fuse chart DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 440 of 2255

3. If not OK, repair the open ground circuit to ground

as required.

(3) Reconnect the battery negative cable. Turn the

park lamps on with the headlamp switch. Rotate the

panel lamps dimmer thumbwheel on the headlamp

switch upward to just before the interior lamps

detent. Check for battery voltage at the fused panel

lamps dimmer switch signal circuit cavity of the

instrument panel wire harness connector for the

heated seat switch. If OK, replace the faulty heated

seat switch. If not OK, repair the open fused panel

lamps dimmer switch signal circuit to the fuse in the

Junction Block (JB) as required.

(4) Check the fused ignition switch output (run)

fuse in the Junction Block (JB). If OK, go to Step 5.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(5) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the JB. If OK, go to Step 6. If

not OK, repair the open fused ignition switch output

(run) circuit to the ignition switch as required.

(6) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the instru-

ment panel wire harness connector from the connec-

tor receptacle on the back of the heated seat switch

to be tested. Reconnect the battery negative cable.

Turn the ignition switch to the On position. Check

for battery voltage at the fused ignition switch out-

put (run) circuit cavity of the instrument panel wire

harness connector for the heated seat switch. If OK,

go to Step 7. If not OK, repair the open fused ignition

switch output (run) circuit to the JB fuse as required.

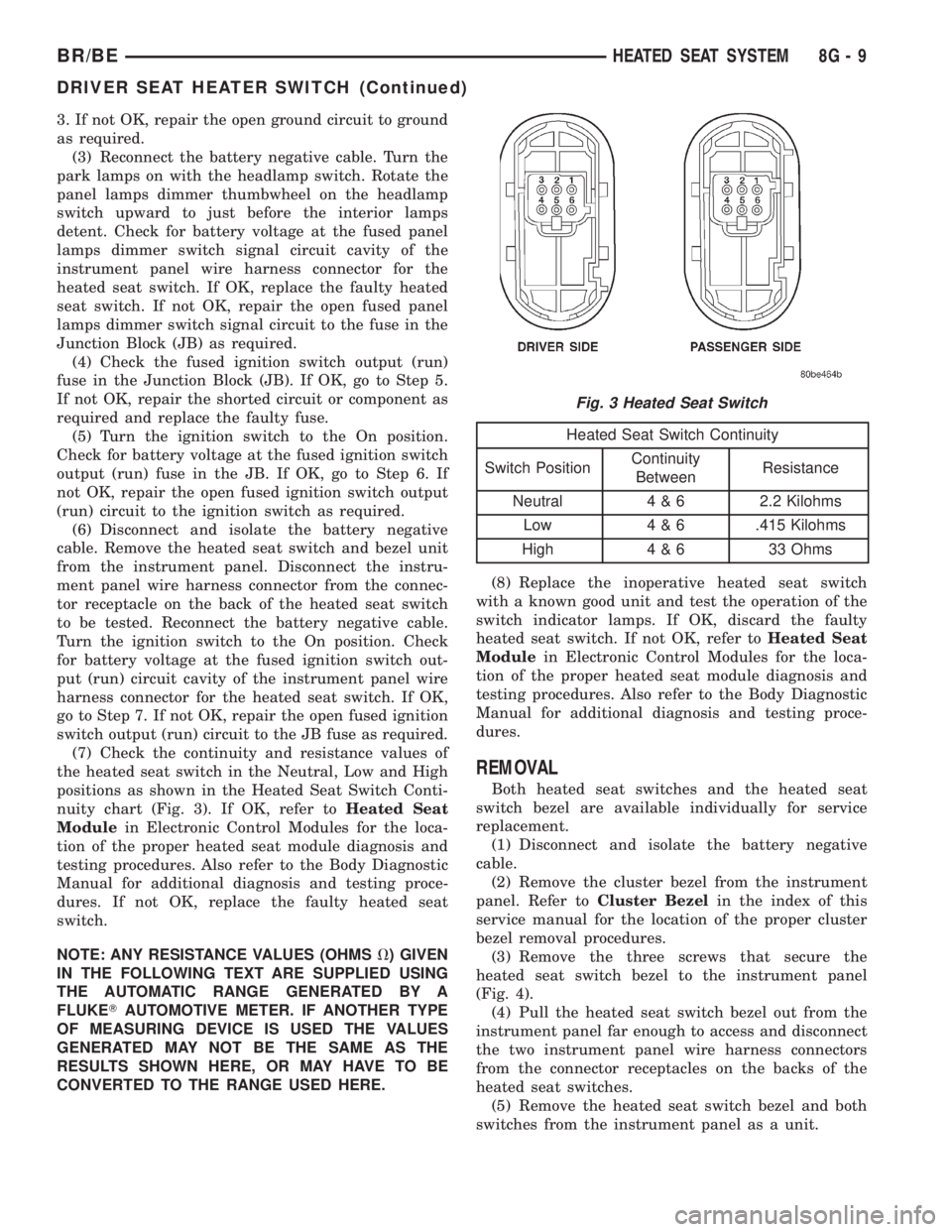

(7) Check the continuity and resistance values of

the heated seat switch in the Neutral, Low and High

positions as shown in the Heated Seat Switch Conti-

nuity chart (Fig. 3). If OK, refer toHeated Seat

Modulein Electronic Control Modules for the loca-

tion of the proper heated seat module diagnosis and

testing procedures. Also refer to the Body Diagnostic

Manual for additional diagnosis and testing proce-

dures. If not OK, replace the faulty heated seat

switch.

NOTE: ANY RESISTANCE VALUES (OHMSV) GIVEN

IN THE FOLLOWING TEXT ARE SUPPLIED USING

THE AUTOMATIC RANGE GENERATED BY A

FLUKETAUTOMOTIVE METER. IF ANOTHER TYPE

OF MEASURING DEVICE IS USED THE VALUES

GENERATED MAY NOT BE THE SAME AS THE

RESULTS SHOWN HERE, OR MAY HAVE TO BE

CONVERTED TO THE RANGE USED HERE.

