service reset DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 347 of 2255

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include an AM/FM/cassette (RAS sales code),

an AM/FM/CD/3-band graphic equalizer (RBR sales

code), or an AM/FM/CD/cassette/3-band graphic

equalizer (RAZ sales code). The factory-installed RAZ

sales code radio receivers can also communicate on

the Chrysler Collision Detection (CCD) data bus net-

work through a separate two-way wire harness con-

nector. All factory-installed receivers are stereo

Electronically Tuned Radios (ETR) and include an

electronic digital clock function.

These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed when the vehicle is

shipped from the factory. This fuse feeds various

accessories that require battery current when the

ignition switch is in the Off position, including the

clock. The IOD fuse is removed to prevent battery

discharge during vehicle storage.

When removing or installing the IOD fuse, it is

important that the ignition switch be in the Off posi-

tion. Failure to place the ignition switch in the Off

position can cause the radio display to become scram-

bled when the IOD fuse is removed and replaced.

Removing and replacing the IOD fuse again, with the

ignition switch in the Off position, will correct the

scrambled display condition.

The IOD fuse should be checked if the radio or

clock displays are inoperative. The IOD fuse is

located in the junction block. Refer to the fuse layout

label on the back of the instrument panel fuse access

panel for IOD fuse identification and location.

OPERATION

The radio receiver operates on fused battery cur-

rent that is available only when the ignition switch is

in the On or Accessory positions. The electronic digi-

tal clock function of the radio operates on fused bat-

tery current supplied through the IOD fuse,

regardless of the ignition switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, see the owner's

manual in the vehicle glove box. For complete circuit

diagrams, refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - RADIO

If the vehicle is equipped with the optional remote

radio switches located on the steering wheel and the

problem being diagnosed is related to one of the

symptoms listed below, be certain to check the

remote radio switches and circuits. Refer to Audio,

Remote Radio Switch prior to attempting radio diag-

nosis or repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CAUTION: The speaker output of the radio receiver

is a ªfloating groundº system. Do not allow any

speaker lead to short to ground, as damage to the

radio receiver may result.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the Power Dis-

tribution Center (PDC) as required.

(3) Check the fused ignition switch output (acc/

run) fuse in the junction block. If OK, go to Step 4. If

not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (acc/run) fuse in the junction block. If OK, go

to Step 5. If not OK, repair the open fused ignition

8A - 10 AUDIOBR/BE

Page 352 of 2255

Electrical, Body Control/Central Timer Module for

more information on this component.

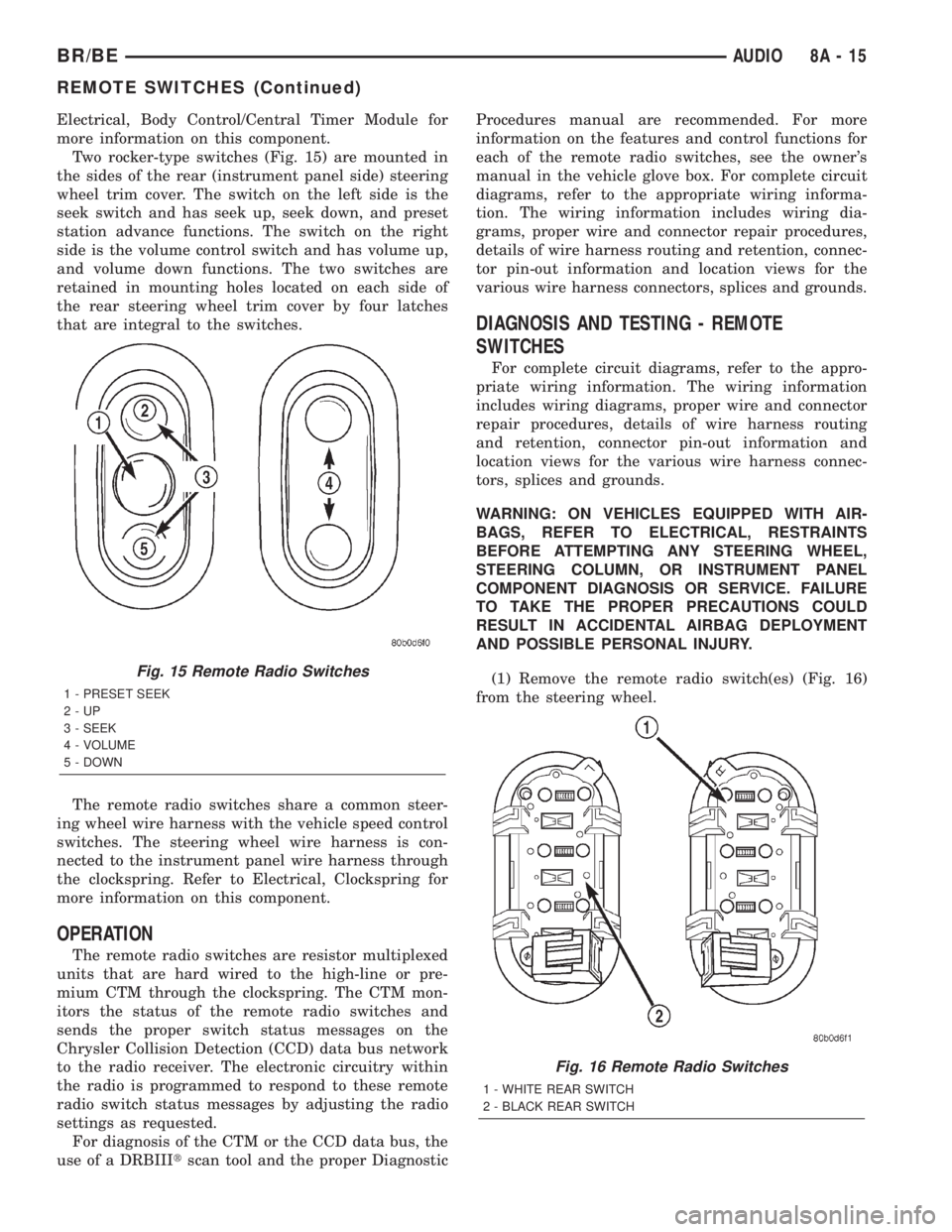

Two rocker-type switches (Fig. 15) are mounted in

the sides of the rear (instrument panel side) steering

wheel trim cover. The switch on the left side is the

seek switch and has seek up, seek down, and preset

station advance functions. The switch on the right

side is the volume control switch and has volume up,

and volume down functions. The two switches are

retained in mounting holes located on each side of

the rear steering wheel trim cover by four latches

that are integral to the switches.

