ac compressor DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1314 of 2255

The fuel rail is not repairable.

CAUTION: The left and right sections of the fuel rail

are connected with a flexible connecting hose. Do

not attempt to separate the rail halves at this con-

necting hose. Due to the design of this connecting

hose, it does not use any clamps. Never attempt to

install a clamping device of any kind to the hose.

When removing the fuel rail assembly for any rea-

son, be careful not to bend or kink the connecting

hose.

OPERATION - 8.0L

High pressure from the fuel pump is routed to the

fuel rail. The fuel rail then supplies the necessary

fuel to each individual fuel injector.

A fuel pressure test port is located on the fuel rail.

A quick-connect fitting with a safety latch clip is

used to attach the fuel line to the fuel rail.

The fuel rail is not repairable.

REMOVAL

REMOVAL - 5.9L

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH ENGINE TURNED

OFF). BEFORE SERVICING FUEL RAIL ASSEMBLY,

FUEL SYSTEM PRESSURE MUST BE RELEASED.

To release fuel pressure, refer to Fuel System Pres-

sure Release Procedure found in this group.

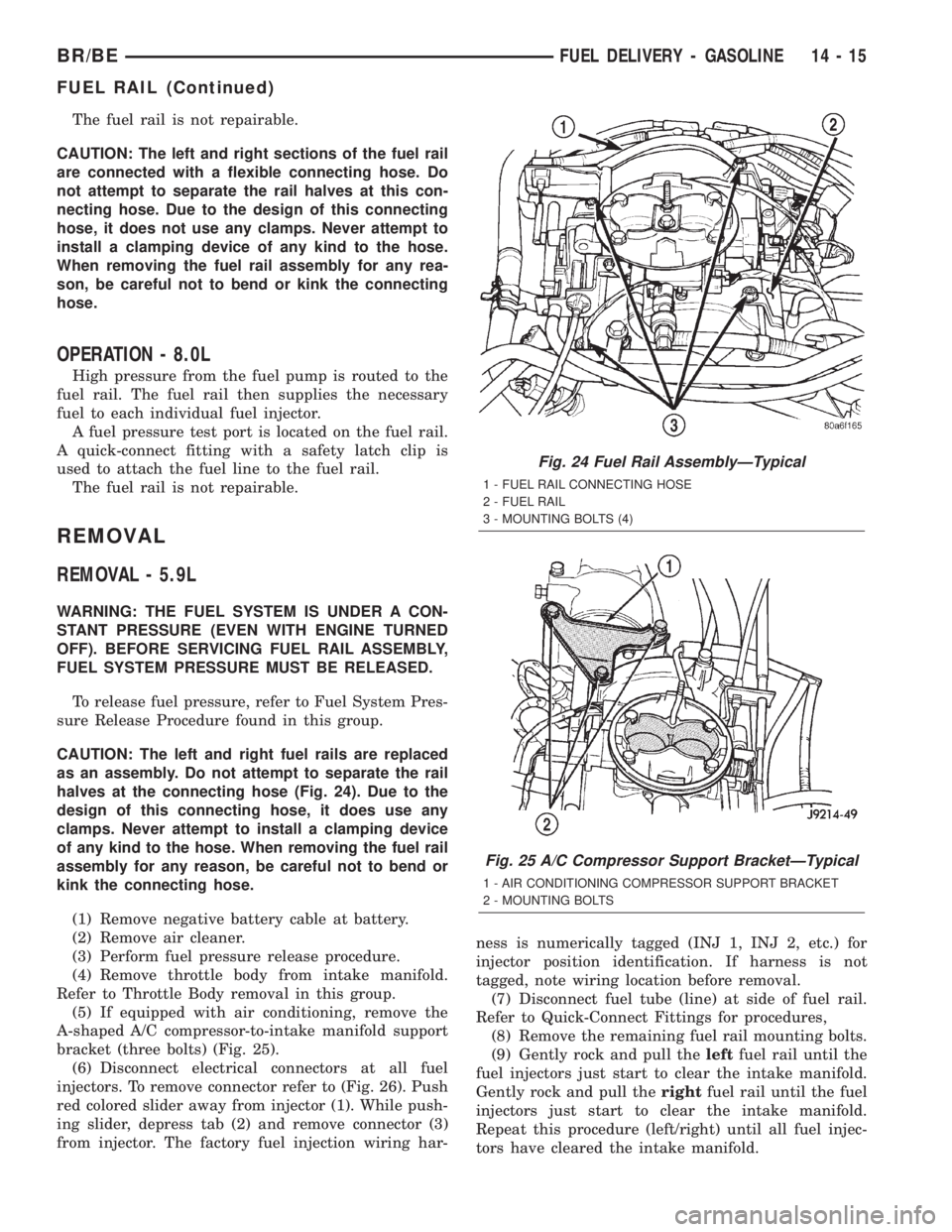

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate the rail

halves at the connecting hose (Fig. 24). Due to the

design of this connecting hose, it does use any

clamps. Never attempt to install a clamping device

of any kind to the hose. When removing the fuel rail

assembly for any reason, be careful not to bend or

kink the connecting hose.

(1) Remove negative battery cable at battery.

(2) Remove air cleaner.

(3) Perform fuel pressure release procedure.

(4) Remove throttle body from intake manifold.

Refer to Throttle Body removal in this group.

