engine DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1839 of 2255

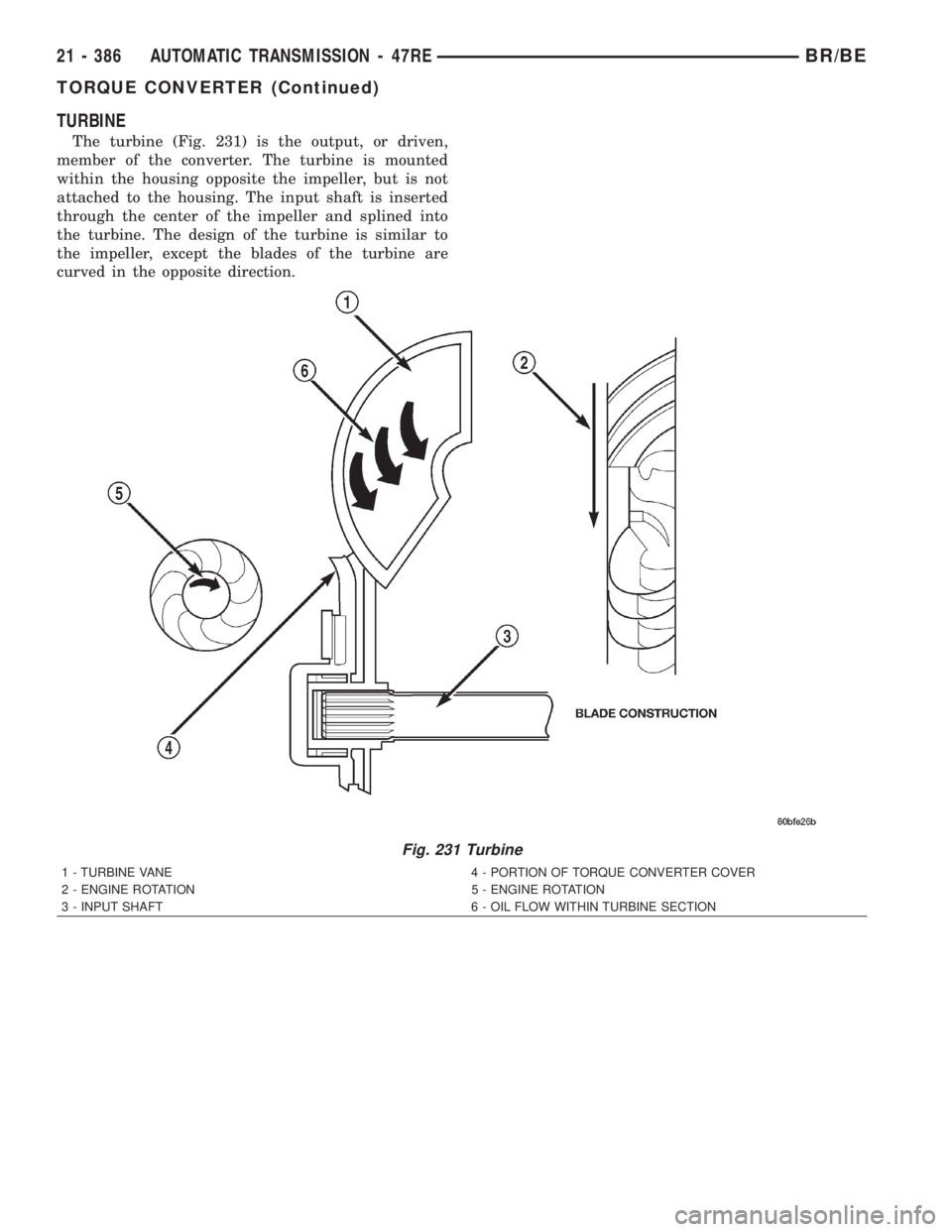

TURBINE

The turbine (Fig. 231) is the output, or driven,

member of the converter. The turbine is mounted

within the housing opposite the impeller, but is not

attached to the housing. The input shaft is inserted

through the center of the impeller and splined into

the turbine. The design of the turbine is similar to

the impeller, except the blades of the turbine are

curved in the opposite direction.

Fig. 231 Turbine

1 - TURBINE VANE 4 - PORTION OF TORQUE CONVERTER COVER

2 - ENGINE ROTATION 5 - ENGINE ROTATION

3 - INPUT SHAFT 6 - OIL FLOW WITHIN TURBINE SECTION

21 - 386 AUTOMATIC TRANSMISSION - 47REBR/BE

TORQUE CONVERTER (Continued)

