engine DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1665 of 2255

TORQUE CONVERTER

DESCRIPTION

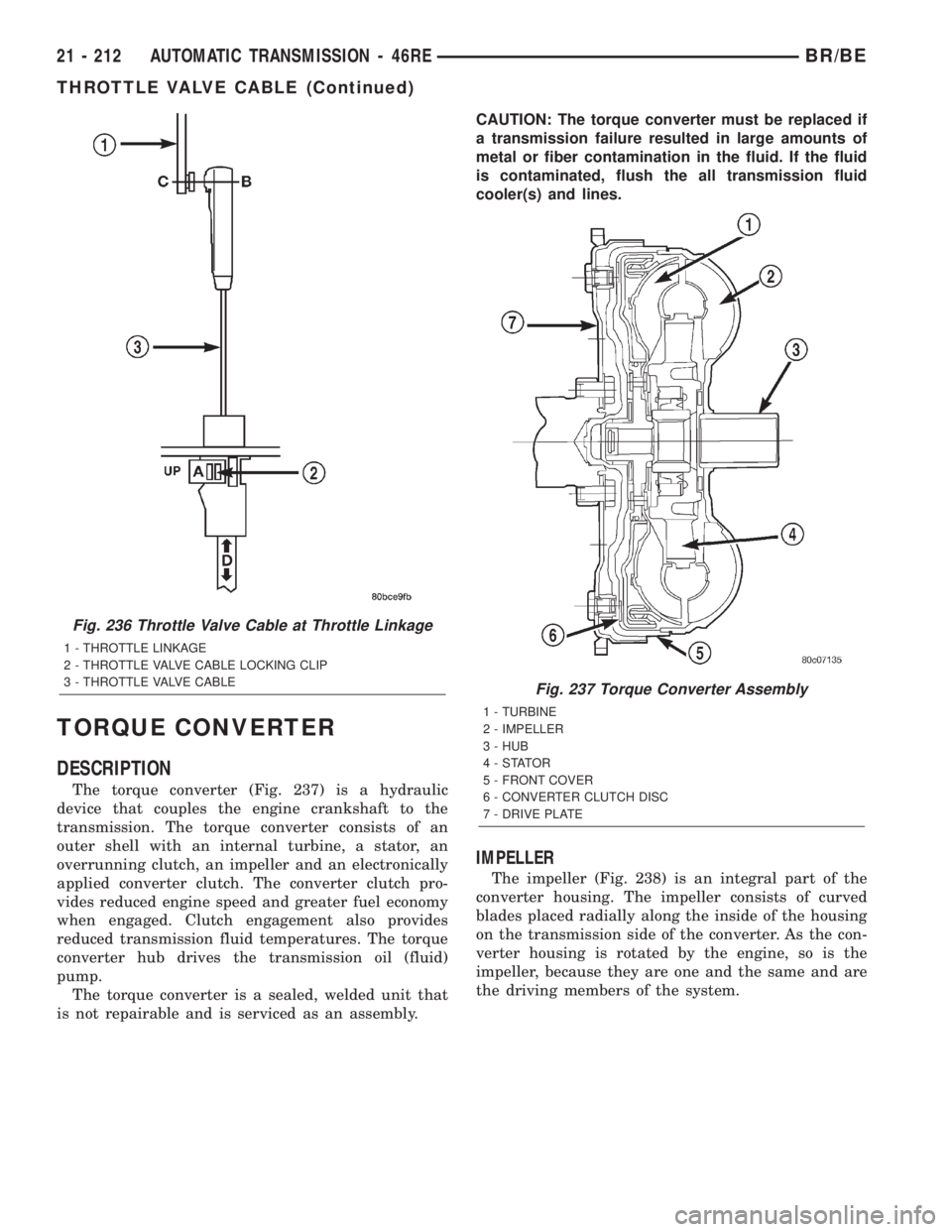

The torque converter (Fig. 237) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The torque

converter hub drives the transmission oil (fluid)

pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the all transmission fluid

cooler(s) and lines.

