clock DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 241 of 2255

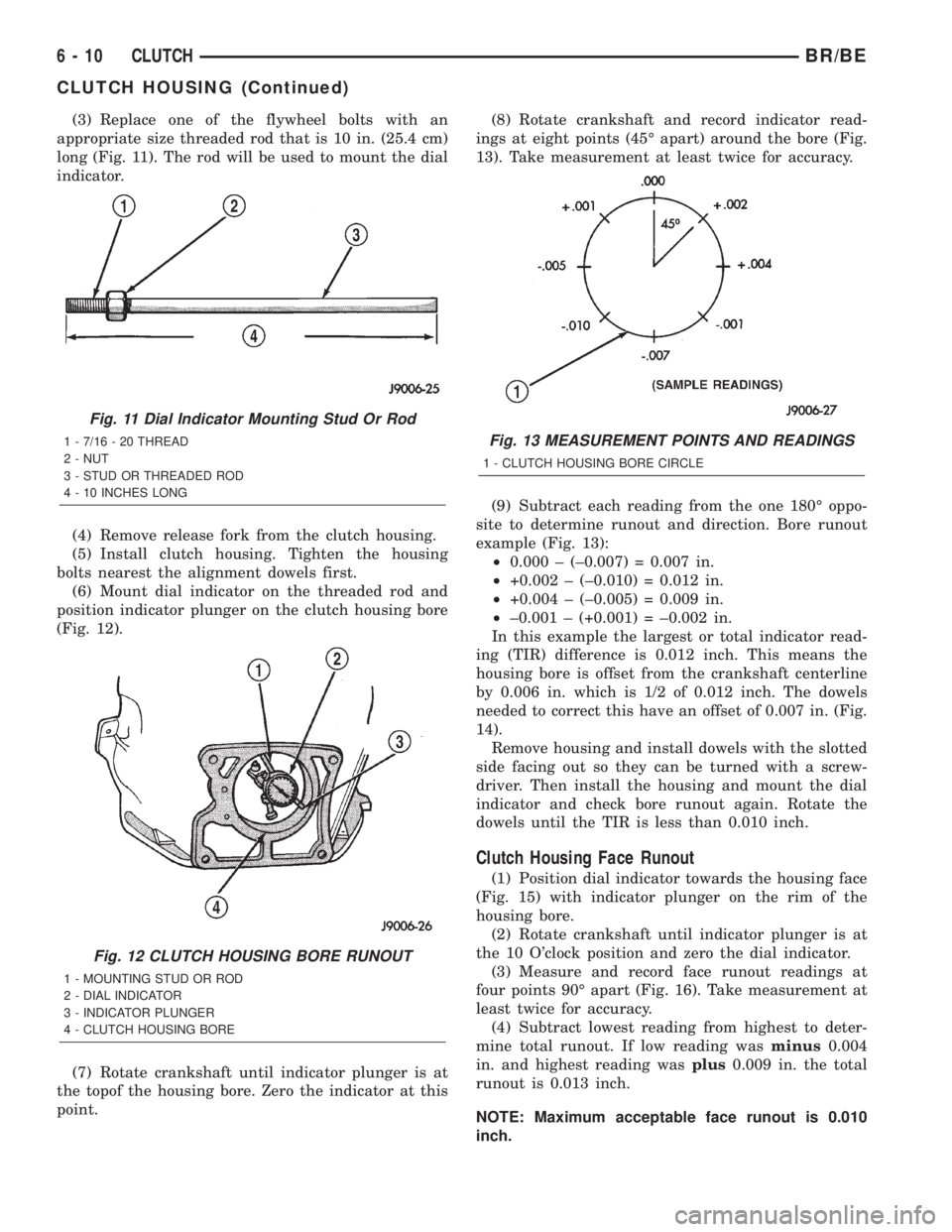

(3) Replace one of the flywheel bolts with an

appropriate size threaded rod that is 10 in. (25.4 cm)

long (Fig. 11). The rod will be used to mount the dial

indicator.

(4) Remove release fork from the clutch housing.

(5) Install clutch housing. Tighten the housing

bolts nearest the alignment dowels first.

(6) Mount dial indicator on the threaded rod and

position indicator plunger on the clutch housing bore

(Fig. 12).

