towing DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 14 of 2255

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

INTERNATIONAL SYMBOLS

DESCRIPTION...........................1

PARTS & LUBRICANT RECOMMENDATION

STANDARD PROCEDURE

STANDARD PROCEDURE -

CLASSIFICATION OF LUBRICANTS..........1

FLUID TYPES

DESCRIPTION...........................2

OPERATION.............................6

FLUID CAPACITIES

SPECIFICATIONS.........................6

MAINTENANCE SCHEDULES

DESCRIPTION...........................7JUMP STARTING

STANDARD PROCEDURE

STANDARD PROCEDURE - JUMP

STARTING.............................7

HOISTING

STANDARD PROCEDURE

STANDARD PROCEDURE - HOISTING.......9

TOWING

STANDARD PROCEDURE

STANDARD PROCEDURE - TOWING.......10

INTERNATIONAL SYMBOLS

DESCRIPTION

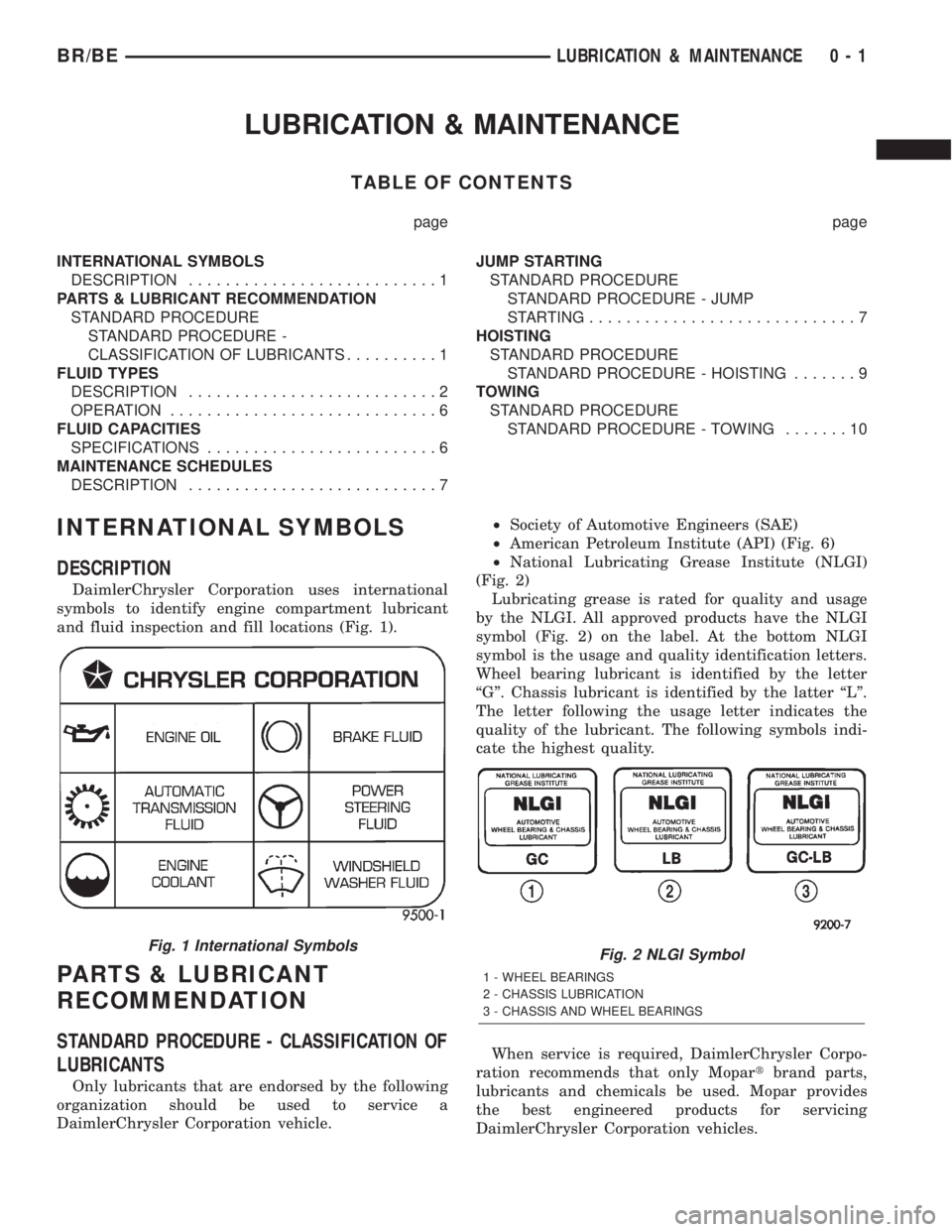

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 1).

PARTS & LUBRICANT

RECOMMENDATION

STANDARD PROCEDURE - CLASSIFICATION OF

LUBRICANTS

Only lubricants that are endorsed by the following

organization should be used to service a

DaimlerChrysler Corporation vehicle.²Society of Automotive Engineers (SAE)

²American Petroleum Institute (API) (Fig. 6)

²National Lubricating Grease Institute (NLGI)

(Fig. 2)

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 2) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

When service is required, DaimlerChrysler Corpo-

ration recommends that only Mopartbrand parts,

lubricants and chemicals be used. Mopar provides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

