ignition DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 449 of 2255

involves inoperative heated seat switch indicator

lamps and the heated seat elements do heat, go to

Step 8. If the problem being diagnosed involves a

heated seat switch indicator lamp that remains illu-

minated after the heated seat has been turned Off,

refer toHeated Seat Modulein Electronic Control

Modules for the location of the proper heated seat

module diagnosis and testing procedures. Also refer

to the Body Diagnostic Manual for additional diagno-

sis and testing procedures.

(2) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the instru-

ment panel wire harness connector from the connec-

tor receptacle on the back of the heated seat switch

to be tested. Check for continuity between the ground

circuit cavity of the instrument panel wire harness

connector for the heated seat switch and a good

ground. There should be continuity. If OK, go to Step

3. If not OK, repair the open ground circuit to ground

as required.

(3) Reconnect the battery negative cable. Turn the

park lamps on with the headlamp switch. Rotate the

panel lamps dimmer thumbwheel on the headlamp

switch upward to just before the interior lamps

detent. Check for battery voltage at the fused panel

lamps dimmer switch signal circuit cavity of the

instrument panel wire harness connector for the

heated seat switch. If OK, replace the faulty heated

seat switch. If not OK, repair the open fused panel

lamps dimmer switch signal circuit to the fuse in the

Junction Block (JB) as required.

(4) Check the fused ignition switch output (run)

fuse in the Junction Block (JB). If OK, go to Step 5.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(5) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the JB. If OK, go to Step 6. If

not OK, repair the open fused ignition switch output

(run) circuit to the ignition switch as required.

(6) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the instru-

ment panel wire harness connector from the connec-

tor receptacle on the back of the heated seat switch

to be tested. Reconnect the battery negative cable.

Turn the ignition switch to the On position. Check

for battery voltage at the fused ignition switch out-

put (run) circuit cavity of the instrument panel wire

harness connector for the heated seat switch. If OK,

go to Step 7. If not OK, repair the open fused ignition

switch output (run) circuit to the JB fuse as required.

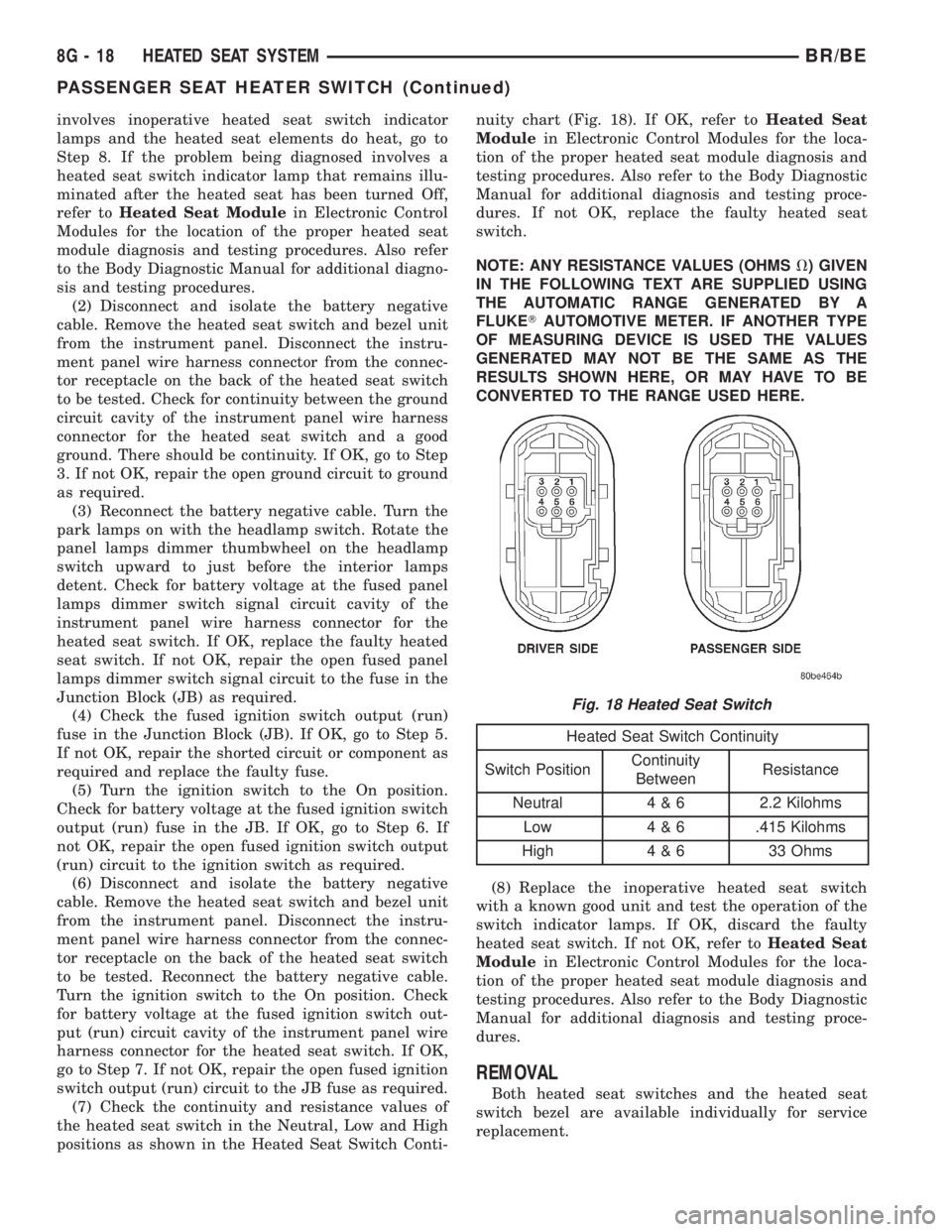

(7) Check the continuity and resistance values of

the heated seat switch in the Neutral, Low and High

positions as shown in the Heated Seat Switch Conti-nuity chart (Fig. 18). If OK, refer toHeated Seat

Modulein Electronic Control Modules for the loca-

tion of the proper heated seat module diagnosis and

testing procedures. Also refer to the Body Diagnostic

Manual for additional diagnosis and testing proce-

dures. If not OK, replace the faulty heated seat

switch.

NOTE: ANY RESISTANCE VALUES (OHMSV) GIVEN

IN THE FOLLOWING TEXT ARE SUPPLIED USING

THE AUTOMATIC RANGE GENERATED BY A

FLUKETAUTOMOTIVE METER. IF ANOTHER TYPE

OF MEASURING DEVICE IS USED THE VALUES

GENERATED MAY NOT BE THE SAME AS THE

RESULTS SHOWN HERE, OR MAY HAVE TO BE

CONVERTED TO THE RANGE USED HERE.

