Cooling system DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 653 of 2255

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the headlamp and dash wire har-

ness connector for the washer pump/motor from the

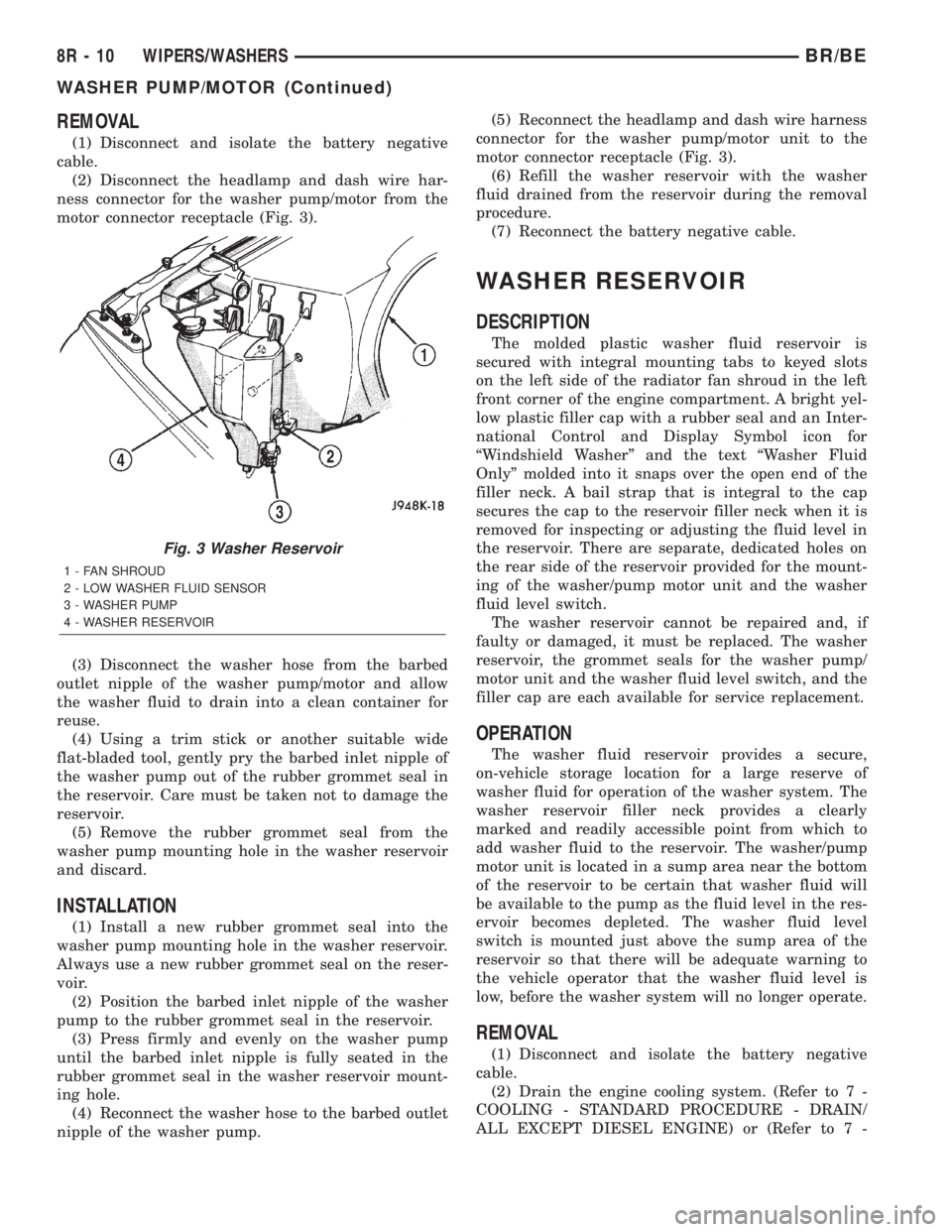

motor connector receptacle (Fig. 3).

(3) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor and allow

the washer fluid to drain into a clean container for

reuse.

(4) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed inlet nipple of

the washer pump out of the rubber grommet seal in

the reservoir. Care must be taken not to damage the

reservoir.

(5) Remove the rubber grommet seal from the

washer pump mounting hole in the washer reservoir

and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer pump mounting hole in the washer reservoir.

Always use a new rubber grommet seal on the reser-

voir.

(2) Position the barbed inlet nipple of the washer

pump to the rubber grommet seal in the reservoir.

(3) Press firmly and evenly on the washer pump

until the barbed inlet nipple is fully seated in the

rubber grommet seal in the washer reservoir mount-

ing hole.

(4) Reconnect the washer hose to the barbed outlet

nipple of the washer pump.(5) Reconnect the headlamp and dash wire harness

connector for the washer pump/motor unit to the

motor connector receptacle (Fig. 3).

(6) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(7) Reconnect the battery negative cable.

WASHER RESERVOIR

DESCRIPTION

The molded plastic washer fluid reservoir is

secured with integral mounting tabs to keyed slots

on the left side of the radiator fan shroud in the left

front corner of the engine compartment. A bright yel-

low plastic filler cap with a rubber seal and an Inter-

national Control and Display Symbol icon for

ªWindshield Washerº and the text ªWasher Fluid

Onlyº molded into it snaps over the open end of the

filler neck. A bail strap that is integral to the cap

secures the cap to the reservoir filler neck when it is

removed for inspecting or adjusting the fluid level in

the reservoir. There are separate, dedicated holes on

the rear side of the reservoir provided for the mount-

ing of the washer/pump motor unit and the washer

fluid level switch.

The washer reservoir cannot be repaired and, if

faulty or damaged, it must be replaced. The washer

reservoir, the grommet seals for the washer pump/

motor unit and the washer fluid level switch, and the

filler cap are each available for service replacement.

OPERATION

The washer fluid reservoir provides a secure,

on-vehicle storage location for a large reserve of

washer fluid for operation of the washer system. The

washer reservoir filler neck provides a clearly

marked and readily accessible point from which to

add washer fluid to the reservoir. The washer/pump

motor unit is located in a sump area near the bottom

of the reservoir to be certain that washer fluid will

be available to the pump as the fluid level in the res-

ervoir becomes depleted. The washer fluid level

switch is mounted just above the sump area of the

reservoir so that there will be adequate warning to

the vehicle operator that the washer fluid level is

low, before the washer system will no longer operate.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Drain the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - DRAIN/

ALL EXCEPT DIESEL ENGINE) or (Refer to 7 -

Fig. 3 Washer Reservoir

1 - FAN SHROUD

2 - LOW WASHER FLUID SENSOR

3 - WASHER PUMP

4 - WASHER RESERVOIR

8R - 10 WIPERS/WASHERSBR/BE

WASHER PUMP/MOTOR (Continued)

Page 654 of 2255

COOLING - STANDARD PROCEDURE - DRAIN/

DIESEL ENGINE).

(3) Disconnect the upper radiator hose from the

radiator.

(4) Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the switch connector receptacle.

(5) Disconnect the headlamp and dash wire har-

ness connector for the washer pump/motor unit from

the motor connector receptacle.

(6) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor and allow

the washer fluid to drain into a clean container for

reuse.

