catalytic converter DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 16 of 2255

²The use of leaded gas is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance, damage the emission control system, and

could result in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.

²When pulling a heavy load or driving a fully

loaded vehicle when the humidity is low and the tem-

perature is high, use a premium unleaded fuel to

help prevent spark knock. If spark knock persists,

lighten the load, or engine piston damage may result.

²The use of fuel additives which are now being

sold as octane enhancers is not recommended. Most

of these products contain high concentrations of

methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such fuels

or additives is not the responsibility of

DaimlerChrysler Corporation and may not be covered

under the new vehicle warranty.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE

DESCRIPTION

WARNING: Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under certain

conditions and hazardous or explosive when mixed

with diesel fuel.

Use good quality diesel fuel from a reputable sup-

plier in your Dodge truck. For most year-round ser-

vice, number 2 diesel fuel meeting ASTM

specification D-975 will provide good performance. If

the vehicle is exposed to extreme cold (below 0ÉF/-

18ÉC), or is required to operate at colder-than-normal

conditions for prolonged periods, use climatized No. 2

diesel fuel or dilute the No. 2 diesel fuel with 50%

No. 1 diesel fuel. This will provide better protection

from fuel gelling or wax-plugging of the fuel filters.

Diesel fuel is seldom completely free of water. To

prevent fuel system trouble, including fuel line freez-

ing in winter, drain the accumulated water from the

fuel/water separator using the fuel/water separator

drain provided. If you buy good-quality fuel and fol-

low the cold-weather advice above, fuel conditioners

should not be required in your vehicle. If available in

your area, a high cetane ªpremiumº diesel fuel mayoffer improved cold starting and warm-up perfor-

mance.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less corrosion protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with organic corro-

sion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Mixing of

coolants other than specified (non-HOAT or other

HOAT), may result in engine damage that may not

be covered under the new vehicle warranty, and

decreased corrosion protection.

BR/BELUBRICATION & MAINTENANCE 0 - 3

FLUID TYPES (Continued)

Page 255 of 2255

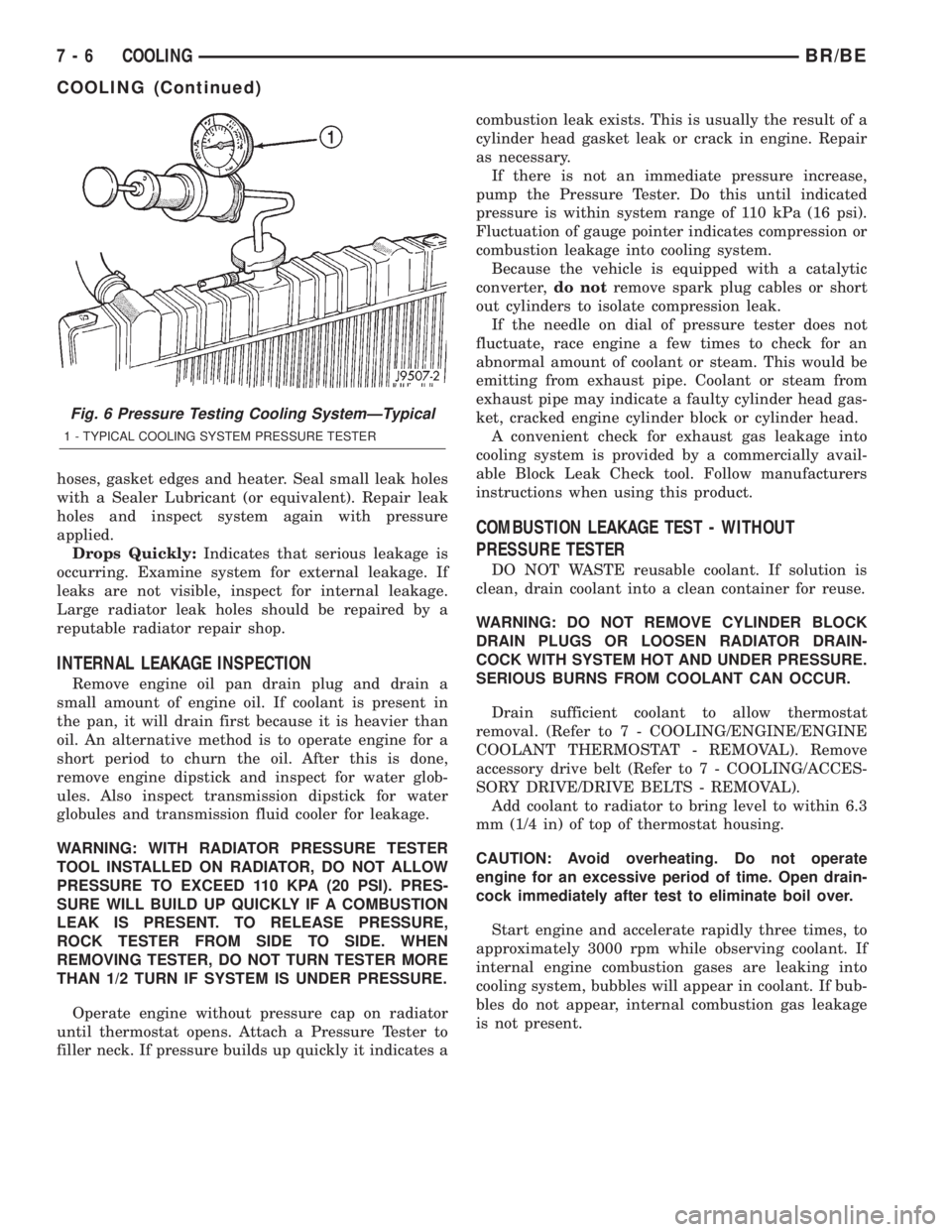

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water glob-

ules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on radiator

until thermostat opens. Attach a Pressure Tester to

filler neck. If pressure builds up quickly it indicates acombustion leak exists. This is usually the result of a

cylinder head gasket leak or crack in engine. Repair

as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notremove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT THERMOSTAT - REMOVAL). Remove

accessory drive belt (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of top of thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

Fig. 6 Pressure Testing Cooling SystemÐTypical

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

7 - 6 COOLINGBR/BE

COOLING (Continued)

Page 478 of 2255

CAUTION: Do not leave any one spark plug cable

disconnected for longer than necessary during test-

ing. This may cause possible heat damage to the

catalytic converter. Total test time must not exceed

ten minutes.