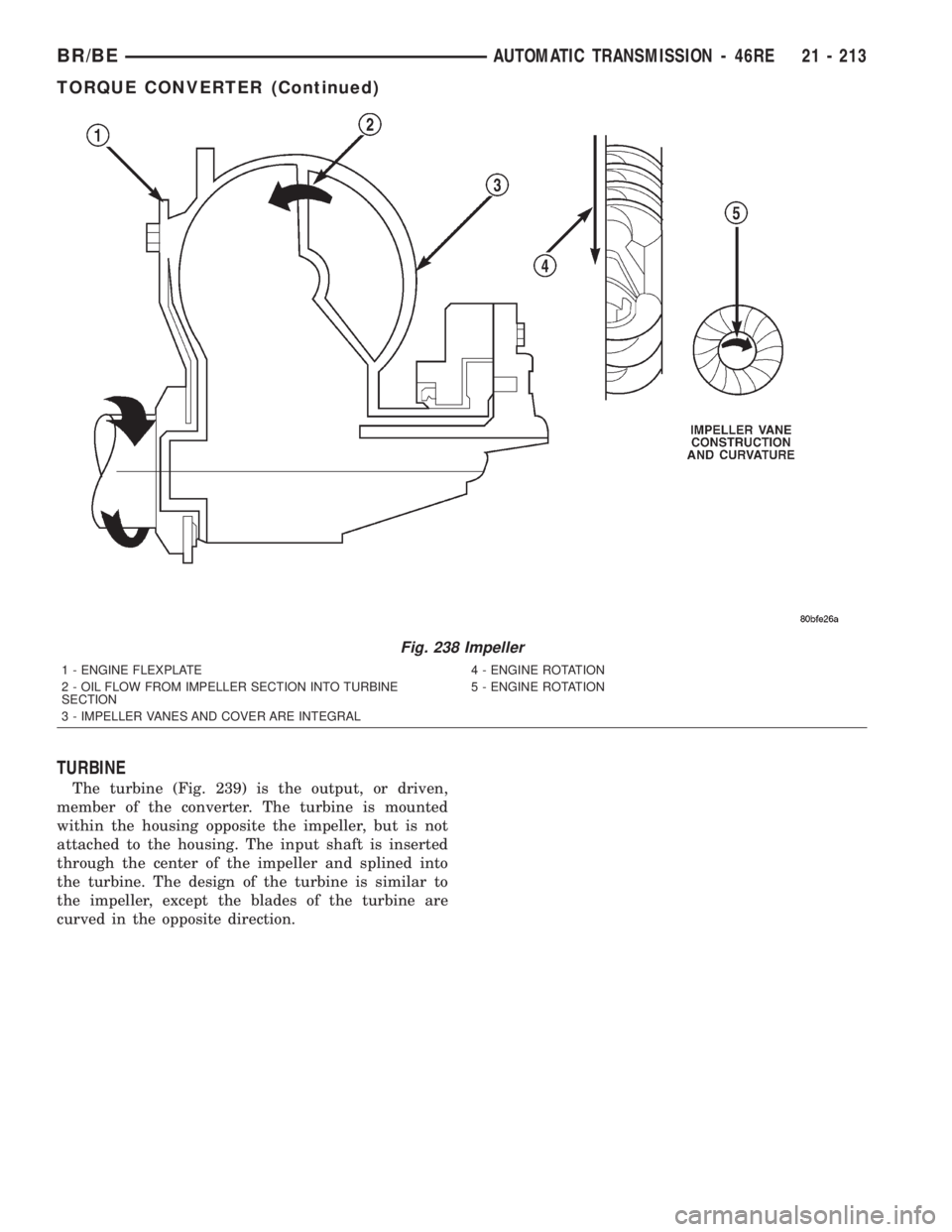

IMPELLER

The impeller (Fig. 238) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving members of the system.

Fig. 236 Throttle Valve Cable at Throttle Linkage

1 - THROTTLE LINKAGE

2 - THROTTLE VALVE CABLE LOCKING CLIP

3 - THROTTLE VALVE CABLE

Fig. 237 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - FRONT COVER

6 - CONVERTER CLUTCH DISC

7 - DRIVE PLATE

21 - 212 AUTOMATIC TRANSMISSION - 46REBR/BE

THROTTLE VALVE CABLE (Continued)

Page 1666 of 2255

TURBINE

The turbine (Fig. 239) is the output, or driven,

member of the converter. The turbine is mounted

within the housing opposite the impeller, but is not

attached to the housing. The input shaft is inserted

through the center of the impeller and splined into

the turbine. The design of the turbine is similar to

the impeller, except the blades of the turbine are

curved in the opposite direction.

Fig. 238 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 213

TORQUE CONVERTER (Continued)

Page 1667 of 2255

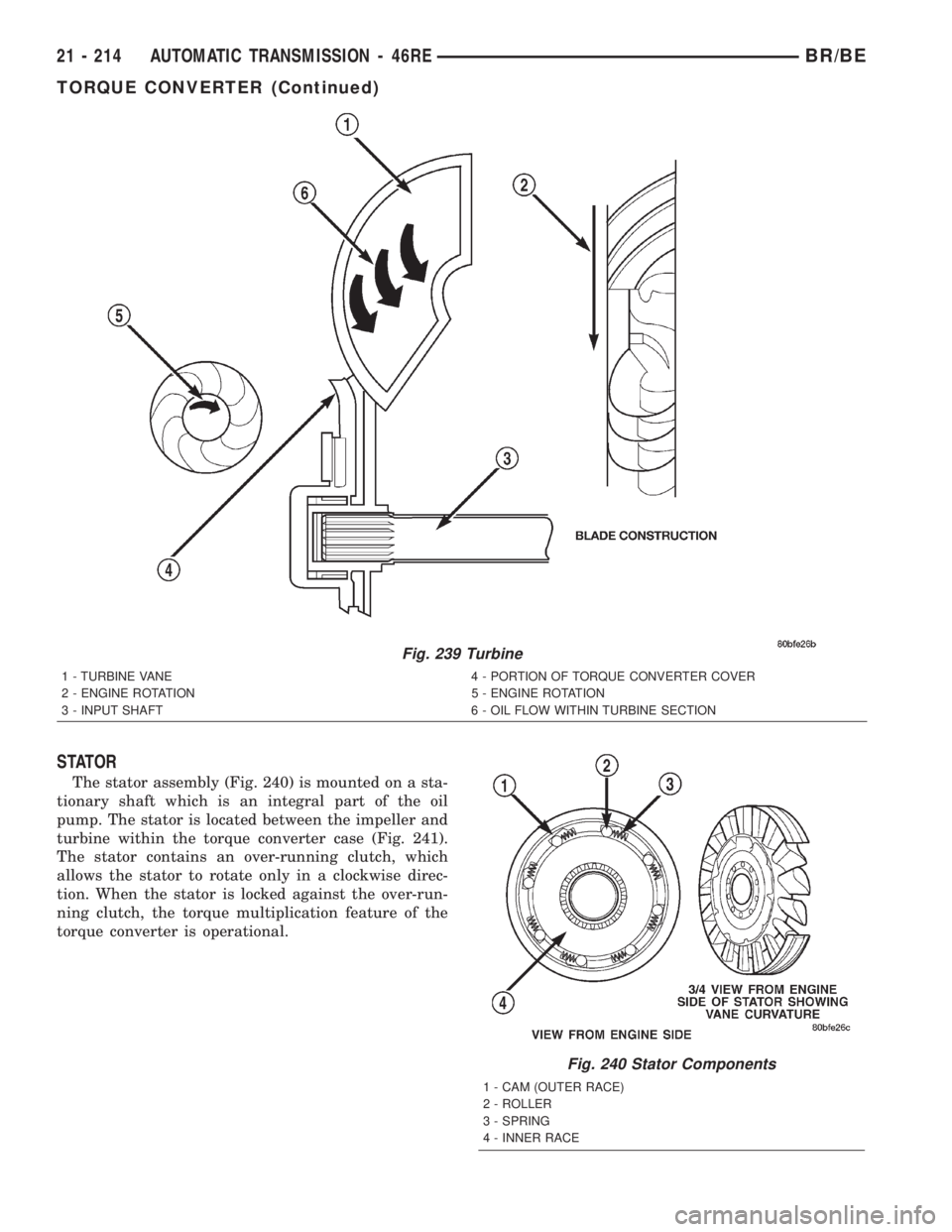

STATOR

The stator assembly (Fig. 240) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 241).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

Fig. 239 Turbine

1 - TURBINE VANE 4 - PORTION OF TORQUE CONVERTER COVER

2 - ENGINE ROTATION 5 - ENGINE ROTATION

3 - INPUT SHAFT 6 - OIL FLOW WITHIN TURBINE SECTION

Fig. 240 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

21 - 214 AUTOMATIC TRANSMISSION - 46REBR/BE

TORQUE CONVERTER (Continued)