Fig. 1 International SymbolsFig. 2 NLGI Symbol

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

BR/BELUBRICATION & MAINTENANCE 0 - 1

Page 23 of 2255

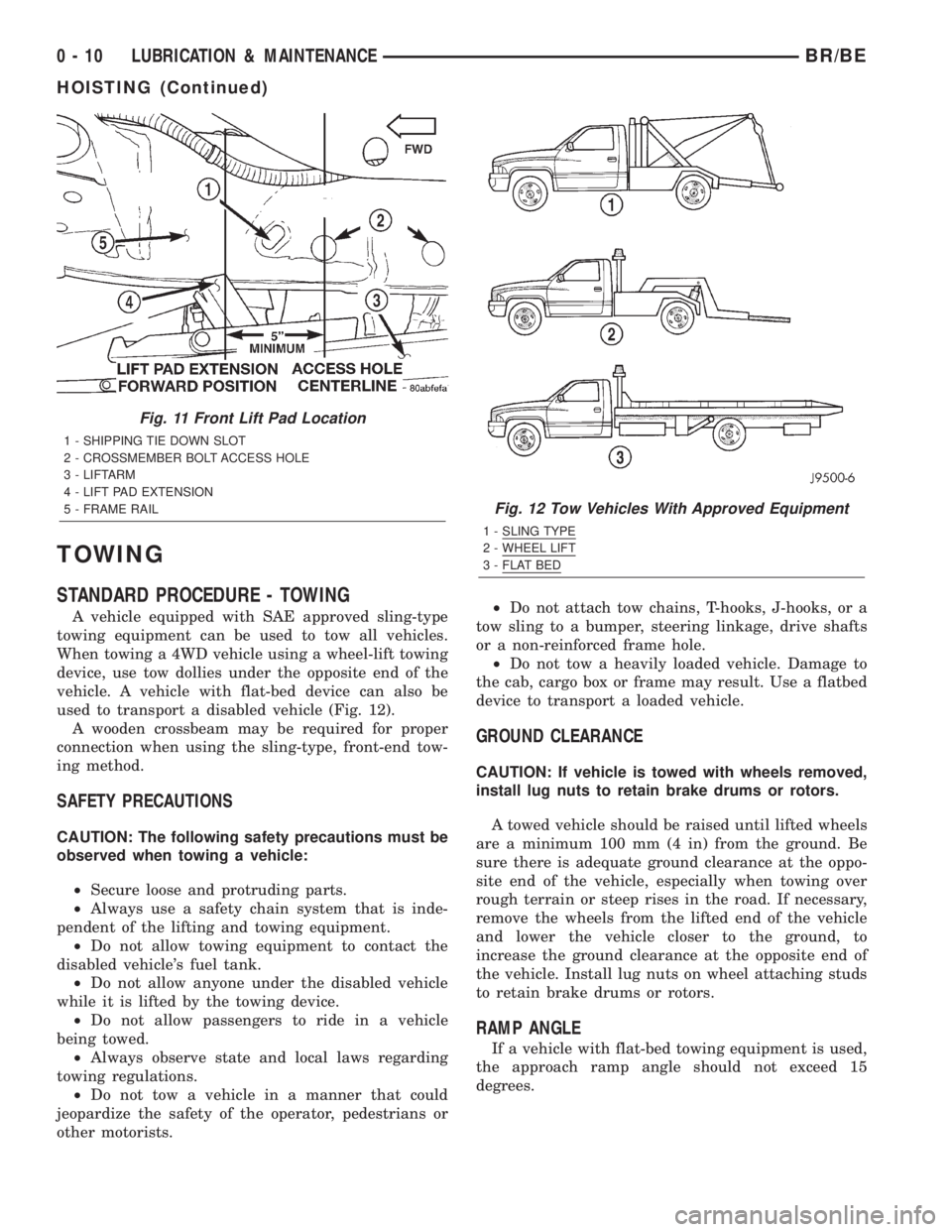

TOWING

STANDARD PROCEDURE - TOWING

A vehicle equipped with SAE approved sling-type

towing equipment can be used to tow all vehicles.

When towing a 4WD vehicle using a wheel-lift towing

device, use tow dollies under the opposite end of the

vehicle. A vehicle with flat-bed device can also be

used to transport a disabled vehicle (Fig. 12).

A wooden crossbeam may be required for proper

connection when using the sling-type, front-end tow-

ing method.

SAFETY PRECAUTIONS

CAUTION: The following safety precautions must be

observed when towing a vehicle:

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.²Do not attach tow chains, T-hooks, J-hooks, or a

tow sling to a bumper, steering linkage, drive shafts

or a non-reinforced frame hole.

²Do not tow a heavily loaded vehicle. Damage to

the cab, cargo box or frame may result. Use a flatbed

device to transport a loaded vehicle.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain or steep rises in the road. If necessary,

remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to

increase the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums or rotors.

RAMP ANGLE

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15

degrees.

Fig. 11 Front Lift Pad Location

1 - SHIPPING TIE DOWN SLOT

2 - CROSSMEMBER BOLT ACCESS HOLE

3 - LIFTARM

4 - LIFT PAD EXTENSION

5 - FRAME RAIL

Fig. 12 Tow Vehicles With Approved Equipment

1 - SLING TYPE

2 - WHEEL LIFT

3 - FLAT BED

0 - 10 LUBRICATION & MAINTENANCEBR/BE

HOISTING (Continued)

Page 24 of 2255

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not avail-

able, use a flat bed hauler. A Wheel-lift or Sling-type

device can be used on 4WD vehicles providedall the

wheels are lifted off the ground using tow dol-

lies.

FOUR-WHEEL-DRIVE VEHICLE TOWING

Chrysler Corporation recommends that a vehicle be

transported on a flat-bed device. A Wheel-lift or

Sling-type device can be used providedall the

wheels are lifted off the ground using tow dol-

lies.WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION (AUTO-

MATIC TRANSMISSION) OR A FORWARD DRIVE

GEAR (MANUAL TRANSMISSION).