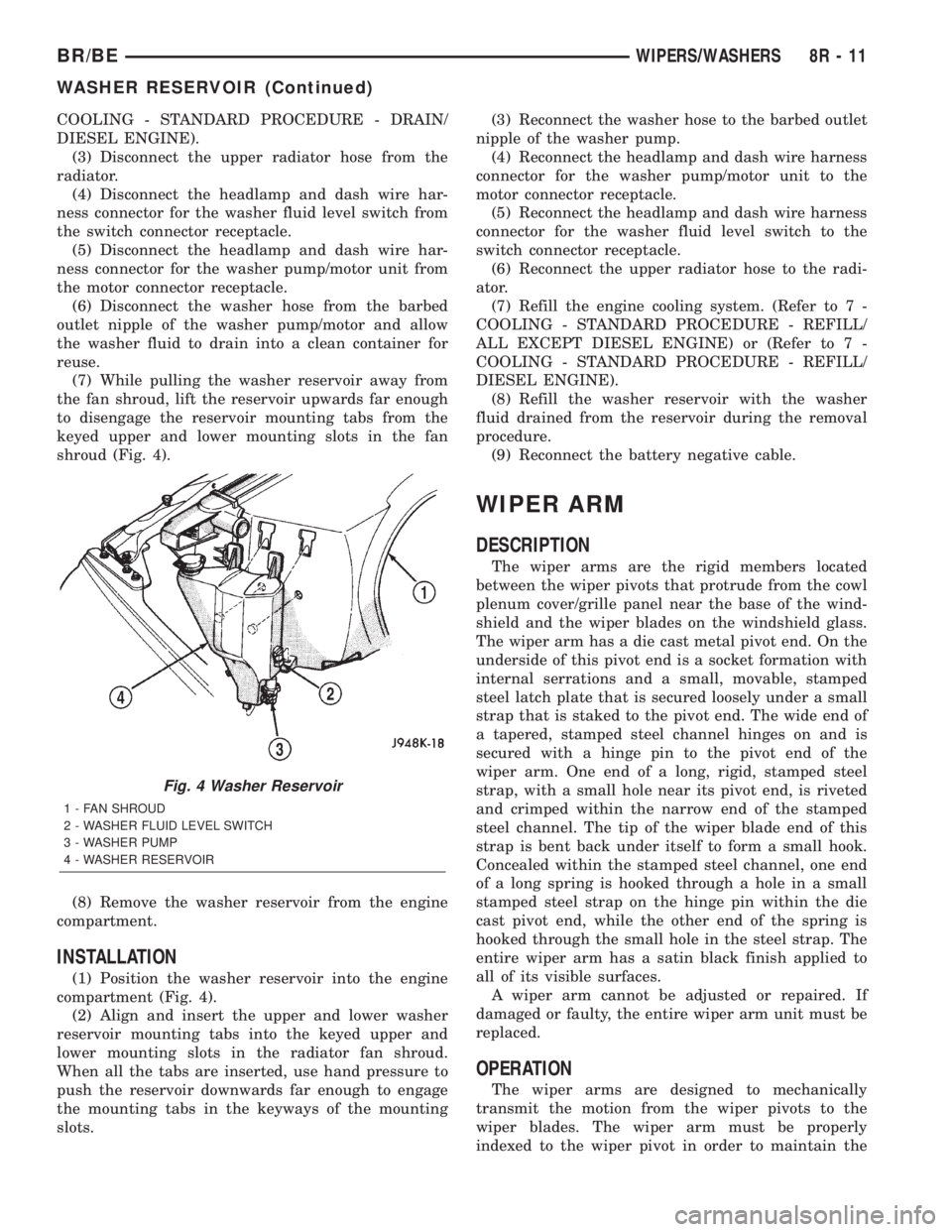

(7) While pulling the washer reservoir away from

the fan shroud, lift the reservoir upwards far enough

to disengage the reservoir mounting tabs from the

keyed upper and lower mounting slots in the fan

shroud (Fig. 4).

(8) Remove the washer reservoir from the engine

compartment.

INSTALLATION

(1) Position the washer reservoir into the engine

compartment (Fig. 4).

(2) Align and insert the upper and lower washer

reservoir mounting tabs into the keyed upper and

lower mounting slots in the radiator fan shroud.

When all the tabs are inserted, use hand pressure to

push the reservoir downwards far enough to engage

the mounting tabs in the keyways of the mounting

slots.(3) Reconnect the washer hose to the barbed outlet

nipple of the washer pump.

(4) Reconnect the headlamp and dash wire harness

connector for the washer pump/motor unit to the

motor connector receptacle.

(5) Reconnect the headlamp and dash wire harness

connector for the washer fluid level switch to the

switch connector receptacle.

(6) Reconnect the upper radiator hose to the radi-

ator.

(7) Refill the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - REFILL/

ALL EXCEPT DIESEL ENGINE) or (Refer to 7 -

COOLING - STANDARD PROCEDURE - REFILL/

DIESEL ENGINE).

(8) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(9) Reconnect the battery negative cable.

WIPER ARM

DESCRIPTION

The wiper arms are the rigid members located

between the wiper pivots that protrude from the cowl

plenum cover/grille panel near the base of the wind-

shield and the wiper blades on the windshield glass.

The wiper arm has a die cast metal pivot end. On the

underside of this pivot end is a socket formation with

internal serrations and a small, movable, stamped

steel latch plate that is secured loosely under a small

strap that is staked to the pivot end. The wide end of

a tapered, stamped steel channel hinges on and is

secured with a hinge pin to the pivot end of the

wiper arm. One end of a long, rigid, stamped steel

strap, with a small hole near its pivot end, is riveted

and crimped within the narrow end of the stamped

steel channel. The tip of the wiper blade end of this

strap is bent back under itself to form a small hook.

Concealed within the stamped steel channel, one end

of a long spring is hooked through a hole in a small

stamped steel strap on the hinge pin within the die

cast pivot end, while the other end of the spring is

hooked through the small hole in the steel strap. The

entire wiper arm has a satin black finish applied to

all of its visible surfaces.

A wiper arm cannot be adjusted or repaired. If

damaged or faulty, the entire wiper arm unit must be

replaced.

OPERATION

The wiper arms are designed to mechanically

transmit the motion from the wiper pivots to the

wiper blades. The wiper arm must be properly

indexed to the wiper pivot in order to maintain the

Fig. 4 Washer Reservoir

1 - FAN SHROUD

2 - WASHER FLUID LEVEL SWITCH

3 - WASHER PUMP

4 - WASHER RESERVOIR

BR/BEWIPERS/WASHERS 8R - 11

WASHER RESERVOIR (Continued)

Page 1087 of 2255

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Recover refrigerant from a/c system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(4) Remove the a/c condenser, if equipped (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

(6) Remove the washer bottle from the fan shroud.

(7) Remove the viscous fan/drive (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(8) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(9) Remove the upper crossmember and top core

support.

(10) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).(11) Remove the A/C compressor with the lines

attached. Secure compressor out of the way.

(12) Remove generator assembly (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR - REMOV-

AL).

(13) Remove the air cleaner resonator and duct

work as an assembly.

(14) Disconnect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL).

(15) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(16) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(17) Remove the distributor cap and wiring.

(18) Disconnect the heater hoses.

(19) Disconnect the power steering hoses, if

equipped.

(20) Perform the Fuel System Pressure Release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).

(21) Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(22) On Manual Transmission vehicles, remove the

shift lever (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/SHIFT COVER - REMOVAL).

(23) Raise and support the vehicle on a hoist and

drain the engine oil.

(24) Remove engine front mount thru-bolt nuts.

(25) Disconnect the transmission oil cooler lines

from their retainers at the oil pan bolts.

(26) Disconnect exhaust pipe at manifolds.

(27) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(28) Remove the dust shield and transmission

inspection cover.

(29) Remove drive plate to converter bolts (Auto-

matic transmission equipped vehicles).

(30) Remove transmission bell housing to engine

block bolts.

