4 - ELECTRICAL CONNECTOR

5 - LOCKNUT

6 - ROLLOVER VALVE

Fig. 57 Locknut Removal/InstallationÐTYPICAL

MODULE

1 - SPECIAL TOOL 6856

2 - LOCKNUT

BR/BEFUEL DELIVERY - DIESEL 14 - 83

FUEL TANK MODULE (Continued)

Page 1388 of 2255

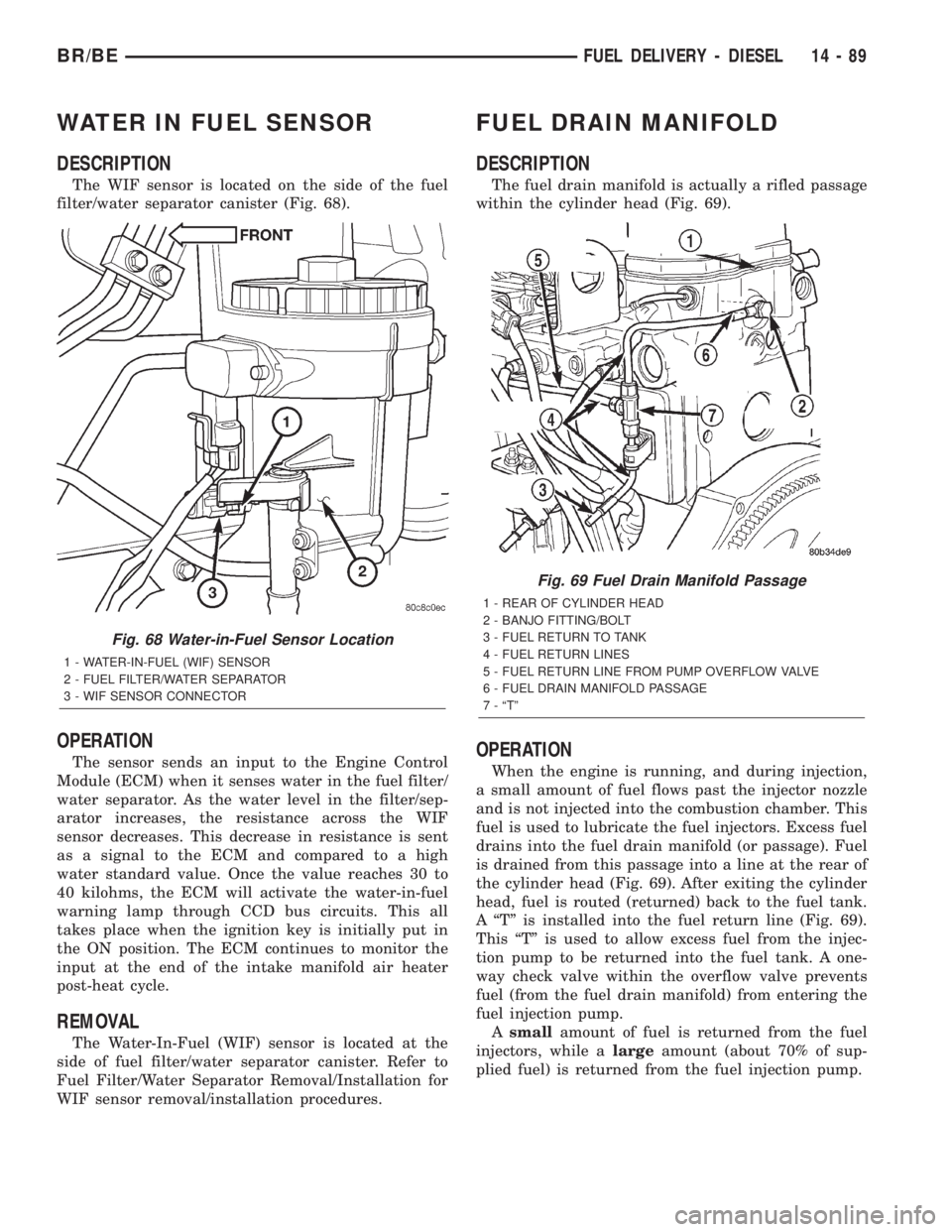

WATER IN FUEL SENSOR

DESCRIPTION

The WIF sensor is located on the side of the fuel

filter/water separator canister (Fig. 68).

OPERATION

The sensor sends an input to the Engine Control

Module (ECM) when it senses water in the fuel filter/

water separator. As the water level in the filter/sep-

arator increases, the resistance across the WIF

sensor decreases. This decrease in resistance is sent

as a signal to the ECM and compared to a high

water standard value. Once the value reaches 30 to

40 kilohms, the ECM will activate the water-in-fuel

warning lamp through CCD bus circuits. This all

takes place when the ignition key is initially put in

the ON position. The ECM continues to monitor the

input at the end of the intake manifold air heater

post-heat cycle.

