steering wheel adjustment DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 26 of 2255

SUSPENSION

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT......................1

FRONT - 2WD............................7FRONT - 4WD...........................14

REAR.................................25

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - PRE-ALIGNMENT . 2

STANDARD PROCEDURE

STANDARD PROCEDURES - ALIGNMENT

I.F.S. ................................3STANDARD PROCEDURE - CASTER

CORRECTION MEASUREMENT...........3

STANDARD PROCEDURE - ALIGNMENT

LINK/COIL SUSPENSION.................5

SPECIFICATIONS

ALIGNMENT..........................6

WHEEL ALIGNMENT

DESCRIPTION

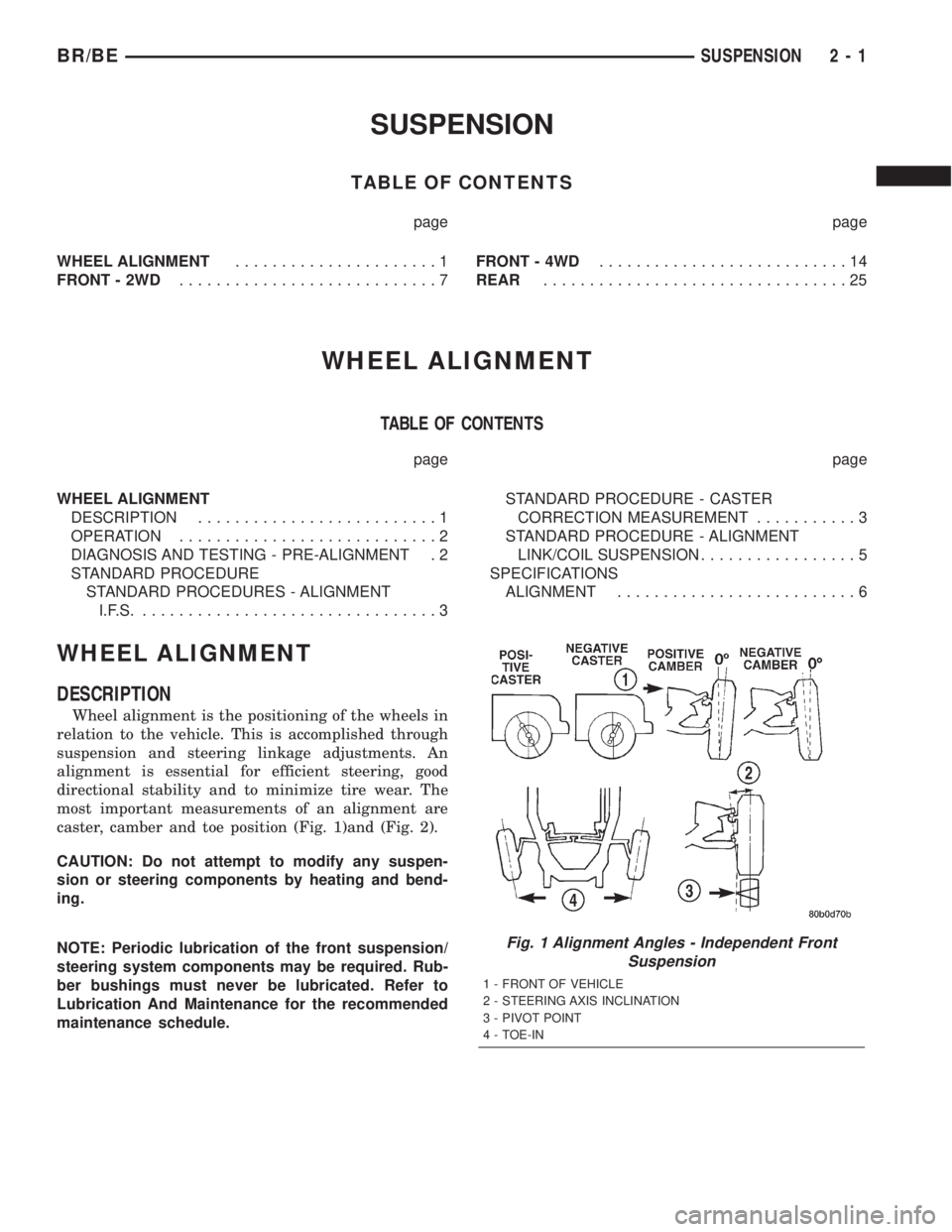

Wheel alignment is the positioning of the wheels in

relation to the vehicle. This is accomplished through

suspension and steering linkage adjustments. An

alignment is essential for efficient steering, good

directional stability and to minimize tire wear. The

most important measurements of an alignment are

caster, camber and toe position (Fig. 1)and (Fig. 2).

CAUTION: Do not attempt to modify any suspen-

sion or steering components by heating and bend-

ing.

NOTE: Periodic lubrication of the front suspension/

steering system components may be required. Rub-

ber bushings must never be lubricated. Refer to

Lubrication And Maintenance for the recommended

maintenance schedule.