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

BR/BELUBRICATION & MAINTENANCE 0 - 11

TOWING (Continued)

Page 250 of 2255

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM FLOW -

5.9L ENGINE..........................1

DESCRIPTIONÐCOOLING SYSTEM FLOW -

5.9L DIESEL..........................2

DESCRIPTIONÐHOSE CLAMPS...........4

OPERATION

OPERATIONÐHOSE CLAMPS............4

OPERATIONÐCOOLING SYSTEM.........4

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS.............................4

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)...................5

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAKS.......................5

DIAGNOSIS AND TESTING - COOLING

SYSTEM GAS ENGINE..................7

DIAGNOSIS AND TESTING - COOLING

SYSTEM DIESEL ENGINE...............13

STANDARD PROCEDURE

STANDARD PROCEDURE - DRAINING

COOLING SYSTEM 5.9L/8.0L ENGINES....15STANDARD PROCEDUREÐDRAINING

COOLING SYSTEM 5.9L DIESEL ENGINE . . . 15

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 5.9L/8.0L ENGINES....16

STANDARD PROCEDUREÐREFILLING

COOLING SYSTEM 5.9L DIESEL ENGINE . . . 16

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................16

STANDARD PROCEDUREÐCOOLANT

LEVEL CHECK........................16

STANDARD PROCEDURE - COOLING

SYSTEM CLEANING/REVERSE FLUSHING . . 17

STANDARD PROCEDURE - COOLANT

SELECTION - ADDITIVES...............17

SPECIFICATIONS

TORQUE............................18

SPECIAL TOOLS

COOLING...........................18

ACCESSORY DRIVE......................19

ENGINE...............................38

TRANSMISSION.........................78

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM FLOW -

5.9L ENGINE

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures (Fig. 1).

BR/BECOOLING 7 - 1

Page 253 of 2255

DESCRIPTIONÐHOSE CLAMPS

The cooling system utilizes both worm drive and

spring type hose clamps. If a spring type clamp

replacement is necessary, replace with the original

Mopartequipment spring type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 4).

OPERATION

OPERATIONÐHOSE CLAMPS

The worm type hose clamp uses a specified torque

value to maintain proper tension on a hose connec-

tion.

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

OPERATIONÐCOOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

²SLIGHT TAIL WIND AT IDLE

²SLOW TRAFFIC

²TRAFFIC JAMS

²HIGH SPEED OR STEEP GRADES

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

²Increasing engine speed for more air flow is rec-

ommended.

TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

AIR CONDITIONING; ADD-ON OR AFTER MARKET:

A maximum cooling package should have been

ordered with vehicle if add-on or after market A/C is

installed. If not, maximum cooling system compo-

nents should be installed for model involved per

manufacturer's specifications.

RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts. Incorrect water pump or pump

rotating in wrong direction due to belt not correctly

routed

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, (Refer to 7 - COOLING - DIAGNOSIS AND

TESTING)

Fig. 4 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

7 - 4 COOLINGBR/BE

COOLING (Continued)

