wheel DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1 of 2255

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

6Clutch

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission and Transfer Case

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

NOTE: For New Vehicle Preparation

information, see the separate

publication, 81-170-00003.

Page 2 of 2255

INTRODUCTION

TABLE OF CONTENTS

page page

VEHICLE SAFETY CERTIFICATION LABEL

DESCRIPTION..........................1

VEHICLE IDENTIFICATION NUMBER

DESCRIPTION..........................1

VEHICLE EMISSION CONTROL INFORMATION

(VECI)

DESCRIPTION..........................3

EQUIPMENT IDENTIFICATION PLATE

DESCRIPTION..........................3

BODY CODE PLATE

DESCRIPTION..........................4

INTERNATIONAL VEHICLE CONTROL &

DISPLAY SYMBOLS

DESCRIPTION - INTERNATIONAL SYMBOLS . . . 5FASTENER IDENTIFICATION

DESCRIPTION..........................6

FASTENER USAGE

DESCRIPTION..........................9

THREADED HOLE REPAIR

DESCRIPTION..........................9

METRIC SYSTEM

DESCRIPTION..........................9

TORQUE REFERENCES

DESCRIPTION.........................11

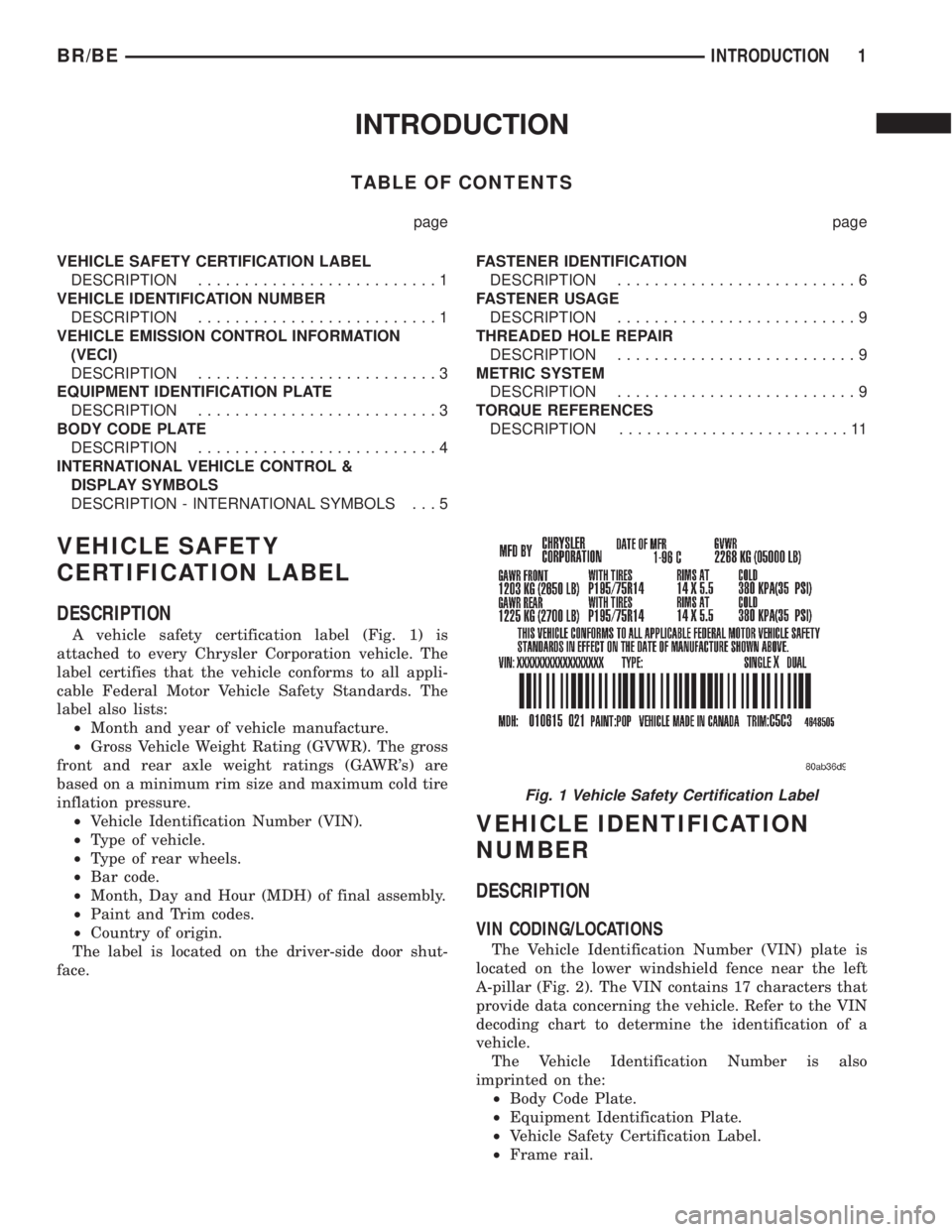

VEHICLE SAFETY

CERTIFICATION LABEL

DESCRIPTION

A vehicle safety certification label (Fig. 1) is

attached to every Chrysler Corporation vehicle. The

label certifies that the vehicle conforms to all appli-

cable Federal Motor Vehicle Safety Standards. The

label also lists:

²Month and year of vehicle manufacture.

²Gross Vehicle Weight Rating (GVWR). The gross

front and rear axle weight ratings (GAWR's) are

based on a minimum rim size and maximum cold tire

inflation pressure.

²Vehicle Identification Number (VIN).

²Type of vehicle.

²Type of rear wheels.

²Bar code.

²Month, Day and Hour (MDH) of final assembly.

²Paint and Trim codes.

²Country of origin.

The label is located on the driver-side door shut-

face.

VEHICLE IDENTIFICATION

NUMBER

DESCRIPTION

VIN CODING/LOCATIONS

The Vehicle Identification Number (VIN) plate is

located on the lower windshield fence near the left

A-pillar (Fig. 2). The VIN contains 17 characters that

provide data concerning the vehicle. Refer to the VIN

decoding chart to determine the identification of a

vehicle.

The Vehicle Identification Number is also

imprinted on the:

²Body Code Plate.

²Equipment Identification Plate.

²Vehicle Safety Certification Label.

²Frame rail.

