engine DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 2175 of 2255

(2) Reassemble and reinstall the HVAC housing in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

NOTE: If the evaporator is replaced, add 60 millili-

ters (2 fluid ounces) of refrigerant oil to the refrig-

erant system.

A/C ORIFICE TUBE

DESCRIPTION

The fixed orifice tube is installed in the liquid line

between the outlet of the condenser and the inlet of

the evaporator. The fixed orifice tube is only serviced

as an integral part of the liquid line.

OPERATION

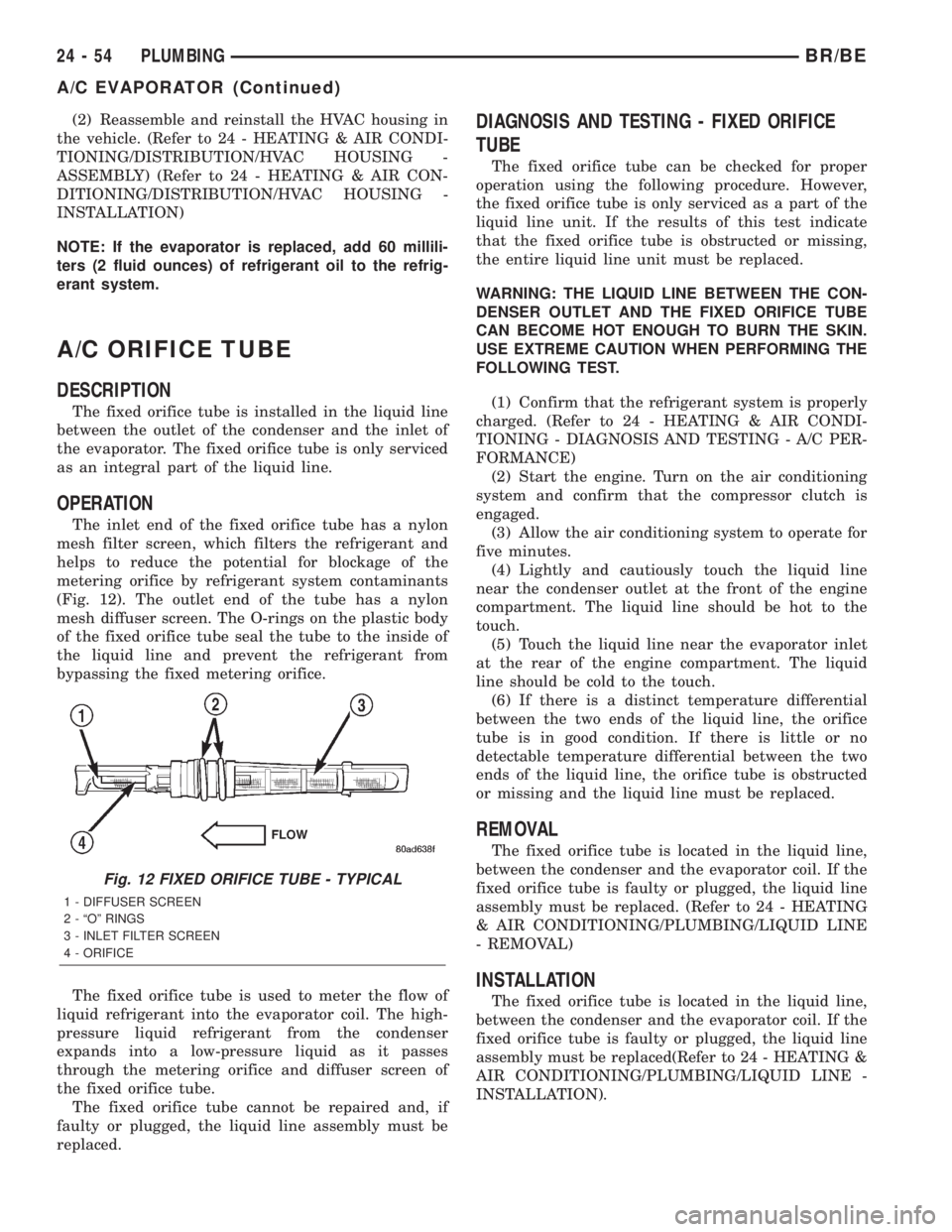

The inlet end of the fixed orifice tube has a nylon

mesh filter screen, which filters the refrigerant and

helps to reduce the potential for blockage of the

metering orifice by refrigerant system contaminants

(Fig. 12). The outlet end of the tube has a nylon

mesh diffuser screen. The O-rings on the plastic body

of the fixed orifice tube seal the tube to the inside of

the liquid line and prevent the refrigerant from

bypassing the fixed metering orifice.

The fixed orifice tube is used to meter the flow of

liquid refrigerant into the evaporator coil. The high-

pressure liquid refrigerant from the condenser

expands into a low-pressure liquid as it passes

through the metering orifice and diffuser screen of

the fixed orifice tube.

The fixed orifice tube cannot be repaired and, if

faulty or plugged, the liquid line assembly must be

replaced.

DIAGNOSIS AND TESTING - FIXED ORIFICE

TUBE

The fixed orifice tube can be checked for proper

operation using the following procedure. However,

the fixed orifice tube is only serviced as a part of the

liquid line unit. If the results of this test indicate

that the fixed orifice tube is obstructed or missing,

the entire liquid line unit must be replaced.

WARNING: THE LIQUID LINE BETWEEN THE CON-

DENSER OUTLET AND THE FIXED ORIFICE TUBE

CAN BECOME HOT ENOUGH TO BURN THE SKIN.

USE EXTREME CAUTION WHEN PERFORMING THE

FOLLOWING TEST.

(1) Confirm that the refrigerant system is properly

charged. (Refer to 24 - HEATING & AIR CONDI-

TIONING - DIAGNOSIS AND TESTING - A/C PER-

FORMANCE)

(2) Start the engine. Turn on the air conditioning

system and confirm that the compressor clutch is

engaged.

(3) Allow the air conditioning system to operate for

five minutes.

(4) Lightly and cautiously touch the liquid line

near the condenser outlet at the front of the engine

compartment. The liquid line should be hot to the

touch.

(5) Touch the liquid line near the evaporator inlet

at the rear of the engine compartment. The liquid

line should be cold to the touch.

(6) If there is a distinct temperature differential

between the two ends of the liquid line, the orifice

tube is in good condition. If there is little or no

detectable temperature differential between the two

ends of the liquid line, the orifice tube is obstructed

or missing and the liquid line must be replaced.

REMOVAL

The fixed orifice tube is located in the liquid line,

between the condenser and the evaporator coil. If the

fixed orifice tube is faulty or plugged, the liquid line

assembly must be replaced. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/LIQUID LINE

- REMOVAL)

INSTALLATION

The fixed orifice tube is located in the liquid line,

between the condenser and the evaporator coil. If the

fixed orifice tube is faulty or plugged, the liquid line

assembly must be replaced(Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/LIQUID LINE -

INSTALLATION).