REMOVAL

The Water-In-Fuel (WIF) sensor is located at the

side of fuel filter/water separator canister. Refer to

Fuel Filter/Water Separator Removal/Installation for

WIF sensor removal/installation procedures.

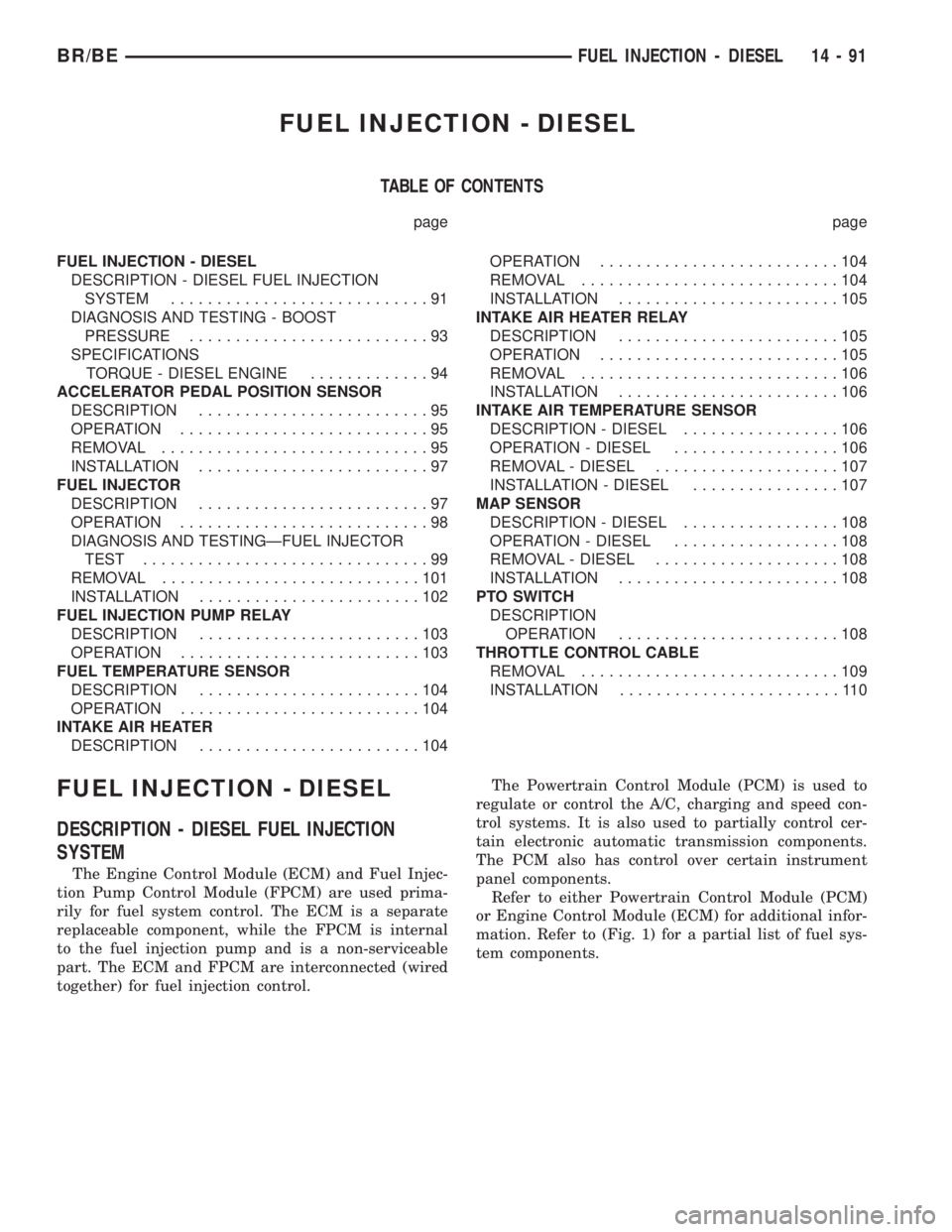

FUEL DRAIN MANIFOLD

DESCRIPTION

The fuel drain manifold is actually a rifled passage

within the cylinder head (Fig. 69).

OPERATION

When the engine is running, and during injection,

a small amount of fuel flows past the injector nozzle

and is not injected into the combustion chamber. This

fuel is used to lubricate the fuel injectors. Excess fuel

drains into the fuel drain manifold (or passage). Fuel

is drained from this passage into a line at the rear of

the cylinder head (Fig. 69). After exiting the cylinder

head, fuel is routed (returned) back to the fuel tank.

A ªTº is installed into the fuel return line (Fig. 69).