Page 1841 of 2255

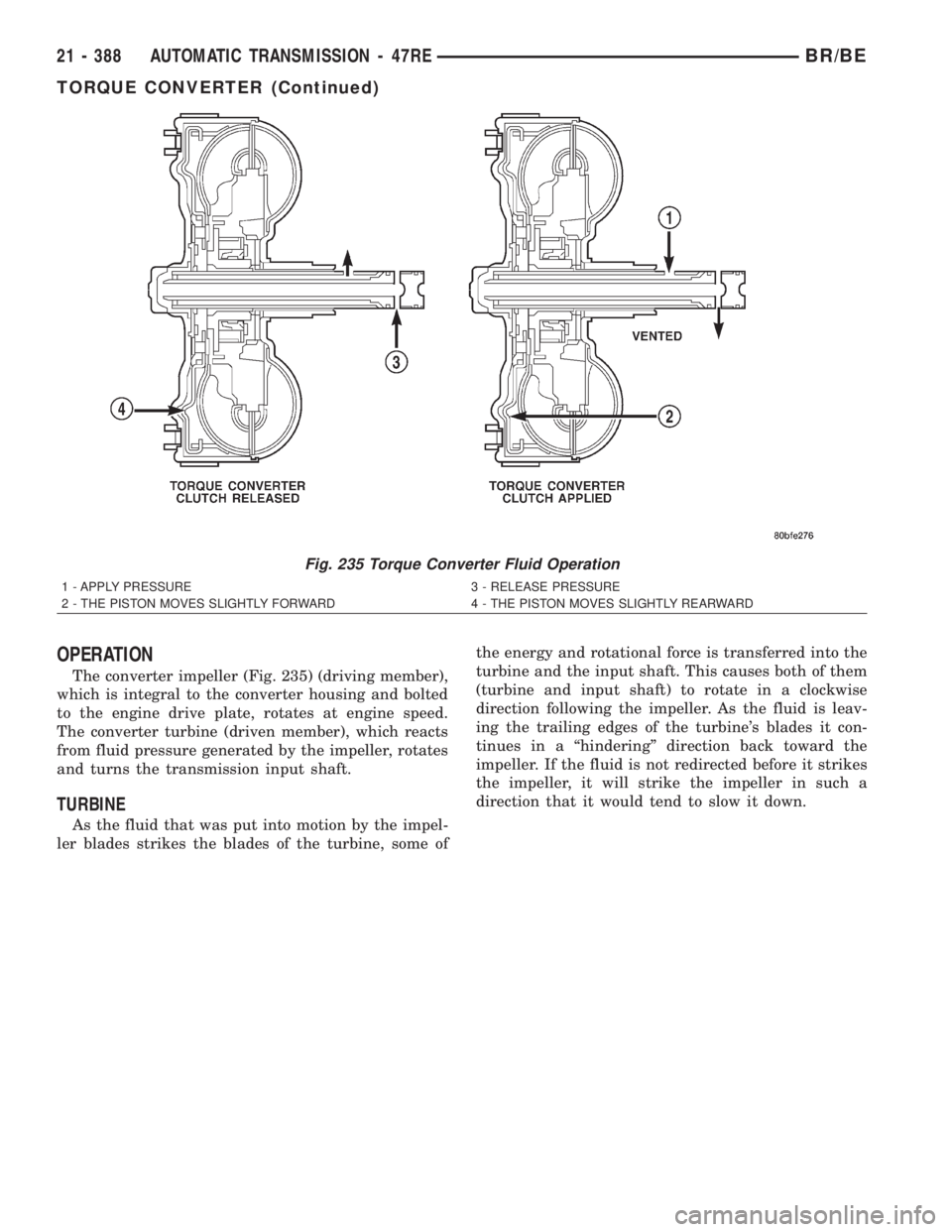

OPERATION

The converter impeller (Fig. 235) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some ofthe energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

Fig. 235 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

21 - 388 AUTOMATIC TRANSMISSION - 47REBR/BE

TORQUE CONVERTER (Continued)

Page 1842 of 2255

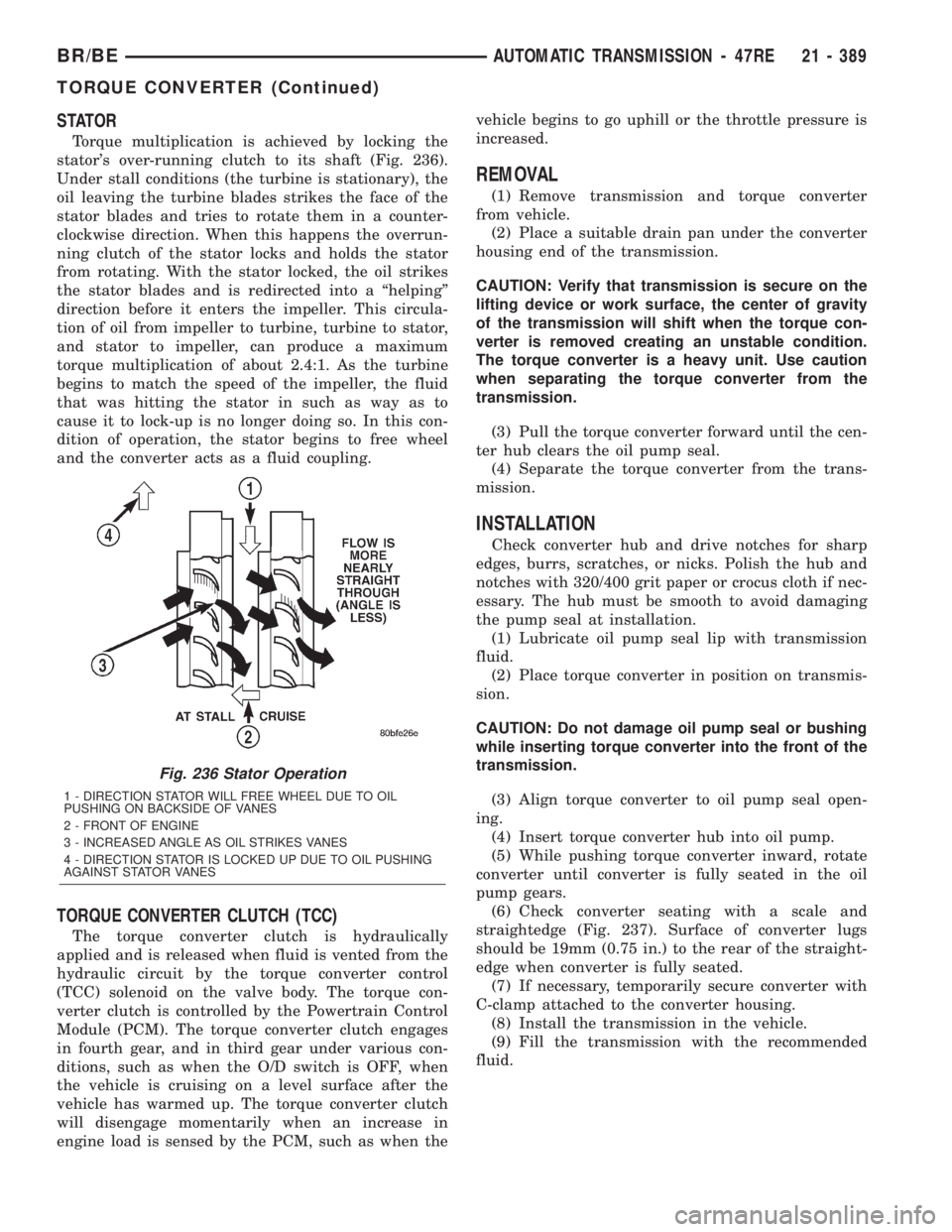

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 236).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the overrun-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

The torque converter clutch is hydraulically

applied and is released when fluid is vented from the

hydraulic circuit by the torque converter control

(TCC) solenoid on the valve body. The torque con-

verter clutch is controlled by the Powertrain Control

Module (PCM). The torque converter clutch engages

in fourth gear, and in third gear under various con-

ditions, such as when the O/D switch is OFF, when

the vehicle is cruising on a level surface after the

vehicle has warmed up. The torque converter clutch

will disengage momentarily when an increase in

engine load is sensed by the PCM, such as when thevehicle begins to go uphill or the throttle pressure is

increased.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 237). Surface of converter lugs

should be 19mm (0.75 in.) to the rear of the straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

(9) Fill the transmission with the recommended

fluid.