Fig. 12 FIXED ORIFICE TUBE - TYPICAL

1 - DIFFUSER SCREEN

2 - ªOº RINGS

3 - INLET FILTER SCREEN

4 - ORIFICE

24 - 54 PLUMBINGBR/BE

A/C EVAPORATOR (Continued)

Page 2176 of 2255

ACCUMULATOR

DESCRIPTION

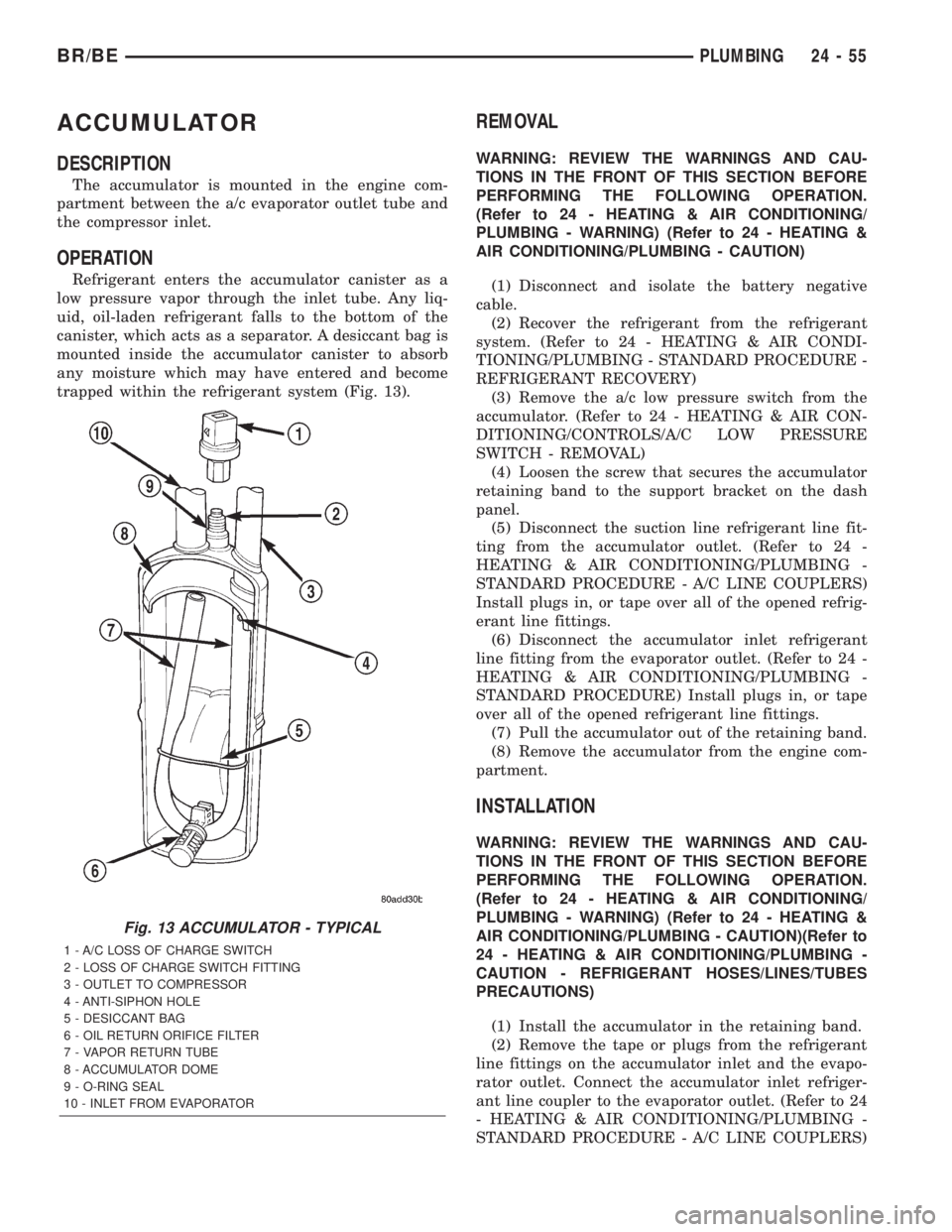

The accumulator is mounted in the engine com-

partment between the a/c evaporator outlet tube and

the compressor inlet.

OPERATION

Refrigerant enters the accumulator canister as a

low pressure vapor through the inlet tube. Any liq-

uid, oil-laden refrigerant falls to the bottom of the

canister, which acts as a separator. A desiccant bag is

mounted inside the accumulator canister to absorb

any moisture which may have entered and become

trapped within the refrigerant system (Fig. 13).

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Remove the a/c low pressure switch from the

accumulator. (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/A/C LOW PRESSURE

SWITCH - REMOVAL)

(4) Loosen the screw that secures the accumulator

retaining band to the support bracket on the dash

panel.

(5) Disconnect the suction line refrigerant line fit-

ting from the accumulator outlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(6) Disconnect the accumulator inlet refrigerant

line fitting from the evaporator outlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE) Install plugs in, or tape

over all of the opened refrigerant line fittings.

(7) Pull the accumulator out of the retaining band.

(8) Remove the accumulator from the engine com-

partment.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install the accumulator in the retaining band.

(2) Remove the tape or plugs from the refrigerant

line fittings on the accumulator inlet and the evapo-

rator outlet. Connect the accumulator inlet refriger-

ant line coupler to the evaporator outlet. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Fig. 13 ACCUMULATOR - TYPICAL

1 - A/C LOSS OF CHARGE SWITCH

2 - LOSS OF CHARGE SWITCH FITTING

3 - OUTLET TO COMPRESSOR

4 - ANTI-SIPHON HOLE

5 - DESICCANT BAG

6 - OIL RETURN ORIFICE FILTER

7 - VAPOR RETURN TUBE

8 - ACCUMULATOR DOME

9 - O-RING SEAL

10 - INLET FROM EVAPORATOR

BR/BEPLUMBING 24 - 55

Page 2177 of 2255

(3) Tighten the accumulator retaining band screw

to 4.5 N´m (40 in. lbs.).

(4) Remove the tape or plugs from the refrigerant

line fittings on the suction line and the accumulator

outlet. Connect the suction line refrigerant line cou-

pler to the accumulator outlet. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(5) Reinstall the a/c low pressure switch on the

accumulator. (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/A/C LOW PRESSURE

SWITCH - INSTALLATION)

(6) Connect the battery negative cable.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

NOTE: If the accumulator is replaced, add 60 milli-

liters (2 fluid ounces) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

HEATER CORE

DESCRIPTION

The heater core is located in the HVAC housing,

under the instrument panel. It is a heat exchanger

made of rows of tubes and fins.