Page 304 of 2255

FAN DRIVE VISCOUS CLUTCH

- 5.9L/8.0L

DESCRIPTION

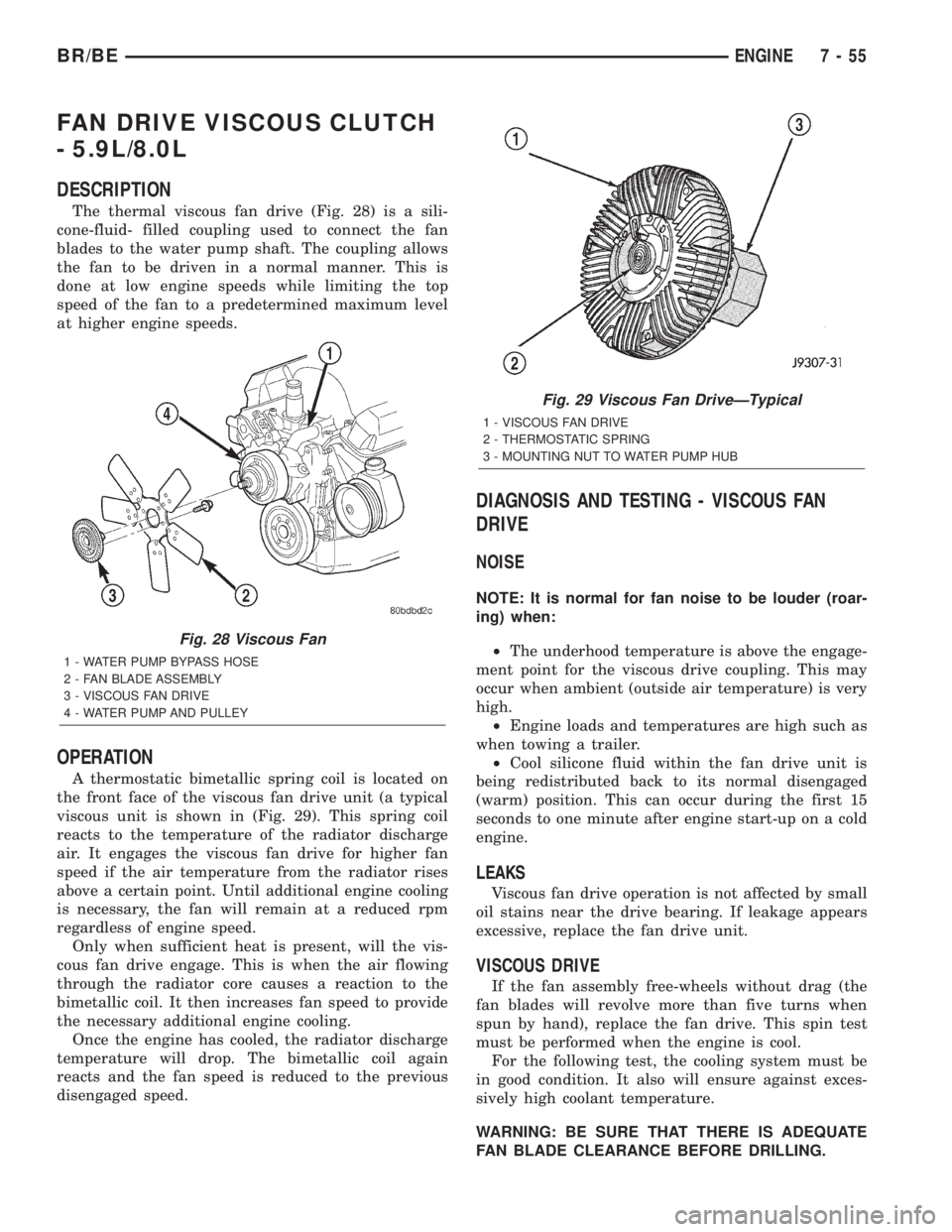

The thermal viscous fan drive (Fig. 28) is a sili-

cone-fluid- filled coupling used to connect the fan

blades to the water pump shaft. The coupling allows

the fan to be driven in a normal manner. This is

done at low engine speeds while limiting the top

speed of the fan to a predetermined maximum level

at higher engine speeds.

OPERATION

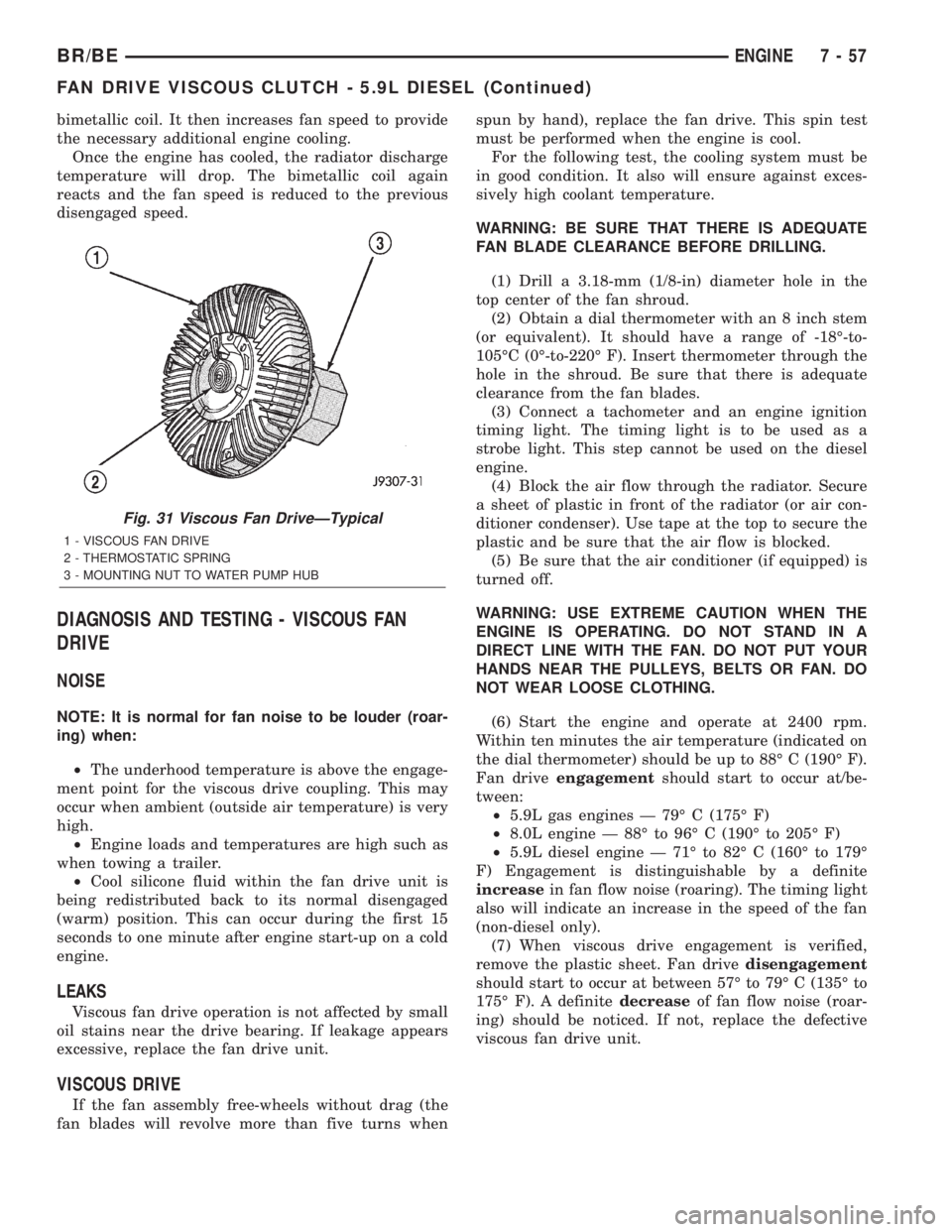

A thermostatic bimetallic spring coil is located on

the front face of the viscous fan drive unit (a typical

viscous unit is shown in (Fig. 29). This spring coil

reacts to the temperature of the radiator discharge

air. It engages the viscous fan drive for higher fan

speed if the air temperature from the radiator rises

above a certain point. Until additional engine cooling

is necessary, the fan will remain at a reduced rpm

regardless of engine speed.