Fig. 236 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 389

TORQUE CONVERTER (Continued)

Page 1849 of 2255

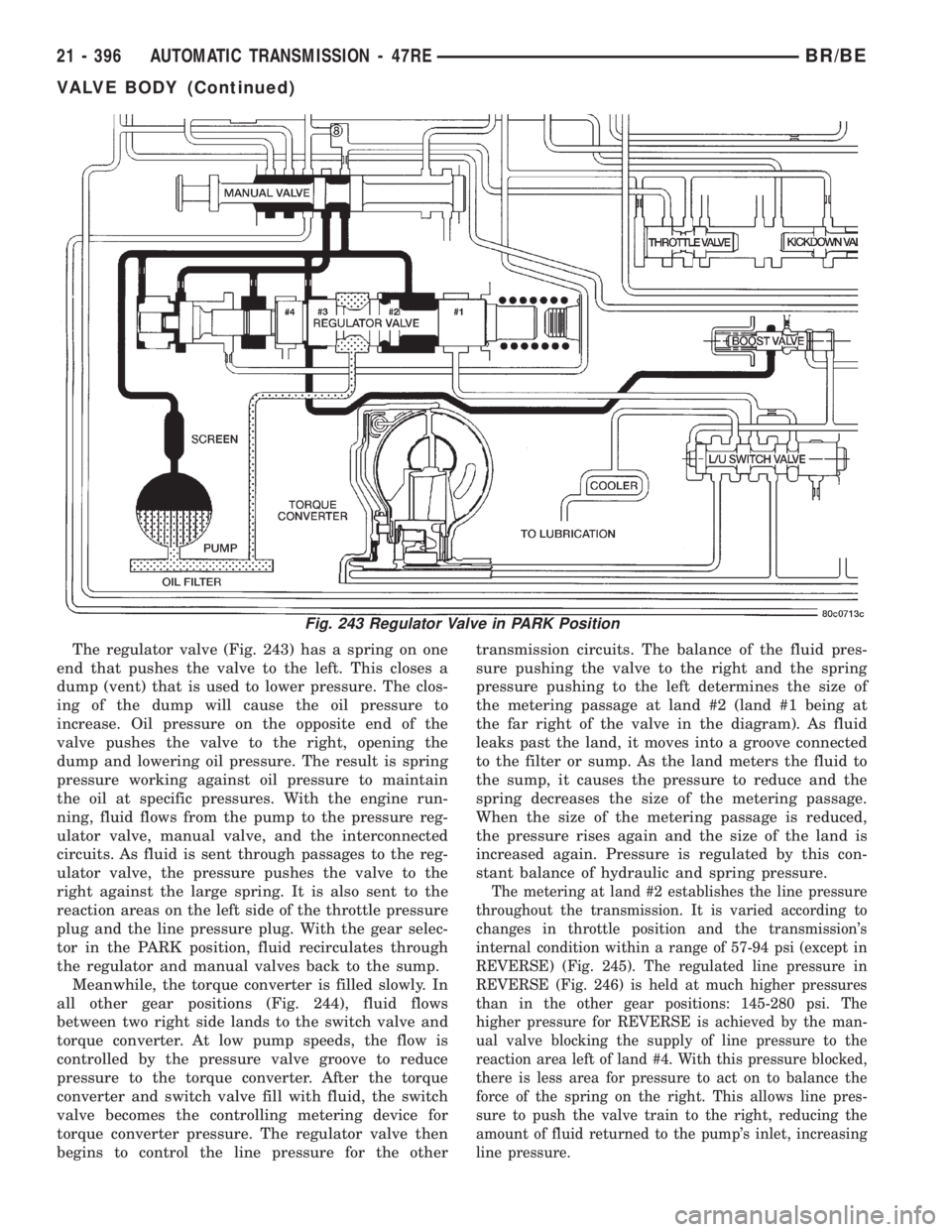

The regulator valve (Fig. 243) has a spring on one

end that pushes the valve to the left. This closes a

dump (vent) that is used to lower pressure. The clos-

ing of the dump will cause the oil pressure to

increase. Oil pressure on the opposite end of the

valve pushes the valve to the right, opening the

dump and lowering oil pressure. The result is spring

pressure working against oil pressure to maintain

the oil at specific pressures. With the engine run-

ning, fluid flows from the pump to the pressure reg-

ulator valve, manual valve, and the interconnected

circuits. As fluid is sent through passages to the reg-

ulator valve, the pressure pushes the valve to the

right against the large spring. It is also sent to the

reaction areas on the left side of the throttle pressure

plug and the line pressure plug. With the gear selec-

tor in the PARK position, fluid recirculates through

the regulator and manual valves back to the sump.

Meanwhile, the torque converter is filled slowly. In

all other gear positions (Fig. 244), fluid flows

between two right side lands to the switch valve and

torque converter. At low pump speeds, the flow is

controlled by the pressure valve groove to reduce

pressure to the torque converter. After the torque

converter and switch valve fill with fluid, the switch

valve becomes the controlling metering device for

torque converter pressure. The regulator valve then

begins to control the line pressure for the othertransmission circuits. The balance of the fluid pres-

sure pushing the valve to the right and the spring

pressure pushing to the left determines the size of

the metering passage at land #2 (land #1 being at

the far right of the valve in the diagram). As fluid

leaks past the land, it moves into a groove connected

to the filter or sump. As the land meters the fluid to

the sump, it causes the pressure to reduce and the

spring decreases the size of the metering passage.

When the size of the metering passage is reduced,

the pressure rises again and the size of the land is

increased again. Pressure is regulated by this con-

stant balance of hydraulic and spring pressure.