This ªTº is used to allow excess fuel from the injec-

tion pump to be returned into the fuel tank. A one-

way check valve within the overflow valve prevents

fuel (from the fuel drain manifold) from entering the

fuel injection pump.

Asmallamount of fuel is returned from the fuel

injectors, while alargeamount (about 70% of sup-

plied fuel) is returned from the fuel injection pump.

Fig. 68 Water-in-Fuel Sensor Location

1 - WATER-IN-FUEL (WIF) SENSOR

2 - FUEL FILTER/WATER SEPARATOR

3 - WIF SENSOR CONNECTOR

Fig. 69 Fuel Drain Manifold Passage

1 - REAR OF CYLINDER HEAD

2 - BANJO FITTING/BOLT

3 - FUEL RETURN TO TANK

4 - FUEL RETURN LINES

5 - FUEL RETURN LINE FROM PUMP OVERFLOW VALVE

6 - FUEL DRAIN MANIFOLD PASSAGE

7 - ªTº

BR/BEFUEL DELIVERY - DIESEL 14 - 89

Page 1390 of 2255

FUEL INJECTION - DIESEL

TABLE OF CONTENTS

page page

FUEL INJECTION - DIESEL

DESCRIPTION - DIESEL FUEL INJECTION

SYSTEM............................91

DIAGNOSIS AND TESTING - BOOST

PRESSURE..........................93

SPECIFICATIONS

TORQUE - DIESEL ENGINE.............94

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................95

OPERATION...........................95

REMOVAL.............................95

INSTALLATION.........................97

FUEL INJECTOR

DESCRIPTION.........................97

OPERATION...........................98

DIAGNOSIS AND TESTINGÐFUEL INJECTOR

TEST...............................99

REMOVAL............................101

INSTALLATION........................102

FUEL INJECTION PUMP RELAY

DESCRIPTION........................103

OPERATION..........................103

FUEL TEMPERATURE SENSOR

DESCRIPTION........................104

OPERATION..........................104

INTAKE AIR HEATER

DESCRIPTION........................104OPERATION..........................104

REMOVAL............................104

INSTALLATION........................105

INTAKE AIR HEATER RELAY

DESCRIPTION........................105

OPERATION..........................105

REMOVAL............................106

INSTALLATION........................106

INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION - DIESEL.................106