Heated Seat Switch Continuity

Switch PositionContinuity

BetweenResistance

Neutral 4 & 6 2.2 Kilohms

Low 4 & 6 .415 Kilohms

High 4 & 6 33 Ohms

(8) Replace the inoperative heated seat switch

with a known good unit and test the operation of the

switch indicator lamps. If OK, discard the faulty

heated seat switch. If not OK, refer toHeated Seat

Modulein Electronic Control Modules for the loca-

tion of the proper heated seat module diagnosis and

testing procedures. Also refer to the Body Diagnostic

Manual for additional diagnosis and testing proce-

dures.

REMOVAL

Both heated seat switches and the heated seat

switch bezel are available individually for service

replacement.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cluster bezel from the instrument

panel. Refer toCluster Bezelin the index of this

service manual for the location of the proper cluster

bezel removal procedures.

(3) Remove the three screws that secure the

heated seat switch bezel to the instrument panel

(Fig. 4).

(4) Pull the heated seat switch bezel out from the

instrument panel far enough to access and disconnect

the two instrument panel wire harness connectors

from the connector receptacles on the backs of the

heated seat switches.

(5) Remove the heated seat switch bezel and both

switches from the instrument panel as a unit.

Fig. 3 Heated Seat Switch

BR/BEHEATED SEAT SYSTEM 8G - 9

DRIVER SEAT HEATER SWITCH (Continued)

Page 449 of 2255

involves inoperative heated seat switch indicator

lamps and the heated seat elements do heat, go to

Step 8. If the problem being diagnosed involves a

heated seat switch indicator lamp that remains illu-

minated after the heated seat has been turned Off,

refer toHeated Seat Modulein Electronic Control

Modules for the location of the proper heated seat

module diagnosis and testing procedures. Also refer

to the Body Diagnostic Manual for additional diagno-

sis and testing procedures.

(2) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the instru-

ment panel wire harness connector from the connec-

tor receptacle on the back of the heated seat switch

to be tested. Check for continuity between the ground

circuit cavity of the instrument panel wire harness

connector for the heated seat switch and a good

ground. There should be continuity. If OK, go to Step

3. If not OK, repair the open ground circuit to ground

as required.

(3) Reconnect the battery negative cable. Turn the

park lamps on with the headlamp switch. Rotate the

panel lamps dimmer thumbwheel on the headlamp

switch upward to just before the interior lamps

detent. Check for battery voltage at the fused panel

lamps dimmer switch signal circuit cavity of the

instrument panel wire harness connector for the

heated seat switch. If OK, replace the faulty heated

seat switch. If not OK, repair the open fused panel

lamps dimmer switch signal circuit to the fuse in the

Junction Block (JB) as required.

(4) Check the fused ignition switch output (run)

fuse in the Junction Block (JB). If OK, go to Step 5.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(5) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the JB. If OK, go to Step 6. If

not OK, repair the open fused ignition switch output

(run) circuit to the ignition switch as required.

(6) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the instru-

ment panel wire harness connector from the connec-

tor receptacle on the back of the heated seat switch

to be tested. Reconnect the battery negative cable.

Turn the ignition switch to the On position. Check

for battery voltage at the fused ignition switch out-

put (run) circuit cavity of the instrument panel wire

harness connector for the heated seat switch. If OK,

go to Step 7. If not OK, repair the open fused ignition

switch output (run) circuit to the JB fuse as required.

