Transmission diagram DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 361 of 2255

²Head/Park Lights-On Warning- The CTM

chime tone generator will generate repetitive chime

tones at a fast rate to announce that hard wired

inputs from the driver door ajar switch, headlamp

switch, and ignition switch indicate that the exterior

lamps are turned On with the driver side front door

opened and the ignition switch in the Off position.

The chimes will continue to sound until the exterior

lamps are turned Off, the driver side front door is

closed, or the ignition switch is turned to the On

position, whichever occurs first.

²Key-In-Ignition Warning- The CTM chime

tone generator will generate repetitive chime tones at

a fast rate to announce that hard wired inputs from

the driver door ajar switch, headlamp switch, and

ignition switch indicate that the key is in the ignition

lock cylinder with the driver side front door opened

and the ignition switch in the Off position. The

chimes will continue to sound until the key is

removed from the ignition lock cylinder, the driver

side front door is closed, or the ignition switch is

turned to the On position, whichever occurs first.

²Warning Chime Support- The CTM chime

tone generator will generate repetitive chime tones at

a slow rate to announce that a hard wired chime

request input has been received from the EMIC.

These chime tones provide an audible alert to the

vehicle operator that supplements certain visual indi-

cations displayed by the EMIC. Supplemented indica-

tions include the following:

²The ªAirbagº indicator is illuminated. The

chimes will continue to sound for a duration of about

four seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªCheck Gagesº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Fuelº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Washº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªTrans Tempº indicator is illuminated (auto-

matic transmission only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.²The vehicle is over a programmed speed value

(Middle East Gulf Coast Country (GCC) only). The

CTM chime tone generator will generate repetitive

chime tones at a slow rate to announce that the vehi-

cle speed exceeds a programmed value. The chimes

will continue to sound until the vehicle speed is

below the programmed value.

²The ªWater-In-Fuelº indicator is illuminated

(diesel engine only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.

The CTM provides chime service for all available

features in the chime warning system. The CTM

relies upon hard wired inputs from the driver door

ajar switch, the EMIC, the headlamp switch, and the

key-in ignition switch (ignition switch) to provide

chime service for all of the chime warning system

features. Upon receiving the proper inputs, the CTM

activates the integral chime tone generator to pro-

vide the audible chime tone to the vehicle operator.

The chime tone generator in the CTM is capable of

producing repeated chime tones at two different

rates, slow or fast. The slow chime rate is about fifty

chime tones per minute, while the fast chime rate is

about 180 chime tones per minute. The internal pro-

gramming of the CTM and the EMIC determines the

priority of each chime tone request input that is

received, as well as the rate and duration of each

chime tone that is to be generated.

The hard wired chime warning system inputs to

the CTM and the EMIC, as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

See the owner's manual in the vehicle glove box for

more information on the features provided by the

chime warning system.

DIAGNOSIS AND TESTING - CHIME WARNING

SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. The hard wired

chime warning system inputs to the Central Timer

Module (CTM) and the Electro-Mechanical Instru-

ment Cluster (EMIC), as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

8B - 2 CHIME/BUZZERBR/BE

CHIME WARNING SYSTEM (Continued)

Page 421 of 2255

This normally open switch prevents the starter relay

from being energized and the starter motor from

operating unless the automatic transmission gear

selector is in the Neutral or Park positions.

When the starter relay coil is energized, the nor-

mally open relay contacts close. The relay contacts

connect the relay common feed terminal to the relay

normally open terminal. The closed relay contacts

energize the starter solenoid coil windings.

The energized solenoid pull-in coil pulls in the sole-

noid plunger. The solenoid plunger pulls the shift

lever in the starter motor. This engages the starter

overrunning clutch and pinion gear with the starter

ring gear on the manual transmission flywheel or on

the automatic transmission torque converter or

torque converter drive plate.

As the solenoid plunger reaches the end of its

travel, the solenoid contact disc completes the high-

amperage starter feed circuit and energizes the sole-

noid plunger hold-in coil. Current now flows between

the solenoid battery terminal and the starter motor,

energizing the starter.

Once the engine starts, the overrunning clutch pro-

tects the starter motor from damage by allowing thestarter pinion gear to spin faster than the pinion

shaft. When the driver releases the ignition switch to

the On position, the starter relay coil is de-energized.

This causes the relay contacts to open. When the

relay contacts open, the starter solenoid plunger

hold-in coil is de-energized.

When the solenoid plunger hold-in coil is de-ener-

gized, the solenoid plunger return spring returns the

plunger to its relaxed position. This causes the con-

tact disc to open the starter feed circuit, and the shift

lever to disengage the overrunning clutch and pinion

gear from the starter ring gear.

DIAGNOSIS AND TESTING - STARTING

SYSTEM

The battery, starting, and charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct starting/

charging system operation, all of the components

involved in these 3 systems must perform within

specifications.