The metering at land #2 establishes the line pressure

throughout the transmission. It is varied according to

changes in throttle position and the transmission's

internal condition within a range of 57-94 psi (except in

REVERSE) (Fig. 245). The regulated line pressure in

REVERSE (Fig. 246) is held at much higher pressures

than in the other gear positions: 145-280 psi. The

higher pressure for REVERSE is achieved by the man-

ual valve blocking the supply of line pressure to the

reaction area left of land #4. With this pressure blocked,

there is less area for pressure to act on to balance the

force of the spring on the right. This allows line pres-

sure to push the valve train to the right, reducing the

amount of fluid returned to the pump's inlet, increasing

line pressure.

Fig. 243 Regulator Valve in PARK Position

21 - 396 AUTOMATIC TRANSMISSION - 47REBR/BE

VALVE BODY (Continued)

Page 1857 of 2255

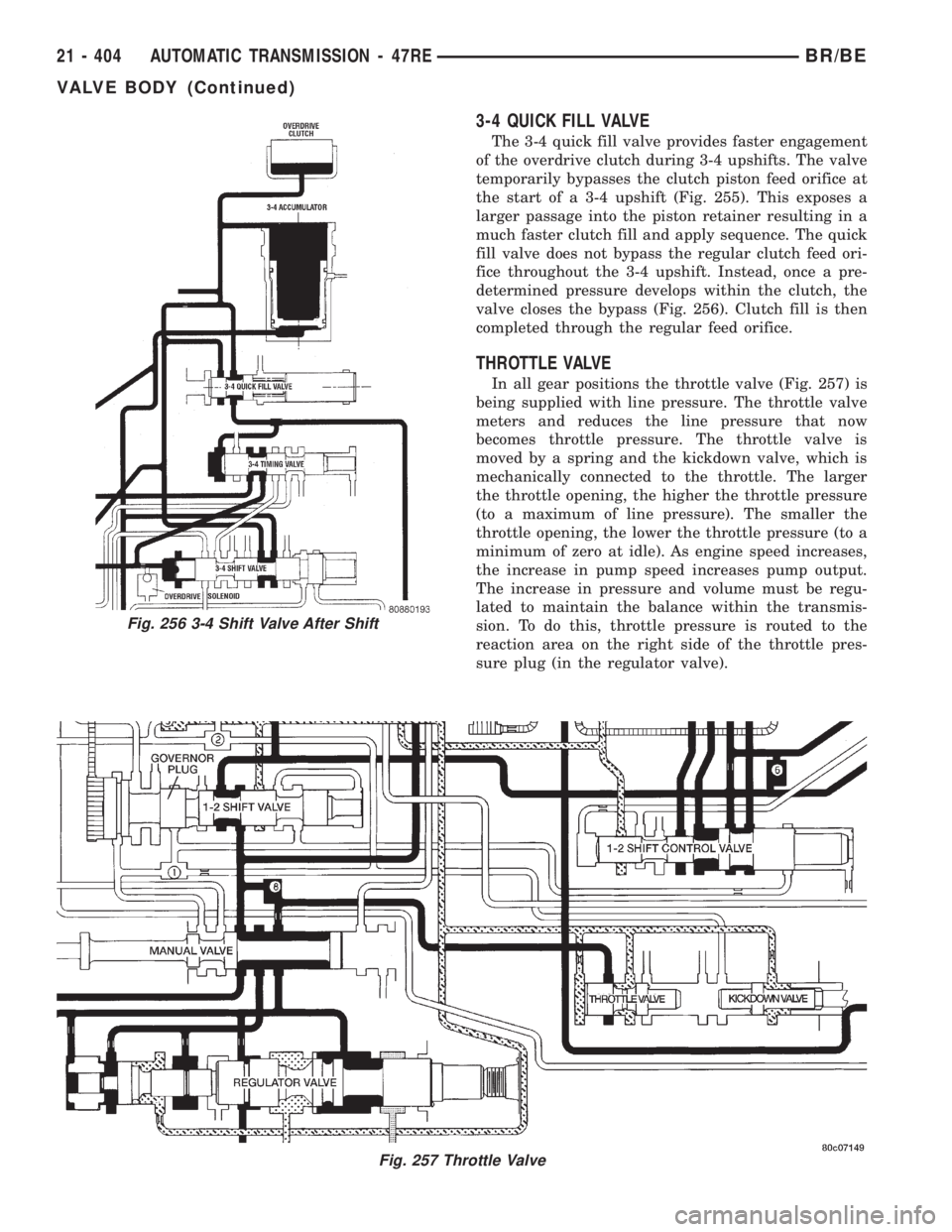

3-4 QUICK FILL VALVE

The 3-4 quick fill valve provides faster engagement

of the overdrive clutch during 3-4 upshifts. The valve

temporarily bypasses the clutch piston feed orifice at

the start of a 3-4 upshift (Fig. 255). This exposes a

larger passage into the piston retainer resulting in a

much faster clutch fill and apply sequence. The quick

fill valve does not bypass the regular clutch feed ori-

fice throughout the 3-4 upshift. Instead, once a pre-

determined pressure develops within the clutch, the

valve closes the bypass (Fig. 256). Clutch fill is then

completed through the regular feed orifice.