(7) Rotate crankshaft until indicator plunger is at

the topof the housing bore. Zero the indicator at this

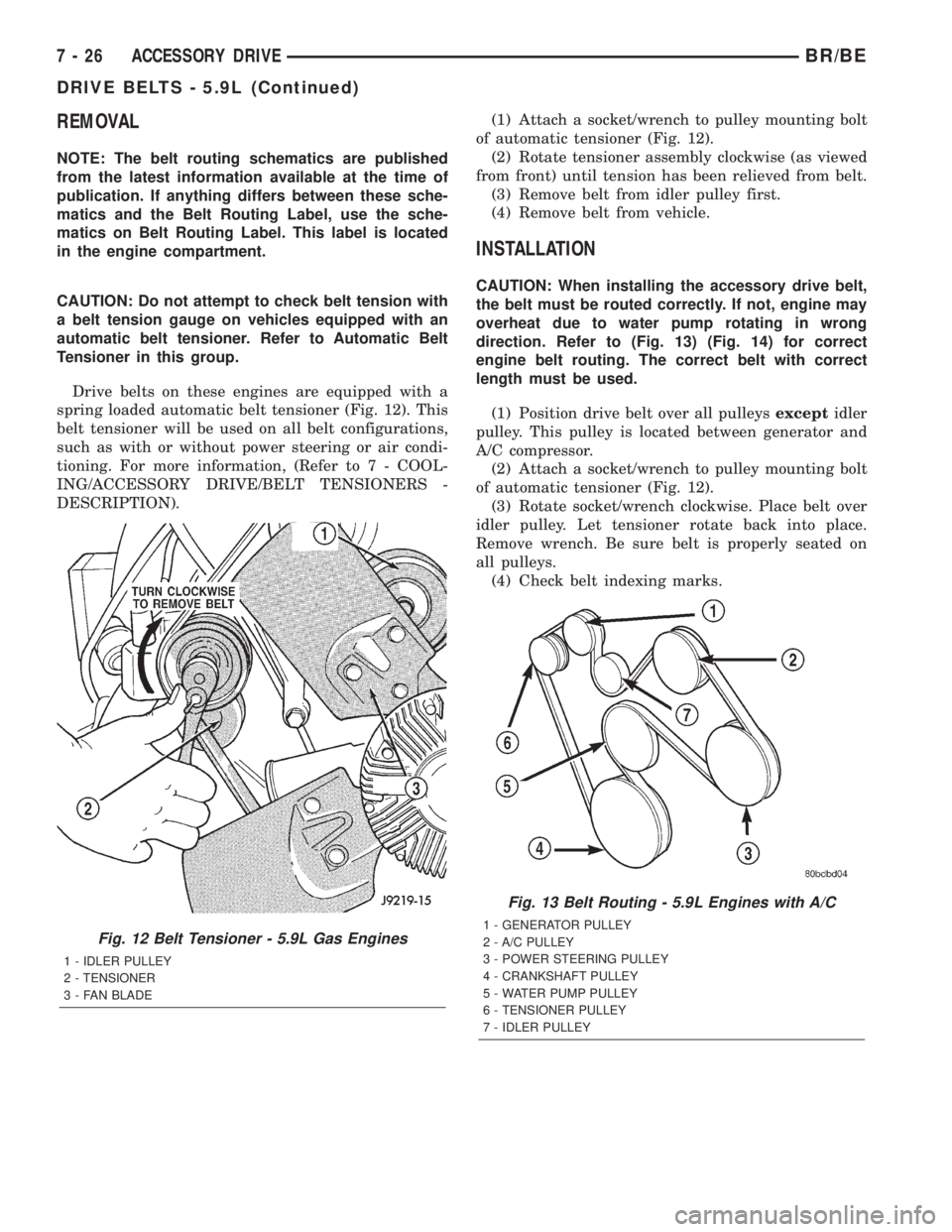

point.(8) Rotate crankshaft and record indicator read-

ings at eight points (45É apart) around the bore (Fig.

13). Take measurement at least twice for accuracy.

(9) Subtract each reading from the one 180É oppo-

site to determine runout and direction. Bore runout

example (Fig. 13):

²0.000 ± (±0.007) = 0.007 in.

²+0.002 ± (±0.010) = 0.012 in.

²+0.004 ± (±0.005) = 0.009 in.

²±0.001 ± (+0.001) = ±0.002 in.

In this example the largest or total indicator read-

ing (TIR) difference is 0.012 inch. This means the

housing bore is offset from the crankshaft centerline

by 0.006 in. which is 1/2 of 0.012 inch. The dowels

needed to correct this have an offset of 0.007 in. (Fig.

14).

Remove housing and install dowels with the slotted

side facing out so they can be turned with a screw-

driver. Then install the housing and mount the dial

indicator and check bore runout again. Rotate the

dowels until the TIR is less than 0.010 inch.

Clutch Housing Face Runout

(1) Position dial indicator towards the housing face

(Fig. 15) with indicator plunger on the rim of the

housing bore.

(2) Rotate crankshaft until indicator plunger is at

the 10 O'clock position and zero the dial indicator.

(3) Measure and record face runout readings at

four points 90É apart (Fig. 16). Take measurement at

least twice for accuracy.

(4) Subtract lowest reading from highest to deter-

mine total runout. If low reading wasminus0.004

in. and highest reading wasplus0.009 in. the total

runout is 0.013 inch.

NOTE: Maximum acceptable face runout is 0.010

inch.

Fig. 11 Dial Indicator Mounting Stud Or Rod

1 - 7/16 - 20 THREAD

2 - NUT

3 - STUD OR THREADED ROD

4 - 10 INCHES LONG

Fig. 12 CLUTCH HOUSING BORE RUNOUT

1 - MOUNTING STUD OR ROD

2 - DIAL INDICATOR

3 - INDICATOR PLUNGER

4 - CLUTCH HOUSING BORE

Fig. 13 MEASUREMENT POINTS AND READINGS

1 - CLUTCH HOUSING BORE CIRCLE

6 - 10 CLUTCHBR/BE

CLUTCH HOUSING (Continued)

Page 275 of 2255

REMOVAL

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label. This label is located

in the engine compartment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

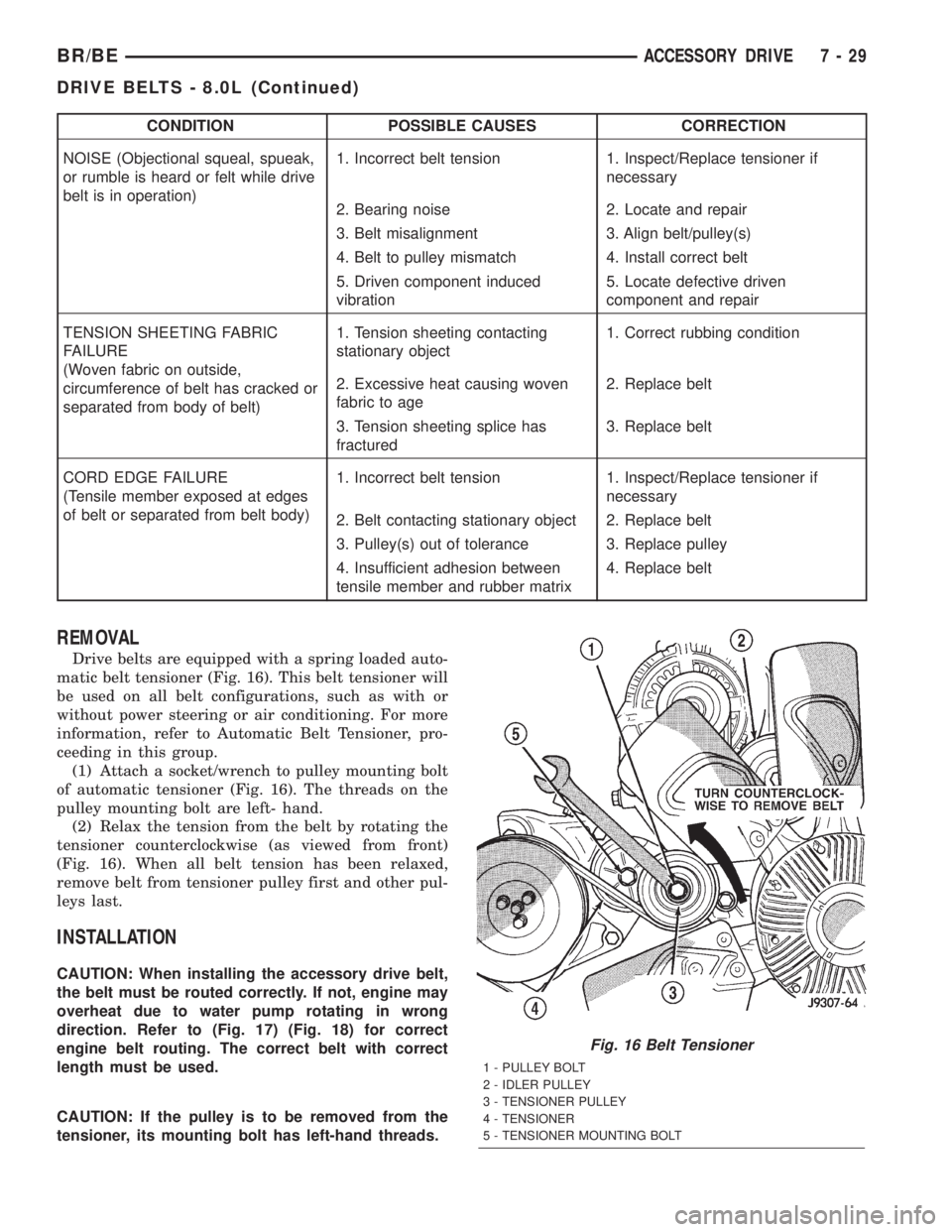

Drive belts on these engines are equipped with a

spring loaded automatic belt tensioner (Fig. 12). This

belt tensioner will be used on all belt configurations,

such as with or without power steering or air condi-

tioning. For more information, (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELT TENSIONERS -

DESCRIPTION).(1) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 12).