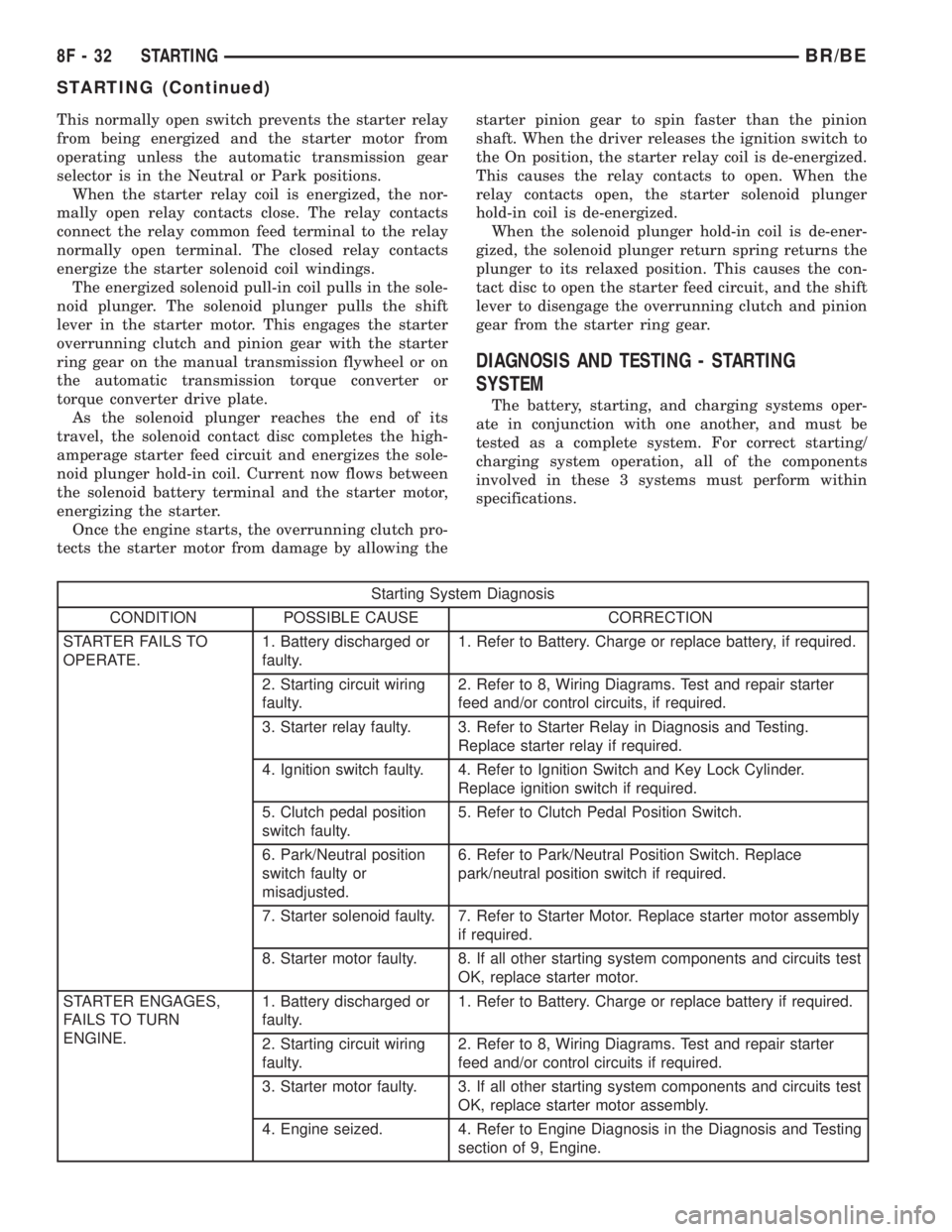

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO

OPERATE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery, if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits, if required.

3. Starter relay faulty. 3. Refer to Starter Relay in Diagnosis and Testing.

Replace starter relay if required.

4. Ignition switch faulty. 4. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch if required.

5. Clutch pedal position

switch faulty.5. Refer to Clutch Pedal Position Switch.

6. Park/Neutral position

switch faulty or

misadjusted.6. Refer to Park/Neutral Position Switch. Replace

park/neutral position switch if required.

7. Starter solenoid faulty. 7. Refer to Starter Motor. Replace starter motor assembly

if required.

8. Starter motor faulty. 8. If all other starting system components and circuits test

OK, replace starter motor.

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits if required.

3. Starter motor faulty. 3. If all other starting system components and circuits test

OK, replace starter motor assembly.

4. Engine seized. 4. Refer to Engine Diagnosis in the Diagnosis and Testing

section of 9, Engine.

8F - 32 STARTINGBR/BE

STARTING (Continued)

Page 422 of 2255

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Starter ring gear faulty. 1. Refer to Starter Motor Removal and Installation.

Remove starter motor to inspect starter ring gear.

Replace starter ring gear if required.

2. Starter motor faulty. 2. If all other starting system components and circuits test

OK, replace starter motor assembly.

STARTER DOES NOT

DISENGAGE.1. Starter motor

improperly installed.1. Refer to Starter Motor Removal and Installation.

Tighten starter mounting hardware to correct torque

specifications.

2. Starter relay faulty. 2. Refer to Starter Relay Diagnosis and Testing. Replace

starter relay if required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace starter motor.

INSPECTION

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. Before removing any unit

from starting system for repair or diagnosis, perform

the following inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO 8, PASSIVE RESTRAINT SYS-

TEMS, BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY.

²Battery- Visually inspect battery for indica-

tions of physical damage and loose or corroded cable

connections. Determine state-of-charge and cranking

capacity of battery. Charge or replace battery if

required. Refer toBatteryin 8, Battery.Note: If

equipped with diesel engine, a dual battery sys-

tem may be used, and both batteries must be

inspected.

²Ignition Switch- Visually inspect ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinder.

²Clutch Pedal Position Switch- If equipped

with manual transmission, visually inspect clutch

pedal position switch for indications of physical dam-

age and loose or corroded wire harness connections.

Refer toClutch Pedal Position Switchin 6,

Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, visually inspect park/

neutral position switch for indications of physical

damage and loose or corroded wire harness connec-tions. Refer toPark/Neutral Position Switchin

21, Transmission.

²Starter Relay- Visually inspect starter relay

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Motor- Visually inspect starter motor

for indications of physical damage and loose or cor-

roded wire harness connections.

²Starter Solenoid- Visually inspect starter sole-

noid for indications of physical damage and loose or

corroded wire harness connections.

²Wiring- Visually inspect wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to 8, Wiring Diagrams.

TESTING

COLD CRANKING TEST

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. The battery must be fully-

charged and load-tested before proceeding. Refer to

Batteryin 8, Battery.