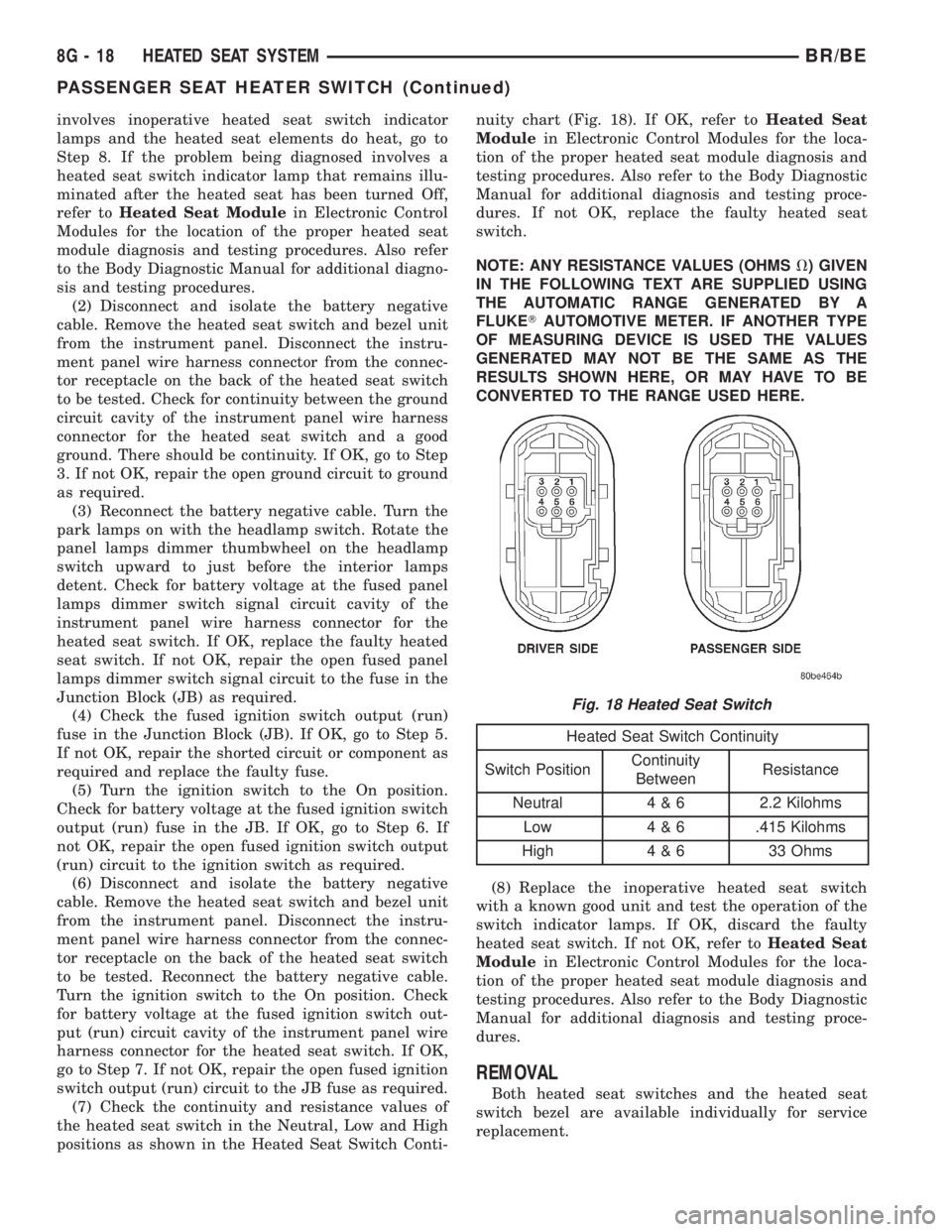

(7) Check the continuity and resistance values of

the heated seat switch in the Neutral, Low and High

positions as shown in the Heated Seat Switch Conti-nuity chart (Fig. 18). If OK, refer toHeated Seat

Modulein Electronic Control Modules for the loca-

tion of the proper heated seat module diagnosis and

testing procedures. Also refer to the Body Diagnostic

Manual for additional diagnosis and testing proce-

dures. If not OK, replace the faulty heated seat

switch.

NOTE: ANY RESISTANCE VALUES (OHMSV) GIVEN

IN THE FOLLOWING TEXT ARE SUPPLIED USING

THE AUTOMATIC RANGE GENERATED BY A

FLUKETAUTOMOTIVE METER. IF ANOTHER TYPE

OF MEASURING DEVICE IS USED THE VALUES

GENERATED MAY NOT BE THE SAME AS THE

RESULTS SHOWN HERE, OR MAY HAVE TO BE

CONVERTED TO THE RANGE USED HERE.

Heated Seat Switch Continuity

Switch PositionContinuity

BetweenResistance

Neutral 4 & 6 2.2 Kilohms

Low 4 & 6 .415 Kilohms

High 4 & 6 33 Ohms

(8) Replace the inoperative heated seat switch

with a known good unit and test the operation of the

switch indicator lamps. If OK, discard the faulty

heated seat switch. If not OK, refer toHeated Seat

Modulein Electronic Control Modules for the loca-

tion of the proper heated seat module diagnosis and

testing procedures. Also refer to the Body Diagnostic

Manual for additional diagnosis and testing proce-

dures.

REMOVAL

Both heated seat switches and the heated seat

switch bezel are available individually for service

replacement.

Fig. 18 Heated Seat Switch

8G - 18 HEATED SEAT SYSTEMBR/BE

PASSENGER SEAT HEATER SWITCH (Continued)

Page 486 of 2255

(10) Disconnect and isolate the battery negative

cable. Remove the instrument cluster. Check for con-

tinuity between the ground circuit (Z2) cavity of the

instrument panel wire harness connector (Connector

C1) and a good ground. There should be continuity. If

OK, refer to ACTUATOR TEST . If not OK, repair

the open ground circuit to ground (G200) as required.

ACTUATOR TEST

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The instrument cluster actuator test will put the

instrument cluster into its self-diagnostic mode. In

this mode the instrument cluster can perform a self-

diagnostic test that will confirm that the instrument

cluster circuitry, the gauges, and the CCD data bus

message-controlled indicators are capable of operat-

ing as designed. During the actuator test the instru-

ment cluster circuitry position each of the gaugeneedles at various calibration points, illuminate each

of the segments in the Vacuum-Fluorescent Display

(VFD), and turn all of the CCD data bus message-

controlled indicators on and off.

Successful completion of the actuator test will con-

firm that the instrument cluster is operational. How-

ever, there may still be a problem with the CCD data

bus, the Powertrain Control Module (PCM), the

Engine Control Module (ECM), the Airbag Control

Module (ACM), the Controller Anti-lock Brake (CAB),

or the inputs to one of these electronic control mod-

ules. Use a DRBIIItscan tool to diagnose these com-

ponents. Refer to the appropriate diagnostic

information.

(1) Begin the test with the ignition switch in the

Off position.

(2) Depress the odometer/trip odometer switch but-

ton.

(3) While still holding the odometer/trip odometer

switch button depressed, turn the ignition switch to

the On position, but do not start the engine.

(4) Keep the odometer/trip odometer switch button

depressed for about ten seconds, untilCHEC

appears in the odometer display, then release the

odometer/trip odometer switch button.