The remote radio switches share a common steer-

ing wheel wire harness with the vehicle speed control

switches. The steering wheel wire harness is con-

nected to the instrument panel wire harness through

the clockspring. Refer to Electrical, Clockspring for

more information on this component.

OPERATION

The remote radio switches are resistor multiplexed

units that are hard wired to the high-line or pre-

mium CTM through the clockspring. The CTM mon-

itors the status of the remote radio switches and

sends the proper switch status messages on the

Chrysler Collision Detection (CCD) data bus network

to the radio receiver. The electronic circuitry within

the radio is programmed to respond to these remote

radio switch status messages by adjusting the radio

settings as requested.

For diagnosis of the CTM or the CCD data bus, the

use of a DRBIIItscan tool and the proper DiagnosticProcedures manual are recommended. For more

information on the features and control functions for

each of the remote radio switches, see the owner's

manual in the vehicle glove box. For complete circuit

diagrams, refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Remove the remote radio switch(es) (Fig. 16)

from the steering wheel.

Fig. 15 Remote Radio Switches

1 - PRESET SEEK

2-UP

3 - SEEK

4 - VOLUME

5 - DOWN

Fig. 16 Remote Radio Switches

1 - WHITE REAR SWITCH

2 - BLACK REAR SWITCH

BR/BEAUDIO 8A - 15

REMOTE SWITCHES (Continued)

Page 369 of 2255

HARD WIRED OUTPUTS

The hard wired outputs of the CTM include the fol-

lowing:

²CCD bus± - high-line/premium version only

²CCD bus+ - high-line/premium version only

²Courtesy lamp switch output - high-line/pre-

mium version only

²Door lock driver - high-line/premium version

only

²Door unlock driver - high-line/premium version

only

²Headlamp relay control - high-line/premium ver-

sion only

²Heated seat relay control - premium version

only

²Horn relay control - high-line/premium version

only

²VTSS indicator driver - high-line/premium ver-

sion only

²Wiper motor relay control

MESSAGING

The high-line/premium CTM uses the following

messages received from other electronic modules over

the CCD data bus:

²Airbag Deploy (ACM)

²Charging System Failure (PCM)

²Engine RPM (PCM)

²System Voltage (PCM)

²Vehicle Speed (PCM)

²Voltage Fault (PCM)

The high-line/premium CTM provides the following

messages to other electronic modules over the CCD

data bus:

²Engine Enable (PCM)

²Radio Seek Up (Radio)

²Radio Seek Down (Radio)

²Radio Volume Up (Radio)

²Radio Volume Down (Radio)

²Preset Scan (Radio)

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE

The hard wired inputs to and outputs from the

Central Timer Module (CTM) may be diagnosed and

tested using conventional diagnostic tools and meth-

ods. Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the high-line/pre-

mium CTM. In order to obtain conclusive testing of

the high-line/premium CTM, the Chrysler CollisionDetection (CCD) data bus network and all of the elec-

tronic modules that provide inputs to or receive out-

puts from the CTM must also be checked. The most

reliable, efficient, and accurate means to diagnose

the high-line/premium CTM, the CCD data bus net-

work, and the electronic modules that provide inputs

to or receive outputs from the high-line/premium

CTM requires the use of a DRBIIItscan tool and the

appropriate diagnostic information. The DRBIIIt

scan tool can provide confirmation that the CCD data

bus network is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages over the CCD data bus, and that the CTM is

receiving the proper hard wired inputs and respond-

ing with the proper hard wired outputs needed to

perform its many functions.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of the high-line or premium

versions of the Central Timer Module (CTM). The

most reliable, efficient, and accurate means to diag-

nose the high-line or premium CTM requires the

use of a DRBIIITscan tool and the appropriate diag-

nostic information.

(1) Check the fused B(+) fuse (Fuse 13 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 13 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) For a base version CTM, check the fused igni-

tion switch output (st-run) fuse (Fuse 11 - 10 ampere)

in the JB. For a high-line/premium version CTM,

check the fused ignition switch output (run-acc) fuse

(Fuse6-25ampere) in the JB. If OK, go to Step 4. If

not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

8E - 4 ELECTRONIC CONTROL MODULESBR/BE

CENTRAL TIMER MODULE (Continued)