Fig. 1 Alignment Angles - Independent Front

Suspension

1 - FRONT OF VEHICLE

2 - STEERING AXIS INCLINATION

3 - PIVOT POINT

4 - TOE-IN

BR/BESUSPENSION 2 - 1

Page 27 of 2255

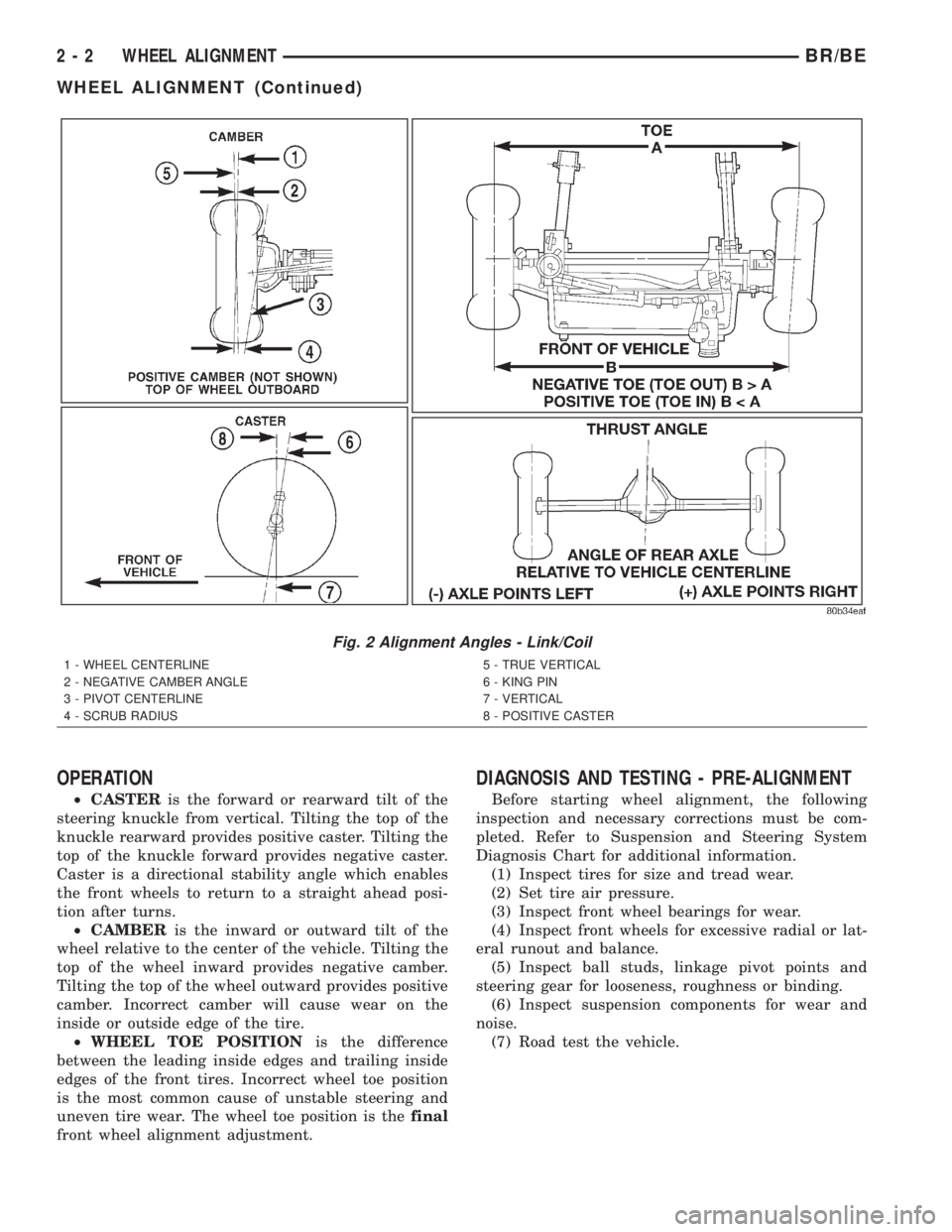

OPERATION

²CASTERis the forward or rearward tilt of the

steering knuckle from vertical. Tilting the top of the

knuckle rearward provides positive caster. Tilting the

top of the knuckle forward provides negative caster.

Caster is a directional stability angle which enables

the front wheels to return to a straight ahead posi-

tion after turns.

²CAMBERis the inward or outward tilt of the

wheel relative to the center of the vehicle. Tilting the

top of the wheel inward provides negative camber.

Tilting the top of the wheel outward provides positive

camber. Incorrect camber will cause wear on the

inside or outside edge of the tire.

²WHEEL TOE POSITIONis the difference

between the leading inside edges and trailing inside

edges of the front tires. Incorrect wheel toe position

is the most common cause of unstable steering and

uneven tire wear. The wheel toe position is thefinal

front wheel alignment adjustment.

DIAGNOSIS AND TESTING - PRE-ALIGNMENT

Before starting wheel alignment, the following

inspection and necessary corrections must be com-

pleted. Refer to Suspension and Steering System

Diagnosis Chart for additional information.

(1) Inspect tires for size and tread wear.

(2) Set tire air pressure.

(3) Inspect front wheel bearings for wear.

(4) Inspect front wheels for excessive radial or lat-

eral runout and balance.

(5) Inspect ball studs, linkage pivot points and

steering gear for looseness, roughness or binding.

(6) Inspect suspension components for wear and

noise.

(7) Road test the vehicle.

Fig. 2 Alignment Angles - Link/Coil

1 - WHEEL CENTERLINE

2 - NEGATIVE CAMBER ANGLE

3 - PIVOT CENTERLINE

4 - SCRUB RADIUS5 - TRUE VERTICAL

6 - KING PIN

7 - VERTICAL

8 - POSITIVE CASTER

2 - 2 WHEEL ALIGNMENTBR/BE

WHEEL ALIGNMENT (Continued)

Page 28 of 2255

STANDARD PROCEDURE

STANDARD PROCEDURES - ALIGNMENT I.F.S.

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down several times. Always release the bumper in

the down position.Set the front end alignment to

specifications while the vehicle is in its NOR-

MALLY LOADED CONDITION.