(2) Rotate tensioner assembly clockwise (as viewed

from front) until tension has been relieved from belt.

(3) Remove belt from idler pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 13) (Fig. 14) for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleysexceptidler

pulley. This pulley is located between generator and

A/C compressor.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 12).

(3) Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place.

Remove wrench. Be sure belt is properly seated on

all pulleys.

(4) Check belt indexing marks.

Fig. 12 Belt Tensioner - 5.9L Gas Engines

1 - IDLER PULLEY

2 - TENSIONER

3 - FAN BLADE

Fig. 13 Belt Routing - 5.9L Engines with A/C

1 - GENERATOR PULLEY

2 - A/C PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

7 - IDLER PULLEY

7 - 26 ACCESSORY DRIVEBR/BE

DRIVE BELTS - 5.9L (Continued)

Page 278 of 2255

CONDITION POSSIBLE CAUSES CORRECTION

NOISE (Objectional squeal, spueak,

or rumble is heard or felt while drive

belt is in operation)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration5. Locate defective driven

component and repair

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has cracked or

separated from body of belt)1. Tension sheeting contacting

stationary object1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age2. Replace belt

3. Tension sheeting splice has

fractured3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

REMOVAL

Drive belts are equipped with a spring loaded auto-

matic belt tensioner (Fig. 16). This belt tensioner will

be used on all belt configurations, such as with or

without power steering or air conditioning. For more

information, refer to Automatic Belt Tensioner, pro-

ceeding in this group.

(1) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 16). The threads on the

pulley mounting bolt are left- hand.

(2) Relax the tension from the belt by rotating the

tensioner counterclockwise (as viewed from front)

(Fig. 16). When all belt tension has been relaxed,

remove belt from tensioner pulley first and other pul-

leys last.

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 17) (Fig. 18) for correct

engine belt routing. The correct belt with correct

length must be used.

CAUTION: If the pulley is to be removed from the

tensioner, its mounting bolt has left-hand threads.

Fig. 16 Belt Tensioner

1 - PULLEY BOLT

2 - IDLER PULLEY

3 - TENSIONER PULLEY

4 - TENSIONER

5 - TENSIONER MOUNTING BOLT

BR/BEACCESSORY DRIVE 7 - 29

DRIVE BELTS - 8.0L (Continued)

Page 279 of 2255

(1) Position drive belt over all pulleysexceptten-

sioner pulley.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 16).

(3) Rotate socket/wrench counterclockwise. Install

belt over tensioner pulley. Let tensioner rotate back

into place. Remove wrench. Be sure belt is properly

seated on all pulleys.

DRIVE BELTS - 5.9L DIESEL

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

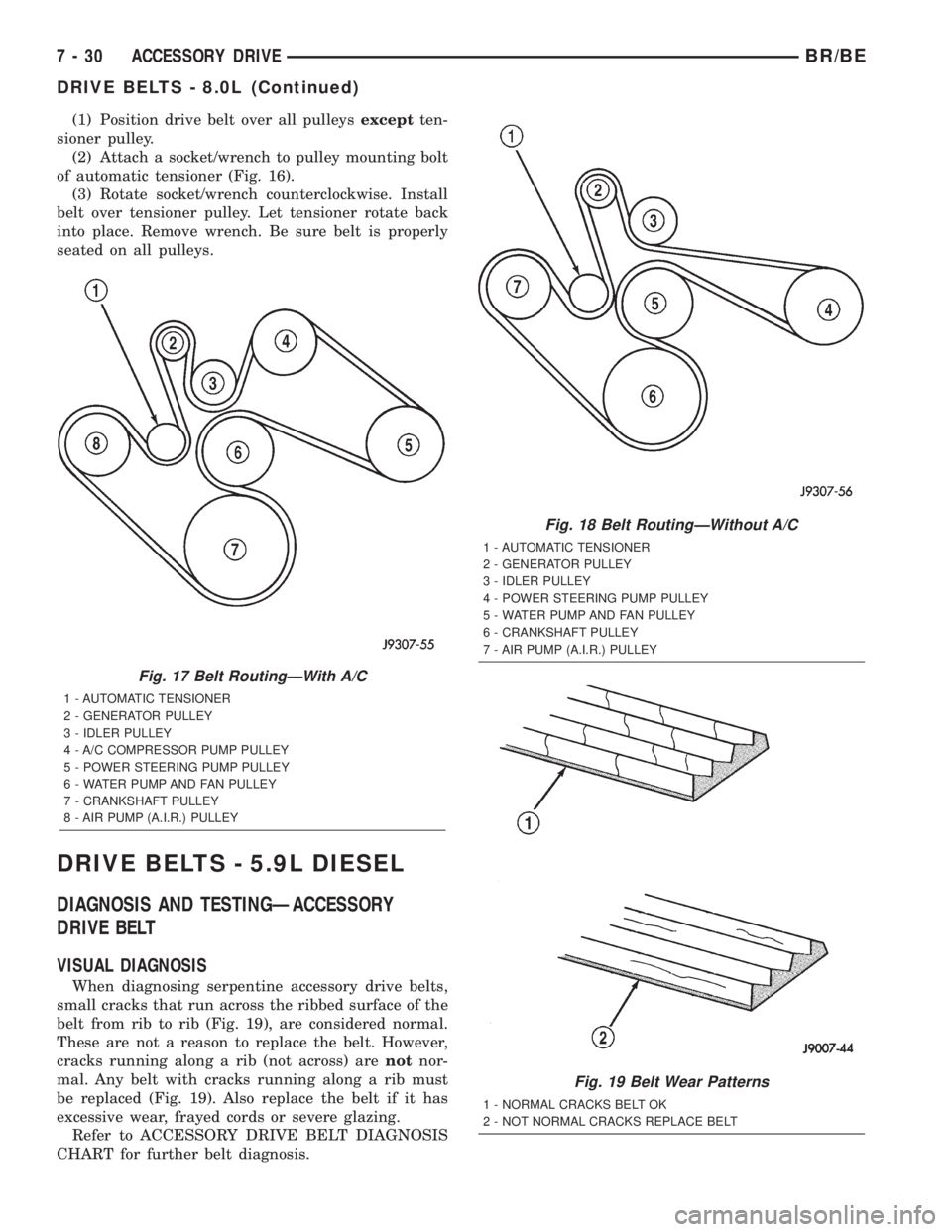

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 19), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 19). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