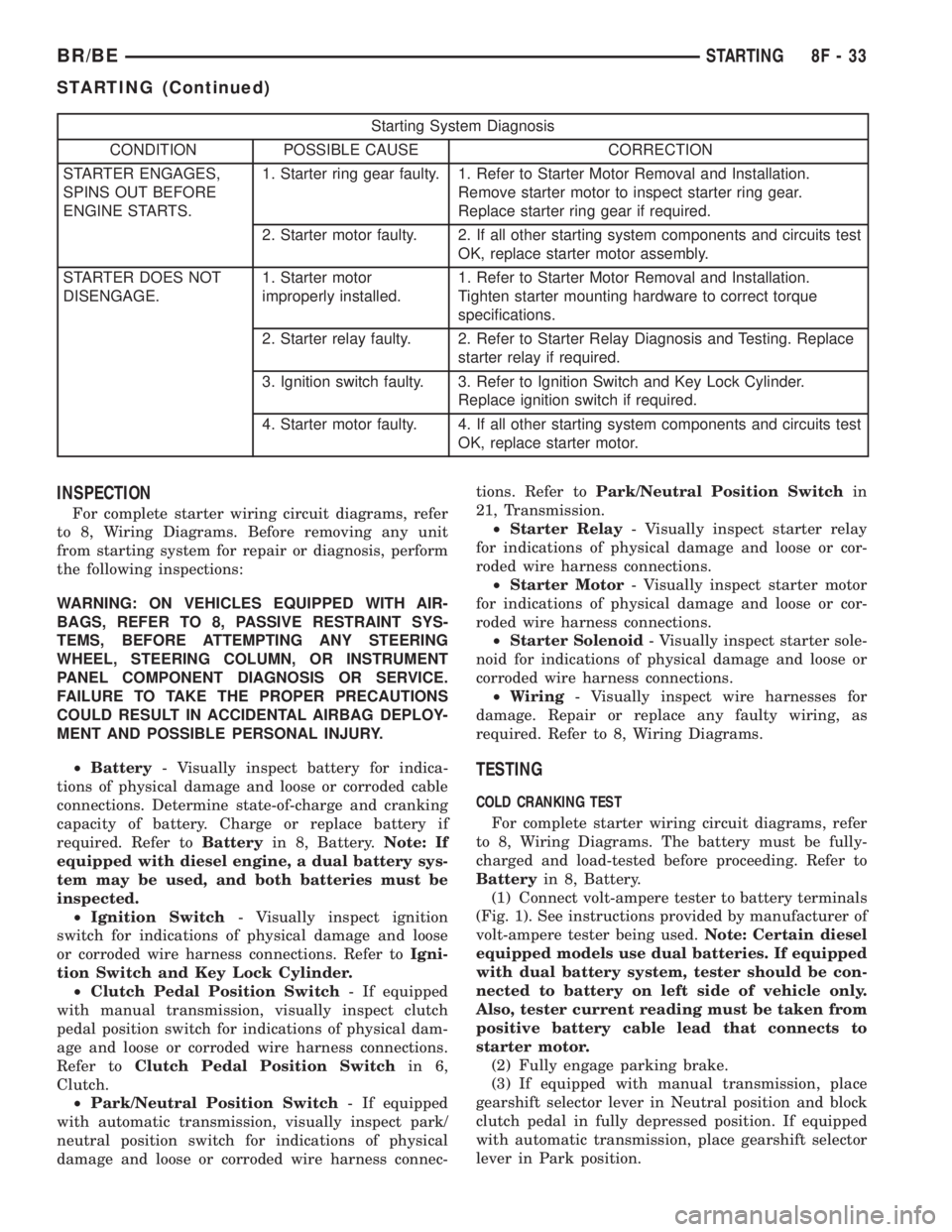

(1) Connect volt-ampere tester to battery terminals

(Fig. 1). See instructions provided by manufacturer of

volt-ampere tester being used.Note: Certain diesel

equipped models use dual batteries. If equipped

with dual battery system, tester should be con-

nected to battery on left side of vehicle only.

Also, tester current reading must be taken from

positive battery cable lead that connects to

starter motor.

(2) Fully engage parking brake.

(3) If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

BR/BESTARTING 8F - 33

STARTING (Continued)

Page 423 of 2255

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent a gasoline engine from starting,

remove Automatic ShutDown (ASD) relay. To prevent

a diesel engine from starting, remove Fuel Pump

Relay. These relays are located in Power Distribution

Center (PDC). Refer to label on PDC cover for relay

location.

WARNING: IF EQUIPPED WITH DIESEL ENGINE,

ATTEMPT TO START ENGINE A FEW TIMES

BEFORE PROCEEDING WITH FOLLOWING STEP.

(6) Rotate and hold ignition switch in Start posi-

tion. Note cranking voltage and current (amperage)

draw readings shown on volt-ampere tester.

(a) If voltage reads below 9.6 volts, refer to

Starter Motorin Diagnosis and Testing. If starter

motor is OK, refer toEngine Diagnosisin 9,

Engine for further testing of engine. If starter

motor is not OK, replace faulty starter motor.

(b) If voltage reads above 9.6 volts and current

(amperage) draw reads below specifications, refer

toFeed Circuit Testin this section.

(c) If voltage reads 12.5 volts or greater and

starter motor does not turn, refer toControl Cir-

cuit Testingin this section.

(d) If voltage reads 12.5 volts or greater and

starter motor turns very slowly, refer toFeed Cir-

cuit Testin this section.

NOTE: A cold engine will increase starter current

(amperage) draw reading, and reduce battery volt-

age reading.FEED CIRCUIT TEST

The starter feed circuit test (voltage drop method)

will determine if there is excessive resistance in

high-amperage feed circuit. For complete starter wir-

ing circuit diagrams, refer 8, Wiring Diagrams.

When performing these tests, it is important to

remember that voltage drop is giving an indication of

resistance between two points at which voltmeter

probes are attached.

Example:When testing resistance of positive bat-

tery cable, touch voltmeter leads to positive battery

cable clamp and cable connector at starter solenoid.

If you probe positive battery terminal post and cable

connector at starter solenoid, you are reading com-

bined voltage drop in positive battery cable clamp-to-

terminal post connection and positive battery cable.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing tests,

be certain that following procedures are accom-

plished:

²Battery is fully-charged and load-tested. Refer to

Batteryin 8, Battery.

²Fully engage parking brake.

²If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

²Verify that all lamps and accessories are turned

off.

²To prevent a gasoline engine from starting,

remove Automatic ShutDown (ASD) relay. To prevent

a diesel engine from starting, remove Fuel Pump

Relay. These relays are located in Power Distribution

Center (PDC). Refer to label on PDC cover for relay

location.