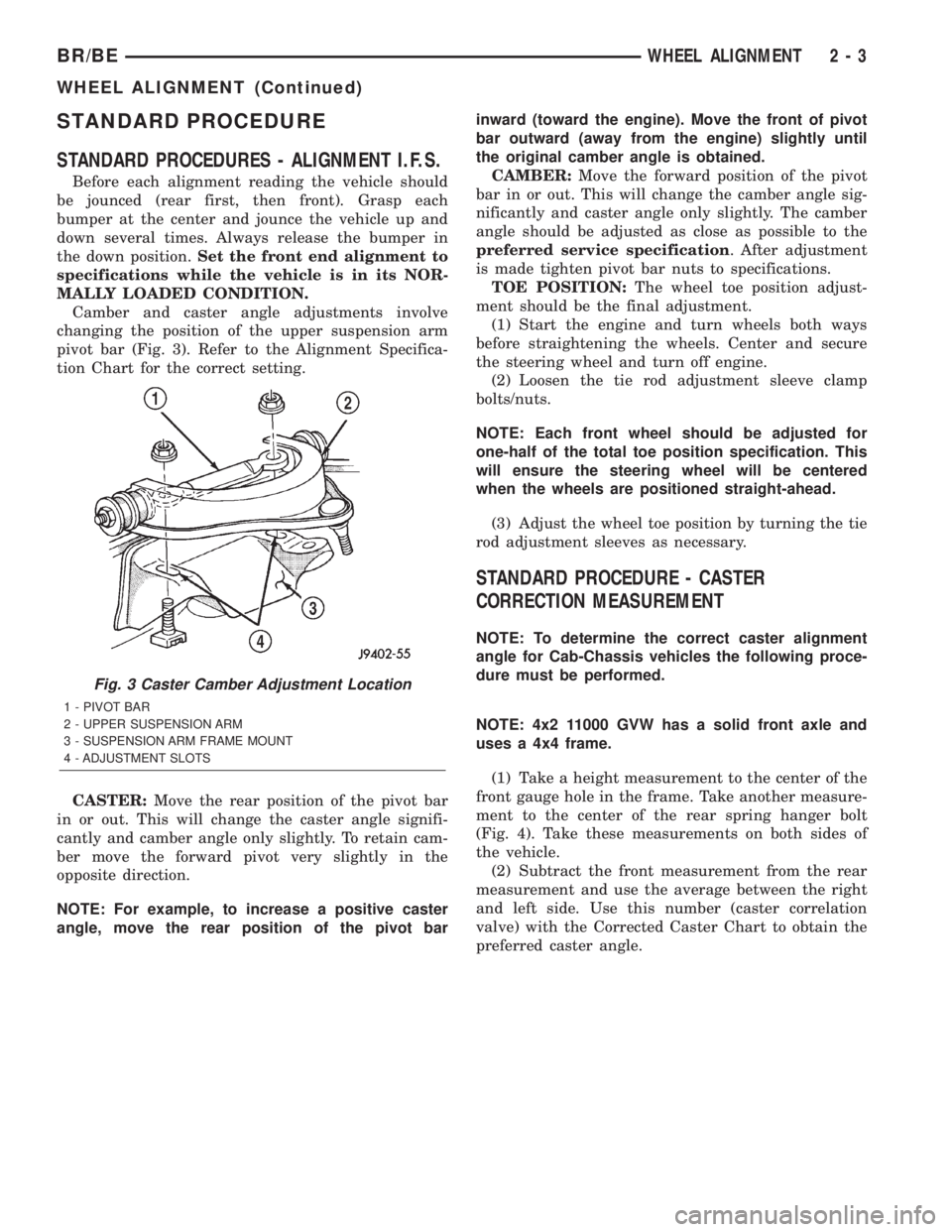

Camber and caster angle adjustments involve

changing the position of the upper suspension arm

pivot bar (Fig. 3). Refer to the Alignment Specifica-

tion Chart for the correct setting.

CASTER:Move the rear position of the pivot bar

in or out. This will change the caster angle signifi-

cantly and camber angle only slightly. To retain cam-

ber move the forward pivot very slightly in the

opposite direction.

NOTE: For example, to increase a positive caster

angle, move the rear position of the pivot barinward (toward the engine). Move the front of pivot

bar outward (away from the engine) slightly until

the original camber angle is obtained.

CAMBER:Move the forward position of the pivot

bar in or out. This will change the camber angle sig-

nificantly and caster angle only slightly. The camber

angle should be adjusted as close as possible to the

preferred service specification. After adjustment

is made tighten pivot bar nuts to specifications.

TOE POSITION:The wheel toe position adjust-

ment should be the final adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Center and secure

the steering wheel and turn off engine.

(2) Loosen the tie rod adjustment sleeve clamp

bolts/nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the tie

rod adjustment sleeves as necessary.

STANDARD PROCEDURE - CASTER

CORRECTION MEASUREMENT

NOTE: To determine the correct caster alignment

angle for Cab-Chassis vehicles the following proce-

dure must be performed.

NOTE: 4x2 11000 GVW has a solid front axle and

uses a 4x4 frame.

(1) Take a height measurement to the center of the

front gauge hole in the frame. Take another measure-

ment to the center of the rear spring hanger bolt

(Fig. 4). Take these measurements on both sides of

the vehicle.

(2) Subtract the front measurement from the rear

measurement and use the average between the right

and left side. Use this number (caster correlation

valve) with the Corrected Caster Chart to obtain the

preferred caster angle.

Fig. 3 Caster Camber Adjustment Location

1 - PIVOT BAR

2 - UPPER SUSPENSION ARM

3 - SUSPENSION ARM FRAME MOUNT

4 - ADJUSTMENT SLOTS

BR/BEWHEEL ALIGNMENT 2 - 3

WHEEL ALIGNMENT (Continued)