Fig. 17 Belt RoutingÐWith A/C

1 - AUTOMATIC TENSIONER

2 - GENERATOR PULLEY

3 - IDLER PULLEY

4 - A/C COMPRESSOR PUMP PULLEY

5 - POWER STEERING PUMP PULLEY

6 - WATER PUMP AND FAN PULLEY

7 - CRANKSHAFT PULLEY

8 - AIR PUMP (A.I.R.) PULLEY

Fig. 18 Belt RoutingÐWithout A/C

1 - AUTOMATIC TENSIONER

2 - GENERATOR PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - WATER PUMP AND FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AIR PUMP (A.I.R.) PULLEY

Fig. 19 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

7 - 30 ACCESSORY DRIVEBR/BE

DRIVE BELTS - 8.0L (Continued)

Page 281 of 2255

CONDITION POSSIBLE CAUSES CORRECTION

BELT BROKEN

(Note: Identify and correct problem

before new belt is installed)1. Incorrect belt tension 1. Replace Inspect/Replace

tensioner if necessary

2. Tensile member damaged during

belt installation2. Replace belt

3. Severe misalignment 3. Align pulley(s)

4. Bracket, pulley, or bearing failure 4. Replace defective component

and belt

NOISE (Objectional squeal, spueak,

or rumble is heard or felt while drive

belt is in operation)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration5. Locate defective driven

component and repair

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has cracked or

separated from body of belt)1. Tension sheeting contacting

stationary object1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age2. Replace belt

3. Tension sheeting splice has

fractured3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

REMOVAL

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

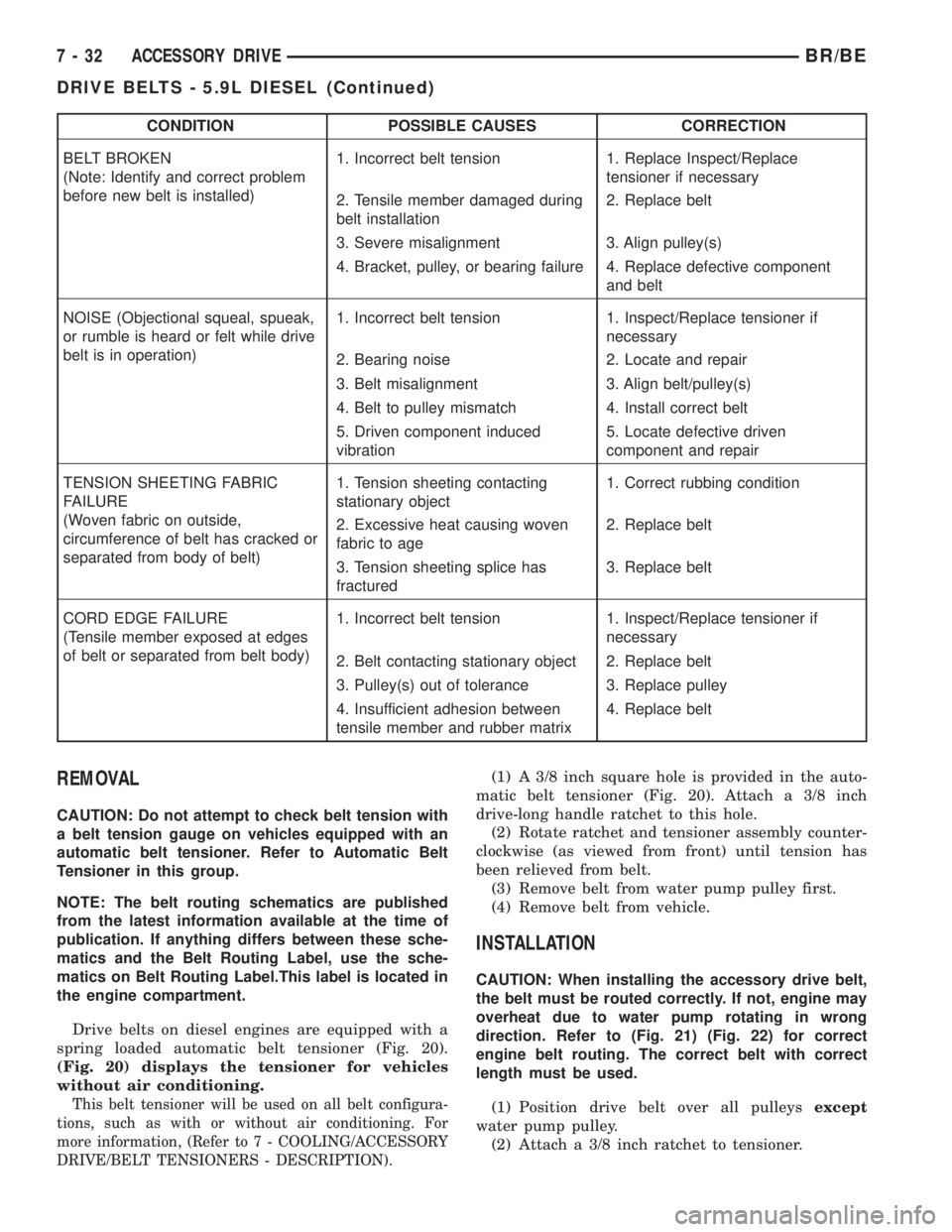

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner (Fig. 20).

(Fig. 20) displays the tensioner for vehicles

without air conditioning.

This belt tensioner will be used on all belt configura-

tions, such as with or without air conditioning. For

more information, (Refer to 7 - COOLING/ACCESSORY

DRIVE/BELT TENSIONERS - DESCRIPTION).

(1) A 3/8 inch square hole is provided in the auto-

matic belt tensioner (Fig. 20). Attach a 3/8 inch

drive-long handle ratchet to this hole.