The heater core is not repairable and if damaged it

must be replaced.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The blend door

allows control of the heater output air temperature

by controlling how much of the air flowing through

the HVAC housing is directed through the heater

core. The blower motor speed controls the volume of

air flowing through the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

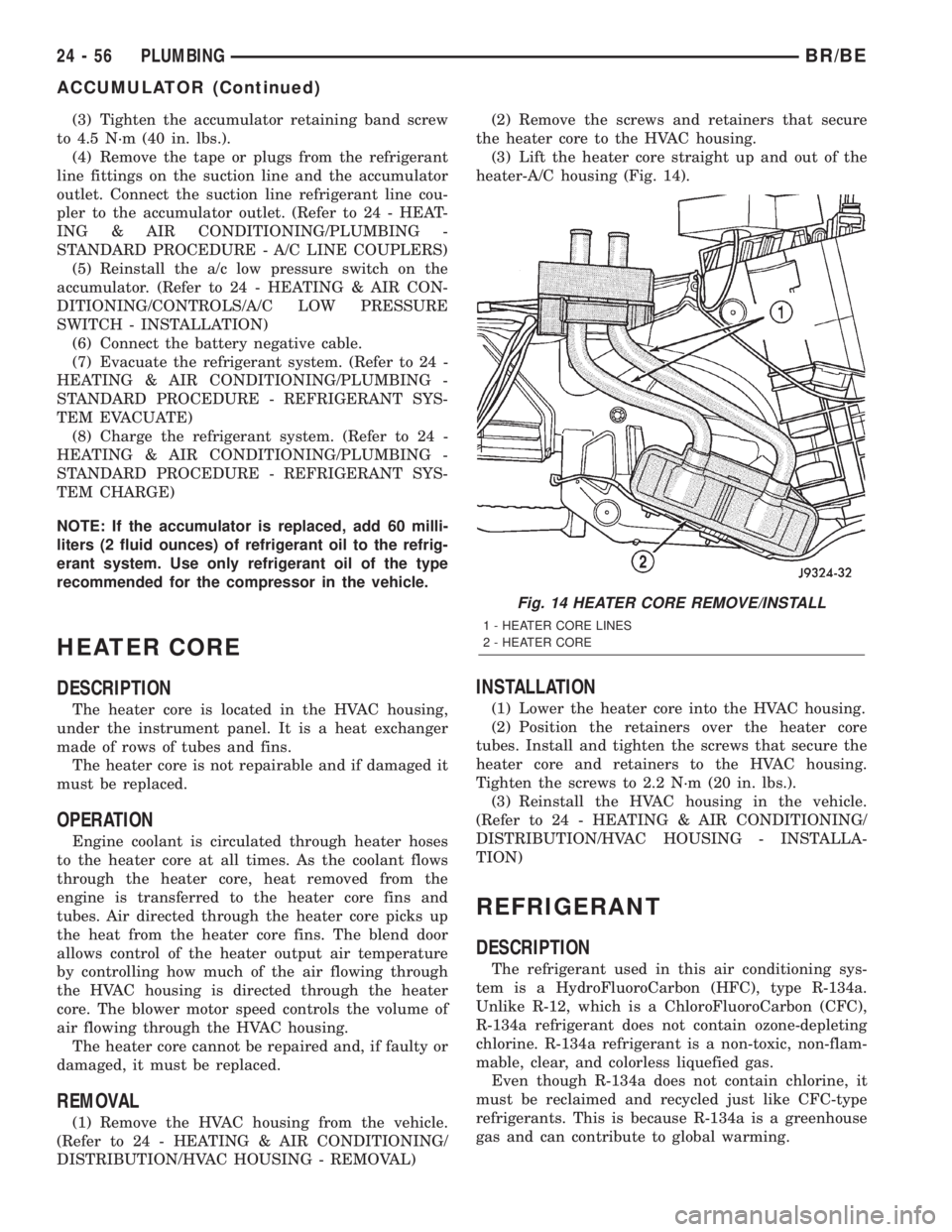

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)(2) Remove the screws and retainers that secure

the heater core to the HVAC housing.

(3) Lift the heater core straight up and out of the

heater-A/C housing (Fig. 14).

INSTALLATION

(1) Lower the heater core into the HVAC housing.

(2) Position the retainers over the heater core

tubes. Install and tighten the screws that secure the

heater core and retainers to the HVAC housing.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Reinstall the HVAC housing in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - INSTALLA-

TION)

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas.

Even though R-134a does not contain chlorine, it

must be reclaimed and recycled just like CFC-type

refrigerants. This is because R-134a is a greenhouse

gas and can contribute to global warming.

Fig. 14 HEATER CORE REMOVE/INSTALL

1 - HEATER CORE LINES

2 - HEATER CORE

24 - 56 PLUMBINGBR/BE

ACCUMULATOR (Continued)

Page 2178 of 2255

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 added to an R-134a refrigerant

system will cause compressor failure, refrigerant oil

sludge or poor air conditioning system performance.

In addition, the PolyAlkylene Glycol (PAG) synthetic

refrigerant oils used in an R-134a refrigerant system

are not compatible with the mineral-based refriger-

ant oils used in an R-12 refrigerant system.

R-134a refrigerant system service ports, service

tool couplers and refrigerant dispensing bottles have

all been designed with unique fittings to ensure that

an R-134a system is not accidentally contaminated

with the wrong refrigerant (R-12). There are also

labels posted in the engine compartment of the vehi-

cle and on the compressor identifying to service tech-

nicians that the air conditioning system is equipped

with R-134a.

REFRIGERANT OIL

DESCRIPTION

The refrigerant oil used in R-134a refrigerant sys-

tems is a synthetic-based, PolyAlkylene Glycol (PAG),

wax-free lubricant. Mineral-based R-12 refrigerant

oils are not compatible with PAG oils, and should

never be introduced to an R-134a refrigerant system.

There are different PAG oils available, and each

contains a different additive package. The SD7H15

compressor used in this vehicle is designed to use an

SP-20 PAG refrigerant oil. Use only refrigerant oil of

this same type to service the refrigerant system.

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.

PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

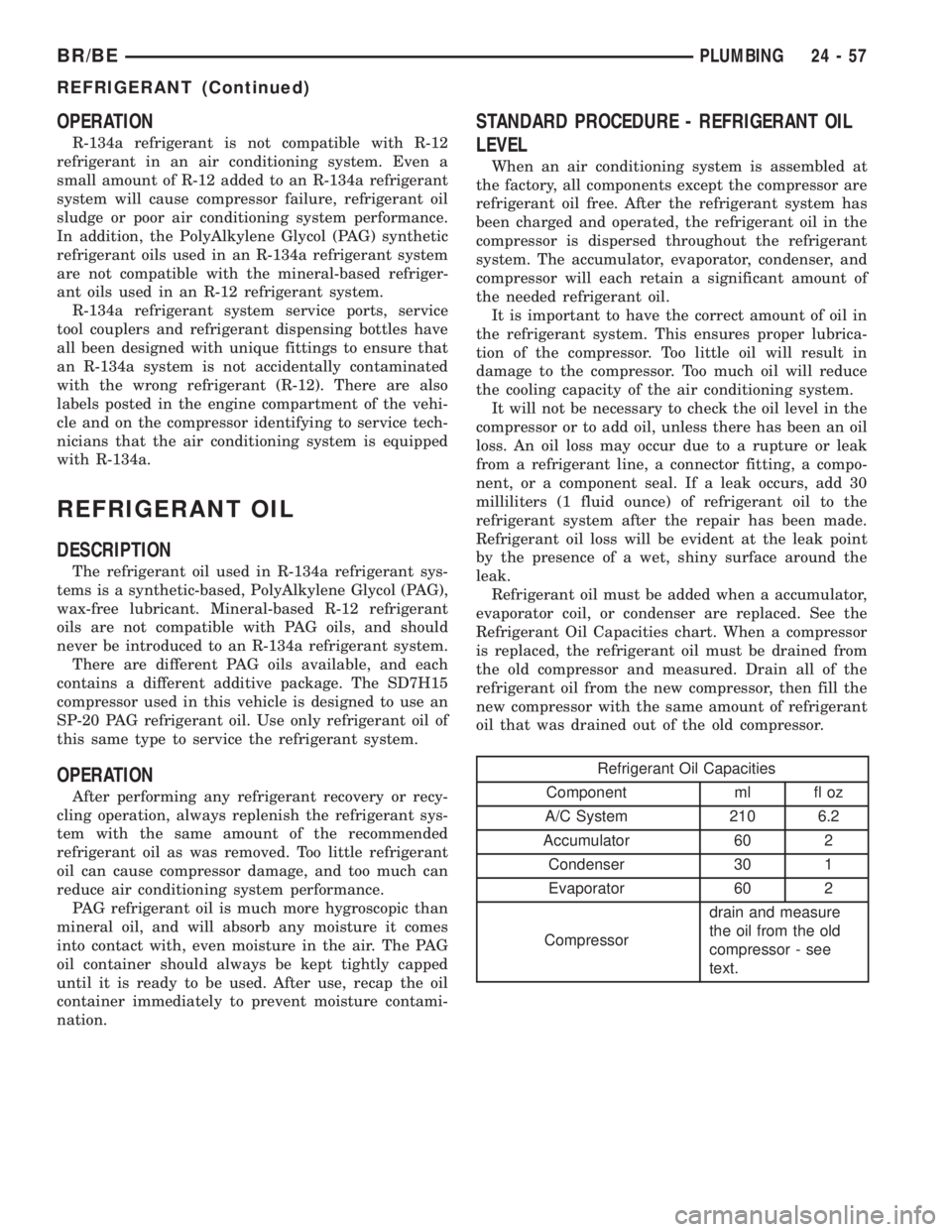

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system has

been charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The accumulator, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrica-

tion of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a compo-

nent, or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.

Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when a accumulator,

evaporator coil, or condenser are replaced. See the

Refrigerant Oil Capacities chart. When a compressor

is replaced, the refrigerant oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of refrigerant

oil that was drained out of the old compressor.

Refrigerant Oil Capacities

Component ml fl oz

A/C System 210 6.2

Accumulator 60 2

Condenser 30 1

Evaporator 60 2

Compressordrain and measure

the oil from the old

compressor - see

text.

BR/BEPLUMBING 24 - 57

REFRIGERANT (Continued)

Page 2180 of 2255

EMISSIONS CONTROL

TABLE OF CONTENTS

page page

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - DIESEL.................1

DESCRIPTION - STATE DISPLAY TEST

MODE...............................1

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE...............................2

DESCRIPTION - DIAGNOSTIC TROUBLE

CODES..............................2

DESCRIPTION - TASK MANAGER.........17

DESCRIPTION - MONITORED SYSTEMS . . . 17

DESCRIPTION - TRIP DEFINITION........19

DESCRIPTION - COMPONENT MONITORS -

GAS ENGINES.......................19DESCRIPTION - COMPONENT MONITORS -

DIESEL ENGINES.....................20

OPERATION

OPERATION - GAS ENGINES............20

OPERATION - DIESEL..................20

OPERATION - TASK MANAGER..........21

OPERATION - NON-MONITORED

CIRCUITS - GAS ENGINES..............24

OPERATION - NON-MONITORED

CIRCUITS - DIESEL....................24

AIR INJECTION.........................26

EVAPORATIVE EMISSIONS................32

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - DIESEL

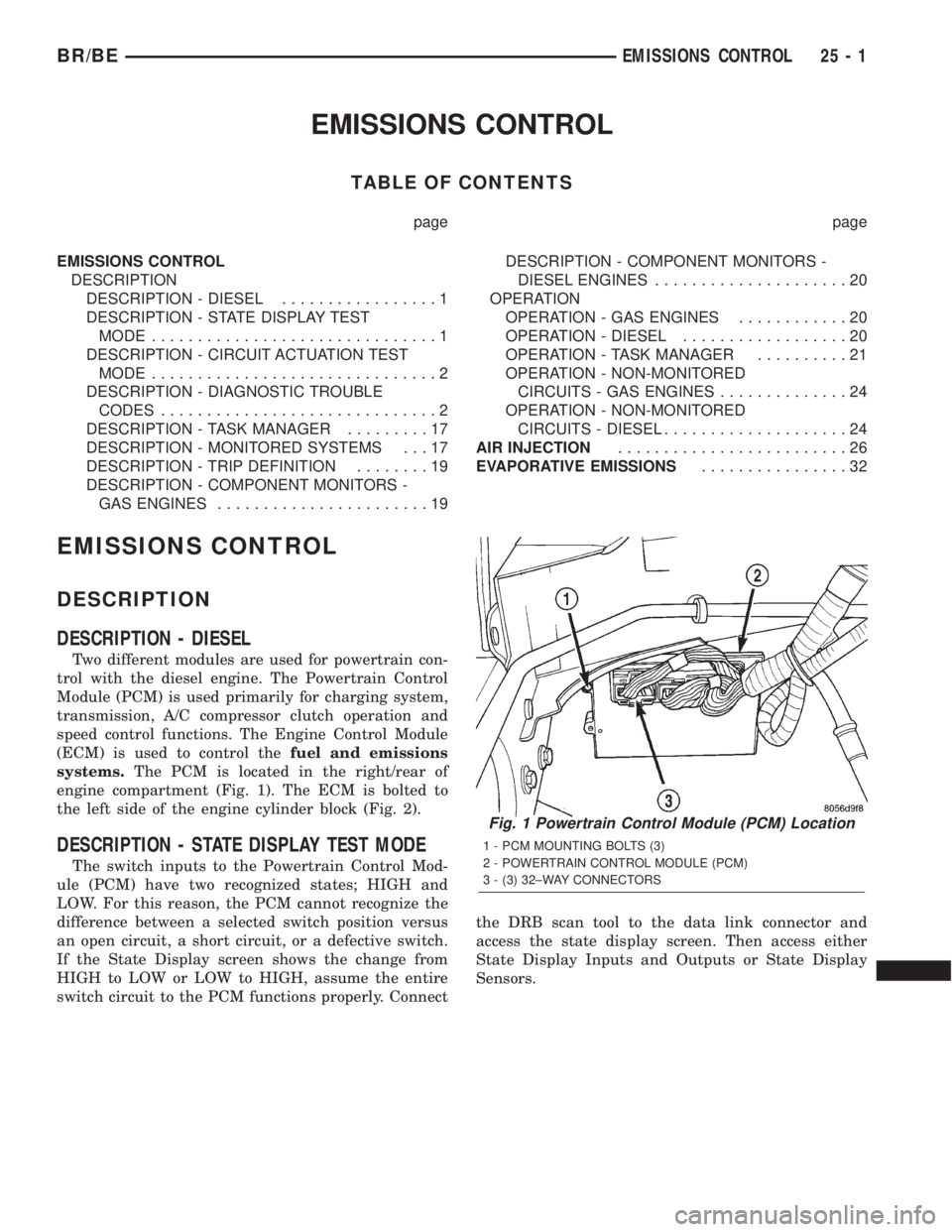

Two different modules are used for powertrain con-

trol with the diesel engine. The Powertrain Control

Module (PCM) is used primarily for charging system,

transmission, A/C compressor clutch operation and

speed control functions. The Engine Control Module

(ECM) is used to control thefuel and emissions

systems.The PCM is located in the right/rear of

engine compartment (Fig. 1). The ECM is bolted to

the left side of the engine cylinder block (Fig. 2).