Only when sufficient heat is present, will the vis-

cous fan drive engage. This is when the air flowing

through the radiator core causes a reaction to the

bimetallic coil. It then increases fan speed to provide

the necessary additional engine cooling.

Once the engine has cooled, the radiator discharge

temperature will drop. The bimetallic coil again

reacts and the fan speed is reduced to the previous

disengaged speed.

DIAGNOSIS AND TESTING - VISCOUS FAN

DRIVE

NOISE

NOTE: It is normal for fan noise to be louder (roar-

ing) when:

²The underhood temperature is above the engage-

ment point for the viscous drive coupling. This may

occur when ambient (outside air temperature) is very

high.

²Engine loads and temperatures are high such as

when towing a trailer.

²Cool silicone fluid within the fan drive unit is

being redistributed back to its normal disengaged

(warm) position. This can occur during the first 15

seconds to one minute after engine start-up on a cold

engine.

LEAKS

Viscous fan drive operation is not affected by small

oil stains near the drive bearing. If leakage appears

excessive, replace the fan drive unit.

VISCOUS DRIVE

If the fan assembly free-wheels without drag (the

fan blades will revolve more than five turns when

spun by hand), replace the fan drive. This spin test

must be performed when the engine is cool.

For the following test, the cooling system must be

in good condition. It also will ensure against exces-

sively high coolant temperature.

WARNING: BE SURE THAT THERE IS ADEQUATE

FAN BLADE CLEARANCE BEFORE DRILLING.

Fig. 28 Viscous Fan

1 - WATER PUMP BYPASS HOSE

2 - FAN BLADE ASSEMBLY

3 - VISCOUS FAN DRIVE

4 - WATER PUMP AND PULLEY

Fig. 29 Viscous Fan DriveÐTypical

1 - VISCOUS FAN DRIVE

2 - THERMOSTATIC SPRING

3 - MOUNTING NUT TO WATER PUMP HUB

BR/BEENGINE 7 - 55

Page 306 of 2255

bimetallic coil. It then increases fan speed to provide

the necessary additional engine cooling.

Once the engine has cooled, the radiator discharge

temperature will drop. The bimetallic coil again

reacts and the fan speed is reduced to the previous

disengaged speed.

DIAGNOSIS AND TESTING - VISCOUS FAN

DRIVE

NOISE

NOTE: It is normal for fan noise to be louder (roar-

ing) when:

²The underhood temperature is above the engage-

ment point for the viscous drive coupling. This may

occur when ambient (outside air temperature) is very

high.

²Engine loads and temperatures are high such as

when towing a trailer.

²Cool silicone fluid within the fan drive unit is

being redistributed back to its normal disengaged

(warm) position. This can occur during the first 15

seconds to one minute after engine start-up on a cold

engine.

LEAKS

Viscous fan drive operation is not affected by small

oil stains near the drive bearing. If leakage appears

excessive, replace the fan drive unit.

VISCOUS DRIVE

If the fan assembly free-wheels without drag (the

fan blades will revolve more than five turns whenspun by hand), replace the fan drive. This spin test

must be performed when the engine is cool.

For the following test, the cooling system must be

in good condition. It also will ensure against exces-

sively high coolant temperature.

WARNING: BE SURE THAT THERE IS ADEQUATE

FAN BLADE CLEARANCE BEFORE DRILLING.