OPERATION - DIESEL..................106

REMOVAL - DIESEL....................107

INSTALLATION - DIESEL................107

MAP SENSOR

DESCRIPTION - DIESEL.................108

OPERATION - DIESEL..................108

REMOVAL - DIESEL....................108

INSTALLATION........................108

PTO SWITCH

DESCRIPTION

OPERATION........................108

THROTTLE CONTROL CABLE

REMOVAL............................109

INSTALLATION........................110

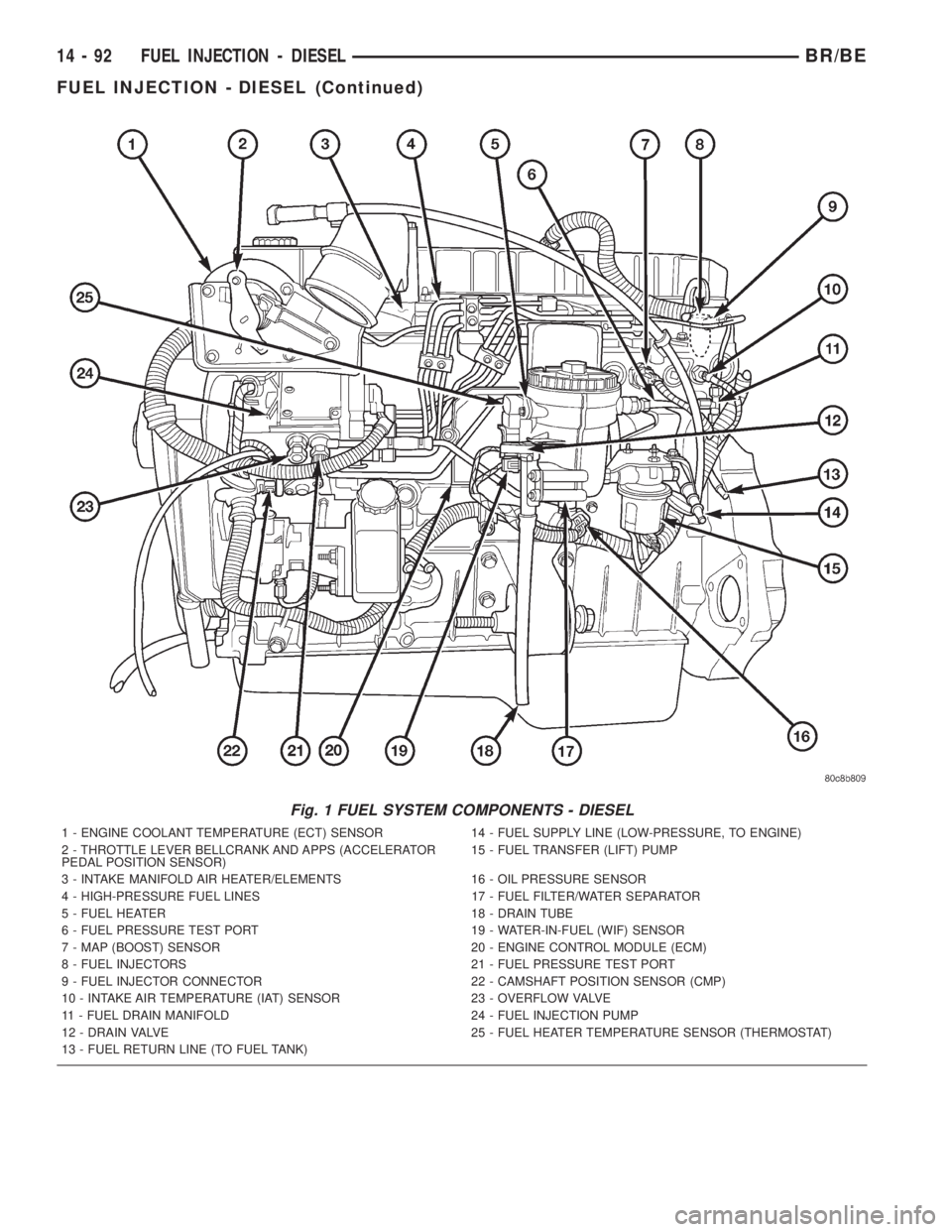

FUEL INJECTION - DIESEL

DESCRIPTION - DIESEL FUEL INJECTION

SYSTEM

The Engine Control Module (ECM) and Fuel Injec-

tion Pump Control Module (FPCM) are used prima-

rily for fuel system control. The ECM is a separate

replaceable component, while the FPCM is internal

to the fuel injection pump and is a non-serviceable

part. The ECM and FPCM are interconnected (wired

together) for fuel injection control.The Powertrain Control Module (PCM) is used to

regulate or control the A/C, charging and speed con-

trol systems. It is also used to partially control cer-

tain electronic automatic transmission components.

The PCM also has control over certain instrument

panel components.

Refer to either Powertrain Control Module (PCM)

or Engine Control Module (ECM) for additional infor-

mation. Refer to (Fig. 1) for a partial list of fuel sys-

tem components.

BR/BEFUEL INJECTION - DIESEL 14 - 91

Page 1391 of 2255

Fig. 1 FUEL SYSTEM COMPONENTS - DIESEL

1 - ENGINE COOLANT TEMPERATURE (ECT) SENSOR 14 - FUEL SUPPLY LINE (LOW-PRESSURE, TO ENGINE)

2 - THROTTLE LEVER BELLCRANK AND APPS (ACCELERATOR

PEDAL POSITION SENSOR)15 - FUEL TRANSFER (LIFT) PUMP

3 - INTAKE MANIFOLD AIR HEATER/ELEMENTS 16 - OIL PRESSURE SENSOR

4 - HIGH-PRESSURE FUEL LINES 17 - FUEL FILTER/WATER SEPARATOR

5 - FUEL HEATER 18 - DRAIN TUBE

6 - FUEL PRESSURE TEST PORT 19 - WATER-IN-FUEL (WIF) SENSOR

7 - MAP (BOOST) SENSOR 20 - ENGINE CONTROL MODULE (ECM)

8 - FUEL INJECTORS 21 - FUEL PRESSURE TEST PORT

9 - FUEL INJECTOR CONNECTOR 22 - CAMSHAFT POSITION SENSOR (CMP)

10 - INTAKE AIR TEMPERATURE (IAT) SENSOR 23 - OVERFLOW VALVE

11 - FUEL DRAIN MANIFOLD 24 - FUEL INJECTION PUMP

12 - DRAIN VALVE 25 - FUEL HEATER TEMPERATURE SENSOR (THERMOSTAT)

13 - FUEL RETURN LINE (TO FUEL TANK)

14 - 92 FUEL INJECTION - DIESELBR/BE

FUEL INJECTION - DIESEL (Continued)