(1) Connect positive lead of voltmeter to negative

battery cable terminal post. Connect negative lead of

voltmeter to negative battery cable clamp (Fig. 2).

Rotate and hold ignition switch in Start position.

Observe voltmeter. If voltage is detected, correct poor

contact between cable clamp and terminal post.

Note: Certain diesel equipped models use dual

batteries. If equipped with dual battery system,

procedure must be performed twice, once for

each battery.

(2) Connect positive lead of voltmeter to positive

battery terminal post. Connect negative lead of volt-

meter to battery positive cable clamp (Fig. 3). Rotate

and hold ignition switch in Start position. Observe

voltmeter. If voltage is detected, correct poor contact

between cable clamp and terminal post.Note: Cer-

tain diesel equipped models use dual batteries.

If equipped with dual battery system, this pro-

cedure must be performed twice, once for each

battery.

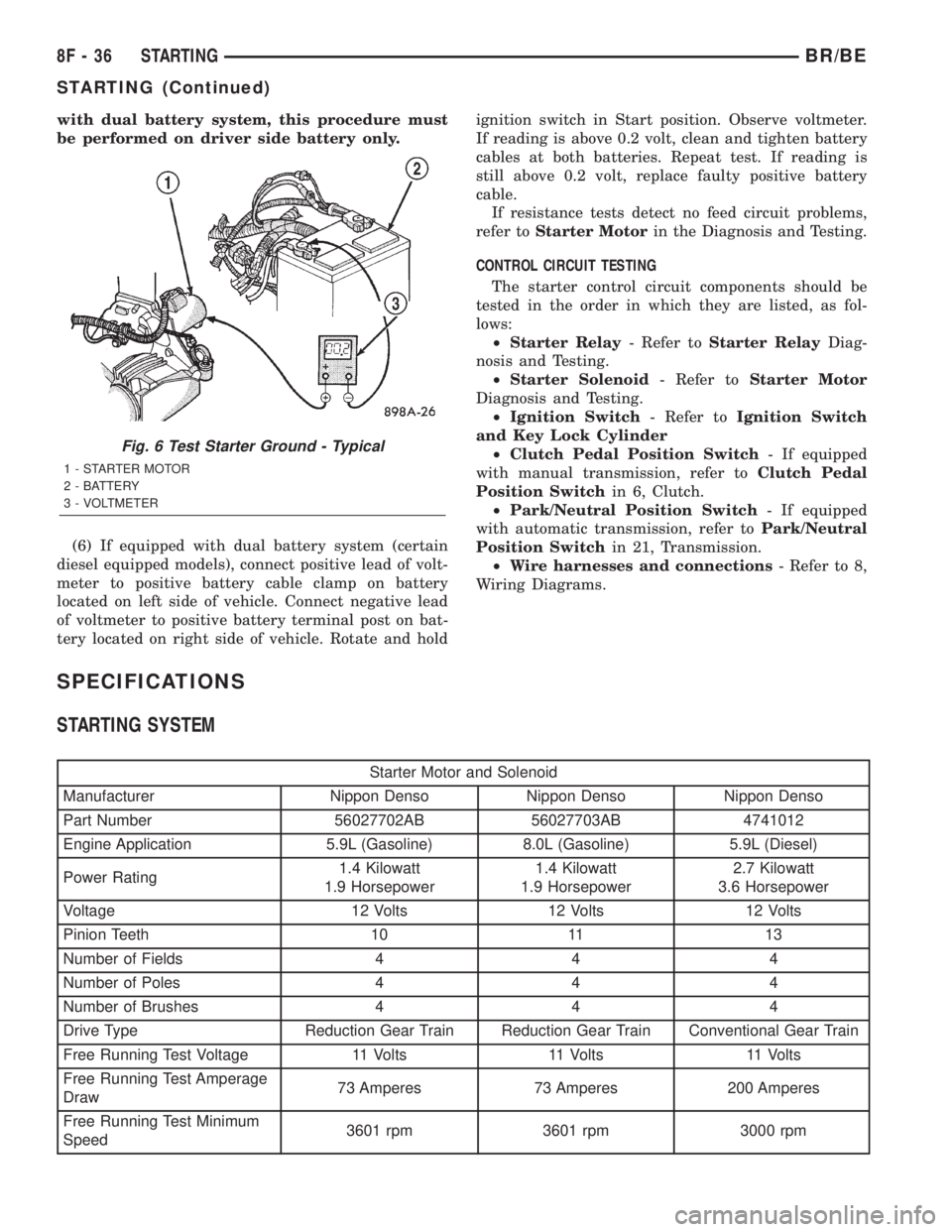

Fig. 1 Volts-Amps Tester Connections - Typical

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

8F - 34 STARTINGBR/BE

STARTING (Continued)

Page 425 of 2255

with dual battery system, this procedure must

be performed on driver side battery only.

(6) If equipped with dual battery system (certain

diesel equipped models), connect positive lead of volt-

meter to positive battery cable clamp on battery

located on left side of vehicle. Connect negative lead

of voltmeter to positive battery terminal post on bat-

tery located on right side of vehicle. Rotate and holdignition switch in Start position. Observe voltmeter.

If reading is above 0.2 volt, clean and tighten battery

cables at both batteries. Repeat test. If reading is

still above 0.2 volt, replace faulty positive battery

cable.

If resistance tests detect no feed circuit problems,

refer toStarter Motorin the Diagnosis and Testing.

CONTROL CIRCUIT TESTING

The starter control circuit components should be

tested in the order in which they are listed, as fol-

lows:

²Starter Relay- Refer toStarter RelayDiag-

nosis and Testing.

²Starter Solenoid- Refer toStarter Motor

Diagnosis and Testing.

²Ignition Switch- Refer toIgnition Switch

and Key Lock Cylinder

²Clutch Pedal Position Switch- If equipped

with manual transmission, refer toClutch Pedal

Position Switchin 6, Clutch.

²Park/Neutral Position Switch- If equipped

with automatic transmission, refer toPark/Neutral

Position Switchin 21, Transmission.