Page 30 of 2255

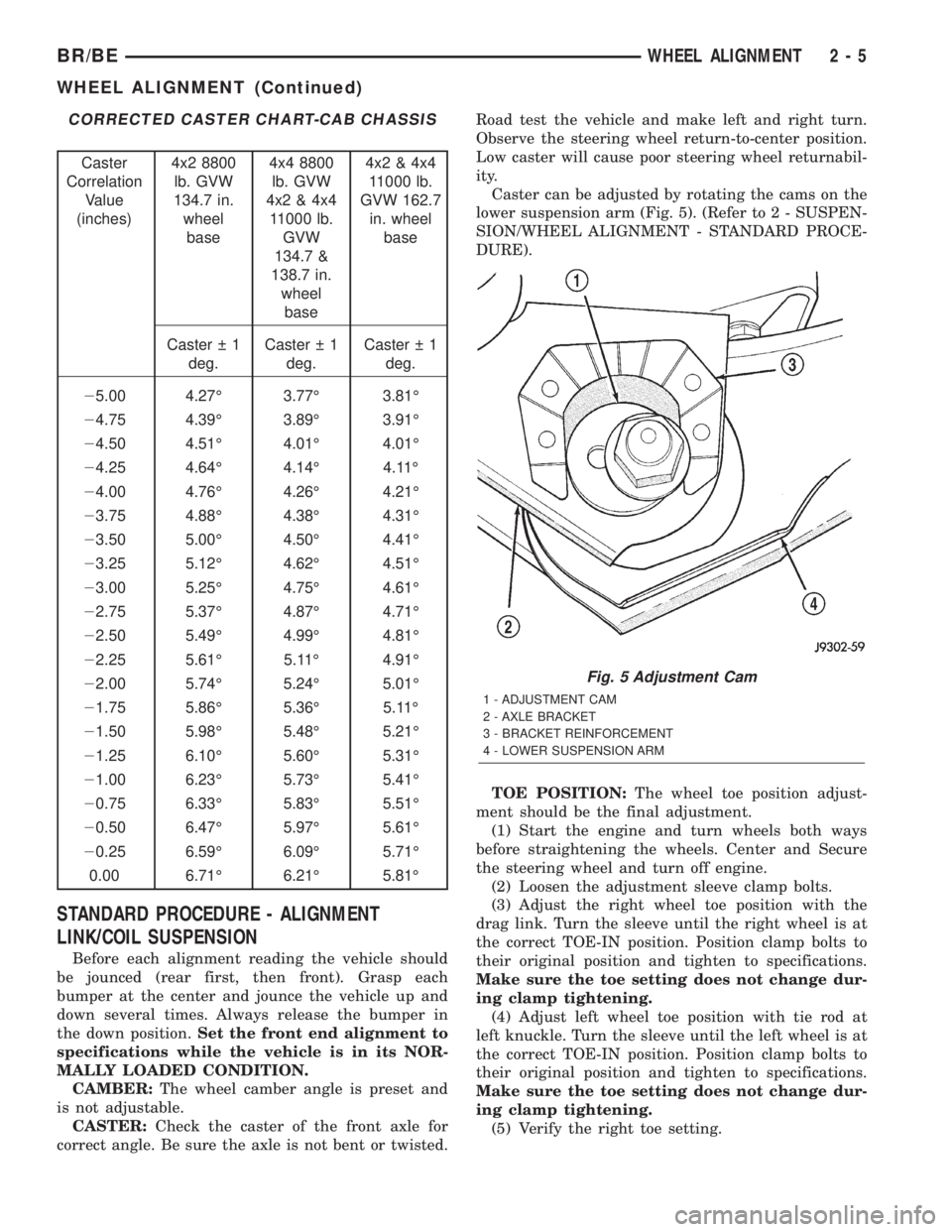

CORRECTED CASTER CHART-CAB CHASSIS

Caster

Correlation

Value

(inches)4x2 8800

lb. GVW

134.7 in.

wheel

base4x4 8800

lb. GVW

4x2 & 4x4

11000 lb.

GVW

134.7 &

138.7 in.

wheel

base4x2 & 4x4

11000 lb.

GVW 162.7

in. wheel

base

Caster 1

deg.Caster 1

deg.Caster 1

deg.

25.00 4.27É 3.77É 3.81É

24.75 4.39É 3.89É 3.91É

24.50 4.51É 4.01É 4.01É

24.25 4.64É 4.14É 4.11É

24.00 4.76É 4.26É 4.21É

23.75 4.88É 4.38É 4.31É

23.50 5.00É 4.50É 4.41É

23.25 5.12É 4.62É 4.51É

23.00 5.25É 4.75É 4.61É

22.75 5.37É 4.87É 4.71É

22.50 5.49É 4.99É 4.81É

22.25 5.61É 5.11É 4.91É

22.00 5.74É 5.24É 5.01É

21.75 5.86É 5.36É 5.11É

21.50 5.98É 5.48É 5.21É

21.25 6.10É 5.60É 5.31É

21.00 6.23É 5.73É 5.41É

20.75 6.33É 5.83É 5.51É

20.50 6.47É 5.97É 5.61É

20.25 6.59É 6.09É 5.71É

0.00 6.71É 6.21É 5.81É

STANDARD PROCEDURE - ALIGNMENT

LINK/COIL SUSPENSION

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down several times. Always release the bumper in

the down position.Set the front end alignment to

specifications while the vehicle is in its NOR-

MALLY LOADED CONDITION.

CAMBER:The wheel camber angle is preset and

is not adjustable.

CASTER:Check the caster of the front axle for

correct angle. Be sure the axle is not bent or twisted.Road test the vehicle and make left and right turn.

Observe the steering wheel return-to-center position.

Low caster will cause poor steering wheel returnabil-

ity.

Caster can be adjusted by rotating the cams on the

lower suspension arm (Fig. 5). (Refer to 2 - SUSPEN-

SION/WHEEL ALIGNMENT - STANDARD PROCE-

DURE).

TOE POSITION:The wheel toe position adjust-

ment should be the final adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Center and Secure

the steering wheel and turn off engine.

(2) Loosen the adjustment sleeve clamp bolts.

(3) Adjust the right wheel toe position with the

drag link. Turn the sleeve until the right wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(4) Adjust left wheel toe position with tie rod at

left knuckle. Turn the sleeve until the left wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(5) Verify the right toe setting.

Fig. 5 Adjustment Cam

1 - ADJUSTMENT CAM

2 - AXLE BRACKET

3 - BRACKET REINFORCEMENT

4 - LOWER SUSPENSION ARM

BR/BEWHEEL ALIGNMENT 2 - 5

WHEEL ALIGNMENT (Continued)

Page 73 of 2255

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheels and tires.

(3) Remove brake calipers and rotors. Refer to 5

Brakes for procedures.

(4) Remove ABS wheel speed sensors, if equipped.

Refer to 5 Brakes for procedures.

(5) Disconnect axle vent hose.

(6) Disconnect vacuum hose and electrical connec-

tor at disconnect housing.

(7) Remove front propeller shaft.