Heated Seat Switch Continuity

Switch PositionContinuity

BetweenResistance

Neutral 4 & 6 2.2 Kilohms

Low 4 & 6 .415 Kilohms

High 4 & 6 33 Ohms

(8) Replace the inoperative heated seat switch

with a known good unit and test the operation of the

switch indicator lamps. If OK, discard the faulty

heated seat switch. If not OK, refer toHeated Seat

Modulein Electronic Control Modules for the loca-

tion of the proper heated seat module diagnosis and

testing procedures. Also refer to the Body Diagnostic

Manual for additional diagnosis and testing proce-

dures.

REMOVAL

Both heated seat switches and the heated seat

switch bezel are available individually for service

replacement.

Fig. 18 Heated Seat Switch

8G - 18 HEATED SEAT SYSTEMBR/BE

PASSENGER SEAT HEATER SWITCH (Continued)

Page 452 of 2255

HORN

TABLE OF CONTENTS

page page

HORN

DESCRIPTION..........................1

OPERATION............................1

HORN

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - HORN..........2

REMOVAL.............................2

INSTALLATION..........................3

HORN RELAY

DESCRIPTION..........................3OPERATION............................3

DIAGNOSIS AND TESTING - HORN RELAY....3

REMOVAL.............................4

INSTALLATION..........................4

HORN SWITCH

DESCRIPTION..........................4

OPERATION............................5

DIAGNOSIS AND TESTING - HORN SWITCH . . . 5

REMOVAL.............................5

HORN

DESCRIPTION

An electric horn system is standard factory-in-

stalled equipment on this model. Two horn systems

are offered on this model. The standard equipment

horn system features a single low-note electromag-

netic horn unit, while the optional dual horn system

features one low-note horn unit and one high-note

horn unit. Both horn systems use a non-switched

source of battery current so that the system will

remain functional, regardless of the ignition switch

position. The horn system includes the following com-

ponents:

²Clockspring

²High-line or premium Central Timer Module

(CTM)

²Horn(s)

²Horn relay

²Horn switch

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - DESCRIPTION) for more information on

this component. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/BODY CONTROL/

CENTRAL TIMER MODUL - DESCRIPTION) for

more information on this component. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds. Following are general

descriptions of the remaining major components in

the horn system.

OPERATION

Each horn system is activated by a horn switch

concealed beneath the driver side airbag module trim

cover in the center of the steering wheel. Depressing

the center of the driver side airbag module trim cover

closes the horn switch. Closing the horn switch acti-

vates the horn relay. The activated horn relay then

switches the battery current needed to energize the

horn(s).

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the horn system.

CENTRAL TIMER MODULE

The high-line or premium Central Timer Module

(CTM) can also operate the horn system. A high-line

CTM is used on high-line versions of this vehicle. A

premium CTM is used on vehicles equipped with the

optional heated seats. The CTM combines the func-

tions of a chime/buzzer module, an intermittent wipe

module, an illuminated entry module, a remote key-

less entry module, and a vehicle theft security sys-

tem module in a single unit.

The high-line or premium CTM also controls and

integrates many of the additional electronic functions

and features included on models with this option.

The horn relay is one of the hard wired outputs of

the CTM. The high-line or premium CTM is pro-

grammed to energize or de-energize the horn relay in

response to certain inputs from the Vehicle Theft

Security System (VTSS) and/or the Remote Keyless

Entry (RKE) system.

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/BODY CONTROL/CENTRAL

TIMER MODUL - DESCRIPTION) for more informa-

tion on the high-line or premium CTM. (Refer to 8 -

BR/BEHORN 8H - 1

Page 458 of 2255

IGNITION CONTROL

TABLE OF CONTENTS

page page

IGNITION CONTROL

DESCRIPTION - 8.0L V-10.................2

OPERATION

OPERATION - 8.0L V-10.................2

OPERATION - V-8......................2

SPECIFICATIONS

SPECIFICATIONS - TORQUE - IGNITION....2

SPARK PLUG CABLE ORDERÐ8.0L V-10

ENGINE..............................3

ENGINE FIRING ORDERÐ5.9L V-8

ENGINES............................3

SPARK PLUG CABLE RESISTANCE........3

SPARK PLUGS........................3

IGNITION COIL RESISTANCEÐ5.9L

ENGINES............................3

IGNITION COIL RESISTANCEÐ8.0L V-10

ENGINE..............................4

IGNITION TIMING......................4

AUTOMATIC SHUT DOWN RELAY

DESCRIPTION - PCM OUTPUT.............4

OPERATION

OPERATION - PCM OUTPUT.............4

OPERATION - ASD SENSE - PCM INPUT....4

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS........................4

REMOVAL.............................5

INSTALLATION..........................5

CAMSHAFT POSITION SENSOR

DESCRIPTION

DESCRIPTION - DIESEL.................6

DESCRIPTION - 5.9L....................6

DESCRIPTION - 8.0L....................6

OPERATION

OPERATION - DIESEL...................6

OPERATION - 5.9L.....................7

OPERATION - 8.0L.....................7

REMOVAL

REMOVAL - DIESEL....................7

REMOVAL - 5.9L.......................7

REMOVAL - 8.0L.......................8

INSTALLATION

INSTALLATION - DIESEL.................9INSTALLATION - 5.9L..................10

INSTALLATION - 8.0L..................10

DISTRIBUTOR

DESCRIPTION.........................11

OPERATION...........................12

REMOVAL.............................12

INSTALLATION.........................13

DISTRIBUTOR CAP

DIAGNOSIS AND TESTING - DISTRIBUTOR

CAP ................................14

DISTRIBUTOR ROTOR

DIAGNOSIS AND TESTING - DISTRIBUTOR

ROTOR .............................14

IGNITION COIL

DESCRIPTION

DESCRIPTION - 5.9L...................15

DESCRIPTION - 8.0L...................15

OPERATION

OPERATION - 5.9L....................15

OPERATION - 8.0L....................15

REMOVAL

REMOVAL - 5.9L......................15

REMOVAL - 8.0L......................16

INSTALLATION

INSTALLATION - 5.9L..................16

INSTALLATION - 8.0L..................16

SPARK PLUG

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS.........................17

REMOVAL.............................19

CLEANING............................20

INSTALLATION.........................20

SPARK PLUG CABLE

DESCRIPTION.........................20

OPERATION...........................20

DIAGNOSIS AND TESTING - SPARK PLUG

CABLES............................20

REMOVAL.............................21

INSTALLATION.........................21

BR/BEIGNITION CONTROL 8I - 1

Page 459 of 2255

IGNITION CONTROL

DESCRIPTION - 8.0L V-10

The ignition system used on the 8.0L V±10 engine

does not use a conventional mechanical distributor.