(31) Lower the vehicle.

(32) Install an engine lifting fixture.

(33) Separate engine from transmission, remove

engine from vehicle, and install engine assembly on a

repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install engine lifting device.

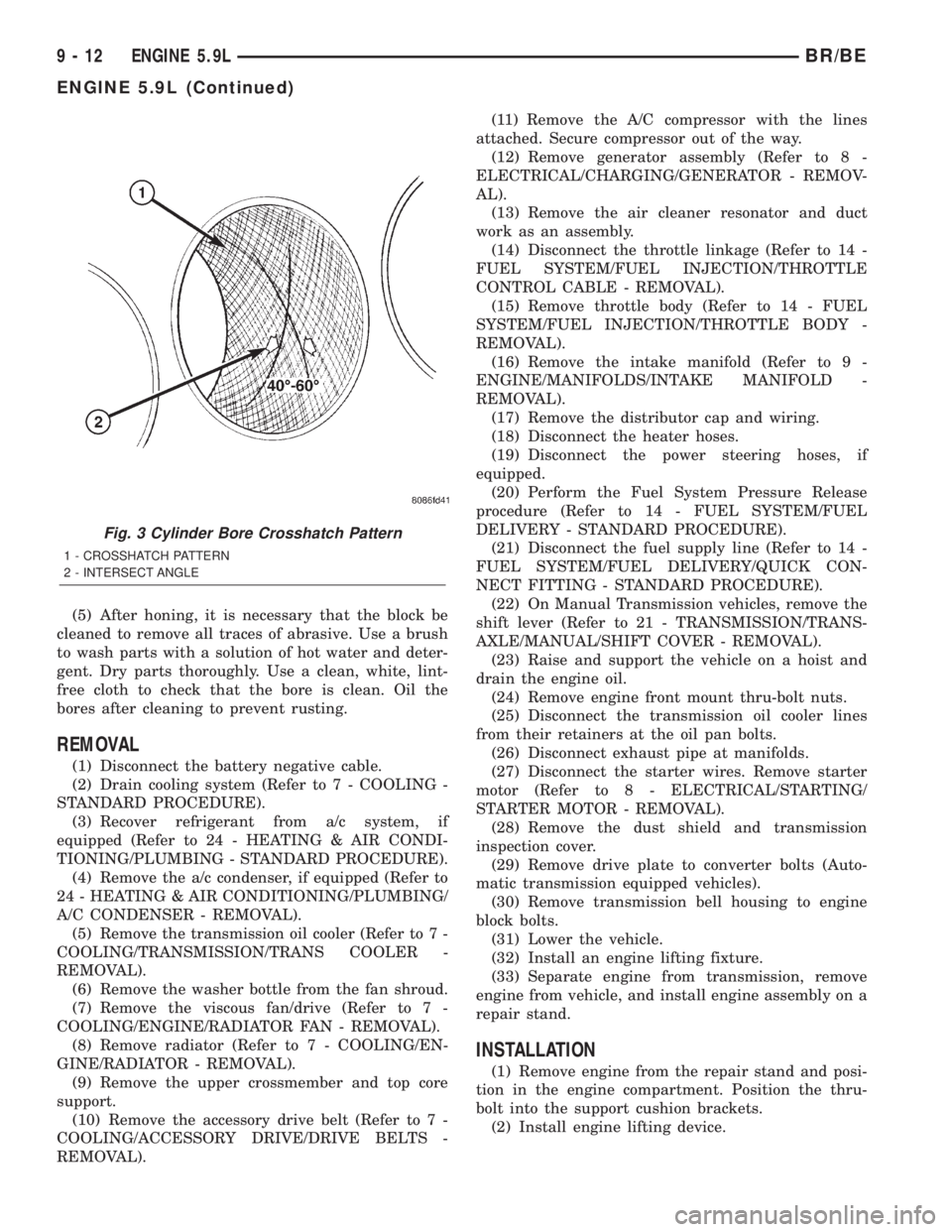

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

9 - 12 ENGINE 5.9LBR/BE

ENGINE 5.9L (Continued)

Page 1088 of 2255

(3) Lower engine into compartment and align

engine with transmission:

²Manual Transmission: Align clutch disc assem-

bly (if disturbed). Install transmission input shaft

into clutch disc while mating engine and transmis-

sion surfaces. Install two transmission to engine

block mounting bolts finger tight.

²Automatic Transmission: Mate engine and trans-

mission and install two transmission to engine block

mounting bolts finger tight.

(4) Lower engine assembly until engine mount

through bolts rest in mount perches.

(5) Install remaining transmission to engine block

mounting bolts and tighten.

(6) Tighten engine mount through bolts.

(7) Install drive plate to torque converter bolts.

(Automatic transmission models)

(8) Install the dust shield and transmission cover.

(9) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(10) Install exhaust pipe to manifold.

(11) Install the transmission cooler line brackets to

the oil pan.

(12) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(13) Lower the vehicle.

(14) Remove engine lifting fixture.

(15) On Manual Transmission vehicles, install the

shift lever (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/SHIFT COVER - INSTALLATION).

(16) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(17) Connect the power steering hoses, if equipped.

(18) Connect the heater hoses.

(19) Install the distributor cap and wiring.

(20) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(21) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(22) Connect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION).

(23) Install the air cleaner resonator and duct

work..

(24) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(25) Install a/c compressor and lines (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).(26) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(27) Install upper radiator support crossmember.

(28) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(29) Connect the radiator lower hose.

(30) Connect the transmission oil cooler lines to

the radiator.

(31) Install the fan shroud.

(32) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(33) Connect the radiator upper hose.

(34) Install the washer bottle.

(35) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(36) Connect the transmission cooler lines.

(37) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(38) Evacuate and charge the air conditioning sys-

tem, if equipped (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(39) Add engine oil to crankcase (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES - SPEC-

IFICATIONS).

(40) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(41) Connect battery negative cable.

(42) Start engine and inspect for leaks.

(43) Road test vehicle.

