fuel DODGE RAM 2002 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 511 of 2255

TURN SIGNAL INDICATOR

DESCRIPTION

Two turn signal indicators are standard equipment

on all instrument clusters. The turn signal indicators

are located near the upper edge of the instrument

cluster overlay, between the speedometer and the

tachometer. Each turn signal indicator consists of a

stenciled cutout of the International Control and Dis-

play Symbol icon for ªTurn Warningº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents these icons from

being clearly visible when their lamps are not illumi-

nated. The icons appear in green through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by a replaceable incandes-

cent bulb and bulb holder unit located on the instru-

ment cluster electronic circuit board. The turn signal

indicators are serviced as a unit with the instrument

cluster.

OPERATION

The turn signal indicators give an indication to the

vehicle operator that the turn signal (left or right

indicator flashing) or hazard warning (both left and

right indicators flashing) have been selected. These

indicators are controlled by two individual hard

wired inputs to the instrument cluster electronic cir-

cuit board. The turn signal indicator bulbs are

grounded on the instrument cluster electronic circuit

board at all times. The turn signal indicator bulbs

only illuminate when they are provided with battery

current by the turn signal and hazard warning

switch circuitry of the left multi-function switch on

the steering column through separate left and right

turn signal inputs to the instrument cluster; there-

fore, these indicators can be illuminated, regardless

of the ignition switch position.

The turn signal indicators are connected in series

between ground and the output of the turn signal

and hazard warning switch circuitry, but in parallel

with the other turn signal circuits. This arrangement

allows the turn signal indicators to remain functional

regardless of the condition of the other circuits in the

turn signal and hazard warning system. For more

information on the turn signal and hazard warning

system, (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR - OPERATION - TURN SIGNAL &

HAZARD WARNING SYSTEM). The turn signal

indicators can be diagnosed using conventional diag-

nostic tools and methods.

DIAGNOSIS AND TESTING - TURN SIGNAL

INDICATOR

The diagnosis found here addresses an inoperative

turn signal indicator lamp condition. If the problem

being diagnosed is related to inoperative turn signals

or hazard warning lamps, be certain to repair the

turn signal and hazard warning system before

attempting to diagnose or repair the turn signal indi-

cators. If no turn signal or hazard warning system

problems are found, the following procedure will help

locate a short or open in the left or right turn signal

indicator circuit. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds.

(1) Disconnect and isolate the battery negative

cable. Remove the instrument cluster.

(2) Connect the battery negative cable. Activate

the hazard warning system by moving the hazard

warning switch button to the On position. Check for

battery voltage at the inoperative (right or left) turn

signal circuit cavity of the instrument panel wire

harness connector (Connector C2) for the instrument

cluster. There should be a switching (on and off) bat-

tery voltage signal. If OK, replace the faulty turn sig-

nal indicator bulb. If not OK, repair the open (right

or left) turn signal circuit to the left multi-function

switch as required.

UPSHIFT INDICATOR

DESCRIPTION

An upshift indicator is standard equipment on all

instrument clusters. However, on vehicles not

equipped with a manual transmission, this indicator

is disabled. The upshift indicator is located near the

fuel gauge in the instrument cluster overlay, to the

left of center. The upshift indicator consists of an

upward pointed arrow icon that is a stenciled cutout

in the opaque layer of the instrument cluster overlay.

The dark outer layer of the overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. An amber lens behind the cutout in the

opaque layer of the overlay causes the icon to appear

in amber through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by a replaceable incandescent bulb and bulb

holder unit located on the instrument cluster elec-

tronic circuit board. The upshift indicator is serviced

as a unit with the instrument cluster.

8J - 32 INSTRUMENT CLUSTERBR/BE

Page 512 of 2255

OPERATION

The upshift indicator gives an indication to the

vehicle operator when the transmission should be

shifted to the next highest gear in order to achieve

the best fuel economy. This indicator is controlled by

a transistor on the instrument cluster circuit board

based upon the cluster programming and electronic

messages received by the cluster from the Powertrain

Control Module (PCM) over the Chrysler Collision

Detection (CCD) data bus. The upshift indicator bulb

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (st-run) circuit whenever the ignition

switch is in the On or Start positions; therefore, the

lamp will always be off when the ignition switch is in

any position except On or Start. The bulb only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. On models not

equipped with a manual transmission, the incandes-

cent bulb and bulb holder unit are not installed at

the factory when the vehicle is built. The instrument

cluster will turn on the upshift indicator for the fol-

lowing reasons:

²Upshift Lamp-On Message- Each time the

cluster receives an upshift lamp-on message from the

PCM indicating the engine speed and load conditions

are right for a transmission upshift to occur, the

upshift indicator is illuminated. The indicator

remains illuminated until the cluster receives an

upshift lamp-off message from the PCM or until the

ignition switch is turned to the Off position, which-

ever occurs first. The PCM will normally send an

upshift lamp-off message three to five seconds after a

lamp-on message, if an upshift is not performed. The

indicator will then remain off until the vehicle stops

accelerating and is brought back into the range of

indicator operation, or until the transmission is

shifted into another gear.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the indicator and the

cluster control circuitry.

The PCM continually monitors the engine speed

and load conditions to determine the proper fuel and

ignition requirements. The PCM then sends the

proper messages to the instrument cluster. If the

upshift indicator fails to light during normal vehicle

operation, replace the bulb with a known good unit.

For further diagnosis of the upshift indicator or the

instrument cluster circuitry that controls the indica-

tor, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). For

proper diagnosis of the PCM, the CCD data bus, or

the message inputs to the instrument cluster that

control the upshift indicator, a DRBIIItscan tool isrequired. Refer to the appropriate diagnostic infor-

mation.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left quadrant of the instrument cluster,

above the temperature gauge. The voltage gauge con-

sists of a movable gauge needle or pointer controlled

by the instrument cluster circuitry and a fixed 90

degree scale on the cluster overlay that reads left-to-

right from 8 volts to 18 volts. An International Con-

trol and Display Symbol icon for ªBattery Charging

Conditionº is located directly below the lowest grad-

uation of the gauge scale. The voltage gauge graphics

are white against a black field except for a single red

graduation at each end of the gauge scale, making

them clearly visible within the instrument cluster in

daylight. When illuminated from behind by the panel

lamps dimmer controlled cluster illumination lighting

with the exterior lamps turned On, the white graph-

ics appear blue-green and the red graphics appear

red. The orange gauge needle is internally illumi-

nated. Gauge illumination is provided by replaceable

incandescent bulb and bulb holder units located on

the instrument cluster electronic circuit board. The

voltage gauge is serviced as a unit with the instru-

ment cluster.

OPERATION

The voltage gauge gives an indication to the vehi-

cle operator of the electrical system voltage. This

gauge is controlled by the instrument cluster circuit

board based upon the cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Chrysler

Collision Detection (CCD) data bus. The voltage

gauge is an air core magnetic unit that receives bat-

tery current on the instrument cluster electronic cir-

cuit board through the fused ignition switch output

(st-run) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Charge Fail Message- Each time the cluster

receives a message from the PCM indicating a charge

fail condition (system voltage is 10.8 volts or lower),

the gauge needle is moved to the 8 volt graduation

on the gauge scale and the check gauges indicator is

illuminated. The gauge needle remains on the 8 volt

BR/BEINSTRUMENT CLUSTER 8J - 33

UPSHIFT INDICATOR (Continued)

Page 515 of 2255

INDICATOR DOES NOT ILLUMINATE WITH WASHER

RESERVOIR EMPTY

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit cav-

ity of the headlamp and dash wire harness connector

for the washer fluid level switch and a good ground.

There should be continuity. If OK, go to Step 2. If not

OK, repair the open ground circuit to ground (G100)

as required.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid switch sense circuit cavities of the headlamp

and dash wire harness connector for the washer fluid

level switch and the instrument panel wire harness

connector (Connector C2) for the instrument cluster.