Page 1393 of 2255

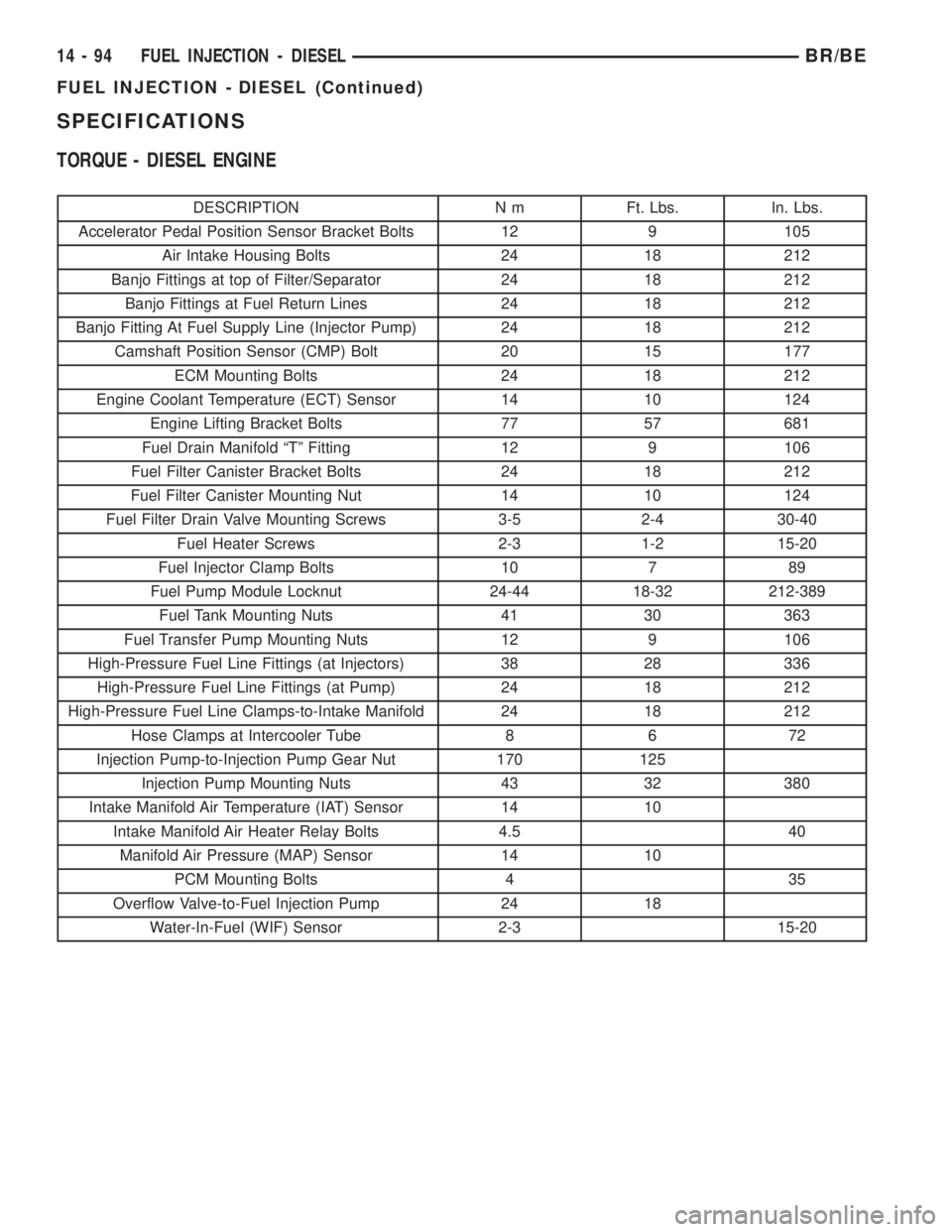

SPECIFICATIONS

TORQUE - DIESEL ENGINE

DESCRIPTION N m Ft. Lbs. In. Lbs.