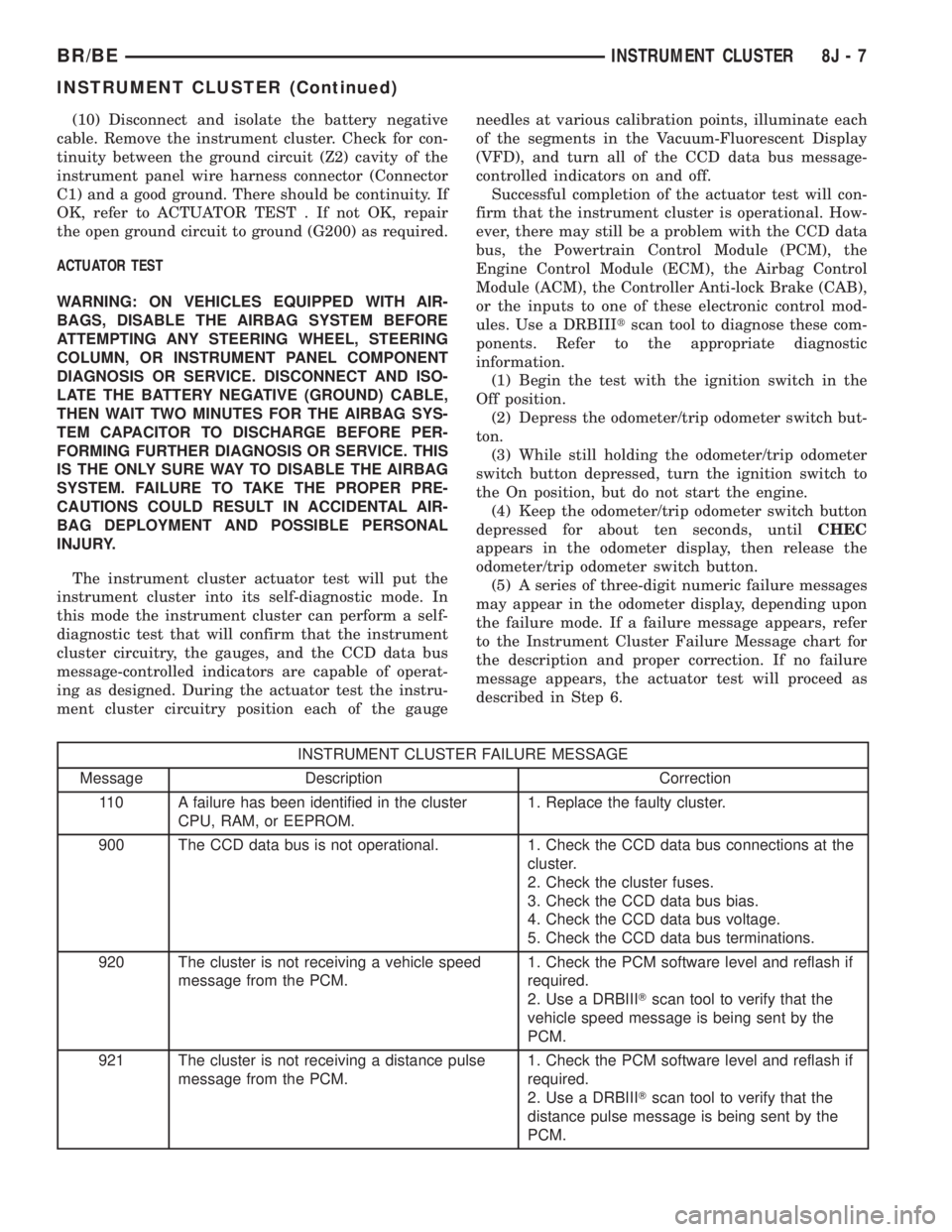

(5) A series of three-digit numeric failure messages

may appear in the odometer display, depending upon

the failure mode. If a failure message appears, refer

to the Instrument Cluster Failure Message chart for

the description and proper correction. If no failure

message appears, the actuator test will proceed as

described in Step 6.

INSTRUMENT CLUSTER FAILURE MESSAGE

Message Description Correction

110 A failure has been identified in the cluster

CPU, RAM, or EEPROM.1. Replace the faulty cluster.

900 The CCD data bus is not operational. 1. Check the CCD data bus connections at the

cluster.

2. Check the cluster fuses.

3. Check the CCD data bus bias.

4. Check the CCD data bus voltage.

5. Check the CCD data bus terminations.

920 The cluster is not receiving a vehicle speed

message from the PCM.1. Check the PCM software level and reflash if

required.

2. Use a DRBIIITscan tool to verify that the

vehicle speed message is being sent by the

PCM.

921 The cluster is not receiving a distance pulse

message from the PCM.1. Check the PCM software level and reflash if

required.

2. Use a DRBIIITscan tool to verify that the

distance pulse message is being sent by the

PCM.

BR/BEINSTRUMENT CLUSTER 8J - 7

INSTRUMENT CLUSTER (Continued)

Page 563 of 2255

will return to the last function being displayed before

the ignition was turned to the Off position. With the

ignition switch in the On position, momentarily

depressing and releasing the Step push button switch

will cause the compass-mini-trip computer to change

its mode of operation, and momentarily depressing

and releasing the U.S./Metric push button will cause

the unit to toggle between U.S. and Metric measure-

ments. While in either compass mode, depressing the

U.S./Metric push button for more than ten seconds

will toggle the display between the compass/temper-

ature and the compass/compass in degrees modes.

This compass mini-trip computer features several

functions that can be reset. If both the Step and U.S./

Metric push buttons are depressed at the same time

with the ignition switch in the On position, the trip

computer information that can be reset is reset.

Depressing and releasing the Step and U.S./Metric

push buttons at the same time for more than 100

milliseconds, but not more than one second while in

any display mode (except the compass/temperature

mode) will cause a local reset. A local reset affects

only the function currently displayed. See the Reset

Chart below for more information on this feature.

Performing a local reset while in the compass/tem-

perature mode enters the module into the compass

variance setting mode.

Depressing and releasing the Step and U.S./Metric

push buttons at the same time for more than two

seconds while in any display mode (except the com-

pass/temperature mode) will cause a global reset. A

global reset changes all of the trip computer func-

tions that can be reset.

For more information on the features and control

functions of the compass mini-trip computer, see the

owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER

If the problem with the compass mini-trip com-

puter module is an inoperative security indicator

lamp, refer toSecurity Indicator Lampin Vehicle

Theft/Security Systems. If the problem with the com-

pass mini-trip computer module is an ªOCº or ªSCº in

the compass/thermometer display, refer toAmbient

Temperature Sensorin this section. If the problem

with the compass mini-trip computer module is an

inaccurate or scrambled display, refer toCMTC Self-

Diagnostic Testin this section. If the problem with

the compass mini-trip computer module is incorrect

Vacuum Fluorescent Display (VFD) dimming levels,

use a DRBtscan tool and the proper Diagnostic Pro-

cedures manual to test for the correct dimming mes-

sage inputs being received from the instrument

cluster over the Chrysler Collision Detection (CCD)

data bus. If the problem is a no-display condition,use the following procedures. For complete circuit

diagrams, refer toOverhead Consolein the Con-

tents of Wiring Diagrams.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the battery as

required.

(3) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 4.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 5. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the overhead console. Check for continuity

between the ground circuit cavities of the roof wire

harness connector for the overhead console and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit to

ground as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

roof wire harness connector for the overhead console.

If OK, go to Step 7. If not OK, repair the open fused

B(+) circuit to the junction block fuse as required.

