spare tire DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1066 of 2255

tor between many of the engine compartment, instru-

ment panel, and body wire harnesses. The JB houses

up to nineteen blade-type fuses (two standard-type

and seventeen mini-type), up to two blade-type auto-

matic resetting circuit breakers, the electronic combi-

nation turn signal and hazard warning flasher, and

one International Standards Organization (ISO)

micro-relay.

The molded plastic JB housing has integral mount-

ing brackets that are secured with two screws to the

left instrument panel end bracket. The left end of the

instrument panel cover has a snap-fit fuse access

panel that can be removed for service of the JB. A

fuse puller and spare fuse holders are located on the

back of the fuse access cover, as well as an adhesive-

backed fuse layout map to ensure proper fuse identi-

fication.

The JB unit cannot be repaired and is only ser-

viced as an assembly. If any internal circuit or the JB

housing is faulty or damaged, the entire JB unit

must be replaced.

OPERATION

All of the circuits entering and leaving the JB do

so through up to nine wire harness connectors, which

are connected to the JB through integral connector

receptacles molded into the JB housing. Internal con-

nection of all of the JB circuits is accomplished by an

intricate combination of hard wiring and bus bars.

Refer toWiring Diagramsfor the location of com-

plete JB circuit diagrams.

DIAGNOSIS AND TESTING - JUNCTION BLOCK

The junction block does not incorporate any self

diagnostic capability. Most of the electrical circuits

incorporated into the vehicle must pass through the

junction block at one point or another. The most effi-

cient means of diagnosing a suspected junction block

problem involves a simple continuity tester or ohm

meter. Using the Wiring Diagrams as a guide trace

the problem circuit to the proper junction block cav-

ity and test all circuits in the effected circuit for

proper continuity. A open or high resistance circuit is

a sign of a problem. Some other possible junction

block problems to look for are:

²Loose fuse receptacle terminals.

²Loose relay / circuit breaker receptacle termi-

nals.

²Bent or distorted electrical circuit pins.

²Incorrect size fuse installed in junction block

fuse cavity.

²Dark areas identifying a source of excess heat.

²Defective fuse, relay or circuit breaker installed

in junction block cavity.

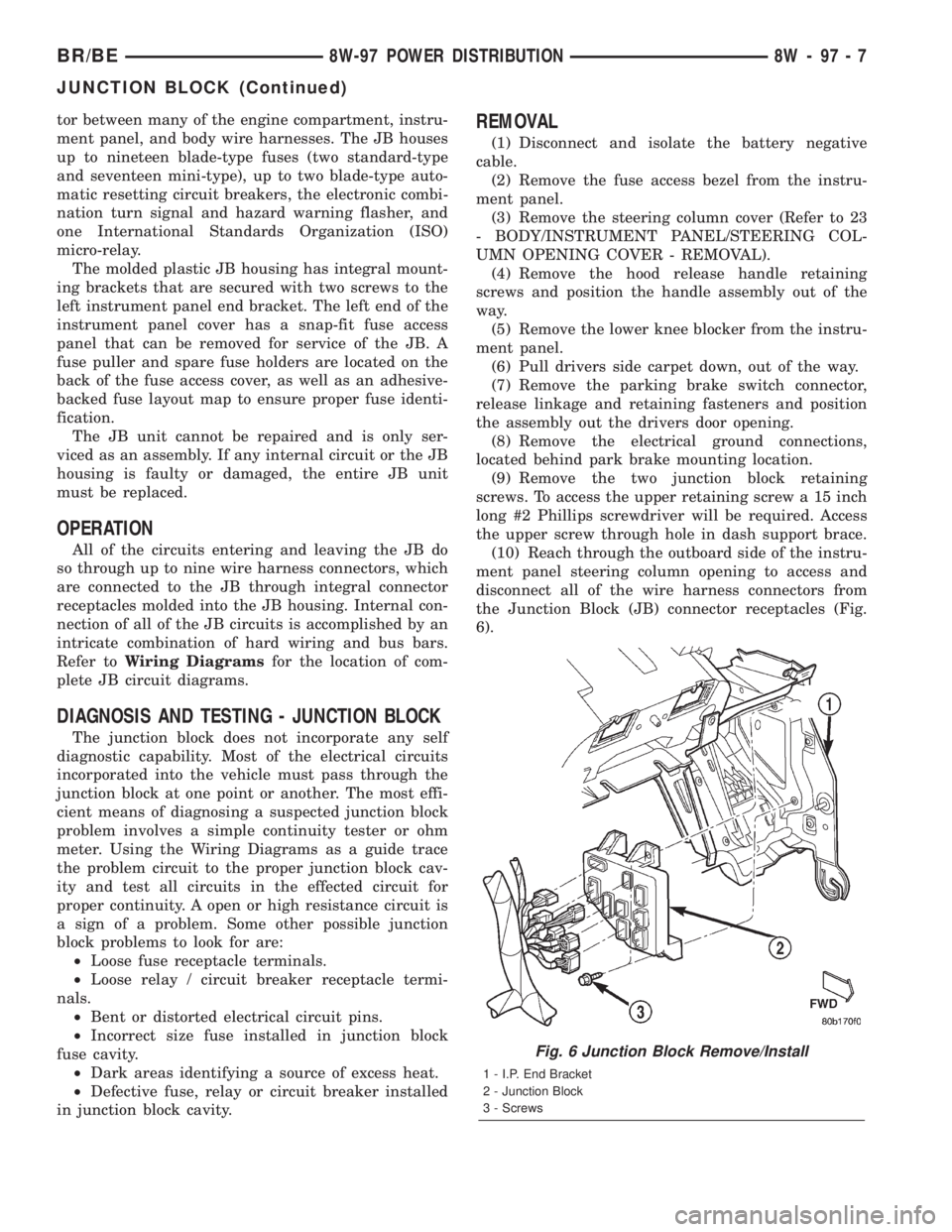

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access bezel from the instru-

ment panel.

(3) Remove the steering column cover (Refer to 23

- BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - REMOVAL).

(4) Remove the hood release handle retaining

screws and position the handle assembly out of the

way.

(5) Remove the lower knee blocker from the instru-

ment panel.

(6) Pull drivers side carpet down, out of the way.

(7) Remove the parking brake switch connector,

release linkage and retaining fasteners and position

the assembly out the drivers door opening.

(8) Remove the electrical ground connections,

located behind park brake mounting location.

(9) Remove the two junction block retaining

screws. To access the upper retaining screw a 15 inch

long #2 Phillips screwdriver will be required. Access

the upper screw through hole in dash support brace.

(10) Reach through the outboard side of the instru-

ment panel steering column opening to access and

disconnect all of the wire harness connectors from

the Junction Block (JB) connector receptacles (Fig.

6).

Fig. 6 Junction Block Remove/Install

1 - I.P. End Bracket

2 - Junction Block

3 - Screws

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 7

JUNCTION BLOCK (Continued)

Page 1288 of 2255

FRAME & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

DESCRIPTION..........................1

SPECIFICATIONS - TORQUE...............1

FRONT AIR DAM

REMOVAL.............................2

INSTALLATION..........................2

FRONT FASCIA

REMOVAL.............................2

INSTALLATION..........................2

ADJUSTMENTS

ADJUSTMENT.........................2

FRONT LOWER FASCIA

REMOVAL.............................3

INSTALLATION..........................3

FRONT FASCIA - SPORT

REMOVAL.............................3

INSTALLATION..........................3

FRONT BUMPER

REMOVAL.............................4

INSTALLATION..........................4

FRONT BUMPER - SPORT

REMOVAL.............................5INSTALLATION..........................5

REAR BUMPER

REMOVAL.............................6

INSTALLATION..........................6

FRAME

DESCRIPTION

DESCRIPTION........................6

FRAME SERVICE......................7

SPECIFICATIONS

FRAME DIMENSION....................8

CAB CHASSIS ADAPTER BRACKET

REMOVAL.............................10

INSTALLATION.........................10

FRONT TOW HOOK

REMOVAL.............................10

INSTALLATION.........................10

TRAILER HITCH

REMOVAL.............................11

INSTALLATION.........................11

TRANSFER CASE SKID PLATE

REMOVAL.............................11

INSTALLATION.........................11

BUMPERS

DESCRIPTION

Bumpers are used at the front and rear of the

vehicle. Bumpers may be chrome or painted.Bumpers are designed to protect the exterior sheet-

metal in low impact situations. The bumpers are

attached to the frame and provide mounting points

for some optional accessories such as fog lights and

tow hooks.