(8) Disconnect stabilizer bar links at the axle

brackets.

(9) Disconnect shock absorbers from axle brackets.

(10) Disconnect track bar from the axle bracket.

(11) Disconnect tie rod and drag link from the

steering knuckles.

(12) Position suitable lifting device under the axle

assembly.(13) Secure axle to lifting device.

(14) Mark suspension alignment cams for installa-

tion reference.

(15) Disconnect upper and lower suspension arms

from the axle bracket.

(16) Lower the axle. The coil springs will drop

with the axle.

(17) Remove the coil springs from the axle bracket.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the weight of the

vehicle on the suspension, at normal height. If

springs are not at their normal ride position, vehicle

ride comfort could be affected and premature bush-

ing wear may occur. Rubber bushings must never

be lubricated.

(1) Support the axle on a suitable lifting device.

3 - 18 FRONT AXLE - 248FBIBR/BE

FRONT AXLE - 248FBI (Continued)

Page 74 of 2255

(2) Secure axle to lifting device.

(3) Position the axle under the vehicle.

(4) Install springs, retainer clip and bolts.

(5) Raise axle and align it with the spring pads.

(6) Position upper and lower suspension arms in

the axle brackets. Install bolts, nuts and align the

suspension alignment cams to the reference marks.

Do not tighten at this time.

(7) Connect track bar to the axle bracket and

install the bolt. Do not tighten at this time.

(8) Install shock absorber and tighten bolts to 121

N´m (89 ft. lbs.).

(9) Install stabilizer bar link to the axle bracket.

Tighten the nut to 37 N´m (27 ft. lbs.).

(10) Install drag link and tie rod to the steering

knuckles and tighten the nuts to 88 N´m (65 ft. lbs.).

(11) Install ABS wheel speed sensors, if equipped.

Refer to 5 Brakes for procedures.

(12) Install rotors and brake calipers, refer to 5

Brakes for procedures.

(13) Connect the vent hose to the tube fitting.

(14) Connect vacuum hose and electrical connector

to disconnect housing.

(15) Install front propeller shaft.

(16) Check and add differential lubricant, if neces-

sary. Refer to Lubricant Specifications for lubricant

requirements.

(17) Install wheel and tire assemblies.

(18) Remove supports and lower the vehicle.

(19) Tighten upper suspension arm nuts at axle to

121 N´m (89 ft. lbs.). Tighten upper suspension arm

nuts at frame to 84 N´m (62 ft. lbs.).

(20) Tighten lower suspension arm nuts at axle to

84 N´m (62 ft. lbs.). Tighten the lower suspension

arm nuts at frame to 119 N´m (88 ft. lbs.).

(21) Tighten track bar bolt at the axle bracket to

176 N´m (130 ft. lbs.).

(22) Check front wheel alignment.

