key DODGE RAM 2002 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 987 of 2255

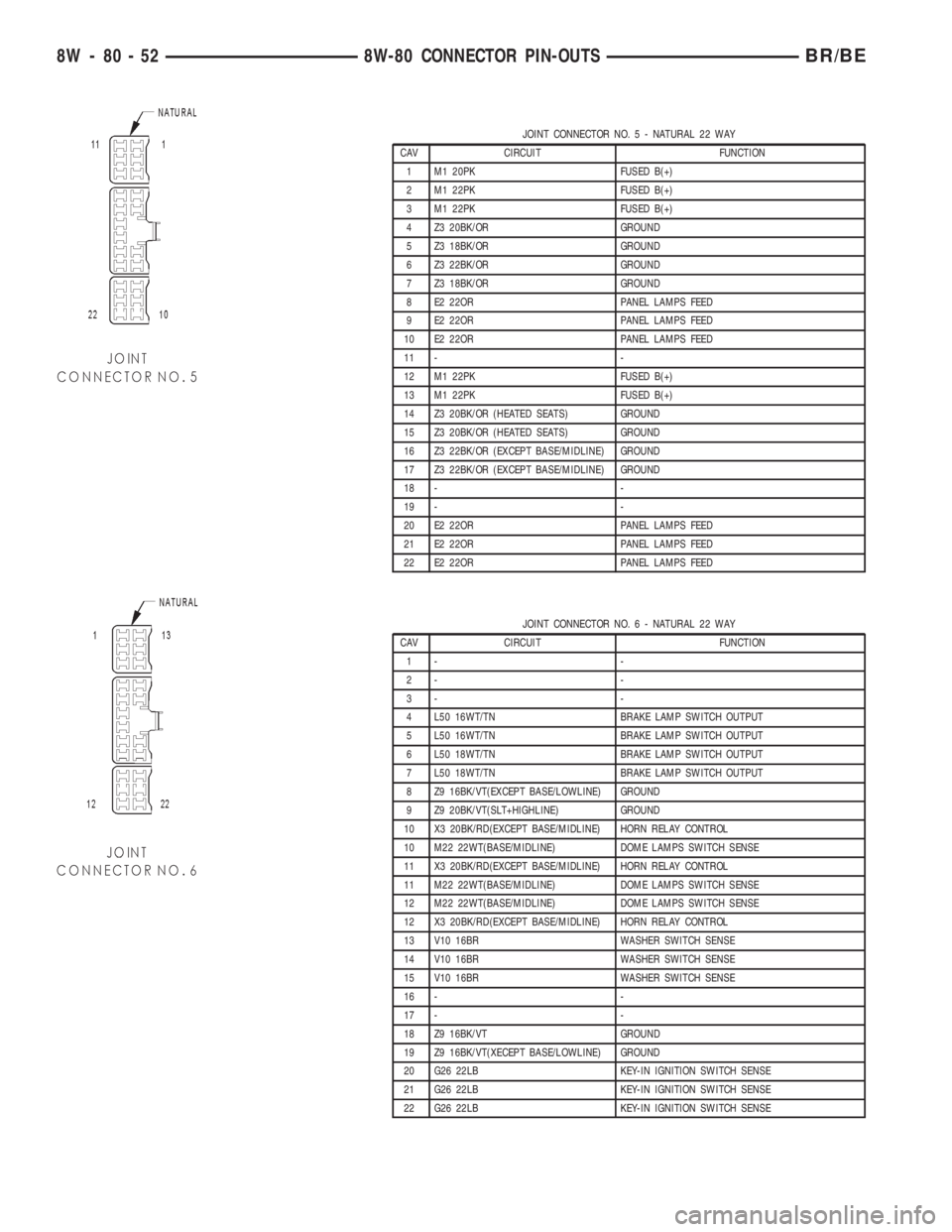

JOINT CONNECTOR NO.5-NATURAL 22 WAY

CAV CIRCUIT FUNCTION

1 M1 20PK FUSED B(+)

2 M1 22PK FUSED B(+)

3 M1 22PK FUSED B(+)

4 Z3 20BK/OR GROUND

5 Z3 18BK/OR GROUND

6 Z3 22BK/OR GROUND

7 Z3 18BK/OR GROUND

8 E2 22OR PANEL LAMPS FEED

9 E2 22OR PANEL LAMPS FEED

10 E2 22OR PANEL LAMPS FEED

11 - -

12 M1 22PK FUSED B(+)

13 M1 22PK FUSED B(+)

14 Z3 20BK/OR (HEATED SEATS) GROUND

15 Z3 20BK/OR (HEATED SEATS) GROUND

16 Z3 22BK/OR (EXCEPT BASE/MIDLINE) GROUND

17 Z3 22BK/OR (EXCEPT BASE/MIDLINE) GROUND

18 - -

19 - -

20 E2 22OR PANEL LAMPS FEED

21 E2 22OR PANEL LAMPS FEED

22 E2 22OR PANEL LAMPS FEED

JOINT CONNECTOR NO.6-NATURAL 22 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3- -