Page 481 of 2255

INSTRUMENT CLUSTER

DESCRIPTION

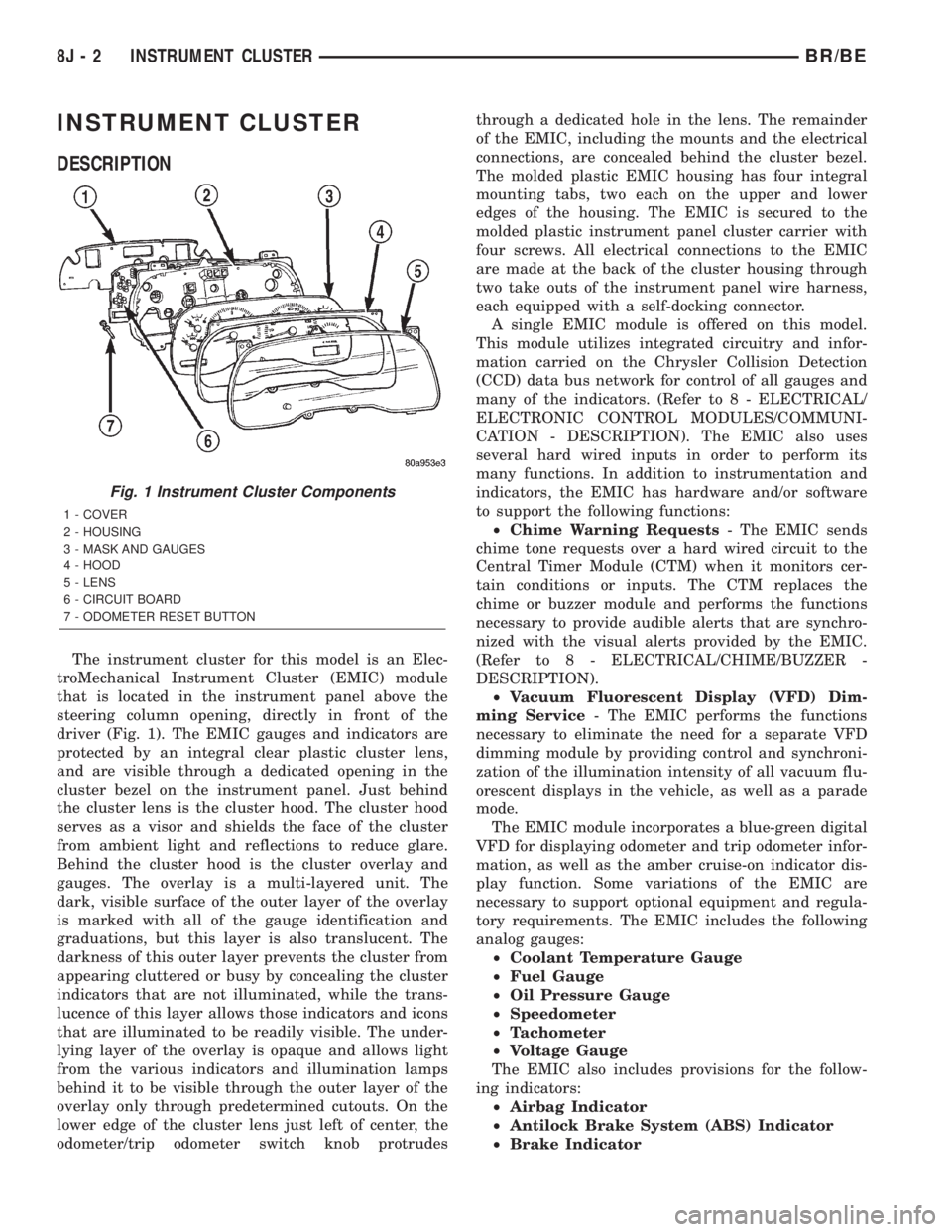

The instrument cluster for this model is an Elec-

troMechanical Instrument Cluster (EMIC) module

that is located in the instrument panel above the

steering column opening, directly in front of the

driver (Fig. 1). The EMIC gauges and indicators are

protected by an integral clear plastic cluster lens,

and are visible through a dedicated opening in the

cluster bezel on the instrument panel. Just behind

the cluster lens is the cluster hood. The cluster hood

serves as a visor and shields the face of the cluster

from ambient light and reflections to reduce glare.

Behind the cluster hood is the cluster overlay and

gauges. The overlay is a multi-layered unit. The

dark, visible surface of the outer layer of the overlay

is marked with all of the gauge identification and

graduations, but this layer is also translucent. The

darkness of this outer layer prevents the cluster from

appearing cluttered or busy by concealing the cluster

indicators that are not illuminated, while the trans-

lucence of this layer allows those indicators and icons

that are illuminated to be readily visible. The under-

lying layer of the overlay is opaque and allows light

from the various indicators and illumination lamps

behind it to be visible through the outer layer of the

overlay only through predetermined cutouts. On the

lower edge of the cluster lens just left of center, the

odometer/trip odometer switch knob protrudesthrough a dedicated hole in the lens. The remainder

of the EMIC, including the mounts and the electrical

connections, are concealed behind the cluster bezel.

The molded plastic EMIC housing has four integral

mounting tabs, two each on the upper and lower

edges of the housing. The EMIC is secured to the

molded plastic instrument panel cluster carrier with

four screws. All electrical connections to the EMIC

are made at the back of the cluster housing through

two take outs of the instrument panel wire harness,

each equipped with a self-docking connector.

A single EMIC module is offered on this model.

This module utilizes integrated circuitry and infor-

mation carried on the Chrysler Collision Detection

(CCD) data bus network for control of all gauges and

many of the indicators. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/COMMUNI-

CATION - DESCRIPTION). The EMIC also uses

several hard wired inputs in order to perform its

many functions. In addition to instrumentation and

indicators, the EMIC has hardware and/or software

to support the following functions:

²Chime Warning Requests- The EMIC sends

chime tone requests over a hard wired circuit to the

Central Timer Module (CTM) when it monitors cer-

tain conditions or inputs. The CTM replaces the

chime or buzzer module and performs the functions

necessary to provide audible alerts that are synchro-

nized with the visual alerts provided by the EMIC.

(Refer to 8 - ELECTRICAL/CHIME/BUZZER -

DESCRIPTION).

²Vacuum Fluorescent Display (VFD) Dim-

ming Service- The EMIC performs the functions

necessary to eliminate the need for a separate VFD

dimming module by providing control and synchroni-

zation of the illumination intensity of all vacuum flu-

orescent displays in the vehicle, as well as a parade

mode.

The EMIC module incorporates a blue-green digital

VFD for displaying odometer and trip odometer infor-

mation, as well as the amber cruise-on indicator dis-

play function. Some variations of the EMIC are

necessary to support optional equipment and regula-

tory requirements. The EMIC includes the following

analog gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

The EMIC also includes provisions for the follow-

ing indicators:

²Airbag Indicator

²Antilock Brake System (ABS) Indicator

²Brake Indicator

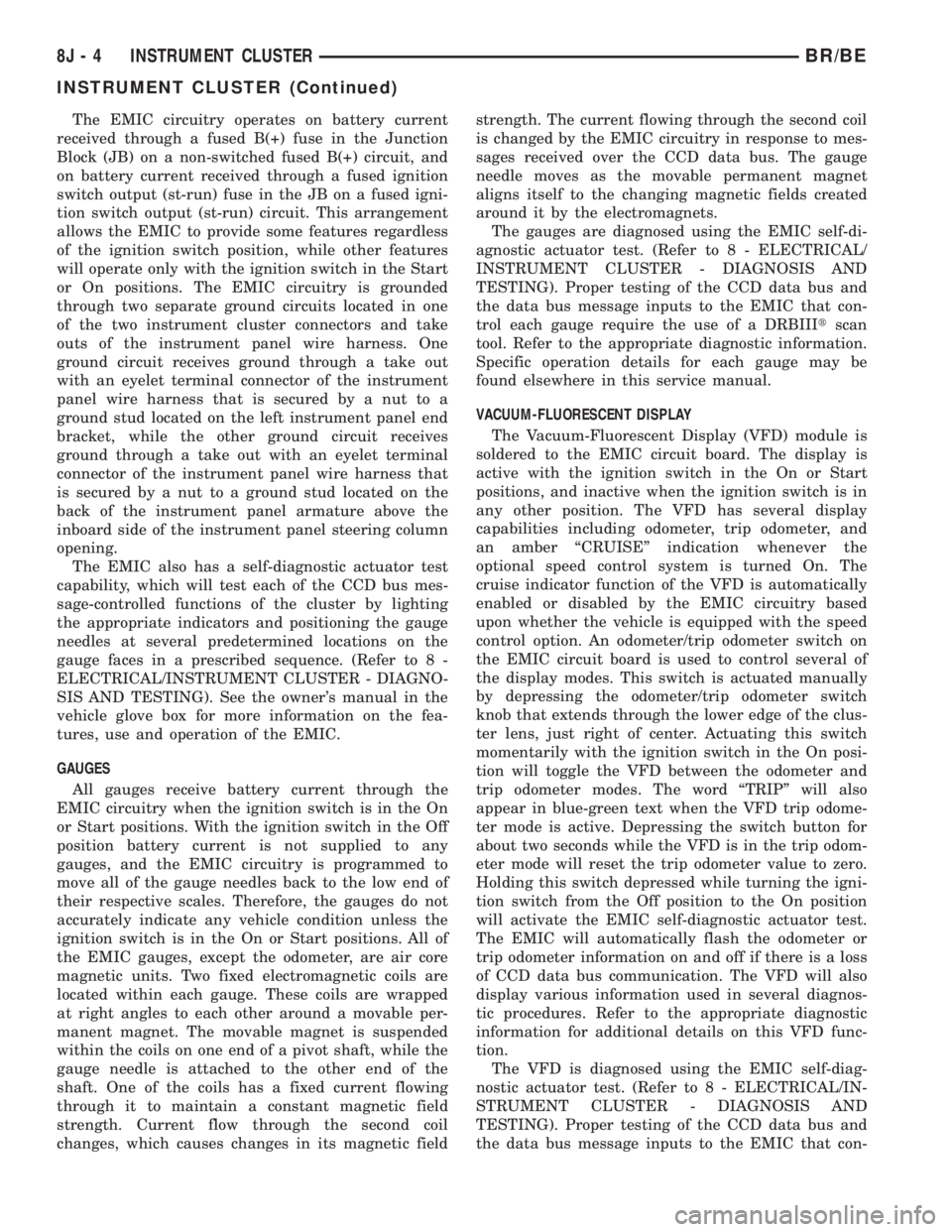

Fig. 1 Instrument Cluster Components

1 - COVER

2 - HOUSING

3 - MASK AND GAUGES

4 - HOOD

5 - LENS

6 - CIRCUIT BOARD

7 - ODOMETER RESET BUTTON

8J - 2 INSTRUMENT CLUSTERBR/BE

Page 483 of 2255

The EMIC circuitry operates on battery current

received through a fused B(+) fuse in the Junction

Block (JB) on a non-switched fused B(+) circuit, and

on battery current received through a fused ignition

switch output (st-run) fuse in the JB on a fused igni-

tion switch output (st-run) circuit. This arrangement

allows the EMIC to provide some features regardless

of the ignition switch position, while other features

will operate only with the ignition switch in the Start

or On positions. The EMIC circuitry is grounded

through two separate ground circuits located in one

of the two instrument cluster connectors and take

outs of the instrument panel wire harness. One

ground circuit receives ground through a take out

with an eyelet terminal connector of the instrument

panel wire harness that is secured by a nut to a

ground stud located on the left instrument panel end

bracket, while the other ground circuit receives

ground through a take out with an eyelet terminal

connector of the instrument panel wire harness that

is secured by a nut to a ground stud located on the

back of the instrument panel armature above the

inboard side of the instrument panel steering column

opening.

The EMIC also has a self-diagnostic actuator test

capability, which will test each of the CCD bus mes-

sage-controlled functions of the cluster by lighting

the appropriate indicators and positioning the gauge

needles at several predetermined locations on the

gauge faces in a prescribed sequence. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). See the owner's manual in the

vehicle glove box for more information on the fea-

tures, use and operation of the EMIC.

GAUGES

All gauges receive battery current through the

EMIC circuitry when the ignition switch is in the On

or Start positions. With the ignition switch in the Off

position battery current is not supplied to any

gauges, and the EMIC circuitry is programmed to

move all of the gauge needles back to the low end of

their respective scales. Therefore, the gauges do not

accurately indicate any vehicle condition unless the

ignition switch is in the On or Start positions. All of

the EMIC gauges, except the odometer, are air core

magnetic units. Two fixed electromagnetic coils are

located within each gauge. These coils are wrapped

at right angles to each other around a movable per-

manent magnet. The movable magnet is suspended

within the coils on one end of a pivot shaft, while the

gauge needle is attached to the other end of the

shaft. One of the coils has a fixed current flowing

through it to maintain a constant magnetic field

strength. Current flow through the second coil

changes, which causes changes in its magnetic fieldstrength. The current flowing through the second coil

is changed by the EMIC circuitry in response to mes-

sages received over the CCD data bus. The gauge

needle moves as the movable permanent magnet

aligns itself to the changing magnetic fields created

around it by the electromagnets.

The gauges are diagnosed using the EMIC self-di-

agnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the CCD data bus and

the data bus message inputs to the EMIC that con-

trol each gauge require the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

Specific operation details for each gauge may be

found elsewhere in this service manual.

VACUUM-FLUORESCENT DISPLAY

The Vacuum-Fluorescent Display (VFD) module is

soldered to the EMIC circuit board. The display is

active with the ignition switch in the On or Start

positions, and inactive when the ignition switch is in

any other position. The VFD has several display

capabilities including odometer, trip odometer, and

an amber ªCRUISEº indication whenever the

optional speed control system is turned On. The

cruise indicator function of the VFD is automatically

enabled or disabled by the EMIC circuitry based

upon whether the vehicle is equipped with the speed

control option. An odometer/trip odometer switch on

the EMIC circuit board is used to control several of

the display modes. This switch is actuated manually

by depressing the odometer/trip odometer switch

knob that extends through the lower edge of the clus-

ter lens, just right of center. Actuating this switch

momentarily with the ignition switch in the On posi-

tion will toggle the VFD between the odometer and

trip odometer modes. The word ªTRIPº will also

appear in blue-green text when the VFD trip odome-

ter mode is active. Depressing the switch button for

about two seconds while the VFD is in the trip odom-

eter mode will reset the trip odometer value to zero.