(2) Rotate ratchet and tensioner assembly counter-

clockwise (as viewed from front) until tension has

been relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

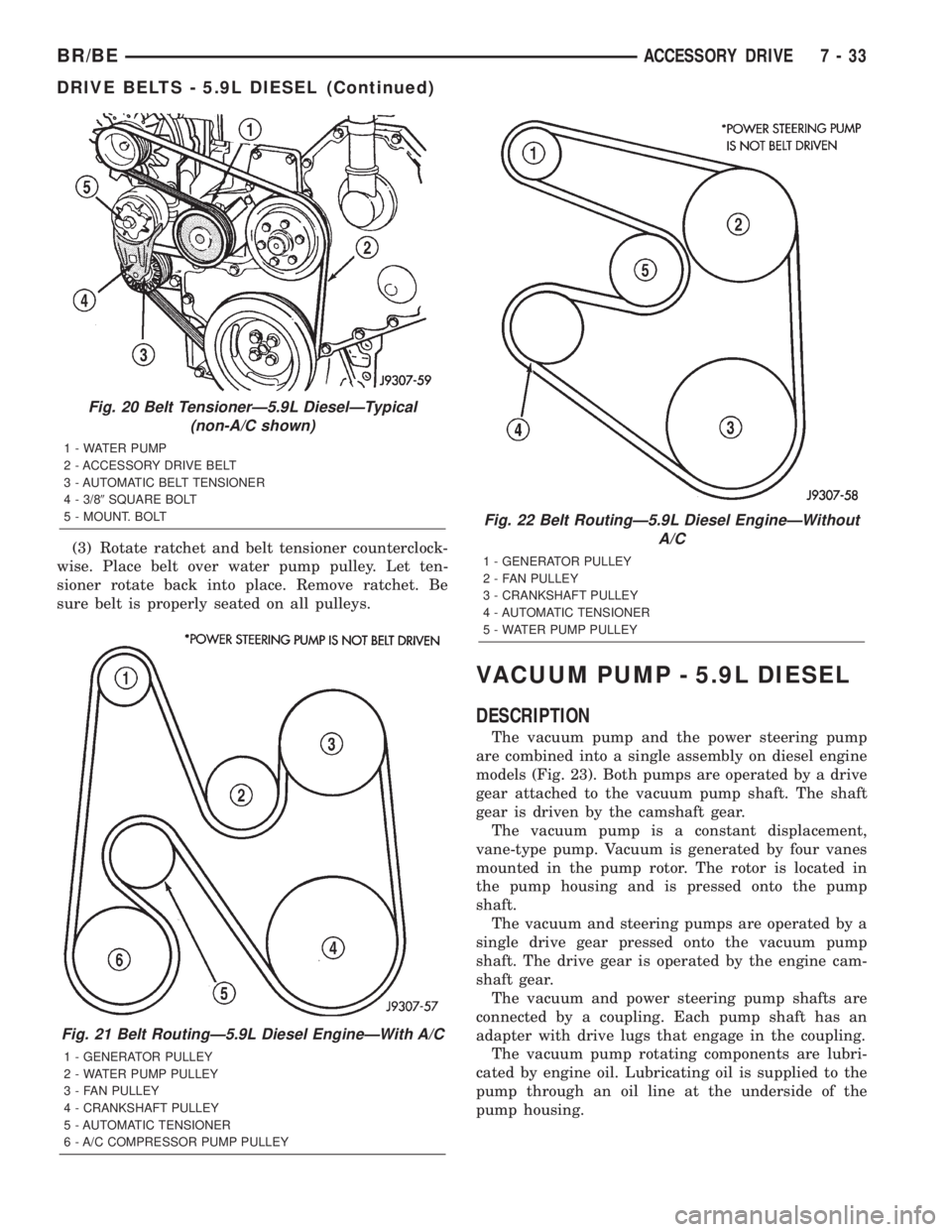

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 21) (Fig. 22) for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleysexcept

water pump pulley.

(2) Attach a 3/8 inch ratchet to tensioner.

7 - 32 ACCESSORY DRIVEBR/BE

DRIVE BELTS - 5.9L DIESEL (Continued)

Page 282 of 2255

(3) Rotate ratchet and belt tensioner counterclock-

wise. Place belt over water pump pulley. Let ten-

sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

VACUUM PUMP - 5.9L DIESEL

DESCRIPTION

The vacuum pump and the power steering pump

are combined into a single assembly on diesel engine

models (Fig. 23). Both pumps are operated by a drive

gear attached to the vacuum pump shaft. The shaft

gear is driven by the camshaft gear.

The vacuum pump is a constant displacement,

vane-type pump. Vacuum is generated by four vanes

mounted in the pump rotor. The rotor is located in

the pump housing and is pressed onto the pump

shaft.

The vacuum and steering pumps are operated by a

single drive gear pressed onto the vacuum pump

shaft. The drive gear is operated by the engine cam-

shaft gear.

The vacuum and power steering pump shafts are

connected by a coupling. Each pump shaft has an

adapter with drive lugs that engage in the coupling.

The vacuum pump rotating components are lubri-

cated by engine oil. Lubricating oil is supplied to the

pump through an oil line at the underside of the

pump housing.

Fig. 20 Belt TensionerÐ5.9L DieselÐTypical

(non-A/C shown)

1 - WATER PUMP

2 - ACCESSORY DRIVE BELT

3 - AUTOMATIC BELT TENSIONER

4 - 3/89SQUARE BOLT

5 - MOUNT. BOLT

Fig. 21 Belt RoutingÐ5.9L Diesel EngineÐWith A/C

1 - GENERATOR PULLEY

2 - WATER PUMP PULLEY

3 - FAN PULLEY

4 - CRANKSHAFT PULLEY

5 - AUTOMATIC TENSIONER

6 - A/C COMPRESSOR PUMP PULLEY

Fig. 22 Belt RoutingÐ5.9L Diesel EngineÐWithout

A/C

1 - GENERATOR PULLEY

2 - FAN PULLEY

3 - CRANKSHAFT PULLEY

4 - AUTOMATIC TENSIONER

5 - WATER PUMP PULLEY

BR/BEACCESSORY DRIVE 7 - 33

DRIVE BELTS - 5.9L DIESEL (Continued)