The system will be referred to as a distributor-less

ignition system.

OPERATION

OPERATION - 8.0L V-10

The ignition coils are individually fired, but each

coil is a dual output. Refer to Ignition Coil for addi-

tional information.

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

The ignition system consists of:

²Spark Plugs

²Ignition Coil packs containing individual coils

²Secondary Ignition Cables²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position and MAP Sen-

sors

OPERATION - V-8

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

The ignition system consists of:

²Spark Plugs

²Ignition Coil

²Secondary Ignition Cables

²Distributor (contains rotor and camshaft position

sensor)

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position and MAP Sen-

sors

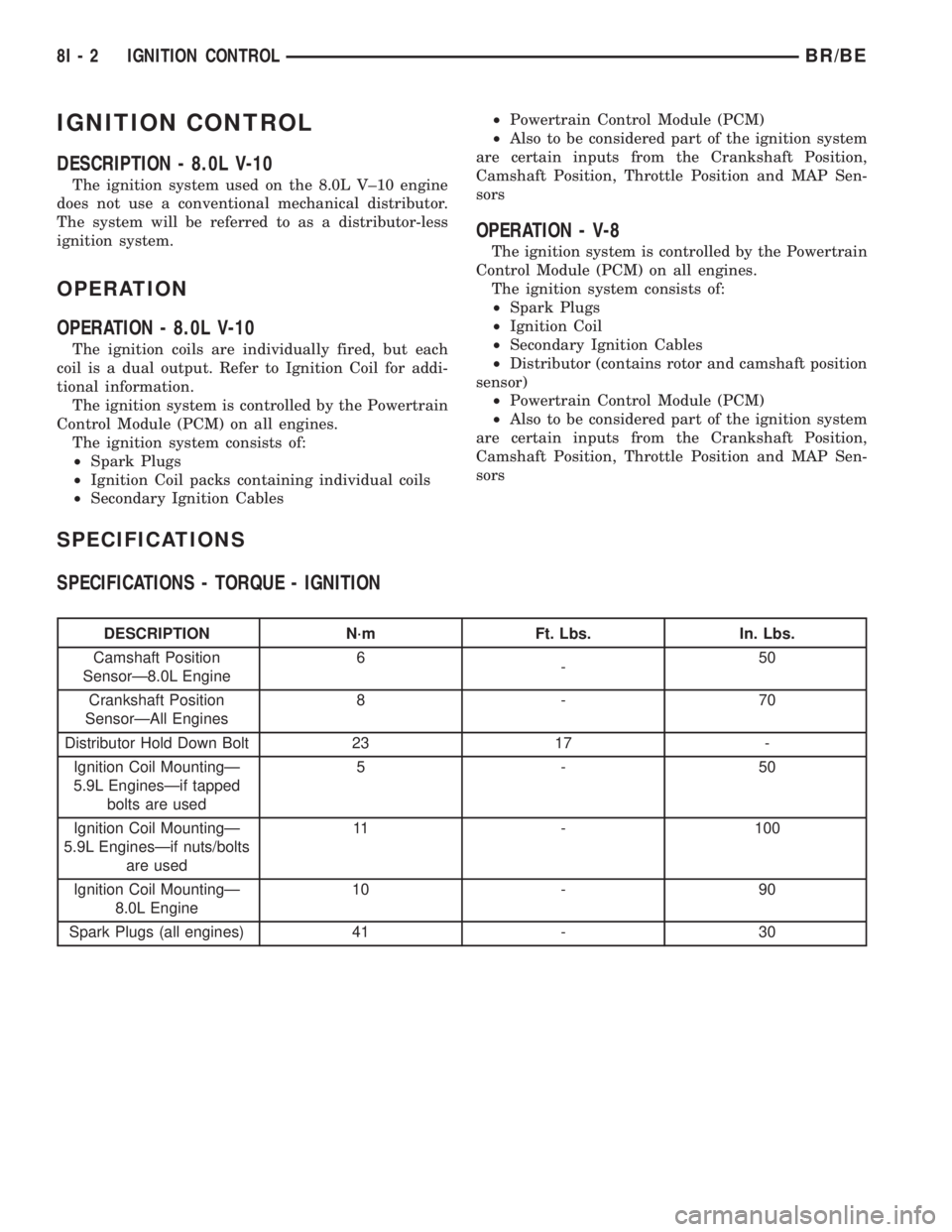

SPECIFICATIONS

SPECIFICATIONS - TORQUE - IGNITION

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Camshaft Position

SensorÐ8.0L Engine6

-50

Crankshaft Position

SensorÐAll Engines8-70

Distributor Hold Down Bolt 23 17 -

Ignition Coil MountingÐ

5.9L EnginesÐif tapped

bolts are used5-50

Ignition Coil MountingÐ

5.9L EnginesÐif nuts/bolts

are used11 - 100

Ignition Coil MountingÐ

8.0L Engine10 - 90

Spark Plugs (all engines) 41 - 30

8I - 2 IGNITION CONTROLBR/BE

Page 460 of 2255

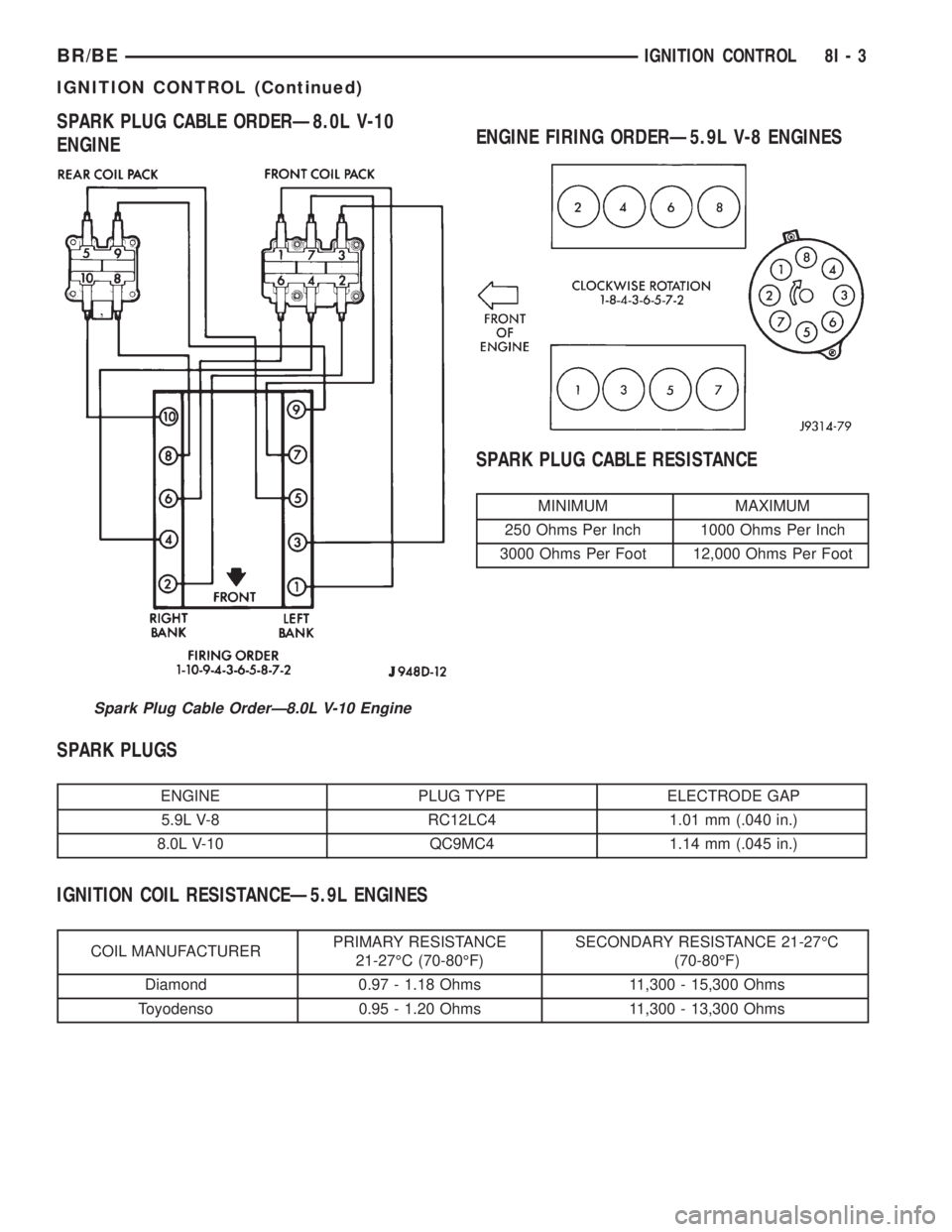

SPARK PLUG CABLE ORDERÐ8.0L V-10

ENGINEENGINE FIRING ORDERÐ5.9L V-8 ENGINES

SPARK PLUG CABLE RESISTANCE

MINIMUM MAXIMUM

250 Ohms Per Inch 1000 Ohms Per Inch

3000 Ohms Per Foot 12,000 Ohms Per Foot

SPARK PLUGS

ENGINE PLUG TYPE ELECTRODE GAP

5.9L V-8 RC12LC4 1.01 mm (.040 in.)

8.0L V-10 QC9MC4 1.14 mm (.045 in.)

IGNITION COIL RESISTANCEÐ5.9L ENGINES

COIL MANUFACTURERPRIMARY RESISTANCE

21-27ÉC (70-80ÉF)SECONDARY RESISTANCE 21-27ÉC

(70-80ÉF)

Diamond 0.97 - 1.18 Ohms 11,300 - 15,300 Ohms