Accelerator Pedal Position Sensor Bracket Bolts 12 9 105

Air Intake Housing Bolts 24 18 212

Banjo Fittings at top of Filter/Separator 24 18 212

Banjo Fittings at Fuel Return Lines 24 18 212

Banjo Fitting At Fuel Supply Line (Injector Pump) 24 18 212

Camshaft Position Sensor (CMP) Bolt 20 15 177

ECM Mounting Bolts 24 18 212

Engine Coolant Temperature (ECT) Sensor 14 10 124

Engine Lifting Bracket Bolts 77 57 681

Fuel Drain Manifold ªTº Fitting 12 9 106

Fuel Filter Canister Bracket Bolts 24 18 212

Fuel Filter Canister Mounting Nut 14 10 124

Fuel Filter Drain Valve Mounting Screws 3-5 2-4 30-40

Fuel Heater Screws 2-3 1-2 15-20

Fuel Injector Clamp Bolts 10 7 89

Fuel Pump Module Locknut 24-44 18-32 212-389

Fuel Tank Mounting Nuts 41 30 363

Fuel Transfer Pump Mounting Nuts 12 9 106

High-Pressure Fuel Line Fittings (at Injectors) 38 28 336

High-Pressure Fuel Line Fittings (at Pump) 24 18 212

High-Pressure Fuel Line Clamps-to-Intake Manifold 24 18 212

Hose Clamps at Intercooler Tube 8 6 72

Injection Pump-to-Injection Pump Gear Nut 170 125

Injection Pump Mounting Nuts 43 32 380

Intake Manifold Air Temperature (IAT) Sensor 14 10

Intake Manifold Air Heater Relay Bolts 4.5 40

Manifold Air Pressure (MAP) Sensor 14 10

PCM Mounting Bolts 4 35

Overflow Valve-to-Fuel Injection Pump 24 18

Water-In-Fuel (WIF) Sensor 2-3 15-20

14 - 94 FUEL INJECTION - DIESELBR/BE

FUEL INJECTION - DIESEL (Continued)

Page 1396 of 2255

(1) Disconnect both negative battery cables at both

batteries.

(2) Remove cable cover (Fig. 6). Cable cover is

attached with 2 Phillips screws, 2 plastic retention

clips and 2 push tabs (Fig. 6). Remove 2 Phillips

screws and carefully pry out 2 retention clips. After

clip removal, push rearward on front tab, and

upward on lower tab for cover removal.

(3) Using finger pressure only, disconnect end of

speed control servo cable from throttle lever pin by

pulling forward on connector while holding lever

rearward (Fig. 7).DO NOT try to pull connector

off perpendicular to lever pin. Connector will

be broken.

(4) Using two small screwdrivers, pry throttle

cable connector socket from throttle lever ball (Fig.

7).Be very careful not to bend throttle lever

arm.

(5) Disconnect transmission control cable at lever

arm (if equipped). Refer to 21, Transmission.

(6) Squeeze pinch tabs on speed control cable (Fig.

7) and pull cable rearward to remove from cable

mounting bracket.

(7) Squeeze pinch tabs on throttle cable (Fig. 7)

and pull cable rearward to remove from cable mount-

ing bracket.

(8) If equipped with an automatic transmission,

refer to 21, Transmission for transmission control

cable removal procedures.

(9) Disconnect wiring harness clip (Fig. 8) at bot-

tom of bracket.

(10) Remove 6 mounting bolts (Fig. 8) and par-

tially remove APPS assembly from engine. After

assembly is partially removed, disconnect electrical

connector from bottom of sensor by pushing on con-

nector tab (Fig. 9).

(11) Remove APPS assembly from engine.

INSTALLATION

The APPS is serviced (replaced) as one assembly

including the lever, brackets and sensor. The APPS is

calibrated to its mounting bracket. The APPS assem-

bly is located at left-front of engine below plastic

cable/lever/linkage cover (Fig. 6) .

(1) Snap electrical connector into bottom of sensor.

(2) Position APPS assembly to engine and install 6

bolts. Tighten bolts to 12 N´m (105 in. lbs.) torque.

(3) Connect wiring harness clip (Fig. 8) at bottom

of bracket.

(4) If equipped with an automatic transmission,

refer to Group 21, Transmission for transmission con-

trol cable installation procedures.

(5) Install speed control cable into mounting

bracket. Be sure pinch tabs (Fig. 7) have secured

cable.(6) Install throttle cable into mounting bracket. Be

sure pinch tabs (Fig. 7) have secured cable.

(7) Connect throttle cable at lever (snaps on).

(8) Connect speed control cable to lever by pushing

cable connector rearward onto lever pin while hold-

ing lever forward.

(9) Install cable cover.

(10) Connect both negative battery cables to both

batteries.

(11)ECM Calibration:Turn key to ON position.

Without starting engine, slowly press throttle pedal

to floor and then slowly release. This step must be

done (one time) to ensure accelerator pedal position

sensor calibration has been learned by ECM. If not

done, possible DTC's may be set.

(12) Use DRB scan tool to erase any DTC's from

ECM/PCM.