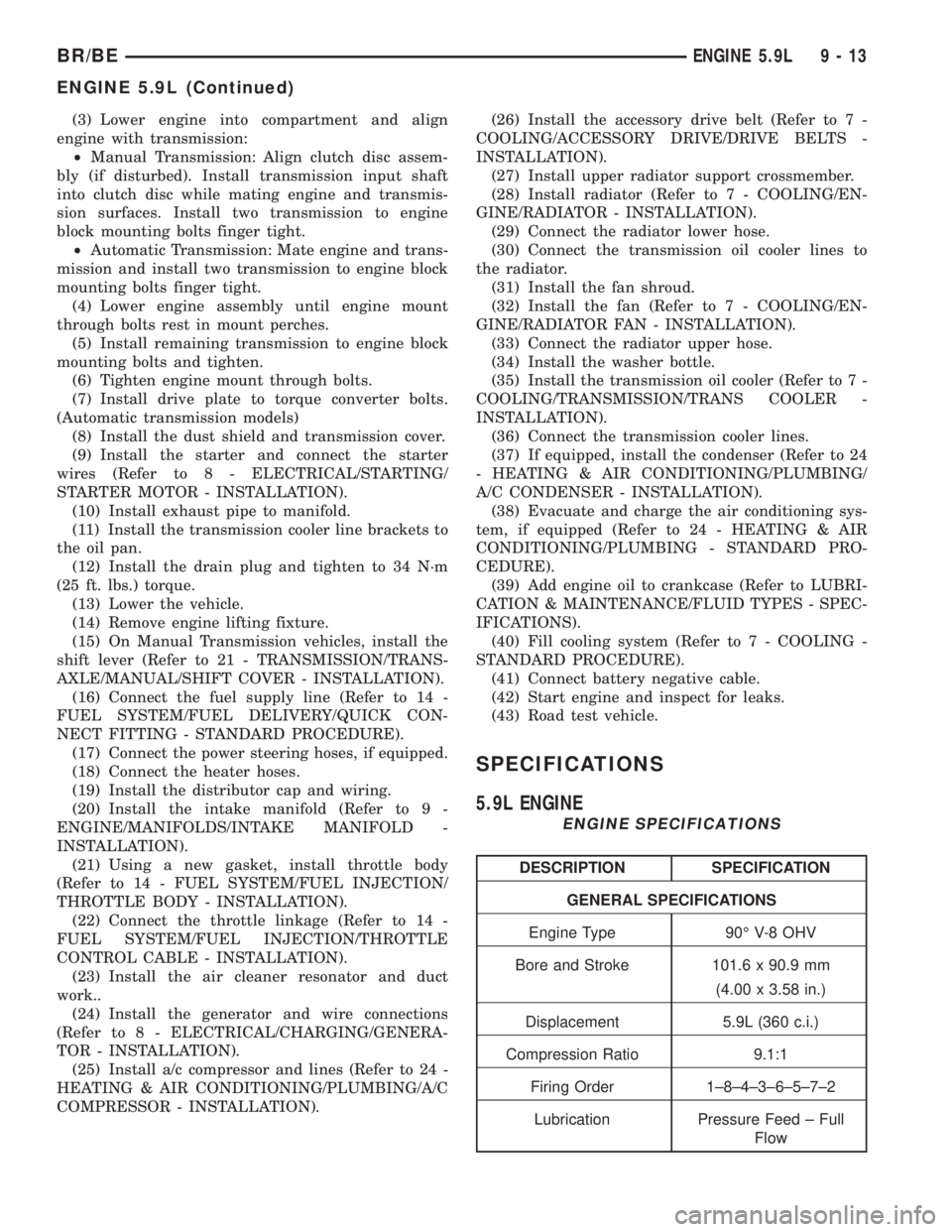

SPECIFICATIONS

5.9L ENGINE

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É V-8 OHV

Bore and Stroke 101.6 x 90.9 mm

(4.00 x 3.58 in.)

Displacement 5.9L (360 c.i.)

Compression Ratio 9.1:1

Firing Order 1±8±4±3±6±5±7±2

Lubrication Pressure Feed ± Full

Flow

BR/BEENGINE 5.9L 9 - 13

ENGINE 5.9L (Continued)

Page 1089 of 2255

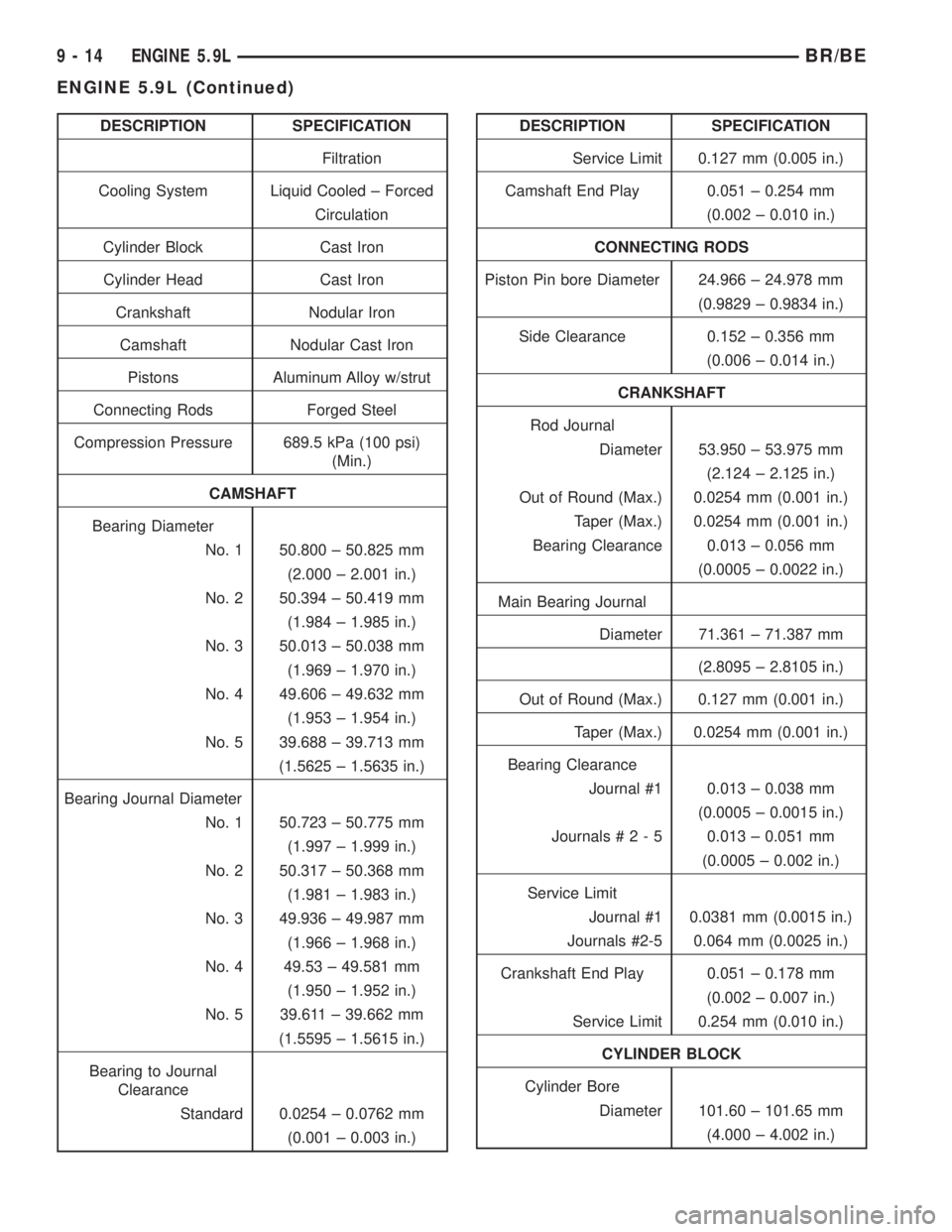

DESCRIPTION SPECIFICATION

Filtration

Cooling System Liquid Cooled ± Forced

Circulation

Cylinder Block Cast Iron

Cylinder Head Cast Iron

Crankshaft Nodular Iron

Camshaft Nodular Cast Iron

Pistons Aluminum Alloy w/strut

Connecting Rods Forged Steel

Compression Pressure 689.5 kPa (100 psi)

(Min.)

CAMSHAFT

Bearing Diameter

No. 1 50.800 ± 50.825 mm

(2.000 ± 2.001 in.)

No. 2 50.394 ± 50.419 mm

(1.984 ± 1.985 in.)

No. 3 50.013 ± 50.038 mm

(1.969 ± 1.970 in.)

No. 4 49.606 ± 49.632 mm

(1.953 ± 1.954 in.)

No. 5 39.688 ± 39.713 mm

(1.5625 ± 1.5635 in.)

Bearing Journal Diameter

No. 1 50.723 ± 50.775 mm

(1.997 ± 1.999 in.)

No. 2 50.317 ± 50.368 mm

(1.981 ± 1.983 in.)

No. 3 49.936 ± 49.987 mm

(1.966 ± 1.968 in.)