Page 290 of 2255

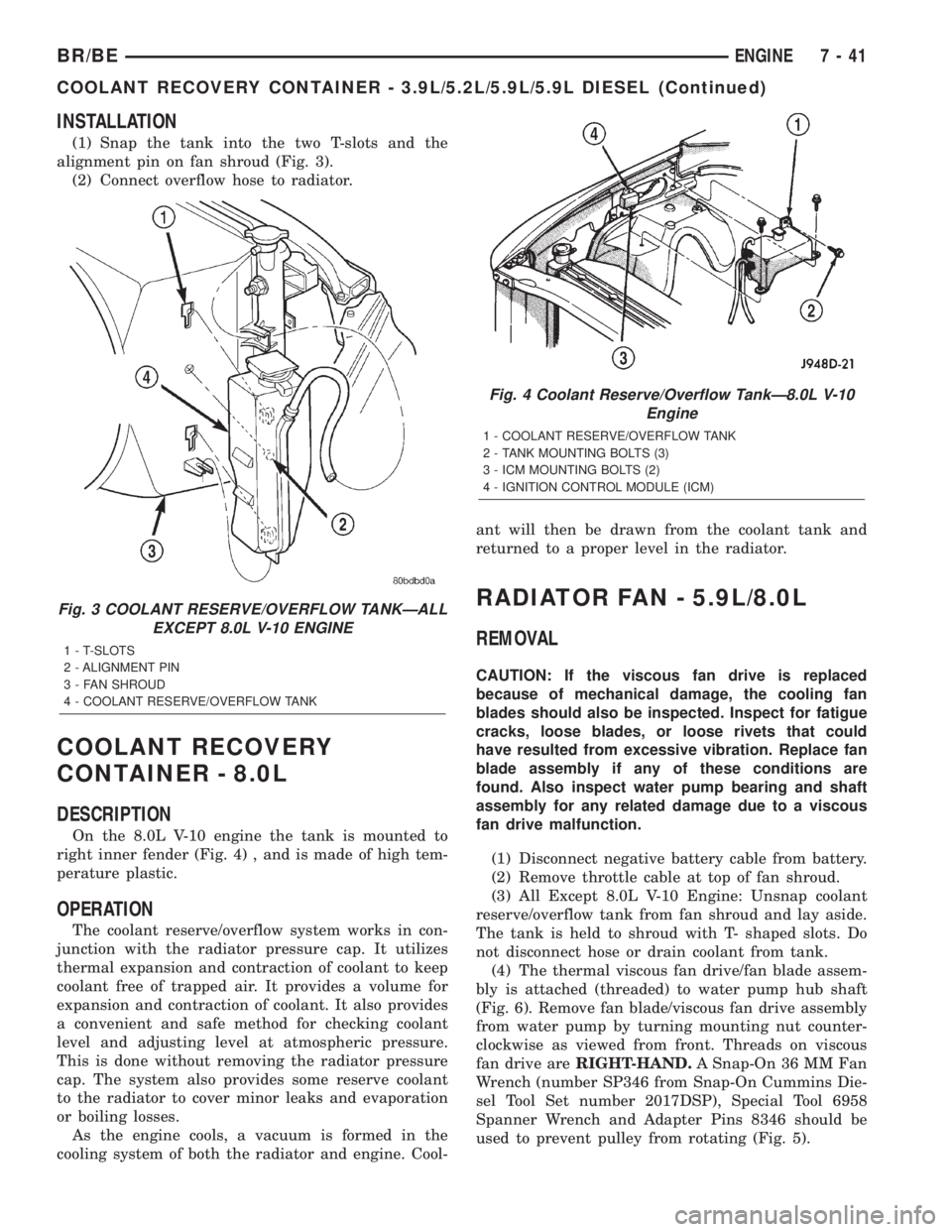

INSTALLATION

(1) Snap the tank into the two T-slots and the

alignment pin on fan shroud (Fig. 3).

(2) Connect overflow hose to radiator.

COOLANT RECOVERY

CONTAINER - 8.0L

DESCRIPTION

On the 8.0L V-10 engine the tank is mounted to

right inner fender (Fig. 4) , and is made of high tem-

perature plastic.

OPERATION

The coolant reserve/overflow system works in con-

junction with the radiator pressure cap. It utilizes

thermal expansion and contraction of coolant to keep

coolant free of trapped air. It provides a volume for

expansion and contraction of coolant. It also provides

a convenient and safe method for checking coolant

level and adjusting level at atmospheric pressure.

This is done without removing the radiator pressure

cap. The system also provides some reserve coolant

to the radiator to cover minor leaks and evaporation

or boiling losses.

As the engine cools, a vacuum is formed in the

cooling system of both the radiator and engine. Cool-ant will then be drawn from the coolant tank and

returned to a proper level in the radiator.

RADIATOR FAN - 5.9L/8.0L

REMOVAL

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks, loose blades, or loose rivets that could

have resulted from excessive vibration. Replace fan

blade assembly if any of these conditions are

found. Also inspect water pump bearing and shaft

assembly for any related damage due to a viscous

fan drive malfunction.

(1) Disconnect negative battery cable from battery.

(2) Remove throttle cable at top of fan shroud.

(3) All Except 8.0L V-10 Engine: Unsnap coolant

reserve/overflow tank from fan shroud and lay aside.

The tank is held to shroud with T- shaped slots. Do

not disconnect hose or drain coolant from tank.

(4) The thermal viscous fan drive/fan blade assem-

bly is attached (threaded) to water pump hub shaft

(Fig. 6). Remove fan blade/viscous fan drive assembly

from water pump by turning mounting nut counter-

clockwise as viewed from front. Threads on viscous

fan drive areRIGHT-HAND.A Snap-On 36 MM Fan

Wrench (number SP346 from Snap-On Cummins Die-

sel Tool Set number 2017DSP), Special Tool 6958

Spanner Wrench and Adapter Pins 8346 should be

used to prevent pulley from rotating (Fig. 5).

Fig. 3 COOLANT RESERVE/OVERFLOW TANKÐALL

EXCEPT 8.0L V-10 ENGINE

1 - T-SLOTS

2 - ALIGNMENT PIN

3 - FAN SHROUD

4 - COOLANT RESERVE/OVERFLOW TANK

Fig. 4 Coolant Reserve/Overflow TankÐ8.0L V-10

Engine

1 - COOLANT RESERVE/OVERFLOW TANK

2 - TANK MOUNTING BOLTS (3)

3 - ICM MOUNTING BOLTS (2)

4 - IGNITION CONTROL MODULE (ICM)

BR/BEENGINE 7 - 41

COOLANT RECOVERY CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL (Continued)

Page 292 of 2255

(4) Install fan blade/viscous fan drive assembly to

water pump shaft (Fig. 6).

(5) Except 8.0L V-10 Engine: Install coolant

reserve/overflow tank to fan shroud. Snaps into posi-

tion.

(6) Install throttle cable to fan shroud.

(7) Connect negative battery cable.

NOTE:

Viscous Fan Drive Fluid Pump Out Requirement:

After installing a new viscous fan drive, bring the

engine speed up to approximately 2000 rpm and

hold for approximately two minutes. This will

ensure proper fluid distribution within the drive.

RADIATOR FAN - 5.9L DIESEL

REMOVAL

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks, loose blades, or loose rivets that could

have resulted from excessive vibration. Replace fan

blade assembly if any of these conditions are

found. Also inspect water pump bearing and shaft

assembly for any related damage due to a viscous

fan drive malfunction.

(1) Disconnect the battery negative cables.

(2) Remove the fan shroud mounting bolts. Posi-

tion fan shroud towards engine.

CAUTION: Do not remove the fan pulley bolts. This

pulley is under spring tension.

(3) The thermal viscous fan drive/fan blade assem-

bly is attached (threaded) to the fan hub shaft (Fig.

7). Remove the fan blade/fan drive assembly from fan

pulley by turning the mounting nut clockwise (as

viewed from front). Threads on the viscous fan drive

areLEFT-HAND.A Snap-On 36 MM Fan Wrench

(number SP346 from Snap-On Cummins Diesel Tool

Set number 2017DSP) can be used. Place a bar or

screwdriver between the fan pulley bolts to prevent

pulley from rotating.

(4) Remove the fan shroud and the fan blade/vis-

cous drive as an assembly from vehicle.

(5) Remove fan blade-to-viscous fan drive mount-

ing bolts.

(6) Inspect the fan for cracks, loose rivets, loose or

bent fan blades.

CAUTION: Some engines equipped with serpentine

drive belts have reverse rotating fans and viscous

fan drives. They are marked with the wordREVERSE to designate their usage. Installation of

the wrong fan or viscous fan drive can result in

engine overheating.

CLEANING

Clean the fan blades using a mild soap and water.

Do not use an abrasive to clean the blades.

INSPECTION

WARNING: DO NOT ATTEMPT TO BEND OR

STRAIGHTEN FAN BLADES IF FAN IS NOT WITHIN

SPECIFICATIONS.

CAUTION: If fan blade assembly is replaced

because of mechanical damage, water pump and

viscous fan drive should also be inspected. These

components could have been damaged due to

excessive vibration.