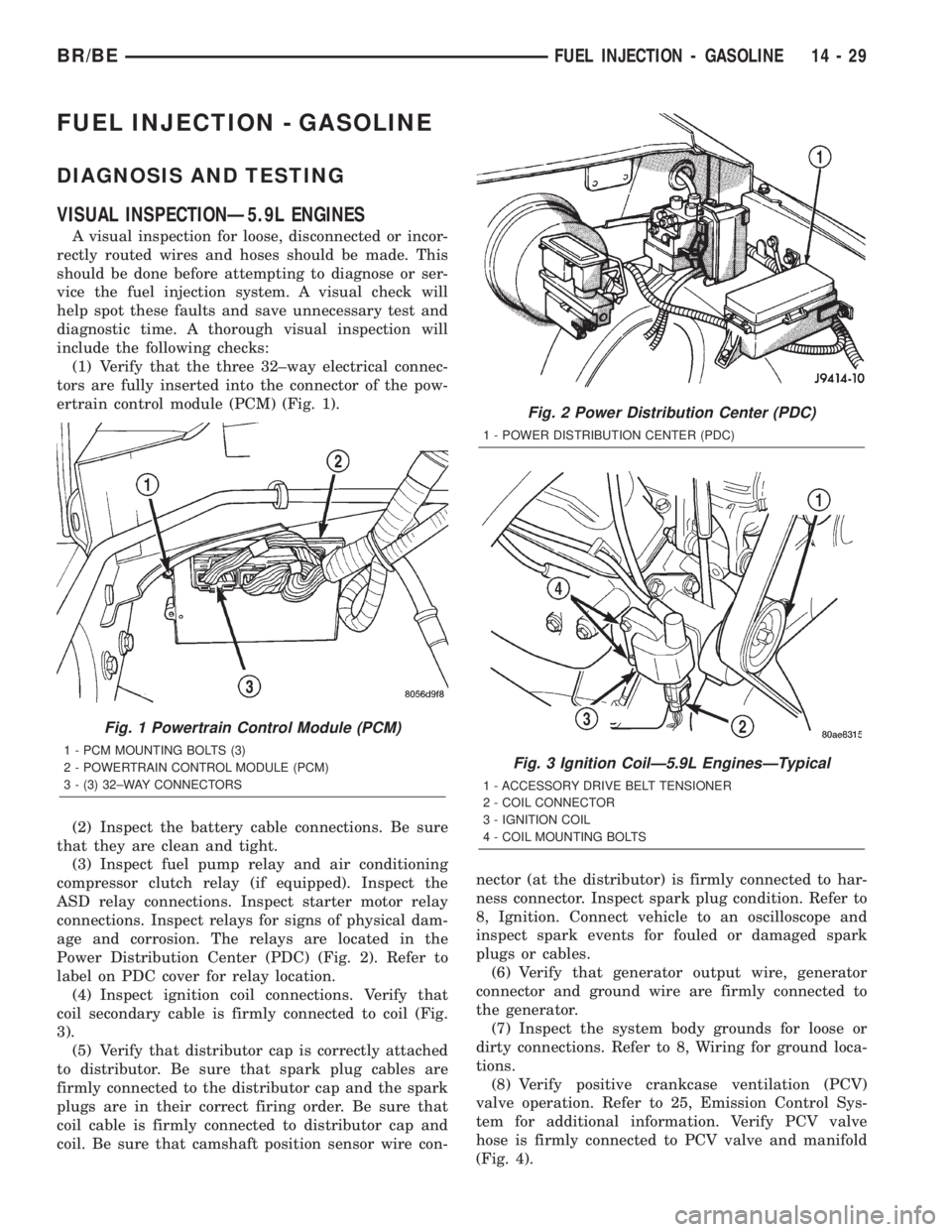

(5) If equipped with air conditioning, remove the

A-shaped A/C compressor-to-intake manifold support

bracket (three bolts) (Fig. 25).

(6) Disconnect electrical connectors at all fuel

injectors. To remove connector refer to (Fig. 26). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(7) Disconnect fuel tube (line) at side of fuel rail.

Refer to Quick-Connect Fittings for procedures,

(8) Remove the remaining fuel rail mounting bolts.

(9) Gently rock and pull theleftfuel rail until the

fuel injectors just start to clear the intake manifold.

Gently rock and pull therightfuel rail until the fuel

injectors just start to clear the intake manifold.

Repeat this procedure (left/right) until all fuel injec-

tors have cleared the intake manifold.

Fig. 24 Fuel Rail AssemblyÐTypical

1 - FUEL RAIL CONNECTING HOSE

2 - FUEL RAIL

3 - MOUNTING BOLTS (4)

Fig. 25 A/C Compressor Support BracketÐTypical

1 - AIR CONDITIONING COMPRESSOR SUPPORT BRACKET

2 - MOUNTING BOLTS

BR/BEFUEL DELIVERY - GASOLINE 14 - 15

FUEL RAIL (Continued)

Page 1328 of 2255

FUEL INJECTION - GASOLINE

DIAGNOSIS AND TESTING

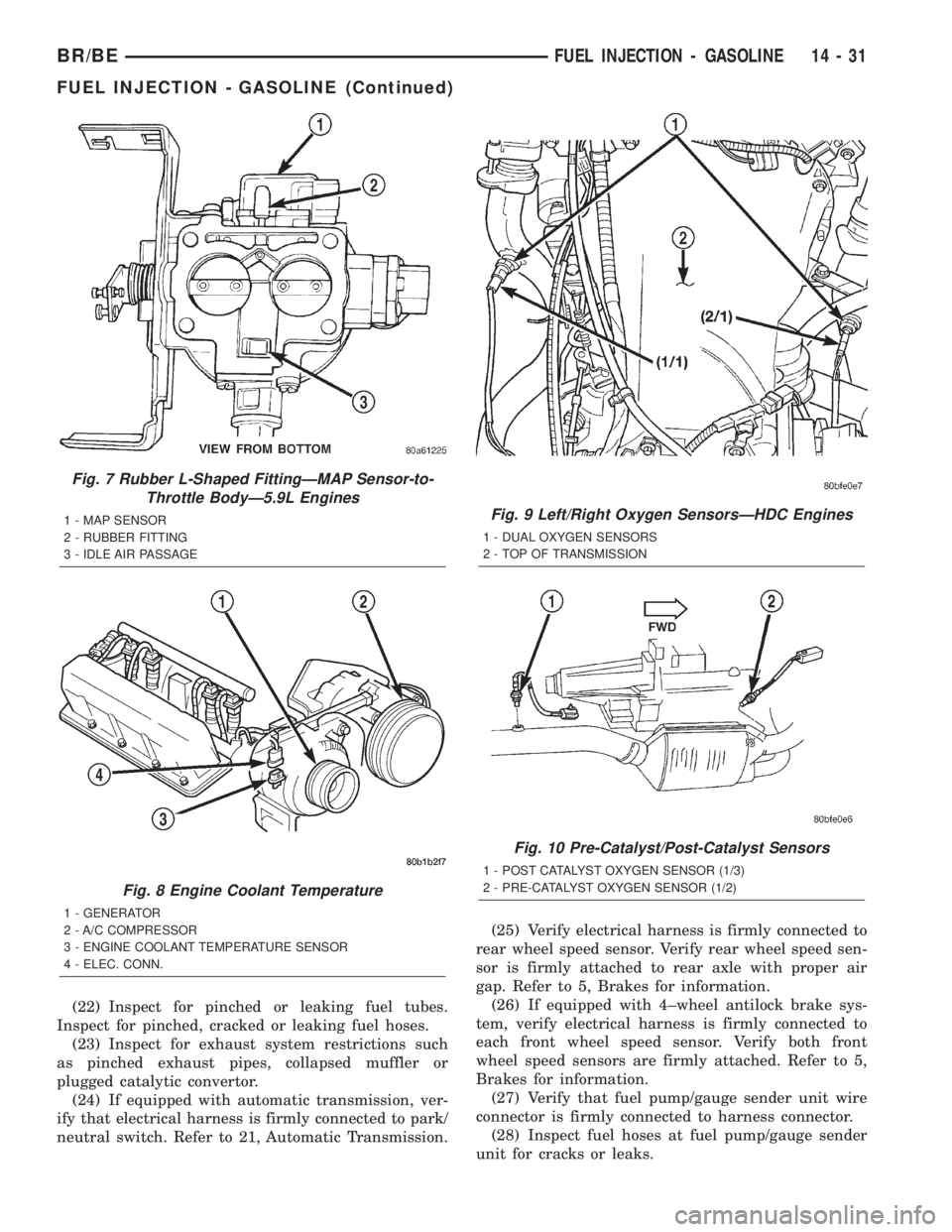

VISUAL INSPECTIONÐ5.9L ENGINES

A visual inspection for loose, disconnected or incor-

rectly routed wires and hoses should be made. This

should be done before attempting to diagnose or ser-

vice the fuel injection system. A visual check will

help spot these faults and save unnecessary test and

diagnostic time. A thorough visual inspection will

include the following checks:

(1) Verify that the three 32±way electrical connec-

tors are fully inserted into the connector of the pow-

ertrain control module (PCM) (Fig. 1).