With the engine running, remove spark plug cable

from spark plug (one at a time) and hold next to a

good engine ground. If the cable and spark plug are

in good condition, the engine rpm should drop and

the engine will run poorly. If engine rpm does not

drop, the cable and/or spark plug may not be operat-

ing properly and should be replaced. Also check

engine cylinder compression.

With the engine not running, connect one end of a

test probe to a good ground. Start the engine and run

the other end of the test probe along the entire

length of all spark plug cables. If cables are cracked

or punctured, there will be a noticeable spark jump

from the damaged area to the test probe. The cable

running from the ignition coil to the distributor cap

can be checked in the same manner. Cracked, dam-

aged or faulty cables should be replaced with resis-

tance type cable. This can be identified by the words

ELECTRONIC SUPPRESSION printed on the cable

jacket.

Use an ohmmeter to test for open circuits, exces-

sive resistance or loose terminals. If equipped,

remove the distributor cap from the distributor.Do

not remove cables from cap.Remove cable from

spark plug. Connect ohmmeter to spark plug termi-

nal end of cable and to corresponding electrode in

distributor cap. Resistance should be 250 to 1000

Ohms per inch of cable. If not, remove cable from dis-

tributor cap tower and connect ohmmeter to the ter-

minal ends of cable. If resistance is not within

specifications as found in the SPARK PLUG CABLE

RESISTANCE chart, replace the cable. Test all spark

plug cables in this manner.

SPARK PLUG CABLE RESISTANCE

MINIMUM MAXIMUM

250 Ohms Per Inch 1000 Ohms Per Inch

3000 Ohms Per Foot 12,000 Ohms Per Foot

To test ignition coil-to-distributor cap cable, do not

remove the cable from the cap. Connect ohmmeter to

rotor button (center contact) of distributor cap and

terminal at ignition coil end of cable. If resistance is

not within specifications as found in the Spark Plug

Cable Resistance chart, remove the cable from the

distributor cap. Connect the ohmmeter to the termi-

nal ends of the cable. If resistance is not within spec-

ifications as found in the Spark Plug CableResistance chart, replace the cable. Inspect the igni-

tion coil tower for cracks, burns or corrosion.

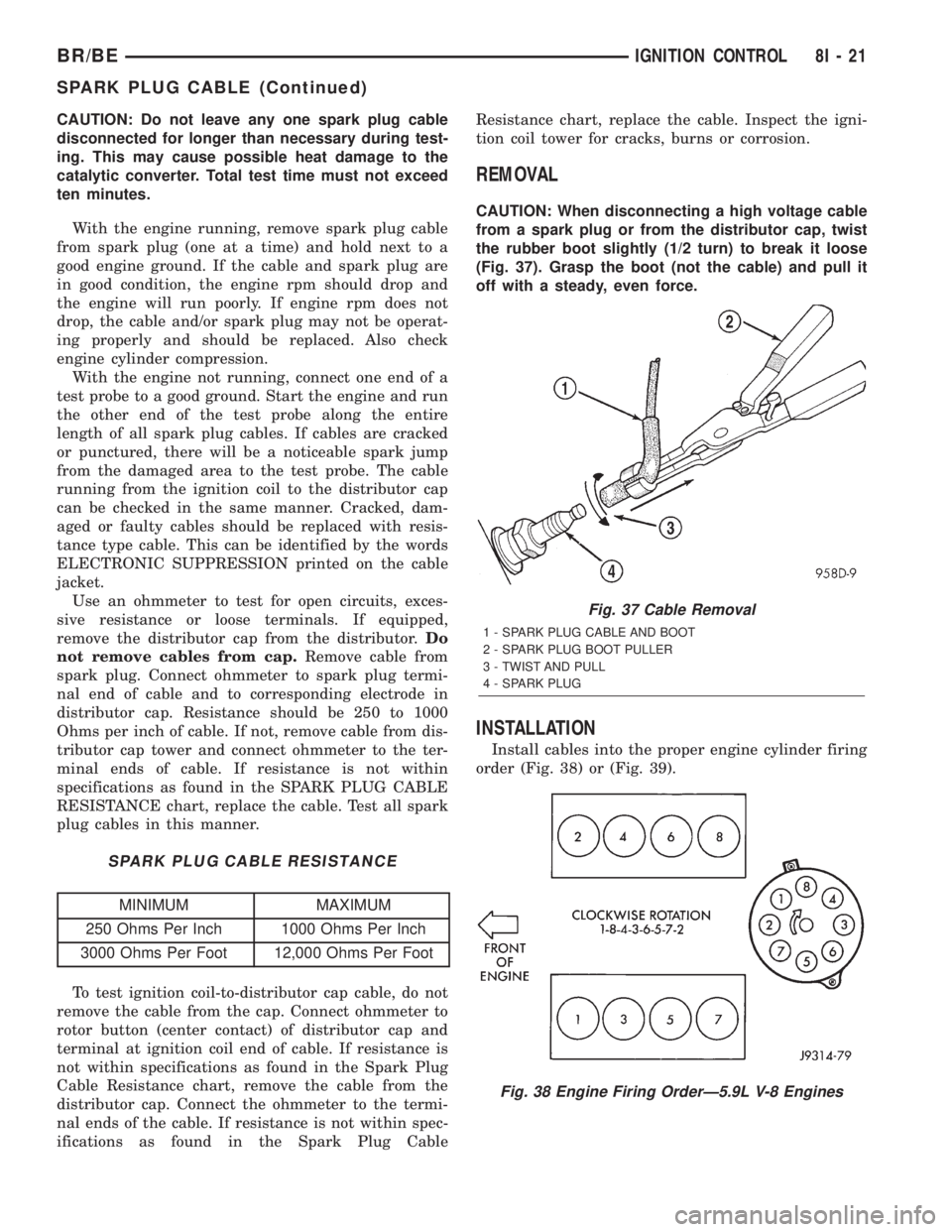

REMOVAL

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twist

the rubber boot slightly (1/2 turn) to break it loose

(Fig. 37). Grasp the boot (not the cable) and pull it

off with a steady, even force.