4 L50 16WT/TN BRAKE LAMP SWITCH OUTPUT

5 L50 16WT/TN BRAKE LAMP SWITCH OUTPUT

6 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

7 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

8 Z9 16BK/VT(EXCEPT BASE/LOWLINE) GROUND

9 Z9 20BK/VT(SLT+HIGHLINE) GROUND

10 X3 20BK/RD(EXCEPT BASE/MIDLINE) HORN RELAY CONTROL

10 M22 22WT(BASE/MIDLINE) DOME LAMPS SWITCH SENSE

11 X3 20BK/RD(EXCEPT BASE/MIDLINE) HORN RELAY CONTROL

11 M22 22WT(BASE/MIDLINE) DOME LAMPS SWITCH SENSE

12 M22 22WT(BASE/MIDLINE) DOME LAMPS SWITCH SENSE

12 X3 20BK/RD(EXCEPT BASE/MIDLINE) HORN RELAY CONTROL

13 V10 16BR WASHER SWITCH SENSE

14 V10 16BR WASHER SWITCH SENSE

15 V10 16BR WASHER SWITCH SENSE

16 - -

17 - -

18 Z9 16BK/VT GROUND

19 Z9 16BK/VT(XECEPT BASE/LOWLINE) GROUND

20 G26 22LB KEY-IN IGNITION SWITCH SENSE

21 G26 22LB KEY-IN IGNITION SWITCH SENSE

22 G26 22LB KEY-IN IGNITION SWITCH SENSE

8W - 80 - 52 8W-80 CONNECTOR PIN-OUTSBR/BE

Page 1124 of 2255

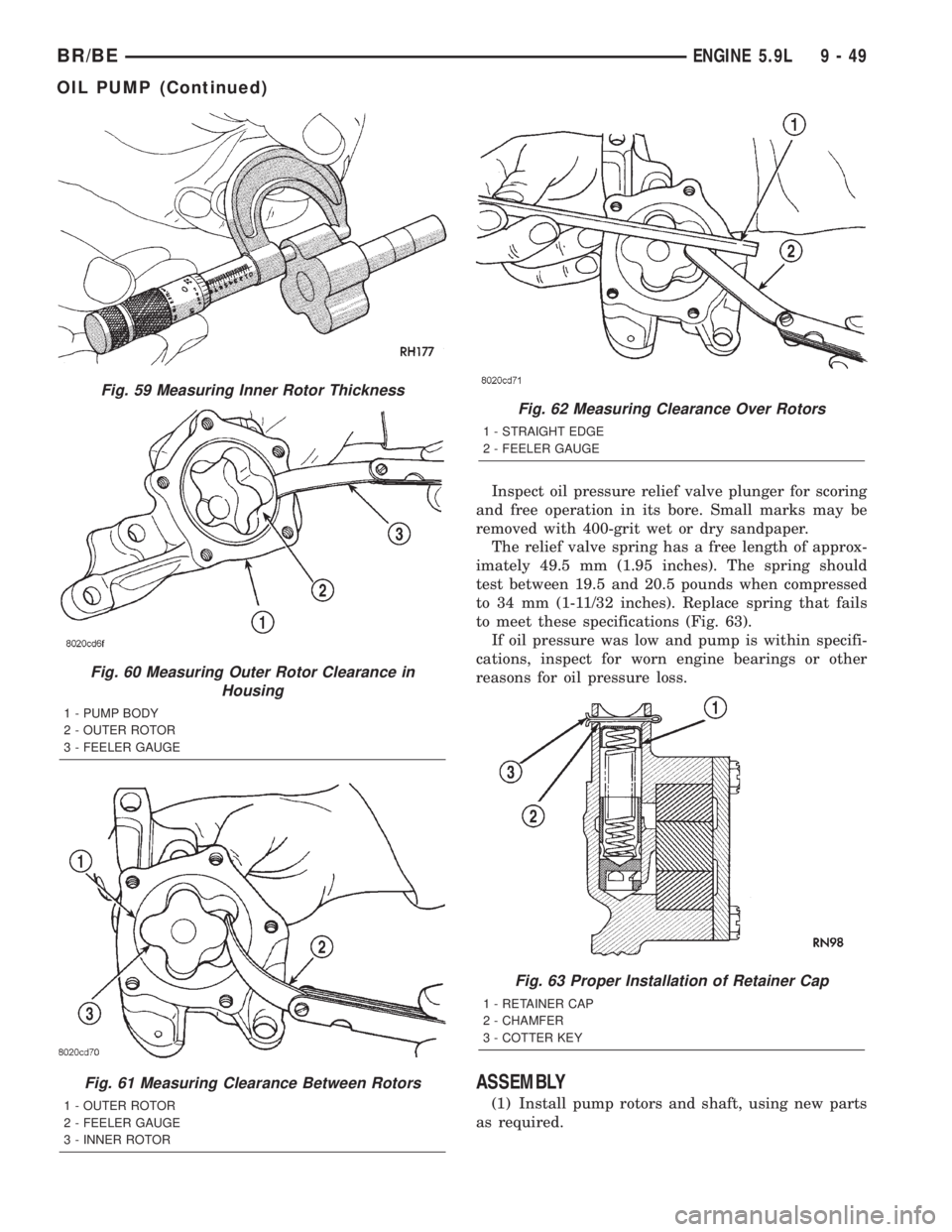

Inspect oil pressure relief valve plunger for scoring

and free operation in its bore. Small marks may be

removed with 400-grit wet or dry sandpaper.

The relief valve spring has a free length of approx-

imately 49.5 mm (1.95 inches). The spring should

test between 19.5 and 20.5 pounds when compressed

to 34 mm (1-11/32 inches). Replace spring that fails

to meet these specifications (Fig. 63).

If oil pressure was low and pump is within specifi-

cations, inspect for worn engine bearings or other

reasons for oil pressure loss.

ASSEMBLY

(1) Install pump rotors and shaft, using new parts

as required.

Fig. 59 Measuring Inner Rotor Thickness

Fig. 60 Measuring Outer Rotor Clearance in

Housing

1 - PUMP BODY

2 - OUTER ROTOR

3 - FEELER GAUGE

Fig. 61 Measuring Clearance Between Rotors

1 - OUTER ROTOR

2 - FEELER GAUGE

3 - INNER ROTOR

Fig. 62 Measuring Clearance Over Rotors

1 - STRAIGHT EDGE

2 - FEELER GAUGE

Fig. 63 Proper Installation of Retainer Cap

1 - RETAINER CAP

2 - CHAMFER

3 - COTTER KEY

BR/BEENGINE 5.9L 9 - 49

OIL PUMP (Continued)

Page 1130 of 2255

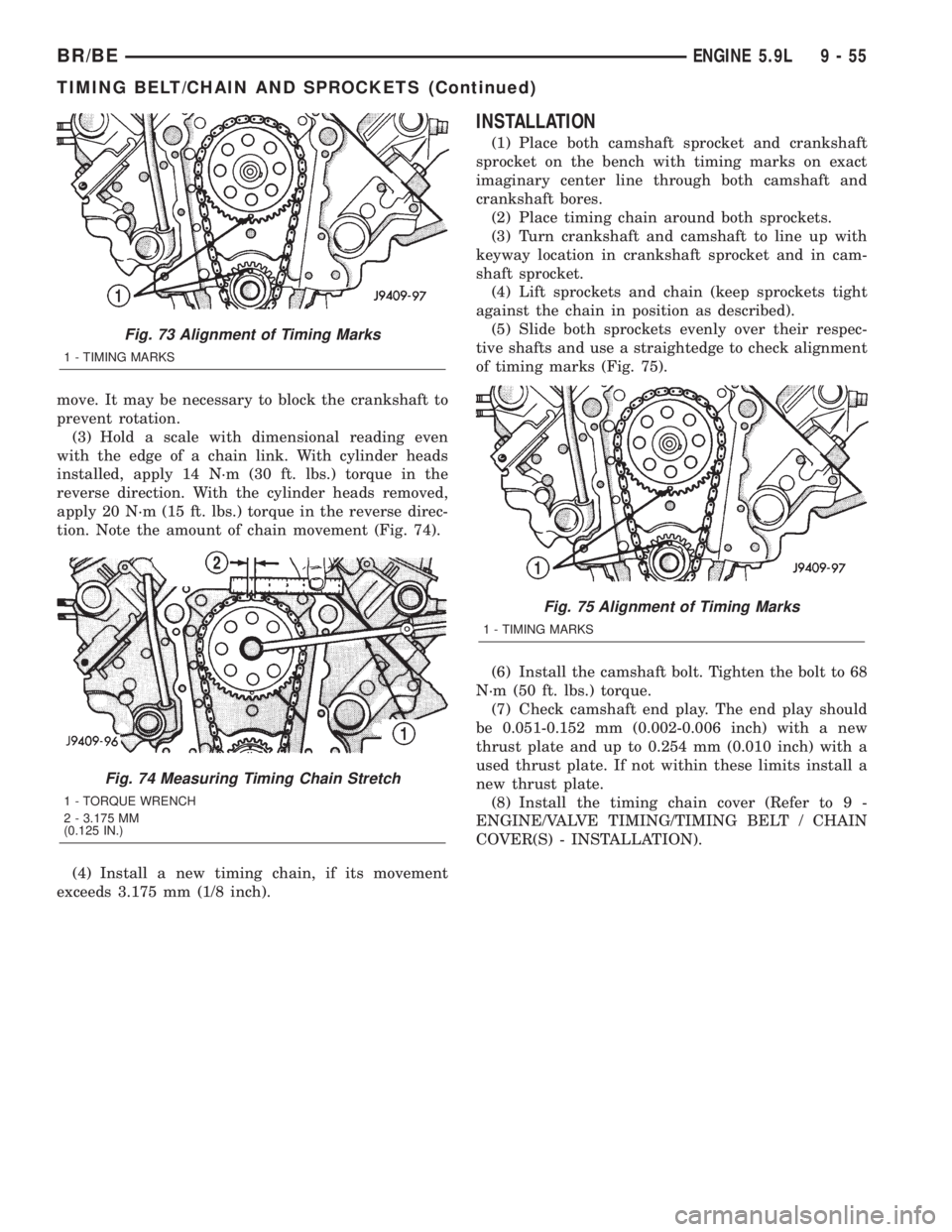

move. It may be necessary to block the crankshaft to

prevent rotation.