Holding this switch depressed while turning the igni-

tion switch from the Off position to the On position

will activate the EMIC self-diagnostic actuator test.

The EMIC will automatically flash the odometer or

trip odometer information on and off if there is a loss

of CCD data bus communication. The VFD will also

display various information used in several diagnos-

tic procedures. Refer to the appropriate diagnostic

information for additional details on this VFD func-

tion.

The VFD is diagnosed using the EMIC self-diag-

nostic actuator test. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the CCD data bus and

the data bus message inputs to the EMIC that con-

8J - 4 INSTRUMENT CLUSTERBR/BE

INSTRUMENT CLUSTER (Continued)

Page 489 of 2255

headlamp switch. Rotate the headlamp switch panel

lamps dimmer thumbwheel upward to just before the

interior lamps detent. Check for battery voltage at

the fused panel lamps dimmer switch signal circuit

cavity of the instrument panel wire harness connec-

tor (Connector C2) for the instrument cluster. If OK,

replace the faulty bulb and bulb holder units. If not

OK, repair the open fused panel lamps dimmer

switch signal circuit between the instrument cluster

and the JB as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

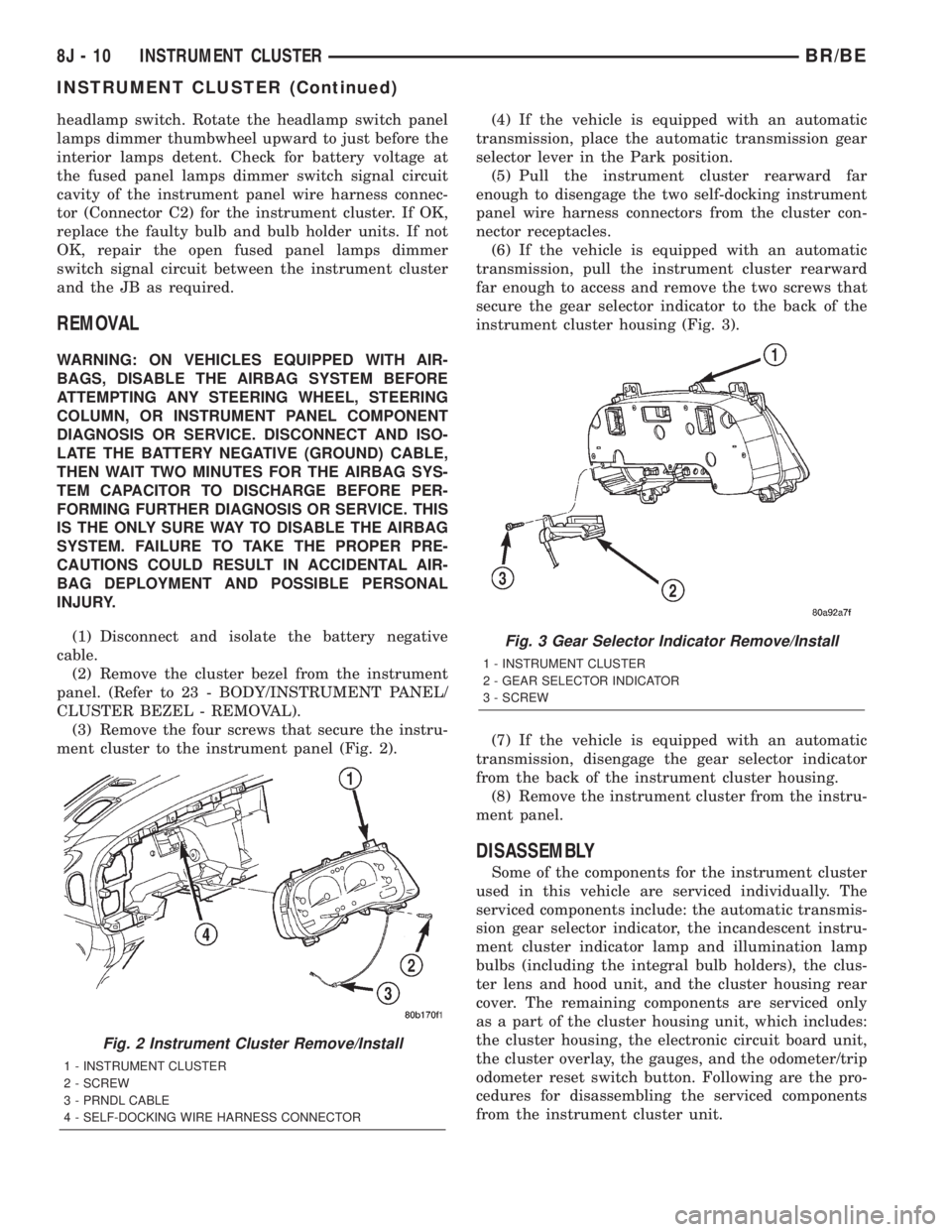

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(3) Remove the four screws that secure the instru-

ment cluster to the instrument panel (Fig. 2).(4) If the vehicle is equipped with an automatic

transmission, place the automatic transmission gear

selector lever in the Park position.

(5) Pull the instrument cluster rearward far

enough to disengage the two self-docking instrument

panel wire harness connectors from the cluster con-

nector receptacles.

(6) If the vehicle is equipped with an automatic

transmission, pull the instrument cluster rearward

far enough to access and remove the two screws that

secure the gear selector indicator to the back of the

instrument cluster housing (Fig. 3).

(7) If the vehicle is equipped with an automatic

transmission, disengage the gear selector indicator

from the back of the instrument cluster housing.

(8) Remove the instrument cluster from the instru-

ment panel.

DISASSEMBLY

Some of the components for the instrument cluster

used in this vehicle are serviced individually. The

serviced components include: the automatic transmis-

sion gear selector indicator, the incandescent instru-

ment cluster indicator lamp and illumination lamp

bulbs (including the integral bulb holders), the clus-

ter lens and hood unit, and the cluster housing rear

cover. The remaining components are serviced only

as a part of the cluster housing unit, which includes:

the cluster housing, the electronic circuit board unit,

the cluster overlay, the gauges, and the odometer/trip

odometer reset switch button. Following are the pro-

cedures for disassembling the serviced components

from the instrument cluster unit.