Toyodenso 0.95 - 1.20 Ohms 11,300 - 13,300 Ohms

Spark Plug Cable OrderÐ8.0L V-10 Engine

BR/BEIGNITION CONTROL 8I - 3

IGNITION CONTROL (Continued)

Page 461 of 2255

IGNITION COIL RESISTANCEÐ8.0L V-10

ENGINE

Primary Resistance: 0.53-0.65 Ohms. Test across the

primary connector. Refer to text for test procedures.

Secondary Resistance: 10.9-14.7K Ohms. Test

across the individual coil towers. Refer to text for test

procedures.

IGNITION TIMING

Ignition timing is not adjustable on any engine.

AUTOMATIC SHUT DOWN

RELAY

DESCRIPTION - PCM OUTPUT

The 5±pin, 12±volt, Automatic Shutdown (ASD)

relay is located in the Power Distribution Center

(PDC). Refer to label on PDC cover for relay location.

OPERATION

OPERATION - PCM OUTPUT

The ASD relay supplies battery voltage (12+ volts)

to the fuel injectors and ignition coil(s). With certain

emissions packages it also supplies 12±volts to the

oxygen sensor heating elements.

The ground circuit for the coil within the ASD

relay is controlled by the Powertrain Control Module

(PCM). The PCM operates the ASD relay by switch-

ing its ground circuit on and off.

The ASD relay will be shut±down, meaning the

12±volt power supply to the ASD relay will be de-ac-

tivated by the PCM if:

²the ignition key is left in the ON position. This

is if the engine has not been running for approxi-

mately 1.8 seconds.

²there is a crankshaft position sensor signal to

the PCM that is lower than pre-determined values.

OPERATION - ASD SENSE - PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The relay is used to

connect the oxygen sensor heater element, ignition

coil and fuel injectors to 12 volt + power supply.

This input is used only to sense that the ASD relay

is energized. If the Powertrain Control Module

(PCM) does not see 12 volts at this input when the

ASD should be activated, it will set a Diagnostic

Trouble Code (DTC).