(3) Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads

installed, apply 14 N´m (30 ft. lbs.) torque in the

reverse direction. With the cylinder heads removed,

apply 20 N´m (15 ft. lbs.) torque in the reverse direc-

tion. Note the amount of chain movement (Fig. 74).

(4) Install a new timing chain, if its movement

exceeds 3.175 mm (1/8 inch).

INSTALLATION

(1) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(2) Place timing chain around both sprockets.

(3) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(4) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(5) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 75).

(6) Install the camshaft bolt. Tighten the bolt to 68

N´m (50 ft. lbs.) torque.

(7) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a

used thrust plate. If not within these limits install a

new thrust plate.

(8) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

Fig. 73 Alignment of Timing Marks

1 - TIMING MARKS

Fig. 74 Measuring Timing Chain Stretch

1 - TORQUE WRENCH

2 - 3.175 MM

(0.125 IN.)

Fig. 75 Alignment of Timing Marks

1 - TIMING MARKS

BR/BEENGINE 5.9L 9 - 55

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1161 of 2255

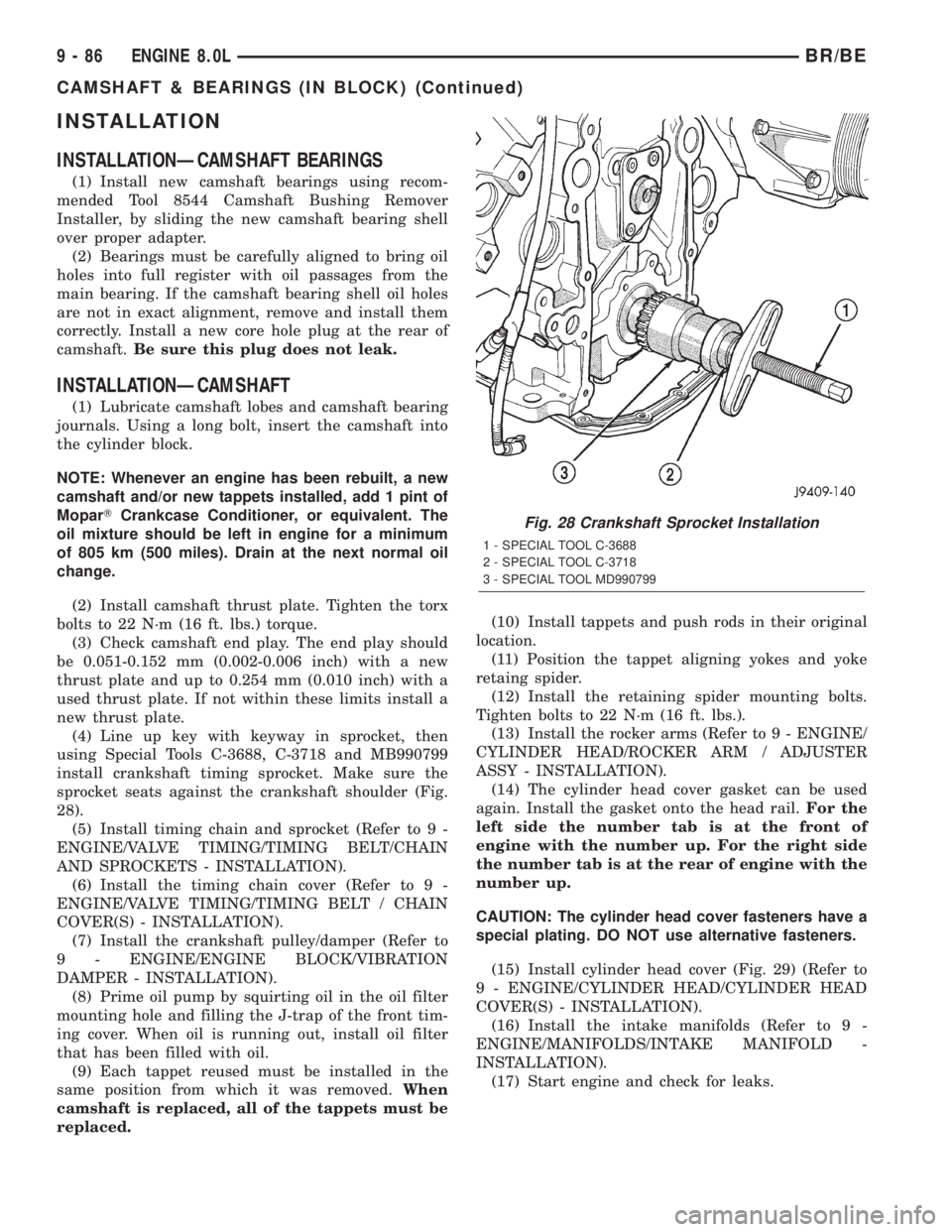

INSTALLATION

INSTALLATIONÐCAMSHAFT BEARINGS

(1) Install new camshaft bearings using recom-

mended Tool 8544 Camshaft Bushing Remover

Installer, by sliding the new camshaft bearing shell

over proper adapter.

(2) Bearings must be carefully aligned to bring oil

holes into full register with oil passages from the

main bearing. If the camshaft bearing shell oil holes

are not in exact alignment, remove and install them

correctly. Install a new core hole plug at the rear of

camshaft.Be sure this plug does not leak.

INSTALLATIONÐCAMSHAFT

(1) Lubricate camshaft lobes and camshaft bearing

journals. Using a long bolt, insert the camshaft into

the cylinder block.

NOTE: Whenever an engine has been rebuilt, a new

camshaft and/or new tappets installed, add 1 pint of

MoparTCrankcase Conditioner, or equivalent. The

oil mixture should be left in engine for a minimum

of 805 km (500 miles). Drain at the next normal oil

change.

(2) Install camshaft thrust plate. Tighten the torx

bolts to 22 N´m (16 ft. lbs.) torque.

(3) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a

used thrust plate. If not within these limits install a

new thrust plate.

(4) Line up key with keyway in sprocket, then

using Special Tools C-3688, C-3718 and MB990799

install crankshaft timing sprocket. Make sure the

sprocket seats against the crankshaft shoulder (Fig.

28).

(5) Install timing chain and sprocket (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION).

(6) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(7) Install the crankshaft pulley/damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

(8) Prime oil pump by squirting oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.

(9) Each tappet reused must be installed in the

same position from which it was removed.When

camshaft is replaced, all of the tappets must be

replaced.(10) Install tappets and push rods in their original

location.

(11) Position the tappet aligning yokes and yoke

retaing spider.

(12) Install the retaining spider mounting bolts.

Tighten bolts to 22 N´m (16 ft. lbs.).

(13) Install the rocker arms (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - INSTALLATION).

(14) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

CAUTION: The cylinder head cover fasteners have a

special plating. DO NOT use alternative fasteners.

(15) Install cylinder head cover (Fig. 29) (Refer to

9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(16) Install the intake manifolds (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(17) Start engine and check for leaks.