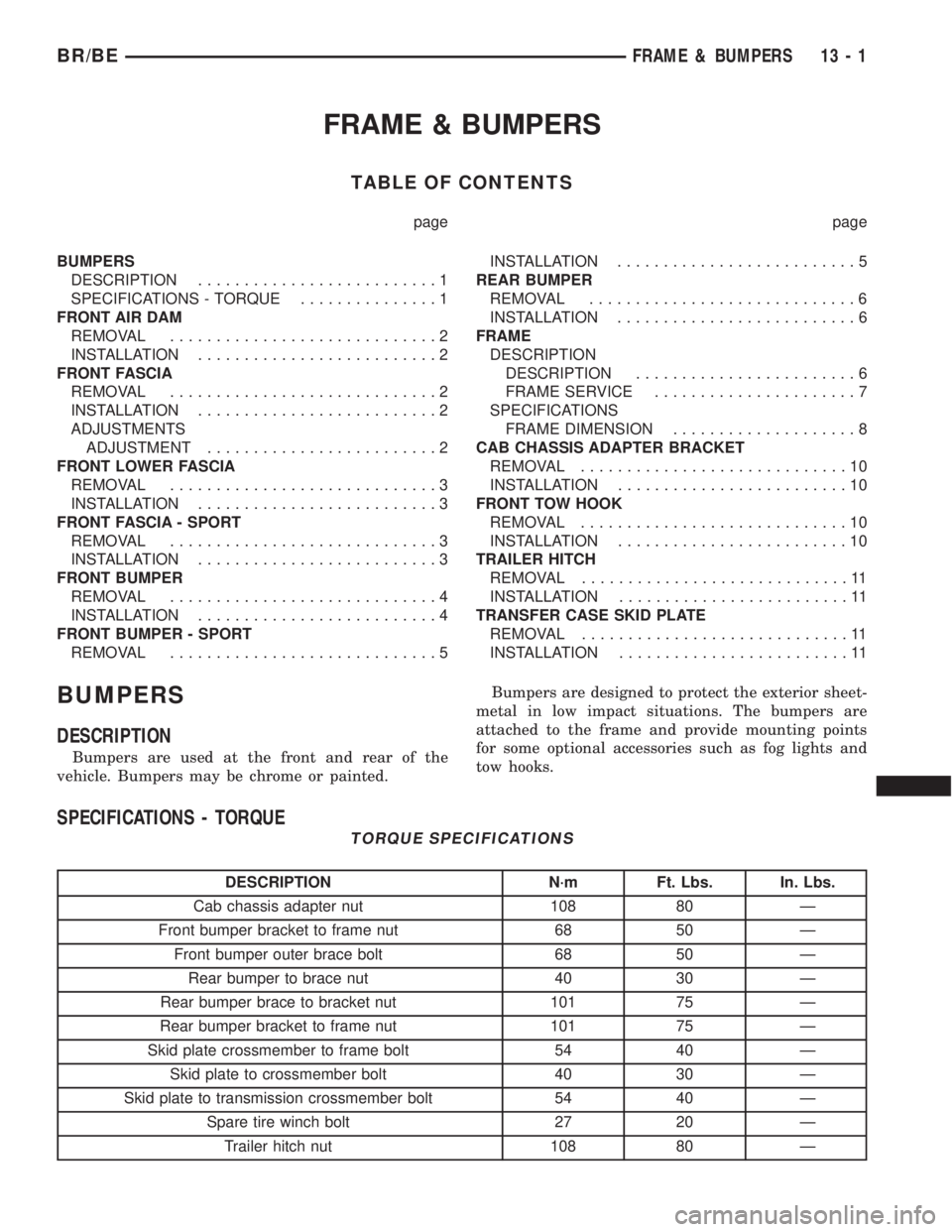

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Cab chassis adapter nut 108 80 Ð

Front bumper bracket to frame nut 68 50 Ð

Front bumper outer brace bolt 68 50 Ð

Rear bumper to brace nut 40 30 Ð

Rear bumper brace to bracket nut 101 75 Ð

Rear bumper bracket to frame nut 101 75 Ð

Skid plate crossmember to frame bolt 54 40 Ð

Skid plate to crossmember bolt 40 30 Ð

Skid plate to transmission crossmember bolt 54 40 Ð

Spare tire winch bolt 27 20 Ð

Trailer hitch nut 108 80 Ð

BR/BEFRAME & BUMPERS 13 - 1

Page 1298 of 2255

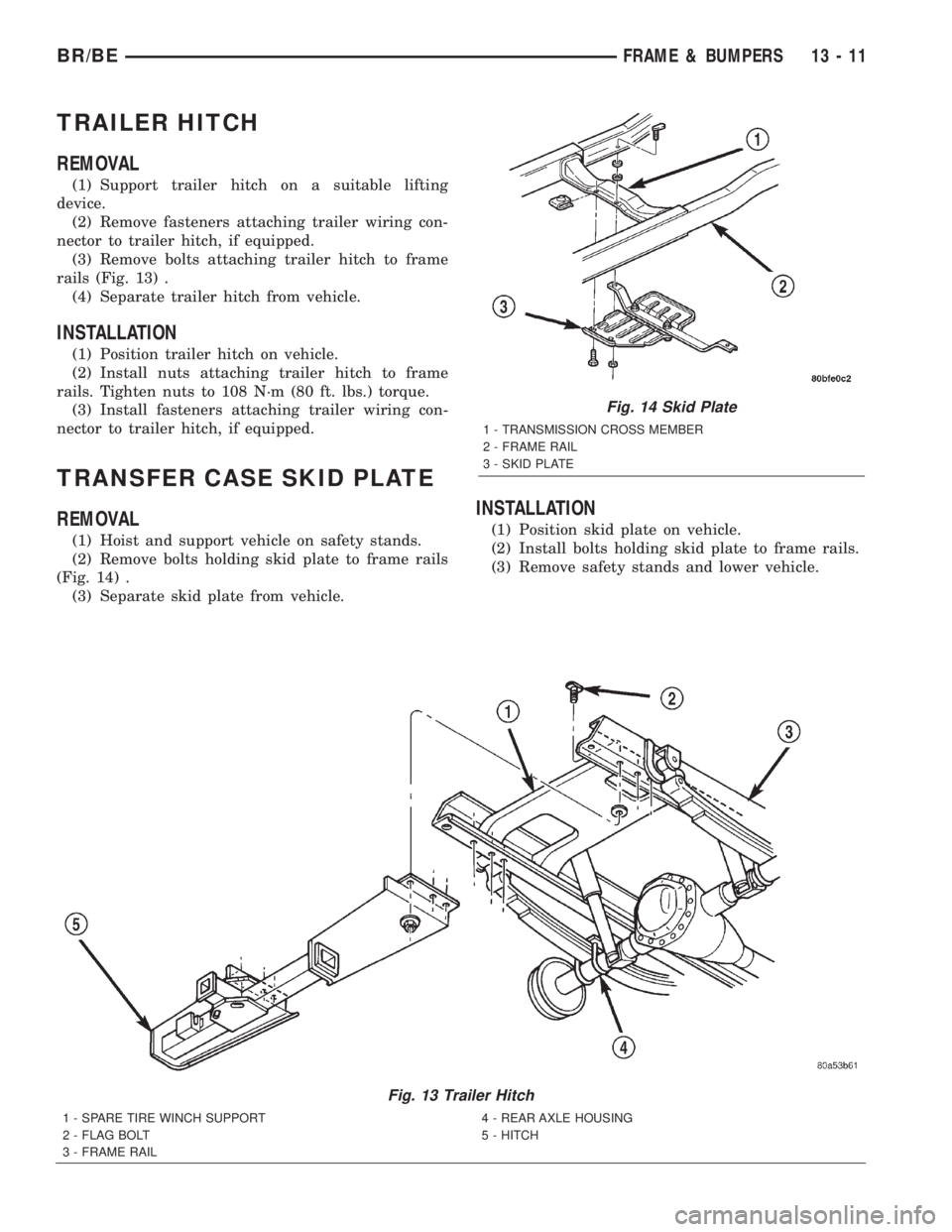

TRAILER HITCH

REMOVAL

(1) Support trailer hitch on a suitable lifting

device.

(2) Remove fasteners attaching trailer wiring con-

nector to trailer hitch, if equipped.

(3) Remove bolts attaching trailer hitch to frame

rails (Fig. 13) .

(4) Separate trailer hitch from vehicle.

INSTALLATION

(1) Position trailer hitch on vehicle.

(2) Install nuts attaching trailer hitch to frame

rails. Tighten nuts to 108 N´m (80 ft. lbs.) torque.

(3) Install fasteners attaching trailer wiring con-

nector to trailer hitch, if equipped.

TRANSFER CASE SKID PLATE

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove bolts holding skid plate to frame rails

(Fig. 14) .

(3) Separate skid plate from vehicle.

INSTALLATION

(1) Position skid plate on vehicle.

(2) Install bolts holding skid plate to frame rails.

(3) Remove safety stands and lower vehicle.