INSTALLATION

Install cables into the proper engine cylinder firing

order (Fig. 38) or (Fig. 39).

Fig. 37 Cable Removal

1 - SPARK PLUG CABLE AND BOOT

2 - SPARK PLUG BOOT PULLER

3 - TWIST AND PULL

4 - SPARK PLUG

Fig. 38 Engine Firing OrderÐ5.9L V-8 Engines

BR/BEIGNITION CONTROL 8I - 21

SPARK PLUG CABLE (Continued)

Page 1023 of 2255

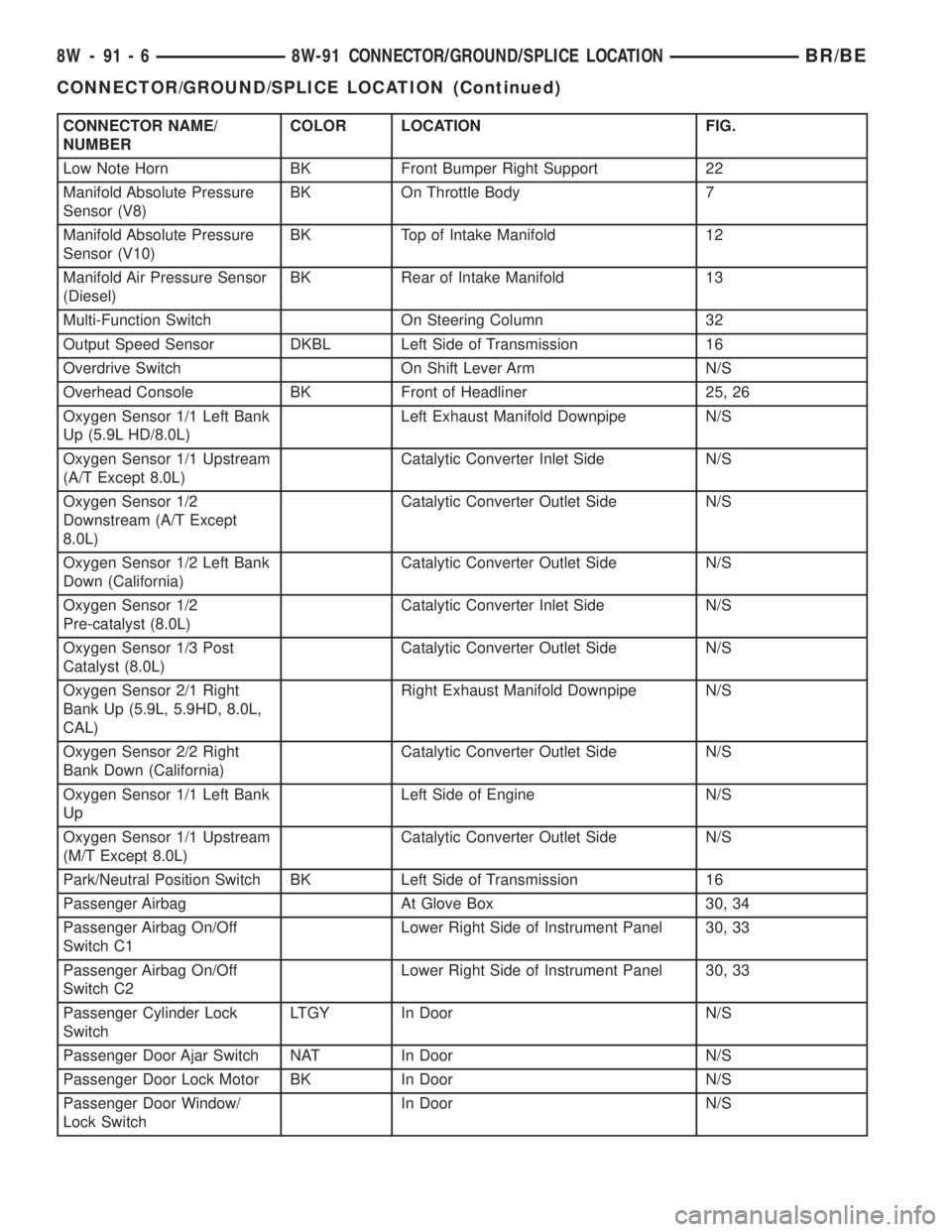

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Low Note Horn BK Front Bumper Right Support 22