If OK, replace the faulty washer fluid level switch. If

not OK, repair the open washer fluid switch sense

circuit between the washer fluid level switch and the

instrument cluster as required.

INDICATOR STAYS ILLUMINATED WITH WASHER

RESERVOIR FULL

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit ter-

minal and the washer fluid switch sense terminal in

the washer fluid level switch connector receptacle.

There should be no continuity. If OK, go to Step 2. If

not OK, replace the faulty washer fluid level switch.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid switch sense circuit cavity of the headlamp and

dash wire harness connector for the washer fluid

level switch and a good ground. There should be no

continuity. If not OK, repair the shorted washer fluid

switch sense circuit between the washer fluid level

switch and the instrument cluster as required.

WATER-IN-FUEL INDICATOR

DESCRIPTION

A water-in-fuel indicator is standard equipment on

all instrument clusters, but is only functional in vehi-

cles equipped with an optional diesel engine. The

water-in-fuel indicator is located near the lower edge

of the instrument cluster overlay, to the left of center.

The water-in-fuel indicator consists of a stencilled

cutout of the text ªWATER IN FUELº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A redlens located behind the cutout causes the ªWATER

IN FUELº text to appear in red through the translu-

cent outer layer of the overlay when the indicator is

illuminated from behind by a Light Emitting Diode

(LED) soldered onto the instrument cluster electronic

circuit board. The water-in-fuel indicator is serviced

as a unit with the instrument cluster.

OPERATION

The water-in-fuel indicator gives an indication to

the vehicle operator when the water accumulated in

the diesel engine fuel filter/separator filter bowl

requires draining. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Engine Control

Module (ECM) over the Chrysler Collision Detection

(CCD) data bus. The water-in-fuel indicator Light

Emitting Diode (LED) receives battery current on the

instrument cluster electronic circuit board through

the fused ignition switch output (st-run) circuit

whenever the ignition switch is in the On or Start

positions; therefore, the indicator will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is

switched to ground by the instrument cluster transis-

tor. The instrument cluster will turn on the water-in-

fuel indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the indicator is illuminated

for about two seconds as a bulb test.

²Water-In-Fuel Lamp-On Message- Each time

the cluster receives a water-in-fuel lamp-on message

from the ECM, the indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a water-in-fuel lamp-off message from the

ECM or until the ignition switch is turned to the Off

position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The ECM continually monitors the water-in-fuel

sensor, then sends the proper messages to the instru-

ment cluster. For further diagnosis of the water-in-

fuel indicator or the instrument cluster circuitry that

controls the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the water-in-fuel

sensor, the ECM, the CCD data bus, or the message

inputs to the instrument cluster that control the

water-in-fuel indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic

information.

8J - 36 INSTRUMENT CLUSTERBR/BE

WASHER FLUID INDICATOR (Continued)

Page 537 of 2255

VEHICLE PREPARATION FOR HEADLAMP

ALIGNMENT

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Verify headlamps are set for low beam opera-

tion.

(3) Correct defective components that could hinder

proper headlamp alignment.

(4) Verify proper tire inflation.

(5) Clean headlamp lenses.

(6) Verify that luggage area is not heavily loaded.

(7) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

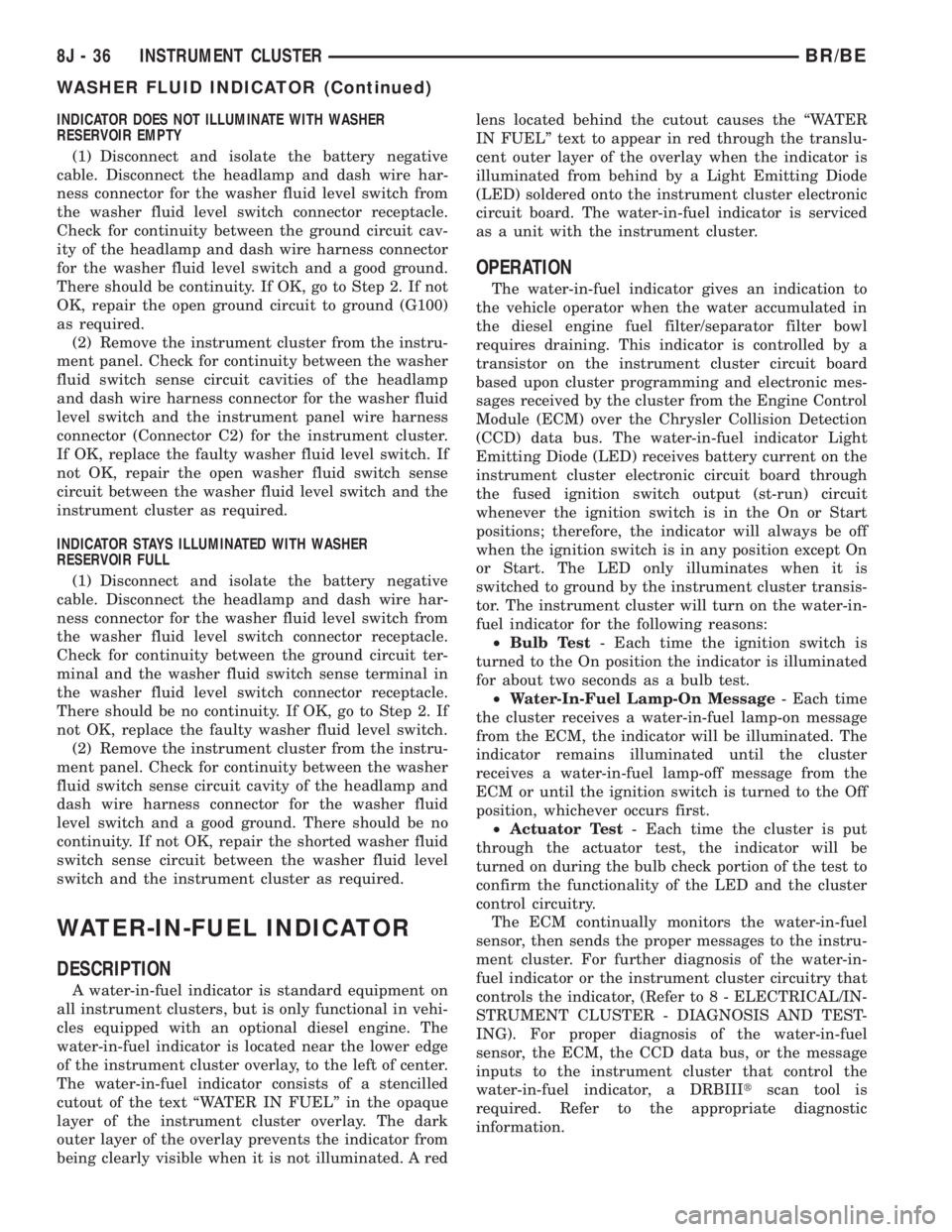

HEADLAMP ADJUSTMENT

Headlamps can be aligned using the screen method

provided or alignment tool C-4466±A or equivalent

can be used. refer to the instructions provided with

the tool for proper procedures.

A properly aimed low beam headlamp will project

top edge of high intensity pattern on screen from 50

mm (2 in.) above to 50 mm (2 in.) below headlamp

centerline. The side-to-side outboard edge of high

intensity pattern should be from 50 mm (2 in.) left to

50 mm (2 in.) right of headlamp centerline. (Fig. 20)

The preferred headlamp alignment is 1º down

for the up/down adjustment and 0 for the left/

right adjustment.The high beam pattern should be

correct when the low beams are aligned properly.

To adjust headlamp aim, rotate alignment screws

(Fig. 21) to achieve the specified high intensity pat-

tern.

LICENSE PLATE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove license plate lamp lens.

(3) Pull bulb from license plate lamp.

INSTALLATION

(1) Install bulb in license plate lamp.

(2) Install license plate lamp lens.

(3) Connect the battery negative cable.