Fig. 13 Trailer Hitch

1 - SPARE TIRE WINCH SUPPORT

2 - FLAG BOLT

3 - FRAME RAIL4 - REAR AXLE HOUSING

5 - HITCH

Fig. 14 Skid Plate

1 - TRANSMISSION CROSS MEMBER

2 - FRAME RAIL

3 - SKID PLATE

BR/BEFRAME & BUMPERS 13 - 11

Page 1956 of 2255

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL RUNOUT......................1

STANDARD PROCEDURE

STANDARD PROCEDURE -

TIRE ROTATION.......................2

STANDARD PROCEDURE - MATCH

MOUNTING...........................3

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................4

TIRES

DESCRIPTION

DESCRIPTION - SPARE TIRE - TEMPORARY...6

DESCRIPTION - TIRES..................6

DESCRIPTION - RADIAL-PLY TIRES........6

DESCRIPTION - TIRE PRESSURE FOR

HIGH SPEEDS.........................7

DESCRIPTION - REPLACEMENT TIRES.....7

DESCRIPTION - TIRE INFLATION

PRESSURES..........................7

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRESSURE

GAUGES.............................8

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS..........................8

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS...........................8DIAGNOSIS AND TESTING - TIRE NOISE

OR VIBRATION........................9

STANDARD PROCEDURE - REPAIRING

LEAKS...............................9

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE...........9

SPARE TIRE

DESCRIPTION.........................10

WHEELS

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING

WHEEL INSPECTION..................11

STANDARD PROCEDURE - DUAL REAR

WHEEL INSTALLATION.................11

SPECIFICATIONS

TORQUE CHART......................11

STUDS

REMOVAL.............................12

INSTALLATION.........................12

WHEEL COVER

REMOVAL.............................12

INSTALLATION

INSTALLATION - REAR.................12

INSTALLATION - FRONT................12

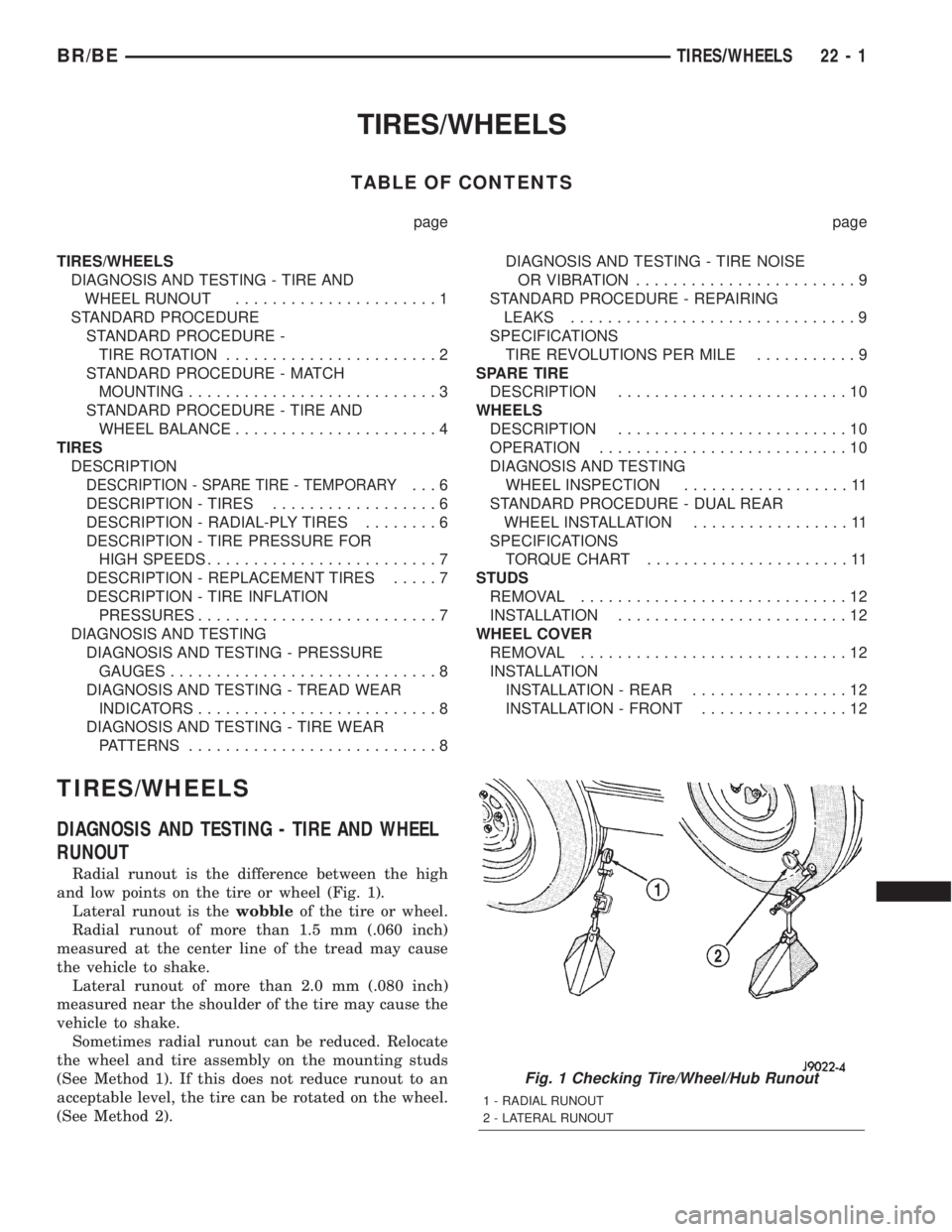

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

RUNOUT

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 1).

Lateral runout is thewobbleof the tire or wheel.

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

Fig. 1 Checking Tire/Wheel/Hub Runout

1 - RADIAL RUNOUT

2 - LATERAL RUNOUT

BR/BETIRES/WHEELS 22 - 1

Page 1961 of 2255

TIRES

DESCRIPTION

DESCRIPTION - SPARE TIRE - TEMPORARY

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M.P.H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details.

DESCRIPTION - TIRES

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe brake applications

²High speed driving

²Excessive speeds on turns

²Striking curbs and other obstacles

Radial-ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation, (Refer to

22 - TIRES/WHEELS - STANDARD PROCEDURE).

This will help to achieve a greater tread life.

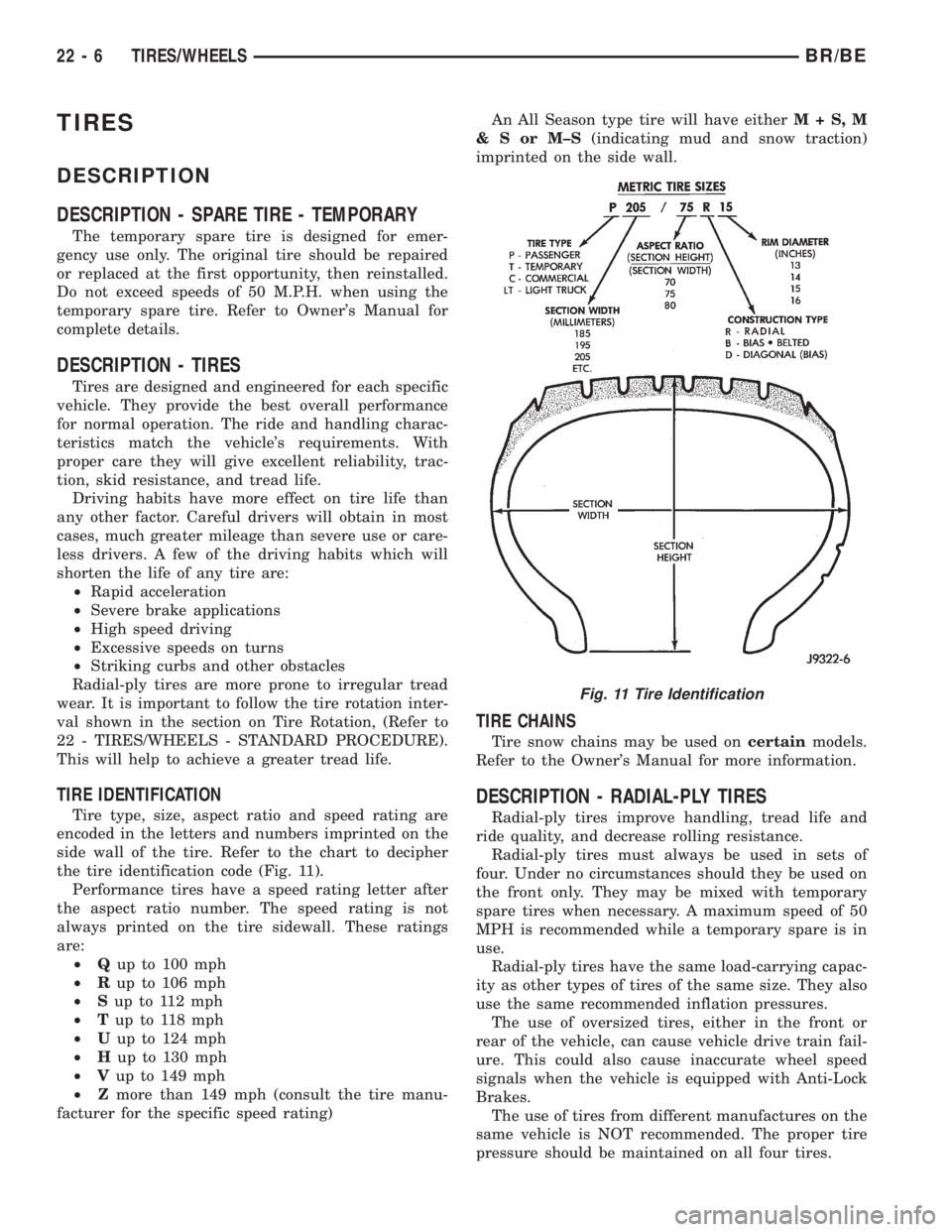

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 11).