Fig. 28 Crankshaft Sprocket Installation

1 - SPECIAL TOOL C-3688

2 - SPECIAL TOOL C-3718

3 - SPECIAL TOOL MD990799

9 - 86 ENGINE 8.0LBR/BE

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1186 of 2255

(6) Prime oil pump by squirting oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.

(7) Install water pump and housing assembly

using new o-ring (Refer to 7 - COOLING/ENGINE/

WATER PUMP - INSTALLATION).

(8) Install generator, air pump, and bracket assem-

bly.

(9) Install A/C compressor (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(10) (10) Install the radiator fan (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(11) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(12) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect the negative cable to the battery.

(15) Road test vehicle and check for leaks.

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Remove timing chain cover and gasket using

extreme caution to avoid damaging oil pan gasket

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(2) Aline camshaft and crankshaft centerline.

Remove camshaft sprocket attaching bolt and remove

timing chain and camshaft sprockets.

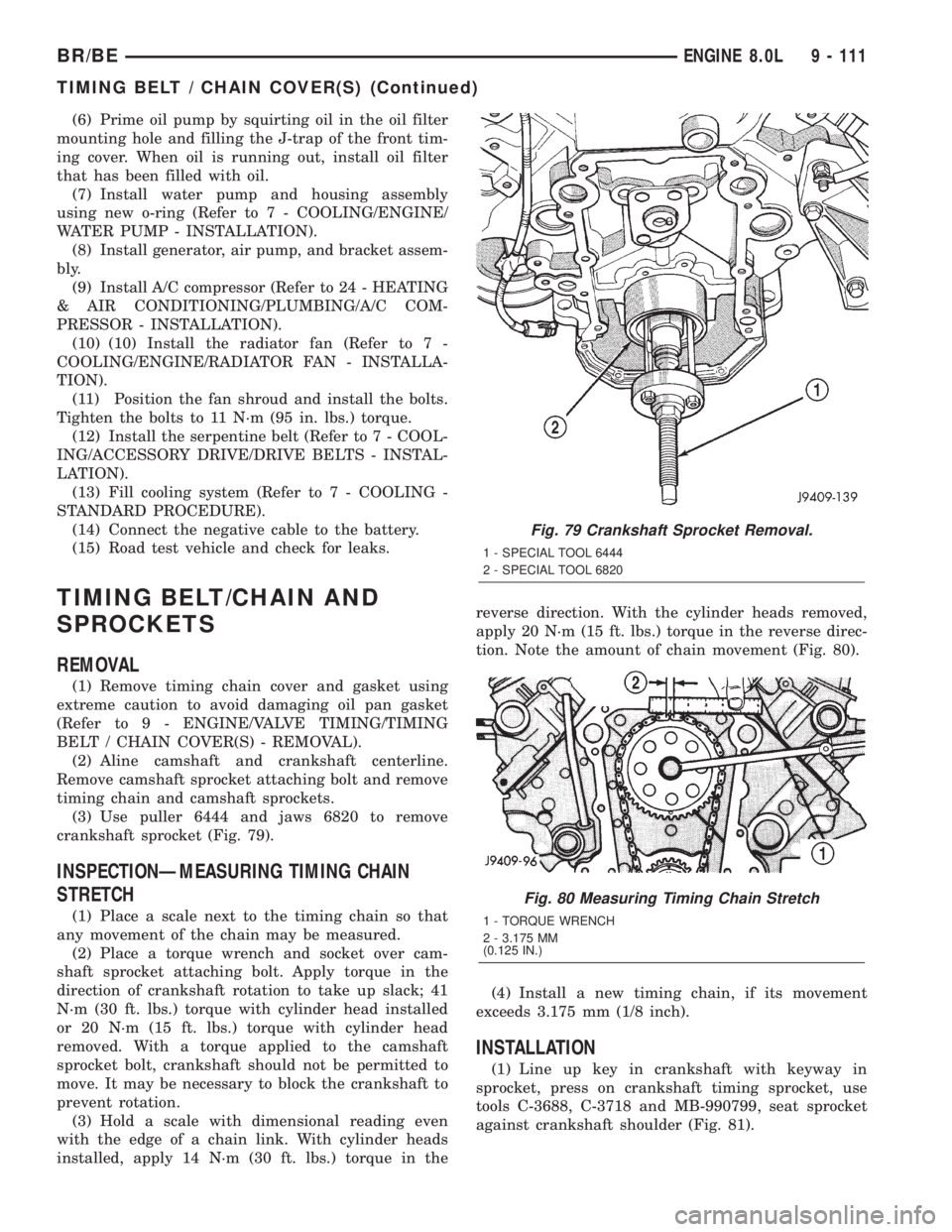

(3) Use puller 6444 and jaws 6820 to remove

crankshaft sprocket (Fig. 79).

INSPECTIONÐMEASURING TIMING CHAIN

STRETCH

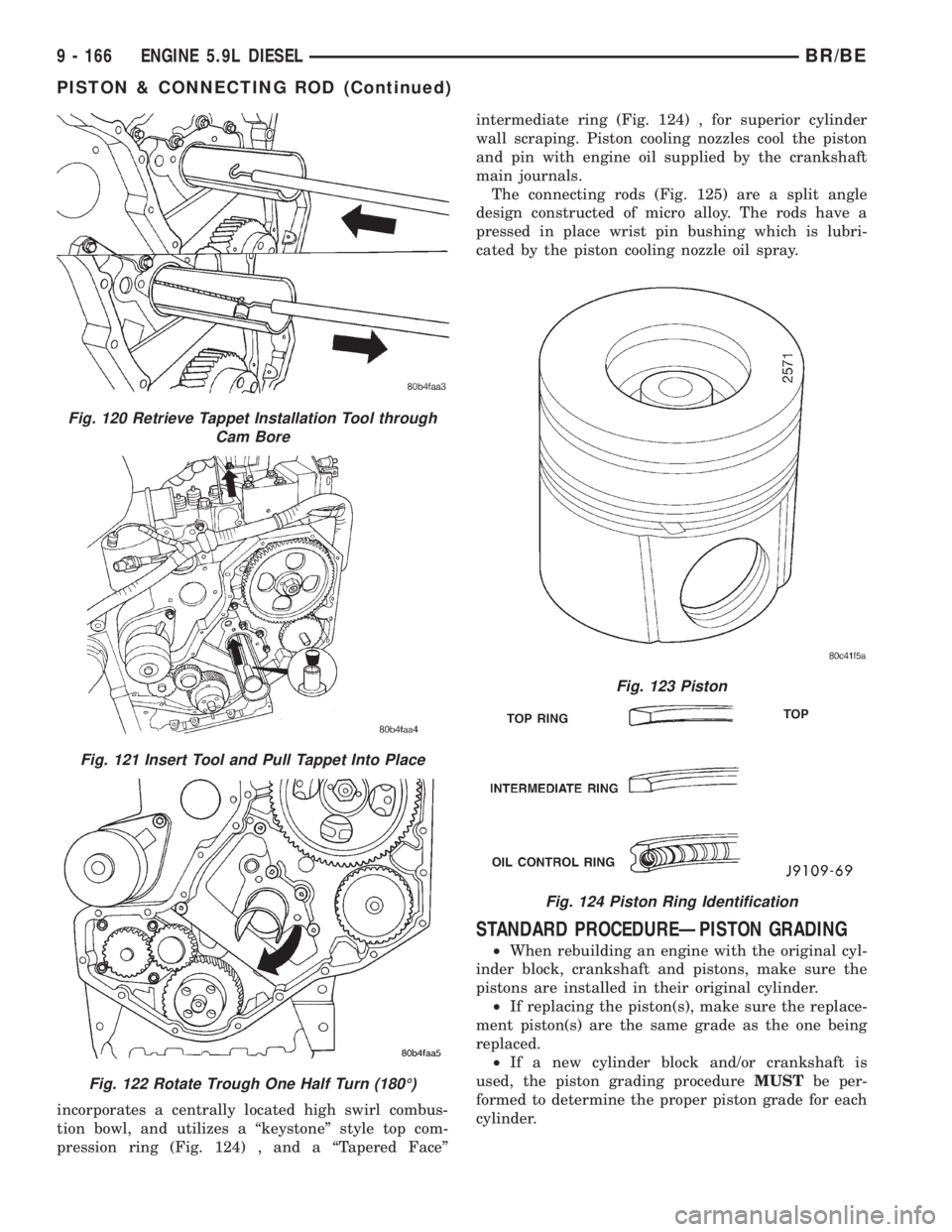

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2) Place a torque wrench and socket over cam-