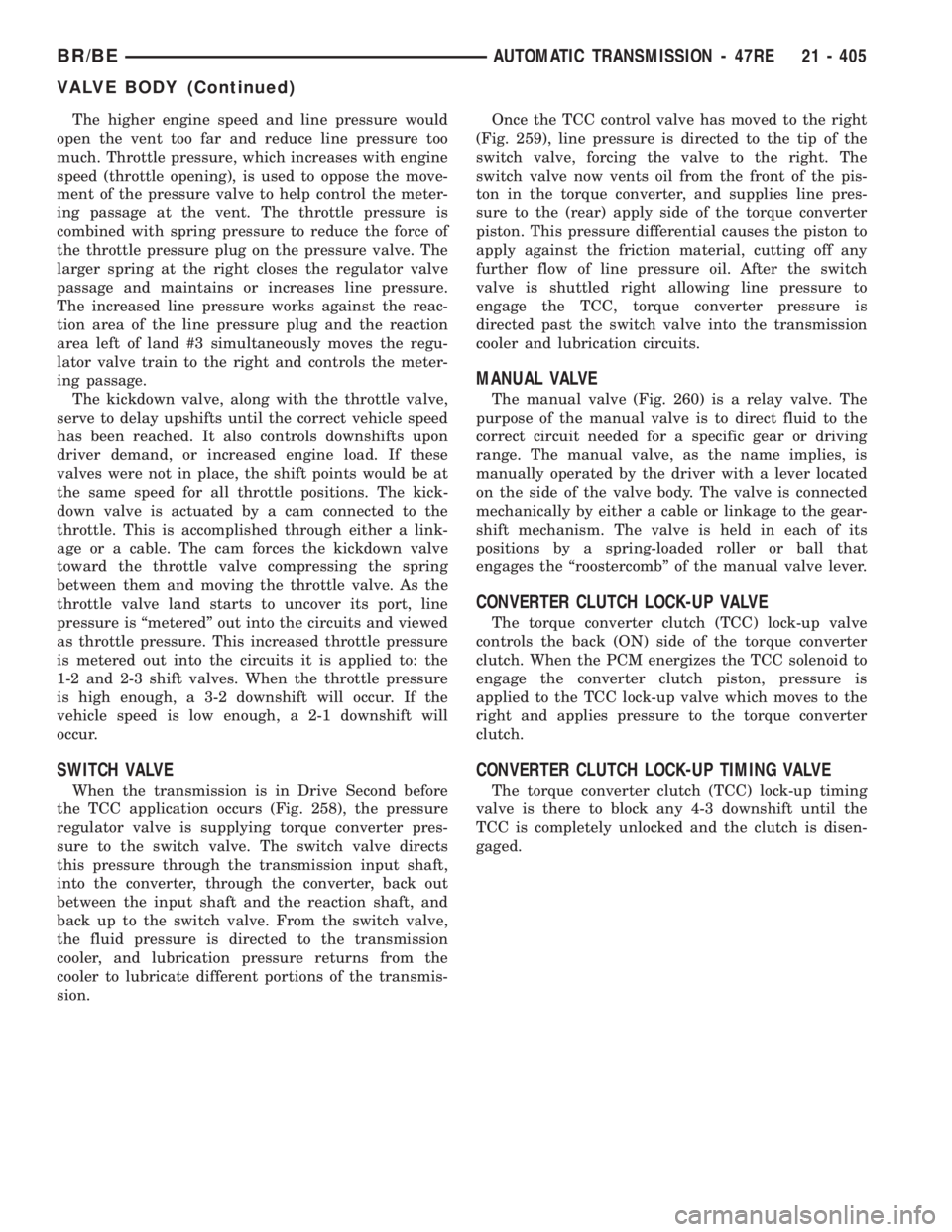

THROTTLE VALVE

In all gear positions the throttle valve (Fig. 257) is

being supplied with line pressure. The throttle valve

meters and reduces the line pressure that now

becomes throttle pressure. The throttle valve is

moved by a spring and the kickdown valve, which is

mechanically connected to the throttle. The larger

the throttle opening, the higher the throttle pressure

(to a maximum of line pressure). The smaller the

throttle opening, the lower the throttle pressure (to a

minimum of zero at idle). As engine speed increases,

the increase in pump speed increases pump output.

The increase in pressure and volume must be regu-

lated to maintain the balance within the transmis-

sion. To do this, throttle pressure is routed to the

reaction area on the right side of the throttle pres-

sure plug (in the regulator valve).

Fig. 257 Throttle Valve

Fig. 256 3-4 Shift Valve After Shift

21 - 404 AUTOMATIC TRANSMISSION - 47REBR/BE

VALVE BODY (Continued)

Page 1858 of 2255

The higher engine speed and line pressure would

open the vent too far and reduce line pressure too

much. Throttle pressure, which increases with engine

speed (throttle opening), is used to oppose the move-

ment of the pressure valve to help control the meter-

ing passage at the vent. The throttle pressure is

combined with spring pressure to reduce the force of

the throttle pressure plug on the pressure valve. The

larger spring at the right closes the regulator valve

passage and maintains or increases line pressure.

The increased line pressure works against the reac-

tion area of the line pressure plug and the reaction

area left of land #3 simultaneously moves the regu-

lator valve train to the right and controls the meter-

ing passage.

The kickdown valve, along with the throttle valve,

serve to delay upshifts until the correct vehicle speed

has been reached. It also controls downshifts upon

driver demand, or increased engine load. If these

valves were not in place, the shift points would be at

the same speed for all throttle positions. The kick-

down valve is actuated by a cam connected to the

throttle. This is accomplished through either a link-

age or a cable. The cam forces the kickdown valve

toward the throttle valve compressing the spring

between them and moving the throttle valve. As the

throttle valve land starts to uncover its port, line

pressure is ªmeteredº out into the circuits and viewed

as throttle pressure. This increased throttle pressure

is metered out into the circuits it is applied to: the

1-2 and 2-3 shift valves. When the throttle pressure

is high enough, a 3-2 downshift will occur. If the

vehicle speed is low enough, a 2-1 downshift will

occur.

SWITCH VALVE

When the transmission is in Drive Second before

the TCC application occurs (Fig. 258), the pressure

regulator valve is supplying torque converter pres-

sure to the switch valve. The switch valve directs

this pressure through the transmission input shaft,

into the converter, through the converter, back out

between the input shaft and the reaction shaft, and

back up to the switch valve. From the switch valve,

the fluid pressure is directed to the transmission

cooler, and lubrication pressure returns from the

cooler to lubricate different portions of the transmis-

sion.Once the TCC control valve has moved to the right

(Fig. 259), line pressure is directed to the tip of the

switch valve, forcing the valve to the right. The

switch valve now vents oil from the front of the pis-

ton in the torque converter, and supplies line pres-

sure to the (rear) apply side of the torque converter

piston. This pressure differential causes the piston to

apply against the friction material, cutting off any

further flow of line pressure oil. After the switch

valve is shuttled right allowing line pressure to

engage the TCC, torque converter pressure is

directed past the switch valve into the transmission

cooler and lubrication circuits.

MANUAL VALVE

The manual valve (Fig. 260) is a relay valve. The

purpose of the manual valve is to direct fluid to the

correct circuit needed for a specific gear or driving

range. The manual valve, as the name implies, is

manually operated by the driver with a lever located

on the side of the valve body. The valve is connected

mechanically by either a cable or linkage to the gear-

shift mechanism. The valve is held in each of its

positions by a spring-loaded roller or ball that

engages the ªroostercombº of the manual valve lever.