Performance tires have a speed rating letter after

the aspect ratio number. The speed rating is not

always printed on the tire sidewall. These ratings

are:

²Qup to 100 mph

²Rup to 106 mph

²Sup to 112 mph

²Tup to 118 mph

²Uup to 124 mph

²Hup to 130 mph

²Vup to 149 mph

²Zmore than 149 mph (consult the tire manu-

facturer for the specific speed rating)An All Season type tire will have eitherM+S,M

&SorM±S(indicating mud and snow traction)

imprinted on the side wall.

TIRE CHAINS

Tire snow chains may be used oncertainmodels.

Refer to the Owner's Manual for more information.

DESCRIPTION - RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life and

ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

Fig. 11 Tire Identification

22 - 6 TIRES/WHEELSBR/BE

Page 1965 of 2255

SPARE TIRE

DESCRIPTION

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M.P.H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details.

WHEELS

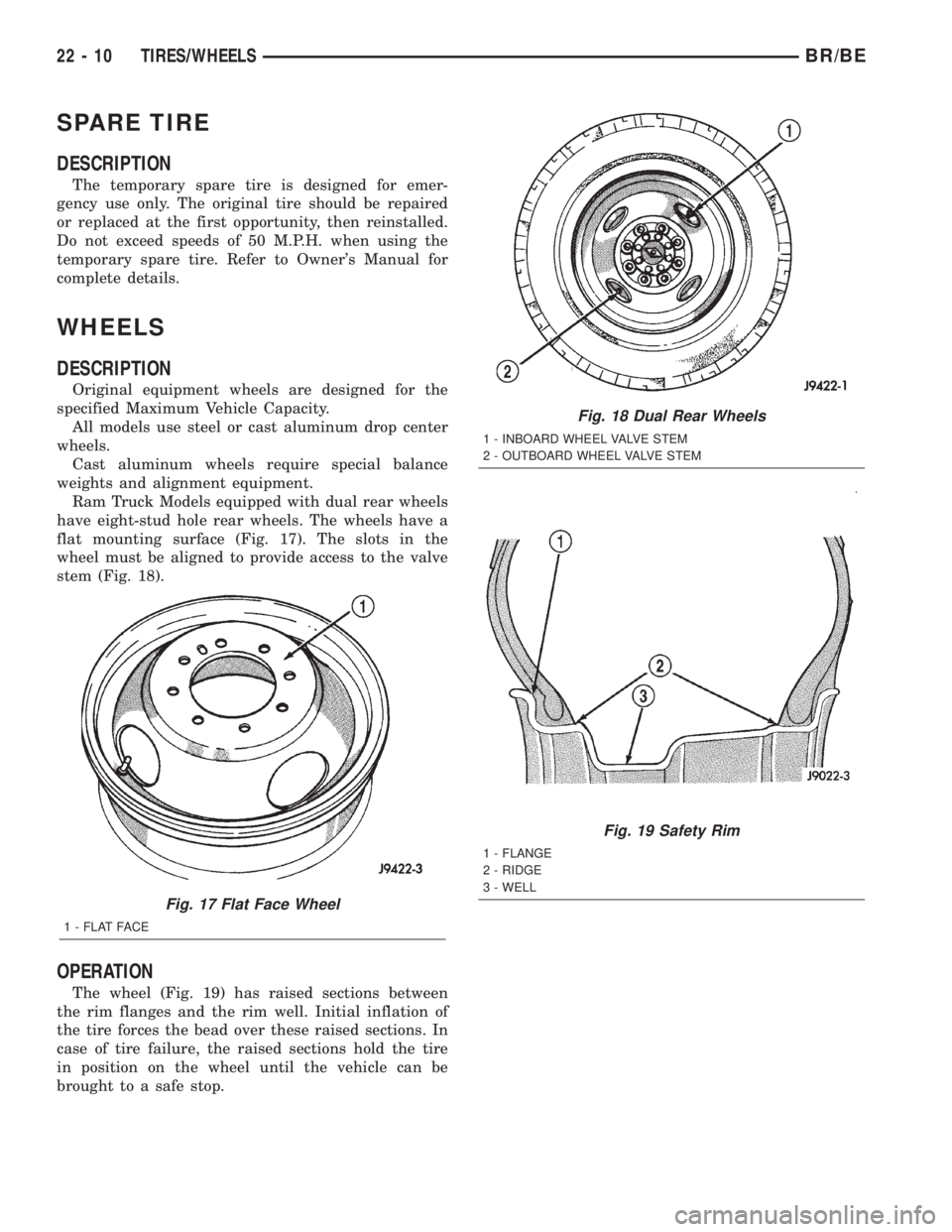

DESCRIPTION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or cast aluminum drop center

wheels.

Cast aluminum wheels require special balance

weights and alignment equipment.

Ram Truck Models equipped with dual rear wheels

have eight-stud hole rear wheels. The wheels have a

flat mounting surface (Fig. 17). The slots in the

wheel must be aligned to provide access to the valve

stem (Fig. 18).

OPERATION

The wheel (Fig. 19) has raised sections between

the rim flanges and the rim well. Initial inflation of

the tire forces the bead over these raised sections. In

case of tire failure, the raised sections hold the tire

in position on the wheel until the vehicle can be

brought to a safe stop.

Fig. 17 Flat Face Wheel

1 - FLAT FACE

Fig. 18 Dual Rear Wheels

1 - INBOARD WHEEL VALVE STEM

2 - OUTBOARD WHEEL VALVE STEM

Fig. 19 Safety Rim

1 - FLANGE

2 - RIDGE

3 - WELL

22 - 10 TIRES/WHEELSBR/BE

Page 2245 of 2255

SENSOR - REMOVAL, FUEL LEVEL

SENDING UNIT.......................14-7

SENSOR - REMOVAL, O2..............14-46

SENSOR - REMOVAL, REAR WHEEL

SPEED..............................5-40

SENSOR - REMOVAL, WATER IN FUEL....14-89

SENSOR RETURN - DESCRIPTION.......8E-17

SENSOR/SWITCH - INSTALLATION, OIL

PRESSURE.........................9-181

SENSOR/SWITCH - REMOVAL, OIL

PRESSURE.........................9-181

SEPARATOR - DESCRIPTION, FUEL

FILTER / WATER .....................14-63

SEPARATOR - INSTALLATION, FUEL

FILTER / WATER .....................14-65

SEPARATOR - OPERATION, FUEL FILTER

/ WATER ...........................14-63

SEPARATOR - REMOVAL, FUEL FILTER /

WATER.............................14-64

SERVO - ASSEMBLY, FRONT.....21-164,21-335

SERVO - ASSEMBLY, REAR......21-207,21-379

SERVO - CLEANING, FRONT.....21-164,21-334

SERVO - CLEANING, REAR......21-207,21-379

SERVO - DESCRIPTION, FRONT . . 21-164,21-334

SERVO - DESCRIPTION, REAR . . . 21-207,21-378

SERVO - DESCRIPTION, SPEED

CONTROL...........................8P-6

SERVO - DISASSEMBLY, FRONT . . 21-164,21-334

SERVO - DISASSEMBLY, REAR . . . 21-207,21-378

SERVO - INSPECTION, FRONT.....21-164,21-335

SERVO - OPERATION, FRONT....21-164,21-334

SERVO - OPERATION, REAR.....21-207,21-378

SERVO - OPERATION, SPEED CONTROL . . . 8P-6

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO GROUND ON FUSES POWERING . . . 8W-01-9

SHAFT - ASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT...........21-199,21-371

SHAFT - DESCRIPTION, PLANETARY

GEARTRAIN/OUTPUT...........21-197,21-369

SHAFT - DIAGNOSIS AND TESTING,

PROPELLER...........................3-1

SHAFT - DISASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT...........21-198,21-369