LICENSE PLATE LAMP UNIT

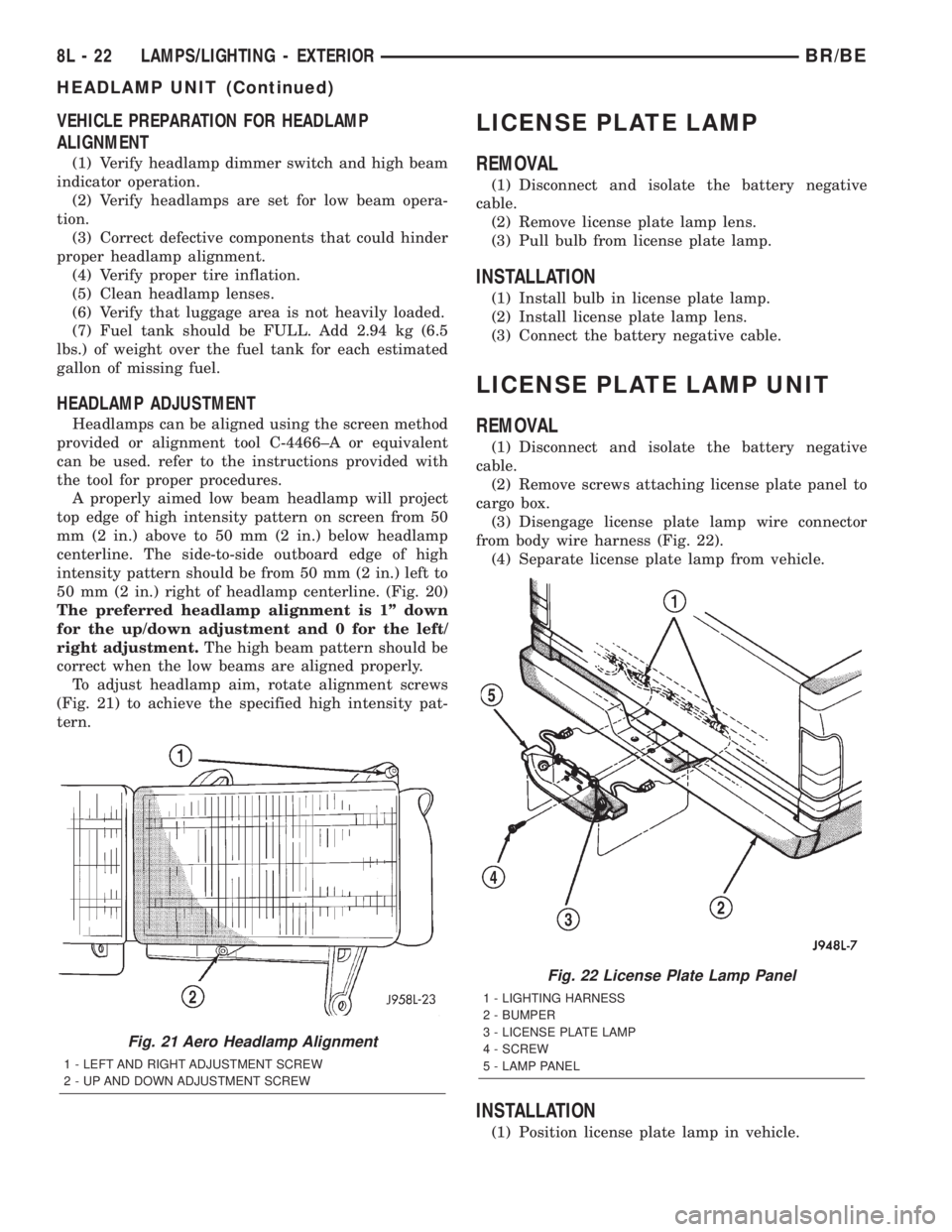

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screws attaching license plate panel to

cargo box.

(3) Disengage license plate lamp wire connector

from body wire harness (Fig. 22).

(4) Separate license plate lamp from vehicle.

INSTALLATION

(1) Position license plate lamp in vehicle.

Fig. 21 Aero Headlamp Alignment

1 - LEFT AND RIGHT ADJUSTMENT SCREW

2 - UP AND DOWN ADJUSTMENT SCREW

Fig. 22 License Plate Lamp Panel

1 - LIGHTING HARNESS

2 - BUMPER

3 - LICENSE PLATE LAMP

4 - SCREW

5 - LAMP PANEL

8L - 22 LAMPS/LIGHTING - EXTERIORBR/BE

HEADLAMP UNIT (Continued)