(7) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the roof wire har-

ness connector for the overhead console. If OK, refer

toSelf-Diagnostic Testin the Diagnosis and Test-

ing section of this group for further diagnosis of the

compass mini-trip computer module and the CCD

data bus. If not OK, repair the open fused ignition

switch output (run/start) circuit to the junction block

fuse as required.

CMTC SELF-DIAGNOSTIC TEST

A self-diagnostic test is used to determine that the

compass mini-trip computer module is operating

properly electrically. Initiate the self-diagnostic test

as follows:

(1) With the ignition switch in the Off position,

simultaneously depress and hold the Step button and

the U.S./Metric button.

(2) Turn the ignition switch to the On position.

(3) Continue to hold both buttons depressed until

the compass mini-trip computer module enters the

8M - 10 MESSAGE SYSTEMSBR/BE

COMPASS/MINI-TRIP COMPUTER (Continued)

Page 576 of 2255

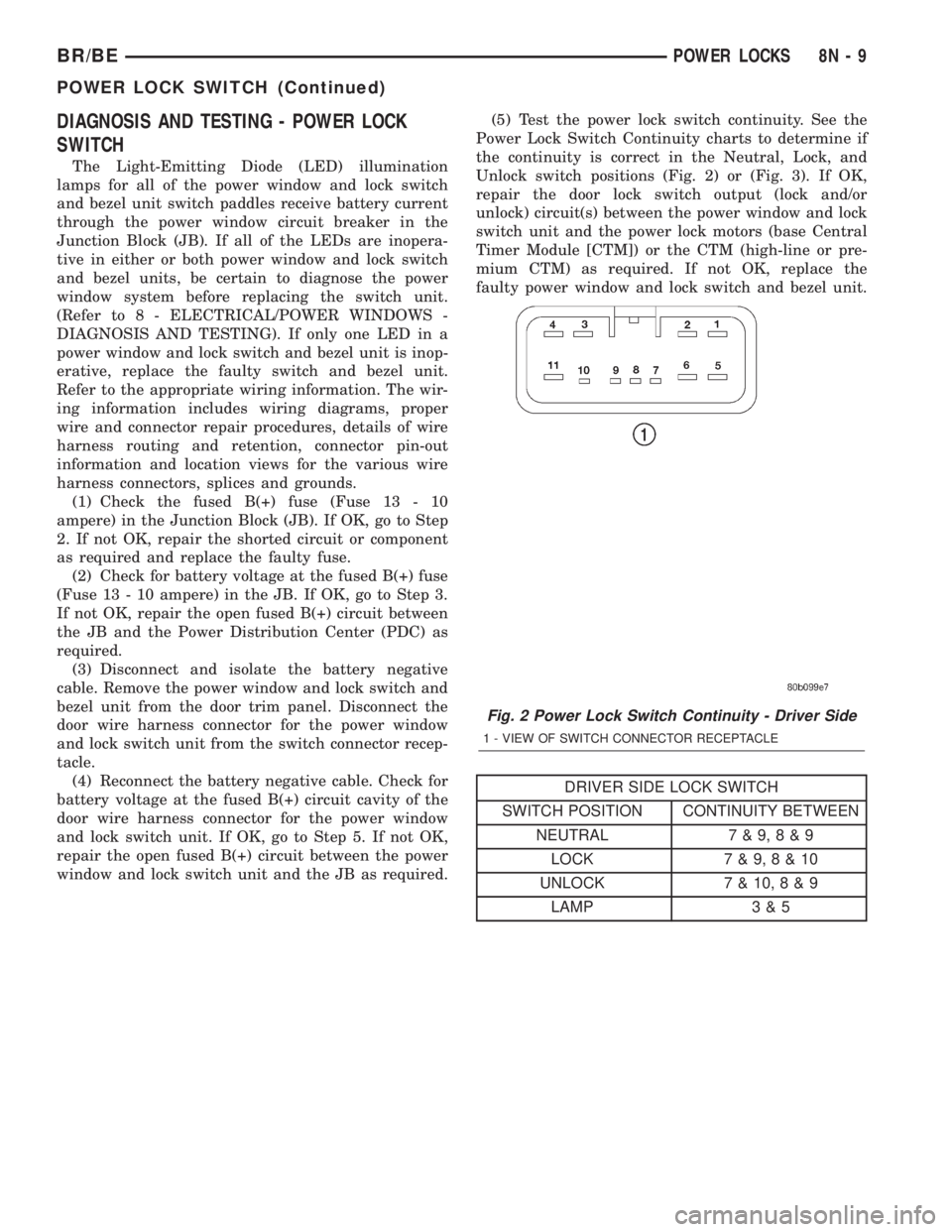

DIAGNOSIS AND TESTING - POWER LOCK

SWITCH

The Light-Emitting Diode (LED) illumination

lamps for all of the power window and lock switch

and bezel unit switch paddles receive battery current

through the power window circuit breaker in the

Junction Block (JB). If all of the LEDs are inopera-

tive in either or both power window and lock switch

and bezel units, be certain to diagnose the power

window system before replacing the switch unit.

(Refer to 8 - ELECTRICAL/POWER WINDOWS -

DIAGNOSIS AND TESTING). If only one LED in a

power window and lock switch and bezel unit is inop-

erative, replace the faulty switch and bezel unit.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(1) Check the fused B(+) fuse (Fuse 13 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 13 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the power window and lock switch and

bezel unit from the door trim panel. Disconnect the

door wire harness connector for the power window

and lock switch unit from the switch connector recep-

tacle.

(4) Reconnect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

door wire harness connector for the power window

and lock switch unit. If OK, go to Step 5. If not OK,

repair the open fused B(+) circuit between the power

window and lock switch unit and the JB as required.(5) Test the power lock switch continuity. See the

Power Lock Switch Continuity charts to determine if

the continuity is correct in the Neutral, Lock, and

Unlock switch positions (Fig. 2) or (Fig. 3). If OK,

repair the door lock switch output (lock and/or

unlock) circuit(s) between the power window and lock

switch unit and the power lock motors (base Central

Timer Module [CTM]) or the CTM (high-line or pre-

mium CTM) as required. If not OK, replace the

faulty power window and lock switch and bezel unit.