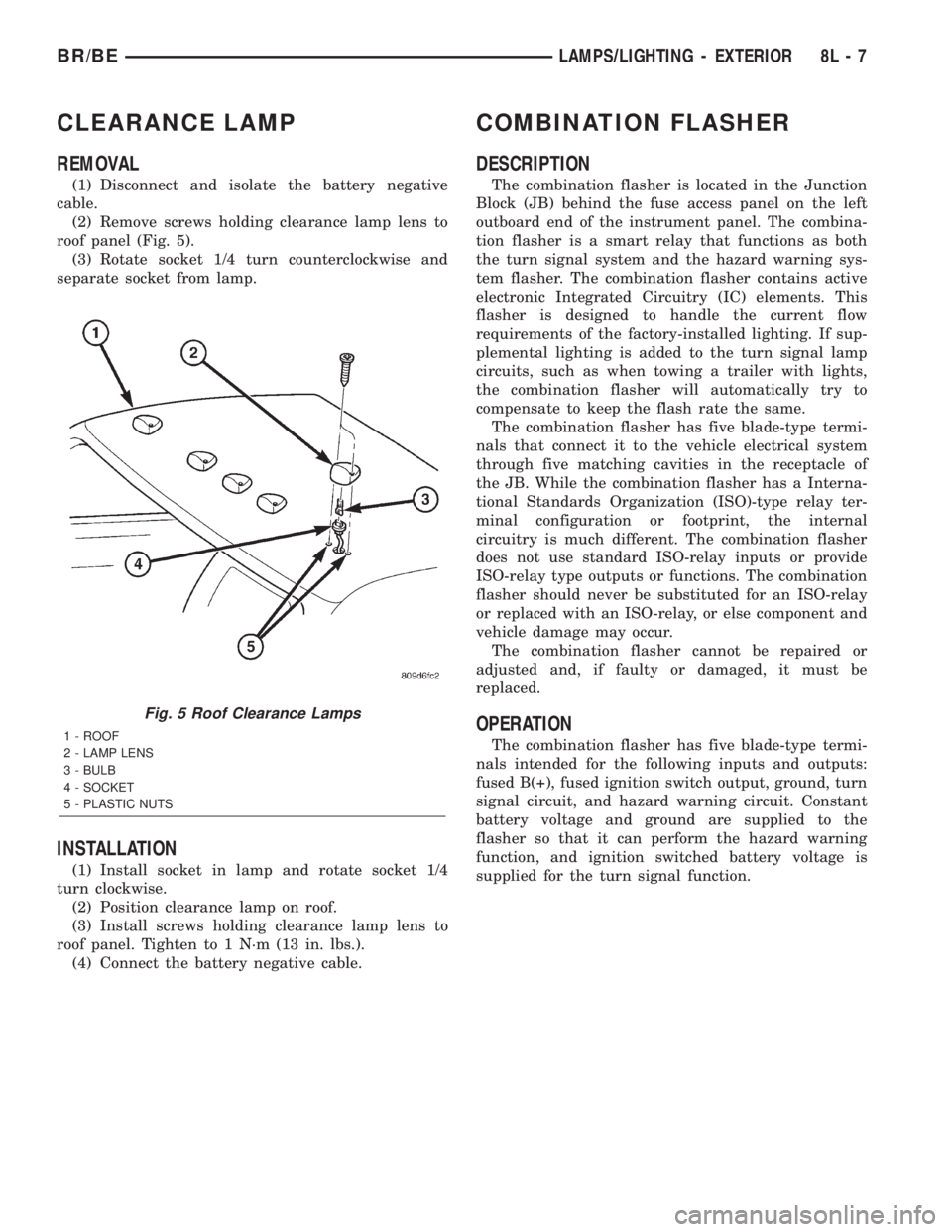

(1) Drill a 3.18-mm (1/8-in) diameter hole in the

top center of the fan shroud.

(2) Obtain a dial thermometer with an 8 inch stem

(or equivalent). It should have a range of -18É-to-

105ÉC (0É-to-220É F). Insert thermometer through the

hole in the shroud. Be sure that there is adequate

clearance from the fan blades.

(3) Connect a tachometer and an engine ignition

timing light. The timing light is to be used as a

strobe light. This step cannot be used on the diesel

engine.

(4) Block the air flow through the radiator. Secure

a sheet of plastic in front of the radiator (or air con-

ditioner condenser). Use tape at the top to secure the

plastic and be sure that the air flow is blocked.

(5) Be sure that the air conditioner (if equipped) is

turned off.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(6) Start the engine and operate at 2400 rpm.

Within ten minutes the air temperature (indicated on

the dial thermometer) should be up to 88É C (190É F).

Fan driveengagementshould start to occur at/be-

tween:

²5.9L gas engines Ð 79É C (175É F)

²8.0L engine Ð 88É to 96É C (190É to 205É F)

²5.9L diesel engine Ð 71É to 82É C (160É to 179É

F) Engagement is distinguishable by a definite

increasein fan flow noise (roaring). The timing light

also will indicate an increase in the speed of the fan

(non-diesel only).

(7) When viscous drive engagement is verified,

remove the plastic sheet. Fan drivedisengagement

should start to occur at between 57É to 79É C (135É to

175É F). A definitedecreaseof fan flow noise (roar-

ing) should be noticed. If not, replace the defective

viscous fan drive unit.

Fig. 31 Viscous Fan DriveÐTypical

1 - VISCOUS FAN DRIVE

2 - THERMOSTATIC SPRING

3 - MOUNTING NUT TO WATER PUMP HUB

BR/BEENGINE 7 - 57

FAN DRIVE VISCOUS CLUTCH - 5.9L DIESEL (Continued)