Page 548 of 2255

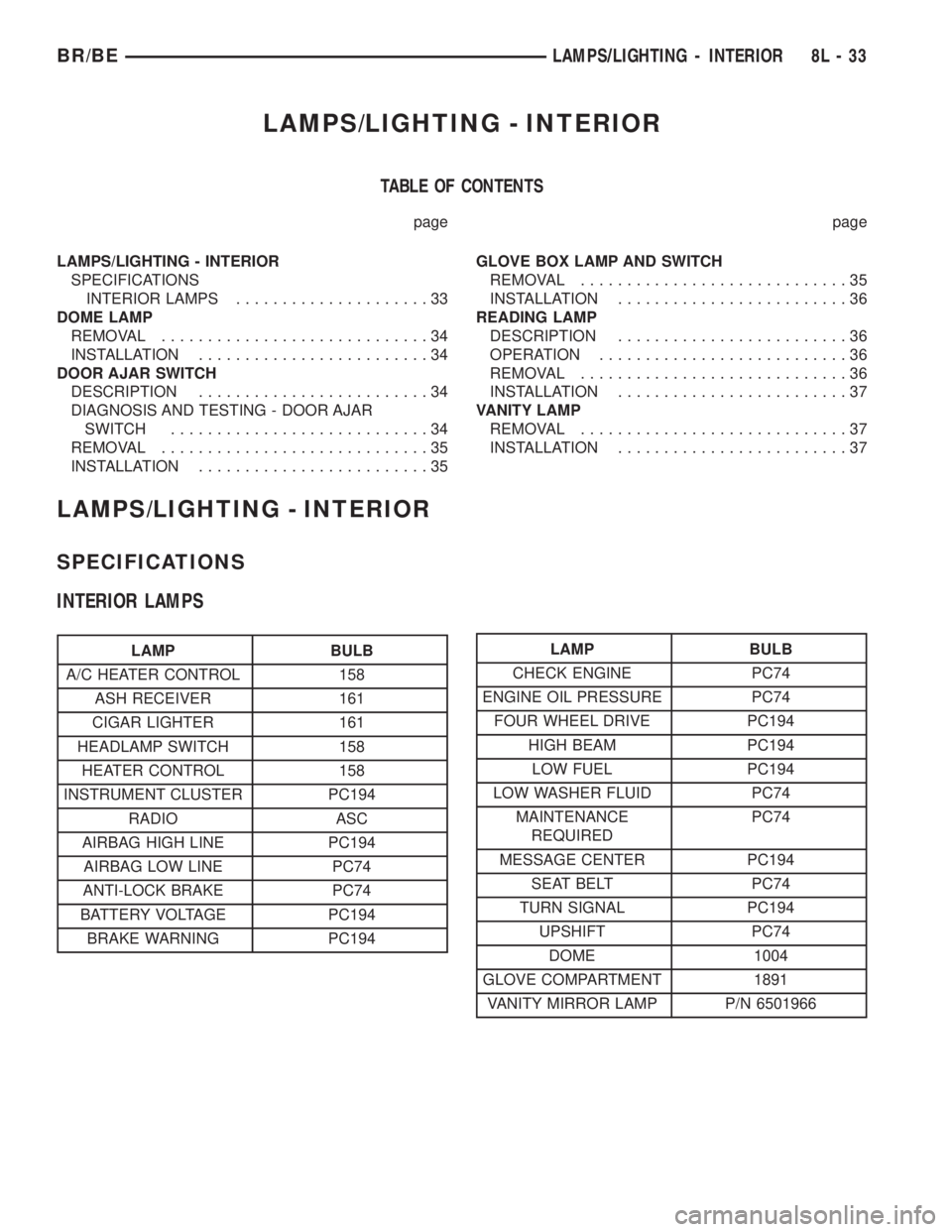

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS.....................33

DOME LAMP

REMOVAL.............................34

INSTALLATION.........................34

DOOR AJAR SWITCH

DESCRIPTION.........................34

DIAGNOSIS AND TESTING - DOOR AJAR

SWITCH............................34

REMOVAL.............................35

INSTALLATION.........................35GLOVE BOX LAMP AND SWITCH

REMOVAL.............................35

INSTALLATION.........................36

READING LAMP

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................37

VANITY LAMP

REMOVAL.............................37

INSTALLATION.........................37

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS

LAMP BULB

A/C HEATER CONTROL 158

ASH RECEIVER 161

CIGAR LIGHTER 161

HEADLAMP SWITCH 158

HEATER CONTROL 158

INSTRUMENT CLUSTER PC194

RADIO ASC

AIRBAG HIGH LINE PC194

AIRBAG LOW LINE PC74

ANTI-LOCK BRAKE PC74

BATTERY VOLTAGE PC194

BRAKE WARNING PC194LAMP BULB

CHECK ENGINE PC74

ENGINE OIL PRESSURE PC74

FOUR WHEEL DRIVE PC194

HIGH BEAM PC194

LOW FUEL PC194

LOW WASHER FLUID PC74

MAINTENANCE

REQUIREDPC74

MESSAGE CENTER PC194

SEAT BELT PC74

TURN SIGNAL PC194

UPSHIFT PC74

DOME 1004

GLOVE COMPARTMENT 1891

VANITY MIRROR LAMP P/N 6501966

BR/BELAMPS/LIGHTING - INTERIOR 8L - 33

Page 562 of 2255

(3) Engage the two mounting hooks on the rear of

the overhead console housing in the mounting holes

in the inner roof panel.

(4) Slide the overhead console forward far enough

to align the two latches on the front of the housing

with their receptacles in the inner roof panel.

(5) Push upward firmly and evenly on the front of

the overhead console until each of the two latches is

fully engaged in its receptacle in the inner roof panel.

(6) Close the garage door opener storage bin door.

(7) Reconnect the battery negative cable.

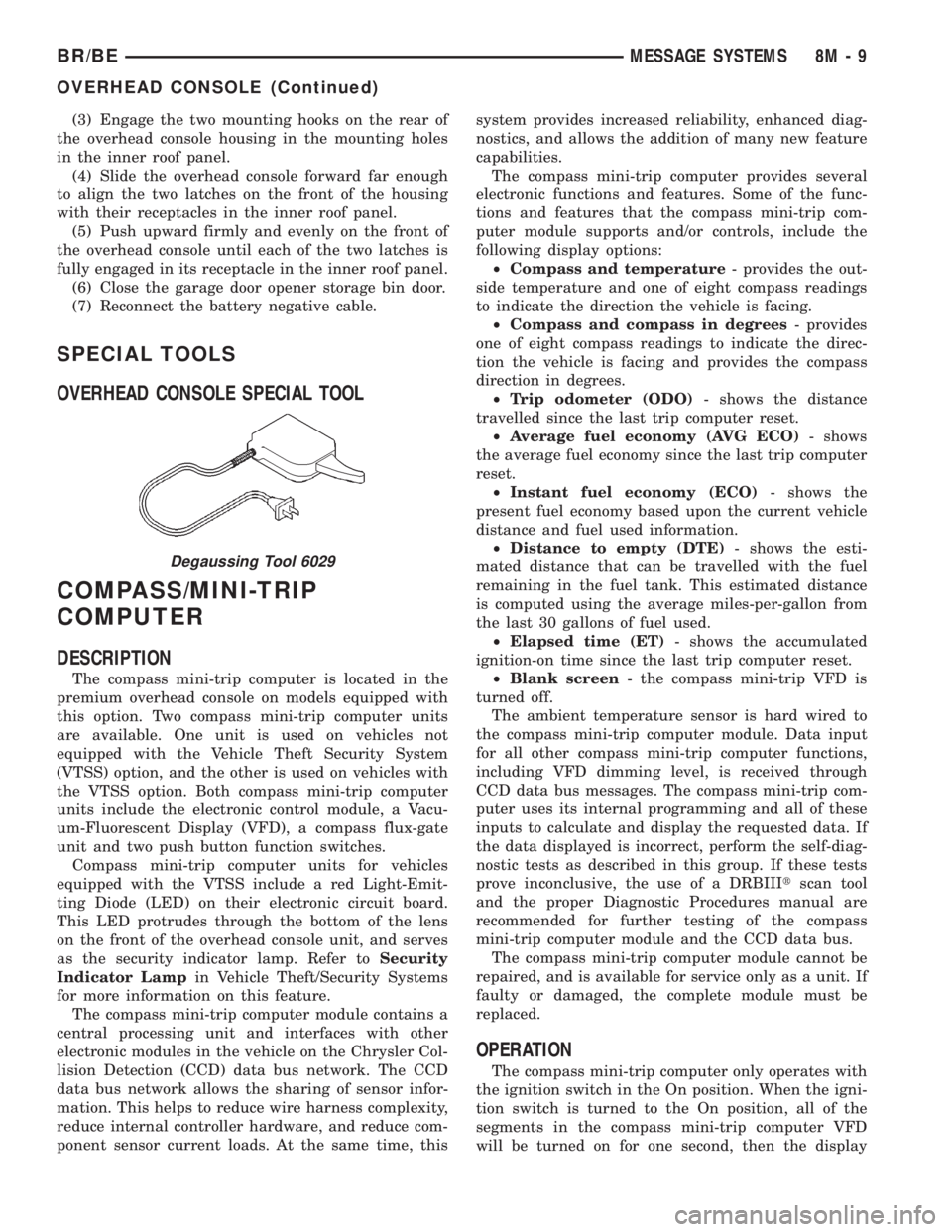

SPECIAL TOOLS

OVERHEAD CONSOLE SPECIAL TOOL

COMPASS/MINI-TRIP

COMPUTER

DESCRIPTION

The compass mini-trip computer is located in the

premium overhead console on models equipped with

this option. Two compass mini-trip computer units

are available. One unit is used on vehicles not

equipped with the Vehicle Theft Security System

(VTSS) option, and the other is used on vehicles with

the VTSS option. Both compass mini-trip computer

units include the electronic control module, a Vacu-

um-Fluorescent Display (VFD), a compass flux-gate

unit and two push button function switches.

Compass mini-trip computer units for vehicles

equipped with the VTSS include a red Light-Emit-

ting Diode (LED) on their electronic circuit board.

This LED protrudes through the bottom of the lens

on the front of the overhead console unit, and serves

as the security indicator lamp. Refer toSecurity

Indicator Lampin Vehicle Theft/Security Systems

for more information on this feature.

The compass mini-trip computer module contains a

central processing unit and interfaces with other

electronic modules in the vehicle on the Chrysler Col-

lision Detection (CCD) data bus network. The CCD

data bus network allows the sharing of sensor infor-

mation. This helps to reduce wire harness complexity,

reduce internal controller hardware, and reduce com-

ponent sensor current loads. At the same time, thissystem provides increased reliability, enhanced diag-

nostics, and allows the addition of many new feature

capabilities.

The compass mini-trip computer provides several

electronic functions and features. Some of the func-

tions and features that the compass mini-trip com-

puter module supports and/or controls, include the

following display options:

²Compass and temperature- provides the out-

side temperature and one of eight compass readings

to indicate the direction the vehicle is facing.

²Compass and compass in degrees- provides

one of eight compass readings to indicate the direc-

tion the vehicle is facing and provides the compass

direction in degrees.

²Trip odometer (ODO)- shows the distance

travelled since the last trip computer reset.

²Average fuel economy (AVG ECO)- shows

the average fuel economy since the last trip computer

reset.

²Instant fuel economy (ECO)- shows the

present fuel economy based upon the current vehicle

distance and fuel used information.