shaft sprocket attaching bolt. Apply torque in the

direction of crankshaft rotation to take up slack; 41

N´m (30 ft. lbs.) torque with cylinder head installed

or 20 N´m (15 ft. lbs.) torque with cylinder head

removed. With a torque applied to the camshaft

sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3) Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads

installed, apply 14 N´m (30 ft. lbs.) torque in thereverse direction. With the cylinder heads removed,

apply 20 N´m (15 ft. lbs.) torque in the reverse direc-

tion. Note the amount of chain movement (Fig. 80).

(4) Install a new timing chain, if its movement

exceeds 3.175 mm (1/8 inch).

INSTALLATION

(1) Line up key in crankshaft with keyway in

sprocket, press on crankshaft timing sprocket, use

tools C-3688, C-3718 and MB-990799, seat sprocket

against crankshaft shoulder (Fig. 81).

Fig. 79 Crankshaft Sprocket Removal.

1 - SPECIAL TOOL 6444

2 - SPECIAL TOOL 6820

Fig. 80 Measuring Timing Chain Stretch

1 - TORQUE WRENCH

2 - 3.175 MM

(0.125 IN.)

BR/BEENGINE 8.0L 9 - 111

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1241 of 2255

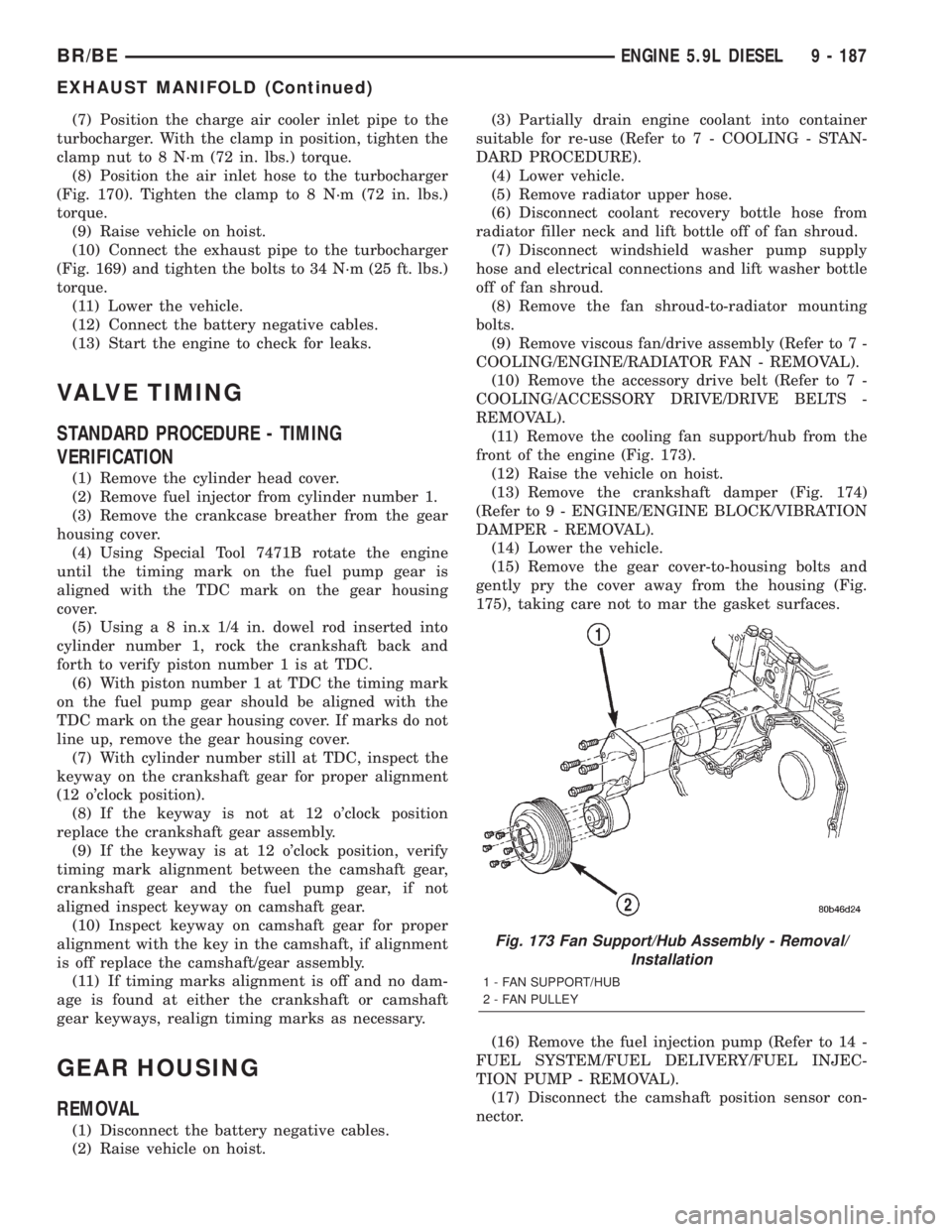

incorporates a centrally located high swirl combus-

tion bowl, and utilizes a ªkeystoneº style top com-

pression ring (Fig. 124) , and a ªTapered Faceºintermediate ring (Fig. 124) , for superior cylinder

wall scraping. Piston cooling nozzles cool the piston

and pin with engine oil supplied by the crankshaft

main journals.

The connecting rods (Fig. 125) are a split angle

design constructed of micro alloy. The rods have a

pressed in place wrist pin bushing which is lubri-

cated by the piston cooling nozzle oil spray.

STANDARD PROCEDUREÐPISTON GRADING

²When rebuilding an engine with the original cyl-

inder block, crankshaft and pistons, make sure the

pistons are installed in their original cylinder.

²If replacing the piston(s), make sure the replace-

ment piston(s) are the same grade as the one being

replaced.

²If a new cylinder block and/or crankshaft is

used, the piston grading procedureMUSTbe per-

formed to determine the proper piston grade for each

cylinder.

Fig. 120 Retrieve Tappet Installation Tool through

Cam Bore

Fig. 121 Insert Tool and Pull Tappet Into Place

Fig. 122 Rotate Trough One Half Turn (180É)

Fig. 123 Piston

Fig. 124 Piston Ring Identification

9 - 166 ENGINE 5.9L DIESELBR/BE

PISTON & CONNECTING ROD (Continued)

Page 1262 of 2255

(7) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 8 N´m (72 in. lbs.) torque.

(8) Position the air inlet hose to the turbocharger

(Fig. 170). Tighten the clamp to 8 N´m (72 in. lbs.)

torque.