DRIVER SIDE LOCK SWITCH

SWITCH POSITION CONTINUITY BETWEEN

NEUTRAL 7 & 9,8&9

LOCK 7 & 9,8&10

UNLOCK 7 & 10,8&9

LAMP 3 & 5

Fig. 2 Power Lock Switch Continuity - Driver Side

1 - VIEW OF SWITCH CONNECTOR RECEPTACLE

BR/BEPOWER LOCKS 8N - 9

POWER LOCK SWITCH (Continued)

Page 667 of 2255

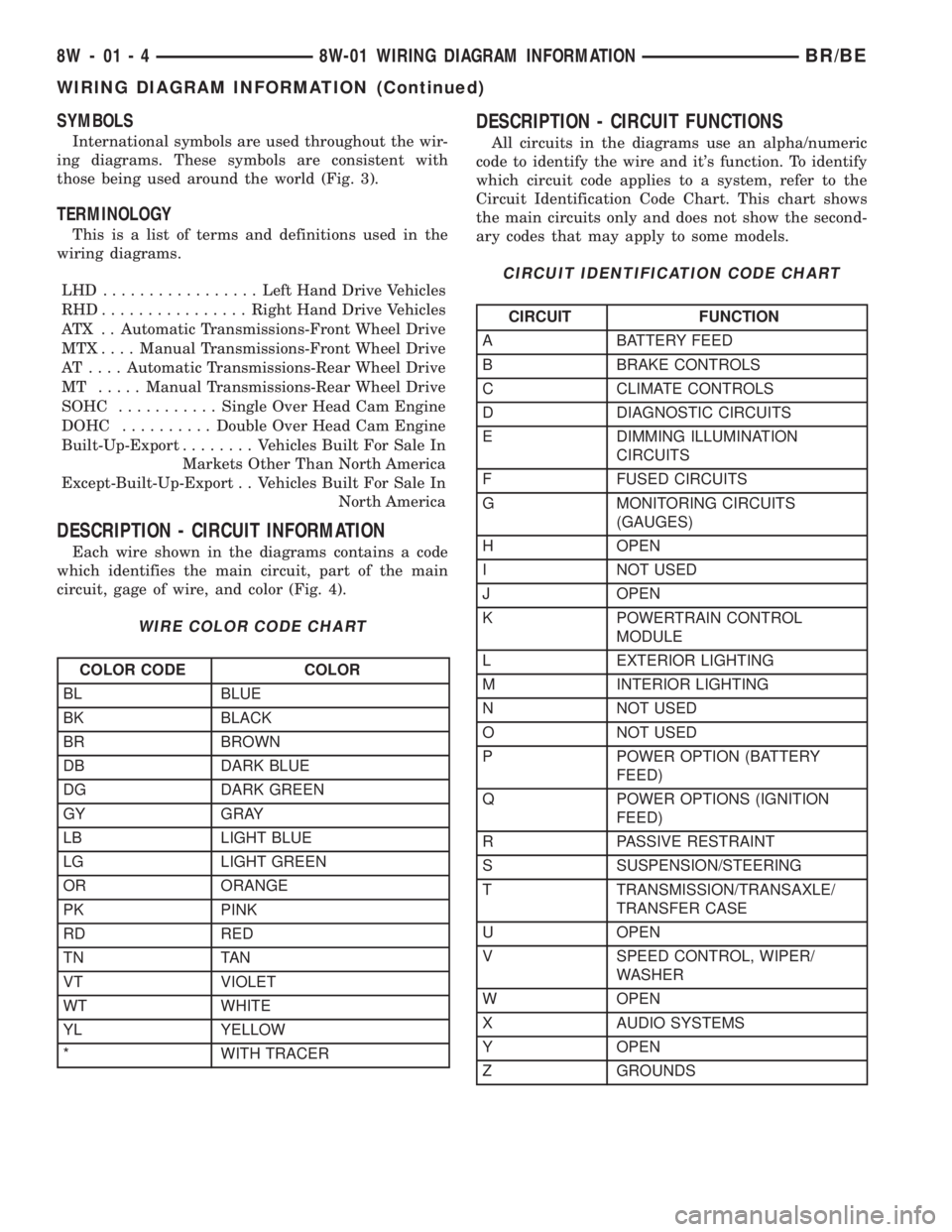

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world (Fig. 3).

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD .................Left Hand Drive Vehicles

RHD................Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX....Manual Transmissions-Front Wheel Drive

AT ....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export........ Vehicles Built For Sale In

Markets Other Than North America

Except-Built-Up-Export . . Vehicles Built For Sale In

North America

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 4).

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

8W - 01 - 4 8W-01 WIRING DIAGRAM INFORMATIONBR/BE

WIRING DIAGRAM INFORMATION (Continued)

Page 2245 of 2255

SENSOR - REMOVAL, FUEL LEVEL

SENDING UNIT.......................14-7

SENSOR - REMOVAL, O2..............14-46

SENSOR - REMOVAL, REAR WHEEL

SPEED..............................5-40

SENSOR - REMOVAL, WATER IN FUEL....14-89

SENSOR RETURN - DESCRIPTION.......8E-17

SENSOR/SWITCH - INSTALLATION, OIL

PRESSURE.........................9-181

SENSOR/SWITCH - REMOVAL, OIL

PRESSURE.........................9-181

SEPARATOR - DESCRIPTION, FUEL

FILTER / WATER .....................14-63

SEPARATOR - INSTALLATION, FUEL

FILTER / WATER .....................14-65

SEPARATOR - OPERATION, FUEL FILTER

/ WATER ...........................14-63

SEPARATOR - REMOVAL, FUEL FILTER /

WATER.............................14-64

SERVO - ASSEMBLY, FRONT.....21-164,21-335

SERVO - ASSEMBLY, REAR......21-207,21-379

SERVO - CLEANING, FRONT.....21-164,21-334

SERVO - CLEANING, REAR......21-207,21-379

SERVO - DESCRIPTION, FRONT . . 21-164,21-334

SERVO - DESCRIPTION, REAR . . . 21-207,21-378

SERVO - DESCRIPTION, SPEED

CONTROL...........................8P-6

SERVO - DISASSEMBLY, FRONT . . 21-164,21-334

SERVO - DISASSEMBLY, REAR . . . 21-207,21-378

SERVO - INSPECTION, FRONT.....21-164,21-335

SERVO - OPERATION, FRONT....21-164,21-334

SERVO - OPERATION, REAR.....21-207,21-378

SERVO - OPERATION, SPEED CONTROL . . . 8P-6

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO GROUND ON FUSES POWERING . . . 8W-01-9