Manifold Absolute Pressure

Sensor (V8)BK On Throttle Body 7

Manifold Absolute Pressure

Sensor (V10)BK Top of Intake Manifold 12

Manifold Air Pressure Sensor

(Diesel)BK Rear of Intake Manifold 13

Multi-Function Switch On Steering Column 32

Output Speed Sensor DKBL Left Side of Transmission 16

Overdrive Switch On Shift Lever Arm N/S

Overhead Console BK Front of Headliner 25, 26

Oxygen Sensor 1/1 Left Bank

Up (5.9L HD/8.0L)Left Exhaust Manifold Downpipe N/S

Oxygen Sensor 1/1 Upstream

(A/T Except 8.0L)Catalytic Converter Inlet Side N/S

Oxygen Sensor 1/2

Downstream (A/T Except

8.0L)Catalytic Converter Outlet Side N/S

Oxygen Sensor 1/2 Left Bank

Down (California)Catalytic Converter Outlet Side N/S

Oxygen Sensor 1/2

Pre-catalyst (8.0L)Catalytic Converter Inlet Side N/S

Oxygen Sensor 1/3 Post

Catalyst (8.0L)Catalytic Converter Outlet Side N/S

Oxygen Sensor 2/1 Right

Bank Up (5.9L, 5.9HD, 8.0L,

CAL)Right Exhaust Manifold Downpipe N/S

Oxygen Sensor 2/2 Right

Bank Down (California)Catalytic Converter Outlet Side N/S

Oxygen Sensor 1/1 Left Bank

UpLeft Side of Engine N/S

Oxygen Sensor 1/1 Upstream

(M/T Except 8.0L)Catalytic Converter Outlet Side N/S

Park/Neutral Position Switch BK Left Side of Transmission 16

Passenger Airbag At Glove Box 30, 34

Passenger Airbag On/Off

Switch C1Lower Right Side of Instrument Panel 30, 33

Passenger Airbag On/Off

Switch C2Lower Right Side of Instrument Panel 30, 33

Passenger Cylinder Lock

SwitchLTGY In Door N/S

Passenger Door Ajar Switch NAT In Door N/S

Passenger Door Lock Motor BK In Door N/S

Passenger Door Window/

Lock SwitchIn Door N/S

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONBR/BE

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1268 of 2255

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION

DESCRIPTION - 5.9/8.0L.................2

DESCRIPTIONÐ5.9L DIESEL.............3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - GAS ENGINE . . . 4

DIAGNOSIS AND TESTING - DIESEL

ENGINE..............................4

SPECIFICATIONS

TORQUE.............................5

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................5

INSPECTION...........................6

INSTALLATION..........................6

CATALYTIC CONVERTER - 5.9L HD/8.0L

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSPECTION...........................6