ADJUSTMENTS

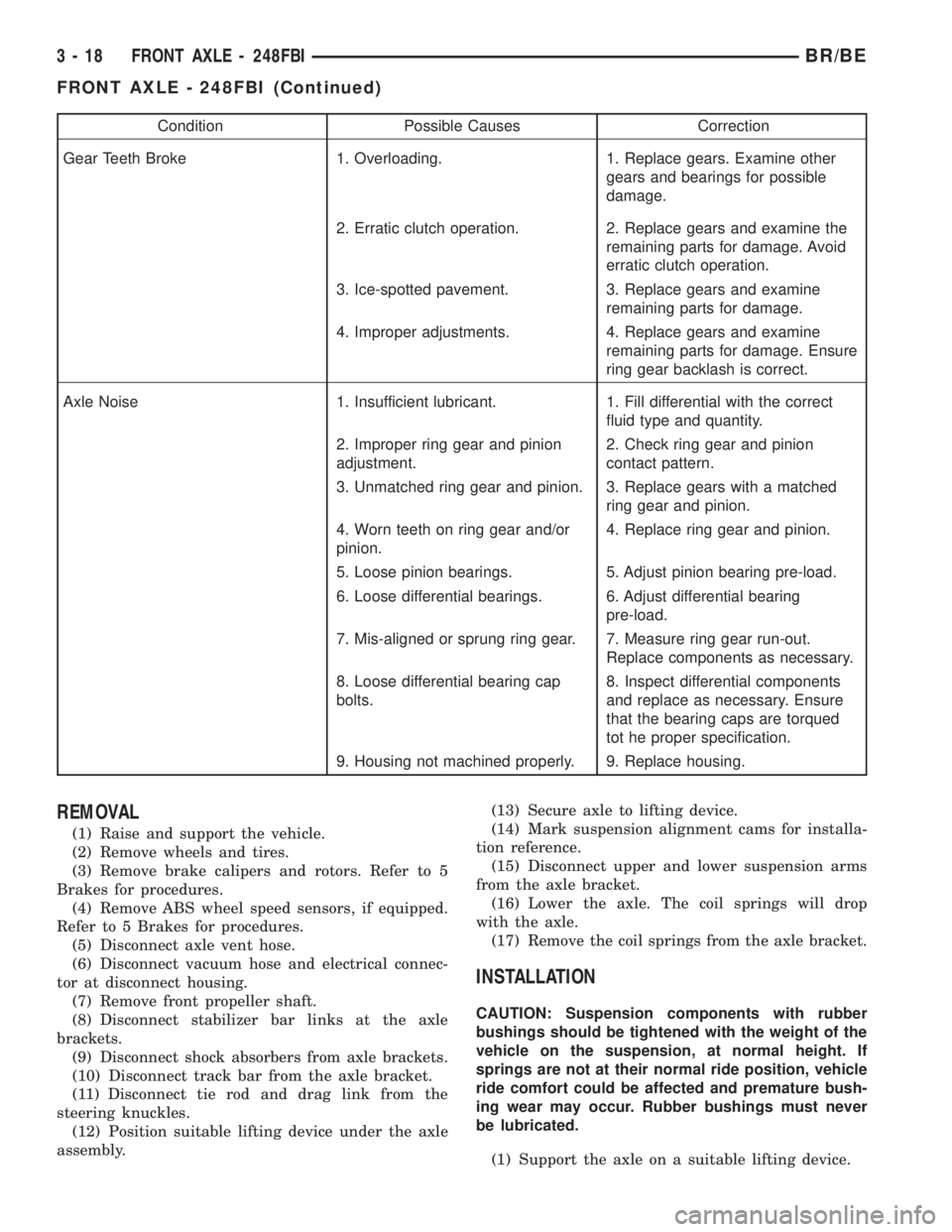

Ring and pinion gears are supplied as matched sets

only. The identifying numbers for the ring and pinion

gear are etched into the face of each gear (Fig. 3). A

plus (+) number, minus (±) number or zero (0) is etched

into the face of the pinion gear. This number is the

amount (in thousandths of an inch) the depth varies

from the standard depth setting of a pinion etched with

a (0). The standard setting from the center line of the

ring gear to the back face of the pinion is 127 mm (5.00

in.). The standard depth provides the best gear tooth

contact pattern. Refer to Backlash and Contact Pattern

in this section for additional information.

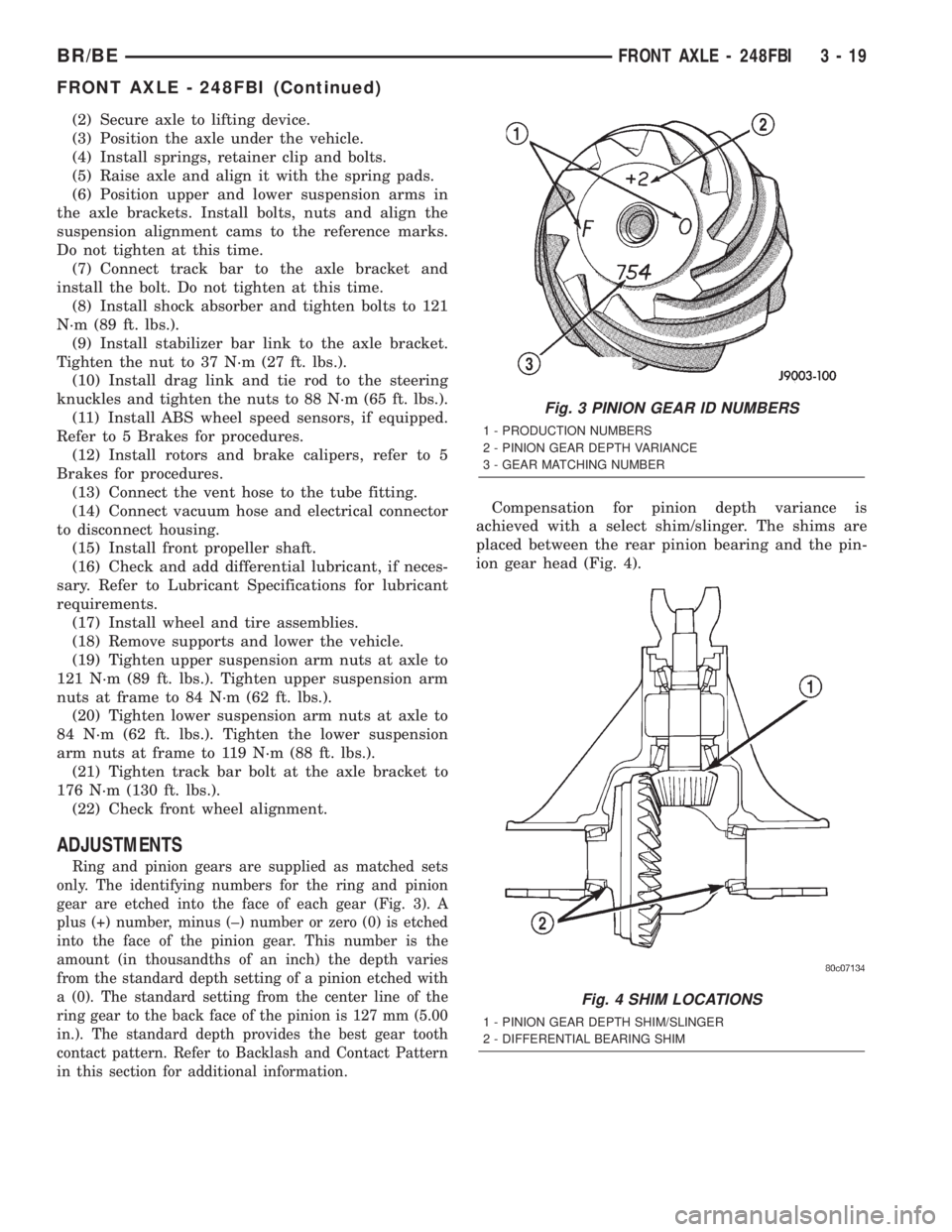

Compensation for pinion depth variance is

achieved with a select shim/slinger. The shims are

placed between the rear pinion bearing and the pin-

ion gear head (Fig. 4).

Fig. 3 PINION GEAR ID NUMBERS

1 - PRODUCTION NUMBERS

2 - PINION GEAR DEPTH VARIANCE

3 - GEAR MATCHING NUMBER

Fig. 4 SHIM LOCATIONS

1 - PINION GEAR DEPTH SHIM/SLINGER

2 - DIFFERENTIAL BEARING SHIM

BR/BEFRONT AXLE - 248FBI 3 - 19

FRONT AXLE - 248FBI (Continued)

Page 194 of 2255

CAUTION: Never use gasoline, kerosene, alcohol,

motor oil, transmission fluid, or any fluid containing

mineral oil to clean the system components. These

fluids damage rubber cups and seals. Use only

fresh brake fluid or Mopar brake cleaner to clean or

flush brake system components. These are the only

cleaning materials recommended. If system contam-

ination is suspected, check the fluid for dirt, discol-

oration, or separation into distinct layers. Also

check the reservoir cap seal for distortion. Drain

and flush the system with new brake fluid if con-

tamination is suspected.