FUEL INJECTOR

DESCRIPTION

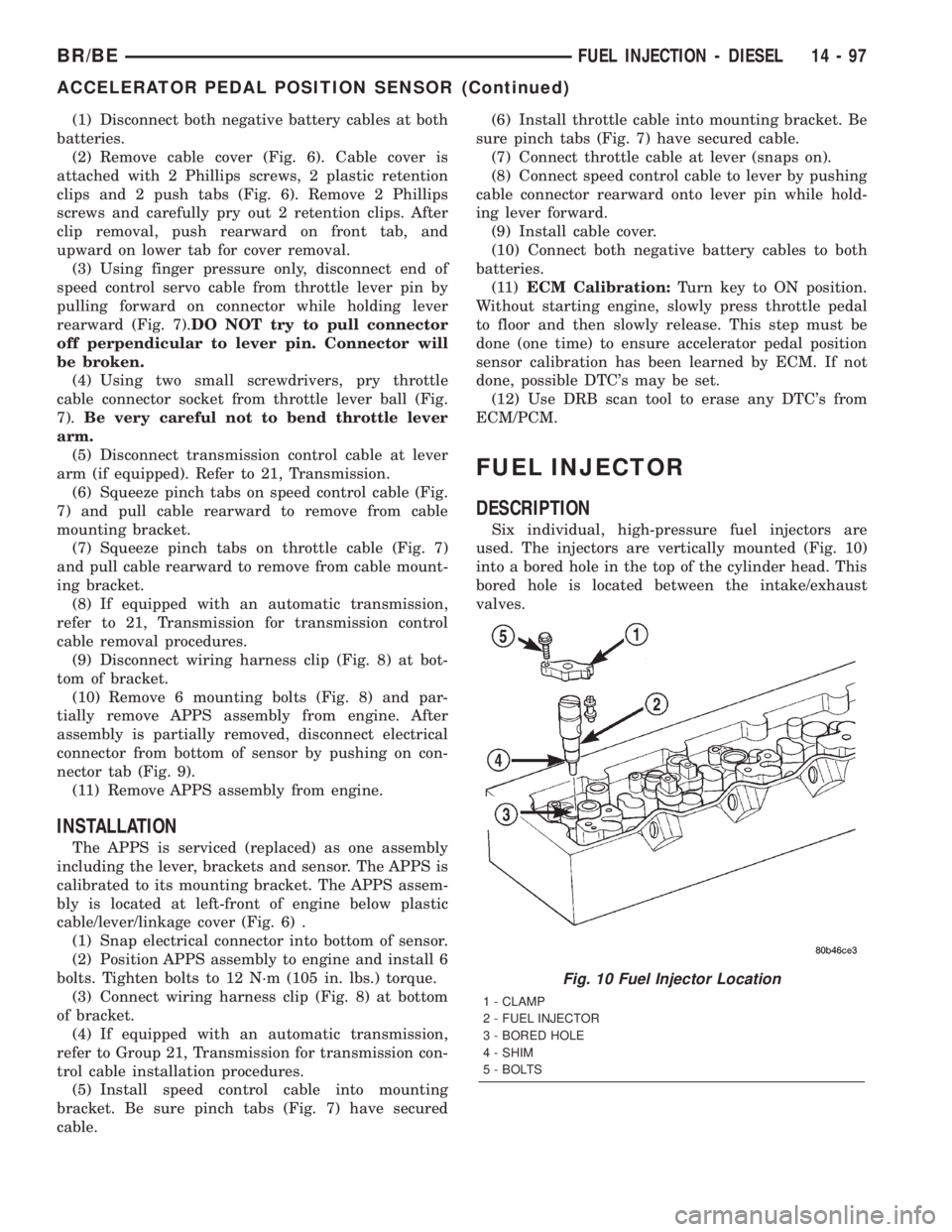

Six individual, high-pressure fuel injectors are

used. The injectors are vertically mounted (Fig. 10)

into a bored hole in the top of the cylinder head. This

bored hole is located between the intake/exhaust

valves.

Fig. 10 Fuel Injector Location

1 - CLAMP

2 - FUEL INJECTOR

3 - BORED HOLE

4 - SHIM

5 - BOLTS

BR/BEFUEL INJECTION - DIESEL 14 - 97

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1397 of 2255

OPERATION

High-pressure fuel is supplied from the injection

pump, through a high-pressure fuel line, through a

steel connector and into the fuel injector. When fuel

pressure rises to approximately 31,026 kPa (4,500

psi), the needle valve spring tension is overcome. The

needle valve rises and fuel flows through the spray

holes in the nozzle tip into the combustion chamber.

The pressure required to lift the needle valve is the

nozzle opening pressure. This is sometimes referred

to as the ªpopº pressure setting.