Page 522 of 2255

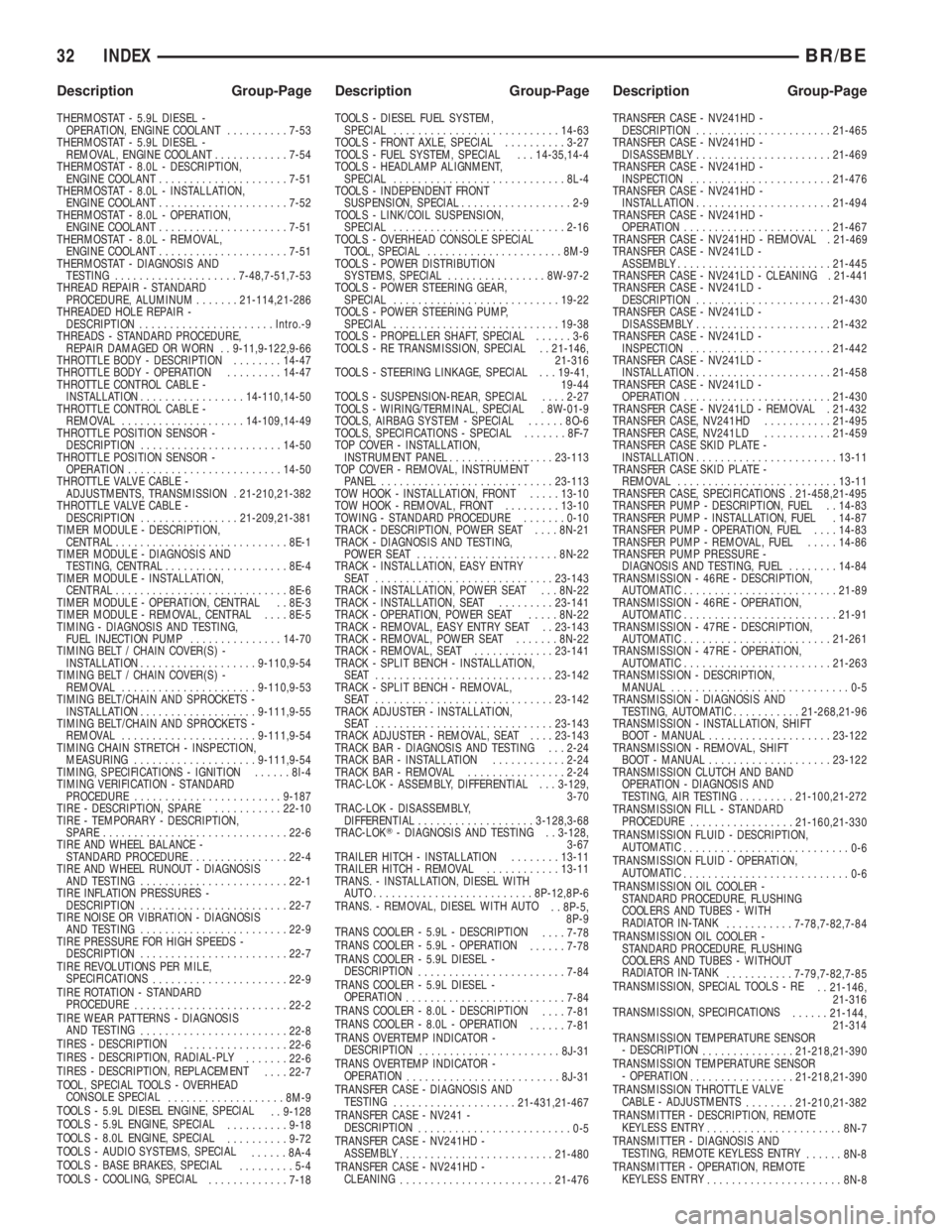

CLEARANCE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screws holding clearance lamp lens to

roof panel (Fig. 5).

(3) Rotate socket 1/4 turn counterclockwise and

separate socket from lamp.

INSTALLATION

(1) Install socket in lamp and rotate socket 1/4

turn clockwise.

(2) Position clearance lamp on roof.

(3) Install screws holding clearance lamp lens to

roof panel. Tighten to 1 N´m (13 in. lbs.).

(4) Connect the battery negative cable.

COMBINATION FLASHER

DESCRIPTION

The combination flasher is located in the Junction

Block (JB) behind the fuse access panel on the left

outboard end of the instrument panel. The combina-

tion flasher is a smart relay that functions as both

the turn signal system and the hazard warning sys-

tem flasher. The combination flasher contains active

electronic Integrated Circuitry (IC) elements. This

flasher is designed to handle the current flow

requirements of the factory-installed lighting. If sup-

plemental lighting is added to the turn signal lamp

circuits, such as when towing a trailer with lights,

the combination flasher will automatically try to

compensate to keep the flash rate the same.

The combination flasher has five blade-type termi-

nals that connect it to the vehicle electrical system

through five matching cavities in the receptacle of

the JB. While the combination flasher has a Interna-

tional Standards Organization (ISO)-type relay ter-

minal configuration or footprint, the internal

circuitry is much different. The combination flasher

does not use standard ISO-relay inputs or provide

ISO-relay type outputs or functions. The combination

flasher should never be substituted for an ISO-relay

or replaced with an ISO-relay, or else component and

vehicle damage may occur.

The combination flasher cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The combination flasher has five blade-type termi-

nals intended for the following inputs and outputs:

fused B(+), fused ignition switch output, ground, turn

signal circuit, and hazard warning circuit. Constant

battery voltage and ground are supplied to the

flasher so that it can perform the hazard warning

function, and ignition switched battery voltage is

supplied for the turn signal function.

Fig. 5 Roof Clearance Lamps

1 - ROOF

2 - LAMP LENS

3 - BULB

4 - SOCKET

5 - PLASTIC NUTS

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 7

Page 2249 of 2255

THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE COOLANT..........7-53

THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE COOLANT............7-54

THERMOSTAT - 8.0L - DESCRIPTION,

ENGINE COOLANT.....................7-51

THERMOSTAT - 8.0L - INSTALLATION,

ENGINE COOLANT.....................7-52

THERMOSTAT - 8.0L - OPERATION,

ENGINE COOLANT.....................7-51

THERMOSTAT - 8.0L - REMOVAL,

ENGINE COOLANT.....................7-51

THERMOSTAT - DIAGNOSIS AND

TESTING....................7-48,7-51,7-53

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM.......21-114,21-286

THREADED HOLE REPAIR -

DESCRIPTION......................Intro.-9

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN . . 9-11,9-122,9-66

THROTTLE BODY - DESCRIPTION........14-47

THROTTLE BODY - OPERATION.........14-47

THROTTLE CONTROL CABLE -

INSTALLATION.................14-110,14-50

THROTTLE CONTROL CABLE -

REMOVAL....................14-109,14-49

THROTTLE POSITION SENSOR -

DESCRIPTION.......................14-50

THROTTLE POSITION SENSOR -

OPERATION.........................14-50

THROTTLE VALVE CABLE -

ADJUSTMENTS, TRANSMISSION . 21-210,21-382

THROTTLE VALVE CABLE -

DESCRIPTION................21-209,21-381

TIMER MODULE - DESCRIPTION,

CENTRAL............................8E-1

TIMER MODULE - DIAGNOSIS AND

TESTING, CENTRAL....................8E-4

TIMER MODULE - INSTALLATION,

CENTRAL............................8E-6

TIMER MODULE - OPERATION, CENTRAL . . 8E-3

TIMER MODULE - REMOVAL, CENTRAL....8E-5

TIMING - DIAGNOSIS AND TESTING,

FUEL INJECTION PUMP...............14-70

TIMING BELT / CHAIN COVER(S) -

INSTALLATION...................9-110,9-54

TIMING BELT / CHAIN COVER(S) -

REMOVAL......................9-110,9-53

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION...................9-111,9-55