CAUTION: Use Mopar brake fluid, or an equivalent

quality fluid meeting SAE/DOT standards J1703 and

DOT 3. Brake fluid must be clean and free of con-

taminants. Use fresh fluid from sealed containers

only to ensure proper antilock component opera-

tion.

CAUTION: Use Mopar multi-mileage or high temper-

ature grease to lubricate caliper slide surfaces,

drum brake pivot pins, and shoe contact points on

the backing plates. Use multi-mileage grease or GE

661 or Dow 111 silicone grease on caliper slide pins

to ensure proper operation.

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake shoes,

calipers, wheel cylinders, brake drums, rotors, brake

lines, master cylinder, booster, and parking brake

components.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, wheel cylinders, brake

lines, and master cylinder.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals

and cups will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and pedal. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper/wheel cylinder. If leakage is severe, fluid will

be evident at or around the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action is

to inspect and replace all worn component and make

the proper adjustments.

BR/BEBRAKES - BASE 5 - 5

HYDRAULIC/MECHANICAL (Continued)

Page 1412 of 2255

BINDING AND STICKING

CONDITION POSSIBLE CAUSE CORRECTION

DIFFICULT TO TURN WHEEL

STICKS OR BINDS1. Low fluid level. 1. Fill to proper level.

2. Tire pressure. 2. Adjust tire pressure.

3. Steering components (ball

joints/tie rod ends).3. Lube, inspect and repair as

necessary.

4. Loose belt. 4. Adjust or replace.

5. Low pump pressure. 5. Pressure test and replace if

necessary.

6. Column shaft coupler binding. 6. Replace coupler.

7. Steering gear worn or out of

adjustment.7. Repair or replace gear.

INSUFFICIENT ASST. OR POOR RETURN TO CENTER

CONDITION POSSIBLE CAUSE CORRECTION

HARD TURNING OR MOMENTARY

INCREASE IN TURNING EFFORT1. Tire pressure. 1. Adjust tire pressure.

2. Low fluid level. 2. Fill to proper level.

3. Loose belt. 3. Adjust or replace.

4. Lack of lubrication. 4. Inspect and lubricate steering and

suspension compnents.

5. Low pump pressure. 5. Pressure test and repair as

necessary.

6. Internal gear leak. 6. Pressure and flow test, and repair

as necessary.

STEERING WHEEL DOES NOT

WANT TO RETURN TO CENTER

POSITION1. Tire pressure. 1. Adjust tire pressure.

2. Wheel alignment. 2. Align front end.

3. Lack of lubrication. 3. Inspect and lubricate steering and

suspension compnents.

4. High friction in steering gear. 4. Test and adjust gear as

necessary.

BR/BESTEERING 19 - 3

STEERING (Continued)

Page 1413 of 2255

LOOSE STEERING AND VEHICLE LEAD

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE PLAY IN STEERING

WHEEL1. Worn or loose suspension or

steering components.1. Inspect and repair as necessary.

2. Worn or loose wheel bearings. 2. Inspect and repair or adjust

bearings.

3. Steering gear mounting. 3. Tighten gear mounting bolts to

specification.

4. Gear out of adjustment. 4. Adjust gear to specification.

5. Worn or loose steering coupler. 5. Inspect and replace as

necessary.

VEHICLE PULLS OR LEADS TO

ONE SIDE.1. Tire Pressure. 1. Adjust tire pressure.