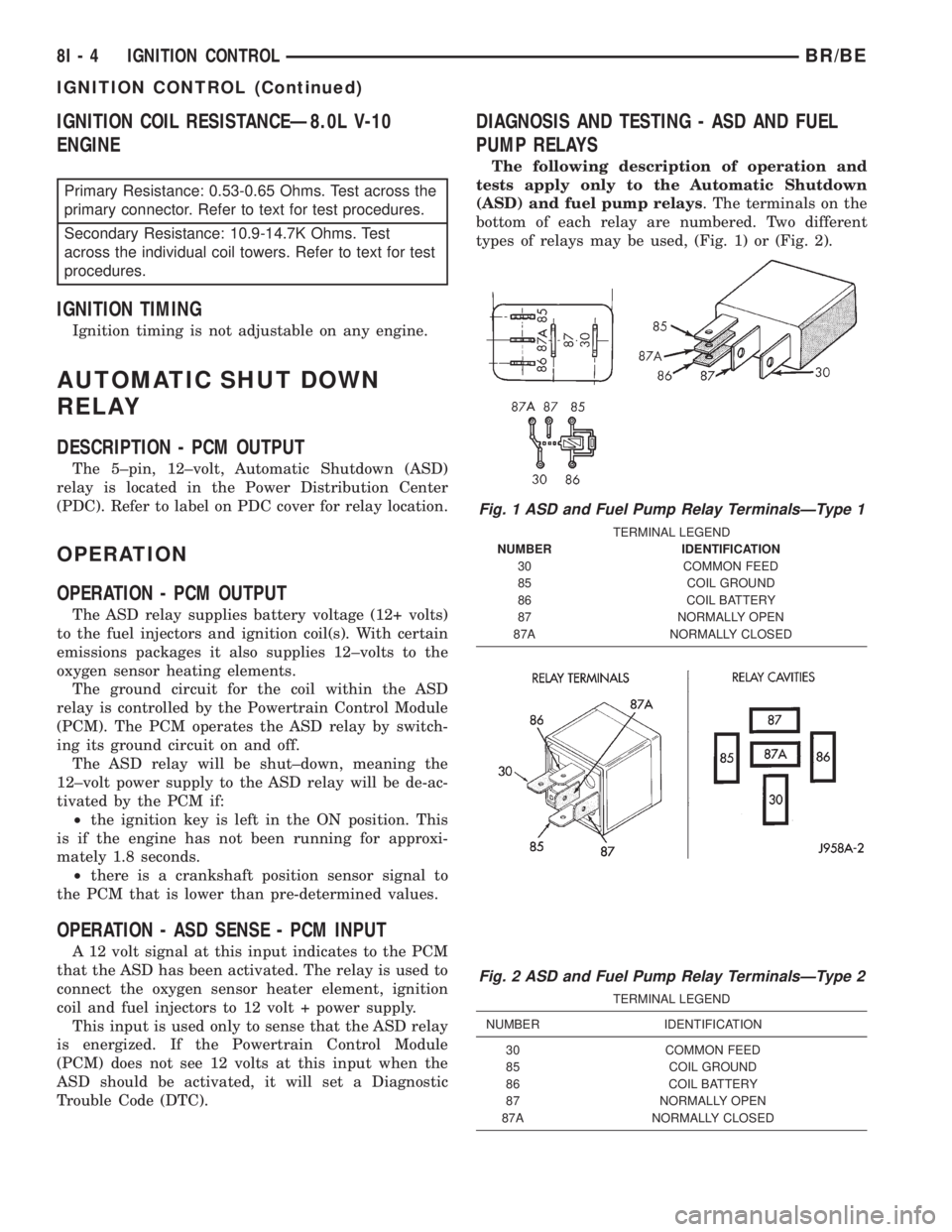

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS

The following description of operation and

tests apply only to the Automatic Shutdown

(ASD) and fuel pump relays. The terminals on the

bottom of each relay are numbered. Two different

types of relays may be used, (Fig. 1) or (Fig. 2).

Fig. 1 ASD and Fuel Pump Relay TerminalsÐType 1

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 2 ASD and Fuel Pump Relay TerminalsÐType 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8I - 4 IGNITION CONTROLBR/BE

IGNITION CONTROL (Continued)

Page 462 of 2255

²Terminal number 30 is connected to battery volt-

age. For both the ASD and fuel pump relays, termi-

nal 30 is connected to battery voltage at all times.

²The PCM grounds the coil side of the relay

through terminal number 85.

²Terminal number 86 supplies voltage to the coil

side of the relay.

²When the PCM de-energizes the ASD and fuel

pump relays, terminal number 87A connects to termi-

nal 30. This is the Off position. In the off position,

voltage is not supplied to the rest of the circuit. Ter-

minal 87A is the center terminal on the relay.

²When the PCM energizes the ASD and fuel

pump relays, terminal 87 connects to terminal 30.

This is the On position. Terminal 87 supplies voltage

to the rest of the circuit.

The following procedure applies to the ASD and

fuel pump relays.

(1) Remove relay from connector before testing.

(2) With the relay removed from the vehicle, use

an ohmmeter to check the resistance between termi-

nals 85 and 86. The resistance should be 75 ohms +/-

5 ohms.

(3) Connect the ohmmeter between terminals 30

and 87A. The ohmmeter should show continuity

between terminals 30 and 87A.

(4) Connect the ohmmeter between terminals 87

and 30. The ohmmeter should not show continuity at

this time.

(5) Connect one end of a jumper wire (16 gauge or

smaller) to relay terminal 85. Connect the other end

of the jumper wire to the ground side of a 12 volt

power source.

(6) Connect one end of another jumper wire (16

gauge or smaller) to the power side of the 12 volt

power source.Do not attach the other end of the

jumper wire to the relay at this time.

WARNING: DO NOT ALLOW OHMMETER TO CON-

TACT TERMINALS 85 OR 86 DURING THIS TEST.

DAMAGE TO OHMMETER MAY RESULT.

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohm-

meter should now show continuity between relay ter-

minals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.(9) Replace the relay if it did not pass the continu-

ity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the ASD

and fuel pump relay circuits. Refer to 8, Wiring Dia-

grams.