(2) Inspect the battery cable connections. Be sure

that they are clean and tight.

(3) Inspect fuel pump relay and air conditioning

compressor clutch relay (if equipped). Inspect the

ASD relay connections. Inspect starter motor relay

connections. Inspect relays for signs of physical dam-

age and corrosion. The relays are located in the

Power Distribution Center (PDC) (Fig. 2). Refer to

label on PDC cover for relay location.

(4) Inspect ignition coil connections. Verify that

coil secondary cable is firmly connected to coil (Fig.

3).

(5) Verify that distributor cap is correctly attached

to distributor. Be sure that spark plug cables are

firmly connected to the distributor cap and the spark

plugs are in their correct firing order. Be sure that

coil cable is firmly connected to distributor cap and

coil. Be sure that camshaft position sensor wire con-nector (at the distributor) is firmly connected to har-

ness connector. Inspect spark plug condition. Refer to

8, Ignition. Connect vehicle to an oscilloscope and

inspect spark events for fouled or damaged spark

plugs or cables.

(6) Verify that generator output wire, generator

connector and ground wire are firmly connected to

the generator.

(7) Inspect the system body grounds for loose or

dirty connections. Refer to 8, Wiring for ground loca-

tions.

(8) Verify positive crankcase ventilation (PCV)

valve operation. Refer to 25, Emission Control Sys-

tem for additional information. Verify PCV valve

hose is firmly connected to PCV valve and manifold

(Fig. 4).

Fig. 1 Powertrain Control Module (PCM)

1 - PCM MOUNTING BOLTS (3)

2 - POWERTRAIN CONTROL MODULE (PCM)

3 - (3) 32±WAY CONNECTORS

Fig. 2 Power Distribution Center (PDC)

1 - POWER DISTRIBUTION CENTER (PDC)

Fig. 3 Ignition CoilÐ5.9L EnginesÐTypical

1 - ACCESSORY DRIVE BELT TENSIONER

2 - COIL CONNECTOR

3 - IGNITION COIL

4 - COIL MOUNTING BOLTS

BR/BEFUEL INJECTION - GASOLINE 14 - 29

Page 1330 of 2255

(22) Inspect for pinched or leaking fuel tubes.

Inspect for pinched, cracked or leaking fuel hoses.

(23) Inspect for exhaust system restrictions such

as pinched exhaust pipes, collapsed muffler or

plugged catalytic convertor.

(24) If equipped with automatic transmission, ver-

ify that electrical harness is firmly connected to park/

neutral switch. Refer to 21, Automatic Transmission.(25) Verify electrical harness is firmly connected to

rear wheel speed sensor. Verify rear wheel speed sen-

sor is firmly attached to rear axle with proper air

gap. Refer to 5, Brakes for information.

(26) If equipped with 4±wheel antilock brake sys-

tem, verify electrical harness is firmly connected to

each front wheel speed sensor. Verify both front

wheel speed sensors are firmly attached. Refer to 5,

Brakes for information.

(27) Verify that fuel pump/gauge sender unit wire

connector is firmly connected to harness connector.

(28) Inspect fuel hoses at fuel pump/gauge sender

unit for cracks or leaks.

Fig. 7 Rubber L-Shaped FittingÐMAP Sensor-to-

Throttle BodyÐ5.9L Engines

1 - MAP SENSOR

2 - RUBBER FITTING

3 - IDLE AIR PASSAGE

Fig. 8 Engine Coolant Temperature

1 - GENERATOR

2 - A/C COMPRESSOR

3 - ENGINE COOLANT TEMPERATURE SENSOR

4 - ELEC. CONN.

Fig. 9 Left/Right Oxygen SensorsÐHDC Engines

1 - DUAL OXYGEN SENSORS

2 - TOP OF TRANSMISSION

Fig. 10 Pre-Catalyst/Post-Catalyst Sensors

1 - POST CATALYST OXYGEN SENSOR (1/3)

2 - PRE-CATALYST OXYGEN SENSOR (1/2)

BR/BEFUEL INJECTION - GASOLINE 14 - 31

FUEL INJECTION - GASOLINE (Continued)

Page 1331 of 2255

(29) Inspect transmission torque convertor housing

(automatic transmission) or clutch housing (manual

transmission) for damage to timing ring on drive

plate/flywheel.

(30) Verify that battery cable and solenoid feed

wire connections to the starter solenoid are tight and

clean. Inspect for chaffed wires or wires rubbing up

against other components.