Fig. 1 Vehicle Safety Certification Label

BR/BEINTRODUCTION 1

Page 4 of 2255

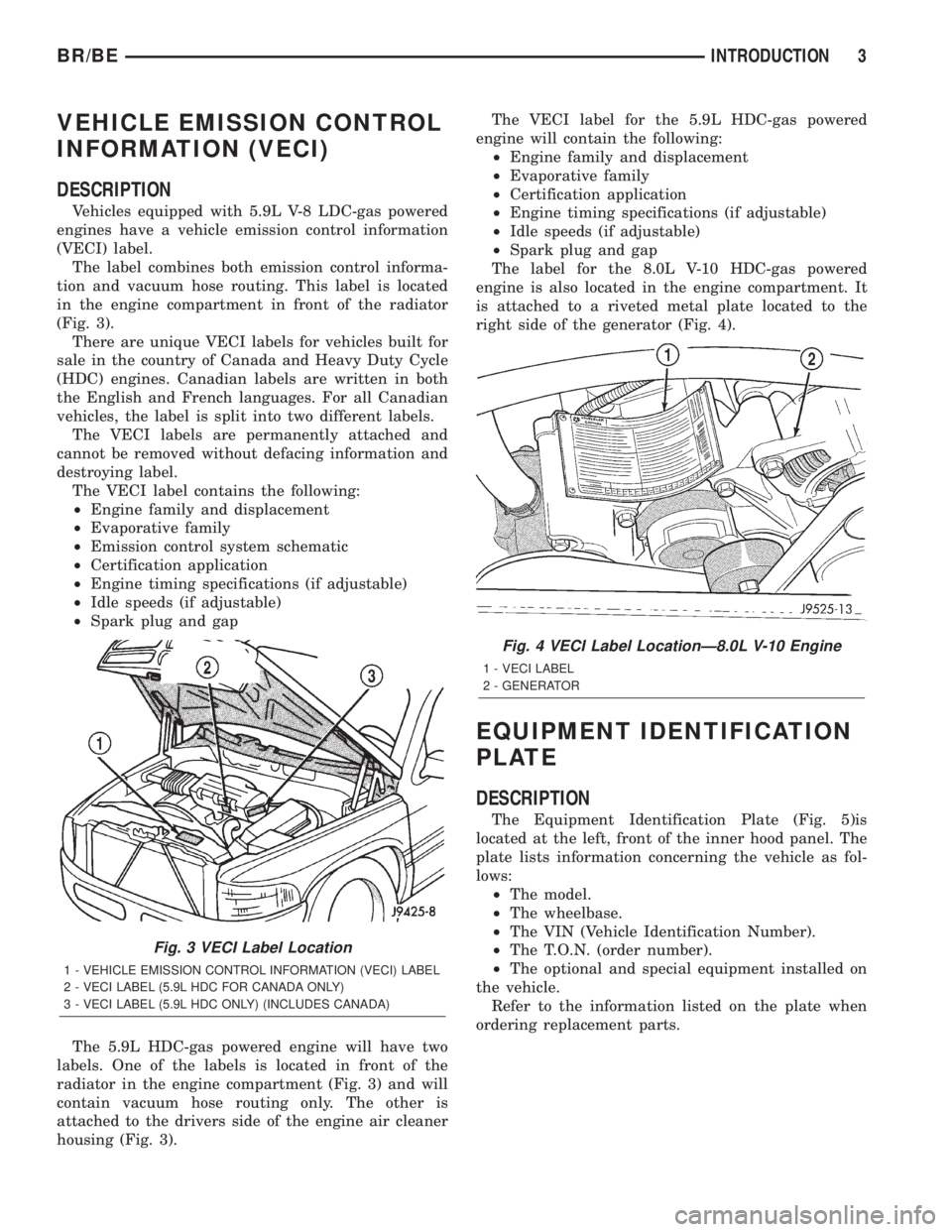

VEHICLE EMISSION CONTROL

INFORMATION (VECI)

DESCRIPTION

Vehicles equipped with 5.9L V-8 LDC-gas powered

engines have a vehicle emission control information

(VECI) label.

The label combines both emission control informa-

tion and vacuum hose routing. This label is located

in the engine compartment in front of the radiator

(Fig. 3).

There are unique VECI labels for vehicles built for

sale in the country of Canada and Heavy Duty Cycle

(HDC) engines. Canadian labels are written in both

the English and French languages. For all Canadian

vehicles, the label is split into two different labels.

The VECI labels are permanently attached and

cannot be removed without defacing information and

destroying label.

The VECI label contains the following:

²Engine family and displacement

²Evaporative family

²Emission control system schematic

²Certification application

²Engine timing specifications (if adjustable)

²Idle speeds (if adjustable)

²Spark plug and gap

The 5.9L HDC-gas powered engine will have two

labels. One of the labels is located in front of the

radiator in the engine compartment (Fig. 3) and will

contain vacuum hose routing only. The other is

attached to the drivers side of the engine air cleaner

housing (Fig. 3).The VECI label for the 5.9L HDC-gas powered

engine will contain the following:

²Engine family and displacement

²Evaporative family

²Certification application

²Engine timing specifications (if adjustable)

²Idle speeds (if adjustable)

²Spark plug and gap

The label for the 8.0L V-10 HDC-gas powered

engine is also located in the engine compartment. It

is attached to a riveted metal plate located to the

right side of the generator (Fig. 4).

EQUIPMENT IDENTIFICATION

PLATE

DESCRIPTION

The Equipment Identification Plate (Fig. 5)is

located at the left, front of the inner hood panel. The

plate lists information concerning the vehicle as fol-

lows:

²The model.

²The wheelbase.

²The VIN (Vehicle Identification Number).

²The T.O.N. (order number).

²The optional and special equipment installed on

the vehicle.

Refer to the information listed on the plate when

ordering replacement parts.