CONVERTER CLUTCH LOCK-UP VALVE

The torque converter clutch (TCC) lock-up valve

controls the back (ON) side of the torque converter

clutch. When the PCM energizes the TCC solenoid to

engage the converter clutch piston, pressure is

applied to the TCC lock-up valve which moves to the

right and applies pressure to the torque converter

clutch.

CONVERTER CLUTCH LOCK-UP TIMING VALVE

The torque converter clutch (TCC) lock-up timing

valve is there to block any 4-3 downshift until the

TCC is completely unlocked and the clutch is disen-

gaged.

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 405

VALVE BODY (Continued)

Page 1883 of 2255

TRANSFER CASE - NV241LD

TABLE OF CONTENTS

page page

TRANSFER CASE - NV241LD

DESCRIPTION........................430

OPERATION..........................430

DIAGNOSIS AND TESTING - TRANSFER

CASE..............................431

REMOVAL............................432

DISASSEMBLY........................432

CLEANING...........................441

INSPECTION.........................442

ASSEMBLY...........................445

INSTALLATION........................458

SPECIFICATIONS

TRANSFER CASE....................458

SPECIAL TOOLS

TRANSFER CASE - NV241LD...........459EXTENSION HOUSING BUSHING AND SEAL

REMOVAL............................460

INSTALLATION........................460

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................460

FRONT OUTPUT SHAFT SEAL

REMOVAL............................461

INSTALLATION........................461

SHIFT LEVER

REMOVAL............................462

INSTALLATION........................462

ADJUSTMENTS

ADJUSTMENT - SHIFT LEVER..........463

TRANSFER CASE - NV241LD

DESCRIPTION

The NV241LD transfer case is a part-time transfer

case with a low-range gear system. It provides three

operating ranges plus a NEUTRAL position. The low

range position provides a gear reduction ratio of

2.72:1 for increased low speed torque capability.

The synchronizer mechanism consists of a brass

stop ring, synchro hub, and the sliding clutch. The

synchronizer components allow the transfer case to

be shifted between the 2H and 4H operating ranges

while the vehicle is in motion.

The gear cases, retainer and extension are all of

aluminum. Drive sprockets and an interconnecting

drive chain are used to transmit engine torque to the

front/rear propeller shafts. The mainshaft, input gear

and front output shaft are supported by ball and nee-

dle bearings.

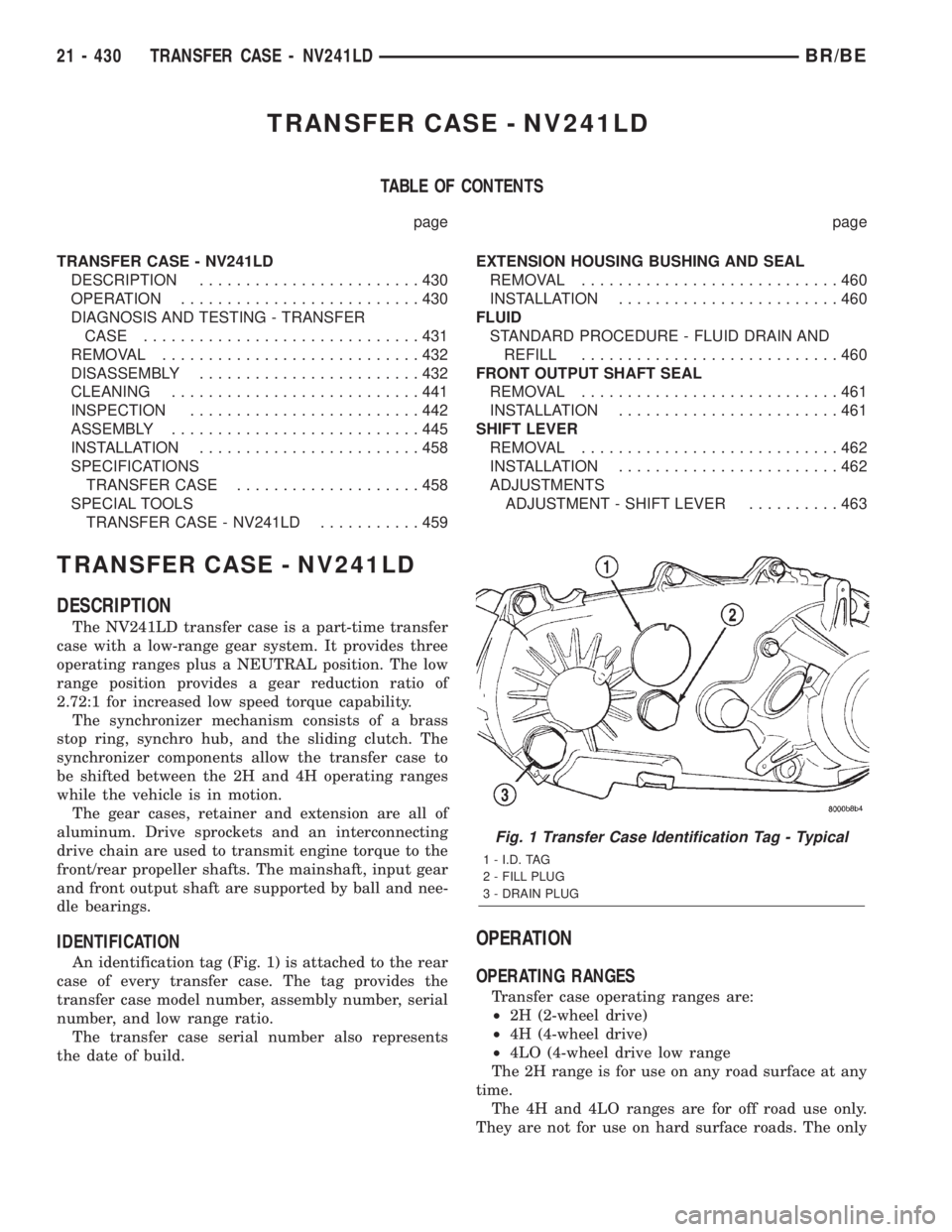

IDENTIFICATION

An identification tag (Fig. 1) is attached to the rear

case of every transfer case. The tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

OPERATING RANGES

Transfer case operating ranges are:

²2H (2-wheel drive)

²4H (4-wheel drive)

²4LO (4-wheel drive low range

The 2H range is for use on any road surface at any

time.