DESCRIPTION - STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. Connectthe DRB scan tool to the data link connector and

access the state display screen. Then access either

State Display Inputs and Outputs or State Display

Sensors.

Fig. 1 Powertrain Control Module (PCM) Location

1 - PCM MOUNTING BOLTS (3)

2 - POWERTRAIN CONTROL MODULE (PCM)

3 - (3) 32±WAY CONNECTORS

BR/BEEMISSIONS CONTROL 25 - 1

Page 2181 of 2255

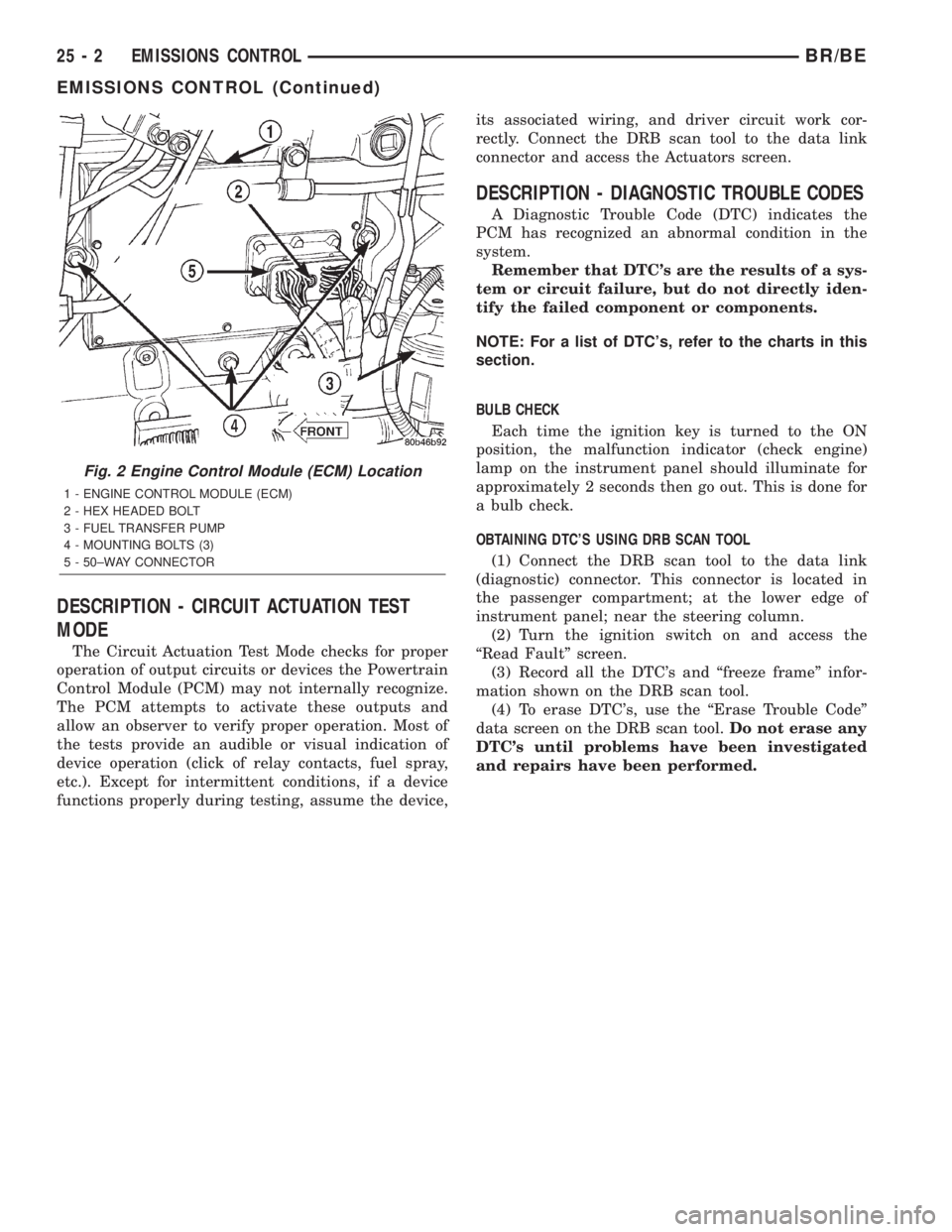

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,its associated wiring, and driver circuit work cor-

rectly. Connect the DRB scan tool to the data link

connector and access the Actuators screen.

DESCRIPTION - DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

Fig. 2 Engine Control Module (ECM) Location

1 - ENGINE CONTROL MODULE (ECM)

2 - HEX HEADED BOLT

3 - FUEL TRANSFER PUMP

4 - MOUNTING BOLTS (3)