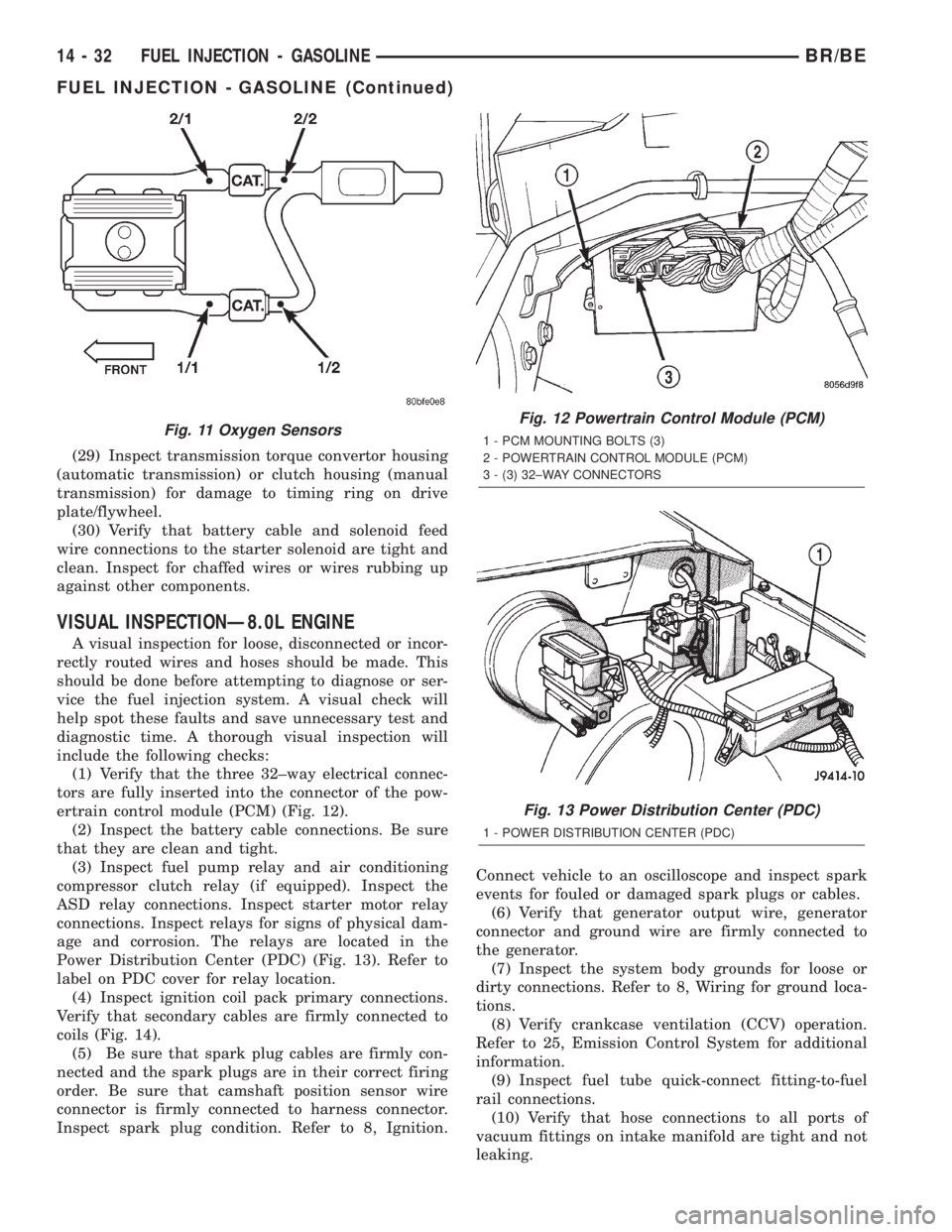

VISUAL INSPECTIONÐ8.0L ENGINE

A visual inspection for loose, disconnected or incor-

rectly routed wires and hoses should be made. This

should be done before attempting to diagnose or ser-

vice the fuel injection system. A visual check will

help spot these faults and save unnecessary test and

diagnostic time. A thorough visual inspection will

include the following checks:

(1) Verify that the three 32±way electrical connec-

tors are fully inserted into the connector of the pow-

ertrain control module (PCM) (Fig. 12).

(2) Inspect the battery cable connections. Be sure

that they are clean and tight.

(3) Inspect fuel pump relay and air conditioning

compressor clutch relay (if equipped). Inspect the

ASD relay connections. Inspect starter motor relay

connections. Inspect relays for signs of physical dam-

age and corrosion. The relays are located in the

Power Distribution Center (PDC) (Fig. 13). Refer to

label on PDC cover for relay location.

(4) Inspect ignition coil pack primary connections.

Verify that secondary cables are firmly connected to

coils (Fig. 14).

(5) Be sure that spark plug cables are firmly con-

nected and the spark plugs are in their correct firing

order. Be sure that camshaft position sensor wire

connector is firmly connected to harness connector.

Inspect spark plug condition. Refer to 8, Ignition.Connect vehicle to an oscilloscope and inspect spark

events for fouled or damaged spark plugs or cables.

(6) Verify that generator output wire, generator

connector and ground wire are firmly connected to

the generator.

(7) Inspect the system body grounds for loose or

dirty connections. Refer to 8, Wiring for ground loca-

tions.

(8) Verify crankcase ventilation (CCV) operation.

Refer to 25, Emission Control System for additional

information.

(9) Inspect fuel tube quick-connect fitting-to-fuel

rail connections.

(10) Verify that hose connections to all ports of

vacuum fittings on intake manifold are tight and not

leaking.

Fig. 11 Oxygen SensorsFig. 12 Powertrain Control Module (PCM)

1 - PCM MOUNTING BOLTS (3)

2 - POWERTRAIN CONTROL MODULE (PCM)

3 - (3) 32±WAY CONNECTORS

Fig. 13 Power Distribution Center (PDC)

1 - POWER DISTRIBUTION CENTER (PDC)

14 - 32 FUEL INJECTION - GASOLINEBR/BE

FUEL INJECTION - GASOLINE (Continued)