²Wire harnesses and connections- Refer to 8,

Wiring Diagrams.

SPECIFICATIONS

STARTING SYSTEM

Starter Motor and Solenoid

Manufacturer Nippon Denso Nippon Denso Nippon Denso

Part Number 56027702AB 56027703AB 4741012

Engine Application 5.9L (Gasoline) 8.0L (Gasoline) 5.9L (Diesel)

Power Rating1.4 Kilowatt

1.9 Horsepower1.4 Kilowatt

1.9 Horsepower2.7 Kilowatt

3.6 Horsepower

Voltage 12 Volts 12 Volts 12 Volts

Pinion Teeth 10 11 13

Number of Fields 4 4 4

Number of Poles 4 4 4

Number of Brushes 4 4 4

Drive Type Reduction Gear Train Reduction Gear Train Conventional Gear Train

Free Running Test Voltage 11 Volts 11 Volts 11 Volts

Free Running Test Amperage

Draw73 Amperes 73 Amperes 200 Amperes

Free Running Test Minimum

Speed3601 rpm 3601 rpm 3000 rpm

Fig. 6 Test Starter Ground - Typical

1 - STARTER MOTOR

2 - BATTERY

3 - VOLTMETER

8F - 36 STARTINGBR/BE

STARTING (Continued)

Page 430 of 2255

STARTER MOTOR RELAY

DESCRIPTION

The starter relay is an electromechanical device

that switches battery current to the pull-in coil of the

starter solenoid when ignition switch is turned to

Start position. The starter relay is located in the

Power Distribution Center (PDC) in the engine com-

partment. See PDC cover for relay identification and

location.

The starter relay is a International Standards

Organization (ISO) relay. Relays conforming to ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions.

The starter relay cannot be repaired or adjusted

and, if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When electro-

magnetic coil is energized, it draws the movable con-

tact away from normally closed fixed contact, and

holds it against the other (normally open) fixed con-

tact.

When electromagnetic coil is de-energized, spring

pressure returns movable contact to normally closed

position. The resistor or diode is connected in parallel

with electromagnetic coil within relay, and helps to

dissipate voltage spikes produced when coil is de-en-

ergized.

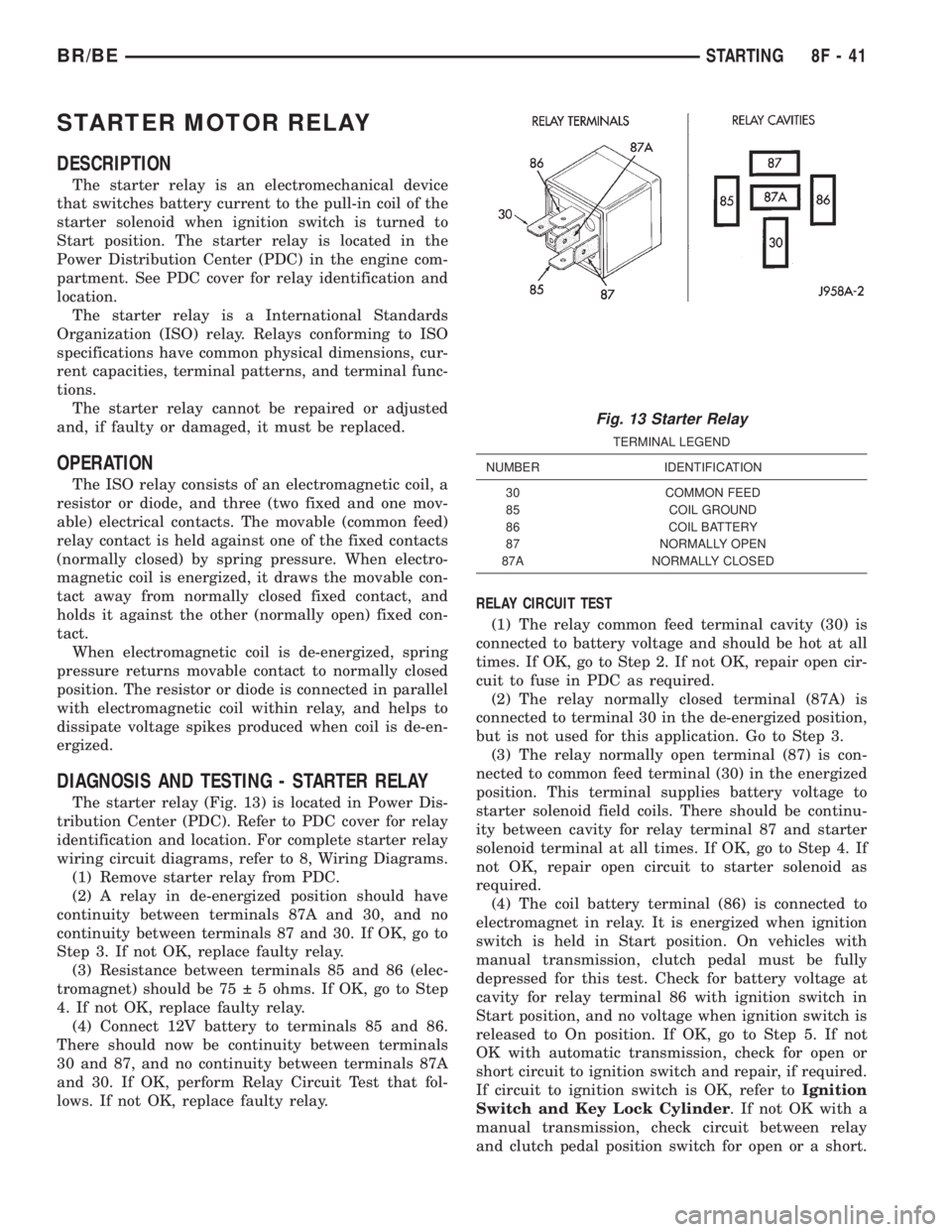

DIAGNOSIS AND TESTING - STARTER RELAY

The starter relay (Fig. 13) is located in Power Dis-

tribution Center (PDC). Refer to PDC cover for relay

identification and location. For complete starter relay

wiring circuit diagrams, refer to 8, Wiring Diagrams.