SHAFT - FRONT - INSTALLATION,

PROPELLER...........................3-7

SHAFT - FRONT - REMOVAL,

PROPELLER...........................3-6

SHAFT - INSPECTION, PLANETARY

GEARTRAIN/OUTPUT...........21-199,21-371

SHAFT - INSTALLATION, PITMAN........19-25

SHAFT - INSTALLATION, WORM.........19-31

SHAFT - OPERATION, PLANETARY

GEARTRAIN/OUTPUT...........21-197,21-369

SHAFT - REAR - INSTALLATION,

PROPELLER...........................3-7

SHAFT - REAR - REMOVAL, PROPELLER....3-7

SHAFT - REMOVAL, PITMAN............19-24

SHAFT - REMOVAL, WORM............19-30

SHAFT - STANDARD PROCEDURES,

PROPELLER...........................3-3

SHAFT FRONT BEARING -

INSTALLATION, OUTPUT........21-171,21-342

SHAFT FRONT BEARING - REMOVAL,

OUTPUT.....................21-171,21-342

SHAFT REAR BEARING - INSTALLATION,

OUTPUT.....................21-172,21-343

SHAFT REAR BEARING - REMOVAL,

OUTPUT.....................21-171,21-343

SHAFT SEAL - INSTALLATION, FRONT

OUTPUT.....................21-461,21-498

SHAFT SEAL - INSTALLATION, PITMAN

. . . 19-26

SHAFT SEAL - REMOVAL, FRONT

OUTPUT

.....................21-461,21-498

SHAFT SEAL - REMOVAL, PITMAN

.......19-25

SHAFT SEALS - INSTALLATION, AXLE

.....3-31

SHAFT SEALS - REMOVAL, AXLE

.........3-31

SHAFT, SPECIAL TOOLS - PROPELLER

......3-6

SHAFT, SPECIFICATIONS - PROPELLER

.....3-6

SHAFTS - INSTALLATION,

AXLE

..................3-123,3-29,3-62,3-94

SHAFTS - INTERMEDIATE - REMOVAL,

AXLE

...............................3-30

SHAFTS - REMOVAL, AXLE

. 3-123,3-29,3-62,3-94

SHIELD - INSTALLATION, REAR SPLASH

. . 23-96

SHIELD - REMOVAL, REAR SPLASH

......23-96

SHIELDS - DESCRIPTION, HEAT

.........11-10SHIELDS - INSTALLATION, FRONT END

SPLASH............................23-92

SHIELDS - INSTALLATION, HEAT........11-10

SHIELDS - REMOVAL, FRONT END

SPLASH............................23-92

SHIELDS - REMOVAL, HEAT............11-10

SHIFT BOOT - INSTALLATION, 4WD

FLOOR............................23-122

SHIFT BOOT - MANUAL TRANSMISSION

- INSTALLATION....................23-122

SHIFT BOOT - MANUAL TRANSMISSION

- REMOVAL........................23-122

SHIFT BOOT - REMOVAL, 4WD FLOOR . . . 23-122

SHIFT COVER - NV4500 - INSTALLATION . . 21-45

SHIFT COVER - NV4500 - REMOVAL.....21-45

SHIFT COVER - NV5600 - INSTALLATION . . 21-86

SHIFT COVER - NV5600 - REMOVAL.....21-86

SHIFT INDICATOR (TRANSFER CASE) -

DESCRIPTION.......................8J-28

SHIFT INDICATOR (TRANSFER CASE) -

OPERATION.........................8J-28

SHIFT LEVER - ADJUSTMENT....21-463,21-500

SHIFT LEVER - INSTALLATION . . . 21-462,21-500

SHIFT LEVER - INSTALLATION, GEAR.....19-15

SHIFT LEVER - REMOVAL.......21-462,21-499

SHIFT LEVER - REMOVAL, GEAR........19-14

SHIFT MECHANISM - DESCRIPTION....21-208,

21-379

SHIFT MECHANISM - NV4500 -

INSTALLATION........................21-44

SHIFT MECHANISM - NV4500 -

REMOVAL..........................21-43

SHIFT MECHANISM - OPERATION......21-208,

21-379

SHOCK - DIAGNOSIS AND TESTING . . . 2-11,2-22

SHOCK - DIAGNOSIS AND TESTING,

SPRING.............................2-25

SHOCK - INSTALLATION........2-11,2-22,2-27

SHOCK - REMOVAL............2-11,2-22,2-27

SHOES - ADJUSTMENT, PARKING BRAKE . . 5-33

SHOES - INSTALLATION................5-32

SHOES - REMOVAL....................5-32

SHORT TO GROUND - STANDARD

PROCEDURE, TESTING FOR A........8W-01-9

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A ...........................8W-01-9

SHUTFACE HANDLE - INSTALLATION.....23-83

SHUTFACE HANDLE - REMOVAL.........23-83

SIDE MOLDINGS - INSTALLATION, BODY . . 23-87

SIDE MOLDINGS - REMOVAL, BODY.....23-86

SIDE PANEL SPEAKER - INSTALLATION,

REAR CAB..........................8A-20

SIDE PANEL SPEAKER - REMOVAL,

REAR CAB..........................8A-20

SIDE VIEW MIRROR - INSTALLATION.....23-98

SIDE VIEW MIRROR - LOW MOUNTED -

INSTALLATION.......................23-98

SIDE VIEW MIRROR - LOW MOUNTED -

REMOVAL..........................23-98

SIDE VIEW MIRROR - REMOVAL........23-97

SIDE VIEW MIRROR FLAG -

INSTALLATION.......................23-75

SIDE VIEW MIRROR FLAG - REMOVAL . . . 23-74

SIDE VIEW MIRROR GLASS -

INSTALLATION.......................23-98

SIDE VIEW MIRROR GLASS - REMOVAL . . 23-98

SIDEVIEW MIRROR - DESCRIPTION......8N-14

SIDEVIEW MIRROR - DIAGNOSIS AND

TESTING...........................8N-14

SIDEVIEW MIRROR - OPERATION.......8N-14

SIDEVIEW MIRROR - REMOVAL.........8N-15

SIGNAL & HAZARD WARNING SYSTEM -

DESCRIPTION, TURN..................8L-2

SIGNAL & HAZARD WARNING SYSTEM -

DIAGNOSIS AND TESTING, TURN.........8L-3

SIGNAL & HAZARD WARNING SYSTEM -

OPERATION, TURN....................8L-2

SIGNAL CANCEL CAM - DESCRIPTION,

TURN

..............................8L-31

SIGNAL CANCEL CAM - OPERATION,

TURN

..............................8L-31

SIGNAL GROUND - DESCRIPTION

.......8E-17

SIGNAL INDICATOR - DESCRIPTION,

TURN

..............................8J-32

SIGNAL INDICATOR - DIAGNOSIS AND

TESTING, TURN

......................8J-32SIGNAL INDICATOR - OPERATION, TURN . . 8J-32

SIGNAL LAMP - INSTALLATION,

PARK/TURN.........................8L-29

SIGNAL LAMP - REMOVAL, PARK/TURN . . 8L-29

SIGNAL LAMP UNIT - INSTALLATION,

PARK/TURN.........................8L-29

SIGNAL LAMP UNIT - REMOVAL,

PARK/TURN.........................8L-29

SILENCER PAD - INSTALLATION........23-104

SILENCER PAD - REMOVAL...........23-104

SILL TRIM - INSTALLATION, DOOR.....23-121

SILL TRIM - REMOVAL, DOOR.........23-121

SINGLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY...........................3-9

SINGLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY.........................3-8