Page 1340 of 2255

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

REMOVAL

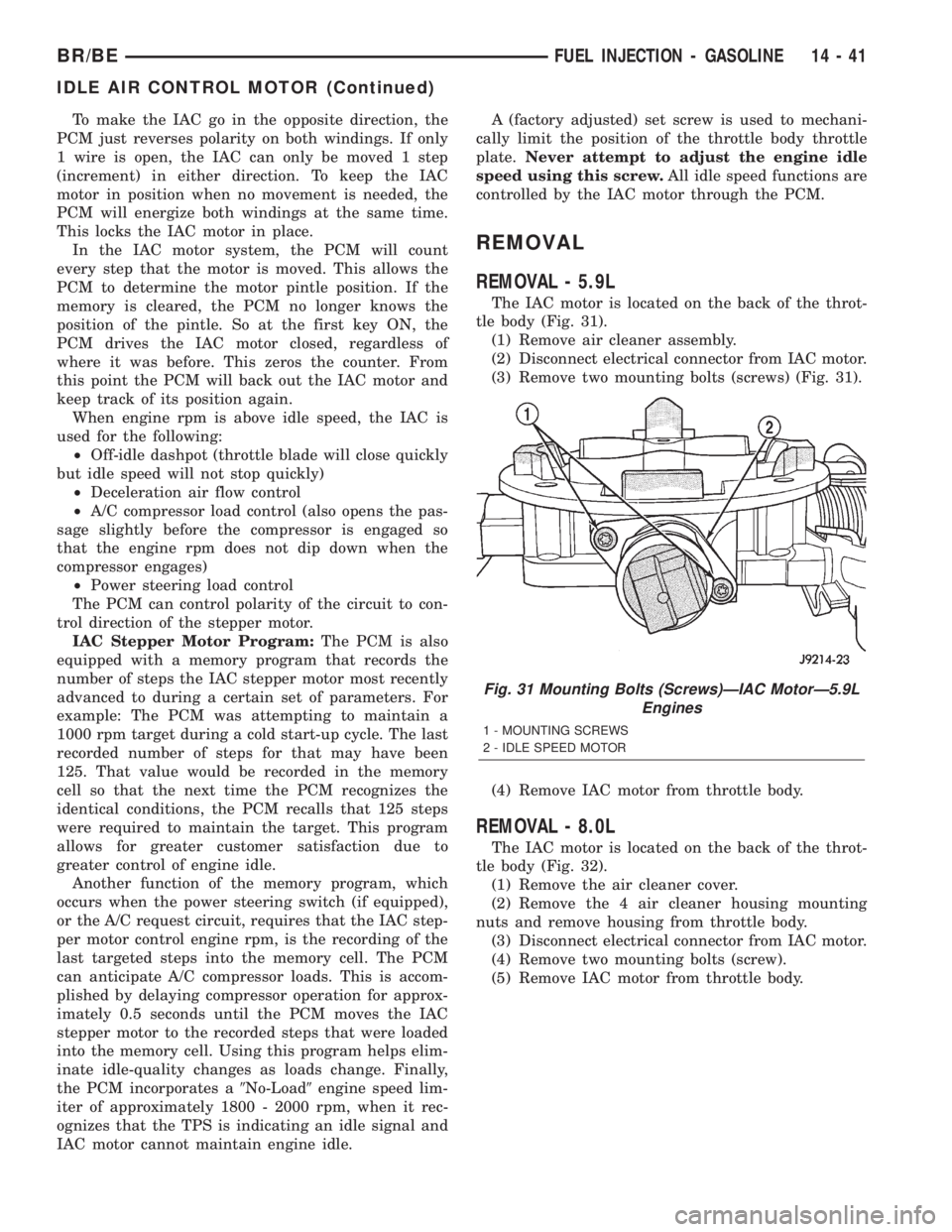

REMOVAL - 5.9L

The IAC motor is located on the back of the throt-

tle body (Fig. 31).

(1) Remove air cleaner assembly.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws) (Fig. 31).

(4) Remove IAC motor from throttle body.

REMOVAL - 8.0L

The IAC motor is located on the back of the throt-

tle body (Fig. 32).

(1) Remove the air cleaner cover.

(2) Remove the 4 air cleaner housing mounting

nuts and remove housing from throttle body.

(3) Disconnect electrical connector from IAC motor.

(4) Remove two mounting bolts (screw).

(5) Remove IAC motor from throttle body.

Fig. 31 Mounting Bolts (Screws)ÐIAC MotorÐ5.9L

Engines

1 - MOUNTING SCREWS

2 - IDLE SPEED MOTOR

BR/BEFUEL INJECTION - GASOLINE 14 - 41

IDLE AIR CONTROL MOTOR (Continued)

Page 1573 of 2255

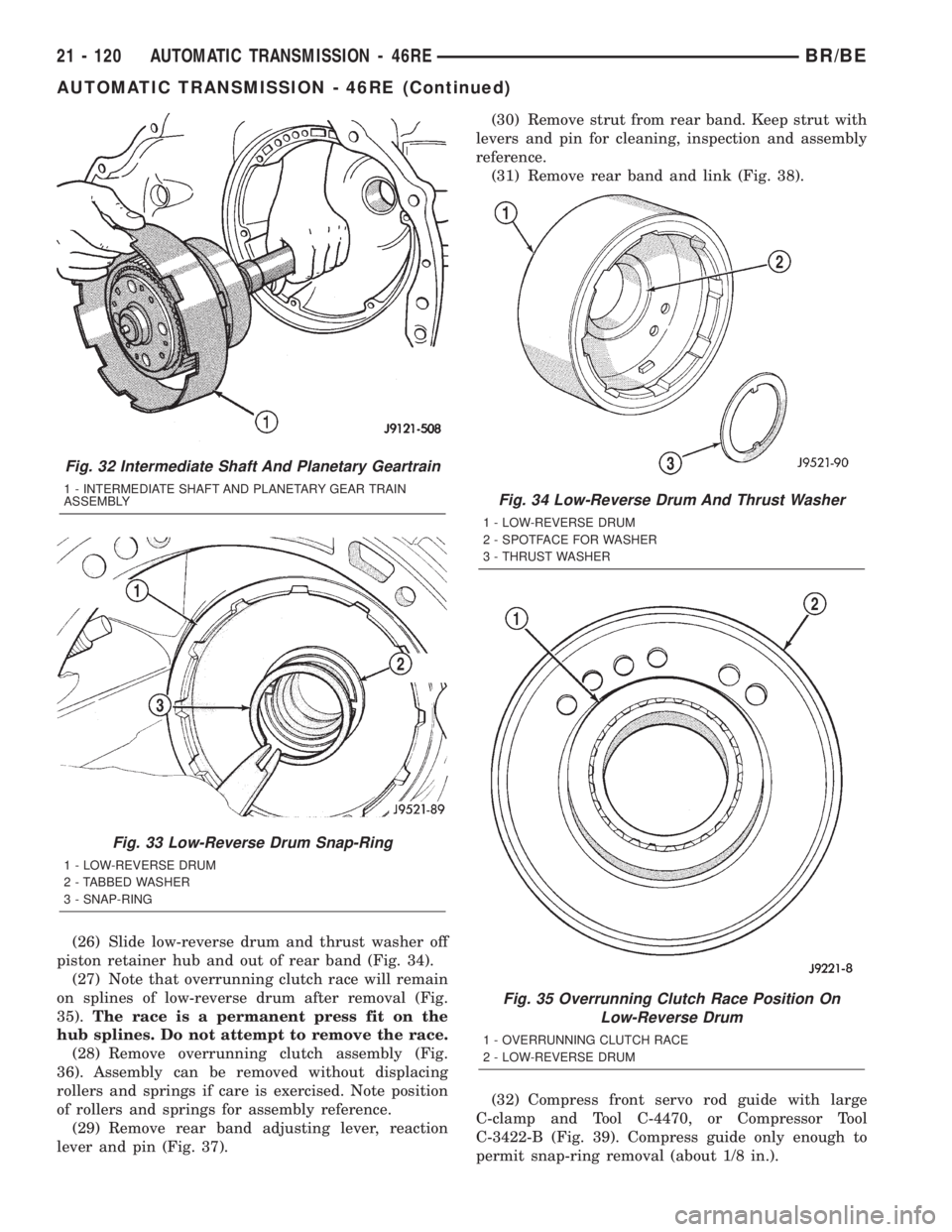

(26) Slide low-reverse drum and thrust washer off

piston retainer hub and out of rear band (Fig. 34).

(27) Note that overrunning clutch race will remain

on splines of low-reverse drum after removal (Fig.

35).The race is a permanent press fit on the

hub splines. Do not attempt to remove the race.

(28) Remove overrunning clutch assembly (Fig.

36). Assembly can be removed without displacing

rollers and springs if care is exercised. Note position

of rollers and springs for assembly reference.

(29) Remove rear band adjusting lever, reaction

lever and pin (Fig. 37).(30) Remove strut from rear band. Keep strut with

levers and pin for cleaning, inspection and assembly

reference.

(31) Remove rear band and link (Fig. 38).