Page 1668 of 2255

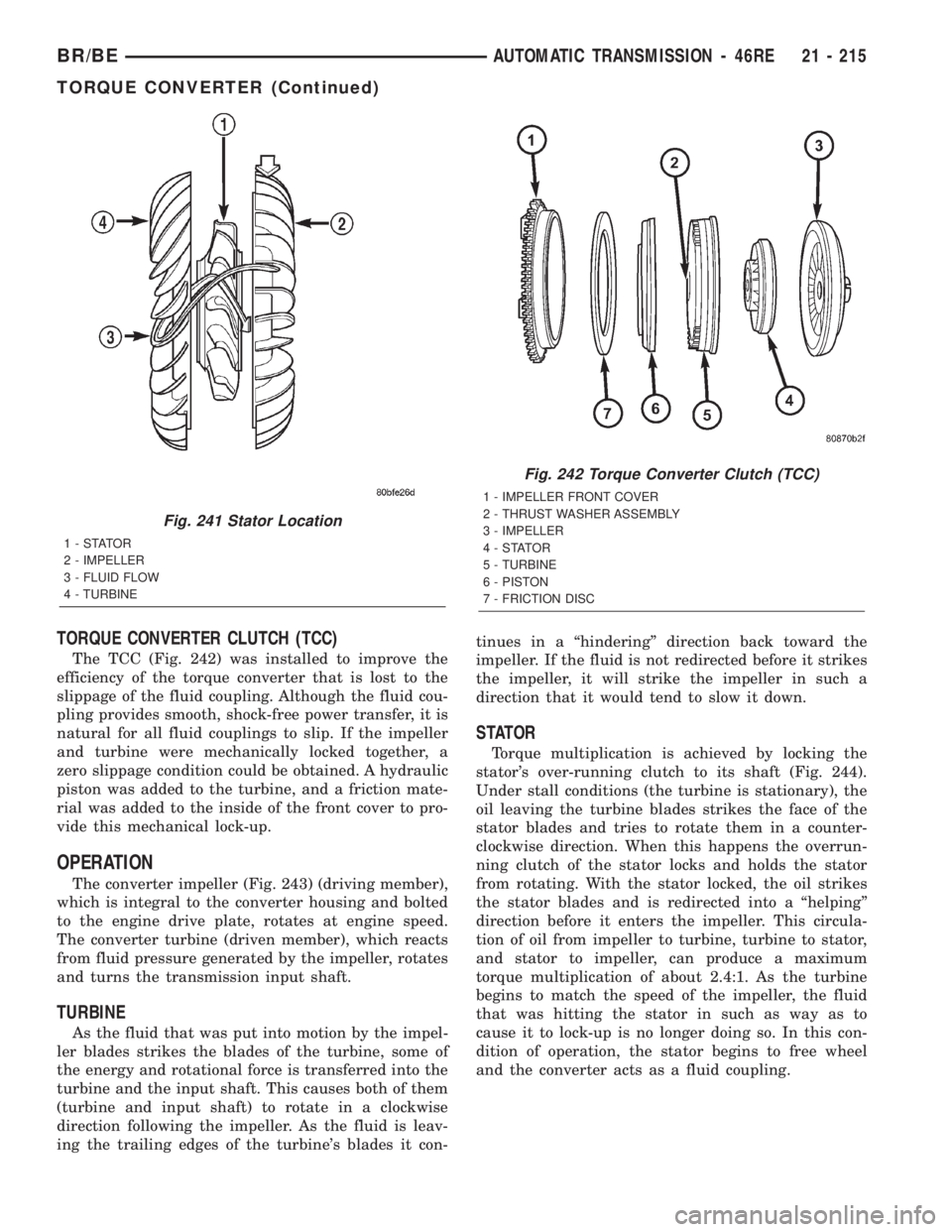

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 242) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston was added to the turbine, and a friction mate-

rial was added to the inside of the front cover to pro-

vide this mechanical lock-up.