Fig. 2 Instrument Cluster Remove/Install

1 - INSTRUMENT CLUSTER

2 - SCREW

3 - PRNDL CABLE

4 - SELF-DOCKING WIRE HARNESS CONNECTOR

Fig. 3 Gear Selector Indicator Remove/Install

1 - INSTRUMENT CLUSTER

2 - GEAR SELECTOR INDICATOR

3 - SCREW

8J - 10 INSTRUMENT CLUSTERBR/BE

INSTRUMENT CLUSTER (Continued)

Page 491 of 2255

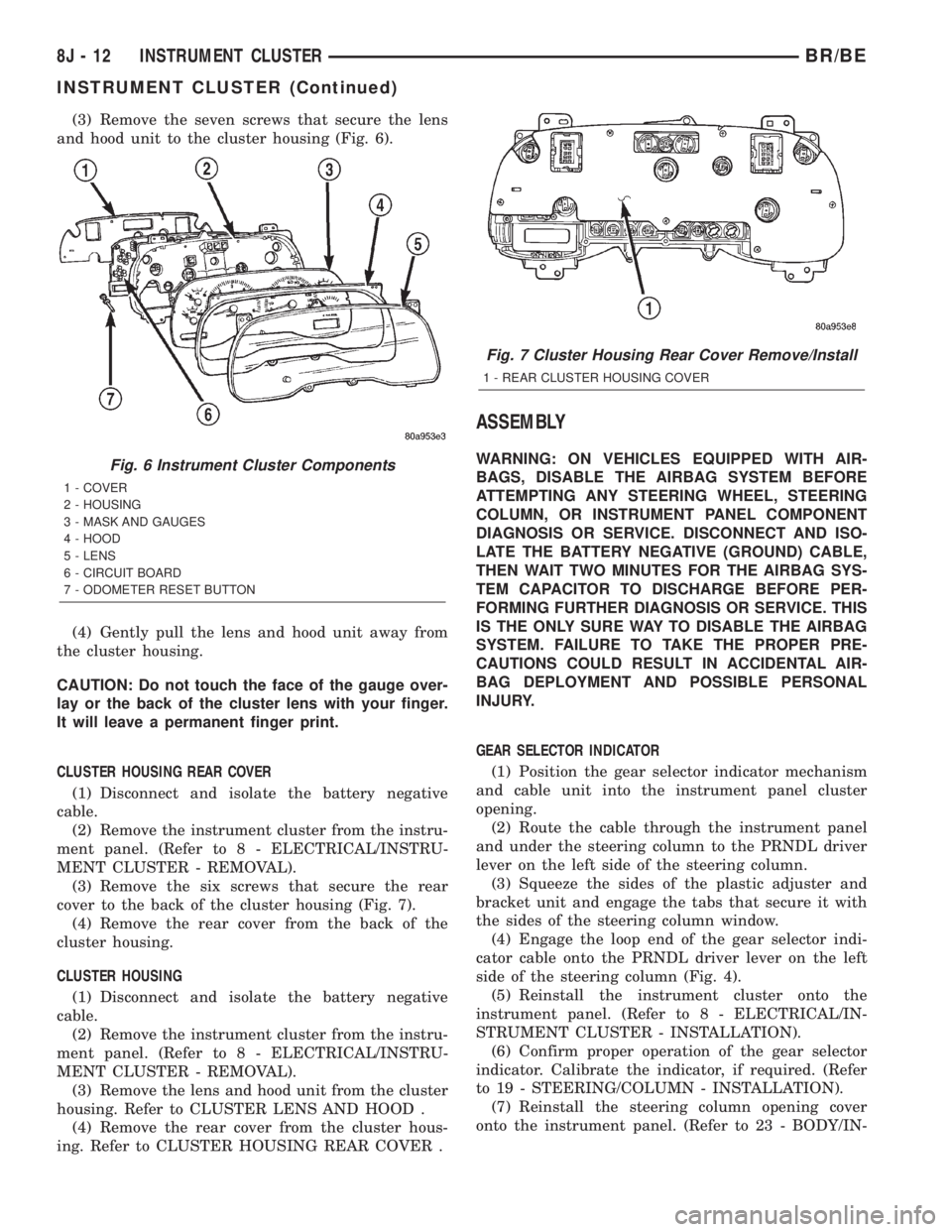

(3) Remove the seven screws that secure the lens

and hood unit to the cluster housing (Fig. 6).

(4) Gently pull the lens and hood unit away from

the cluster housing.

CAUTION: Do not touch the face of the gauge over-

lay or the back of the cluster lens with your finger.

It will leave a permanent finger print.

CLUSTER HOUSING REAR COVER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(3) Remove the six screws that secure the rear

cover to the back of the cluster housing (Fig. 7).

(4) Remove the rear cover from the back of the

cluster housing.

CLUSTER HOUSING

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(3) Remove the lens and hood unit from the cluster

housing. Refer to CLUSTER LENS AND HOOD .

(4) Remove the rear cover from the cluster hous-

ing. Refer to CLUSTER HOUSING REAR COVER .

ASSEMBLY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

GEAR SELECTOR INDICATOR

(1) Position the gear selector indicator mechanism

and cable unit into the instrument panel cluster

opening.

(2) Route the cable through the instrument panel

and under the steering column to the PRNDL driver

lever on the left side of the steering column.

(3) Squeeze the sides of the plastic adjuster and

bracket unit and engage the tabs that secure it with

the sides of the steering column window.

(4) Engage the loop end of the gear selector indi-

cator cable onto the PRNDL driver lever on the left

side of the steering column (Fig. 4).

(5) Reinstall the instrument cluster onto the

instrument panel. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - INSTALLATION).

(6) Confirm proper operation of the gear selector

indicator. Calibrate the indicator, if required. (Refer

to 19 - STEERING/COLUMN - INSTALLATION).

(7) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-Fig. 6 Instrument Cluster Components

1 - COVER

2 - HOUSING

3 - MASK AND GAUGES

4 - HOOD

5 - LENS

6 - CIRCUIT BOARD

7 - ODOMETER RESET BUTTON

Fig. 7 Cluster Housing Rear Cover Remove/Install

1 - REAR CLUSTER HOUSING COVER

8J - 12 INSTRUMENT CLUSTERBR/BE

INSTRUMENT CLUSTER (Continued)

Page 503 of 2255

²PCM Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the PCM or

ECM, the indicator will be illuminated. The indicator

can be flashed on and off, or illuminated solid, as dic-

tated by the PCM or ECM message. For some DTC's,

if a problem does not recur, the PCM or ECM will

send a lamp-off message automatically. Other DTC's

may require that a fault be repaired and the PCM or

ECM be reset before a lamp-off message will be sent.