(32) Compress front servo rod guide with large

C-clamp and Tool C-4470, or Compressor Tool

C-3422-B (Fig. 39). Compress guide only enough to

permit snap-ring removal (about 1/8 in.).

Fig. 32 Intermediate Shaft And Planetary Geartrain

1 - INTERMEDIATE SHAFT AND PLANETARY GEAR TRAIN

ASSEMBLY

Fig. 33 Low-Reverse Drum Snap-Ring

1 - LOW-REVERSE DRUM

2 - TABBED WASHER

3 - SNAP-RING

Fig. 34 Low-Reverse Drum And Thrust Washer

1 - LOW-REVERSE DRUM

2 - SPOTFACE FOR WASHER

3 - THRUST WASHER

Fig. 35 Overrunning Clutch Race Position On

Low-Reverse Drum

1 - OVERRUNNING CLUTCH RACE

2 - LOW-REVERSE DRUM

21 - 120 AUTOMATIC TRANSMISSION - 46REBR/BE

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1574 of 2255

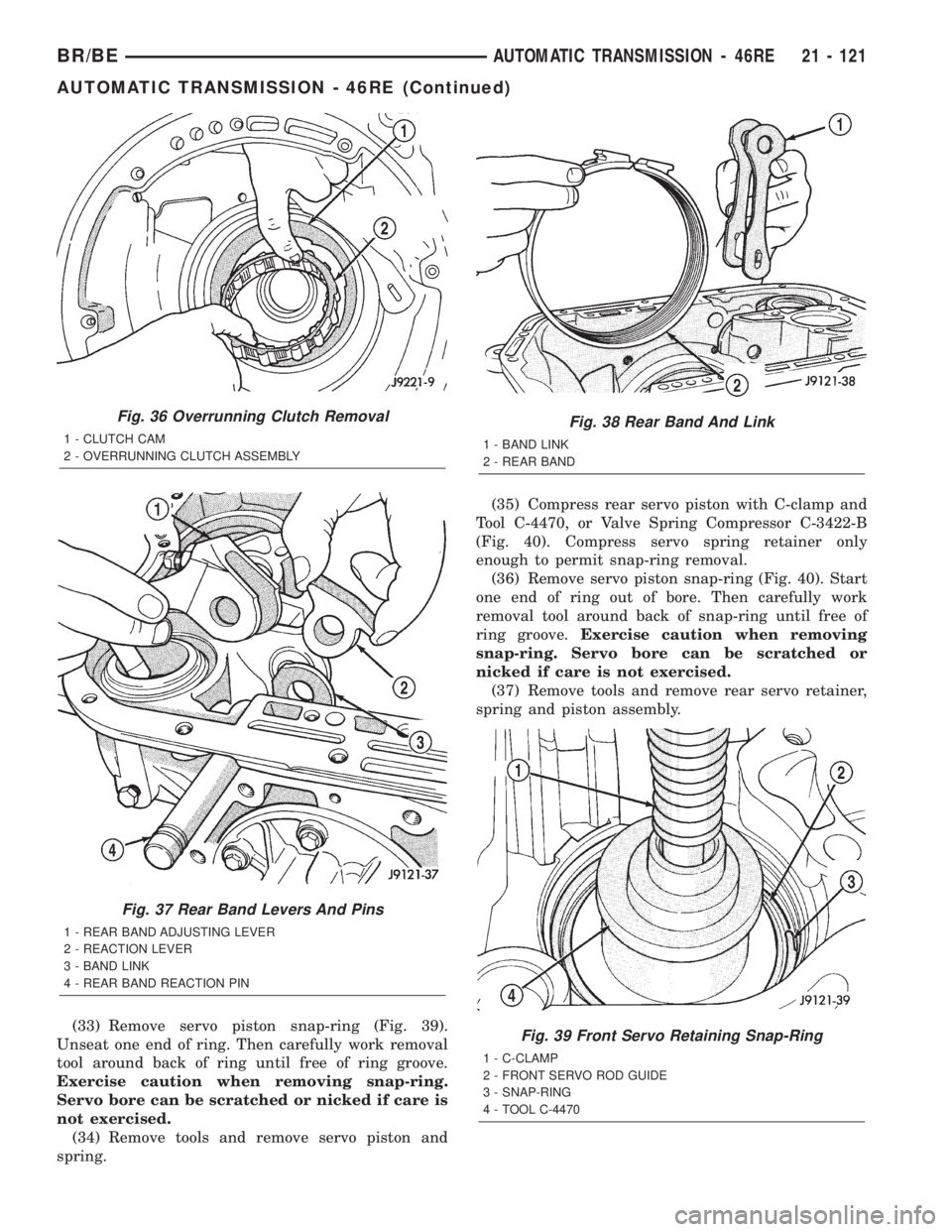

(33) Remove servo piston snap-ring (Fig. 39).

Unseat one end of ring. Then carefully work removal

tool around back of ring until free of ring groove.

Exercise caution when removing snap-ring.

Servo bore can be scratched or nicked if care is

not exercised.

(34) Remove tools and remove servo piston and

spring.(35) Compress rear servo piston with C-clamp and

Tool C-4470, or Valve Spring Compressor C-3422-B

(Fig. 40). Compress servo spring retainer only

enough to permit snap-ring removal.

(36) Remove servo piston snap-ring (Fig. 40). Start

one end of ring out of bore. Then carefully work

removal tool around back of snap-ring until free of

ring groove.Exercise caution when removing

snap-ring. Servo bore can be scratched or

nicked if care is not exercised.

(37) Remove tools and remove rear servo retainer,

spring and piston assembly.

Fig. 36 Overrunning Clutch Removal

1 - CLUTCH CAM

2 - OVERRUNNING CLUTCH ASSEMBLY

Fig. 37 Rear Band Levers And Pins

1 - REAR BAND ADJUSTING LEVER

2 - REACTION LEVER

3 - BAND LINK

4 - REAR BAND REACTION PIN

Fig. 38 Rear Band And Link

1 - BAND LINK

2 - REAR BAND

Fig. 39 Front Servo Retaining Snap-Ring

1 - C-CLAMP

2 - FRONT SERVO ROD GUIDE

3 - SNAP-RING

4 - TOOL C-4470

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 121

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1576 of 2255

The planetary geartrain, front/rear clutch assem-

blies and oil pump are all much easier to install

when the transmission case is upright. Either tilt the

case upward with wood blocks, or cut a hole in the

bench large enough for the intermediate shaft and

rear support. Then lower the shaft and support into

the hole and support the rear of the case directly on

the bench.