INSTALLATION..........................7

EXHAUST PIPE - 3.9L/5.2L/5.9L

REMOVAL.............................7

INSPECTION...........................7

INSTALLATION..........................7

EXHAUST PIPE - 5.9L HD/8.0L

REMOVAL.............................7

INSPECTION...........................8

INSTALLATION..........................8

EXHAUST PIPE - 5.9L DIESEL

REMOVAL.............................9

INSPECTION...........................9

INSTALLATION..........................9

HEAT SHIELDS

DESCRIPTION.........................10

REMOVAL.............................10

INSTALLATION.........................10

MUFFLER - 3.9L/5.2L/5.9L/8.0L

REMOVAL.............................10INSTALLATION.........................10

MUFFLER - 5.9L DIESEL

REMOVAL.............................11

INSTALLATION.........................11

TAILPIPE - 3.9L/5.2L/5.9L

REMOVAL.............................11

INSPECTION..........................11

INSTALLATION.........................11

TAILPIPE - 5.9L HD/8.0L

REMOVAL.............................12

INSPECTION..........................12

INSTALLATION.........................12

TAILPIPE - 5.9L DIESEL

REMOVAL.............................12

INSPECTION..........................12

INSTALLATION.........................13

RESONATOR

REMOVAL.............................13

INSTALLATION.........................13

TURBOCHARGER SYSTEM

DIAGNOSIS AND TESTING -

TURBOCHARGER BOOST PRESSURE.....13

TURBOCHARGER

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................15

CLEANING............................16

INSPECTION..........................16

INSTALLATION.........................17

CHARGE AIR COOLER AND PLUMBING

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING - CHARGE AIR

COOLER SYSTEM - LEAKS..............18

REMOVAL.............................18

CLEANING............................19

INSPECTION..........................19

INSTALLATION.........................20

BR/BEEXHAUST SYSTEM 11 - 1

Page 1269 of 2255

EXHAUST SYSTEM

DESCRIPTION

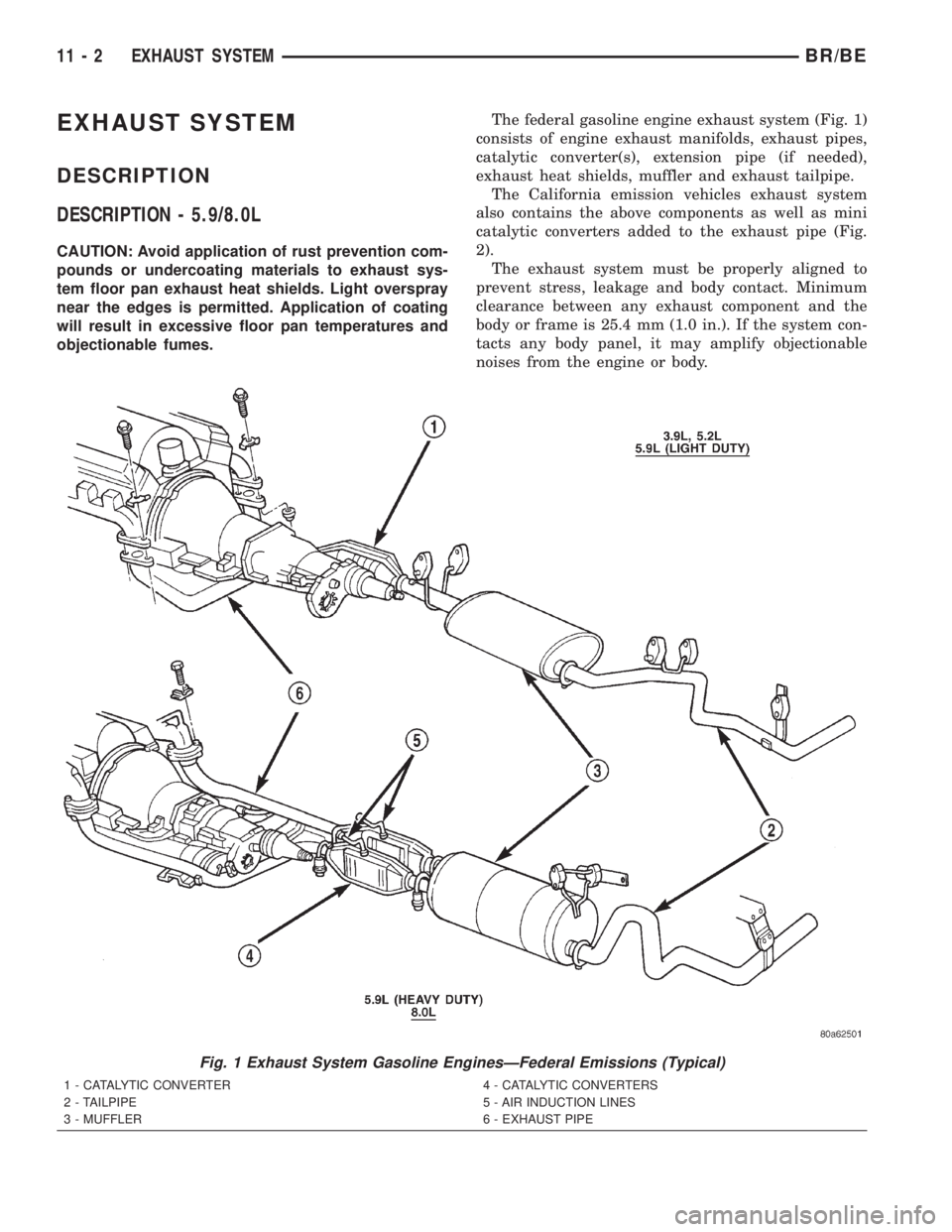

DESCRIPTION - 5.9/8.0L

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.The federal gasoline engine exhaust system (Fig. 1)

consists of engine exhaust manifolds, exhaust pipes,

catalytic converter(s), extension pipe (if needed),

exhaust heat shields, muffler and exhaust tailpipe.

The California emission vehicles exhaust system

also contains the above components as well as mini

catalytic converters added to the exhaust pipe (Fig.

2).

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. Minimum

clearance between any exhaust component and the

body or frame is 25.4 mm (1.0 in.). If the system con-

tacts any body panel, it may amplify objectionable

noises from the engine or body.

Fig. 1 Exhaust System Gasoline EnginesÐFederal Emissions (Typical)

1 - CATALYTIC CONVERTER

2 - TAILPIPE

3 - MUFFLER4 - CATALYTIC CONVERTERS

5 - AIR INDUCTION LINES

6 - EXHAUST PIPE

11 - 2 EXHAUST SYSTEMBR/BE

Page 1270 of 2255

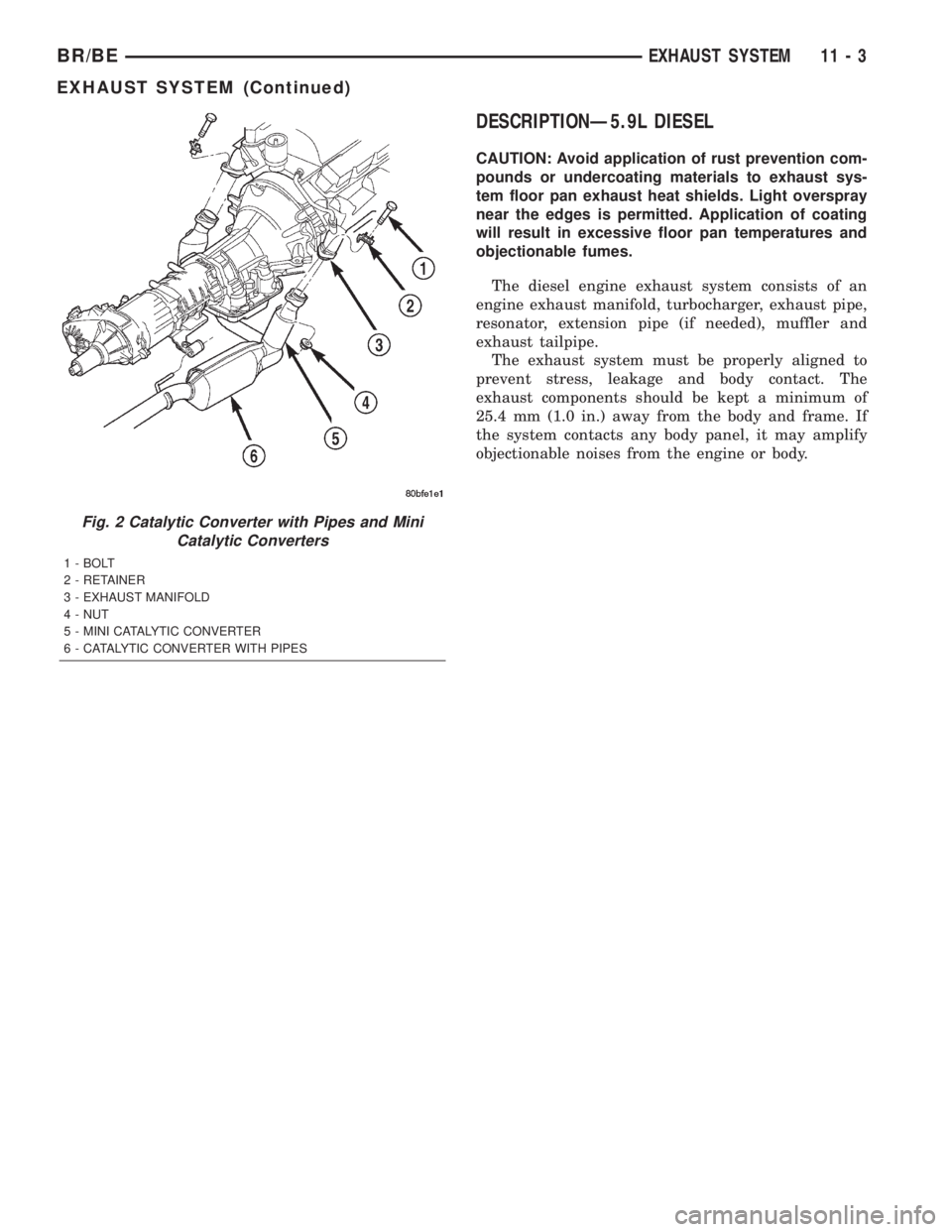

DESCRIPTIONÐ5.9L DIESEL

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

The diesel engine exhaust system consists of an

engine exhaust manifold, turbocharger, exhaust pipe,

resonator, extension pipe (if needed), muffler and

exhaust tailpipe.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. The

exhaust components should be kept a minimum of

25.4 mm (1.0 in.) away from the body and frame. If

the system contacts any body panel, it may amplify

objectionable noises from the engine or body.