(1) Remove starter relay from PDC.

(2) A relay in de-energized position should have

continuity between terminals 87A and 30, and no

continuity between terminals 87 and 30. If OK, go to

Step 3. If not OK, replace faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace faulty relay.

(4) Connect 12V battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform Relay Circuit Test that fol-

lows. If not OK, replace faulty relay.RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair open cir-

cuit to fuse in PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to common feed terminal (30) in the energized

position. This terminal supplies battery voltage to

starter solenoid field coils. There should be continu-

ity between cavity for relay terminal 87 and starter

solenoid terminal at all times. If OK, go to Step 4. If

not OK, repair open circuit to starter solenoid as

required.

(4) The coil battery terminal (86) is connected to

electromagnet in relay. It is energized when ignition

switch is held in Start position. On vehicles with

manual transmission, clutch pedal must be fully

depressed for this test. Check for battery voltage at

cavity for relay terminal 86 with ignition switch in

Start position, and no voltage when ignition switch is

released to On position. If OK, go to Step 5. If not

OK with automatic transmission, check for open or

short circuit to ignition switch and repair, if required.

If circuit to ignition switch is OK, refer toIgnition

Switch and Key Lock Cylinder. If not OK with a

manual transmission, check circuit between relay

and clutch pedal position switch for open or a short.

Fig. 13 Starter Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

BR/BESTARTING 8F - 41

Page 495 of 2255

on the instrument cluster circuit board based upon a

hard wired input to the instrument cluster, cluster

programming, and electronic messages received by

the cluster from the Controller Antilock Brake (CAB)

over the Chrysler Collision Detection (CCD) data bus.

The brake indicator Light Emitting Diode (LED)

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (st-run) circuit whenever the ignition

switch is in the On or Start positions; therefore, the

LED will always be off when the ignition switch is in

any position except On or Start. The LED only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. The instrument cluster

will turn on the brake indicator for the following rea-

sons:

²Bulb Test- Each time the ignition switch is

turned to the On position the brake indicator is illu-

minated by the instrument cluster for about four sec-

onds as a bulb test.

²Park Brake-On- If the park brake is applied

or not fully released with the ignition switch in the

On position, the brake indicator is illuminated solid.

The brake indicator will blink on and off repeatedly

when the park brake is applied or not fully released

and the ignition switch is in the On position if a

vehicle with an automatic transmission is not in

Park or Neutral, or if the engine is running on vehi-

cles with a manual transmission.

²Brake Lamp-On Message- Each time the

cluster receives a lamp-on message from the CAB,

the brake indicator will be illuminated. The indicator

remains illuminated until the cluster receives a

lamp-off message from the CAB, or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Actuator Test- Each time the instrument clus-

ter is put through the actuator test, the brake indi-

cator will be turned on during the bulb check portion

of the test to confirm the functionality of the LED

and the cluster control circuitry.

The park brake switch on the park brake pedal

mechanism provides a hard wired ground input to

the instrument cluster circuitry through the park

brake switch sense circuit whenever the park brake

is applied or not fully released. The CAB continually

monitors the brake pressure switch on the brake

combination valve to determine if the pressures in

the two halves of the split brake hydraulic system

are unequal. The CAB then sends the proper lamp-on

or lamp-off messages to the instrument cluster. If the

CAB sends a lamp-on message after the bulb test, it

indicates that the CAB has detected a brake hydrau-

lic system malfunction and/or that the ABS system

has become inoperative. The CAB will store a Diag-

nostic Trouble Code (DTC) for any malfunction itdetects. The park brake switch input to the instru-

ment cluster can be diagnosed using conventional

diagnostic tools and methods. For proper diagnosis of

the antilock brake system, the CAB, the CCD data

bus, or the message inputs to the instrument cluster

that control the brake indicator, a DRBIIItscan tool

is required. Refer to the appropriate diagnostic infor-

mation.

DIAGNOSIS AND TESTING - BRAKE INDICATOR

The diagnosis found here addresses an inoperative

brake indicator condition. If the brake indicator

comes on or stays on with the ignition switch in the

On position and the park brake released, or comes on

while driving, the brake system must be diagnosed

and repaired prior to performing the following tests.

(Refer to 5 - BRAKES - DIAGNOSIS AND TEST-

ING). If no brake system problem is found, the fol-

lowing procedure will help locate a faulty park brake

switch or park brake switch sense circuit. Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the park brake switch from the switch

terminal. With the park brake released, check for

continuity between the park brake switch terminal

and a good ground. There should be no continuity. If

OK, go to Step 2. If not OK, adjust or replace the

faulty park brake switch.

(2) Remove the instrument cluster from the instru-

ment panel. With the park brake switch still discon-

nected, check for continuity between the park brake

switch sense circuit cavity of the instrument panel

wire harness connector for the park brake switch and

a good ground. There should be no continuity. If OK,

go to Step 3. If not OK, repair the shorted park

8J - 16 INSTRUMENT CLUSTERBR/BE

BRAKE/PARK BRAKE INDICATOR (Continued)

Page 511 of 2255

TURN SIGNAL INDICATOR

DESCRIPTION

Two turn signal indicators are standard equipment

on all instrument clusters. The turn signal indicators

are located near the upper edge of the instrument

cluster overlay, between the speedometer and the

tachometer. Each turn signal indicator consists of a

stenciled cutout of the International Control and Dis-

play Symbol icon for ªTurn Warningº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents these icons from

being clearly visible when their lamps are not illumi-

nated. The icons appear in green through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by a replaceable incandes-

cent bulb and bulb holder unit located on the instru-

ment cluster electronic circuit board. The turn signal

indicators are serviced as a unit with the instrument

cluster.