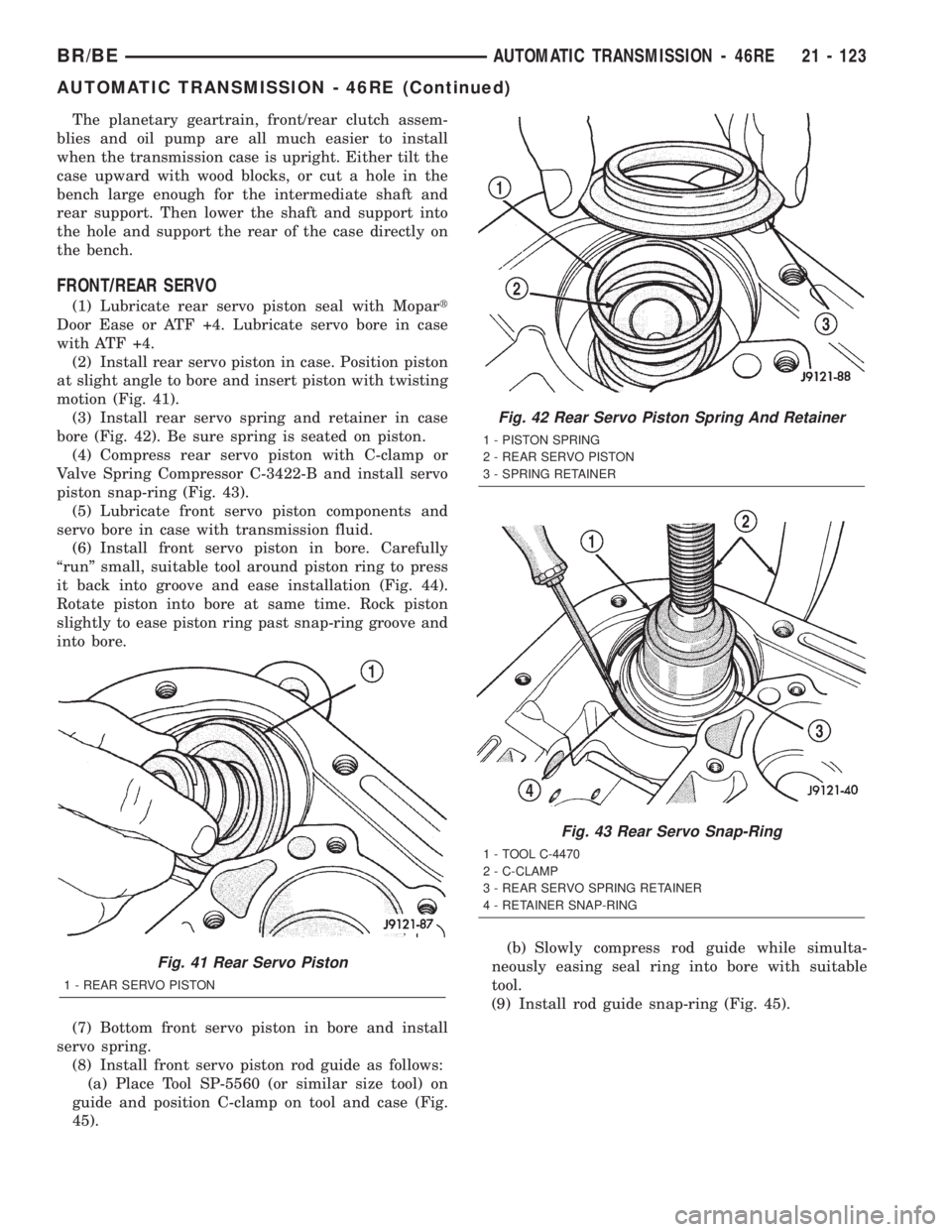

FRONT/REAR SERVO

(1) Lubricate rear servo piston seal with Mopart

Door Ease or ATF +4. Lubricate servo bore in case

with ATF +4.

(2) Install rear servo piston in case. Position piston

at slight angle to bore and insert piston with twisting

motion (Fig. 41).

(3) Install rear servo spring and retainer in case

bore (Fig. 42). Be sure spring is seated on piston.

(4) Compress rear servo piston with C-clamp or

Valve Spring Compressor C-3422-B and install servo

piston snap-ring (Fig. 43).

(5) Lubricate front servo piston components and

servo bore in case with transmission fluid.

(6) Install front servo piston in bore. Carefully

ªrunº small, suitable tool around piston ring to press

it back into groove and ease installation (Fig. 44).

Rotate piston into bore at same time. Rock piston

slightly to ease piston ring past snap-ring groove and

into bore.

(7) Bottom front servo piston in bore and install

servo spring.

(8) Install front servo piston rod guide as follows:

(a) Place Tool SP-5560 (or similar size tool) on

guide and position C-clamp on tool and case (Fig.

45).(b) Slowly compress rod guide while simulta-

neously easing seal ring into bore with suitable

tool.

(9) Install rod guide snap-ring (Fig. 45).