(9) Raise vehicle on hoist.

(10) Connect the exhaust pipe to the turbocharger

(Fig. 169) and tighten the bolts to 34 N´m (25 ft. lbs.)

torque.

(11) Lower the vehicle.

(12) Connect the battery negative cables.

(13) Start the engine to check for leaks.

VALVE TIMING

STANDARD PROCEDURE - TIMING

VERIFICATION

(1) Remove the cylinder head cover.

(2) Remove fuel injector from cylinder number 1.

(3) Remove the crankcase breather from the gear

housing cover.

(4) Using Special Tool 7471B rotate the engine

until the timing mark on the fuel pump gear is

aligned with the TDC mark on the gear housing

cover.

(5) Using a 8 in.x 1/4 in. dowel rod inserted into

cylinder number 1, rock the crankshaft back and

forth to verify piston number 1 is at TDC.

(6) With piston number 1 at TDC the timing mark

on the fuel pump gear should be aligned with the

TDC mark on the gear housing cover. If marks do not

line up, remove the gear housing cover.

(7) With cylinder number still at TDC, inspect the

keyway on the crankshaft gear for proper alignment

(12 o'clock position).

(8) If the keyway is not at 12 o'clock position

replace the crankshaft gear assembly.

(9) If the keyway is at 12 o'clock position, verify

timing mark alignment between the camshaft gear,

crankshaft gear and the fuel pump gear, if not

aligned inspect keyway on camshaft gear.

(10) Inspect keyway on camshaft gear for proper

alignment with the key in the camshaft, if alignment

is off replace the camshaft/gear assembly.

(11) If timing marks alignment is off and no dam-

age is found at either the crankshaft or camshaft

gear keyways, realign timing marks as necessary.

GEAR HOUSING

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove the fan shroud-to-radiator mounting

bolts.

(9) Remove viscous fan/drive assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(10) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

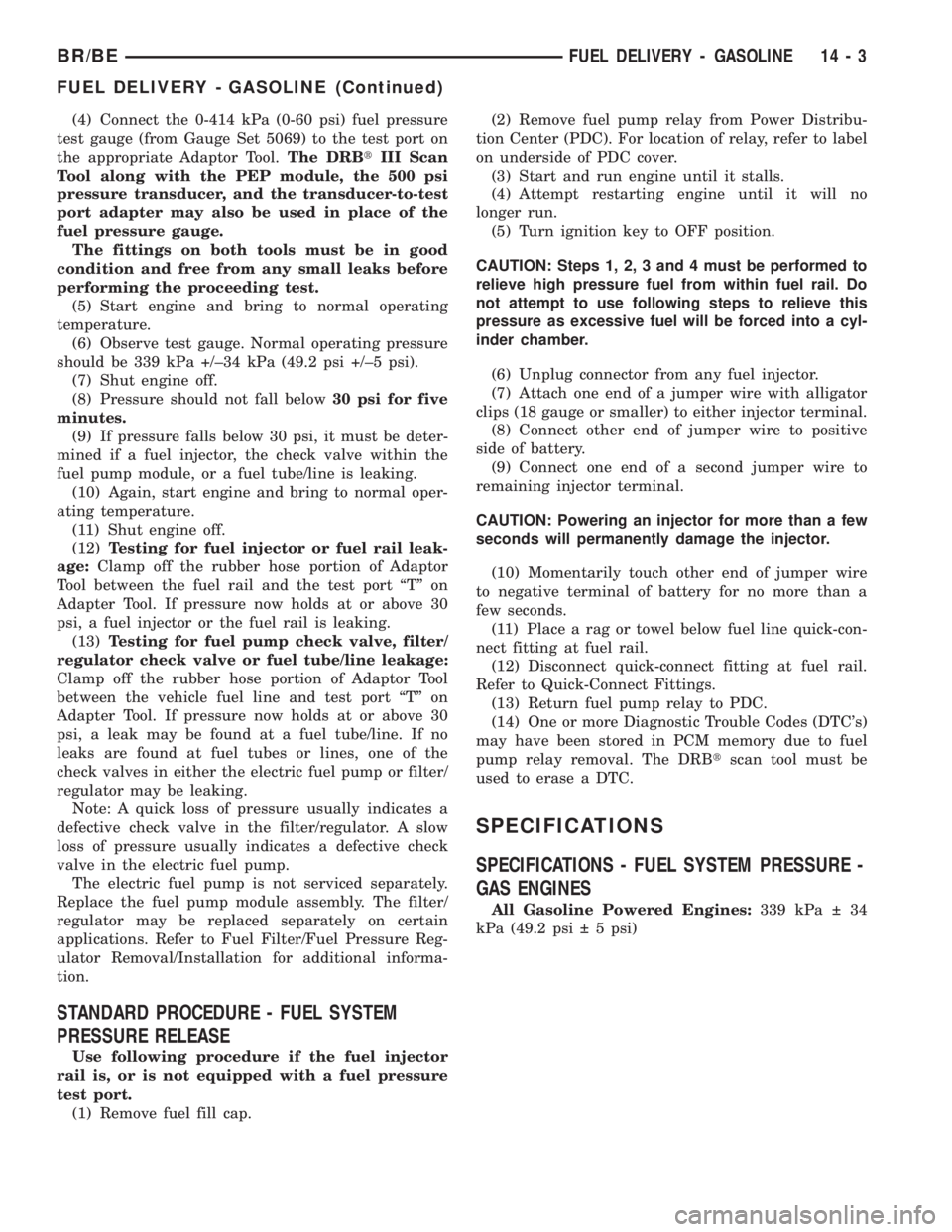

(11) Remove the cooling fan support/hub from the

front of the engine (Fig. 173).

(12) Raise the vehicle on hoist.

(13) Remove the crankshaft damper (Fig. 174)

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(14) Lower the vehicle.

(15) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing (Fig.

175), taking care not to mar the gasket surfaces.

(16) Remove the fuel injection pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(17) Disconnect the camshaft position sensor con-

nector.

Fig. 173 Fan Support/Hub Assembly - Removal/

Installation

1 - FAN SUPPORT/HUB

2 - FAN PULLEY

BR/BEENGINE 5.9L DIESEL 9 - 187

EXHAUST MANIFOLD (Continued)

Page 1302 of 2255

(4) Connect the 0-414 kPa (0-60 psi) fuel pressure

test gauge (from Gauge Set 5069) to the test port on

the appropriate Adaptor Tool.The DRBtIII Scan

Tool along with the PEP module, the 500 psi

pressure transducer, and the transducer-to-test

port adapter may also be used in place of the

fuel pressure gauge.

The fittings on both tools must be in good

condition and free from any small leaks before

performing the proceeding test.

(5) Start engine and bring to normal operating

temperature.

(6) Observe test gauge. Normal operating pressure

should be 339 kPa +/±34 kPa (49.2 psi +/±5 psi).

(7) Shut engine off.

(8) Pressure should not fall below30 psi for five

minutes.

(9) If pressure falls below 30 psi, it must be deter-

mined if a fuel injector, the check valve within the

fuel pump module, or a fuel tube/line is leaking.

(10) Again, start engine and bring to normal oper-

ating temperature.

(11) Shut engine off.

(12)Testing for fuel injector or fuel rail leak-

age:Clamp off the rubber hose portion of Adaptor

Tool between the fuel rail and the test port ªTº on

Adapter Tool. If pressure now holds at or above 30

psi, a fuel injector or the fuel rail is leaking.