Fig. 3 VECI Label Location

1 - VEHICLE EMISSION CONTROL INFORMATION (VECI) LABEL

2 - VECI LABEL (5.9L HDC FOR CANADA ONLY)

3 - VECI LABEL (5.9L HDC ONLY) (INCLUDES CANADA)

Fig. 4 VECI Label LocationÐ8.0L V-10 Engine

1 - VECI LABEL

2 - GENERATOR

BR/BEINTRODUCTION 3

Page 5 of 2255

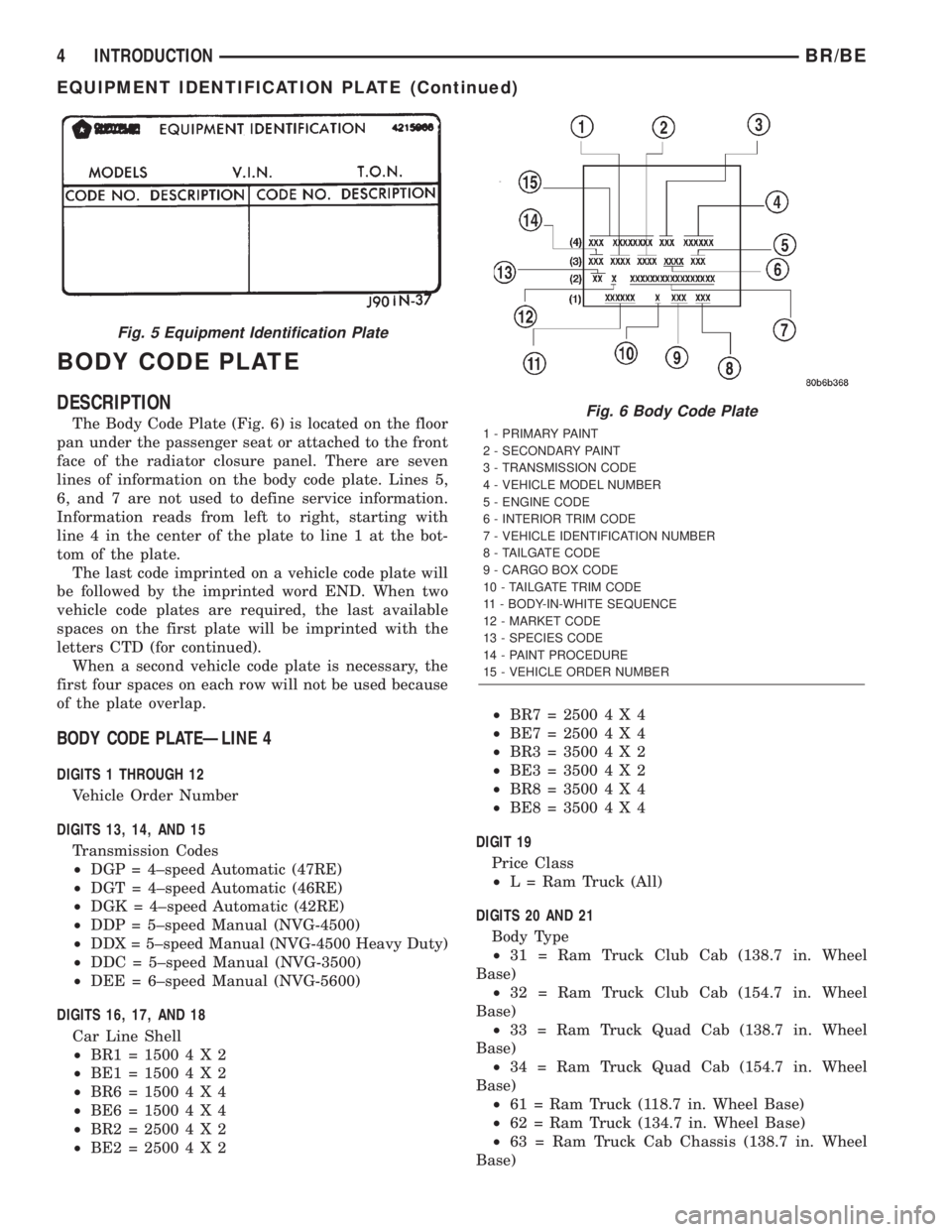

BODY CODE PLATE

DESCRIPTION

The Body Code Plate (Fig. 6) is located on the floor

pan under the passenger seat or attached to the front

face of the radiator closure panel. There are seven

lines of information on the body code plate. Lines 5,

6, and 7 are not used to define service information.

Information reads from left to right, starting with

line 4 in the center of the plate to line 1 at the bot-

tom of the plate.

The last code imprinted on a vehicle code plate will

be followed by the imprinted word END. When two

vehicle code plates are required, the last available

spaces on the first plate will be imprinted with the

letters CTD (for continued).

When a second vehicle code plate is necessary, the

first four spaces on each row will not be used because

of the plate overlap.

BODY CODE PLATEÐLINE 4

DIGITS 1 THROUGH 12

Vehicle Order Number

DIGITS 13, 14, AND 15

Transmission Codes

²DGP = 4±speed Automatic (47RE)

²DGT = 4±speed Automatic (46RE)

²DGK = 4±speed Automatic (42RE)

²DDP = 5±speed Manual (NVG-4500)

²DDX = 5±speed Manual (NVG-4500 Heavy Duty)

²DDC = 5±speed Manual (NVG-3500)

²DEE = 6±speed Manual (NVG-5600)

DIGITS 16, 17, AND 18

Car Line Shell

²BR1=15004X2

²BE1=15004X2

²BR6=15004X4

²BE6=15004X4

²BR2=25004X2

²BE2=25004X2²BR7=25004X4

²BE7=25004X4

²BR3=35004X2

²BE3=35004X2

²BR8=35004X4

²BE8=35004X4

DIGIT 19

Price Class

²L = Ram Truck (All)

DIGITS 20 AND 21

Body Type

²31 = Ram Truck Club Cab (138.7 in. Wheel

Base)

²32 = Ram Truck Club Cab (154.7 in. Wheel

Base)

²33 = Ram Truck Quad Cab (138.7 in. Wheel

Base)

²34 = Ram Truck Quad Cab (154.7 in. Wheel

Base)

²61 = Ram Truck (118.7 in. Wheel Base)

²62 = Ram Truck (134.7 in. Wheel Base)

²63 = Ram Truck Cab Chassis (138.7 in. Wheel

Base)

Fig. 5 Equipment Identification Plate

Fig. 6 Body Code Plate

1 - PRIMARY PAINT

2 - SECONDARY PAINT

3 - TRANSMISSION CODE

4 - VEHICLE MODEL NUMBER

5 - ENGINE CODE

6 - INTERIOR TRIM CODE

7 - VEHICLE IDENTIFICATION NUMBER

8 - TAILGATE CODE

9 - CARGO BOX CODE

10 - TAILGATE TRIM CODE

11 - BODY-IN-WHITE SEQUENCE

12 - MARKET CODE

13 - SPECIES CODE

14 - PAINT PROCEDURE

15 - VEHICLE ORDER NUMBER

4 INTRODUCTIONBR/BE

EQUIPMENT IDENTIFICATION PLATE (Continued)

Page 6 of 2255

²64 = Ram Truck Cab Chassis (162.7 in. Wheel

Base)

BODY CODE PLATEÐLINE 3

DIGITS 1,2, AND 3

Paint Procedure

²APA = Monotone

²AP9 = Special

²APB = Two-tone (Waterfall)

²APC = Two-tone (Centerband)

²APD = Two-tone (Lower break)

DIGIT 4

Open Space

DIGITS 5 THROUGH 8

Primary Paint

Refer to Group 23, Body for color codes.