2. Radial tire lead. 2. Rotate tires.

3. Brakes dragging. 3. Repair as necessary.

4. Wheel alignment. 4. Align front end.

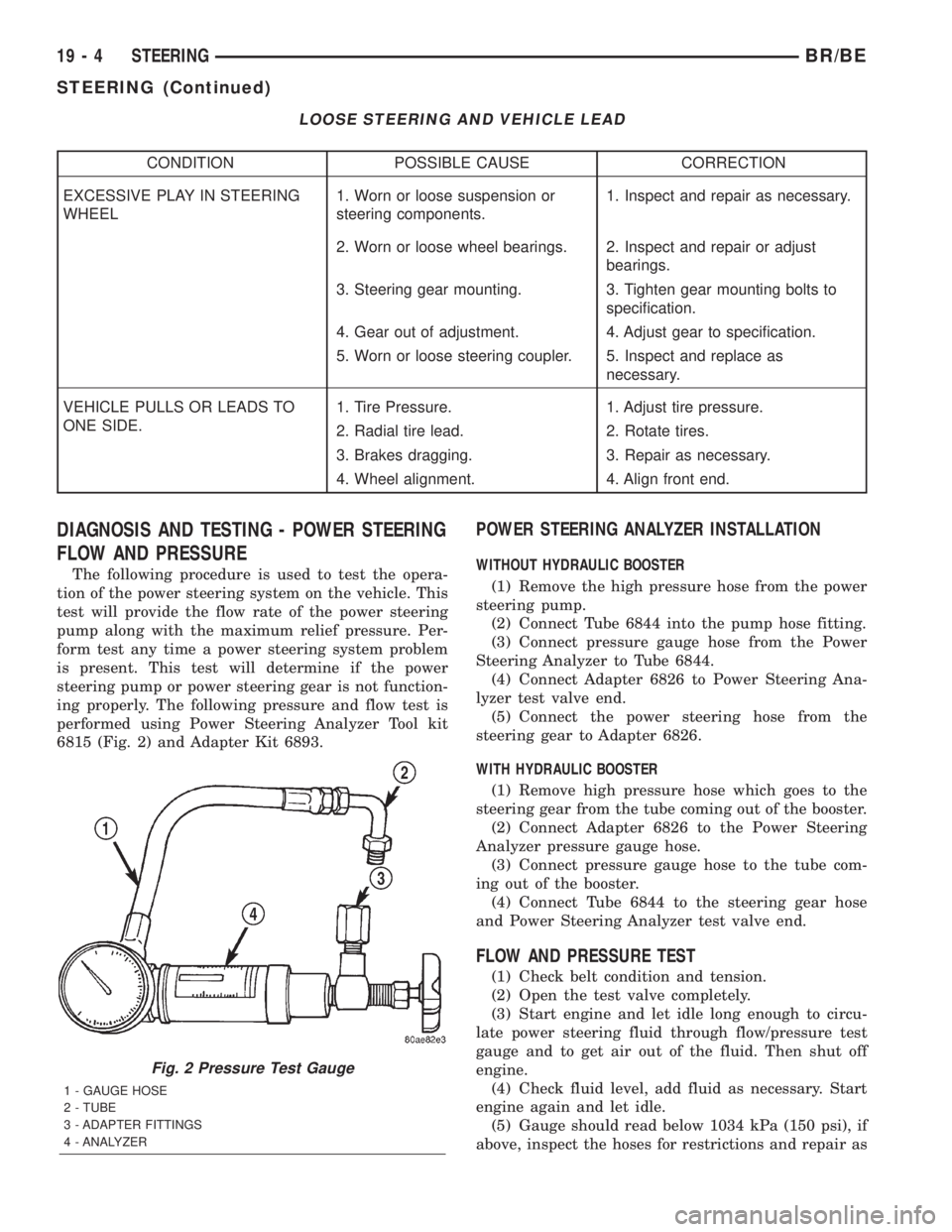

DIAGNOSIS AND TESTING - POWER STEERING

FLOW AND PRESSURE

The following procedure is used to test the opera-

tion of the power steering system on the vehicle. This

test will provide the flow rate of the power steering

pump along with the maximum relief pressure. Per-

form test any time a power steering system problem

is present. This test will determine if the power

steering pump or power steering gear is not function-

ing properly. The following pressure and flow test is

performed using Power Steering Analyzer Tool kit

6815 (Fig. 2) and Adapter Kit 6893.

POWER STEERING ANALYZER INSTALLATION

WITHOUT HYDRAULIC BOOSTER

(1) Remove the high pressure hose from the power

steering pump.

(2) Connect Tube 6844 into the pump hose fitting.

(3) Connect pressure gauge hose from the Power

Steering Analyzer to Tube 6844.

(4) Connect Adapter 6826 to Power Steering Ana-

lyzer test valve end.

(5) Connect the power steering hose from the

steering gear to Adapter 6826.

WITH HYDRAULIC BOOSTER

(1) Remove high pressure hose which goes to the

steering gear from the tube coming out of the booster.

(2) Connect Adapter 6826 to the Power Steering

Analyzer pressure gauge hose.

(3) Connect pressure gauge hose to the tube com-

ing out of the booster.

(4) Connect Tube 6844 to the steering gear hose

and Power Steering Analyzer test valve end.

FLOW AND PRESSURE TEST

(1) Check belt condition and tension.

(2) Open the test valve completely.

(3) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

gauge and to get air out of the fluid. Then shut off

engine.

(4) Check fluid level, add fluid as necessary. Start

engine again and let idle.

(5) Gauge should read below 1034 kPa (150 psi), if

above, inspect the hoses for restrictions and repair as

Fig. 2 Pressure Test Gauge

1 - GAUGE HOSE

2 - TUBE

3 - ADAPTER FITTINGS

4 - ANALYZER

19 - 4 STEERINGBR/BE

STEERING (Continued)

Page 1418 of 2255

(3) Remove the shipping lock pin if necessary.

(4) Install the column through the floor pan.

(5) Position the column bracket breakaway cap-

sules on the mounting studs. Install, butloose

assemblethe two upper bracket nuts.

(6) With the front wheels in the straight-ahead

position. Align steering column shaft to the coupler.

Install anewpinch bolt and tighten to 49 N´m (36

ft. lbs.).

(7) Clip the wiring harness on the steering column.

Connect the multi- function switch wiring and

tighten with 7mm socket.

(8) Install the upper fixed shroud.

(9) Be sure both breakaway capsules are fully

seated in the slots in the column support bracket.

Pull the column rearward then tighten upper bracket

nuts to 12 N´m (105 in. lbs.).

(10) Tighten the toe plate to floor pan attaching

nuts to 22.5 N´m (200 in. lbs.).

(11) Install the wiring connections to the column.

Install the lower fixed shroud.

(12) Column shift vehicles, install the PRNDL

driver cable. Place shifter in Park position. If indica-tor needs adjusting, turn thumb screw on cable

retainer to adjust cable.

(13) Install the lock housing shrouds. Install the

tilt lever (if equipped).

(14) Install the knee blocker and steering column

opening cover, (Refer to 23 - BODY/INSTRUMENT

PANEL/STEERING COLUMN OPENING COVER -

INSTALLATION).

(15) Install steering wheel and tighten nut to 61

N´m (45 ft. lbs.), (Refer to 19 - STEERING/COL-

UMN/STEERING WHEEL - INSTALLATION).

(16) Install the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(17) Column shift vehicles, connect the shift link

rod to the transmission shift lever. Use multi-purpose

lubricant, or an equivalent product, to aid the instal-

lation.

(18) Install the battery ground (negative) cable.

(19) Verify operation of the automatic transmission

shift linkage and adjust as necessary, (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

44RE/GEAR SHIFT CABLE - ADJUSTMENTS).

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Wheel

Nut61 45 Ð

Steering Coupler

Bolt49 36 Ð

Steering Column

Upper Bracket12 Ð 105

Steering Column

Toe Plate23 Ð 200

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the left side of the

steering column. It closes a path to ground for the

Central Timer Module (CTM) when the ignition key

is inserted in the ignition lock cylinder and the

driver door ajar switch is closed (driver door is open).

The key-in ignition switch opens the ground path

when the key is removed from the ignition lock cyl-

inder. The ground path is also opened when the

driver door ajar switch is open (driver door is closed).The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced, (Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

DIAGNOSIS AND TESTING - IGNITION SWITCH

AND KEY LOCK CYLINDER

ELECTRICAL DIAGNOSIS

For ignition switch electrical schematics, refer to

Ignition Switch in the appropriate section of Electri-

cal Wiring Diagrams.

BR/BECOLUMN 19 - 9

COLUMN (Continued)