OPERATION

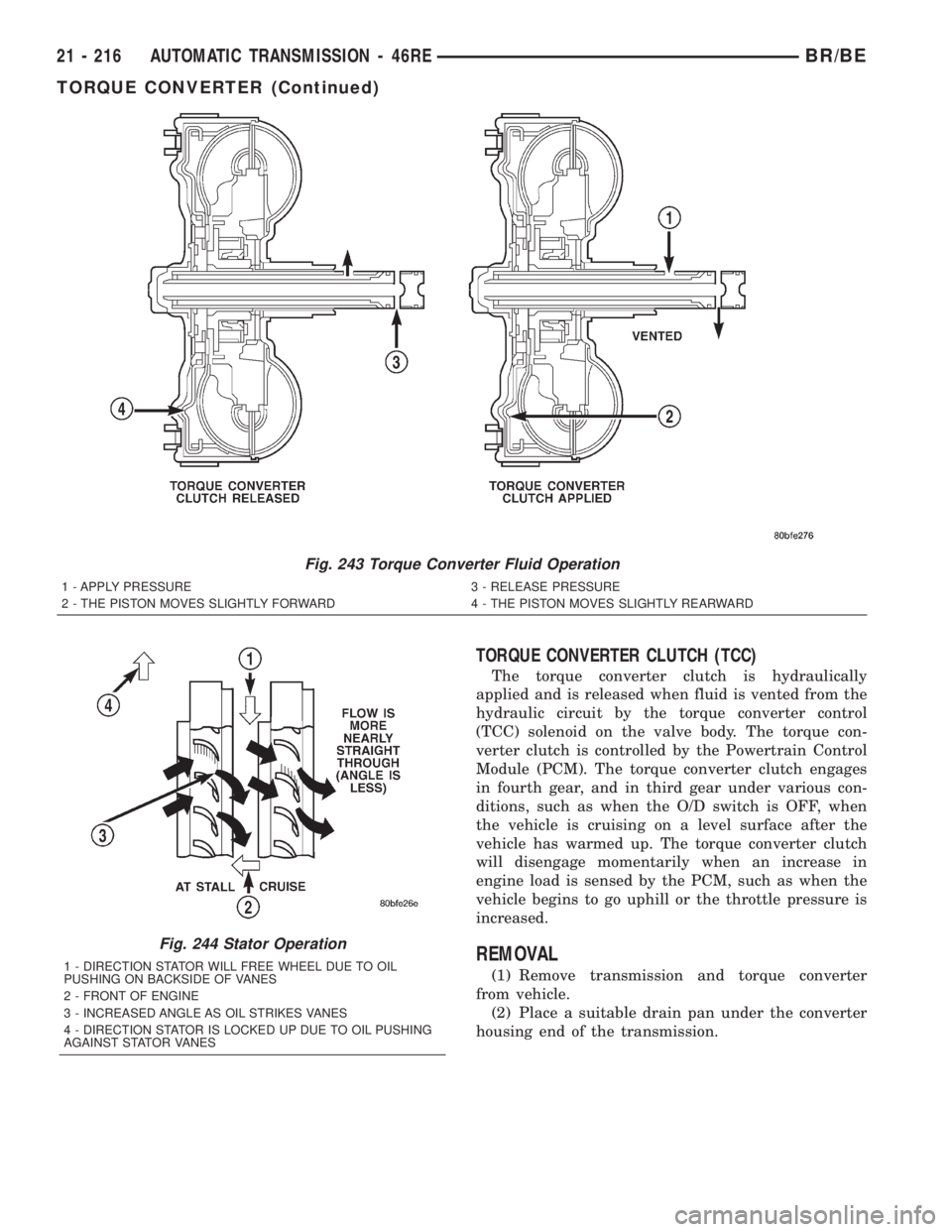

The converter impeller (Fig. 243) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

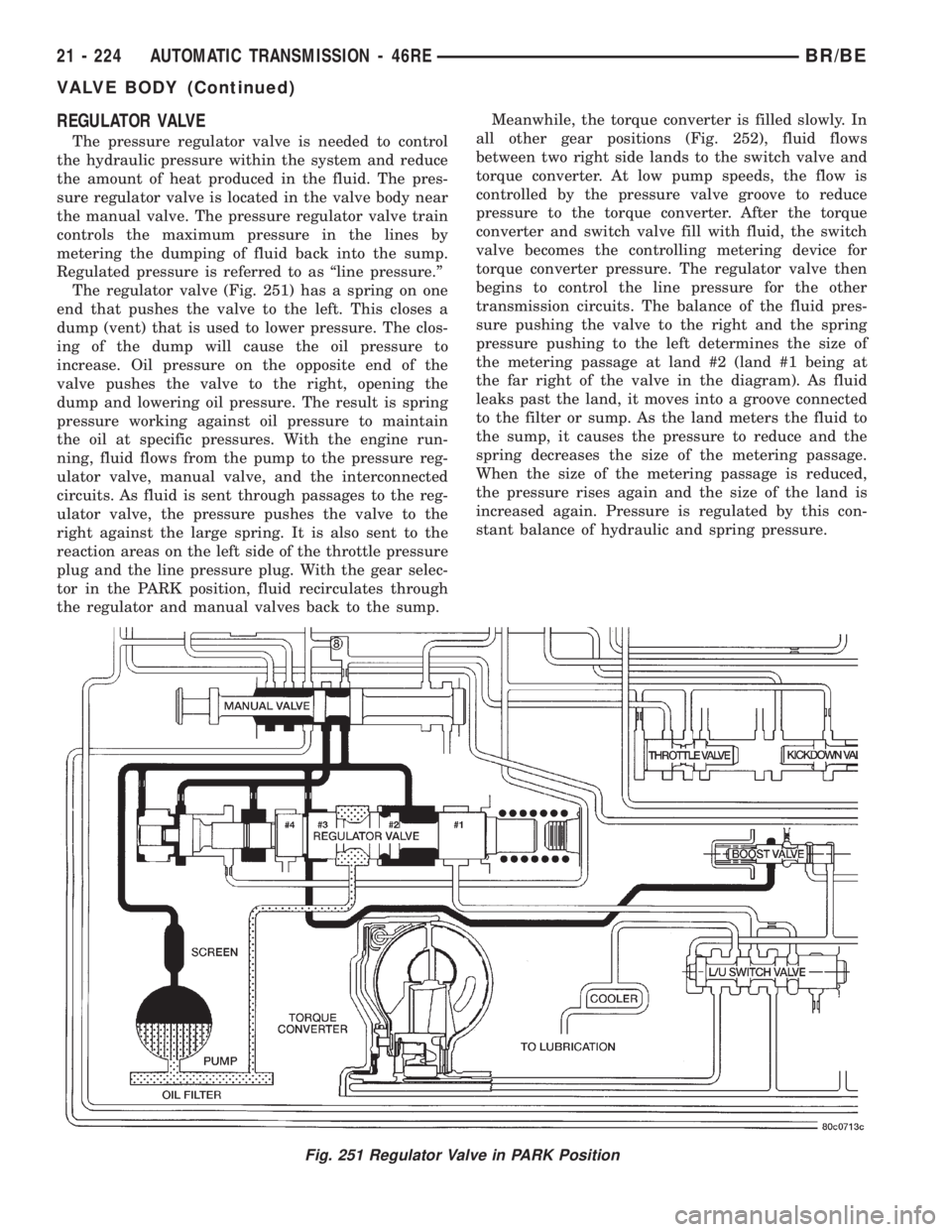

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 244).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the overrun-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

Fig. 241 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 242 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 215

TORQUE CONVERTER (Continued)

Page 1669 of 2255

TORQUE CONVERTER CLUTCH (TCC)

The torque converter clutch is hydraulically

applied and is released when fluid is vented from the

hydraulic circuit by the torque converter control

(TCC) solenoid on the valve body. The torque con-

verter clutch is controlled by the Powertrain Control

Module (PCM). The torque converter clutch engages

in fourth gear, and in third gear under various con-

ditions, such as when the O/D switch is OFF, when

the vehicle is cruising on a level surface after the

vehicle has warmed up. The torque converter clutch

will disengage momentarily when an increase in

engine load is sensed by the PCM, such as when the

vehicle begins to go uphill or the throttle pressure is

increased.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

Fig. 243 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

Fig. 244 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

21 - 216 AUTOMATIC TRANSMISSION - 46REBR/BE

TORQUE CONVERTER (Continued)