No. 4 49.53 ± 49.581 mm

(1.950 ± 1.952 in.)

No. 5 39.611 ± 39.662 mm

(1.5595 ± 1.5615 in.)

Bearing to Journal

Clearance

Standard 0.0254 ± 0.0762 mm

(0.001 ± 0.003 in.)DESCRIPTION SPECIFICATION

Service Limit 0.127 mm (0.005 in.)

Camshaft End Play 0.051 ± 0.254 mm

(0.002 ± 0.010 in.)

CONNECTING RODS

Piston Pin bore Diameter 24.966 ± 24.978 mm

(0.9829 ± 0.9834 in.)

Side Clearance 0.152 ± 0.356 mm

(0.006 ± 0.014 in.)

CRANKSHAFT

Rod Journal

Diameter 53.950 ± 53.975 mm

(2.124 ± 2.125 in.)

Out of Round (Max.) 0.0254 mm (0.001 in.)

Taper (Max.) 0.0254 mm (0.001 in.)

Bearing Clearance 0.013 ± 0.056 mm

(0.0005 ± 0.0022 in.)

Main Bearing Journal

Diameter 71.361 ± 71.387 mm

(2.8095 ± 2.8105 in.)

Out of Round (Max.) 0.127 mm (0.001 in.)

Taper (Max.) 0.0254 mm (0.001 in.)

Bearing Clearance

Journal #1 0.013 ± 0.038 mm

(0.0005 ± 0.0015 in.)

Journals#2-50.013 ± 0.051 mm

(0.0005 ± 0.002 in.)

Service Limit

Journal #1 0.0381 mm (0.0015 in.)

Journals #2-5 0.064 mm (0.0025 in.)

Crankshaft End Play 0.051 ± 0.178 mm

(0.002 ± 0.007 in.)

Service Limit 0.254 mm (0.010 in.)

CYLINDER BLOCK

Cylinder Bore

Diameter 101.60 ± 101.65 mm

(4.000 ± 4.002 in.)

9 - 14 ENGINE 5.9LBR/BE

ENGINE 5.9L (Continued)

Page 1096 of 2255

OPERATION

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture

to the correct ratio for ignition. The valves located in

the cylinder head open and close to either allow clean

air into the combustion chamber or to allow the

exhaust gases out, depending on the stroke of the

engine.

OPERATION - CYLINDER HEAD COVER

GASKET

The steel-backed silicone gasket is designed to seal

the cylinder head cover for long periods of time

through extensive heat and cold, without failure. The

gasket is designed to be reusable.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the air cleaner resonator and duct

work.

(4) Remove the intake manifold-to-generator

bracket support rod. Remove the generator.

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Perform the Fuel System Pressure Release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel supply line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(9) Remove distributor cap and wires.

(10) Disconnect the coil wires.

(11) Disconnect heat indicator sending unit wire.

(12) Disconnect heater hoses and bypass hose.

(13) Remove cylinder head covers and gaskets

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(14) Remove intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL) and throttle body as an assembly. Dis-

card the flange side gaskets and the front and rear

cross-over gaskets.

BR/BEENGINE 5.9L 9 - 21

CYLINDER HEAD (Continued)

Page 1097 of 2255

(15) Remove exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

REMOVAL).

(16) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(17) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

(18) Remove spark plugs.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness

exceeds 0.00075mm/mm (0.0001in/in.) times the span

length in any direction, either replace head or lightly

machine the head surface.

FOR EXAMPLE:ÐA 305 mm (12 in.) span is

0.102 mm (0.004 in.) out-of-flat. The allowable out-of-

flat is 305 x 0.00075 (12 x 0.00075) equals 0.23 mm

(0.009 in.). This amount of out-of-flat is acceptable.

The cylinder head surface finish should be

1.78-3.00 microns (70-125 microinches).

Inspect push rods. Replace worn or bent rods.

INSTALLATION

(1) Clean all surfaces of cylinder block and cylin-

der heads.

(2) Clean cylinder block front and rear gasket sur-

faces using a suitable solvent.

(3) Position new cylinder head gaskets onto the

cylinder block.

(4) Position cylinder heads onto head gaskets and

cylinder block.

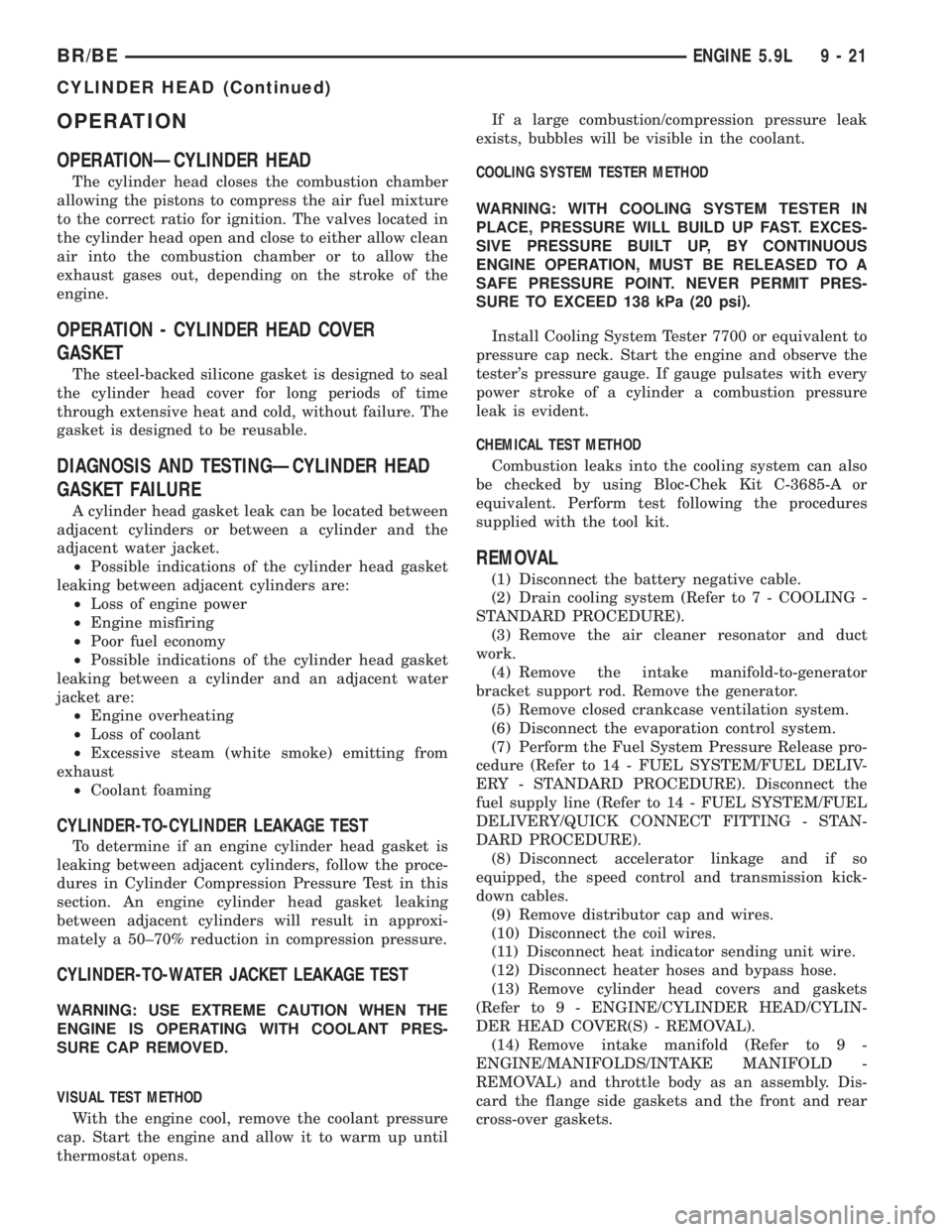

(5) Starting at top center, tighten all cylinder head

bolts, in sequence (Fig. 6).