Fig. 2 Catalytic Converter with Pipes and Mini

Catalytic Converters

1 - BOLT

2 - RETAINER

3 - EXHAUST MANIFOLD

4 - NUT

5 - MINI CATALYTIC CONVERTER

6 - CATALYTIC CONVERTER WITH PIPES

BR/BEEXHAUST SYSTEM 11 - 3

EXHAUST SYSTEM (Continued)

Page 1271 of 2255

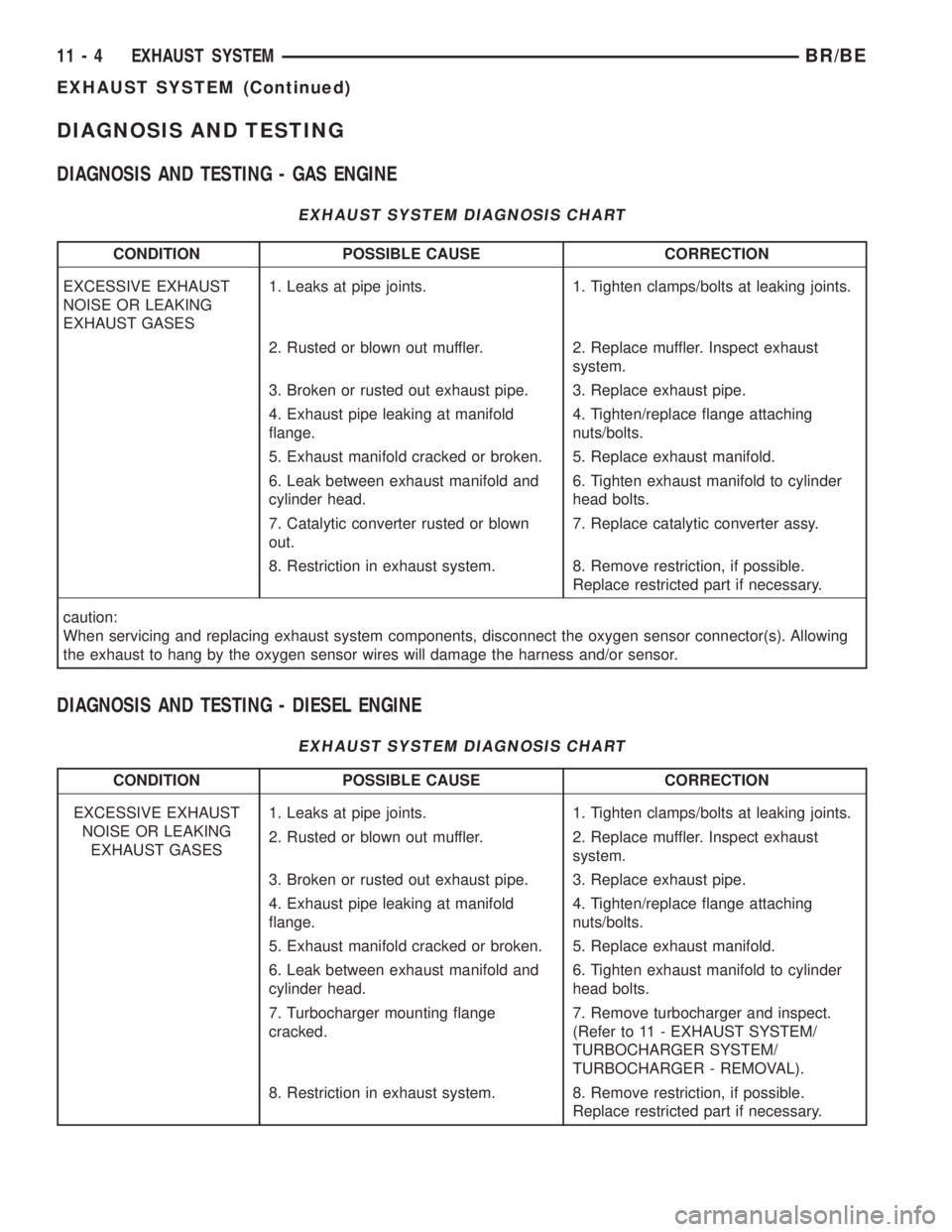

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - GAS ENGINE

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST

NOISE OR LEAKING

EXHAUST GASES1. Leaks at pipe joints. 1. Tighten clamps/bolts at leaking joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust pipe. 3. Replace exhaust pipe.

4. Exhaust pipe leaking at manifold

flange.4. Tighten/replace flange attaching

nuts/bolts.

5. Exhaust manifold cracked or broken. 5. Replace exhaust manifold.

6. Leak between exhaust manifold and

cylinder head.6. Tighten exhaust manifold to cylinder

head bolts.

7. Catalytic converter rusted or blown

out.7. Replace catalytic converter assy.

8. Restriction in exhaust system. 8. Remove restriction, if possible.

Replace restricted part if necessary.

caution:

When servicing and replacing exhaust system components, disconnect the oxygen sensor connector(s). Allowing

the exhaust to hang by the oxygen sensor wires will damage the harness and/or sensor.

DIAGNOSIS AND TESTING - DIESEL ENGINE

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST

NOISE OR LEAKING

EXHAUST GASES1. Leaks at pipe joints. 1. Tighten clamps/bolts at leaking joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust pipe. 3. Replace exhaust pipe.

4. Exhaust pipe leaking at manifold

flange.4. Tighten/replace flange attaching

nuts/bolts.