(1) Remove fan blade assembly from viscous fan

drive unit (four bolts).

(2) Lay fan on a flat surface with leading edge fac-

ing down. With tip of blade touching flat surface,

replace fan if clearance between opposite blade and

surface is greater than 2.0 mm (.090 inch). Rocking

motion of opposite blades should not exceed 2.0 mm

(.090 inch). Test all blades in this manner.

(3) Inspect fan assembly for cracks, bends, loose

rivets or broken welds. Replace fan if any damage is

found.

Fig. 7 Fan Blade/Viscous Fan Drive

1 - THREADED SHAFT

2 - BOLT (4)

3 - FAN BLADE

4 - THREADED NUT

5 - VISCOUS FAN DRIVE

BR/BEENGINE 7 - 43

RADIATOR FAN - 5.9L/8.0L (Continued)

Page 314 of 2255

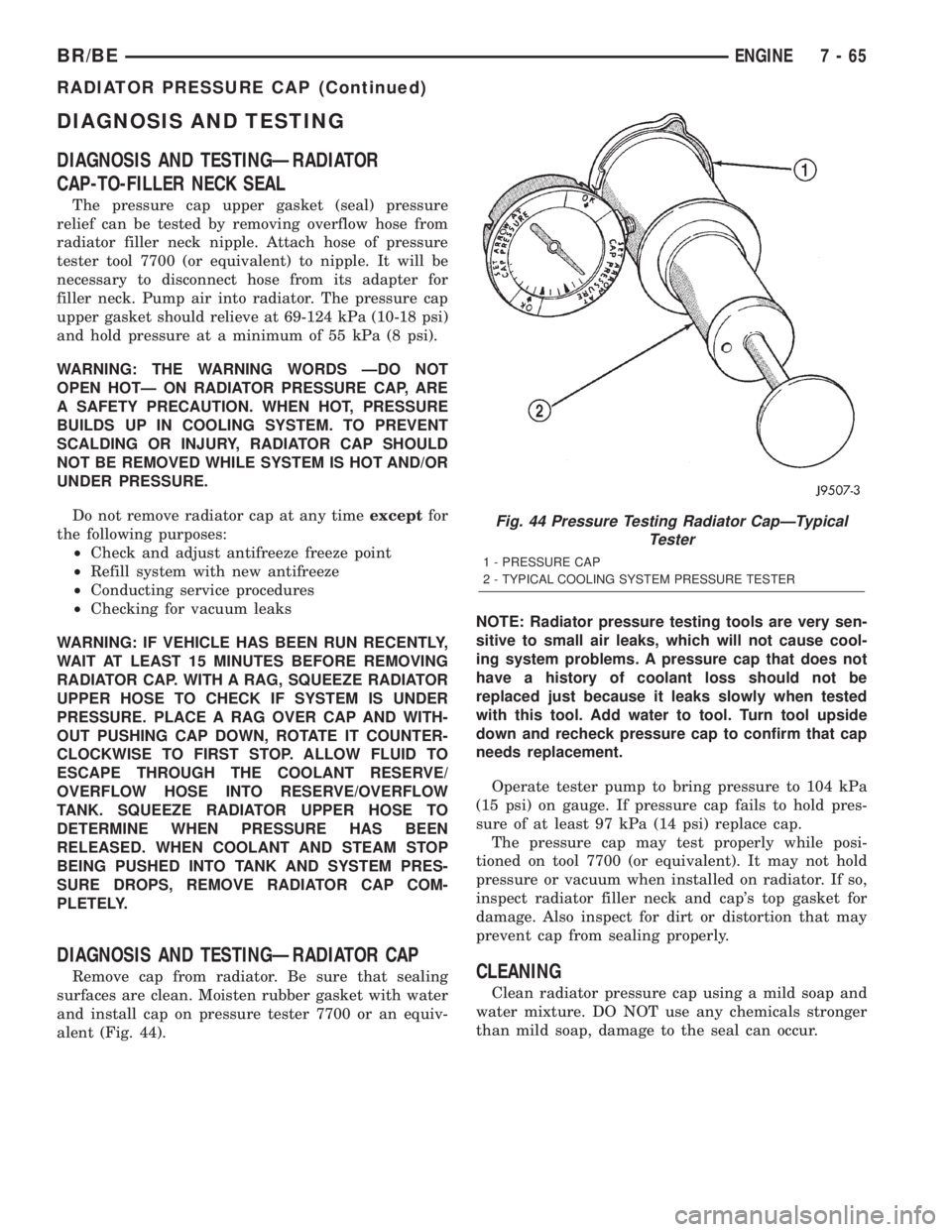

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐRADIATOR

CAP-TO-FILLER NECK SEAL

The pressure cap upper gasket (seal) pressure

relief can be tested by removing overflow hose from

radiator filler neck nipple. Attach hose of pressure

tester tool 7700 (or equivalent) to nipple. It will be

necessary to disconnect hose from its adapter for

filler neck. Pump air into radiator. The pressure cap

upper gasket should relieve at 69-124 kPa (10-18 psi)

and hold pressure at a minimum of 55 kPa (8 psi).

WARNING: THE WARNING WORDS ÐDO NOT

OPEN HOTÐ ON RADIATOR PRESSURE CAP, ARE

A SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, RADIATOR CAP SHOULD

NOT BE REMOVED WHILE SYSTEM IS HOT AND/OR

UNDER PRESSURE.

Do not remove radiator cap at any timeexceptfor

the following purposes:

²Check and adjust antifreeze freeze point

²Refill system with new antifreeze

²Conducting service procedures

²Checking for vacuum leaks

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT AT LEAST 15 MINUTES BEFORE REMOVING

RADIATOR CAP. WITH A RAG, SQUEEZE RADIATOR

UPPER HOSE TO CHECK IF SYSTEM IS UNDER

PRESSURE. PLACE A RAG OVER CAP AND WITH-

OUT PUSHING CAP DOWN, ROTATE IT COUNTER-

CLOCKWISE TO FIRST STOP. ALLOW FLUID TO

ESCAPE THROUGH THE COOLANT RESERVE/

OVERFLOW HOSE INTO RESERVE/OVERFLOW

TANK. SQUEEZE RADIATOR UPPER HOSE TO

DETERMINE WHEN PRESSURE HAS BEEN

RELEASED. WHEN COOLANT AND STEAM STOP

BEING PUSHED INTO TANK AND SYSTEM PRES-

SURE DROPS, REMOVE RADIATOR CAP COM-

PLETELY.

DIAGNOSIS AND TESTINGÐRADIATOR CAP

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install cap on pressure tester 7700 or an equiv-

alent (Fig. 44).NOTE: Radiator pressure testing tools are very sen-

sitive to small air leaks, which will not cause cool-

ing system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to tool. Turn tool upside

down and recheck pressure cap to confirm that cap

needs replacement.

Operate tester pump to bring pressure to 104 kPa

(15 psi) on gauge. If pressure cap fails to hold pres-

sure of at least 97 kPa (14 psi) replace cap.