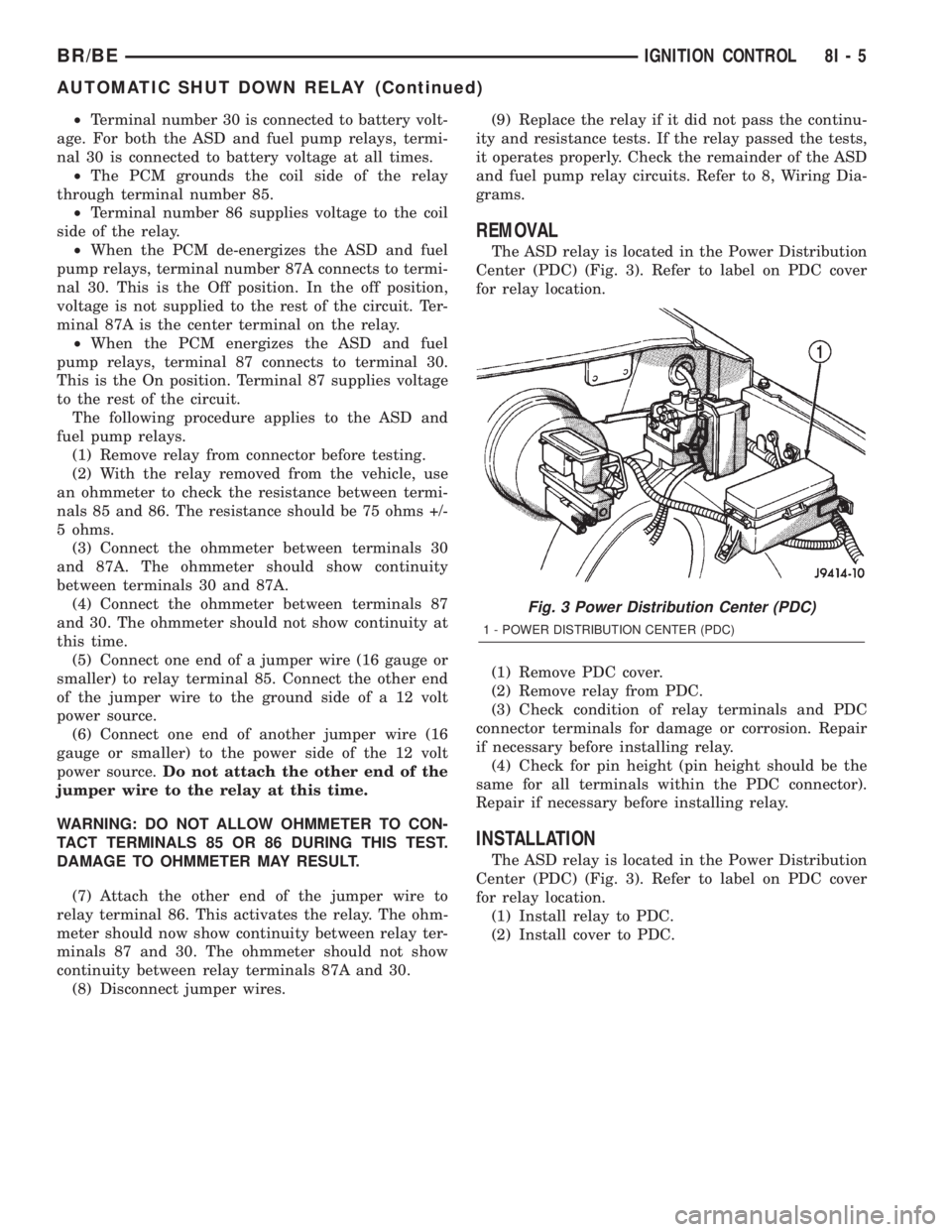

REMOVAL

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 3). Refer to label on PDC cover

for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 3). Refer to label on PDC cover

for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

Fig. 3 Power Distribution Center (PDC)

1 - POWER DISTRIBUTION CENTER (PDC)

BR/BEIGNITION CONTROL 8I - 5

AUTOMATIC SHUT DOWN RELAY (Continued)

Page 463 of 2255

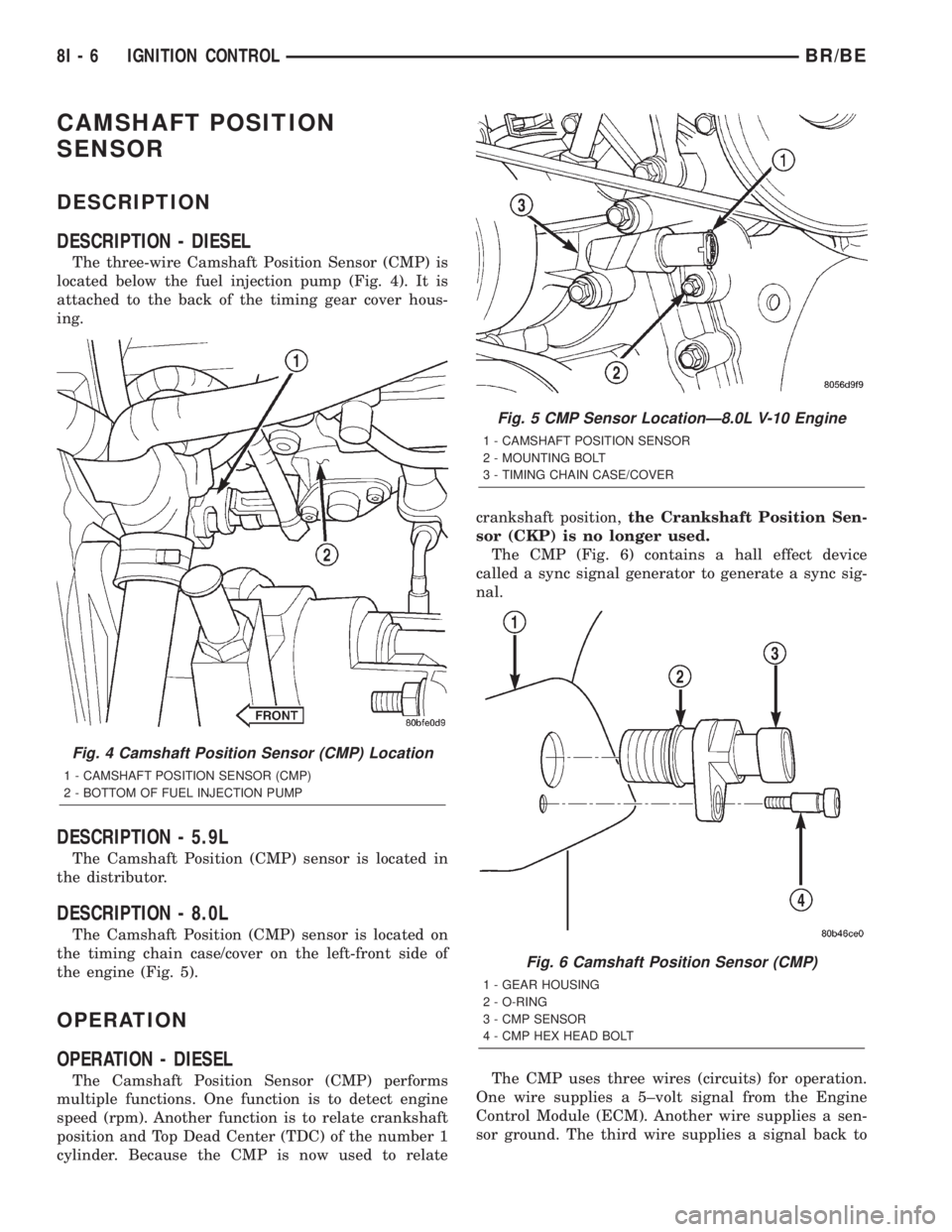

CAMSHAFT POSITION

SENSOR

DESCRIPTION

DESCRIPTION - DIESEL

The three-wire Camshaft Position Sensor (CMP) is

located below the fuel injection pump (Fig. 4). It is

attached to the back of the timing gear cover hous-

ing.

DESCRIPTION - 5.9L

The Camshaft Position (CMP) sensor is located in

the distributor.

DESCRIPTION - 8.0L

The Camshaft Position (CMP) sensor is located on

the timing chain case/cover on the left-front side of

the engine (Fig. 5).

OPERATION

OPERATION - DIESEL

The Camshaft Position Sensor (CMP) performs

multiple functions. One function is to detect engine

speed (rpm). Another function is to relate crankshaft

position and Top Dead Center (TDC) of the number 1

cylinder. Because the CMP is now used to relatecrankshaft position,the Crankshaft Position Sen-

sor (CKP) is no longer used.