OPERATION

The turn signal indicators give an indication to the

vehicle operator that the turn signal (left or right

indicator flashing) or hazard warning (both left and

right indicators flashing) have been selected. These

indicators are controlled by two individual hard

wired inputs to the instrument cluster electronic cir-

cuit board. The turn signal indicator bulbs are

grounded on the instrument cluster electronic circuit

board at all times. The turn signal indicator bulbs

only illuminate when they are provided with battery

current by the turn signal and hazard warning

switch circuitry of the left multi-function switch on

the steering column through separate left and right

turn signal inputs to the instrument cluster; there-

fore, these indicators can be illuminated, regardless

of the ignition switch position.

The turn signal indicators are connected in series

between ground and the output of the turn signal

and hazard warning switch circuitry, but in parallel

with the other turn signal circuits. This arrangement

allows the turn signal indicators to remain functional

regardless of the condition of the other circuits in the

turn signal and hazard warning system. For more

information on the turn signal and hazard warning

system, (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR - OPERATION - TURN SIGNAL &

HAZARD WARNING SYSTEM). The turn signal

indicators can be diagnosed using conventional diag-

nostic tools and methods.

DIAGNOSIS AND TESTING - TURN SIGNAL

INDICATOR

The diagnosis found here addresses an inoperative

turn signal indicator lamp condition. If the problem

being diagnosed is related to inoperative turn signals

or hazard warning lamps, be certain to repair the

turn signal and hazard warning system before

attempting to diagnose or repair the turn signal indi-

cators. If no turn signal or hazard warning system

problems are found, the following procedure will help

locate a short or open in the left or right turn signal

indicator circuit. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds.

(1) Disconnect and isolate the battery negative

cable. Remove the instrument cluster.

(2) Connect the battery negative cable. Activate

the hazard warning system by moving the hazard

warning switch button to the On position. Check for

battery voltage at the inoperative (right or left) turn

signal circuit cavity of the instrument panel wire

harness connector (Connector C2) for the instrument

cluster. There should be a switching (on and off) bat-

tery voltage signal. If OK, replace the faulty turn sig-

nal indicator bulb. If not OK, repair the open (right

or left) turn signal circuit to the left multi-function

switch as required.

UPSHIFT INDICATOR

DESCRIPTION

An upshift indicator is standard equipment on all

instrument clusters. However, on vehicles not

equipped with a manual transmission, this indicator

is disabled. The upshift indicator is located near the

fuel gauge in the instrument cluster overlay, to the

left of center. The upshift indicator consists of an

upward pointed arrow icon that is a stenciled cutout

in the opaque layer of the instrument cluster overlay.

The dark outer layer of the overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. An amber lens behind the cutout in the

opaque layer of the overlay causes the icon to appear

in amber through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by a replaceable incandescent bulb and bulb

holder unit located on the instrument cluster elec-

tronic circuit board. The upshift indicator is serviced

as a unit with the instrument cluster.

8J - 32 INSTRUMENT CLUSTERBR/BE

Page 579 of 2255

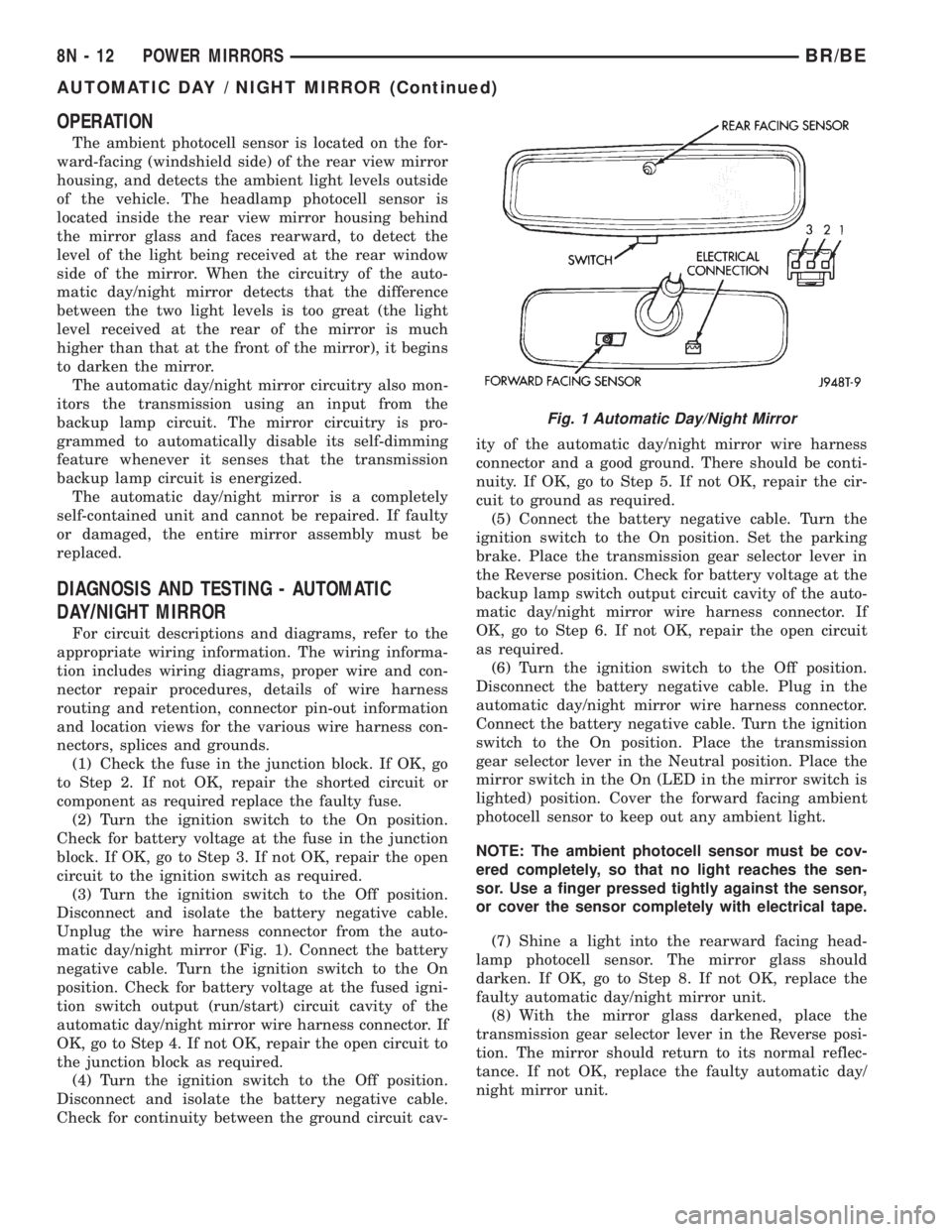

OPERATION

The ambient photocell sensor is located on the for-

ward-facing (windshield side) of the rear view mirror

housing, and detects the ambient light levels outside

of the vehicle. The headlamp photocell sensor is

located inside the rear view mirror housing behind

the mirror glass and faces rearward, to detect the

level of the light being received at the rear window

side of the mirror. When the circuitry of the auto-

matic day/night mirror detects that the difference

between the two light levels is too great (the light

level received at the rear of the mirror is much

higher than that at the front of the mirror), it begins

to darken the mirror.