²Distance to empty (DTE)- shows the esti-

mated distance that can be travelled with the fuel

remaining in the fuel tank. This estimated distance

is computed using the average miles-per-gallon from

the last 30 gallons of fuel used.

²Elapsed time (ET)- shows the accumulated

ignition-on time since the last trip computer reset.

²Blank screen- the compass mini-trip VFD is

turned off.

The ambient temperature sensor is hard wired to

the compass mini-trip computer module. Data input

for all other compass mini-trip computer functions,

including VFD dimming level, is received through

CCD data bus messages. The compass mini-trip com-

puter uses its internal programming and all of these

inputs to calculate and display the requested data. If

the data displayed is incorrect, perform the self-diag-

nostic tests as described in this group. If these tests

prove inconclusive, the use of a DRBIIItscan tool

and the proper Diagnostic Procedures manual are

recommended for further testing of the compass

mini-trip computer module and the CCD data bus.

The compass mini-trip computer module cannot be

repaired, and is available for service only as a unit. If

faulty or damaged, the complete module must be

replaced.

OPERATION

The compass mini-trip computer only operates with

the ignition switch in the On position. When the igni-

tion switch is turned to the On position, all of the

segments in the compass mini-trip computer VFD

will be turned on for one second, then the display

Degaussing Tool 6029

BR/BEMESSAGE SYSTEMS 8M - 9

OVERHEAD CONSOLE (Continued)

Page 662 of 2255

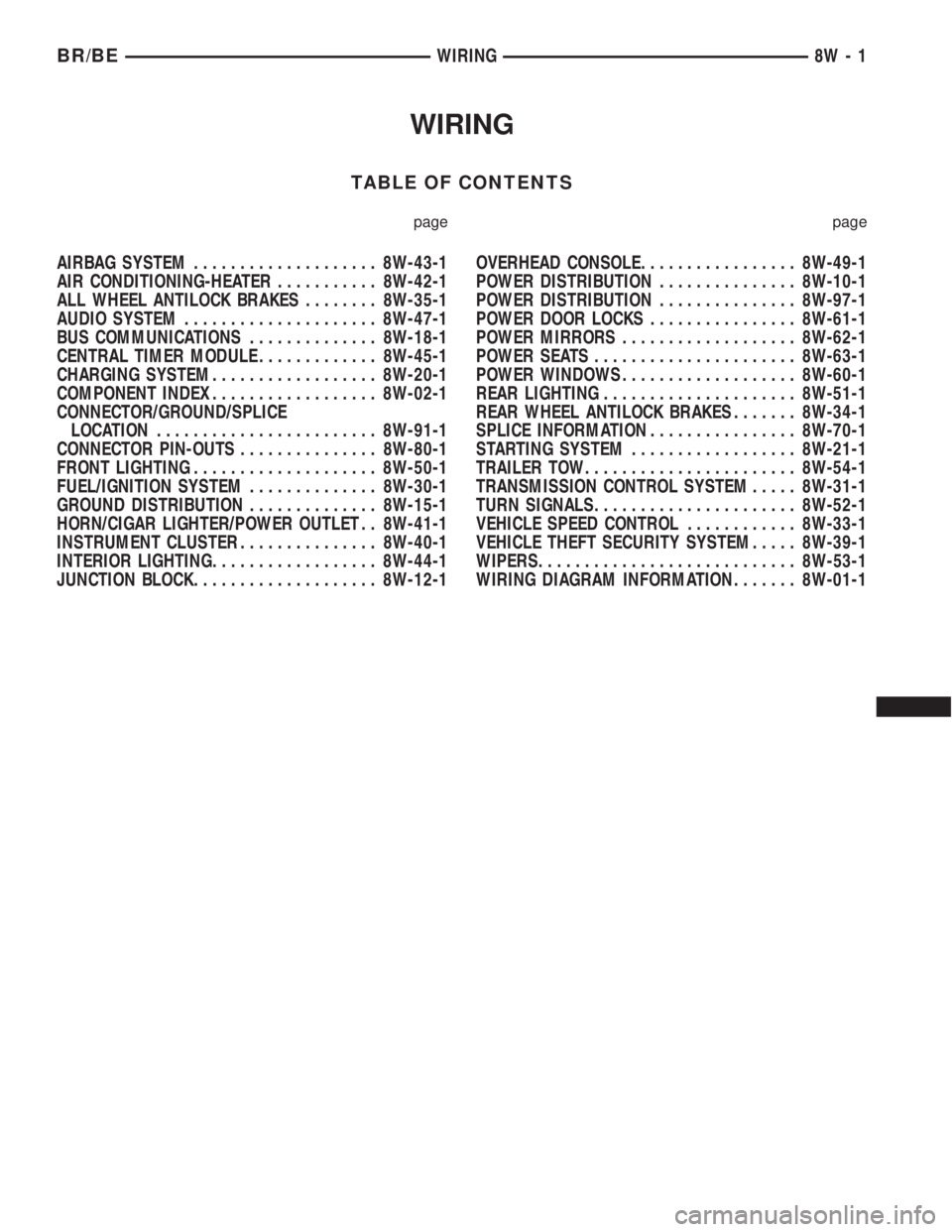

WIRING

TABLE OF CONTENTS

page page

AIRBAG SYSTEM.................... 8W-43-1

AIR CONDITIONING-HEATER........... 8W-42-1

ALL WHEEL ANTILOCK BRAKES........ 8W-35-1

AUDIO SYSTEM..................... 8W-47-1

BUS COMMUNICATIONS.............. 8W-18-1

CENTRAL TIMER MODULE............. 8W-45-1

CHARGING SYSTEM.................. 8W-20-1

COMPONENT INDEX.................. 8W-02-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

CONNECTOR PIN-OUTS............... 8W-80-1

FRONT LIGHTING.................... 8W-50-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

GROUND DISTRIBUTION.............. 8W-15-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

INSTRUMENT CLUSTER............... 8W-40-1

INTERIOR LIGHTING.................. 8W-44-1

JUNCTION BLOCK.................... 8W-12-1OVERHEAD CONSOLE................. 8W-49-1

POWER DISTRIBUTION............... 8W-10-1

POWER DISTRIBUTION............... 8W-97-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

POWER WINDOWS................... 8W-60-1

REAR LIGHTING..................... 8W-51-1

REAR WHEEL ANTILOCK BRAKES....... 8W-34-1

SPLICE INFORMATION................ 8W-70-1

STARTING SYSTEM.................. 8W-21-1

TRAILER TOW....................... 8W-54-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

TURN SIGNALS...................... 8W-52-1

VEHICLE SPEED CONTROL............ 8W-33-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