CAUTION: When tightening the rocker arm bolts,

make sure the piston in that cylinder is NOT at

TDC. Contact between the valves and piston could

occur.

(6) Install push rods and rocker arm assemblies in

their original position. Tighten the bolts to 28 N´m

(21 ft. lbs.) torque.

(7) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION) and throttle body assembly.

(8) Install exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSTALLATION).(9) If required, adjust spark plugs to specifications.

Install the plugs and tighten to 41 N´m (30 ft. lbs.)

torque.

(10) Install coil wire.

(11) Connect heat indicator sending unit wire.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(15) Install the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(16) Install the generator and drive belt (Refer to 7

- COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION). Tighten generator mounting bolt

to 41 N´m (30 ft. lbs.) torque. Tighten the adjusting

strap bolt to 23 N´m (200 in. lbs.) torque.

(17) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts.

(18) Place the cylinder head cover gaskets in posi-

tion and install cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(19) Install closed crankcase ventilation system.

(20) Connect the evaporation control system.

(21) Install the air cleaner.

(22) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(23) Connect the negative cable to the battery.

(24) Start engine check for leaks.

Fig. 6 Cylinder Head Bolt Tightening Sequence

9 - 22 ENGINE 5.9LBR/BE

CYLINDER HEAD (Continued)

Page 1115 of 2255

lower rails. Insert oil rail spacer first, then side

rails.

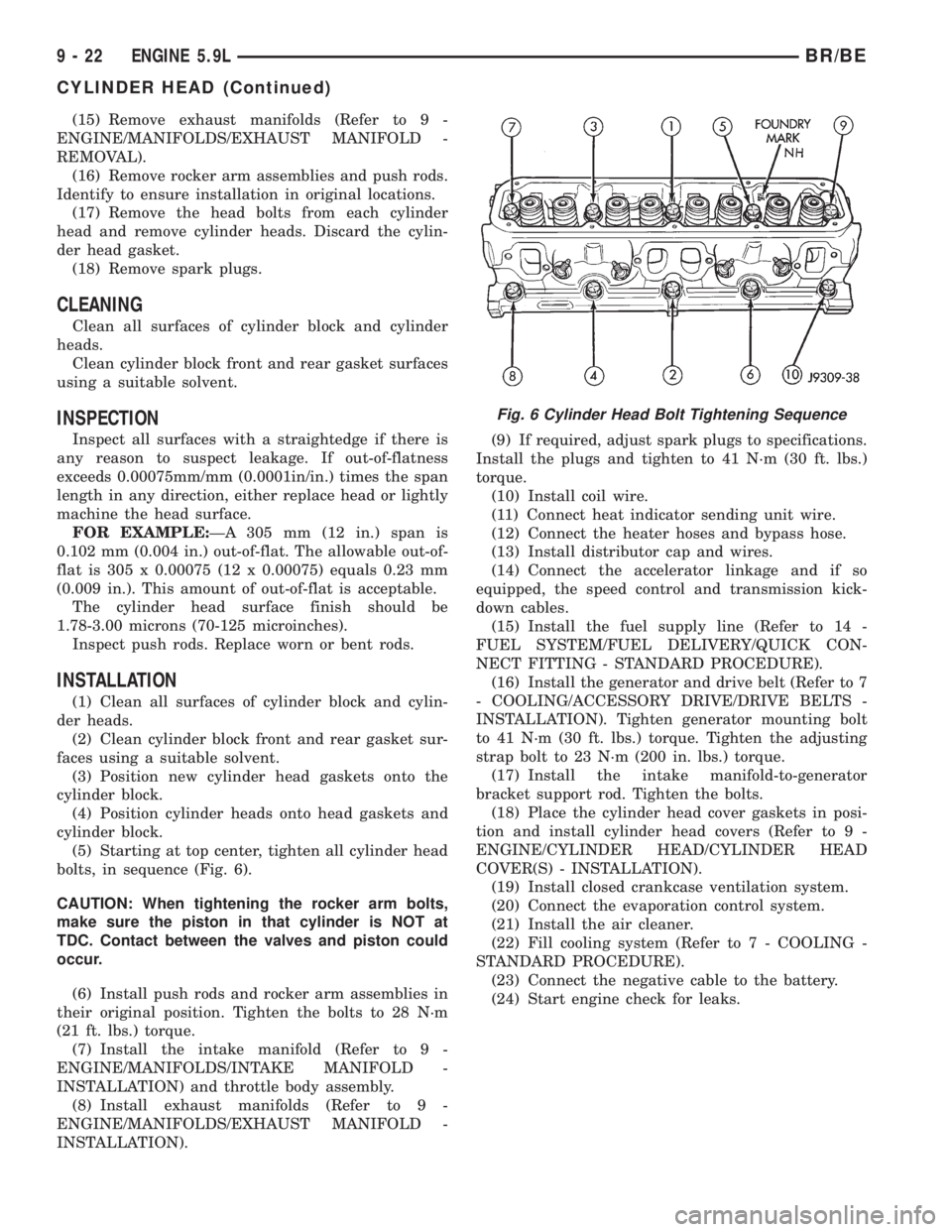

(b) Install the second compression rings using

Installation Tool C-4184. The compression rings

must be installed with the identification mark face

up (toward top of piston) and chamfer facing down.

An identification mark on the ring is a drill point,

a stamped letter ªOº, an oval depression, or the

word ªTOPº (Fig. 39) (Fig. 41).

(c) Using a ring installer, install the top com-

pression ring with the chamfer facing up (Fig. 40)

(Fig. 41). An identification mark on the ring is a

drill point, a stamped letter ªOº, an oval depression

or the word ªTOPº facing up.

(d) Measure side clearance between piston ring

and ring land. Clearance should be 0.074-0.097 mm

(0.0029-0.0038 in.) for the compression rings. The

steel rail oil ring should be free in groove, but

should not exceed 0.246 mm (0.0097 in.) side clear-

ance.

(e) Pistons with insufficient, or excessive, side

clearance should be replaced.