Page 1677 of 2255

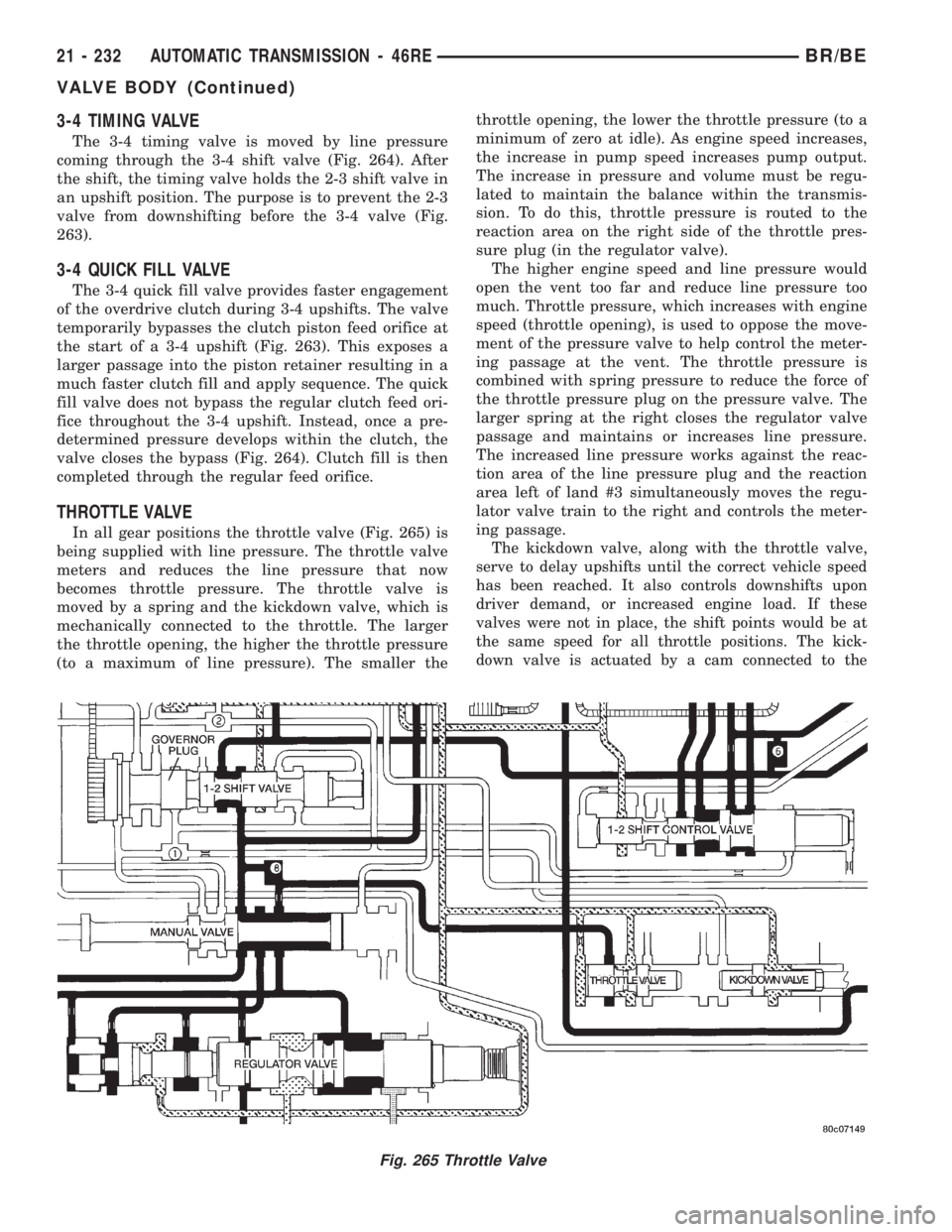

REGULATOR VALVE

The pressure regulator valve is needed to control

the hydraulic pressure within the system and reduce

the amount of heat produced in the fluid. The pres-

sure regulator valve is located in the valve body near

the manual valve. The pressure regulator valve train

controls the maximum pressure in the lines by

metering the dumping of fluid back into the sump.

Regulated pressure is referred to as ªline pressure.º

The regulator valve (Fig. 251) has a spring on one

end that pushes the valve to the left. This closes a

dump (vent) that is used to lower pressure. The clos-

ing of the dump will cause the oil pressure to

increase. Oil pressure on the opposite end of the

valve pushes the valve to the right, opening the

dump and lowering oil pressure. The result is spring

pressure working against oil pressure to maintain

the oil at specific pressures. With the engine run-

ning, fluid flows from the pump to the pressure reg-

ulator valve, manual valve, and the interconnected

circuits. As fluid is sent through passages to the reg-

ulator valve, the pressure pushes the valve to the

right against the large spring. It is also sent to the

reaction areas on the left side of the throttle pressure

plug and the line pressure plug. With the gear selec-

tor in the PARK position, fluid recirculates through

the regulator and manual valves back to the sump.Meanwhile, the torque converter is filled slowly. In

all other gear positions (Fig. 252), fluid flows

between two right side lands to the switch valve and

torque converter. At low pump speeds, the flow is

controlled by the pressure valve groove to reduce

pressure to the torque converter. After the torque

converter and switch valve fill with fluid, the switch

valve becomes the controlling metering device for

torque converter pressure. The regulator valve then

begins to control the line pressure for the other

transmission circuits. The balance of the fluid pres-

sure pushing the valve to the right and the spring

pressure pushing to the left determines the size of

the metering passage at land #2 (land #1 being at

the far right of the valve in the diagram). As fluid

leaks past the land, it moves into a groove connected

to the filter or sump. As the land meters the fluid to

the sump, it causes the pressure to reduce and the

spring decreases the size of the metering passage.

When the size of the metering passage is reduced,

the pressure rises again and the size of the land is

increased again. Pressure is regulated by this con-

stant balance of hydraulic and spring pressure.

Fig. 251 Regulator Valve in PARK Position

21 - 224 AUTOMATIC TRANSMISSION - 46REBR/BE

VALVE BODY (Continued)

Page 1685 of 2255

3-4 TIMING VALVE

The 3-4 timing valve is moved by line pressure

coming through the 3-4 shift valve (Fig. 264). After

the shift, the timing valve holds the 2-3 shift valve in

an upshift position. The purpose is to prevent the 2-3

valve from downshifting before the 3-4 valve (Fig.

263).

3-4 QUICK FILL VALVE

The 3-4 quick fill valve provides faster engagement

of the overdrive clutch during 3-4 upshifts. The valve

temporarily bypasses the clutch piston feed orifice at

the start of a 3-4 upshift (Fig. 263). This exposes a

larger passage into the piston retainer resulting in a

much faster clutch fill and apply sequence. The quick

fill valve does not bypass the regular clutch feed ori-

fice throughout the 3-4 upshift. Instead, once a pre-

determined pressure develops within the clutch, the

valve closes the bypass (Fig. 264). Clutch fill is then

completed through the regular feed orifice.