SINGLE CARDAN UNIVERSAL JOINTS -

INSTALLATION........................3-35

SINGLE CARDAN UNIVERSAL JOINTS -

REMOVAL...........................3-34

SKID PLATE - INSTALLATION, TRANSFER

CASE..............................13-11

SKID PLATE - REMOVAL, TRANSFER

CASE..............................13-11

SLAM BUMPER - INSTALLATION........23-67

SLAM BUMPER - REMOVAL............23-67

SMOKE DIAGNOSIS CHARTS -

DIAGNOSIS AND TESTING.............9-118

SOLENOID - DESCRIPTION......21-208,21-380

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-33

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-34

SOLENOID - OPERATION........21-209,21-381

SOLENOID - OPERATION, EVAP/PURGE . . . 25-33

SOLENOID - REMOVAL, EVAP/PURGE.....25-33

SOLID LIFTERS/TAPPETS - CLEANING....9-164

SOLID LIFTERS/TAPPETS - INSPECTION . . 9-165

SOLID LIFTERS/TAPPETS -

INSTALLATION.......................9-165

SOLID LIFTERS/TAPPETS - REMOVAL....9-164

SPARE TIRE - DESCRIPTION............22-10

SPARE TIRE - TEMPORARY -

DESCRIPTION........................22-6

SPARK PLUG - CLEANING..............8I-20

SPARK PLUG - DESCRIPTION...........8I-16

SPARK PLUG - INSTALLATION...........8I-20

SPARK PLUG - OPERATION.............8I-16

SPARK PLUG - REMOVAL..............8I-19

SPARK PLUG CABLE - DESCRIPTION.....8I-20

SPARK PLUG CABLE - INSTALLATION.....8I-21

SPARK PLUG CABLE - OPERATION.......8I-20

SPARK PLUG CABLE - REMOVAL........8I-21

SPARK PLUG CABLE ORDER, 8.0L V-10

ENGINE..............................8I-3

SPARK PLUG CABLE RESISTANCE,

SPECIFICATIONS......................8I-3

SPARK PLUG CABLES - DIAGNOSIS AND

TESTING............................8I-20

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-17

SPARK PLUGS, SPECIFICATIONS..........8I-3

SPEAKER - DESCRIPTION..............8A-17

SPEAKER - DIAGNOSIS AND TESTING....8A-17

SPEAKER - INSTALLATION, A-PILLAR

TWEETER..........................8A-19

SPEAKER - INSTALLATION, FRONT DOOR . 8A-19

SPEAKER - INSTALLATION, REAR CAB

SIDE PANEL........................8A-20

SPEAKER - INSTALLATION, REAR DOOR . . 8A-21

SPEAKER - OPERATION...............8A-17

SPEAKER - REMOVAL, A-PILLAR

TWEETER..........................8A-18

SPEAKER - REMOVAL, FRONT DOOR.....8A-19

SPEAKER - REMOVAL, REAR CAB SIDE

PANEL.............................8A-20

SPEAKER - REMOVAL, REAR DOOR......8A-20

SPECIAL TOOL, SPECIAL TOOLS -

OVERHEAD CONSOLE.................8M-9

SPECIFICATIONS - 2002 BR/BE PAINT

COLOR CODES.....................23-129

SPECIFICATIONS - 5.9L DIESEL.........9-127

SPECIFICATIONS - 5.9L ENGINE..........9-13

SPECIFICATIONS - 8.OL ENGINE

..........9-68

SPECIFICATIONS - A/C APPLICATION

TABLE

..............................24-7

SPECIFICATIONS - ALIGNMENT

...........2-6

SPECIFICATIONS - BASE BRAKE

...........5-2

SPECIFICATIONS - BATTERY

.............8F-6

28 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2248 of 2255

SYSTEM - DIAGNOSIS AND TESTING,

POWER LOCK & REMOTE KEYLESS

ENTRY..............................8N-5

SYSTEM - DIAGNOSIS AND TESTING,

POWER SEAT.......................8N-16

SYSTEM - DIAGNOSIS AND TESTING,

POWER STEERING....................19-2

SYSTEM - DIAGNOSIS AND TESTING,

STARTING..........................8F-32

SYSTEM - DIAGNOSIS AND TESTING,

TURN SIGNAL & HAZARD WARNING......8L-3

SYSTEM - DIAGNOSIS AND TESTING,

VACUUM...........................24-10

SYSTEM - DIAGNOSIS AND TESTING,

VEHICLE THEFT SECURITY..............8Q-3

SYSTEM - DIAGNOSIS AND TESTING,

WIPER & WASHER....................8R-3

SYSTEM - INSPECTION, BATTERY........8F-6

SYSTEM - INSPECTION, WIPER &

WASHER............................8R-6

SYSTEM - LEAKS - DIAGNOSIS AND

TESTING, CHARGE AIR COOLER.........11-18

SYSTEM - OPERATION, AIR INJECTION . . . 25-28

SYSTEM - OPERATION, BATTERY.........8F-2

SYSTEM - OPERATION, CHIME

WARNING...........................8B-1

SYSTEM - OPERATION, COOLING..........7-4

SYSTEM - OPERATION, FUEL DELIVERY . . . 14-2

SYSTEM - OPERATION, HEATED MIRROR . . 8G-2

SYSTEM - OPERATION, HEATED SEAT.....8G-6

SYSTEM - OPERATION, INSTRUMENT

PANEL..............................23-106

SYSTEM - OPERATION, POWER SEAT....8N-16

SYSTEM - OPERATION, REMOTE

KEYLESS ENTRY......................8N-4

SYSTEM - OPERATION, SPEED CONTROL . . 8P-2

SYSTEM - OPERATION, TURN SIGNAL &

HAZARD WARNING....................8L-2

SYSTEM - SPECIAL TOOLS, AIRBAG......8O-6

SYSTEM - SPECIFICATIONS, TORQUE -

GENERATOR/CHARGING...............8F-27

SYSTEM - SPECIFICATIONS, TORQUE -

STARTING..........................8F-37

SYSTEM - STANDARD PROCEDURE,

BLEEDING ABS BRAKE.................5-36

SYSTEM - STANDARD PROCEDURE,

FLUSHING POWER STEERING...........19-34

SYSTEM - TORQUE, AIR INJECTION......25-29

SYSTEM - TORQUE, EVAP..............25-32

SYSTEM - TORQUE, SPEED CONTROL.....8P-4

SYSTEM 5.9L DIESEL ENGINE -

STANDARD PROCEDURE, DRAINING

COOLING............................7-15

SYSTEM 5.9L DIESEL ENGINE -

STANDARD PROCEDURE, REFILLING

COOLING............................7-16

SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, DRAINING

COOLING............................7-15

SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, REFILLING

COOLING............................7-16

SYSTEM AIR LEAK VACUUM TEST -

DIAGNOSIS AND TESTING, FUEL........14-57

SYSTEM AIRFLOW - DESCRIPTION,

HVAC..............................24-30

SYSTEM CHARGE - STANDARD

PROCEDURE, REFRIGERANT............24-46

SYSTEM CLEANING/REVERSE FLUSHING

- STANDARD PROCEDURE, COOLING......7-17

SYSTEM DIESEL ENGINE - DIAGNOSIS

AND TESTING, COOLING................7-13

SYSTEM EVACUATE - STANDARD

PROCEDURE, REFRIGERANT............24-46

SYSTEM FLOW - 5.9L DIESEL -

DESCRIPTION, COOLING.................7-2

SYSTEM FLOW - 5.9L ENGINE -

DESCRIPTION, COOLING.................7-1

SYSTEM GAS ENGINE - DIAGNOSIS AND

TESTING, COOLING

.....................7-7

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, COOLING

.....................7-5

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, REFRIGERANT

...............24-43

SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING FUEL

.........14-61

SYSTEM PRESSURE - GAS ENGINES -

SPECIFICATIONS, FUEL

.................14-3SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE, FUEL..........14-3

SYSTEM PRESSURES, DIESEL ENGINES

- FUEL.............................14-62

SYSTEM REQUIREMENTS -

DESCRIPTION, COOLING................24-1

SYSTEM SERVICE EQUIPMENT -

STANDARD PROCEDURE,

REFRIGERANT.......................24-45

SYSTEM SERVICE PORT - DESCRIPTION,

REFRIGERANT........................24-1

SYSTEM SERVICE PORT - OPERATION,

REFRIGERANT........................24-2

SYSTEM, SPECIAL TOOLS - DIESEL

FUEL..............................14-63

SYSTEM, SPECIAL TOOLS - FUEL . . . 14-35,14-4

SYSTEM, SPECIFICATIONS - STARTING . . . 8F-36

SYSTEMS - DESCRIPTION, MONITORED . . 25-17

SYSTEMS, SPECIAL TOOLS - AUDIO......8A-4

SYSTEMS, SPECIAL TOOLS - POWER

DISTRIBUTION....................8W-97-2

TABLE, SPECIFICATIONS - A/C

APPLICATION........................24-7

TACHOMETER - DESCRIPTION..........8J-30

TACHOMETER - OPERATION............8J-30

TAIL LAMP - DESCRIPTION............8L-29

TAIL LAMP - INSTALLATION............8L-30

TAIL LAMP - OPERATION..............8L-29

TAIL LAMP - REMOVAL................8L-29

TAIL LAMP UNIT - INSTALLATION.......8L-30

TAIL LAMP UNIT - REMOVAL...........8L-30

TAILGATE - INSTALLATION.............23-67

TAILGATE - REMOVAL.................23-67

TAILPIPE - 3.9L/5.2L/5.9L - INSPECTION . . 11-11

TAILPIPE - 3.9L/5.2L/5.9L -

INSTALLATION.......................11-11

TAILPIPE - 3.9L/5.2L/5.9L - REMOVAL....11-11

TAILPIPE - 5.9L DIESEL - INSPECTION....11-12

TAILPIPE - 5.9L DIESEL - INSTALLATION . . 11-13

TAILPIPE - 5.9L DIESEL - REMOVAL.....11-12

TAILPIPE - 5.9L HD/8.0L - INSPECTION . . . 11-12

TAILPIPE - 5.9L HD/8.0L -

INSTALLATION.......................11-12

TAILPIPE - 5.9L HD/8.0L - REMOVAL.....11-12

TANK - DESCRIPTION, DIESEL FUEL.....14-82

TANK - DESCRIPTION, FUEL............14-18

TANK - INSTALLATION, FUEL...........14-20

TANK - OPERATION, FUEL..............14-18

TANK - REMOVAL, FUEL...............14-18

TANK CHECK VALVE - DESCRIPTION,

FUEL..............................14-21

TANK CHECK VALVE - INSTALLATION,

FUEL..............................14-23

TANK CHECK VALVE - REMOVAL, FUEL . . . 14-22

TANK MODULE - DESCRIPTION, FUEL....14-82

TANK MODULE - INSTALLATION, FUEL....14-83

TANK MODULE - OPERATION, FUEL......14-82

TANK MODULE - REMOVAL, FUEL.......14-83

TAPE STRIPE - INSTALLATION..........23-89

TAPE STRIPE - REMOVAL..............23-88

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC......................9-36,9-91

TASK MANAGER - DESCRIPTION........25-17

TASK MANAGER - OPERATION..........25-21

TEMP SENSOR - 5.9L - DESCRIPTION,

ENGINE COOLANT.....................7-47

TEMP SENSOR - 5.9L - INSTALLATION,

ENGINE COOLANT.....................7-47

TEMP SENSOR - 5.9L - OPERATION,

ENGINE COOLANT.....................7-47

TEMP SENSOR - 5.9L - REMOVAL,

ENGINE COOLANT.....................7-47

TEMP SENSOR - DESCRIPTION,

AMBIENT..........................8M-12

TEMP SENSOR - INSTALLATION,

AMBIENT..........................8M-13

TEMP SENSOR - OPERATION, AMBIENT . . 8M-12

TEMP SENSOR - REMOVAL, AMBIENT . . . 8M-12

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE

............................8J-18

TEMPERATURE GAUGE - OPERATION,

ENGINE

............................8J-19

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY

...........................8F-27

TEMPERATURE SENSOR - DESCRIPTION,

FUEL

.............................14-104

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION

...............21-218,21-390TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT..............8M-12

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-28

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-27

TEMPERATURE SENSOR - OPERATION,

FUEL.............................14-104

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION...............21-218,21-390