The pressure cap may test properly while posi-

tioned on tool 7700 (or equivalent). It may not hold

pressure or vacuum when installed on radiator. If so,

inspect radiator filler neck and cap's top gasket for

damage. Also inspect for dirt or distortion that may

prevent cap from sealing properly.CLEANING

Clean radiator pressure cap using a mild soap and

water mixture. DO NOT use any chemicals stronger

than mild soap, damage to the seal can occur.

Fig. 44 Pressure Testing Radiator CapÐTypical

Tester

1 - PRESSURE CAP

2 - TYPICAL COOLING SYSTEM PRESSURE TESTER

BR/BEENGINE 7 - 65

RADIATOR PRESSURE CAP (Continued)

Page 316 of 2255

(3) Remove windshield washer reservoir tank from

radiator fan shroud.

(4) Disconnect the coolant reserve/overflow tank-

to-radiator hose at the tank.

(5) Remove the four fan shroud mounting bolts at

the radiator (Fig. 47). Do not attempt to remove

shroud from vehicle at this time.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094). SNAP-ON CLAMP TOOL (NUMBER HPC-20)

MAY BE USED FOR LARGER CLAMPS. ALWAYS

WEAR SAFETY GLASSES WHEN SERVICING CON-

STANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(6) Remove upper radiator hose at radiator.

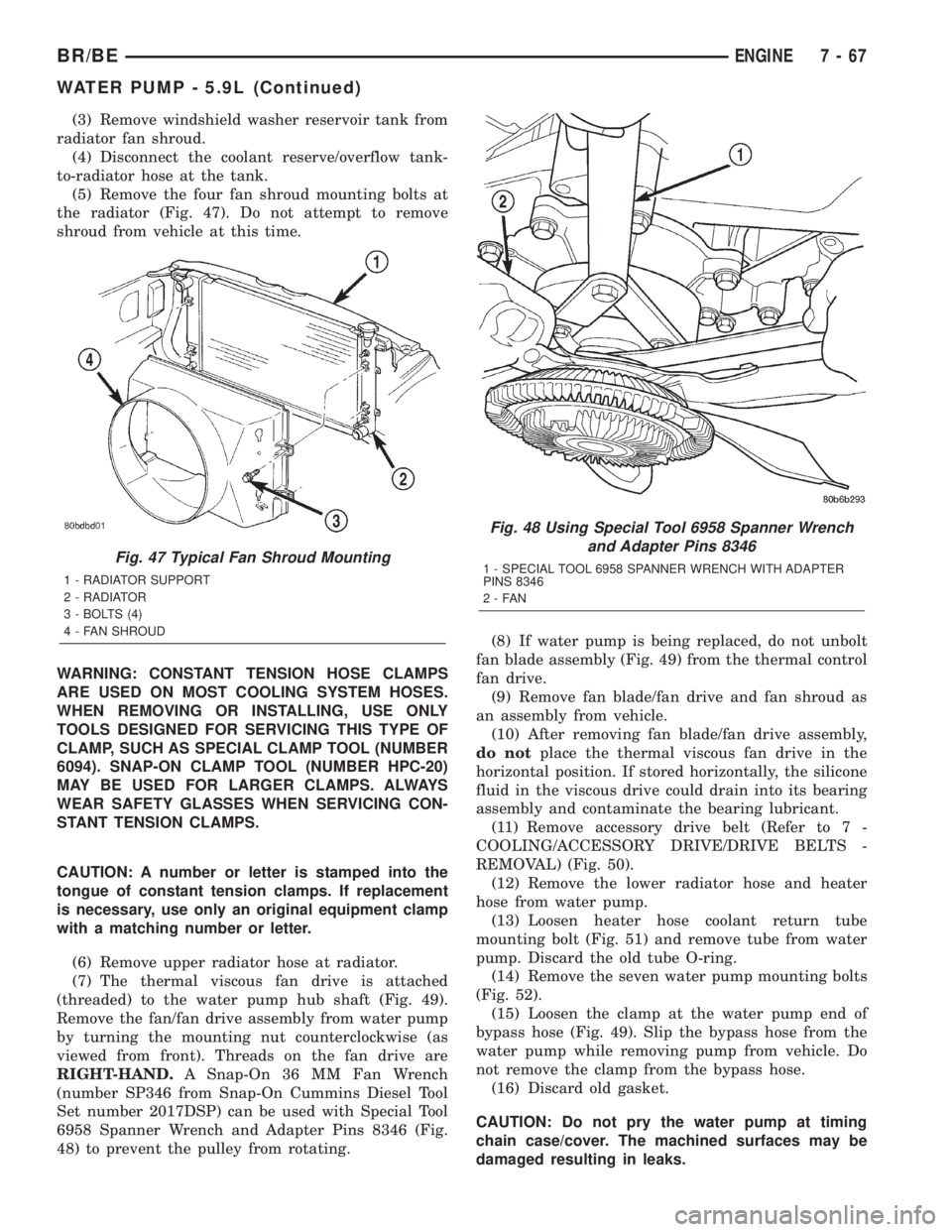

(7) The thermal viscous fan drive is attached

(threaded) to the water pump hub shaft (Fig. 49).

Remove the fan/fan drive assembly from water pump

by turning the mounting nut counterclockwise (as

viewed from front). Threads on the fan drive are

RIGHT-HAND.A Snap-On 36 MM Fan Wrench

(number SP346 from Snap-On Cummins Diesel Tool

Set number 2017DSP) can be used with Special Tool

6958 Spanner Wrench and Adapter Pins 8346 (Fig.

48) to prevent the pulley from rotating.(8) If water pump is being replaced, do not unbolt

fan blade assembly (Fig. 49) from the thermal control

fan drive.

(9) Remove fan blade/fan drive and fan shroud as

an assembly from vehicle.

(10) After removing fan blade/fan drive assembly,

do notplace the thermal viscous fan drive in the

horizontal position. If stored horizontally, the silicone

fluid in the viscous drive could drain into its bearing

assembly and contaminate the bearing lubricant.

(11) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL) (Fig. 50).

(12) Remove the lower radiator hose and heater

hose from water pump.

(13) Loosen heater hose coolant return tube

mounting bolt (Fig. 51) and remove tube from water

pump. Discard the old tube O-ring.

(14) Remove the seven water pump mounting bolts

(Fig. 52).

(15) Loosen the clamp at the water pump end of

bypass hose (Fig. 49). Slip the bypass hose from the

water pump while removing pump from vehicle. Do

not remove the clamp from the bypass hose.

(16) Discard old gasket.

CAUTION: Do not pry the water pump at timing

chain case/cover. The machined surfaces may be

damaged resulting in leaks.

Fig. 47 Typical Fan Shroud Mounting

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

Fig. 48 Using Special Tool 6958 Spanner Wrench

and Adapter Pins 8346

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

BR/BEENGINE 7 - 67

WATER PUMP - 5.9L (Continued)