Fig. 41 Rear Servo Piston

1 - REAR SERVO PISTON

Fig. 42 Rear Servo Piston Spring And Retainer

1 - PISTON SPRING

2 - REAR SERVO PISTON

3 - SPRING RETAINER

Fig. 43 Rear Servo Snap-Ring

1 - TOOL C-4470

2 - C-CLAMP

3 - REAR SERVO SPRING RETAINER

4 - RETAINER SNAP-RING

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 123

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1599 of 2255

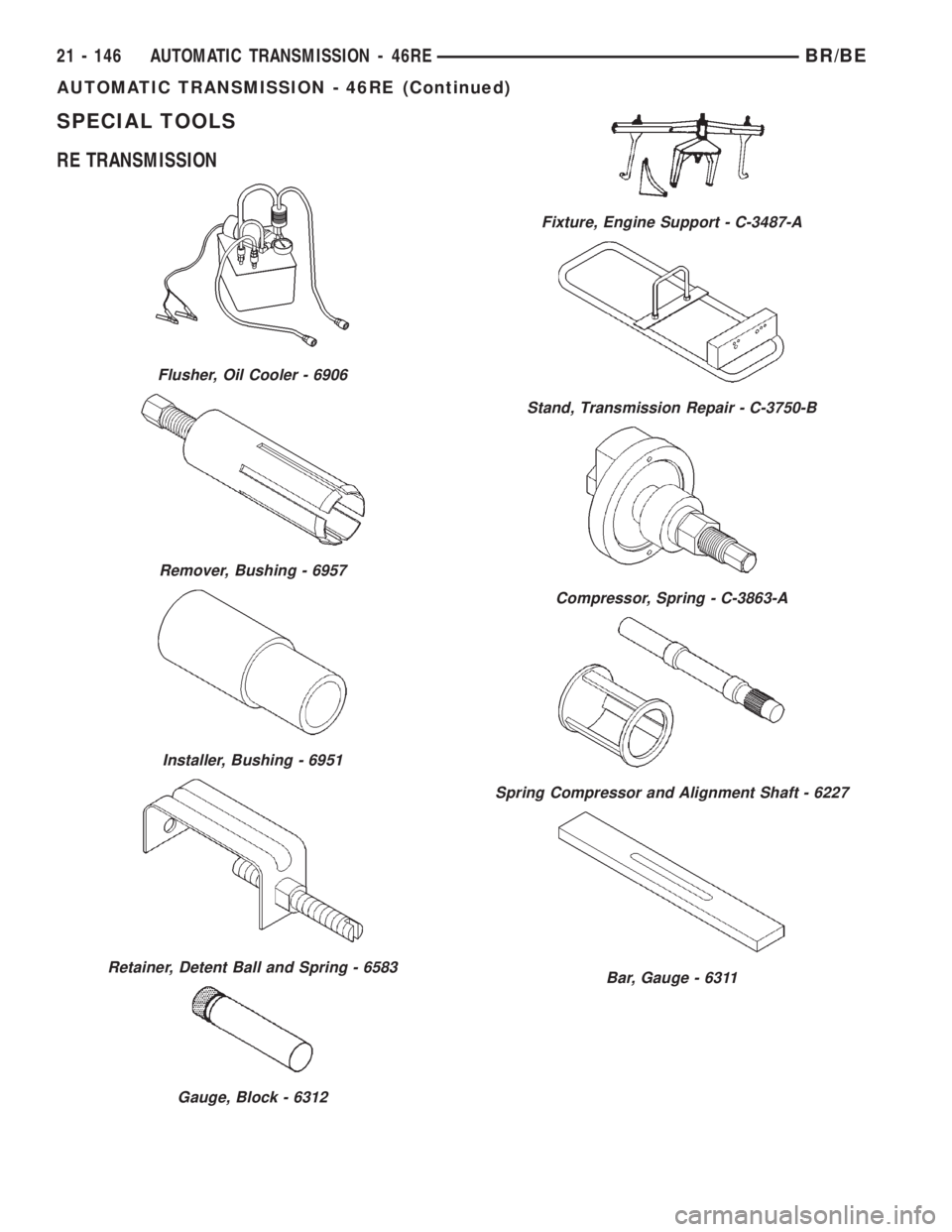

SPECIAL TOOLS

RE TRANSMISSION

Flusher, Oil Cooler - 6906

Remover, Bushing - 6957

Installer, Bushing - 6951

Retainer, Detent Ball and Spring - 6583

Gauge, Block - 6312

Fixture, Engine Support - C-3487-A

Stand, Transmission Repair - C-3750-B

Compressor, Spring - C-3863-A

Spring Compressor and Alignment Shaft - 6227

Bar, Gauge - 6311

21 - 146 AUTOMATIC TRANSMISSION - 46REBR/BE

AUTOMATIC TRANSMISSION - 46RE (Continued)

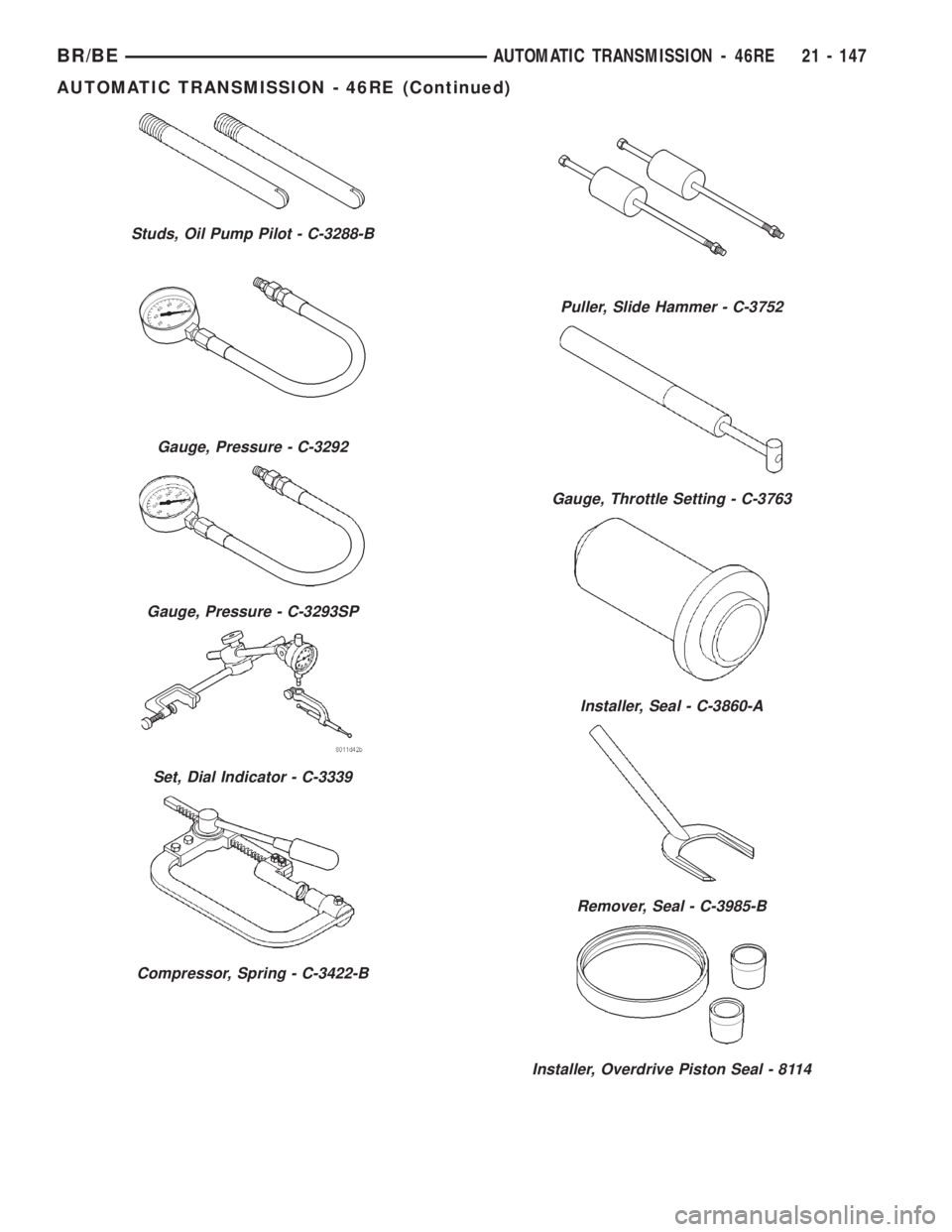

Page 1600 of 2255

Studs, Oil Pump Pilot - C-3288-B

Gauge, Pressure - C-3292

Gauge, Pressure - C-3293SP

Set, Dial Indicator - C-3339

Compressor, Spring - C-3422-B

Puller, Slide Hammer - C-3752

Gauge, Throttle Setting - C-3763

Installer, Seal - C-3860-A

Remover, Seal - C-3985-B

Installer, Overdrive Piston Seal - 8114

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 147

AUTOMATIC TRANSMISSION - 46RE (Continued)