The CMP (Fig. 6) contains a hall effect device

called a sync signal generator to generate a sync sig-

nal.

The CMP uses three wires (circuits) for operation.

One wire supplies a 5±volt signal from the Engine

Control Module (ECM). Another wire supplies a sen-

sor ground. The third wire supplies a signal back to

Fig. 4 Camshaft Position Sensor (CMP) Location

1 - CAMSHAFT POSITION SENSOR (CMP)

2 - BOTTOM OF FUEL INJECTION PUMP

Fig. 5 CMP Sensor LocationÐ8.0L V-10 Engine

1 - CAMSHAFT POSITION SENSOR

2 - MOUNTING BOLT

3 - TIMING CHAIN CASE/COVER

Fig. 6 Camshaft Position Sensor (CMP)

1 - GEAR HOUSING

2 - O-RING

3 - CMP SENSOR

4 - CMP HEX HEAD BOLT

8I - 6 IGNITION CONTROLBR/BE

Page 464 of 2255

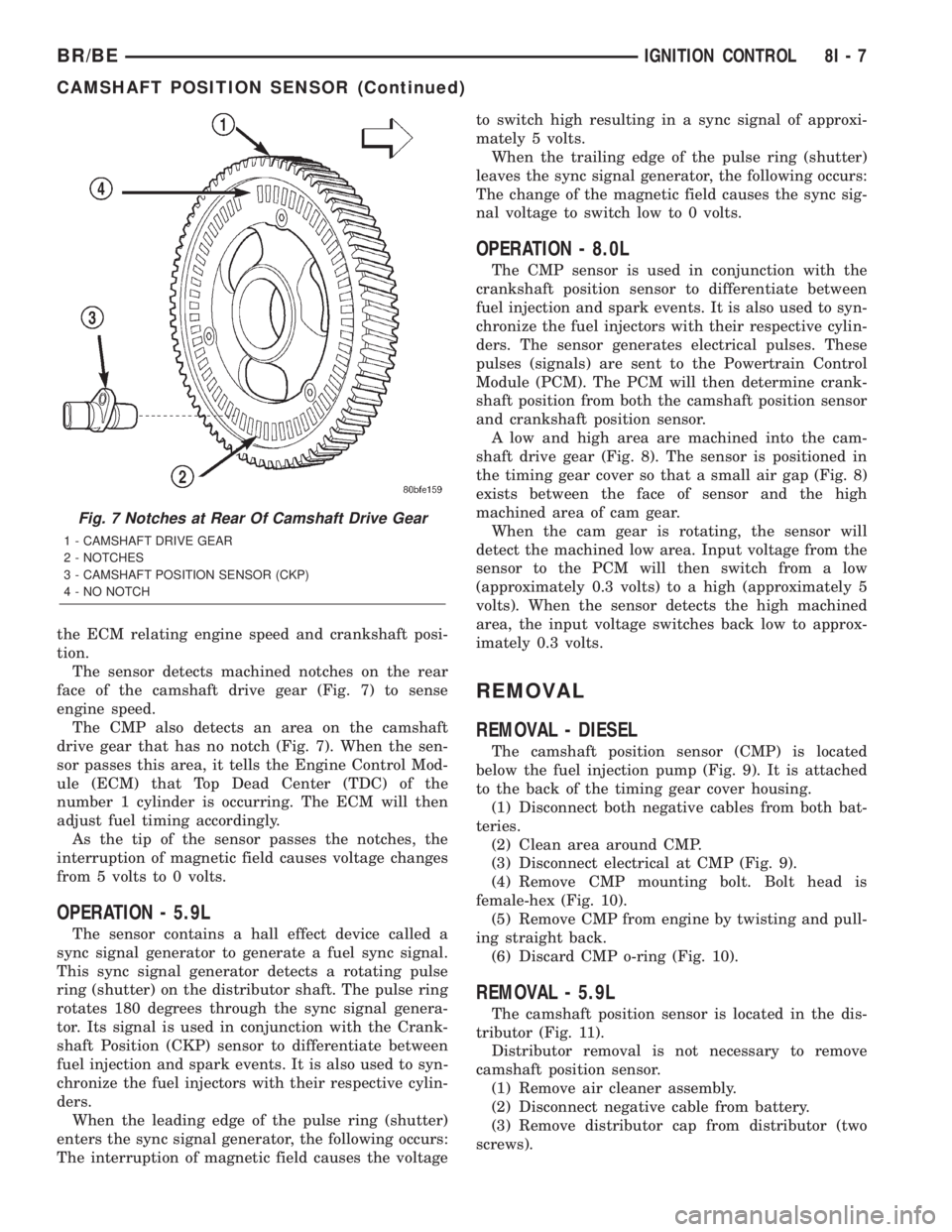

the ECM relating engine speed and crankshaft posi-

tion.

The sensor detects machined notches on the rear

face of the camshaft drive gear (Fig. 7) to sense

engine speed.

The CMP also detects an area on the camshaft

drive gear that has no notch (Fig. 7). When the sen-

sor passes this area, it tells the Engine Control Mod-

ule (ECM) that Top Dead Center (TDC) of the

number 1 cylinder is occurring. The ECM will then

adjust fuel timing accordingly.

As the tip of the sensor passes the notches, the

interruption of magnetic field causes voltage changes

from 5 volts to 0 volts.

OPERATION - 5.9L

The sensor contains a hall effect device called a

sync signal generator to generate a fuel sync signal.

This sync signal generator detects a rotating pulse

ring (shutter) on the distributor shaft. The pulse ring

rotates 180 degrees through the sync signal genera-

tor. Its signal is used in conjunction with the Crank-

shaft Position (CKP) sensor to differentiate between

fuel injection and spark events. It is also used to syn-

chronize the fuel injectors with their respective cylin-

ders.

When the leading edge of the pulse ring (shutter)

enters the sync signal generator, the following occurs:

The interruption of magnetic field causes the voltageto switch high resulting in a sync signal of approxi-

mately 5 volts.

When the trailing edge of the pulse ring (shutter)

leaves the sync signal generator, the following occurs:

The change of the magnetic field causes the sync sig-

nal voltage to switch low to 0 volts.