(13)Testing for fuel pump check valve, filter/

regulator check valve or fuel tube/line leakage:

Clamp off the rubber hose portion of Adaptor Tool

between the vehicle fuel line and test port ªTº on

Adapter Tool. If pressure now holds at or above 30

psi, a leak may be found at a fuel tube/line. If no

leaks are found at fuel tubes or lines, one of the

check valves in either the electric fuel pump or filter/

regulator may be leaking.

Note: A quick loss of pressure usually indicates a

defective check valve in the filter/regulator. A slow

loss of pressure usually indicates a defective check

valve in the electric fuel pump.

The electric fuel pump is not serviced separately.

Replace the fuel pump module assembly. The filter/

regulator may be replaced separately on certain

applications. Refer to Fuel Filter/Fuel Pressure Reg-

ulator Removal/Installation for additional informa-

tion.

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE

Use following procedure if the fuel injector

rail is, or is not equipped with a fuel pressure

test port.

(1) Remove fuel fill cap.(2) Remove fuel pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(3) Start and run engine until it stalls.

(4) Attempt restarting engine until it will no

longer run.

(5) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(6) Unplug connector from any fuel injector.

(7) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.

(8) Connect other end of jumper wire to positive

side of battery.

(9) Connect one end of a second jumper wire to

remaining injector terminal.

CAUTION: Powering an injector for more than a few

seconds will permanently damage the injector.

(10) Momentarily touch other end of jumper wire

to negative terminal of battery for no more than a

few seconds.

(11) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(12) Disconnect quick-connect fitting at fuel rail.

Refer to Quick-Connect Fittings.

(13) Return fuel pump relay to PDC.

(14) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRBtscan tool must be

used to erase a DTC.

SPECIFICATIONS

SPECIFICATIONS - FUEL SYSTEM PRESSURE -

GAS ENGINES

All Gasoline Powered Engines:339 kPa 34

kPa (49.2 psi 5 psi)

BR/BEFUEL DELIVERY - GASOLINE 14 - 3

FUEL DELIVERY - GASOLINE (Continued)

Page 1309 of 2255

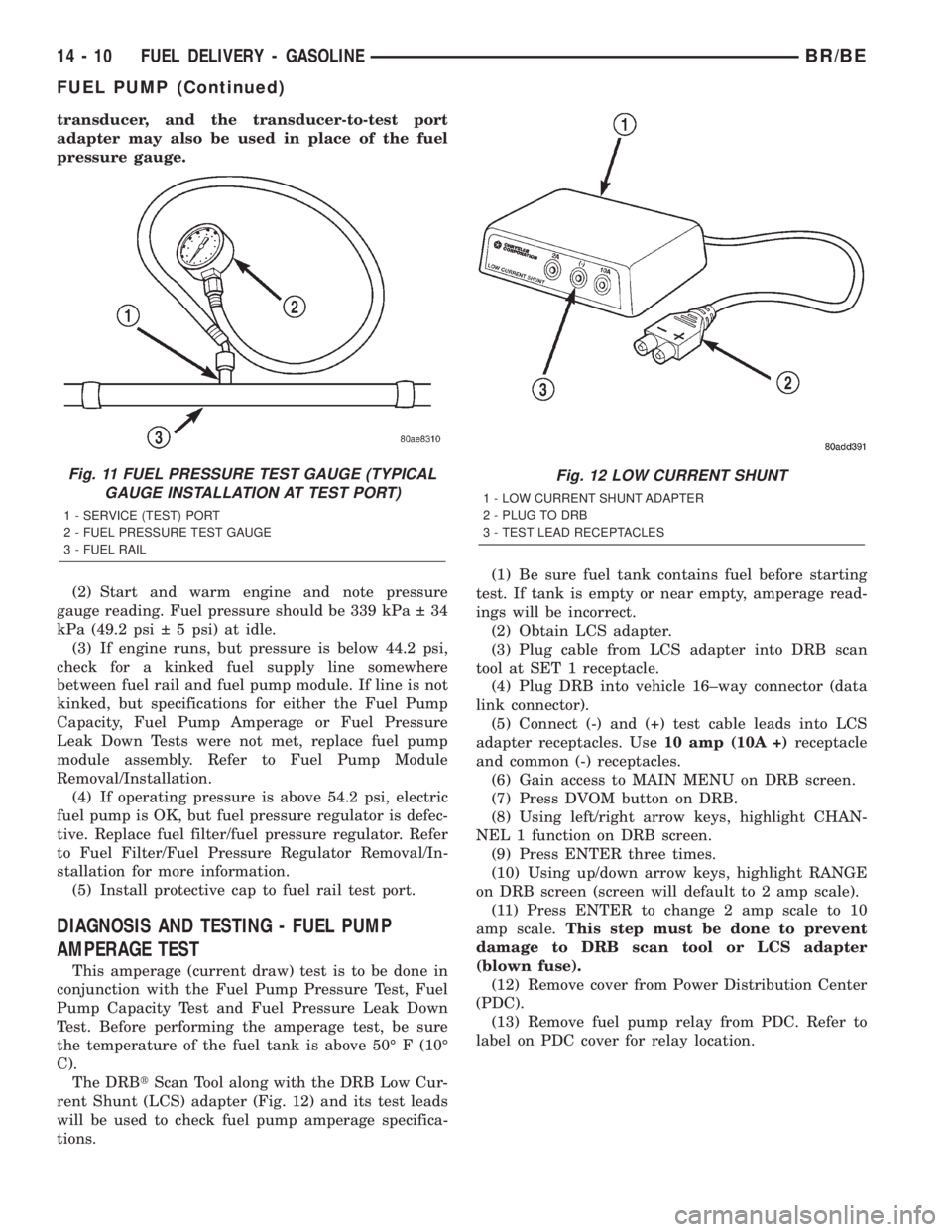

transducer, and the transducer-to-test port

adapter may also be used in place of the fuel

pressure gauge.

(2) Start and warm engine and note pressure

gauge reading. Fuel pressure should be 339 kPa 34

kPa (49.2 psi 5 psi) at idle.

(3) If engine runs, but pressure is below 44.2 psi,

check for a kinked fuel supply line somewhere

between fuel rail and fuel pump module. If line is not

kinked, but specifications for either the Fuel Pump

Capacity, Fuel Pump Amperage or Fuel Pressure

Leak Down Tests were not met, replace fuel pump

module assembly. Refer to Fuel Pump Module

Removal/Installation.

(4) If operating pressure is above 54.2 psi, electric

fuel pump is OK, but fuel pressure regulator is defec-

tive. Replace fuel filter/fuel pressure regulator. Refer

to Fuel Filter/Fuel Pressure Regulator Removal/In-

stallation for more information.

(5) Install protective cap to fuel rail test port.

DIAGNOSIS AND TESTING - FUEL PUMP

AMPERAGE TEST

This amperage (current draw) test is to be done in

conjunction with the Fuel Pump Pressure Test, Fuel

Pump Capacity Test and Fuel Pressure Leak Down

Test. Before performing the amperage test, be sure

the temperature of the fuel tank is above 50É F (10É

C).