The 4H and 4LO ranges are for off road use only.

They are not for use on hard surface roads. The only

Fig. 1 Transfer Case Identification Tag - Typical

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

21 - 430 TRANSFER CASE - NV241LDBR/BE

Page 1918 of 2255

TRANSFER CASE - NV241HD

TABLE OF CONTENTS

page page

TRANSFER CASE - NV241HD

DESCRIPTION........................465

OPERATION..........................467

DIAGNOSIS AND TESTING - TRANSFER

CASE..............................467

REMOVAL............................469

DISASSEMBLY........................469

CLEANING...........................476

INSPECTION.........................476

ASSEMBLY...........................480

INSTALLATION........................494

SPECIFICATIONS

TRANSFER CASE....................495

SPECIAL TOOLS

TRANSFER CASE - NV241HD...........495EXTENSION HOUSING BUSHING AND SEAL

REMOVAL............................497

INSTALLATION........................497

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL............................497

FRONT OUTPUT SHAFT SEAL

REMOVAL............................498

INSTALLATION........................498

SHIFT LEVER

REMOVAL............................499

INSTALLATION........................500

ADJUSTMENTS

ADJUSTMENT - SHIFT LEVER..........500

TRANSFER CASE - NV241HD

DESCRIPTION

The NV241HD is a part-time transfer case with a

low-range gear system. The transfer case provides

three operating ranges plus a NEUTRAL position.

The low range position provides a gear reduction

ratio of 2.72:1 for increased low speed torque capabil-

ity. Operating ranges are: 2H, 4H, and 4LO.

The synchronizer mechanism consists of a brass

stop ring, synchronizer hub, and the sliding clutch

(Fig. 1). The synchronizer components allow the

transfer case to be shifted between the 2H and 4H

operating ranges while the vehicle is in motion.The gear cases, retainer and extension are all of

aluminum. Drive sprockets and an interconnecting

drive chain are used to transmit engine torque to the

front/rear propeller shafts. The mainshaft, input gear

and front output shaft are supported by ball and nee-

dle bearings.

PTO CAPABILITY

The NV241HD transfer case has power take-off

capability. A PTO gear permanently attached to the

planetary carrier, and a removable PTO cover are

provided for this purpose.

BR/BETRANSFER CASE - NV241HD 21 - 465

Page 1961 of 2255

TIRES

DESCRIPTION

DESCRIPTION - SPARE TIRE - TEMPORARY

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M.P.H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details.

DESCRIPTION - TIRES

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe brake applications

²High speed driving

²Excessive speeds on turns

²Striking curbs and other obstacles

Radial-ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation, (Refer to

22 - TIRES/WHEELS - STANDARD PROCEDURE).

This will help to achieve a greater tread life.

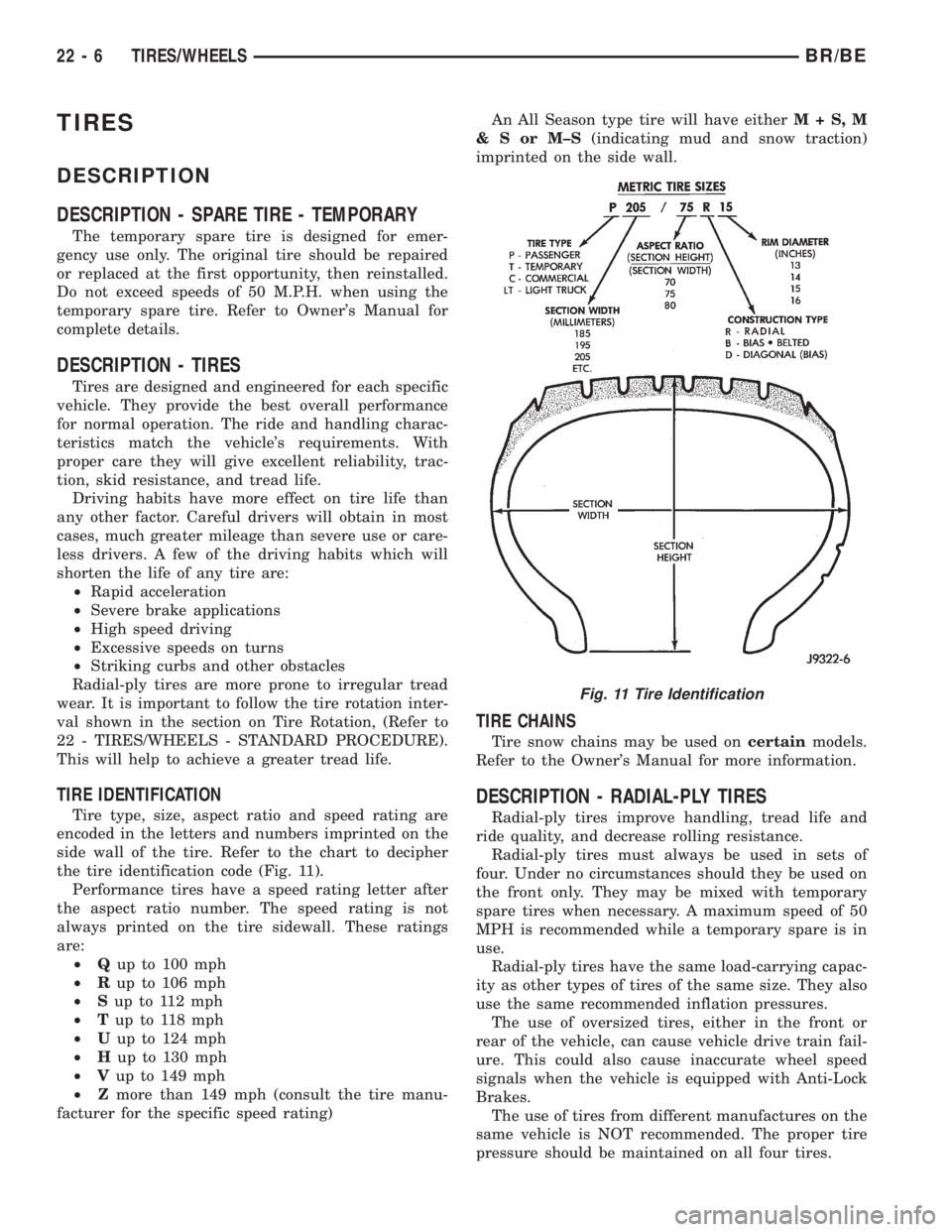

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 11).