WIPERS............................ 8W-53-1

WIRING DIAGRAM INFORMATION....... 8W-01-1 BR/BEWIRING 8W - 1

Page 678 of 2255

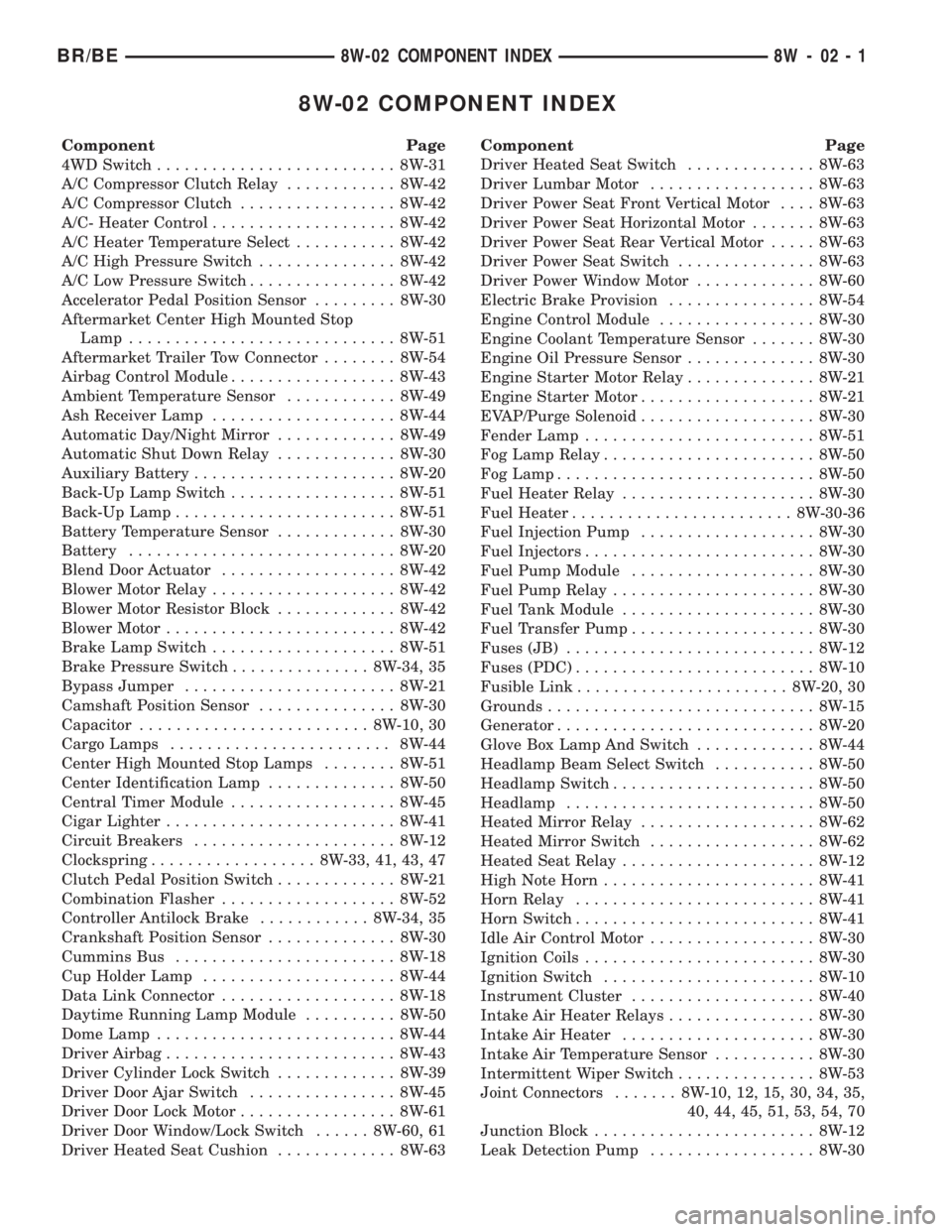

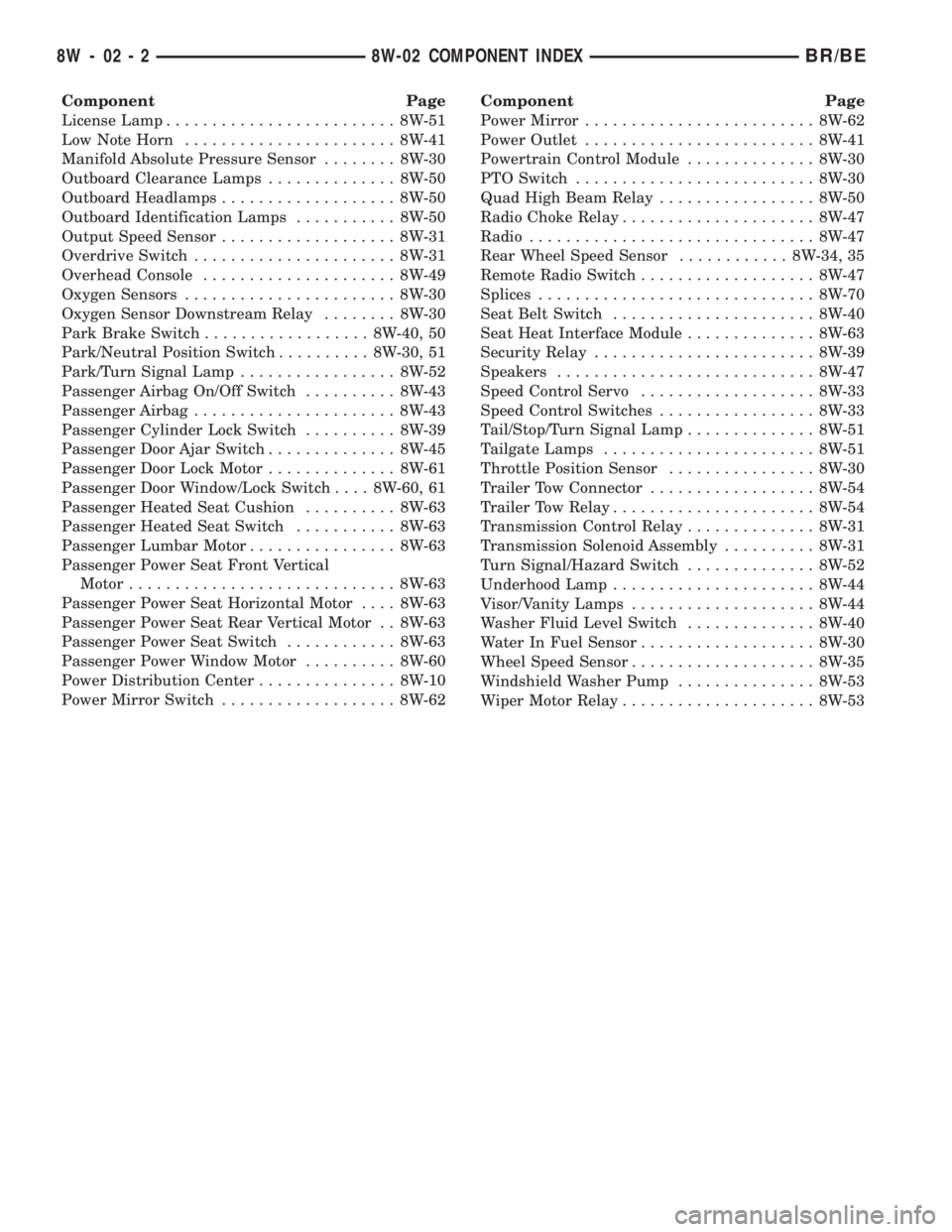

8W-02 COMPONENT INDEX

Component Page

4WD Switch.......................... 8W-31

A/C Compressor Clutch Relay............ 8W-42

A/C Compressor Clutch................. 8W-42

A/C- Heater Control.................... 8W-42

A/C Heater Temperature Select........... 8W-42

A/C High Pressure Switch............... 8W-42

A/C Low Pressure Switch................ 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Aftermarket Center High Mounted Stop

Lamp............................. 8W-51

Aftermarket Trailer Tow Connector........ 8W-54

Airbag Control Module.................. 8W-43

Ambient Temperature Sensor............ 8W-49

Ash Receiver Lamp.................... 8W-44

Automatic Day/Night Mirror............. 8W-49

Automatic Shut Down Relay............. 8W-30

Auxiliary Battery...................... 8W-20

Back-Up Lamp Switch.................. 8W-51

Back-Up Lamp........................ 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Actuator................... 8W-42

Blower Motor Relay.................... 8W-42

Blower Motor Resistor Block............. 8W-42

Blower Motor......................... 8W-42

Brake Lamp Switch.................... 8W-51

Brake Pressure Switch............... 8W-34, 35

Bypass Jumper....................... 8W-21

Camshaft Position Sensor............... 8W-30

Capacitor......................... 8W-10, 30

Cargo Lamps........................ 8W-44

Center High Mounted Stop Lamps........ 8W-51

Center Identification Lamp.............. 8W-50

Central Timer Module.................. 8W-45

Cigar Lighter......................... 8W-41

Circuit Breakers...................... 8W-12

Clockspring.................. 8W-33, 41, 43, 47

Clutch Pedal Position Switch............. 8W-21

Combination Flasher................... 8W-52

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cummins Bus........................ 8W-18