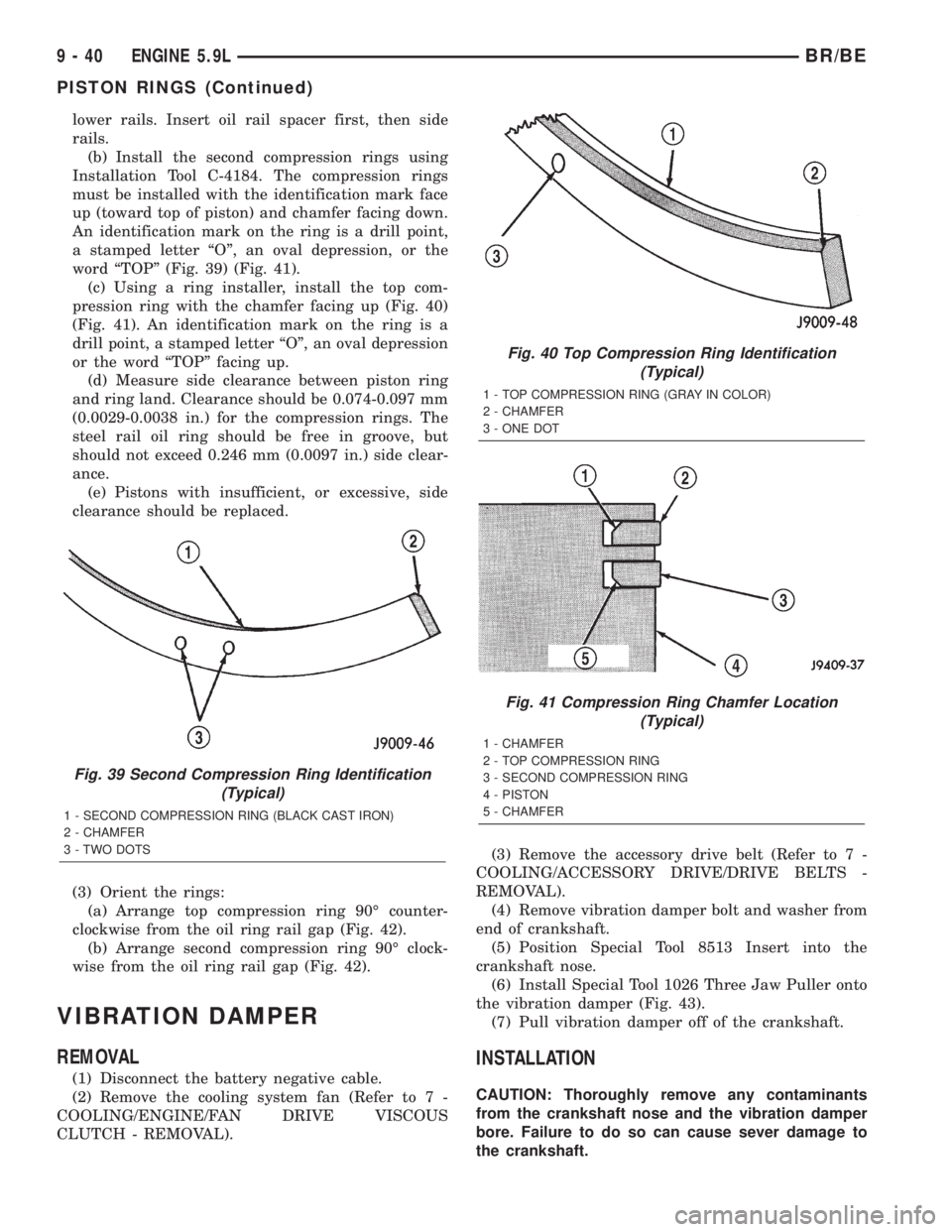

(3) Orient the rings:

(a) Arrange top compression ring 90É counter-

clockwise from the oil ring rail gap (Fig. 42).

(b) Arrange second compression ring 90É clock-

wise from the oil ring rail gap (Fig. 42).

VIBRATION DAMPER

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the cooling system fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove vibration damper bolt and washer from

end of crankshaft.

(5) Position Special Tool 8513 Insert into the

crankshaft nose.

(6) Install Special Tool 1026 Three Jaw Puller onto

the vibration damper (Fig. 43).

(7) Pull vibration damper off of the crankshaft.

INSTALLATION

CAUTION: Thoroughly remove any contaminants

from the crankshaft nose and the vibration damper

bore. Failure to do so can cause sever damage to

the crankshaft.

Fig. 39 Second Compression Ring Identification

(Typical)

1 - SECOND COMPRESSION RING (BLACK CAST IRON)

2 - CHAMFER

3 - TWO DOTS

Fig. 40 Top Compression Ring Identification

(Typical)

1 - TOP COMPRESSION RING (GRAY IN COLOR)

2 - CHAMFER

3 - ONE DOT

Fig. 41 Compression Ring Chamfer Location

(Typical)

1 - CHAMFER

2 - TOP COMPRESSION RING

3 - SECOND COMPRESSION RING

4 - PISTON

5 - CHAMFER

9 - 40 ENGINE 5.9LBR/BE

PISTON RINGS (Continued)

Page 1125 of 2255

(2) Position the oil pump cover onto the pump

body. Tighten cover bolts to 11 N´m (95 in. lbs.)

torque.

(3) Install the relief valve and spring. Insert the

cotter pin.

(4) Tap on a new retainer cap.

(5) Prime oil pump before installation by filling

rotor cavity with engine oil.

INSTALLATION

(1) Install oil pump. During installation slowly

rotate pump body to ensure driveshaft-to-pump rotor

shaft engagement.

(2) Hold the oil pump base flush against mating

surface on No.5 main bearing cap. Finger tighten

pump attaching bolts. Tighten attaching bolts to 41

N´m (30 ft. lbs.) torque.