For more information on the PCM, the ECM, and the

DTC set and reset parameters, (Refer to 25 - EMIS-

SIONS CONTROL - OPERATION).

²Communication Error- If the cluster receives

no lamp-on message from the PCM or ECM for

twenty seconds, the MIL is illuminated by the instru-

ment cluster to indicate a loss of bus communication.

The indicator remains controlled and illuminated by

the cluster until a valid lamp-on message is received

from the PCM or ECM.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The PCM/ECM continually monitor the fuel and

emissions system circuits and sensors to decide

whether the system is in good operating condition.

The PCM or ECM then sends the proper lamp-on or

lamp-off messages to the instrument cluster. For fur-

ther diagnosis of the MIL or the instrument cluster

circuitry that controls the LED, (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). If the instrument cluster turns on

the MIL after the bulb test, it may indicate that a

malfunction has occurred and that the fuel and emis-

sions systems may require service. For proper diag-

nosis of the fuel and emissions systems, the PCM,

the ECM, the CCD data bus, or the message inputs

to the instrument cluster that control the MIL, a

DRBIIItscan tool is required. Refer to the appropri-

ate diagnostic information.

ODOMETER

DESCRIPTION

An odometer and trip odometer are standard

equipment in all instrument clusters. The odometer

and trip odometer information are displayed in a

common electronic Vacuum-Fluorescent Display

(VFD), which is visible through a small window cut-

out located in the left lower quadrant of the cluster

overlay. However, the odometer and trip odometer

information are not displayed simultaneously. The

trip odometer reset switch on the instrument cluster

circuit board toggles the display between odometerand trip odometer modes by depressing the odometer/

trip odometer switch knob that extends through the

lower edge of the cluster lens, just right of the

tachometer. Both the odometer and the trip odometer

information is stored in the instrument cluster mem-

ory.

The odometer can display values up to 499,999

kilometers (499,999 miles). The odometer latches at

these values, and will not roll over to zero. The trip

odometer can display values up to 999.9 kilometers

(999.9 miles) before it rolls over to zero. The odome-

ter display does not have a decimal point and will

not show values less than a full unit (kilometer or

mile), the trip odometer display does have a decimal

point and will show tenths of a unit (kilometer or

mile). The unit of measure (kilometers or miles) for

the odometer and trip odometer display is not shown

in the VFD. The unit of measure for the instrument

cluster odometer/trip odometer is selected at the time

that it is manufactured, and cannot be changed. Dur-

ing daylight hours (exterior lamps Off) the VFD is

illuminated at full brightness for clear visibility. At

night (exterior lamps are On) the VFD lighting level

is adjusted with the other cluster illumination lamps

using the panel lamps dimmer thumbwheel on the

headlamp switch. However, a ªParadeº mode position

of the panel lamps dimmer thumbwheel allows the

VFD to be illuminated at full brightness while the

exterior lamps are turned On during daylight hours.

The VFD, the trip odometer switch, and the trip

odometer switch button are serviced as a unit with

the instrument cluster.

OPERATION

The odometer and trip odometer give an indication

to the vehicle operator of the distance the vehicle has

traveled. This gauge is controlled by the instrument

cluster circuit board based upon the cluster program-

ming and electronic messages received by the cluster

from the Powertrain Control Module (PCM) over the

Chrysler Collision Detection (CCD) data bus. The

odometer and trip odometer information is displayed

by the instrument cluster Vacuum Fluorescent Dis-

play (VFD), and the VFD will not display odometer

or trip odometer information after the ignition switch

is turned to the Off position. The instrument cluster

circuitry controls the VFD and provides the following

features:

²Odometer/Trip Odometer Display Toggling-

Actuating the trip odometer reset switch momen-

tarily with the ignition switch in the On position will

toggle the VFD between the odometer and trip odom-

eter display. Each time the ignition switch is turned

to the On position the VFD will automatically return

to the mode (odometer or trip odometer) last dis-

8J - 24 INSTRUMENT CLUSTERBR/BE

MALFUNCTION INDICATOR LAMP MIL (Continued)

Page 504 of 2255

played when the ignition switch was turned to the

Off position.

²Trip Odometer Reset- When the trip odome-

ter reset switch is pressed and held for longer than

about two seconds, the trip odometer will be reset to

000.0 kilometers (miles). The VFD must be display-

ing the trip odometer information in order for the

trip odometer information to be reset.

²Message Failure- If the cluster fails to receive

a distance message during normal operation, it will

flash the odometer/trip odometer distance informa-

tion on and off repeatedly until a distance message is

received, or until the ignition switch is turned to the

Off position, whichever occurs first. If the cluster

does not receive a distance message within one sec-

ond after the ignition switch is turned to the On posi-

tion, it will display the last distance message stored

in the cluster memory. If the cluster is unable to dis-

play distance information due to an error internal to

the cluster, the VFD display will be blank.

²Actuator Test- Each time the cluster is put

through the actuator test, the VFD will display all of

its characters at once, then step through each char-

acter segment individually during the VFD portion of

the test to confirm the functionality of the VFD and

the cluster control circuitry.

The PCM continually monitors the vehicle speed

sensor, then sends the proper distance messages to

the instrument cluster. For further diagnosis of the

odometer/trip odometer or the instrument cluster cir-

cuitry that controls these functions, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). For proper diagnosis of the

vehicle speed sensor, the PCM, the CCD data bus, or

the message inputs to the instrument cluster that

control the odometer/trip odometer, a DRBIIItscan

tool is required. Refer to the appropriate diagnostic

information.

OIL PRESSURE GAUGE

DESCRIPTION

An oil pressure gauge is standard equipment on all

instrument clusters. The oil pressure gauge is located

in the upper right quadrant of the instrument clus-

ter, above the fuel gauge. The oil pressure gauge con-

sists of a movable gauge needle or pointer controlled

by the instrument cluster circuitry and a fixed 90

degree scale on the cluster overlay that reads left-to-

right either from 0 kPa (0 psi) to 758 kPa (110 psi).