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-27

TEMPORARY - DESCRIPTION, SPARE

TIRE................................22-6

TENSIONERS - 5.9L - DESCRIPTION,

BELT ...............................7-19

TENSIONERS - 5.9L - INSTALLATION,

BELT ...............................7-20

TENSIONERS - 5.9L - OPERATION, BELT . . . 7-19

TENSIONERS - 5.9L - REMOVAL, BELT.....7-19

TENSIONERS - 5.9L DIESEL -

DESCRIPTION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

INSTALLATION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

OPERATION, BELT.....................7-23

TENSIONERS - 5.9L DIESEL - REMOVAL,

BELT ...............................7-23

TENSIONERS - 8.0L - DESCRIPTION,

BELT ...............................7-20

TENSIONERS - 8.0L - INSTALLATION,

BELT ...............................7-22

TENSIONERS - 8.0L - OPERATION, BELT.....7-21

TENSIONERS - 8.0L - REMOVAL, BELT.....7-21

TERMINAL - INSTALLATION.........8W-01-13

TERMINAL - REMOVAL.............8W-01-13

TEST - DIAGNOSIS AND TESTING, FUEL

INJECTOR..........................14-99

TEST - DIAGNOSIS AND TESTING, FUEL

PRESSURE LEAK DOWN................14-2

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP AMPERAGE....................14-10

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP CAPACITY......................14-9

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP PRESSURE.....................14-9

TEST - DIAGNOSIS AND TESTING, FUEL

SYSTEM AIR LEAK VACUUM............14-57

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE.........21-270,21-98

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-4

TEST - DIAGNOSIS AND TESTING,

VACUUM SUPPLY.....................8P-3

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-10

TEST - STANDARD PROCEDURE,

HYDROMETER.......................8F-11

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-13

TEST - STANDARD PROCEDURE, LOAD . . . 8F-12

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE...............8F-12

TEST - STANDARD PROCEDURE,

VERIFICATION........................8O-5

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION

..........................25-2

TEST MODE - DESCRIPTION, STATE

DISPLAY

............................25-1

TETHER - INSTALLATION, CHILD

.........8O-9

TETHER - REMOVAL, CHILD

.............8O-9

THEFT SECURITY - DESCRIPTION,

VEHICLE

............................8Q-1

THEFT SECURITY - OPERATION, VEHICLE

. . 8Q-2

THEFT SECURITY SYSTEM - DIAGNOSIS

AND TESTING, VEHICLE

................8Q-3

THERMOSTAT - 5.9L - DESCRIPTION,

ENGINE COOLANT

.....................7-48

THERMOSTAT - 5.9L - INSTALLATION,

ENGINE COOLANT

.....................7-49

THERMOSTAT - 5.9L - OPERATION,

ENGINE COOLANT

.....................7-48

THERMOSTAT - 5.9L - REMOVAL,

ENGINE COOLANT

.....................7-48

THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE COOLANT

.........7-53

THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE COOLANT

........7-54

BR/BEINDEX 31

Description Group-Page Description Group-Page Description Group-Page

Page 2249 of 2255

THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE COOLANT..........7-53

THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE COOLANT............7-54

THERMOSTAT - 8.0L - DESCRIPTION,

ENGINE COOLANT.....................7-51

THERMOSTAT - 8.0L - INSTALLATION,

ENGINE COOLANT.....................7-52

THERMOSTAT - 8.0L - OPERATION,

ENGINE COOLANT.....................7-51

THERMOSTAT - 8.0L - REMOVAL,

ENGINE COOLANT.....................7-51

THERMOSTAT - DIAGNOSIS AND

TESTING....................7-48,7-51,7-53

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM.......21-114,21-286

THREADED HOLE REPAIR -

DESCRIPTION......................Intro.-9

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN . . 9-11,9-122,9-66

THROTTLE BODY - DESCRIPTION........14-47

THROTTLE BODY - OPERATION.........14-47

THROTTLE CONTROL CABLE -

INSTALLATION.................14-110,14-50

THROTTLE CONTROL CABLE -

REMOVAL....................14-109,14-49

THROTTLE POSITION SENSOR -

DESCRIPTION.......................14-50

THROTTLE POSITION SENSOR -

OPERATION.........................14-50

THROTTLE VALVE CABLE -

ADJUSTMENTS, TRANSMISSION . 21-210,21-382

THROTTLE VALVE CABLE -

DESCRIPTION................21-209,21-381

TIMER MODULE - DESCRIPTION,

CENTRAL............................8E-1

TIMER MODULE - DIAGNOSIS AND

TESTING, CENTRAL....................8E-4

TIMER MODULE - INSTALLATION,

CENTRAL............................8E-6

TIMER MODULE - OPERATION, CENTRAL . . 8E-3

TIMER MODULE - REMOVAL, CENTRAL....8E-5

TIMING - DIAGNOSIS AND TESTING,

FUEL INJECTION PUMP...............14-70

TIMING BELT / CHAIN COVER(S) -

INSTALLATION...................9-110,9-54

TIMING BELT / CHAIN COVER(S) -

REMOVAL......................9-110,9-53

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION...................9-111,9-55

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL......................9-111,9-54

TIMING CHAIN STRETCH - INSPECTION,

MEASURING....................9-111,9-54

TIMING, SPECIFICATIONS - IGNITION......8I-4

TIMING VERIFICATION - STANDARD

PROCEDURE........................9-187

TIRE - DESCRIPTION, SPARE...........22-10

TIRE - TEMPORARY - DESCRIPTION,

SPARE..............................22-6

TIRE AND WHEEL BALANCE -

STANDARD PROCEDURE................22-4

TIRE AND WHEEL RUNOUT - DIAGNOSIS

AND TESTING........................22-1

TIRE INFLATION PRESSURES -

DESCRIPTION........................22-7

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING........................22-9