(3) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

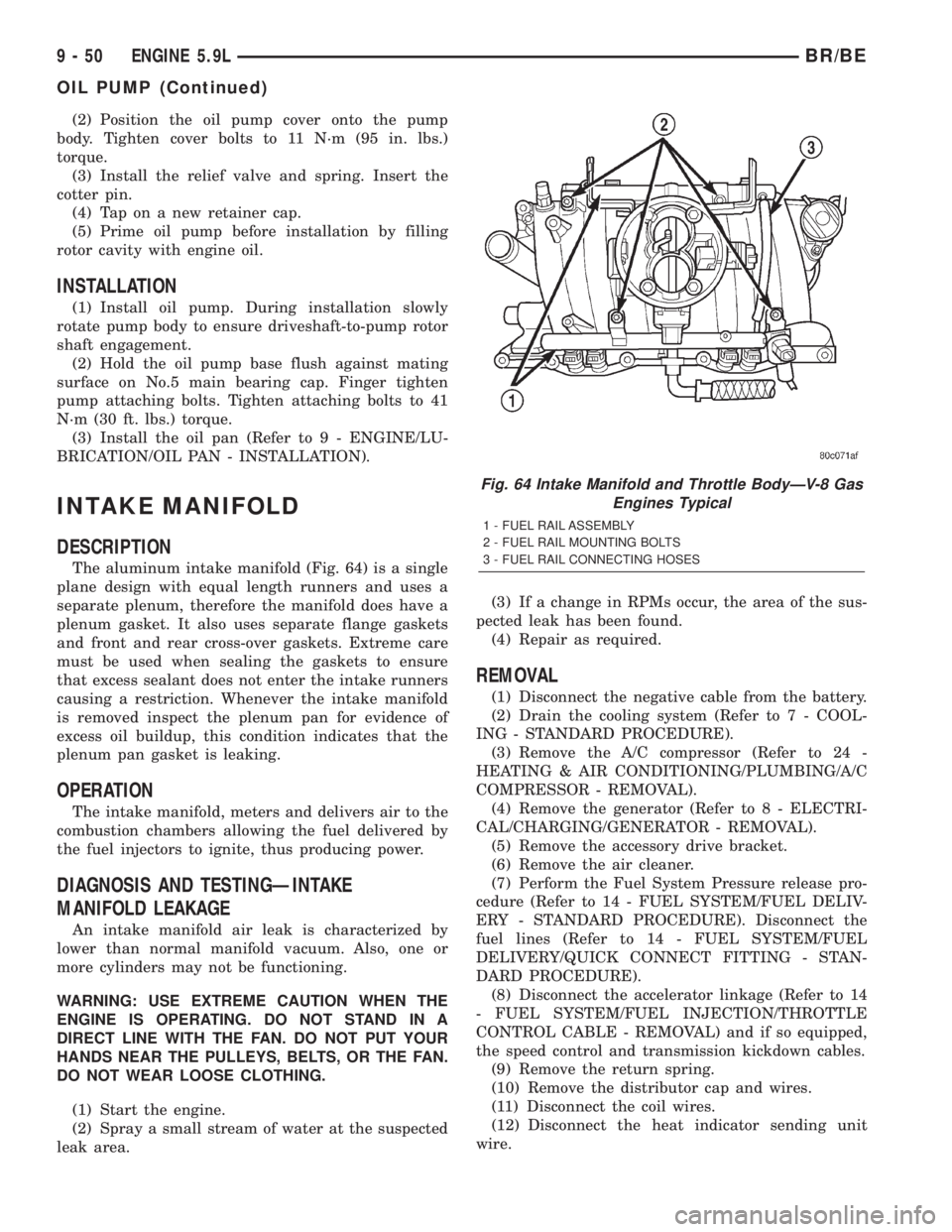

INTAKE MANIFOLD

DESCRIPTION

The aluminum intake manifold (Fig. 64) is a single

plane design with equal length runners and uses a

separate plenum, therefore the manifold does have a

plenum gasket. It also uses separate flange gaskets

and front and rear cross-over gaskets. Extreme care

must be used when sealing the gaskets to ensure

that excess sealant does not enter the intake runners

causing a restriction. Whenever the intake manifold

is removed inspect the plenum pan for evidence of

excess oil buildup, this condition indicates that the

plenum pan gasket is leaking.

OPERATION

The intake manifold, meters and delivers air to the

combustion chambers allowing the fuel delivered by

the fuel injectors to ignite, thus producing power.

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.(3) If a change in RPMs occur, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL).

(4) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(5) Remove the accessory drive bracket.

(6) Remove the air cleaner.

(7) Perform the Fuel System Pressure release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel lines (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect the accelerator linkage (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL) and if so equipped,

the speed control and transmission kickdown cables.

(9) Remove the return spring.

(10) Remove the distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect the heat indicator sending unit

wire.

Fig. 64 Intake Manifold and Throttle BodyÐV-8 Gas

Engines Typical

1 - FUEL RAIL ASSEMBLY

2 - FUEL RAIL MOUNTING BOLTS

3 - FUEL RAIL CONNECTING HOSES

9 - 50 ENGINE 5.9LBR/BE

OIL PUMP (Continued)

Page 1127 of 2255

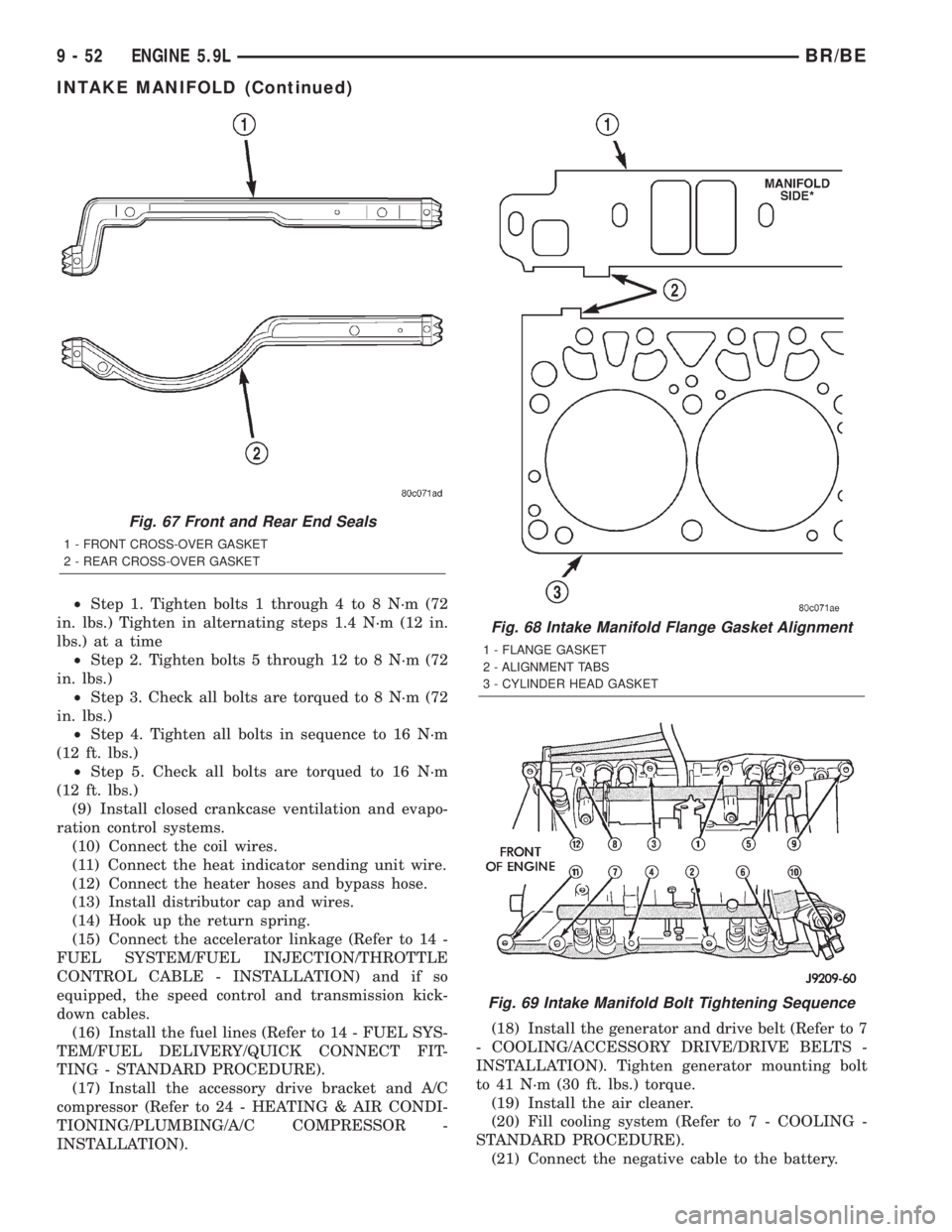

²Step 1. Tighten bolts 1 through 4 to 8 N´m (72

in. lbs.) Tighten in alternating steps 1.4 N´m (12 in.

lbs.) at a time

²Step 2. Tighten bolts 5 through 12 to 8 N´m (72

in. lbs.)

²Step 3. Check all bolts are torqued to 8 N´m (72

in. lbs.)

²Step 4. Tighten all bolts in sequence to 16 N´m

(12 ft. lbs.)

²Step 5. Check all bolts are torqued to 16 N´m

(12 ft. lbs.)

(9) Install closed crankcase ventilation and evapo-

ration control systems.

(10) Connect the coil wires.

(11) Connect the heat indicator sending unit wire.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Hook up the return spring.

(15) Connect the accelerator linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION) and if so

equipped, the speed control and transmission kick-

down cables.

(16) Install the fuel lines (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(17) Install the accessory drive bracket and A/C

compressor (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION).(18) Install the generator and drive belt (Refer to 7

- COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION). Tighten generator mounting bolt

to 41 N´m (30 ft. lbs.) torque.

(19) Install the air cleaner.

(20) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(21) Connect the negative cable to the battery.

Fig. 67 Front and Rear End Seals

1 - FRONT CROSS-OVER GASKET

2 - REAR CROSS-OVER GASKET

Fig. 68 Intake Manifold Flange Gasket Alignment

1 - FLANGE GASKET

2 - ALIGNMENT TABS

3 - CYLINDER HEAD GASKET

Fig. 69 Intake Manifold Bolt Tightening Sequence

9 - 52 ENGINE 5.9LBR/BE

INTAKE MANIFOLD (Continued)