5 - 50±WAY CONNECTOR

25 - 2 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2182 of 2255

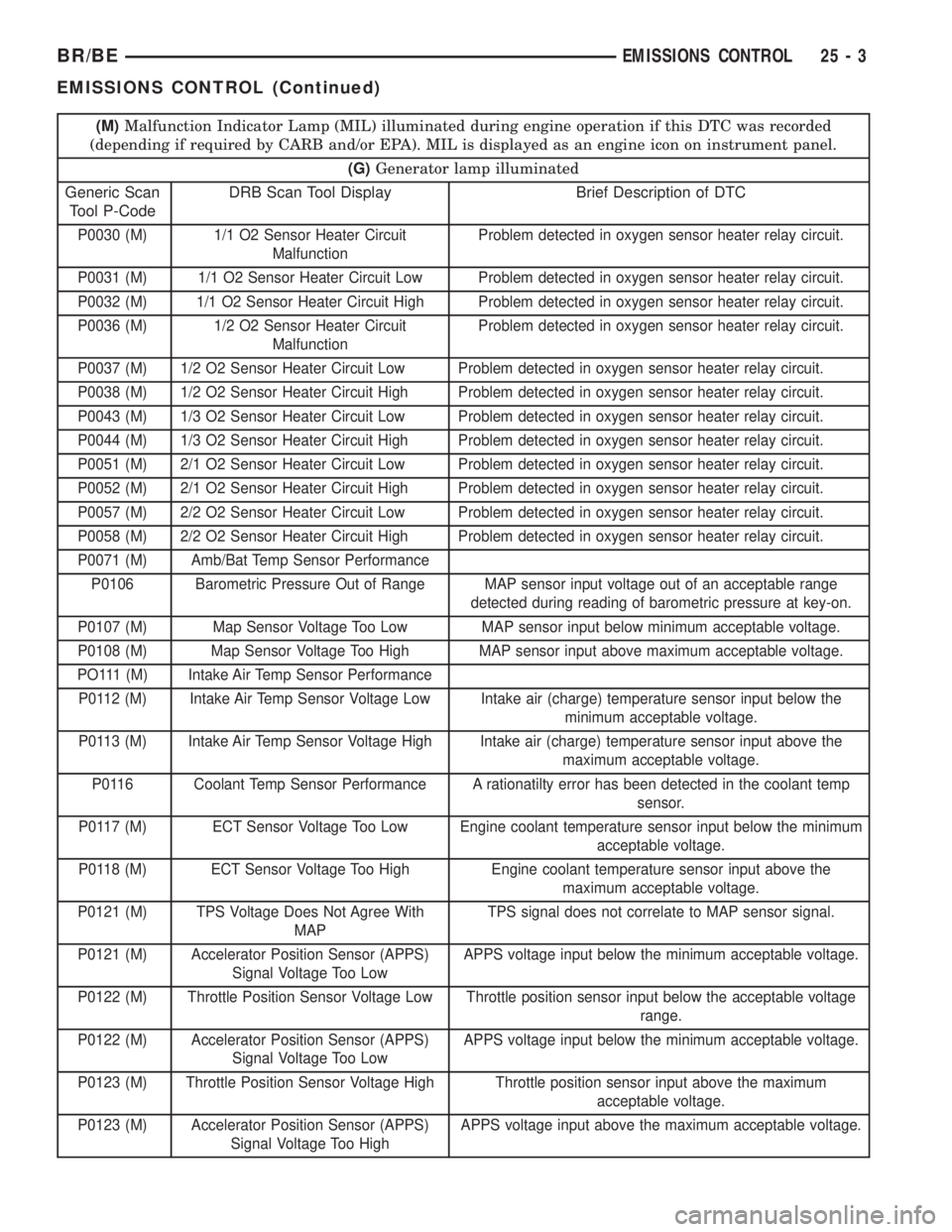

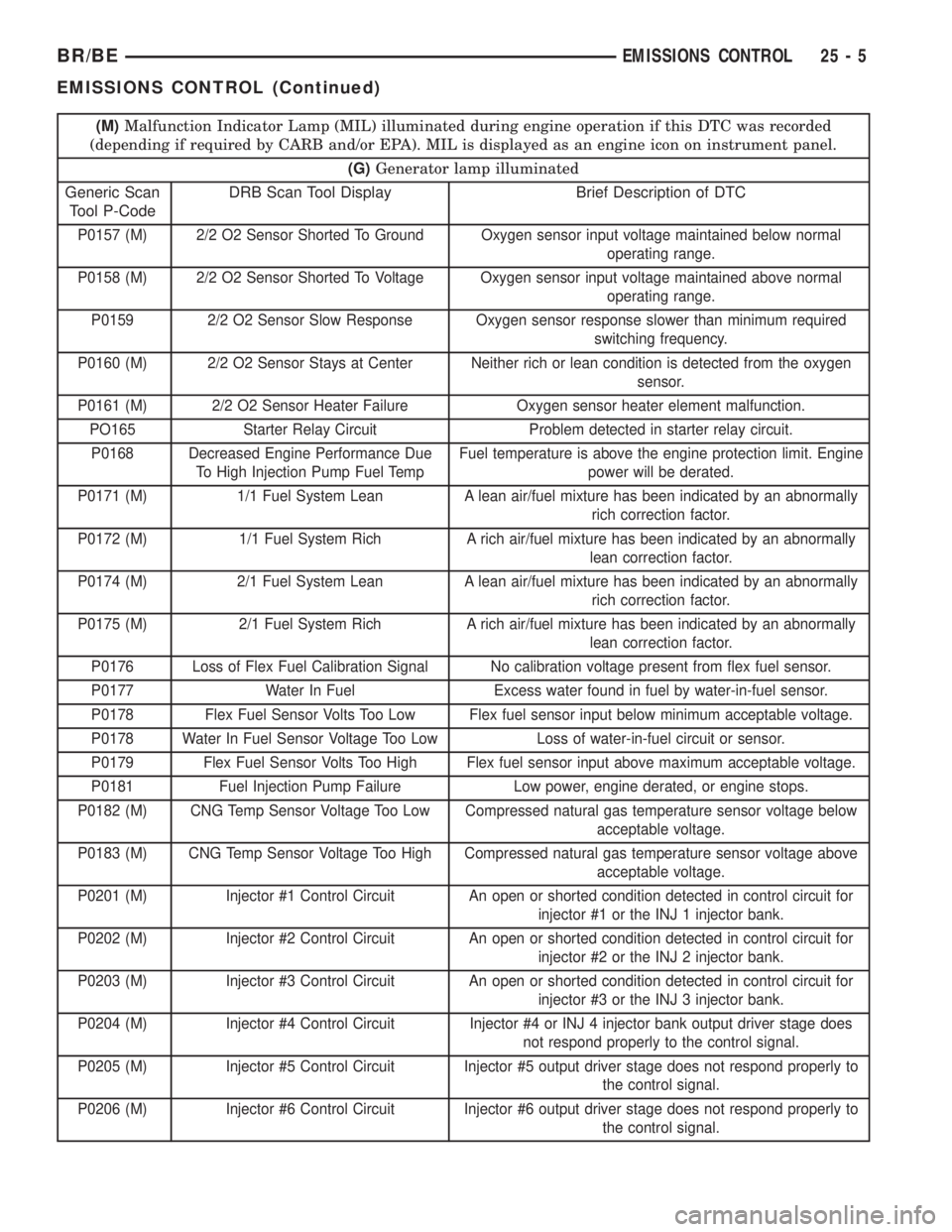

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0030 (M) 1/1 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0031 (M) 1/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0032 (M) 1/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0036 (M) 1/2 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0037 (M) 1/2 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0038 (M) 1/2 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0043 (M) 1/3 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0044 (M) 1/3 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0051 (M) 2/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0052 (M) 2/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0057 (M) 2/2 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0058 (M) 2/2 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0071 (M) Amb/Bat Temp Sensor Performance

P0106 Barometric Pressure Out of Range MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure at key-on.

P0107 (M) Map Sensor Voltage Too Low MAP sensor input below minimum acceptable voltage.

P0108 (M) Map Sensor Voltage Too High MAP sensor input above maximum acceptable voltage.

PO111 (M) Intake Air Temp Sensor Performance

P0112 (M) Intake Air Temp Sensor Voltage Low Intake air (charge) temperature sensor input below the

minimum acceptable voltage.

P0113 (M) Intake Air Temp Sensor Voltage High Intake air (charge) temperature sensor input above the

maximum acceptable voltage.

P0116 Coolant Temp Sensor Performance A rationatilty error has been detected in the coolant temp

sensor.

P0117 (M) ECT Sensor Voltage Too Low Engine coolant temperature sensor input below the minimum

acceptable voltage.

P0118 (M) ECT Sensor Voltage Too High Engine coolant temperature sensor input above the

maximum acceptable voltage.

P0121 (M) TPS Voltage Does Not Agree With

MAPTPS signal does not correlate to MAP sensor signal.

P0121 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too LowAPPS voltage input below the minimum acceptable voltage.

P0122 (M) Throttle Position Sensor Voltage Low Throttle position sensor input below the acceptable voltage

range.

P0122 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too LowAPPS voltage input below the minimum acceptable voltage.

P0123 (M) Throttle Position Sensor Voltage High Throttle position sensor input above the maximum

acceptable voltage.