TIRE PRESSURE FOR HIGH SPEEDS -

DESCRIPTION........................22-7

TIRE REVOLUTIONS PER MILE,

SPECIFICATIONS

......................22-9

TIRE ROTATION - STANDARD

PROCEDURE

.........................22-2

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING

........................22-8

TIRES - DESCRIPTION

.................22-6

TIRES - DESCRIPTION, RADIAL-PLY

.......22-6

TIRES - DESCRIPTION, REPLACEMENT

....22-7

TOOL, SPECIAL TOOLS - OVERHEAD

CONSOLE SPECIAL

...................8M-9

TOOLS - 5.9L DIESEL ENGINE, SPECIAL

. . 9-128

TOOLS - 5.9L ENGINE, SPECIAL

..........9-18

TOOLS - 8.0L ENGINE, SPECIAL

..........9-72

TOOLS - AUDIO SYSTEMS, SPECIAL

......8A-4

TOOLS - BASE BRAKES, SPECIAL

.........5-4

TOOLS - COOLING, SPECIAL

.............7-18TOOLS - DIESEL FUEL SYSTEM,

SPECIAL...........................14-63

TOOLS - FRONT AXLE, SPECIAL..........3-27

TOOLS - FUEL SYSTEM, SPECIAL . . . 14-35,14-4

TOOLS - HEADLAMP ALIGNMENT,

SPECIAL............................8L-4

TOOLS - INDEPENDENT FRONT

SUSPENSION, SPECIAL..................2-9

TOOLS - LINK/COIL SUSPENSION,

SPECIAL............................2-16

TOOLS - OVERHEAD CONSOLE SPECIAL

TOOL, SPECIAL......................8M-9

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL................8W-97-2

TOOLS - POWER STEERING GEAR,

SPECIAL...........................19-22

TOOLS - POWER STEERING PUMP,

SPECIAL...........................19-38

TOOLS - PROPELLER SHAFT, SPECIAL......3-6

TOOLS - RE TRANSMISSION, SPECIAL . . 21-146,

21-316

TOOLS - STEERING LINKAGE, SPECIAL . . . 19-41,

19-44

TOOLS - SUSPENSION-REAR, SPECIAL....2-27

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-9

TOOLS, AIRBAG SYSTEM - SPECIAL......8O-6

TOOLS, SPECIFICATIONS - SPECIAL.......8F-7

TOP COVER - INSTALLATION,

INSTRUMENT PANEL.................23-113

TOP COVER - REMOVAL, INSTRUMENT

PANEL............................23-113

TOW HOOK - INSTALLATION, FRONT.....13-10

TOW HOOK - REMOVAL, FRONT.........13-10

TOWING - STANDARD PROCEDURE.......0-10

TRACK - DESCRIPTION, POWER SEAT....8N-21

TRACK - DIAGNOSIS AND TESTING,

POWER SEAT.......................8N-22

TRACK - INSTALLATION, EASY ENTRY

SEAT .............................23-143

TRACK - INSTALLATION, POWER SEAT . . . 8N-22

TRACK - INSTALLATION, SEAT.........23-141

TRACK - OPERATION, POWER SEAT.....8N-22

TRACK - REMOVAL, EASY ENTRY SEAT . . 23-143

TRACK - REMOVAL, POWER SEAT.......8N-22

TRACK - REMOVAL, SEAT.............23-141

TRACK - SPLIT BENCH - INSTALLATION,

SEAT .............................23-142

TRACK - SPLIT BENCH - REMOVAL,

SEAT .............................23-142

TRACK ADJUSTER - INSTALLATION,

SEAT .............................23-143

TRACK ADJUSTER - REMOVAL, SEAT....23-143

TRACK BAR - DIAGNOSIS AND TESTING . . . 2-24

TRACK BAR - INSTALLATION............2-24

TRACK BAR - REMOVAL................2-24

TRAC-LOK - ASSEMBLY, DIFFERENTIAL . . . 3-129,

3-70

TRAC-LOK - DISASSEMBLY,

DIFFERENTIAL...................3-128,3-68

TRAC-LOKT- DIAGNOSIS AND TESTING . . 3-128,

3-67

TRAILER HITCH - INSTALLATION........13-11

TRAILER HITCH - REMOVAL............13-11

TRANS. - INSTALLATION, DIESEL WITH

AUTO..........................8P-12,8P-6

TRANS. - REMOVAL, DIESEL WITH AUTO

. . 8P-5,

8P-9

TRANS COOLER - 5.9L - DESCRIPTION

....7-78

TRANS COOLER - 5.9L - OPERATION

......7-78

TRANS COOLER - 5.9L DIESEL -

DESCRIPTION

........................7-84

TRANS COOLER - 5.9L DIESEL -

OPERATION

..........................7-84

TRANS COOLER - 8.0L - DESCRIPTION

....7-81

TRANS COOLER - 8.0L - OPERATION

......7-81

TRANS OVERTEMP INDICATOR -

DESCRIPTION

.......................8J-31

TRANS OVERTEMP INDICATOR -

OPERATION

.........................8J-31

TRANSFER CASE - DIAGNOSIS AND

TESTING

....................21-431,21-467

TRANSFER CASE - NV241 -

DESCRIPTION

.........................0-5

TRANSFER CASE - NV241HD -

ASSEMBLY

.........................21-480

TRANSFER CASE - NV241HD -

CLEANING

.........................21-476TRANSFER CASE - NV241HD -

DESCRIPTION......................21-465

TRANSFER CASE - NV241HD -

DISASSEMBLY......................21-469

TRANSFER CASE - NV241HD -

INSPECTION.......................21-476

TRANSFER CASE - NV241HD -

INSTALLATION......................21-494

TRANSFER CASE - NV241HD -

OPERATION........................21-467

TRANSFER CASE - NV241HD - REMOVAL . 21-469

TRANSFER CASE - NV241LD -

ASSEMBLY.........................21-445

TRANSFER CASE - NV241LD - CLEANING . 21-441

TRANSFER CASE - NV241LD -

DESCRIPTION......................21-430

TRANSFER CASE - NV241LD -

DISASSEMBLY......................21-432

TRANSFER CASE - NV241LD -

INSPECTION.......................21-442

TRANSFER CASE - NV241LD -

INSTALLATION......................21-458

TRANSFER CASE - NV241LD -

OPERATION........................21-430

TRANSFER CASE - NV241LD - REMOVAL . 21-432

TRANSFER CASE, NV241HD...........21-495

TRANSFER CASE, NV241LD...........21-459

TRANSFER CASE SKID PLATE -

INSTALLATION.......................13-11

TRANSFER CASE SKID PLATE -

REMOVAL..........................13-11

TRANSFER CASE, SPECIFICATIONS . 21-458,21-495

TRANSFER PUMP - DESCRIPTION, FUEL . . 14-83

TRANSFER PUMP - INSTALLATION, FUEL . 14-87

TRANSFER PUMP - OPERATION, FUEL....14-83

TRANSFER PUMP - REMOVAL, FUEL.....14-86

TRANSFER PUMP PRESSURE -

DIAGNOSIS AND TESTING, FUEL........14-84

TRANSMISSION - 46RE - DESCRIPTION,

AUTOMATIC.........................21-89

TRANSMISSION - 46RE - OPERATION,

AUTOMATIC.........................21-91

TRANSMISSION - 47RE - DESCRIPTION,

AUTOMATIC........................21-261

TRANSMISSION - 47RE - OPERATION,

AUTOMATIC........................21-263

TRANSMISSION - DESCRIPTION,

MANUAL.............................0-5

TRANSMISSION - DIAGNOSIS AND

TESTING, AUTOMATIC...........21-268,21-96

TRANSMISSION - INSTALLATION, SHIFT

BOOT - MANUAL....................23-122

TRANSMISSION - REMOVAL, SHIFT

BOOT - MANUAL....................23-122

TRANSMISSION CLUTCH AND BAND

OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING.........21-100,21-272

TRANSMISSION FILL - STANDARD

PROCEDURE

.................21-160,21-330

TRANSMISSION FLUID - DESCRIPTION,

AUTOMATIC

...........................0-6

TRANSMISSION FLUID - OPERATION,

AUTOMATIC

...........................0-6

TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES - WITH

RADIATOR IN-TANK

...........7-78,7-82,7-84

TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES - WITHOUT

RADIATOR IN-TANK

...........7-79,7-82,7-85

TRANSMISSION, SPECIAL TOOLS - RE

. . 21-146,

21-316

TRANSMISSION, SPECIFICATIONS

......21-144,

21-314

TRANSMISSION TEMPERATURE SENSOR

- DESCRIPTION

...............21-218,21-390

TRANSMISSION TEMPERATURE SENSOR

- OPERATION

.................21-218,21-390

TRANSMISSION THROTTLE VALVE

CABLE - ADJUSTMENTS

........21-210,21-382

TRANSMITTER - DESCRIPTION, REMOTE

KEYLESS ENTRY

......................8N-7

TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS ENTRY

......8N-8

TRANSMITTER - OPERATION, REMOTE

KEYLESS ENTRY

......................8N-8

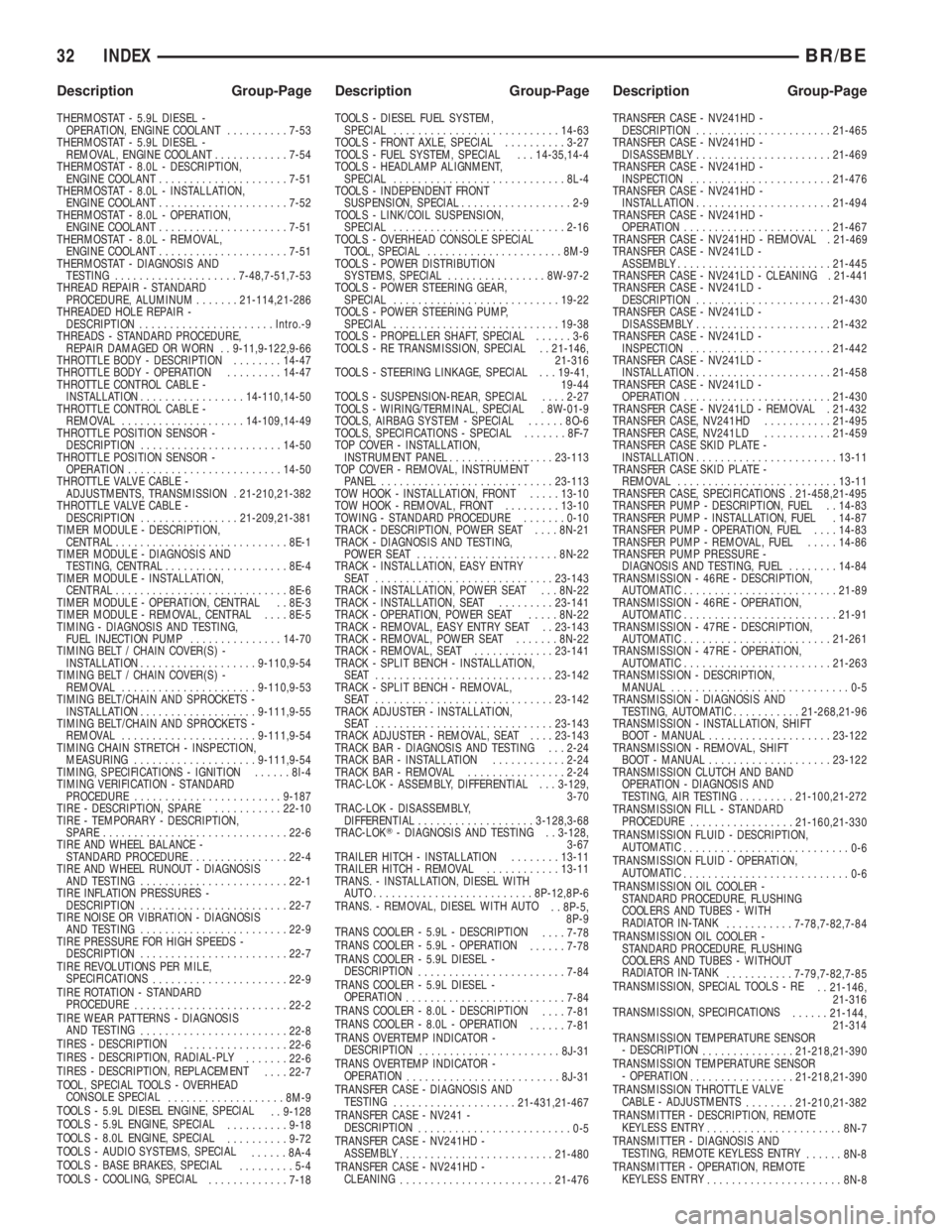

32 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page