SHAFT - ASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT...........21-199,21-371

SHAFT - DESCRIPTION, PLANETARY

GEARTRAIN/OUTPUT...........21-197,21-369

SHAFT - DIAGNOSIS AND TESTING,

PROPELLER...........................3-1

SHAFT - DISASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT...........21-198,21-369

SHAFT - FRONT - INSTALLATION,

PROPELLER...........................3-7

SHAFT - FRONT - REMOVAL,

PROPELLER...........................3-6

SHAFT - INSPECTION, PLANETARY

GEARTRAIN/OUTPUT...........21-199,21-371

SHAFT - INSTALLATION, PITMAN........19-25

SHAFT - INSTALLATION, WORM.........19-31

SHAFT - OPERATION, PLANETARY

GEARTRAIN/OUTPUT...........21-197,21-369

SHAFT - REAR - INSTALLATION,

PROPELLER...........................3-7

SHAFT - REAR - REMOVAL, PROPELLER....3-7

SHAFT - REMOVAL, PITMAN............19-24

SHAFT - REMOVAL, WORM............19-30

SHAFT - STANDARD PROCEDURES,

PROPELLER...........................3-3

SHAFT FRONT BEARING -

INSTALLATION, OUTPUT........21-171,21-342

SHAFT FRONT BEARING - REMOVAL,

OUTPUT.....................21-171,21-342

SHAFT REAR BEARING - INSTALLATION,

OUTPUT.....................21-172,21-343

SHAFT REAR BEARING - REMOVAL,

OUTPUT.....................21-171,21-343

SHAFT SEAL - INSTALLATION, FRONT

OUTPUT.....................21-461,21-498

SHAFT SEAL - INSTALLATION, PITMAN

. . . 19-26

SHAFT SEAL - REMOVAL, FRONT

OUTPUT

.....................21-461,21-498

SHAFT SEAL - REMOVAL, PITMAN

.......19-25

SHAFT SEALS - INSTALLATION, AXLE

.....3-31

SHAFT SEALS - REMOVAL, AXLE

.........3-31

SHAFT, SPECIAL TOOLS - PROPELLER

......3-6

SHAFT, SPECIFICATIONS - PROPELLER

.....3-6

SHAFTS - INSTALLATION,

AXLE

..................3-123,3-29,3-62,3-94

SHAFTS - INTERMEDIATE - REMOVAL,

AXLE

...............................3-30

SHAFTS - REMOVAL, AXLE

. 3-123,3-29,3-62,3-94

SHIELD - INSTALLATION, REAR SPLASH

. . 23-96

SHIELD - REMOVAL, REAR SPLASH

......23-96

SHIELDS - DESCRIPTION, HEAT

.........11-10SHIELDS - INSTALLATION, FRONT END

SPLASH............................23-92

SHIELDS - INSTALLATION, HEAT........11-10

SHIELDS - REMOVAL, FRONT END

SPLASH............................23-92

SHIELDS - REMOVAL, HEAT............11-10

SHIFT BOOT - INSTALLATION, 4WD

FLOOR............................23-122

SHIFT BOOT - MANUAL TRANSMISSION

- INSTALLATION....................23-122

SHIFT BOOT - MANUAL TRANSMISSION

- REMOVAL........................23-122

SHIFT BOOT - REMOVAL, 4WD FLOOR . . . 23-122

SHIFT COVER - NV4500 - INSTALLATION . . 21-45

SHIFT COVER - NV4500 - REMOVAL.....21-45

SHIFT COVER - NV5600 - INSTALLATION . . 21-86

SHIFT COVER - NV5600 - REMOVAL.....21-86

SHIFT INDICATOR (TRANSFER CASE) -

DESCRIPTION.......................8J-28

SHIFT INDICATOR (TRANSFER CASE) -

OPERATION.........................8J-28

SHIFT LEVER - ADJUSTMENT....21-463,21-500

SHIFT LEVER - INSTALLATION . . . 21-462,21-500

SHIFT LEVER - INSTALLATION, GEAR.....19-15

SHIFT LEVER - REMOVAL.......21-462,21-499

SHIFT LEVER - REMOVAL, GEAR........19-14

SHIFT MECHANISM - DESCRIPTION....21-208,

21-379

SHIFT MECHANISM - NV4500 -

INSTALLATION........................21-44

SHIFT MECHANISM - NV4500 -

REMOVAL..........................21-43

SHIFT MECHANISM - OPERATION......21-208,

21-379

SHOCK - DIAGNOSIS AND TESTING . . . 2-11,2-22

SHOCK - DIAGNOSIS AND TESTING,

SPRING.............................2-25

SHOCK - INSTALLATION........2-11,2-22,2-27

SHOCK - REMOVAL............2-11,2-22,2-27

SHOES - ADJUSTMENT, PARKING BRAKE . . 5-33

SHOES - INSTALLATION................5-32

SHOES - REMOVAL....................5-32

SHORT TO GROUND - STANDARD

PROCEDURE, TESTING FOR A........8W-01-9

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A ...........................8W-01-9