P0123 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too HighAPPS voltage input above the maximum acceptable voltage.

BR/BEEMISSIONS CONTROL 25 - 3

EMISSIONS CONTROL (Continued)

Page 2183 of 2255

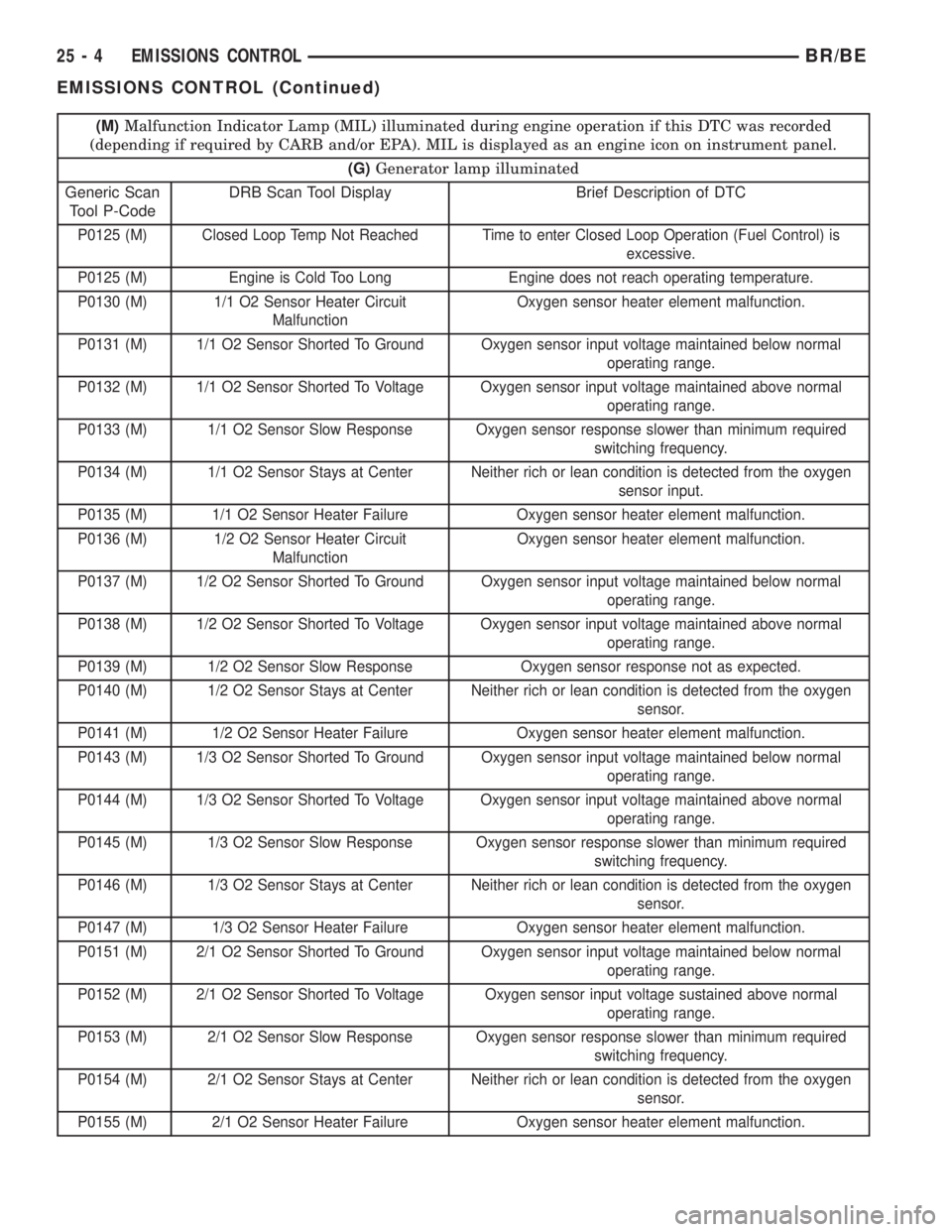

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0125 (M) Closed Loop Temp Not Reached Time to enter Closed Loop Operation (Fuel Control) is

excessive.

P0125 (M) Engine is Cold Too Long Engine does not reach operating temperature.

P0130 (M) 1/1 O2 Sensor Heater Circuit

MalfunctionOxygen sensor heater element malfunction.

P0131 (M) 1/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0132 (M) 1/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0133 (M) 1/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0134 (M) 1/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor input.

P0135 (M) 1/1 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0136 (M) 1/2 O2 Sensor Heater Circuit

MalfunctionOxygen sensor heater element malfunction.

P0137 (M) 1/2 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0138 (M) 1/2 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0139 (M) 1/2 O2 Sensor Slow Response Oxygen sensor response not as expected.

P0140 (M) 1/2 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0141 (M) 1/2 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0143 (M) 1/3 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0144 (M) 1/3 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0145 (M) 1/3 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0146 (M) 1/3 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0147 (M) 1/3 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0151 (M) 2/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0152 (M) 2/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage sustained above normal

operating range.

P0153 (M) 2/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0154 (M) 2/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0155 (M) 2/1 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

25 - 4 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2184 of 2255

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0157 (M) 2/2 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0158 (M) 2/2 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0159 2/2 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0160 (M) 2/2 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0161 (M) 2/2 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

PO165 Starter Relay Circuit Problem detected in starter relay circuit.

P0168 Decreased Engine Performance Due

To High Injection Pump Fuel TempFuel temperature is above the engine protection limit. Engine

power will be derated.

P0171 (M) 1/1 Fuel System Lean A lean air/fuel mixture has been indicated by an abnormally

rich correction factor.

P0172 (M) 1/1 Fuel System Rich A rich air/fuel mixture has been indicated by an abnormally

lean correction factor.

P0174 (M) 2/1 Fuel System Lean A lean air/fuel mixture has been indicated by an abnormally

rich correction factor.

P0175 (M) 2/1 Fuel System Rich A rich air/fuel mixture has been indicated by an abnormally

lean correction factor.

P0176 Loss of Flex Fuel Calibration Signal No calibration voltage present from flex fuel sensor.

P0177 Water In Fuel Excess water found in fuel by water-in-fuel sensor.

P0178 Flex Fuel Sensor Volts Too Low Flex fuel sensor input below minimum acceptable voltage.

P0178 Water In Fuel Sensor Voltage Too Low Loss of water-in-fuel circuit or sensor.

P0179 Flex Fuel Sensor Volts Too High Flex fuel sensor input above maximum acceptable voltage.

P0181 Fuel Injection Pump Failure Low power, engine derated, or engine stops.

P0182 (M) CNG Temp Sensor Voltage Too Low Compressed natural gas temperature sensor voltage below

acceptable voltage.

P0183 (M) CNG Temp Sensor Voltage Too High Compressed natural gas temperature sensor voltage above

acceptable voltage.

P0201 (M) Injector #1 Control Circuit An open or shorted condition detected in control circuit for

injector #1 or the INJ 1 injector bank.

P0202 (M) Injector #2 Control Circuit An open or shorted condition detected in control circuit for

injector #2 or the INJ 2 injector bank.

P0203 (M) Injector #3 Control Circuit An open or shorted condition detected in control circuit for

injector #3 or the INJ 3 injector bank.