DIGIT 9

Open Space

DIGITS 10 THROUGH 13

Secondary Paint

DIGIT 14

Open Space

DIGITS 15 THROUGH 18

Interior Trim Code

DIGIT 19

Open Space

DIGITS 20, 21, AND 22

Engine Code

²EML = 5.9 L 8 cyl. MPI Gasoline

²EMM = 5.9 L 8 cyl. MPI Gasoline (Heavy Duty)

²ETC = 5.9 L 6 cyl. Turbo Diesel

²EWA = 8.0 L 10 cyl. MPI Gasoline

BODY CODE PLATEÐLINE 2

DIGIT 1 Open Space

DIGITS 2 AND 3 Species Code. (Used for Manufacturing)

DIGIT 4

Open SpaceDIGIT 5

Market Code

²B = International

²C = Canada

²M = Mexico

²U = United States

DIGIT 6

Open Space

DIGITS 7 THROUGH 23

Vehicle Identification Number (VIN)

Refer to Vehicle Identification Number (VIN) para-

graph for proper breakdown of VIN code.

BODY CODE PLATEÐLINE 1

DIGITS 1 THROUGH 6 Body-in-white assembly sequence.

DIGIT 7

Open Space

DIGIT 8 Tailgate trim code.

DIGIT 9

Open Space

DIGITS 10 THROUGH 12 Cargo box code

²XBS = Sweptline

DIGIT 13

Open Space

DIGITS 14 THROUGH 16 Tailgate code

²MWD = Plain Tailgate

²MPB = Tailgate Applique (Black)

INTERNATIONAL VEHICLE

CONTROL & DISPLAY

SYMBOLS

DESCRIPTION - INTERNATIONAL SYMBOLS

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

BR/BEINTRODUCTION 5

BODY CODE PLATE (Continued)

Page 14 of 2255

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

INTERNATIONAL SYMBOLS

DESCRIPTION...........................1

PARTS & LUBRICANT RECOMMENDATION

STANDARD PROCEDURE

STANDARD PROCEDURE -

CLASSIFICATION OF LUBRICANTS..........1

FLUID TYPES

DESCRIPTION...........................2

OPERATION.............................6

FLUID CAPACITIES

SPECIFICATIONS.........................6

MAINTENANCE SCHEDULES

DESCRIPTION...........................7JUMP STARTING

STANDARD PROCEDURE

STANDARD PROCEDURE - JUMP

STARTING.............................7

HOISTING

STANDARD PROCEDURE

STANDARD PROCEDURE - HOISTING.......9

TOWING

STANDARD PROCEDURE

STANDARD PROCEDURE - TOWING.......10

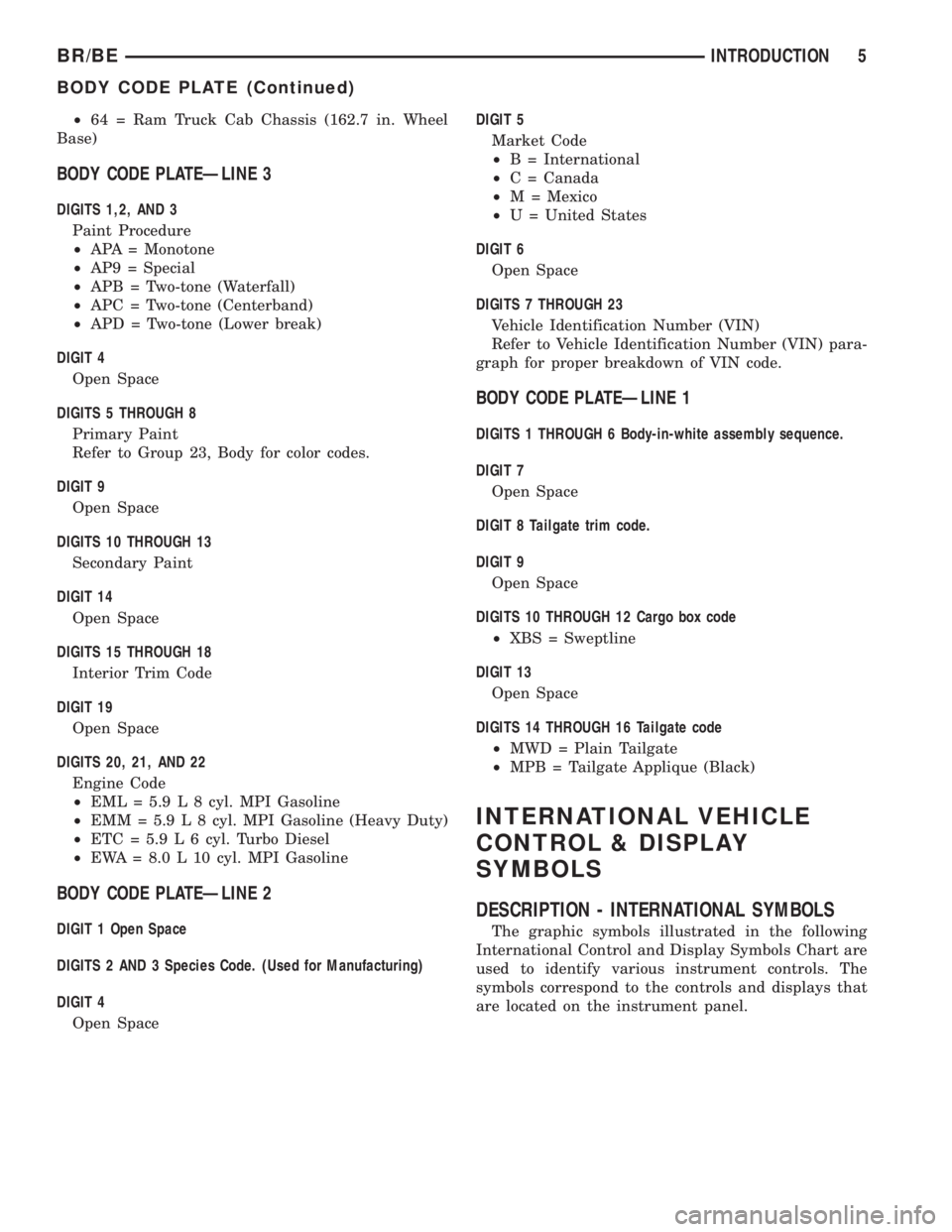

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 1).