5. Exhaust manifold cracked or broken. 5. Replace exhaust manifold.

6. Leak between exhaust manifold and

cylinder head.6. Tighten exhaust manifold to cylinder

head bolts.

7. Turbocharger mounting flange

cracked.7. Remove turbocharger and inspect.

(Refer to 11 - EXHAUST SYSTEM/

TURBOCHARGER SYSTEM/

TURBOCHARGER - REMOVAL).

8. Restriction in exhaust system. 8. Remove restriction, if possible.

Replace restricted part if necessary.

11 - 4 EXHAUST SYSTEMBR/BE

EXHAUST SYSTEM (Continued)

Page 1272 of 2255

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Adjusting StrapÐBolt 23 Ð 200

Air Heater Power SupplyÐ

Nuts14 Ð 124

Air Inlet HousingÐBolts 24 18 Ð

Cab Heater Supply/Return

LineÐNuts24 18 Ð

Exhaust ClampÐNuts 48 35 Ð

Exhaust Manifold to Cylinder

HeadÐBolts

(Diesel Engine) 43 32 Ð

Exhaust Manifold to Cylinder

HeadÐBolts

(5.9L) 31 23 Ð

Exhaust Manifold to Cylinder

HeadÐBolts

(8.0L) 22 Ð 195

Exhaust Pipe to ManifoldÐ

Bolts31 23 Ð

Generator MountingÐBolts 41 30 Ð

Charge Air Cooler

MountingÐBolts2Ð17

Charge Air Cooler DuctÐ

Nuts8Ð72

Heat ShieldÐNuts and Bolts 11 Ð 100

Turbocharger MountingÐ

Nuts32 24 Ð

Turbocharger Oil Drain

TubeÐBolts24 18 Ð

Turbocharger Oil Supply

LineÐFitting15 Ð 133

Turbocharger V-Band

ClampÐNut9Ð75

CATALYTIC CONVERTER -

3.9L/5.2L/5.9L

DESCRIPTION

The stainless steel catalytic converter is located

under the vehicle, integral to the exhaust pipe(s).

OPERATION

The catalytic converter captures and burns any

unburned fuel mixture exiting the combustion cham-

bers during the exhaust stroke of the engine. This

process aids in reducing emissions output.

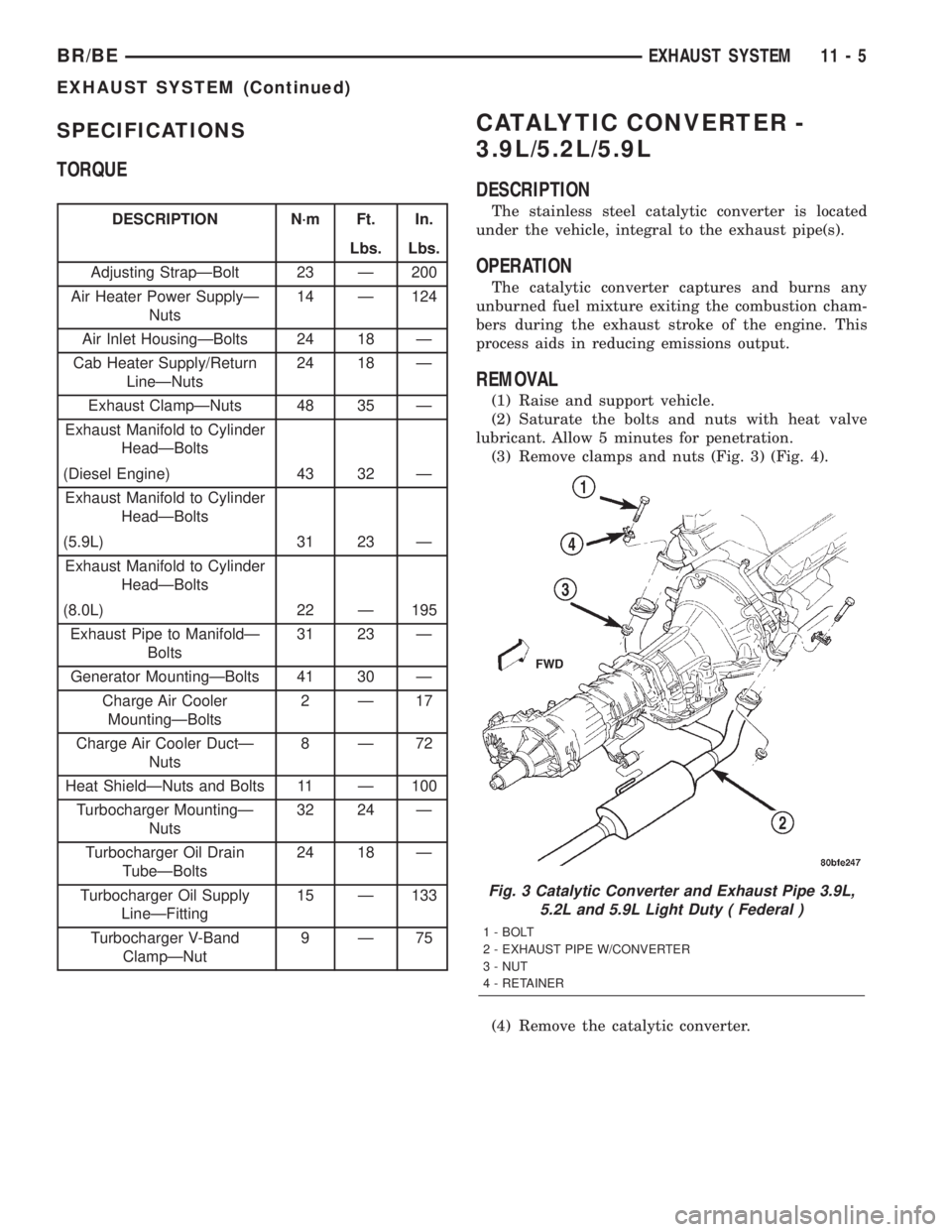

REMOVAL

(1) Raise and support vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove clamps and nuts (Fig. 3) (Fig. 4).