An International Control and Display Symbol icon for

ªEngine Oilº is located on the cluster overlay, directly

below the highest graduation of the gauge scale. The

oil pressure gauge graphics are white against a black

field except for a single red graduation at the lowend of the gauge scale, making them clearly visible

within the instrument cluster in daylight. When illu-

minated from behind by the panel lamps dimmer

controlled cluster illumination lighting with the exte-

rior lamps turned On, the white graphics appear

blue-green and the red graphics appear red. The

orange gauge needle is internally illuminated. Gauge

illumination is provided by replaceable incandescent

bulb and bulb holder units located on the instrument

cluster electronic circuit board. The oil pressure

gauge is serviced as a unit with the instrument clus-

ter.

OPERATION

The oil pressure gauge gives an indication to the

vehicle operator of the engine oil pressure. This

gauge is controlled by the instrument cluster circuit

board based upon the cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Chrysler

Collision Detection (CCD) data bus. The oil pressure

gauge is an air core magnetic unit that receives bat-

tery current on the instrument cluster electronic cir-

cuit board through the fused ignition switch output

(st-run) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Engine Oil Pressure Message- The instru-

ment cluster circuitry restricts the oil pressure gauge

needle operation in order to provide readings that

are consistent with customer expectations. Each time

the cluster receives a message from the PCM indicat-

ing the engine oil pressure is between about 6.9 kPa

(1 psi) and 137.9 kPa (20 psi) for gasoline engines, or

55 kPa (8 psi) and 58.6 kPa (8.5 psi) for diesel

engines, the cluster holds the gauge needle at a point

about 11 degrees above the low end of normal incre-

ment on the gauge scale. Each time the cluster

receives a message from the PCM indicating the

engine oil pressure is between about 517.1 kPa (75

psi) and 755 kPa (109.5 psi) for gasoline engines, or

551.6 kPa (80 psi) and 755 kPa (109.5 psi) for diesel

engines, the cluster holds the gauge needle at a point

about 7.4 degrees below the high end of normal

increment on the gauge scale. When the cluster

receives messages from the PCM indicating the

engine oil pressure is between about 137.9 kPa (20

psi) and 517.1 kPa (75 psi) for gasoline engines, or

58.6 kPa (8.5 psi) and 551.6 kPa (80 psi) for diesel

engines], the gauge needle is moved to the actual

pressure position on the gauge scale.

BR/BEINSTRUMENT CLUSTER 8J - 25

ODOMETER (Continued)

Page 507 of 2255

overlay causes the ªMAINT REQDº text to appear in

amber through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by a Light Emitting Diode (LED) soldered

onto the instrument cluster electronic circuit board.

The SRI is serviced as a unit with the instrument

cluster.

OPERATION

The Service Reminder Indicator (SRI) gives an

indication to the vehicle operator when engine emis-

sions maintenance procedures should be performed.

This indicator is controlled by a transistor on the

instrument cluster circuit board based upon the clus-

ter programming and electronic messages received by

the cluster from the Powertrain Control Module

(PCM) over the Chrysler Collision Detection (CCD)

data bus. The SRI Light Emitting Diode (LED)

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (st-run) circuit whenever the ignition

switch is in the On or Start positions; therefore, the

LED will always be off when the ignition switch is in

any position except On or Start. The LED only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. The instrument cluster

will turn on the SRI for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the SRI is illuminated for

about two seconds as a bulb test.

²Service Required Lamp-On Message- Each

time the cluster receives a service required lamp-on

message from the PCM indicating that an emissions

maintenance interval has been reached, the SRI will

be illuminated. The indicator remains illuminated

until the cluster receives a service required lamp-off

message from the PCM, or until the ignition switch

is turned to the Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the SRI will be turned on

during the bulb check portion of the test to confirm

the functionality of the LED and the cluster control

circuitry.

The PCM continually monitors the vehicle speed

sensor to determine the distance the vehicle has been

driven, then sends the proper messages to the instru-

ment cluster. Once the SRI has been illuminated and

the required emissions maintenance procedures have

been completed, the PCM must be reset using a

DRBIIItscan tool before it will send the proper ser-

vice required lamp-off message to the instrument

cluster. Refer to the appropriate diagnostic informa-

tion. For further diagnosis of the SRI or the instru-

ment cluster circuitry that controls the LED, (Refer

to 8 - ELECTRICAL/INSTRUMENT CLUSTER -

DIAGNOSIS AND TESTING). For proper diagnosisof the PCM, the CCD data bus, or the message

inputs to the instrument cluster that control the SRI,

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.

SHIFT INDICATOR (TRANSFER

CASE)

DESCRIPTION

A four-wheel drive indicator is standard equipment

on all instrument clusters. However, on vehicles not

equipped with the optional four-wheel drive system,

this indicator is mechanically disabled. The four-

wheel drive indicator is located near the lower edge

of the instrument cluster overlay, to the right of cen-

ter. The four-wheel drive indicator consists of a sten-

cilled cutout of the text ª4WDº in the opaque layer of

the instrument cluster overlay. The dark outer layer

of the overlay prevents the indicator from being

clearly visible when it is not illuminated. An amber

lens behind the cutout in the opaque layer of the

overlay causes the ª4WDº text to appear in amber

through the translucent outer layer of the overlay

when the indicator is illuminated from behind by a

Light Emitting Diode (LED) soldered onto the instru-

ment cluster electronic circuit board. The four-wheel

drive indicator is serviced as a unit with the instru-

ment cluster.

OPERATION

The four-wheel drive indicator lamp gives an indi-

cation to the vehicle operator that a four-wheel drive

operating mode is engaged. The indicator will be illu-

minated when either high range (4H) or low range

(4L) have been selected with the transfer case shift

lever. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon the

cluster programming, and a hard wired input from

the four-wheel drive switch on the front axle discon-

nect housing. The four-wheel drive indicator Light

Emitting Diode (LED) receives battery current on the

instrument cluster electronic circuit board through

the fused ignition switch output (st-run) circuit

whenever the ignition switch is in the On or Start

positions; therefore, the lamp will always be off when

the ignition switch is in any position except On or

Start. The LED only illuminates when it is switched

to ground by the instrument cluster transistor.

The four-wheel drive switch is connected in series

between ground and the four-wheel drive switch

sense input to the instrument cluster. For further

information on the transfer case and the transfer

case operating ranges, (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/TRANSFER CASE - OPERA-

TION. For further information on the front axle

8J - 28 INSTRUMENT CLUSTERBR/BE

SERVICE REMINDER INDICATOR (Continued)