PARTS & LUBRICANT

RECOMMENDATION

STANDARD PROCEDURE - CLASSIFICATION OF

LUBRICANTS

Only lubricants that are endorsed by the following

organization should be used to service a

DaimlerChrysler Corporation vehicle.²Society of Automotive Engineers (SAE)

²American Petroleum Institute (API) (Fig. 6)

²National Lubricating Grease Institute (NLGI)

(Fig. 2)

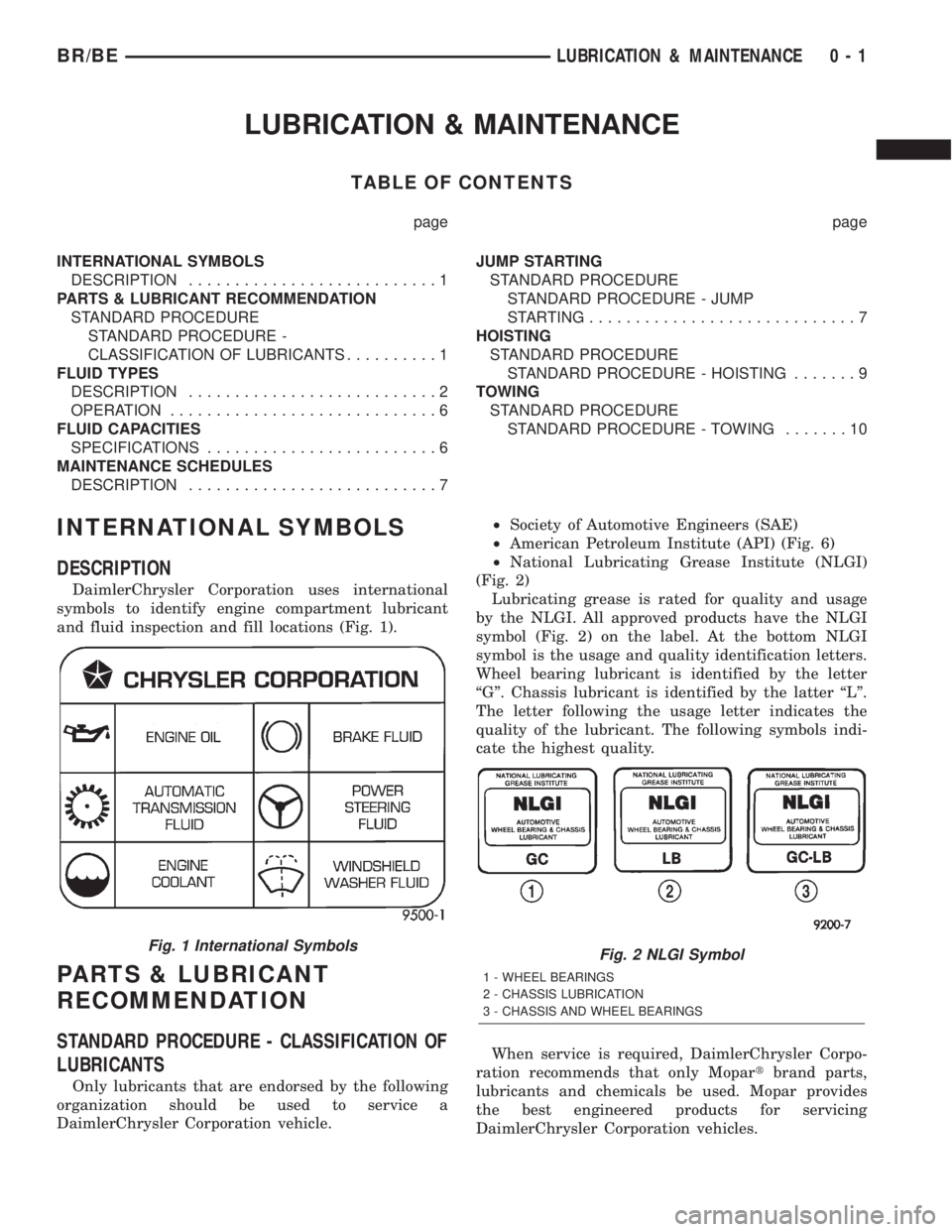

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 2) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

When service is required, DaimlerChrysler Corpo-

ration recommends that only Mopartbrand parts,

lubricants and chemicals be used. Mopar provides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