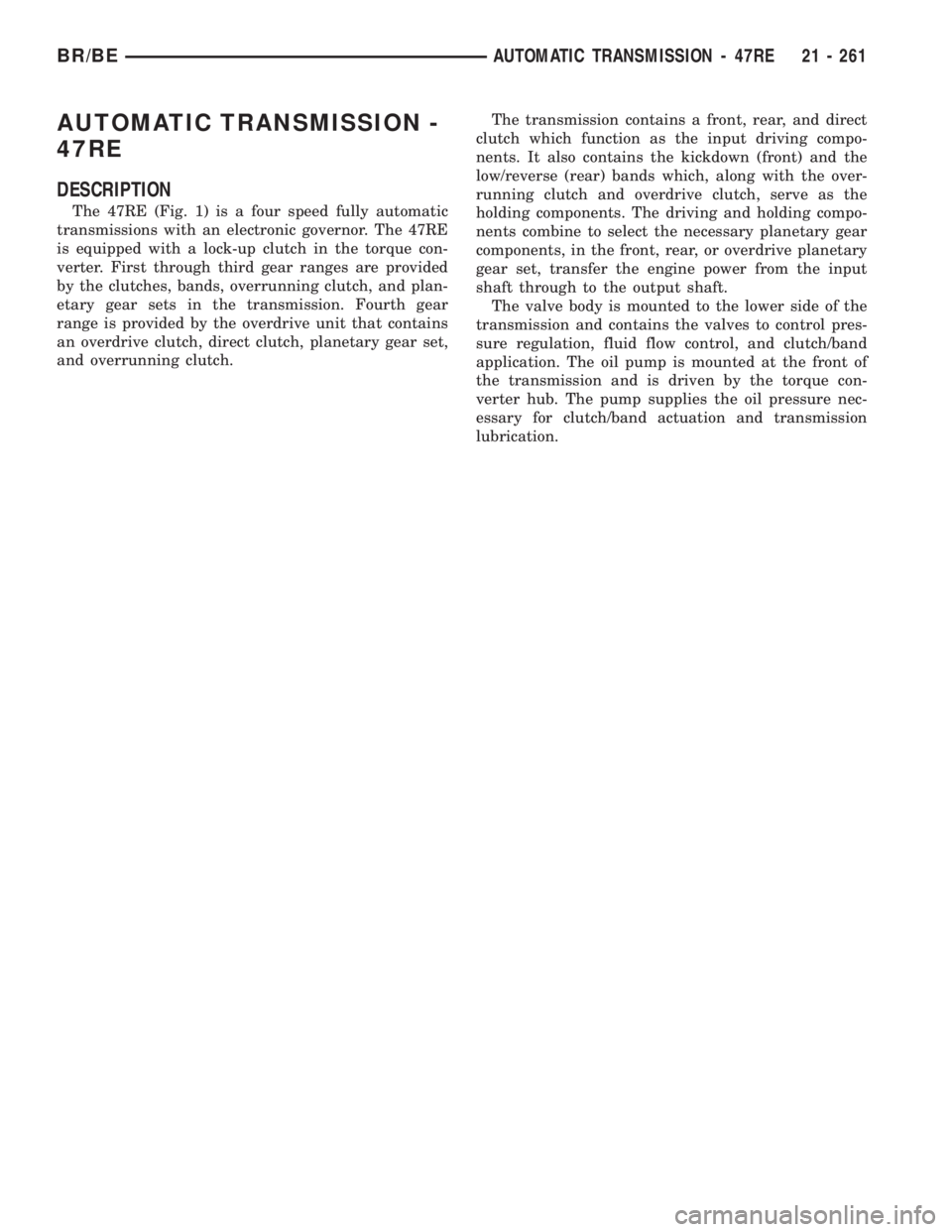

THROTTLE VALVE

In all gear positions the throttle valve (Fig. 265) is

being supplied with line pressure. The throttle valve

meters and reduces the line pressure that now

becomes throttle pressure. The throttle valve is

moved by a spring and the kickdown valve, which is

mechanically connected to the throttle. The larger

the throttle opening, the higher the throttle pressure

(to a maximum of line pressure). The smaller thethrottle opening, the lower the throttle pressure (to a

minimum of zero at idle). As engine speed increases,

the increase in pump speed increases pump output.

The increase in pressure and volume must be regu-

lated to maintain the balance within the transmis-

sion. To do this, throttle pressure is routed to the

reaction area on the right side of the throttle pres-

sure plug (in the regulator valve).

The higher engine speed and line pressure would

open the vent too far and reduce line pressure too

much. Throttle pressure, which increases with engine

speed (throttle opening), is used to oppose the move-

ment of the pressure valve to help control the meter-

ing passage at the vent. The throttle pressure is

combined with spring pressure to reduce the force of

the throttle pressure plug on the pressure valve. The

larger spring at the right closes the regulator valve

passage and maintains or increases line pressure.

The increased line pressure works against the reac-

tion area of the line pressure plug and the reaction

area left of land #3 simultaneously moves the regu-

lator valve train to the right and controls the meter-

ing passage.The kickdown valve, along with the throttle valve,

serve to delay upshifts until the correct vehicle speed

has been reached. It also controls downshifts upon

driver demand, or increased engine load. If these

valves were not in place, the shift points would be at

the same speed for all throttle positions. The kick-

down valve is actuated by a cam connected to the

Fig. 265 Throttle Valve

21 - 232 AUTOMATIC TRANSMISSION - 46REBR/BE

VALVE BODY (Continued)

Page 1714 of 2255

AUTOMATIC TRANSMISSION -

47RE

DESCRIPTION

The 47RE (Fig. 1) is a four speed fully automatic

transmissions with an electronic governor. The 47RE

is equipped with a lock-up clutch in the torque con-

verter. First through third gear ranges are provided

by the clutches, bands, overrunning clutch, and plan-

etary gear sets in the transmission. Fourth gear

range is provided by the overdrive unit that contains

an overdrive clutch, direct clutch, planetary gear set,

and overrunning clutch.The transmission contains a front, rear, and direct

clutch which function as the input driving compo-

nents. It also contains the kickdown (front) and the

low/reverse (rear) bands which, along with the over-

running clutch and overdrive clutch, serve as the

holding components. The driving and holding compo-

nents combine to select the necessary planetary gear

components, in the front, rear, or overdrive planetary

gear set, transfer the engine power from the input

shaft through to the output shaft.