The automatic day/night mirror circuitry also mon-

itors the transmission using an input from the

backup lamp circuit. The mirror circuitry is pro-

grammed to automatically disable its self-dimming

feature whenever it senses that the transmission

backup lamp circuit is energized.

The automatic day/night mirror is a completely

self-contained unit and cannot be repaired. If faulty

or damaged, the entire mirror assembly must be

replaced.

DIAGNOSIS AND TESTING - AUTOMATIC

DAY/NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the junction block. If OK, go

to Step 2. If not OK, repair the shorted circuit or

component as required replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 3. If not OK, repair the open

circuit to the ignition switch as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Unplug the wire harness connector from the auto-

matic day/night mirror (Fig. 1). Connect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused igni-

tion switch output (run/start) circuit cavity of the

automatic day/night mirror wire harness connector. If

OK, go to Step 4. If not OK, repair the open circuit to

the junction block as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the On position. Set the parking

brake. Place the transmission gear selector lever in

the Reverse position. Check for battery voltage at the

backup lamp switch output circuit cavity of the auto-

matic day/night mirror wire harness connector. If

OK, go to Step 6. If not OK, repair the open circuit

as required.

(6) Turn the ignition switch to the Off position.

Disconnect the battery negative cable. Plug in the

automatic day/night mirror wire harness connector.

Connect the battery negative cable. Turn the ignition

switch to the On position. Place the transmission

gear selector lever in the Neutral position. Place the

mirror switch in the On (LED in the mirror switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The mirror glass should

darken. If OK, go to Step 8. If not OK, replace the

faulty automatic day/night mirror unit.

(8) With the mirror glass darkened, place the

transmission gear selector lever in the Reverse posi-

tion. The mirror should return to its normal reflec-

tance. If not OK, replace the faulty automatic day/

night mirror unit.

Fig. 1 Automatic Day/Night Mirror

8N - 12 POWER MIRRORSBR/BE

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 595 of 2255

²Airbag Control Module- The Airbag Control

Module (ACM) is located in a stamped mounting

bracket on the floor panel transmission tunnel, below

the center of the instrument panel.

²Airbag Indicator- The airbag indicator is inte-

gral to the ElectroMechanical Instrument Cluster

(EMIC), which is located on the instrument panel in

front of the driver.

²Clockspring- The clockspring is located near

the top of the steering column, directly beneath the

steering wheel.

²Driver Airbag- The driver airbag is located in

the center of the steering wheel, beneath the driver

airbag trim cover.

²Driver Knee Blocker- The driver knee blocker

is a molded plastic structural unit secured to the

back side of and integral to the instrument panel

steering column opening cover.

²Passenger Airbag- The passenger airbag is

located on the instrument panel, beneath the passen-

ger airbag door on the instrument panel above the

glove box on the passenger side of the vehicle.

²Passenger Airbag On/Off Switch- The pas-

senger airbag on/off switch is located in a dedicated

opening in the upper right corner of the instrument

panel cluster bezel, to the right of the center panel

outlets of the climate control system.

²Passenger Knee Blocker- The passenger knee

blocker is a structural reinforcement that is integral

to and concealed within the glove box door.

The ACM and the EMIC each contain a central

processing unit and programming that allow them to

communicate with each other using the Chrysler Col-

lision Detection (CCD) data bus network. This

method of communication is used for control of the

airbag indicator on all models. (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

COMMUNICATION - DESCRIPTION).Hard wired circuitry connects the airbag system

components to each other through the electrical sys-

tem of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system, and to the air-

bag system components through the use of a combi-

nation of soldered splices, splice block connectors,

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.OPERATION

The airbag system is referred to as a supplemental

restraint system because it was designed and is

intended to enhance the protection for the front seat

occupants of the vehicleonlywhen used in conjunc-

tion with the seat belts. It is referred to as a passive

system because the vehicle occupants are not

required to do anything to make it work. The pri-

mary passenger restraints in this or any other vehi-

cle are the standard equipment factory-installed seat

belts. Seat belts are referred to as an active restraint

because the vehicle occupants are required to physi-

cally fasten and properly adjust these restraints in

order to benefit from them. The vehicle occupants

must be wearing their seat belts in order to obtain

the maximum safety benefit from the factory-in-

stalled airbag system.

The airbag system electrical circuits are continu-

ously monitored and controlled by a microprocessor

and software contained within the Airbag Control

Module (ACM). An airbag indicator in the ElectroMe-

chanical Instrument Cluster (EMIC) lights for about

seven seconds as a bulb test each time the ignition

switch is turned to the On or Start positions. Follow-

ing the bulb test, the airbag indicator is turned on or

off by the ACM to indicate the status of the airbag

system. If the airbag indicator comes on at any time

other than during the bulb test, it indicates that

there is a problem in the airbag system electrical cir-

cuits. Such a problem may cause the airbags not to

deploy when required, or to deploy when not

required.

The clockspring on the top of the steering column

allows a continuous electrical circuit to be main-

tained between the stationary steering column and

the driver airbag inflator, which rotates with the

steering wheel. The passenger airbag on/off switch

allows the passenger side airbag to be disabled when

Fig. 1 SRS Logo

8O - 2 RESTRAINTSBR/BE

RESTRAINTS (Continued)