SHUTFACE HANDLE - INSTALLATION.....23-83

SHUTFACE HANDLE - REMOVAL.........23-83

SIDE MOLDINGS - INSTALLATION, BODY . . 23-87

SIDE MOLDINGS - REMOVAL, BODY.....23-86

SIDE PANEL SPEAKER - INSTALLATION,

REAR CAB..........................8A-20

SIDE PANEL SPEAKER - REMOVAL,

REAR CAB..........................8A-20

SIDE VIEW MIRROR - INSTALLATION.....23-98

SIDE VIEW MIRROR - LOW MOUNTED -

INSTALLATION.......................23-98

SIDE VIEW MIRROR - LOW MOUNTED -

REMOVAL..........................23-98

SIDE VIEW MIRROR - REMOVAL........23-97

SIDE VIEW MIRROR FLAG -

INSTALLATION.......................23-75

SIDE VIEW MIRROR FLAG - REMOVAL . . . 23-74

SIDE VIEW MIRROR GLASS -

INSTALLATION.......................23-98

SIDE VIEW MIRROR GLASS - REMOVAL . . 23-98

SIDEVIEW MIRROR - DESCRIPTION......8N-14

SIDEVIEW MIRROR - DIAGNOSIS AND

TESTING...........................8N-14

SIDEVIEW MIRROR - OPERATION.......8N-14

SIDEVIEW MIRROR - REMOVAL.........8N-15

SIGNAL & HAZARD WARNING SYSTEM -

DESCRIPTION, TURN..................8L-2

SIGNAL & HAZARD WARNING SYSTEM -

DIAGNOSIS AND TESTING, TURN.........8L-3

SIGNAL & HAZARD WARNING SYSTEM -

OPERATION, TURN....................8L-2

SIGNAL CANCEL CAM - DESCRIPTION,

TURN

..............................8L-31

SIGNAL CANCEL CAM - OPERATION,

TURN

..............................8L-31

SIGNAL GROUND - DESCRIPTION

.......8E-17

SIGNAL INDICATOR - DESCRIPTION,

TURN

..............................8J-32

SIGNAL INDICATOR - DIAGNOSIS AND

TESTING, TURN

......................8J-32SIGNAL INDICATOR - OPERATION, TURN . . 8J-32

SIGNAL LAMP - INSTALLATION,

PARK/TURN.........................8L-29

SIGNAL LAMP - REMOVAL, PARK/TURN . . 8L-29

SIGNAL LAMP UNIT - INSTALLATION,

PARK/TURN.........................8L-29

SIGNAL LAMP UNIT - REMOVAL,

PARK/TURN.........................8L-29

SILENCER PAD - INSTALLATION........23-104

SILENCER PAD - REMOVAL...........23-104

SILL TRIM - INSTALLATION, DOOR.....23-121

SILL TRIM - REMOVAL, DOOR.........23-121

SINGLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY...........................3-9

SINGLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY.........................3-8

SINGLE CARDAN UNIVERSAL JOINTS -

INSTALLATION........................3-35

SINGLE CARDAN UNIVERSAL JOINTS -

REMOVAL...........................3-34

SKID PLATE - INSTALLATION, TRANSFER

CASE..............................13-11

SKID PLATE - REMOVAL, TRANSFER

CASE..............................13-11

SLAM BUMPER - INSTALLATION........23-67

SLAM BUMPER - REMOVAL............23-67

SMOKE DIAGNOSIS CHARTS -

DIAGNOSIS AND TESTING.............9-118

SOLENOID - DESCRIPTION......21-208,21-380

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-33

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-34

SOLENOID - OPERATION........21-209,21-381

SOLENOID - OPERATION, EVAP/PURGE . . . 25-33

SOLENOID - REMOVAL, EVAP/PURGE.....25-33

SOLID LIFTERS/TAPPETS - CLEANING....9-164

SOLID LIFTERS/TAPPETS - INSPECTION . . 9-165

SOLID LIFTERS/TAPPETS -

INSTALLATION.......................9-165

SOLID LIFTERS/TAPPETS - REMOVAL....9-164

SPARE TIRE - DESCRIPTION............22-10

SPARE TIRE - TEMPORARY -

DESCRIPTION........................22-6

SPARK PLUG - CLEANING..............8I-20

SPARK PLUG - DESCRIPTION...........8I-16

SPARK PLUG - INSTALLATION...........8I-20

SPARK PLUG - OPERATION.............8I-16

SPARK PLUG - REMOVAL..............8I-19

SPARK PLUG CABLE - DESCRIPTION.....8I-20

SPARK PLUG CABLE - INSTALLATION.....8I-21

SPARK PLUG CABLE - OPERATION.......8I-20

SPARK PLUG CABLE - REMOVAL........8I-21

SPARK PLUG CABLE ORDER, 8.0L V-10

ENGINE..............................8I-3

SPARK PLUG CABLE RESISTANCE,

SPECIFICATIONS......................8I-3

SPARK PLUG CABLES - DIAGNOSIS AND

TESTING............................8I-20

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-17

SPARK PLUGS, SPECIFICATIONS..........8I-3

SPEAKER - DESCRIPTION..............8A-17

SPEAKER - DIAGNOSIS AND TESTING....8A-17

SPEAKER - INSTALLATION, A-PILLAR

TWEETER..........................8A-19

SPEAKER - INSTALLATION, FRONT DOOR . 8A-19

SPEAKER - INSTALLATION, REAR CAB

SIDE PANEL........................8A-20

SPEAKER - INSTALLATION, REAR DOOR . . 8A-21

SPEAKER - OPERATION...............8A-17

SPEAKER - REMOVAL, A-PILLAR

TWEETER..........................8A-18

SPEAKER - REMOVAL, FRONT DOOR.....8A-19

SPEAKER - REMOVAL, REAR CAB SIDE

PANEL.............................8A-20

SPEAKER - REMOVAL, REAR DOOR......8A-20

SPECIAL TOOL, SPECIAL TOOLS -

OVERHEAD CONSOLE.................8M-9

SPECIFICATIONS - 2002 BR/BE PAINT

COLOR CODES.....................23-129

SPECIFICATIONS - 5.9L DIESEL.........9-127

SPECIFICATIONS - 5.9L ENGINE..........9-13

SPECIFICATIONS - 8.OL ENGINE

..........9-68

SPECIFICATIONS - A/C APPLICATION

TABLE

..............................24-7

SPECIFICATIONS - ALIGNMENT

...........2-6

SPECIFICATIONS - BASE BRAKE

...........5-2

SPECIFICATIONS - BATTERY

.............8F-6

28 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page