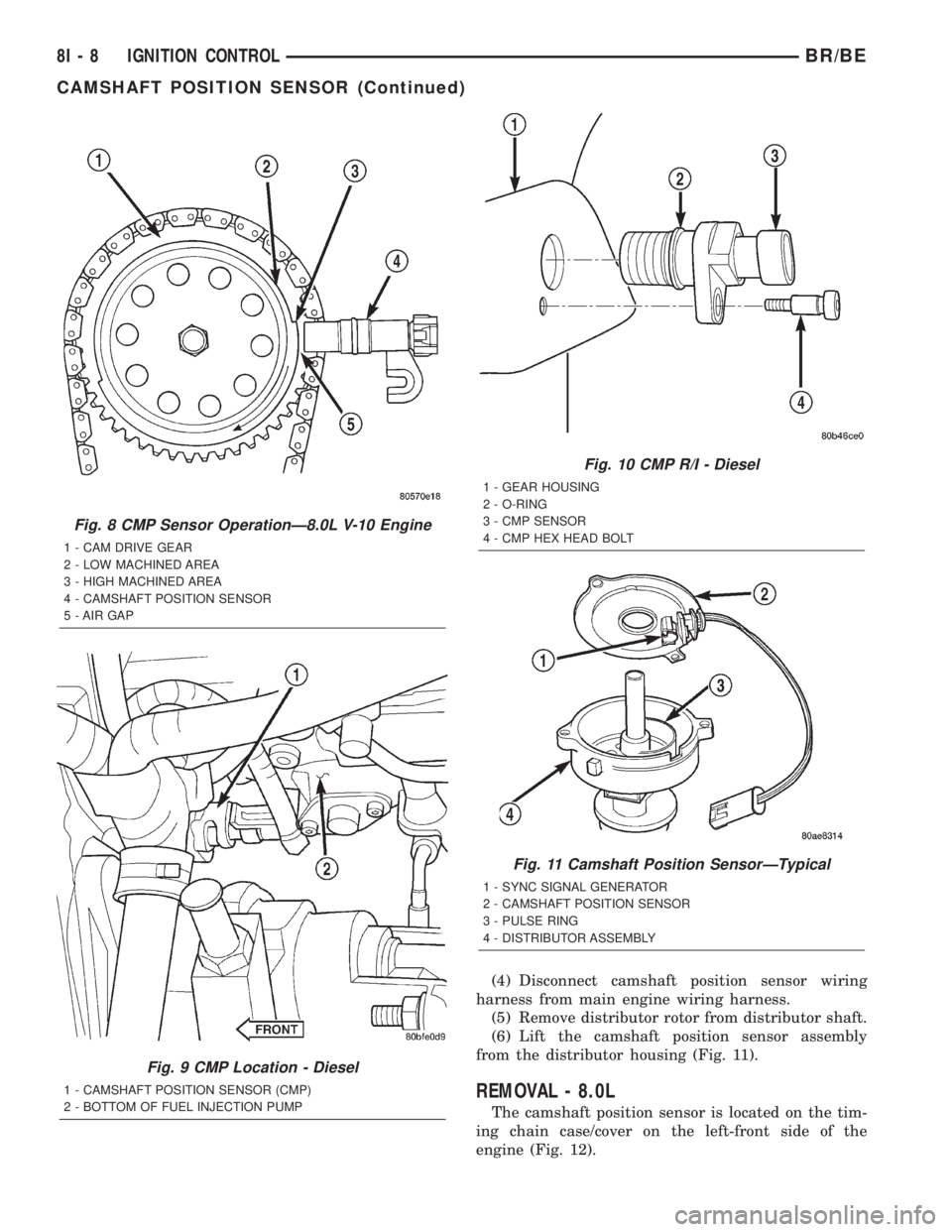

OPERATION - 8.0L

The CMP sensor is used in conjunction with the

crankshaft position sensor to differentiate between

fuel injection and spark events. It is also used to syn-

chronize the fuel injectors with their respective cylin-

ders. The sensor generates electrical pulses. These

pulses (signals) are sent to the Powertrain Control

Module (PCM). The PCM will then determine crank-

shaft position from both the camshaft position sensor

and crankshaft position sensor.

A low and high area are machined into the cam-

shaft drive gear (Fig. 8). The sensor is positioned in

the timing gear cover so that a small air gap (Fig. 8)

exists between the face of sensor and the high

machined area of cam gear.

When the cam gear is rotating, the sensor will

detect the machined low area. Input voltage from the

sensor to the PCM will then switch from a low

(approximately 0.3 volts) to a high (approximately 5

volts). When the sensor detects the high machined

area, the input voltage switches back low to approx-

imately 0.3 volts.

REMOVAL

REMOVAL - DIESEL

The camshaft position sensor (CMP) is located

below the fuel injection pump (Fig. 9). It is attached

to the back of the timing gear cover housing.

(1) Disconnect both negative cables from both bat-

teries.

(2) Clean area around CMP.

(3) Disconnect electrical at CMP (Fig. 9).

(4) Remove CMP mounting bolt. Bolt head is

female-hex (Fig. 10).

(5) Remove CMP from engine by twisting and pull-

ing straight back.

(6) Discard CMP o-ring (Fig. 10).

REMOVAL - 5.9L

The camshaft position sensor is located in the dis-

tributor (Fig. 11).

Distributor removal is not necessary to remove

camshaft position sensor.

(1) Remove air cleaner assembly.

(2) Disconnect negative cable from battery.

(3) Remove distributor cap from distributor (two

screws).

Fig. 7 Notches at Rear Of Camshaft Drive Gear

1 - CAMSHAFT DRIVE GEAR

2 - NOTCHES

3 - CAMSHAFT POSITION SENSOR (CKP)

4 - NO NOTCH

BR/BEIGNITION CONTROL 8I - 7

CAMSHAFT POSITION SENSOR (Continued)

Page 465 of 2255

(4) Disconnect camshaft position sensor wiring

harness from main engine wiring harness.

(5) Remove distributor rotor from distributor shaft.

(6) Lift the camshaft position sensor assembly

from the distributor housing (Fig. 11).

REMOVAL - 8.0L

The camshaft position sensor is located on the tim-

ing chain case/cover on the left-front side of the

engine (Fig. 12).

Fig. 8 CMP Sensor OperationÐ8.0L V-10 Engine

1 - CAM DRIVE GEAR

2 - LOW MACHINED AREA

3 - HIGH MACHINED AREA

4 - CAMSHAFT POSITION SENSOR

5 - AIR GAP

Fig. 9 CMP Location - Diesel

1 - CAMSHAFT POSITION SENSOR (CMP)

2 - BOTTOM OF FUEL INJECTION PUMP

Fig. 10 CMP R/I - Diesel

1 - GEAR HOUSING

2 - O-RING

3 - CMP SENSOR

4 - CMP HEX HEAD BOLT

Fig. 11 Camshaft Position SensorÐTypical

1 - SYNC SIGNAL GENERATOR

2 - CAMSHAFT POSITION SENSOR

3 - PULSE RING

4 - DISTRIBUTOR ASSEMBLY

8I - 8 IGNITION CONTROLBR/BE

CAMSHAFT POSITION SENSOR (Continued)