Cup Holder Lamp..................... 8W-44

Data Link Connector................... 8W-18

Daytime Running Lamp Module.......... 8W-50

Dome Lamp.......................... 8W-44

Driver Airbag......................... 8W-43

Driver Cylinder Lock Switch............. 8W-39

Driver Door Ajar Switch................ 8W-45

Driver Door Lock Motor................. 8W-61

Driver Door Window/Lock Switch...... 8W-60, 61

Driver Heated Seat Cushion............. 8W-63Component Page

Driver Heated Seat Switch.............. 8W-63

Driver Lumbar Motor.................. 8W-63

Driver Power Seat Front Vertical Motor.... 8W-63

Driver Power Seat Horizontal Motor....... 8W-63

Driver Power Seat Rear Vertical Motor..... 8W-63

Driver Power Seat Switch............... 8W-63

Driver Power Window Motor............. 8W-60

Electric Brake Provision................ 8W-54

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Starter Motor Relay.............. 8W-21

Engine Starter Motor................... 8W-21

EVAP/Purge Solenoid................... 8W-30

Fender Lamp......................... 8W-51

Fog Lamp Relay....................... 8W-50

Fog Lamp............................ 8W-50

Fuel Heater Relay..................... 8W-30

Fuel Heater........................ 8W-30-36

Fuel Injection Pump................... 8W-30

Fuel Injectors......................... 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuel Tank Module..................... 8W-30

Fuel Transfer Pump.................... 8W-30

Fuses (JB)........................... 8W-12

Fuses (PDC).......................... 8W-10

Fusible Link....................... 8W-20, 30

Grounds............................. 8W-15

Generator............................ 8W-20

Glove Box Lamp And Switch............. 8W-44

Headlamp Beam Select Switch........... 8W-50

Headlamp Switch...................... 8W-50

Headlamp........................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Mirror Switch.................. 8W-62

Heated Seat Relay..................... 8W-12

High Note Horn....................... 8W-41

Horn Relay.......................... 8W-41

Horn Switch.......................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Coils......................... 8W-30

Ignition Switch....................... 8W-10

Instrument Cluster.................... 8W-40

Intake Air Heater Relays................ 8W-30

Intake Air Heater..................... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intermittent Wiper Switch............... 8W-53