Fig. 1 International SymbolsFig. 2 NLGI Symbol

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

BR/BELUBRICATION & MAINTENANCE 0 - 1

Page 23 of 2255

TOWING

STANDARD PROCEDURE - TOWING

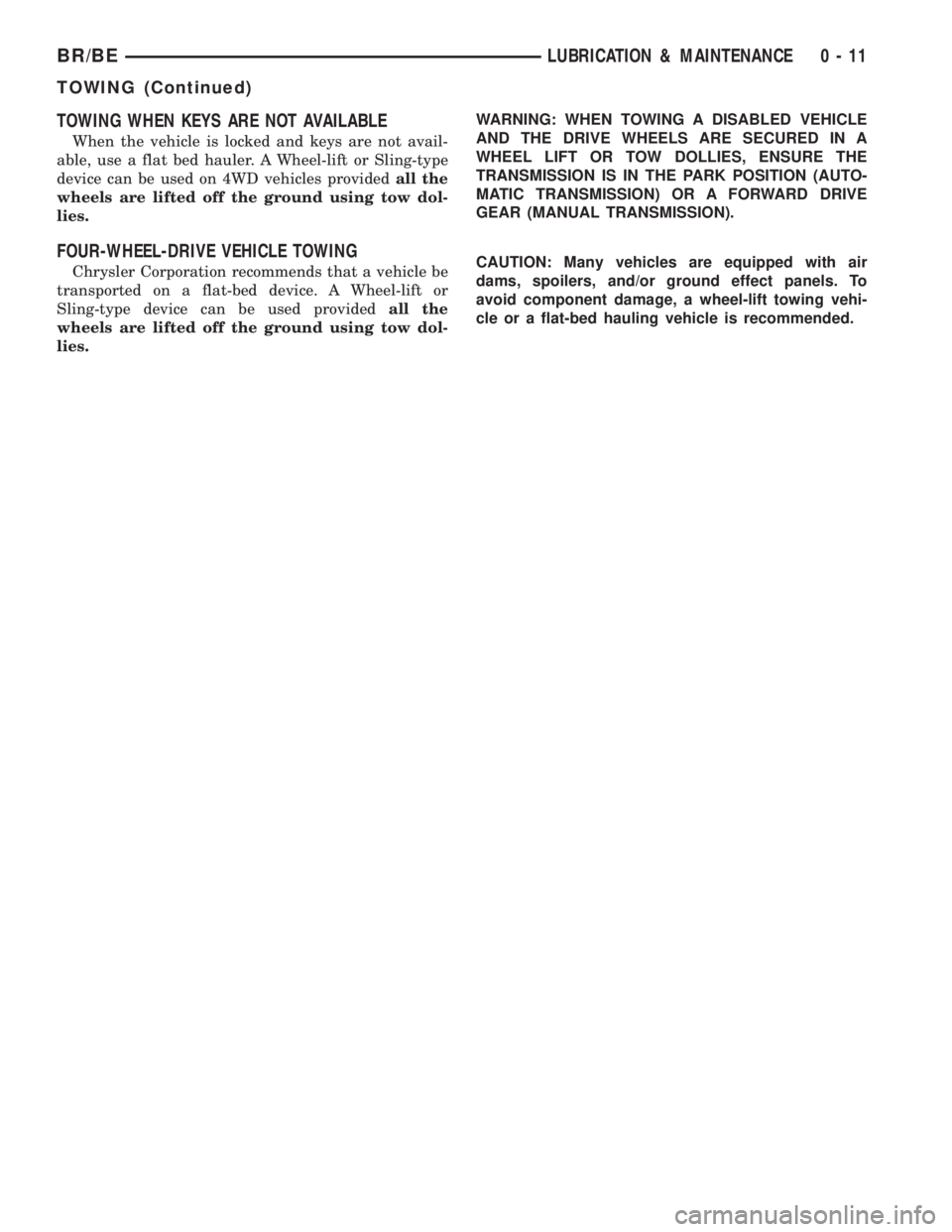

A vehicle equipped with SAE approved sling-type

towing equipment can be used to tow all vehicles.

When towing a 4WD vehicle using a wheel-lift towing

device, use tow dollies under the opposite end of the

vehicle. A vehicle with flat-bed device can also be

used to transport a disabled vehicle (Fig. 12).

A wooden crossbeam may be required for proper

connection when using the sling-type, front-end tow-

ing method.

SAFETY PRECAUTIONS

CAUTION: The following safety precautions must be

observed when towing a vehicle:

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.²Do not attach tow chains, T-hooks, J-hooks, or a

tow sling to a bumper, steering linkage, drive shafts

or a non-reinforced frame hole.

²Do not tow a heavily loaded vehicle. Damage to

the cab, cargo box or frame may result. Use a flatbed

device to transport a loaded vehicle.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain or steep rises in the road. If necessary,

remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to

increase the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums or rotors.

RAMP ANGLE

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15

degrees.