The valve body is mounted to the lower side of the

transmission and contains the valves to control pres-

sure regulation, fluid flow control, and clutch/band

application. The oil pump is mounted at the front of

the transmission and is driven by the torque con-

verter hub. The pump supplies the oil pressure nec-

essary for clutch/band actuation and transmission

lubrication.

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 261

Page 1716 of 2255

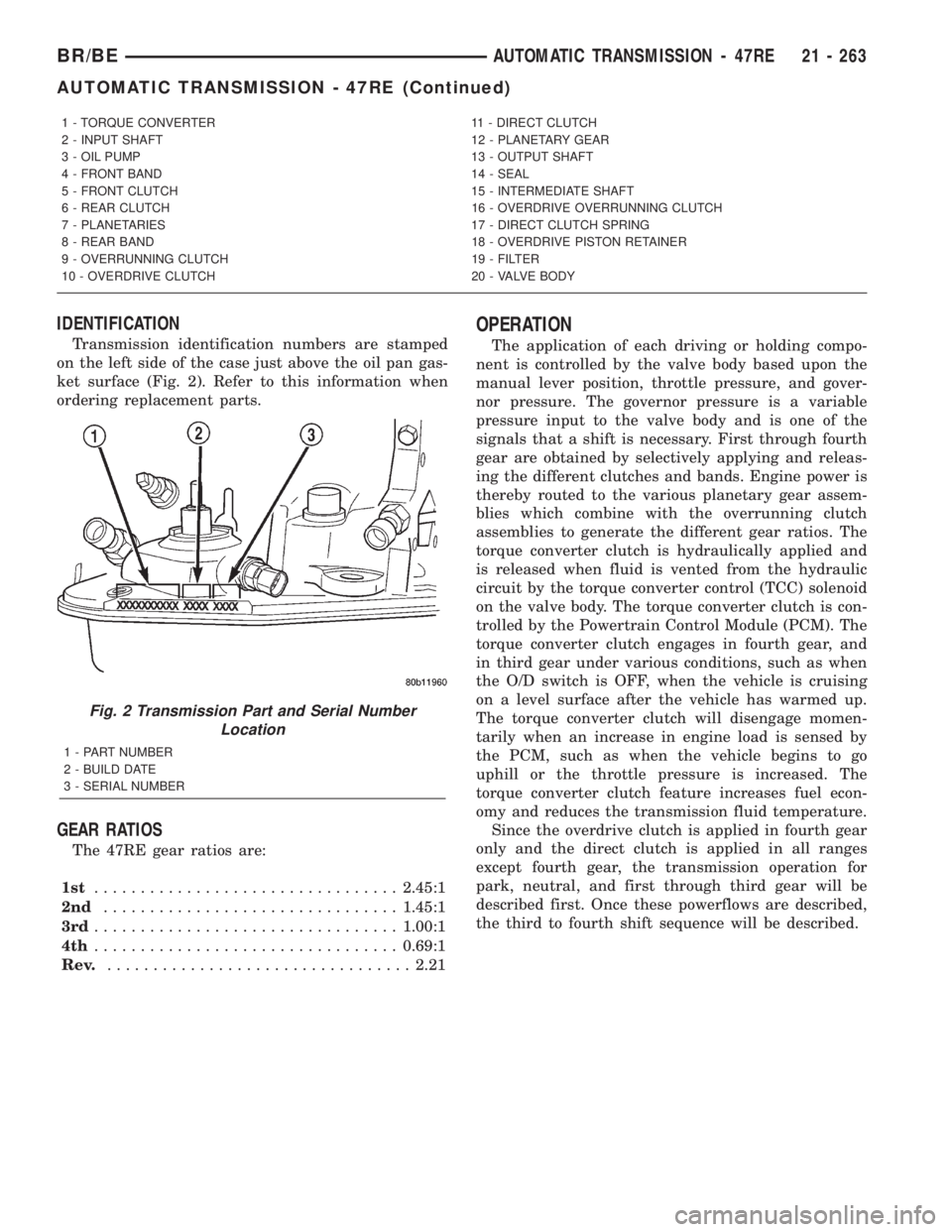

IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan gas-

ket surface (Fig. 2). Refer to this information when

ordering replacement parts.

GEAR RATIOS

The 47RE gear ratios are:

1st.................................2.45:1

2nd................................1.45:1

3rd.................................1.00:1

4th.................................0.69:1

Rev..................................2.21

OPERATION

The application of each driving or holding compo-

nent is controlled by the valve body based upon the

manual lever position, throttle pressure, and gover-

nor pressure. The governor pressure is a variable

pressure input to the valve body and is one of the

signals that a shift is necessary. First through fourth

gear are obtained by selectively applying and releas-

ing the different clutches and bands. Engine power is

thereby routed to the various planetary gear assem-

blies which combine with the overrunning clutch

assemblies to generate the different gear ratios. The

torque converter clutch is hydraulically applied and

is released when fluid is vented from the hydraulic

circuit by the torque converter control (TCC) solenoid

on the valve body. The torque converter clutch is con-

trolled by the Powertrain Control Module (PCM). The

torque converter clutch engages in fourth gear, and

in third gear under various conditions, such as when

the O/D switch is OFF, when the vehicle is cruising

on a level surface after the vehicle has warmed up.

The torque converter clutch will disengage momen-

tarily when an increase in engine load is sensed by

the PCM, such as when the vehicle begins to go

uphill or the throttle pressure is increased. The

torque converter clutch feature increases fuel econ-

omy and reduces the transmission fluid temperature.

Since the overdrive clutch is applied in fourth gear

only and the direct clutch is applied in all ranges

except fourth gear, the transmission operation for

park, neutral, and first through third gear will be

described first. Once these powerflows are described,

the third to fourth shift sequence will be described.