Joint Connectors....... 8W-10, 12, 15, 30, 34, 35,

40, 44, 45, 51, 53, 54, 70

Junction Block........................ 8W-12

Leak Detection Pump.................. 8W-30

BR/BE8W-02 COMPONENT INDEX 8W - 02 - 1

Page 679 of 2255

Component Page

License Lamp......................... 8W-51

Low Note Horn....................... 8W-41

Manifold Absolute Pressure Sensor........ 8W-30

Outboard Clearance Lamps.............. 8W-50

Outboard Headlamps................... 8W-50

Outboard Identification Lamps........... 8W-50

Output Speed Sensor................... 8W-31

Overdrive Switch...................... 8W-31

Overhead Console..................... 8W-49

Oxygen Sensors....................... 8W-30

Oxygen Sensor Downstream Relay........ 8W-30

Park Brake Switch.................. 8W-40, 50

Park/Neutral Position Switch.......... 8W-30, 51

Park/Turn Signal Lamp................. 8W-52

Passenger Airbag On/Off Switch.......... 8W-43

Passenger Airbag...................... 8W-43

Passenger Cylinder Lock Switch.......... 8W-39

Passenger Door Ajar Switch.............. 8W-45

Passenger Door Lock Motor.............. 8W-61

Passenger Door Window/Lock Switch.... 8W-60, 61

Passenger Heated Seat Cushion.......... 8W-63

Passenger Heated Seat Switch........... 8W-63

Passenger Lumbar Motor................ 8W-63

Passenger Power Seat Front Vertical

Motor............................. 8W-63

Passenger Power Seat Horizontal Motor.... 8W-63

Passenger Power Seat Rear Vertical Motor . . 8W-63

Passenger Power Seat Switch............ 8W-63

Passenger Power Window Motor.......... 8W-60

Power Distribution Center............... 8W-10

Power Mirror Switch................... 8W-62Component Page

Power Mirror......................... 8W-62

Power Outlet......................... 8W-41

Powertrain Control Module.............. 8W-30

PTO Switch.......................... 8W-30

Quad High Beam Relay................. 8W-50

Radio Choke Relay..................... 8W-47

Radio............................... 8W-47

Rear Wheel Speed Sensor............ 8W-34, 35

Remote Radio Switch................... 8W-47

Splices.............................. 8W-70

Seat Belt Switch...................... 8W-40

Seat Heat Interface Module.............. 8W-63

Security Relay........................ 8W-39

Speakers............................ 8W-47

Speed Control Servo................... 8W-33

Speed Control Switches................. 8W-33

Tail/Stop/Turn Signal Lamp.............. 8W-51

Tailgate Lamps....................... 8W-51

Throttle Position Sensor................ 8W-30

Trailer Tow Connector.................. 8W-54

Trailer Tow Relay...................... 8W-54

Transmission Control Relay.............. 8W-31

Transmission Solenoid Assembly.......... 8W-31

Turn Signal/Hazard Switch.............. 8W-52

Underhood Lamp...................... 8W-44

Visor/Vanity Lamps.................... 8W-44

Washer Fluid Level Switch.............. 8W-40

Water In Fuel Sensor................... 8W-30

Wheel Speed Sensor.................... 8W-35

Windshield Washer Pump............... 8W-53

Wiper Motor Relay..................... 8W-53

8W - 02 - 2 8W-02 COMPONENT INDEXBR/BE

Page 680 of 2255

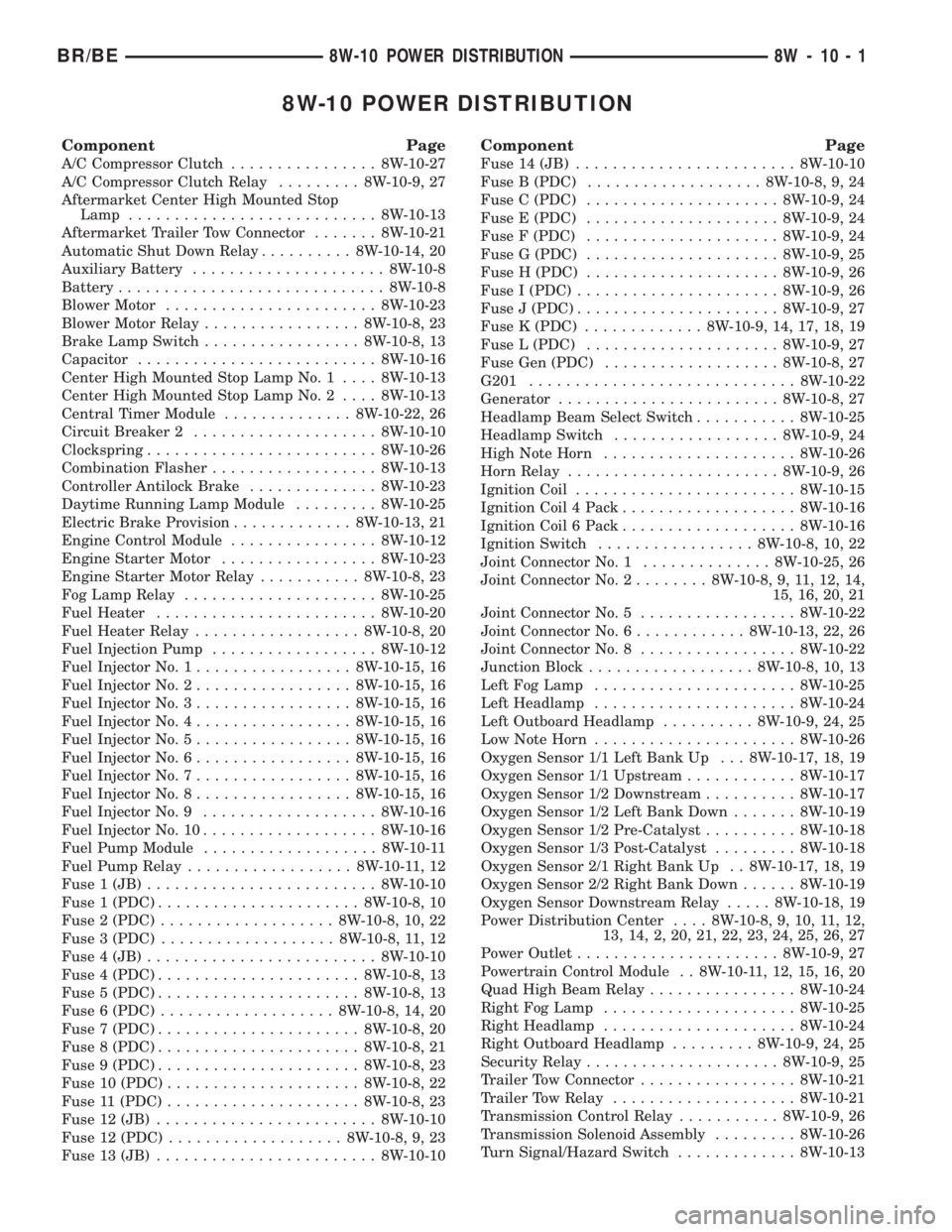

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch................ 8W-10-27

A/C Compressor Clutch Relay......... 8W-10-9, 27

Aftermarket Center High Mounted Stop

Lamp........................... 8W-10-13

Aftermarket Trailer Tow Connector....... 8W-10-21

Automatic Shut Down Relay.......... 8W-10-14, 20

Auxiliary Battery..................... 8W-10-8

Battery............................. 8W-10-8

Blower Motor....................... 8W-10-23

Blower Motor Relay................. 8W-10-8, 23

Brake Lamp Switch................. 8W-10-8, 13

Capacitor.......................... 8W-10-16

Center High Mounted Stop Lamp No. 1.... 8W-10-13

Center High Mounted Stop Lamp No. 2.... 8W-10-13

Central Timer Module.............. 8W-10-22, 26

Circuit Breaker 2.................... 8W-10-10

Clockspring......................... 8W-10-26

Combination Flasher.................. 8W-10-13

Controller Antilock Brake.............. 8W-10-23

Daytime Running Lamp Module......... 8W-10-25

Electric Brake Provision............. 8W-10-13, 21

Engine Control Module................ 8W-10-12

Engine Starter Motor................. 8W-10-23

Engine Starter Motor Relay........... 8W-10-8, 23

Fog Lamp Relay..................... 8W-10-25

Fuel Heater........................ 8W-10-20

Fuel Heater Relay.................. 8W-10-8, 20

Fuel Injection Pump.................. 8W-10-12

Fuel Injector No. 1................. 8W-10-15, 16

Fuel Injector No. 2................. 8W-10-15, 16

Fuel Injector No. 3................. 8W-10-15, 16

Fuel Injector No. 4................. 8W-10-15, 16

Fuel Injector No. 5................. 8W-10-15, 16

Fuel Injector No. 6................. 8W-10-15, 16

Fuel Injector No. 7................. 8W-10-15, 16

Fuel Injector No. 8................. 8W-10-15, 16

Fuel Injector No. 9................... 8W-10-16

Fuel Injector No. 10................... 8W-10-16

Fuel Pump Module................... 8W-10-11

Fuel Pump Relay.................. 8W-10-11, 12

Fuse 1 (JB)......................... 8W-10-10

Fuse 1 (PDC)...................... 8W-10-8, 10

Fuse 2 (PDC)................... 8W-10-8, 10, 22

Fuse 3 (PDC)................... 8W-10-8, 11, 12

Fuse 4 (JB)......................... 8W-10-10

Fuse 4 (PDC)...................... 8W-10-8, 13

Fuse 5 (PDC)...................... 8W-10-8, 13

Fuse 6 (PDC)................... 8W-10-8, 14, 20

Fuse 7 (PDC)...................... 8W-10-8, 20

Fuse 8 (PDC)...................... 8W-10-8, 21

Fuse 9 (PDC)...................... 8W-10-8, 23

Fuse 10 (PDC)..................... 8W-10-8, 22

Fuse 11 (PDC)..................... 8W-10-8, 23

Fuse 12 (JB)........................ 8W-10-10

Fuse 12 (PDC)................... 8W-10-8, 9, 23

Fuse 13 (JB)........................ 8W-10-10

Component Page

Fuse 14 (JB)........................ 8W-10-10

Fuse B (PDC)................... 8W-10-8, 9, 24

Fuse C (PDC)..................... 8W-10-9, 24

Fuse E (PDC)..................... 8W-10-9, 24

Fuse F (PDC)..................... 8W-10-9, 24

Fuse G (PDC)..................... 8W-10-9, 25

Fuse H (PDC)..................... 8W-10-9, 26

Fuse I (PDC)...................... 8W-10-9, 26

Fuse J (PDC)...................... 8W-10-9, 27

Fuse K (PDC)............. 8W-10-9, 14, 17, 18, 19

Fuse L (PDC)..................... 8W-10-9, 27

Fuse Gen (PDC)................... 8W-10-8, 27

G201............................. 8W-10-22

Generator........................ 8W-10-8, 27

Headlamp Beam Select Switch........... 8W-10-25

Headlamp Switch.................. 8W-10-9, 24

High Note Horn..................... 8W-10-26

Horn Relay....................... 8W-10-9, 26

Ignition Coil........................ 8W-10-15

Ignition Coil 4 Pack................... 8W-10-16

Ignition Coil 6 Pack................... 8W-10-16

Ignition Switch................. 8W-10-8, 10, 22

Joint Connector No. 1.............. 8W-10-25, 26

Joint Connector No. 2........ 8W-10-8, 9, 11, 12, 14,

15, 16, 20, 21

Joint Connector No. 5................. 8W-10-22

Joint Connector No. 6............ 8W-10-13, 22, 26

Joint Connector No. 8................. 8W-10-22

Junction Block.................. 8W-10-8, 10, 13

Left Fog Lamp...................... 8W-10-25

Left Headlamp...................... 8W-10-24

Left Outboard Headlamp.......... 8W-10-9, 24, 25

Low Note Horn...................... 8W-10-26

Oxygen Sensor 1/1 Left Bank Up . . . 8W-10-17, 18, 19

Oxygen Sensor 1/1 Upstream............ 8W-10-17

Oxygen Sensor 1/2 Downstream.......... 8W-10-17

Oxygen Sensor 1/2 Left Bank Down....... 8W-10-19

Oxygen Sensor 1/2 Pre-Catalyst.......... 8W-10-18

Oxygen Sensor 1/3 Post-Catalyst......... 8W-10-18

Oxygen Sensor 2/1 Right Bank Up . . 8W-10-17, 18, 19

Oxygen Sensor 2/2 Right Bank Down...... 8W-10-19

Oxygen Sensor Downstream Relay..... 8W-10-18, 19

Power Distribution Center.... 8W-10-8, 9, 10, 11, 12,

13, 14, 2, 20, 21, 22, 23, 24, 25, 26, 27

Power Outlet...................... 8W-10-9, 27

Powertrain Control Module . . 8W-10-11, 12, 15, 16, 20

Quad High Beam Relay................ 8W-10-24

Right Fog Lamp..................... 8W-10-25

Right Headlamp..................... 8W-10-24

Right Outboard Headlamp......... 8W-10-9, 24, 25

Security Relay..................... 8W-10-9, 25

Trailer Tow Connector................. 8W-10-21

Trailer Tow Relay.................... 8W-10-21

Transmission Control Relay........... 8W-10-9, 26

Transmission Solenoid Assembly......... 8W-10-26

Turn Signal/Hazard Switch............. 8W-10-13

BR/BE8W-10 POWER DISTRIBUTION 8W - 10 - 1