(4) Remove the catalytic converter.

Fig. 3 Catalytic Converter and Exhaust Pipe 3.9L,

5.2L and 5.9L Light Duty ( Federal )

1 - BOLT

2 - EXHAUST PIPE W/CONVERTER

3 - NUT

4 - RETAINER

BR/BEEXHAUST SYSTEM 11 - 5

EXHAUST SYSTEM (Continued)

Page 1273 of 2255

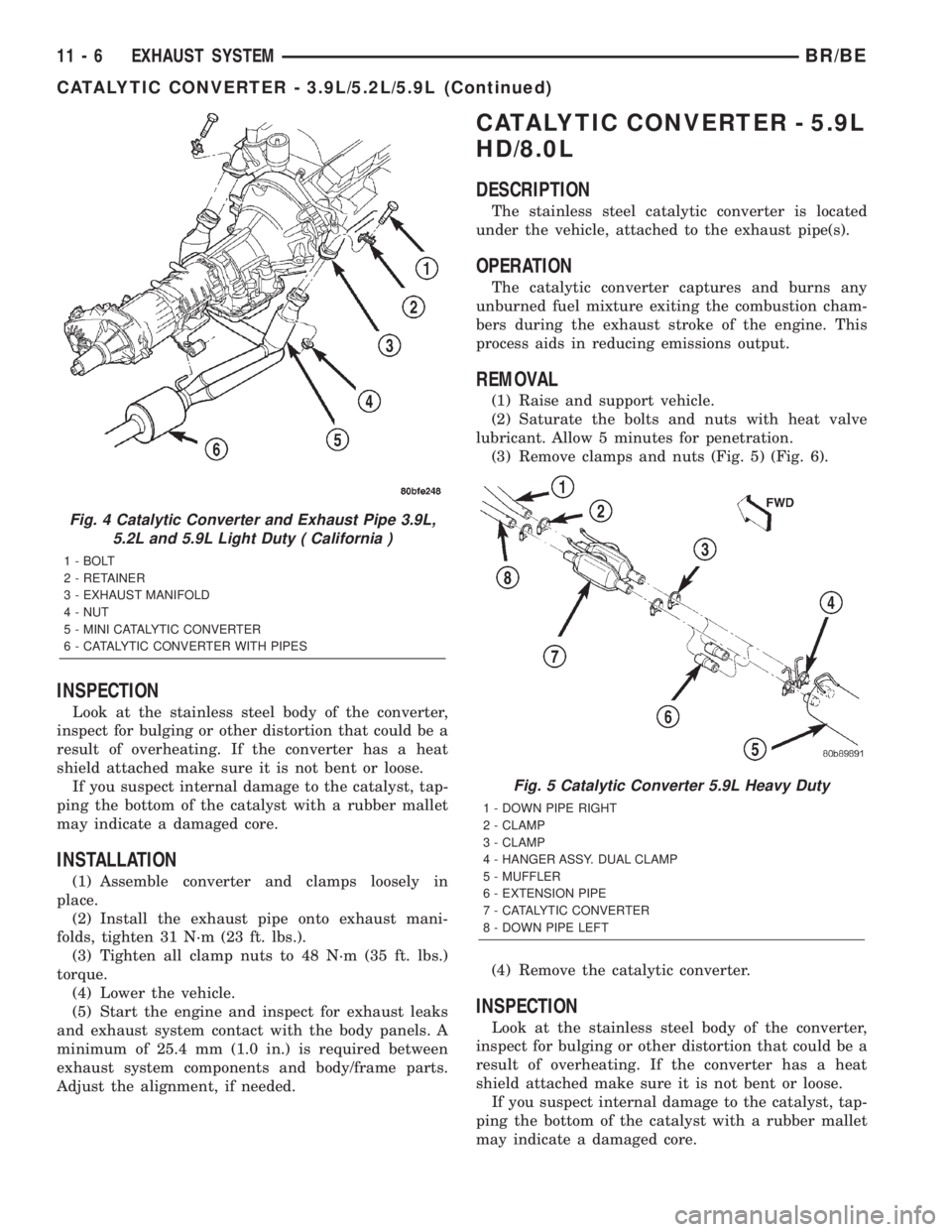

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

(1) Assemble converter and clamps loosely in

place.

(2) Install the exhaust pipe onto exhaust mani-

folds, tighten 31 N´m (23 ft. lbs.).

(3) Tighten all clamp nuts to 48 N´m (35 ft. lbs.)

torque.

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels. A

minimum of 25.4 mm (1.0 in.) is required between

exhaust system components and body/frame parts.

Adjust the alignment, if needed.

CATALYTIC CONVERTER - 5.9L

HD/8.0L

DESCRIPTION

The stainless steel catalytic converter is located

under the vehicle, attached to the exhaust pipe(s).

OPERATION

The catalytic converter captures and burns any

unburned fuel mixture exiting the combustion cham-

bers during the exhaust stroke of the engine. This

process aids in reducing emissions output.

REMOVAL

(1) Raise and support vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove clamps and nuts (Fig. 5) (Fig. 6).

(4) Remove the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

Fig. 4 Catalytic Converter and Exhaust Pipe 3.9L,

5.2L and 5.9L Light Duty ( California )

1 - BOLT

2 - RETAINER

3 - EXHAUST MANIFOLD

4 - NUT

5 - MINI CATALYTIC CONVERTER

6 - CATALYTIC CONVERTER WITH PIPES

Fig. 5 Catalytic Converter 5.9L Heavy Duty

1 - DOWN PIPE RIGHT

2 - CLAMP

3 - CLAMP

4 - HANGER ASSY. DUAL CLAMP

5 - MUFFLER

6 - EXTENSION PIPE

7 - CATALYTIC CONVERTER

8 - DOWN PIPE LEFT

11 - 6 EXHAUST SYSTEMBR/BE

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L (Continued)