1 - TORQUE CONVERTER 11 - DIRECT CLUTCH

2 - INPUT SHAFT 12 - PLANETARY GEAR

3 - OIL PUMP 13 - OUTPUT SHAFT

4 - FRONT BAND 14 - SEAL

5 - FRONT CLUTCH 15 - INTERMEDIATE SHAFT

6 - REAR CLUTCH 16 - OVERDRIVE OVERRUNNING CLUTCH

7 - PLANETARIES 17 - DIRECT CLUTCH SPRING

8 - REAR BAND 18 - OVERDRIVE PISTON RETAINER

9 - OVERRUNNING CLUTCH 19 - FILTER

10 - OVERDRIVE CLUTCH 20 - VALVE BODY

Fig. 2 Transmission Part and Serial Number

Location

1 - PART NUMBER

2 - BUILD DATE

3 - SERIAL NUMBER

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 263

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 1717 of 2255

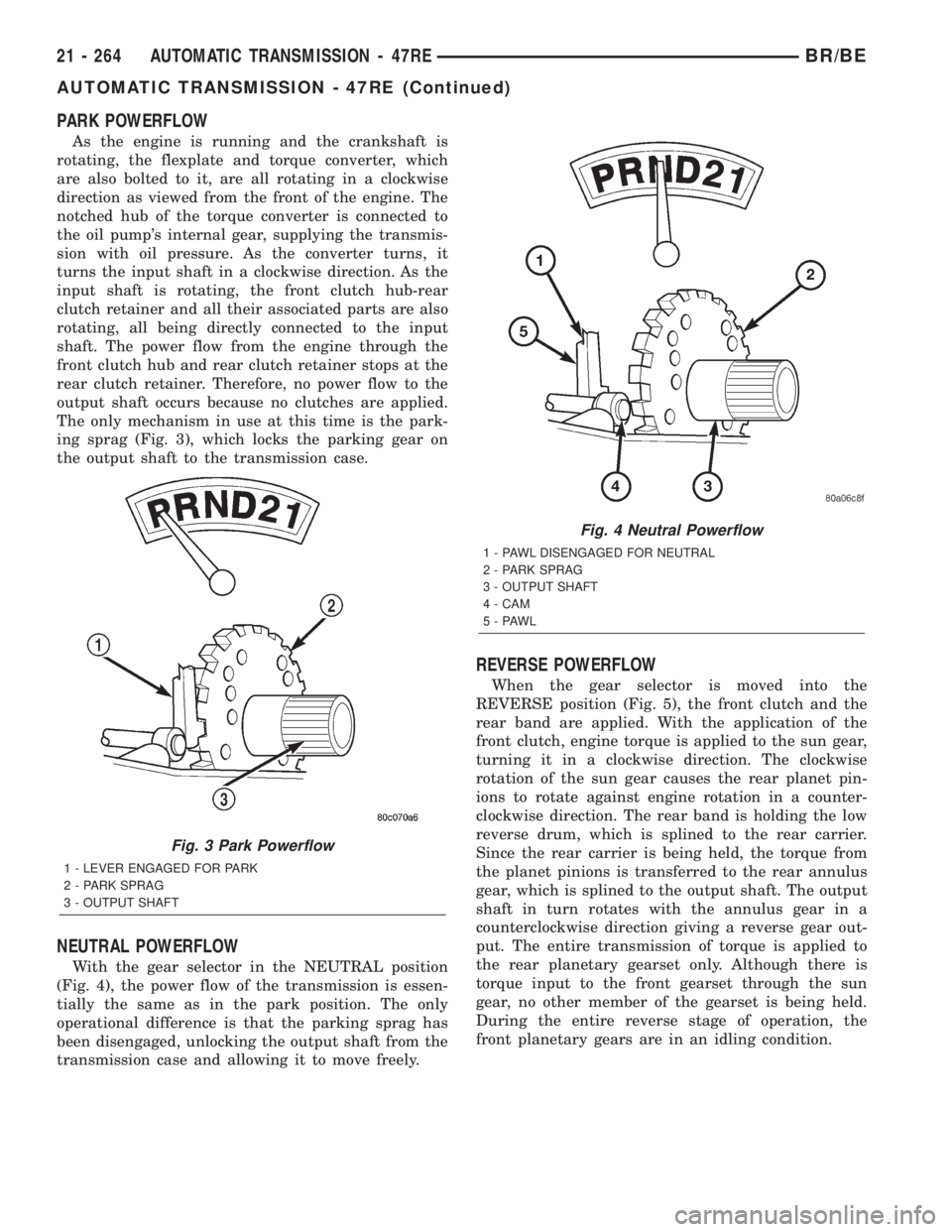

PARK POWERFLOW

As the engine is running and the crankshaft is

rotating, the flexplate and torque converter, which

are also bolted to it, are all rotating in a clockwise

direction as viewed from the front of the engine. The

notched hub of the torque converter is connected to

the oil pump's internal gear, supplying the transmis-

sion with oil pressure. As the converter turns, it

turns the input shaft in a clockwise direction. As the

input shaft is rotating, the front clutch hub-rear

clutch retainer and all their associated parts are also

rotating, all being directly connected to the input

shaft. The power flow from the engine through the

front clutch hub and rear clutch retainer stops at the

rear clutch retainer. Therefore, no power flow to the

output shaft occurs because no clutches are applied.

The only mechanism in use at this time is the park-

ing sprag (Fig. 3), which locks the parking gear on

the output shaft to the transmission case.

NEUTRAL POWERFLOW

With the gear selector in the NEUTRAL position

(Fig. 4), the power flow of the transmission is essen-

tially the same as in the park position. The only

operational difference is that the parking sprag has

been disengaged, unlocking the output shaft from the

transmission case and allowing it to move freely.

REVERSE POWERFLOW

When the gear selector is moved into the

REVERSE position (Fig. 5), the front clutch and the

rear band are applied. With the application of the

front clutch, engine torque is applied to the sun gear,

turning it in a clockwise direction. The clockwise

rotation of the sun gear causes the rear planet pin-

ions to rotate against engine rotation in a counter-

clockwise direction. The rear band is holding the low

reverse drum, which is splined to the rear carrier.

Since the rear carrier is being held, the torque from

the planet pinions is transferred to the rear annulus

gear, which is splined to the output shaft. The output

shaft in turn rotates with the annulus gear in a

counterclockwise direction giving a reverse gear out-

put. The entire transmission of torque is applied to

the rear planetary gearset only. Although there is

torque input to the front gearset through the sun

gear, no other member of the gearset is being held.

During the entire reverse stage of operation, the

front planetary gears are in an idling condition.

Fig. 3 Park Powerflow

1 - LEVER ENGAGED FOR PARK

2 - PARK SPRAG

3 - OUTPUT SHAFT

Fig. 4 Neutral Powerflow

1 - PAWL DISENGAGED FOR NEUTRAL

2 - PARK SPRAG

3 - OUTPUT SHAFT

4 - CAM

5-PAWL

21 - 264 AUTOMATIC TRANSMISSION - 47REBR/BE

AUTOMATIC TRANSMISSION - 47RE (Continued)