P0204 (M) Injector #4 Control Circuit Injector #4 or INJ 4 injector bank output driver stage does

not respond properly to the control signal.

P0205 (M) Injector #5 Control Circuit Injector #5 output driver stage does not respond properly to

the control signal.

P0206 (M) Injector #6 Control Circuit Injector #6 output driver stage does not respond properly to

the control signal.

BR/BEEMISSIONS CONTROL 25 - 5

EMISSIONS CONTROL (Continued)

Page 2185 of 2255

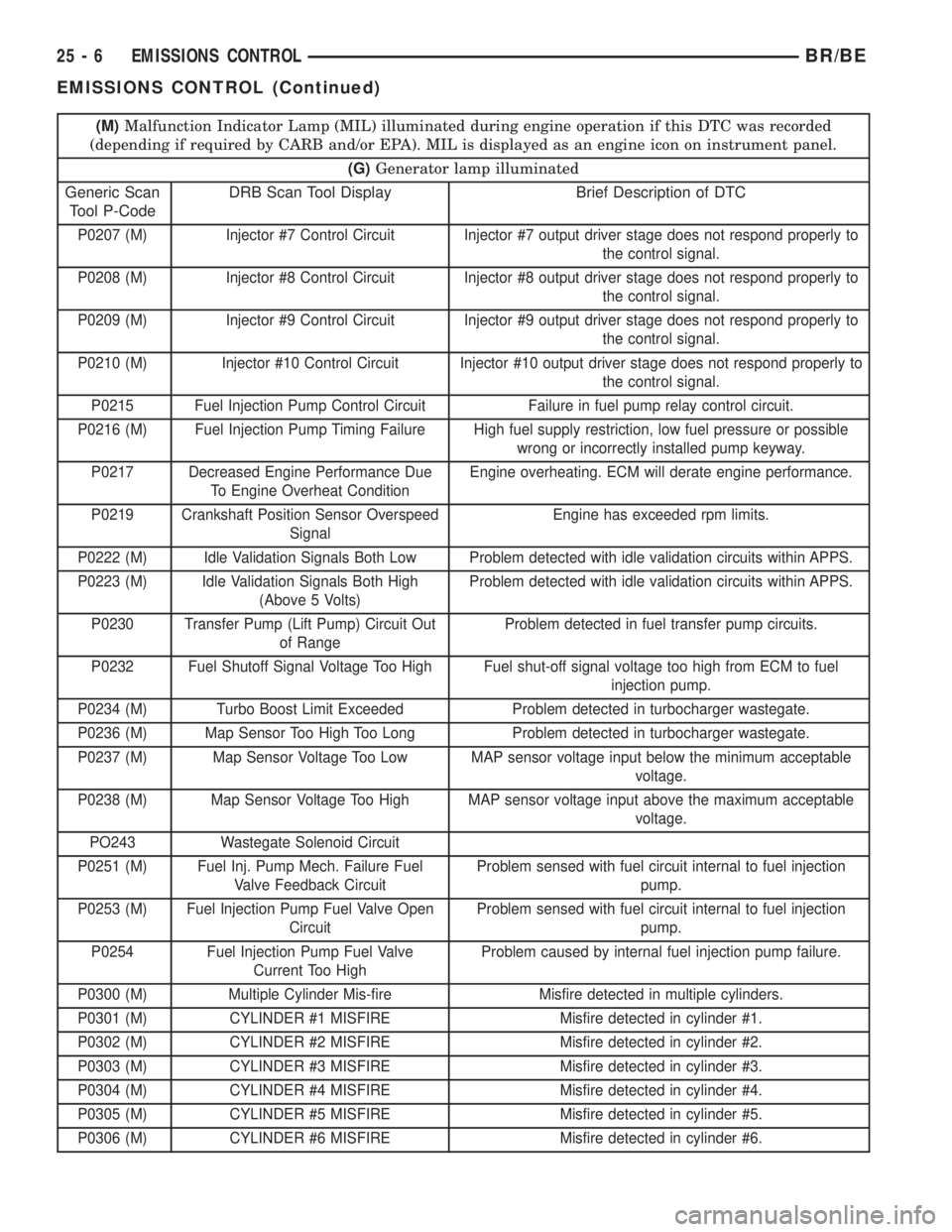

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0207 (M) Injector #7 Control Circuit Injector #7 output driver stage does not respond properly to

the control signal.

P0208 (M) Injector #8 Control Circuit Injector #8 output driver stage does not respond properly to

the control signal.

P0209 (M) Injector #9 Control Circuit Injector #9 output driver stage does not respond properly to

the control signal.

P0210 (M) Injector #10 Control Circuit Injector #10 output driver stage does not respond properly to

the control signal.

P0215 Fuel Injection Pump Control Circuit Failure in fuel pump relay control circuit.

P0216 (M) Fuel Injection Pump Timing Failure High fuel supply restriction, low fuel pressure or possible

wrong or incorrectly installed pump keyway.

P0217 Decreased Engine Performance Due

To Engine Overheat ConditionEngine overheating. ECM will derate engine performance.

P0219 Crankshaft Position Sensor Overspeed

SignalEngine has exceeded rpm limits.

P0222 (M) Idle Validation Signals Both Low Problem detected with idle validation circuits within APPS.

P0223 (M) Idle Validation Signals Both High

(Above 5 Volts)Problem detected with idle validation circuits within APPS.

P0230 Transfer Pump (Lift Pump) Circuit Out

of RangeProblem detected in fuel transfer pump circuits.

P0232 Fuel Shutoff Signal Voltage Too High Fuel shut-off signal voltage too high from ECM to fuel

injection pump.

P0234 (M) Turbo Boost Limit Exceeded Problem detected in turbocharger wastegate.

P0236 (M) Map Sensor Too High Too Long Problem detected in turbocharger wastegate.

P0237 (M) Map Sensor Voltage Too Low MAP sensor voltage input below the minimum acceptable

voltage.

P0238 (M) Map Sensor Voltage Too High MAP sensor voltage input above the maximum acceptable

voltage.

PO243 Wastegate Solenoid Circuit

P0251 (M) Fuel Inj. Pump Mech. Failure Fuel

Valve Feedback CircuitProblem sensed with fuel circuit internal to fuel injection

pump.

P0253 (M) Fuel Injection Pump Fuel Valve Open

CircuitProblem sensed with fuel circuit internal to fuel injection

pump.

P0254 Fuel Injection Pump Fuel Valve

Current Too HighProblem caused by internal fuel injection pump failure.

P0300 (M) Multiple Cylinder Mis-fire Misfire detected in multiple cylinders.

P0301 (M) CYLINDER #1 MISFIRE Misfire detected in cylinder #1.

P0302 (M) CYLINDER #2 MISFIRE Misfire detected in cylinder #2.

P0303 (M) CYLINDER #3 MISFIRE Misfire detected in cylinder #3.

P0304 (M) CYLINDER #4 MISFIRE Misfire detected in cylinder #4.

P0305 (M) CYLINDER #5 MISFIRE Misfire detected in cylinder #5.

P0306 (M) CYLINDER #6 MISFIRE Misfire detected in cylinder #6.

25 - 6 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)