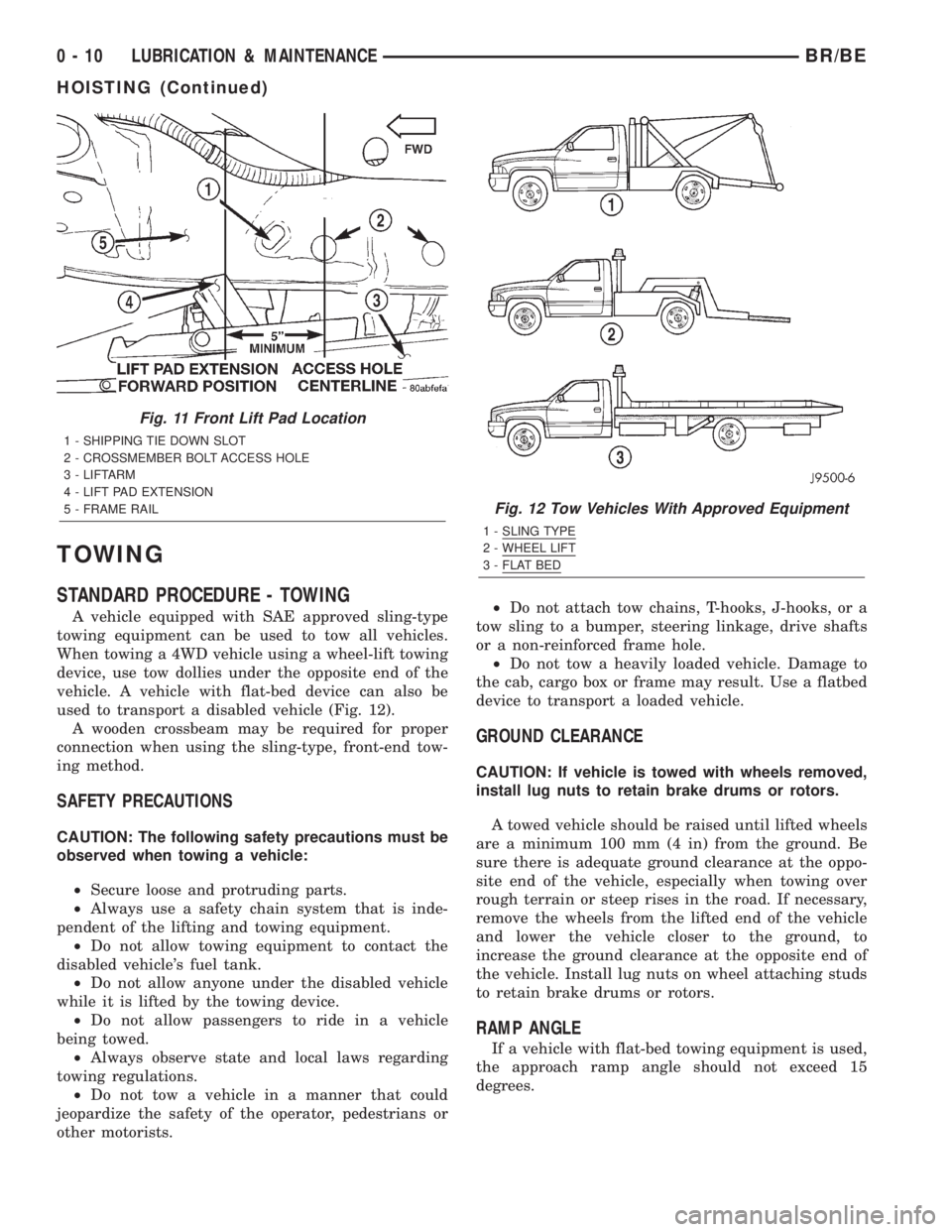

Fig. 11 Front Lift Pad Location

1 - SHIPPING TIE DOWN SLOT

2 - CROSSMEMBER BOLT ACCESS HOLE

3 - LIFTARM

4 - LIFT PAD EXTENSION

5 - FRAME RAIL

Fig. 12 Tow Vehicles With Approved Equipment

1 - SLING TYPE

2 - WHEEL LIFT

3 - FLAT BED

0 - 10 LUBRICATION & MAINTENANCEBR/BE

HOISTING (Continued)

Page 24 of 2255

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not avail-

able, use a flat bed hauler. A Wheel-lift or Sling-type

device can be used on 4WD vehicles providedall the

wheels are lifted off the ground using tow dol-

lies.

FOUR-WHEEL-DRIVE VEHICLE TOWING

Chrysler Corporation recommends that a vehicle be

transported on a flat-bed device. A Wheel-lift or

Sling-type device can be used providedall the

wheels are lifted off the ground using tow dol-

lies.WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION (AUTO-

MATIC TRANSMISSION) OR A FORWARD DRIVE

GEAR (MANUAL TRANSMISSION).

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

BR/BELUBRICATION & MAINTENANCE 0 - 11

TOWING (Continued)