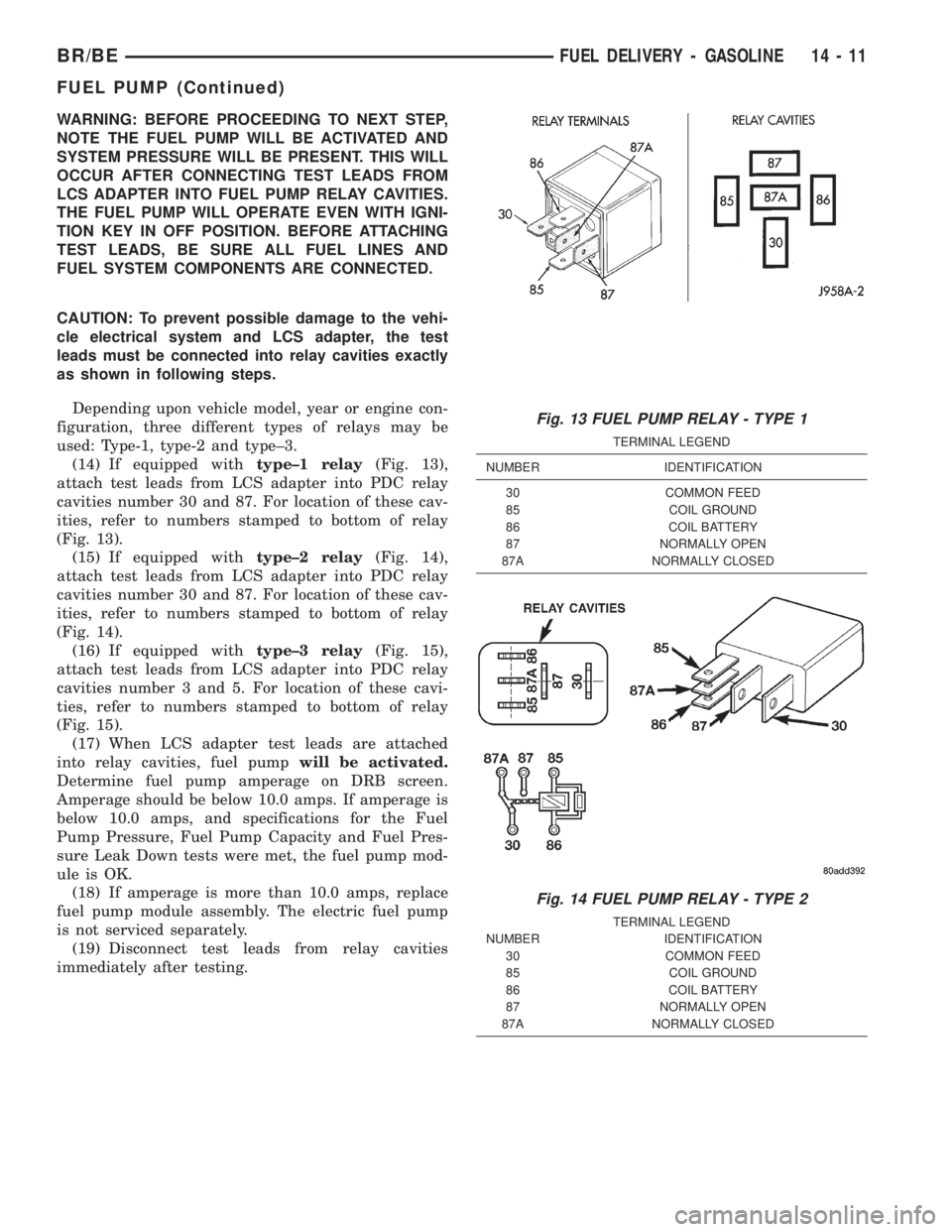

The DRBtScan Tool along with the DRB Low Cur-

rent Shunt (LCS) adapter (Fig. 12) and its test leads

will be used to check fuel pump amperage specifica-

tions.(1) Be sure fuel tank contains fuel before starting

test. If tank is empty or near empty, amperage read-

ings will be incorrect.

(2) Obtain LCS adapter.

(3) Plug cable from LCS adapter into DRB scan

tool at SET 1 receptacle.

(4) Plug DRB into vehicle 16±way connector (data

link connector).

(5) Connect (-) and (+) test cable leads into LCS

adapter receptacles. Use10 amp (10A +)receptacle

and common (-) receptacles.

(6) Gain access to MAIN MENU on DRB screen.

(7) Press DVOM button on DRB.

(8) Using left/right arrow keys, highlight CHAN-

NEL 1 function on DRB screen.

(9) Press ENTER three times.

(10) Using up/down arrow keys, highlight RANGE

on DRB screen (screen will default to 2 amp scale).

(11) Press ENTER to change 2 amp scale to 10

amp scale.This step must be done to prevent

damage to DRB scan tool or LCS adapter

(blown fuse).

(12) Remove cover from Power Distribution Center

(PDC).

(13) Remove fuel pump relay from PDC. Refer to

label on PDC cover for relay location.

Fig. 11 FUEL PRESSURE TEST GAUGE (TYPICAL

GAUGE INSTALLATION AT TEST PORT)

1 - SERVICE (TEST) PORT

2 - FUEL PRESSURE TEST GAUGE

3 - FUEL RAIL

Fig. 12 LOW CURRENT SHUNT

1 - LOW CURRENT SHUNT ADAPTER

2 - PLUG TO DRB

3 - TEST LEAD RECEPTACLES

14 - 10 FUEL DELIVERY - GASOLINEBR/BE

FUEL PUMP (Continued)

Page 1310 of 2255

WARNING: BEFORE PROCEEDING TO NEXT STEP,

NOTE THE FUEL PUMP WILL BE ACTIVATED AND

SYSTEM PRESSURE WILL BE PRESENT. THIS WILL

OCCUR AFTER CONNECTING TEST LEADS FROM

LCS ADAPTER INTO FUEL PUMP RELAY CAVITIES.

THE FUEL PUMP WILL OPERATE EVEN WITH IGNI-

TION KEY IN OFF POSITION. BEFORE ATTACHING

TEST LEADS, BE SURE ALL FUEL LINES AND

FUEL SYSTEM COMPONENTS ARE CONNECTED.

CAUTION: To prevent possible damage to the vehi-

cle electrical system and LCS adapter, the test

leads must be connected into relay cavities exactly

as shown in following steps.

Depending upon vehicle model, year or engine con-

figuration, three different types of relays may be

used: Type-1, type-2 and type±3.

(14) If equipped withtype±1 relay(Fig. 13),

attach test leads from LCS adapter into PDC relay

cavities number 30 and 87. For location of these cav-

ities, refer to numbers stamped to bottom of relay

(Fig. 13).

(15) If equipped withtype±2 relay(Fig. 14),

attach test leads from LCS adapter into PDC relay

cavities number 30 and 87. For location of these cav-

ities, refer to numbers stamped to bottom of relay

(Fig. 14).

(16) If equipped withtype±3 relay(Fig. 15),

attach test leads from LCS adapter into PDC relay

cavities number 3 and 5. For location of these cavi-

ties, refer to numbers stamped to bottom of relay

(Fig. 15).

(17) When LCS adapter test leads are attached

into relay cavities, fuel pumpwill be activated.

Determine fuel pump amperage on DRB screen.

Amperage should be below 10.0 amps. If amperage is

below 10.0 amps, and specifications for the Fuel

Pump Pressure, Fuel Pump Capacity and Fuel Pres-

sure Leak Down tests were met, the fuel pump mod-

ule is OK.

(18) If amperage is more than 10.0 amps, replace

fuel pump module assembly. The electric fuel pump

is not serviced separately.

(19) Disconnect test leads from relay cavities

immediately after testing.

Fig. 13 FUEL PUMP RELAY - TYPE 1

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 14 FUEL PUMP RELAY - TYPE 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

BR/BEFUEL DELIVERY - GASOLINE 14 - 11

FUEL PUMP (Continued)