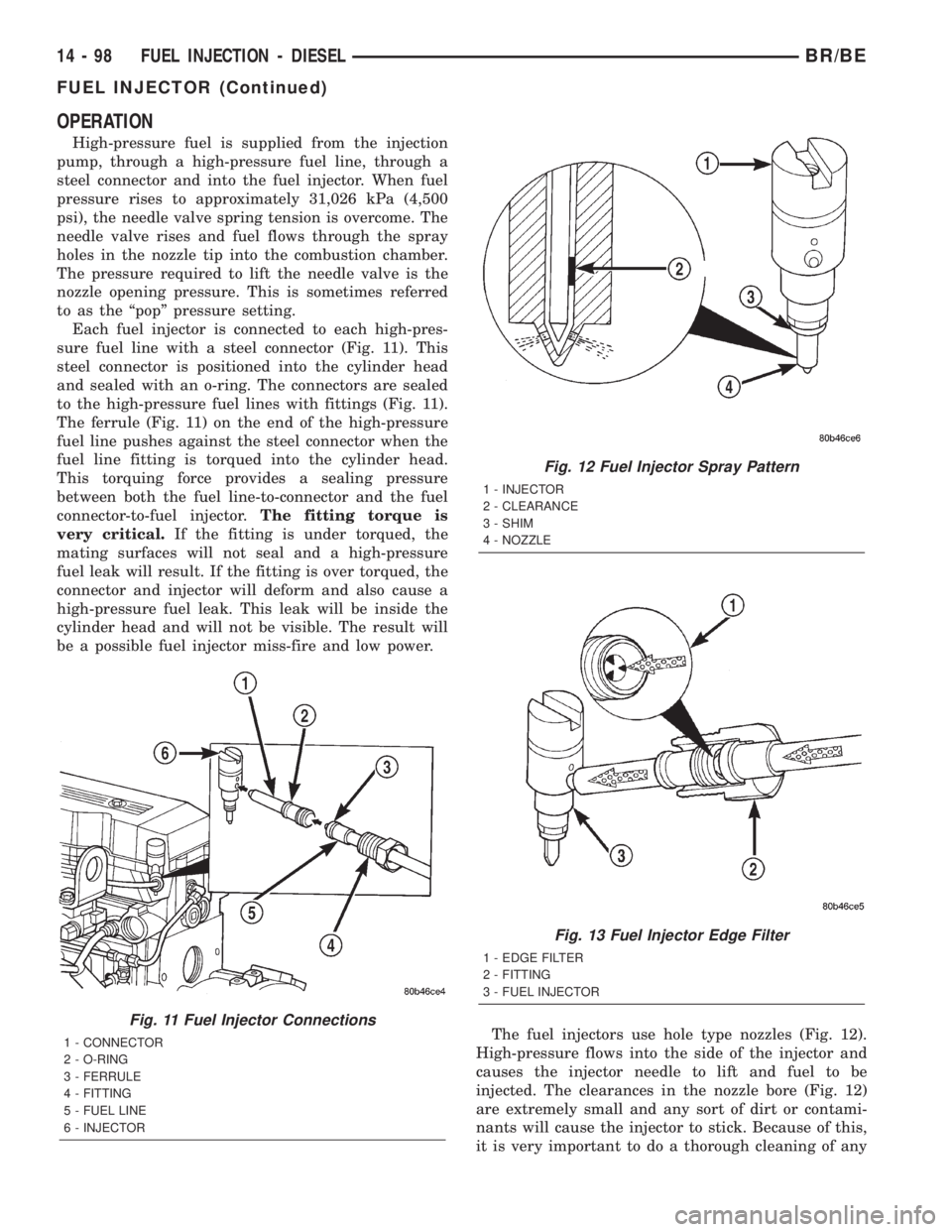

Each fuel injector is connected to each high-pres-

sure fuel line with a steel connector (Fig. 11). This

steel connector is positioned into the cylinder head

and sealed with an o-ring. The connectors are sealed

to the high-pressure fuel lines with fittings (Fig. 11).

The ferrule (Fig. 11) on the end of the high-pressure

fuel line pushes against the steel connector when the

fuel line fitting is torqued into the cylinder head.

This torquing force provides a sealing pressure

between both the fuel line-to-connector and the fuel

connector-to-fuel injector.The fitting torque is

very critical.If the fitting is under torqued, the

mating surfaces will not seal and a high-pressure

fuel leak will result. If the fitting is over torqued, the

connector and injector will deform and also cause a

high-pressure fuel leak. This leak will be inside the

cylinder head and will not be visible. The result will

be a possible fuel injector miss-fire and low power.

The fuel injectors use hole type nozzles (Fig. 12).

High-pressure flows into the side of the injector and

causes the injector needle to lift and fuel to be

injected. The clearances in the nozzle bore (Fig. 12)

are extremely small and any sort of dirt or contami-

nants will cause the injector to stick. Because of this,

it is very important to do a thorough cleaning of any

Fig. 11 Fuel Injector Connections

1 - CONNECTOR

2 - O-RING

3 - FERRULE

4 - FITTING

5 - FUEL LINE

6 - INJECTOR

Fig. 12 Fuel Injector Spray Pattern

1 - INJECTOR

2 - CLEARANCE

3 - SHIM

4 - NOZZLE

Fig. 13 Fuel Injector Edge Filter

1 - EDGE FILTER

2 - FITTING

3 - FUEL INJECTOR

14 - 98 FUEL INJECTION - DIESELBR/BE

FUEL INJECTOR (Continued)