Performance tires have a speed rating letter after

the aspect ratio number. The speed rating is not

always printed on the tire sidewall. These ratings

are:

²Qup to 100 mph

²Rup to 106 mph

²Sup to 112 mph

²Tup to 118 mph

²Uup to 124 mph

²Hup to 130 mph

²Vup to 149 mph

²Zmore than 149 mph (consult the tire manu-

facturer for the specific speed rating)An All Season type tire will have eitherM+S,M

&SorM±S(indicating mud and snow traction)

imprinted on the side wall.

TIRE CHAINS

Tire snow chains may be used oncertainmodels.

Refer to the Owner's Manual for more information.

DESCRIPTION - RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life and

ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

Fig. 11 Tire Identification

22 - 6 TIRES/WHEELSBR/BE

Page 1964 of 2255

DIAGNOSIS AND TESTING - TIRE NOISE OR

VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, vibration, wheel

defects, or possibly tire imbalance.

To find out if tires are causing the noise or vibra-

tion, drive the vehicle over a smooth road at varying

speeds. Note the noise level during acceleration and

deceleration. The engine, differential and exhaust

noises will change as speed varies, while the tire

noise will usually remain constant.

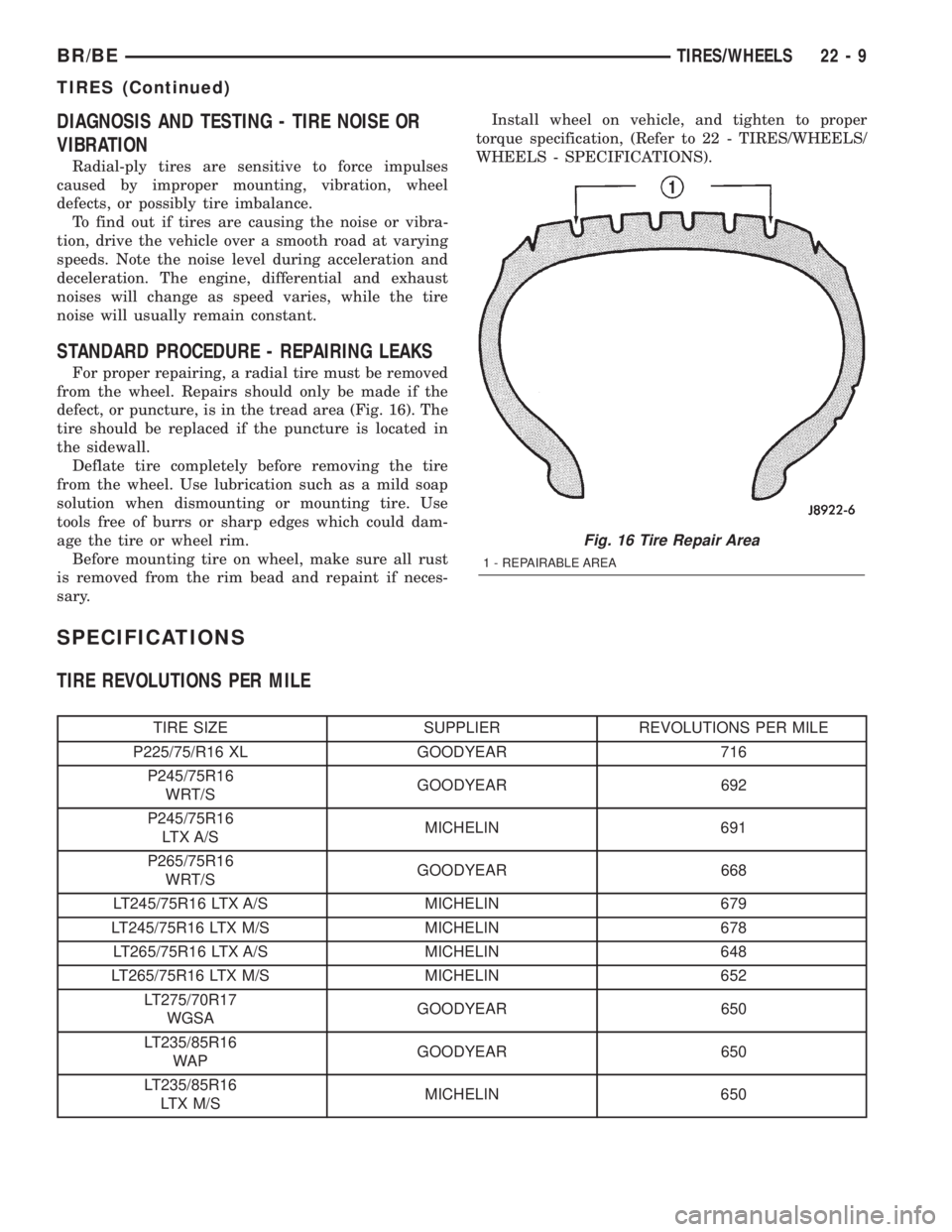

STANDARD PROCEDURE - REPAIRING LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 16). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before removing the tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could dam-

age the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.Install wheel on vehicle, and tighten to proper

torque specification, (Refer to 22 - TIRES/WHEELS/

WHEELS - SPECIFICATIONS).

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE

TIRE SIZE SUPPLIER REVOLUTIONS PER MILE

P225/75/R16 XL GOODYEAR 716

P245/75R16

WRT/SGOODYEAR 692

P245/75R16

LTX A/SMICHELIN 691

P265/75R16

WRT/SGOODYEAR 668

LT245/75R16 LTX A/S MICHELIN 679

LT245/75R16 LTX M/S MICHELIN 678

LT265/75R16 LTX A/S MICHELIN 648

LT265/75R16 LTX M/S MICHELIN 652

LT275/70R17

WGSAGOODYEAR 650

LT235/85R16

WAPGOODYEAR 650

LT235/85R16

LTX M/SMICHELIN 650

Fig. 16 Tire Repair Area

1 - REPAIRABLE AREA

BR/BETIRES/WHEELS 22 - 9

TIRES (Continued)