Page 26 of 2255

SUSPENSION

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT......................1

FRONT - 2WD............................7FRONT - 4WD...........................14

REAR.................................25

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - PRE-ALIGNMENT . 2

STANDARD PROCEDURE

STANDARD PROCEDURES - ALIGNMENT

I.F.S. ................................3STANDARD PROCEDURE - CASTER

CORRECTION MEASUREMENT...........3

STANDARD PROCEDURE - ALIGNMENT

LINK/COIL SUSPENSION.................5

SPECIFICATIONS

ALIGNMENT..........................6

WHEEL ALIGNMENT

DESCRIPTION

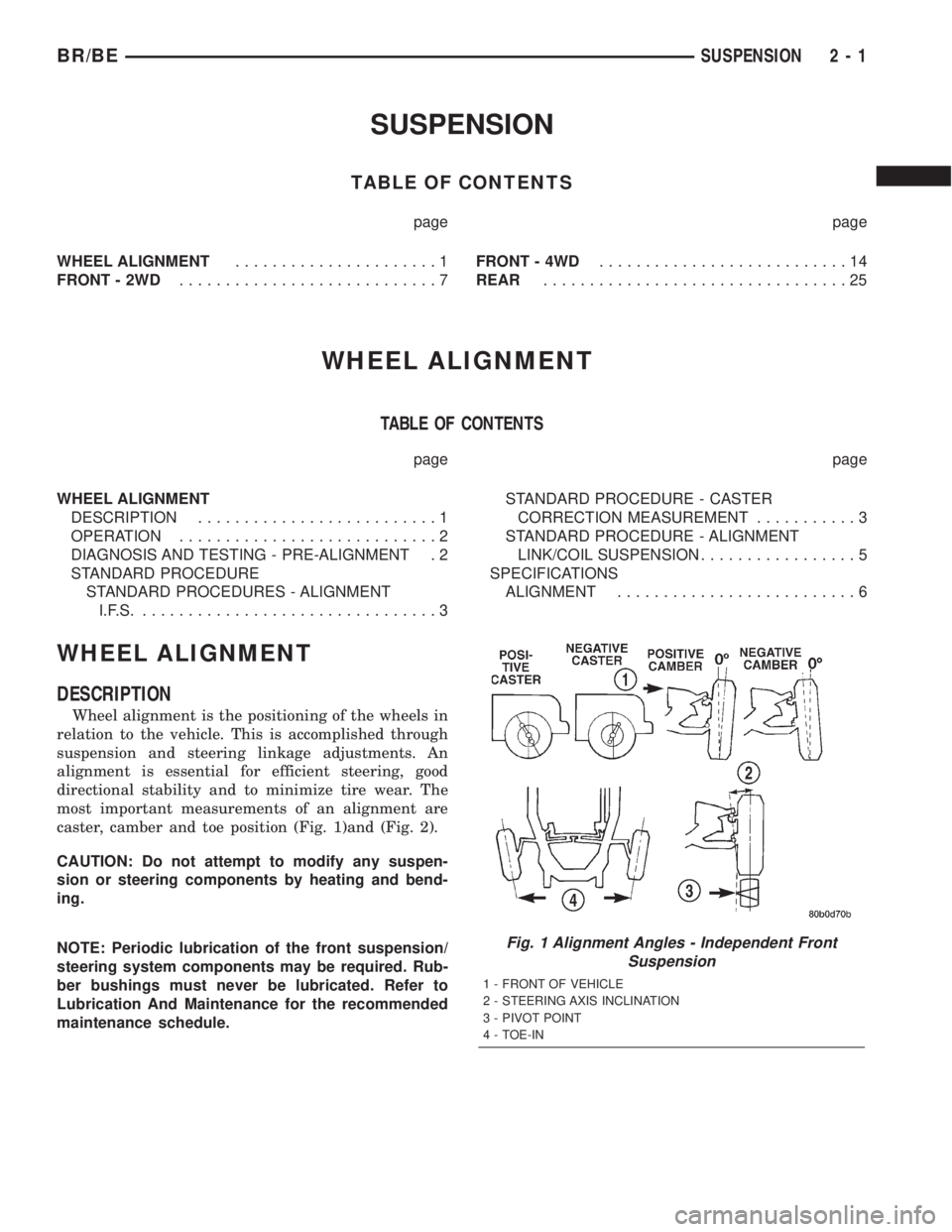

Wheel alignment is the positioning of the wheels in

relation to the vehicle. This is accomplished through

suspension and steering linkage adjustments. An

alignment is essential for efficient steering, good

directional stability and to minimize tire wear. The

most important measurements of an alignment are

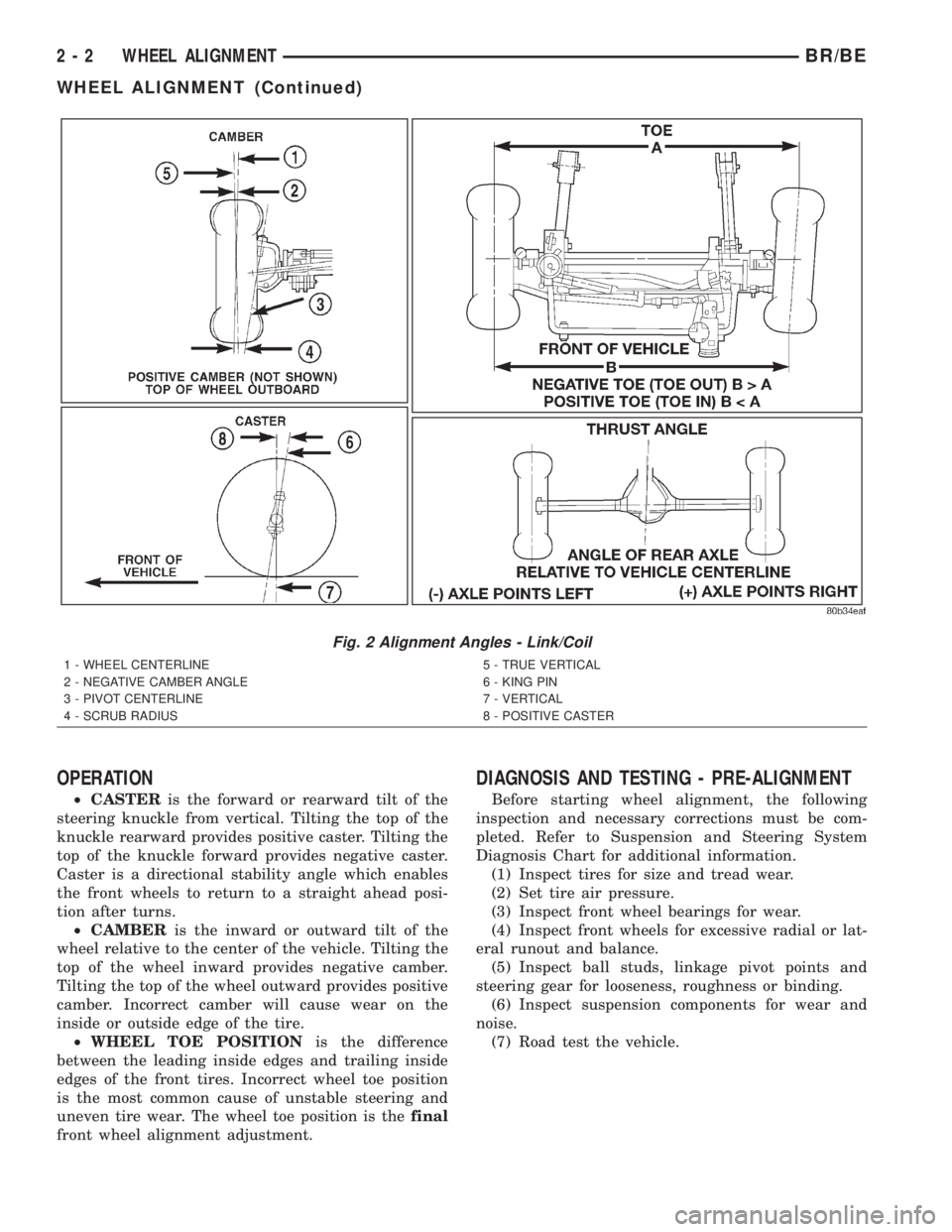

caster, camber and toe position (Fig. 1)and (Fig. 2).

CAUTION: Do not attempt to modify any suspen-

sion or steering components by heating and bend-

ing.

NOTE: Periodic lubrication of the front suspension/

steering system components may be required. Rub-

ber bushings must never be lubricated. Refer to

Lubrication And Maintenance for the recommended

maintenance schedule.

Fig. 1 Alignment Angles - Independent Front

Suspension

1 - FRONT OF VEHICLE

2 - STEERING AXIS INCLINATION

3 - PIVOT POINT

4 - TOE-IN

BR/BESUSPENSION 2 - 1

Page 27 of 2255

OPERATION

²CASTERis the forward or rearward tilt of the

steering knuckle from vertical. Tilting the top of the

knuckle rearward provides positive caster. Tilting the

top of the knuckle forward provides negative caster.

Caster is a directional stability angle which enables

the front wheels to return to a straight ahead posi-

tion after turns.

²CAMBERis the inward or outward tilt of the

wheel relative to the center of the vehicle. Tilting the

top of the wheel inward provides negative camber.

Tilting the top of the wheel outward provides positive

camber. Incorrect camber will cause wear on the

inside or outside edge of the tire.

²WHEEL TOE POSITIONis the difference

between the leading inside edges and trailing inside

edges of the front tires. Incorrect wheel toe position

is the most common cause of unstable steering and

uneven tire wear. The wheel toe position is thefinal

front wheel alignment adjustment.

DIAGNOSIS AND TESTING - PRE-ALIGNMENT

Before starting wheel alignment, the following

inspection and necessary corrections must be com-

pleted. Refer to Suspension and Steering System

Diagnosis Chart for additional information.

(1) Inspect tires for size and tread wear.

(2) Set tire air pressure.

(3) Inspect front wheel bearings for wear.

(4) Inspect front wheels for excessive radial or lat-

eral runout and balance.

(5) Inspect ball studs, linkage pivot points and

steering gear for looseness, roughness or binding.

(6) Inspect suspension components for wear and

noise.

(7) Road test the vehicle.

Fig. 2 Alignment Angles - Link/Coil

1 - WHEEL CENTERLINE

2 - NEGATIVE CAMBER ANGLE

3 - PIVOT CENTERLINE

4 - SCRUB RADIUS5 - TRUE VERTICAL

6 - KING PIN

7 - VERTICAL

8 - POSITIVE CASTER

2 - 2 WHEEL ALIGNMENTBR/BE

WHEEL ALIGNMENT (Continued)