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL......................9-111,9-54

TIMING CHAIN STRETCH - INSPECTION,

MEASURING....................9-111,9-54

TIMING, SPECIFICATIONS - IGNITION......8I-4

TIMING VERIFICATION - STANDARD

PROCEDURE........................9-187

TIRE - DESCRIPTION, SPARE...........22-10

TIRE - TEMPORARY - DESCRIPTION,

SPARE..............................22-6

TIRE AND WHEEL BALANCE -

STANDARD PROCEDURE................22-4

TIRE AND WHEEL RUNOUT - DIAGNOSIS

AND TESTING........................22-1

TIRE INFLATION PRESSURES -

DESCRIPTION........................22-7

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING........................22-9

TIRE PRESSURE FOR HIGH SPEEDS -

DESCRIPTION........................22-7

TIRE REVOLUTIONS PER MILE,

SPECIFICATIONS

......................22-9

TIRE ROTATION - STANDARD

PROCEDURE

.........................22-2

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING

........................22-8

TIRES - DESCRIPTION

.................22-6

TIRES - DESCRIPTION, RADIAL-PLY

.......22-6

TIRES - DESCRIPTION, REPLACEMENT

....22-7

TOOL, SPECIAL TOOLS - OVERHEAD

CONSOLE SPECIAL

...................8M-9

TOOLS - 5.9L DIESEL ENGINE, SPECIAL

. . 9-128

TOOLS - 5.9L ENGINE, SPECIAL

..........9-18

TOOLS - 8.0L ENGINE, SPECIAL

..........9-72

TOOLS - AUDIO SYSTEMS, SPECIAL

......8A-4

TOOLS - BASE BRAKES, SPECIAL

.........5-4

TOOLS - COOLING, SPECIAL

.............7-18TOOLS - DIESEL FUEL SYSTEM,

SPECIAL...........................14-63

TOOLS - FRONT AXLE, SPECIAL..........3-27

TOOLS - FUEL SYSTEM, SPECIAL . . . 14-35,14-4

TOOLS - HEADLAMP ALIGNMENT,

SPECIAL............................8L-4

TOOLS - INDEPENDENT FRONT

SUSPENSION, SPECIAL..................2-9

TOOLS - LINK/COIL SUSPENSION,

SPECIAL............................2-16

TOOLS - OVERHEAD CONSOLE SPECIAL

TOOL, SPECIAL......................8M-9

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL................8W-97-2

TOOLS - POWER STEERING GEAR,

SPECIAL...........................19-22

TOOLS - POWER STEERING PUMP,

SPECIAL...........................19-38

TOOLS - PROPELLER SHAFT, SPECIAL......3-6

TOOLS - RE TRANSMISSION, SPECIAL . . 21-146,

21-316

TOOLS - STEERING LINKAGE, SPECIAL . . . 19-41,

19-44

TOOLS - SUSPENSION-REAR, SPECIAL....2-27

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-9

TOOLS, AIRBAG SYSTEM - SPECIAL......8O-6

TOOLS, SPECIFICATIONS - SPECIAL.......8F-7

TOP COVER - INSTALLATION,

INSTRUMENT PANEL.................23-113

TOP COVER - REMOVAL, INSTRUMENT

PANEL............................23-113

TOW HOOK - INSTALLATION, FRONT.....13-10

TOW HOOK - REMOVAL, FRONT.........13-10

TOWING - STANDARD PROCEDURE.......0-10

TRACK - DESCRIPTION, POWER SEAT....8N-21

TRACK - DIAGNOSIS AND TESTING,

POWER SEAT.......................8N-22

TRACK - INSTALLATION, EASY ENTRY

SEAT .............................23-143

TRACK - INSTALLATION, POWER SEAT . . . 8N-22

TRACK - INSTALLATION, SEAT.........23-141

TRACK - OPERATION, POWER SEAT.....8N-22

TRACK - REMOVAL, EASY ENTRY SEAT . . 23-143

TRACK - REMOVAL, POWER SEAT.......8N-22

TRACK - REMOVAL, SEAT.............23-141

TRACK - SPLIT BENCH - INSTALLATION,

SEAT .............................23-142

TRACK - SPLIT BENCH - REMOVAL,

SEAT .............................23-142

TRACK ADJUSTER - INSTALLATION,

SEAT .............................23-143

TRACK ADJUSTER - REMOVAL, SEAT....23-143

TRACK BAR - DIAGNOSIS AND TESTING . . . 2-24

TRACK BAR - INSTALLATION............2-24

TRACK BAR - REMOVAL................2-24

TRAC-LOK - ASSEMBLY, DIFFERENTIAL . . . 3-129,

3-70

TRAC-LOK - DISASSEMBLY,

DIFFERENTIAL...................3-128,3-68

TRAC-LOKT- DIAGNOSIS AND TESTING . . 3-128,

3-67

TRAILER HITCH - INSTALLATION........13-11

TRAILER HITCH - REMOVAL............13-11

TRANS. - INSTALLATION, DIESEL WITH

AUTO..........................8P-12,8P-6

TRANS. - REMOVAL, DIESEL WITH AUTO

. . 8P-5,

8P-9

TRANS COOLER - 5.9L - DESCRIPTION

....7-78

TRANS COOLER - 5.9L - OPERATION

......7-78

TRANS COOLER - 5.9L DIESEL -

DESCRIPTION

........................7-84

TRANS COOLER - 5.9L DIESEL -

OPERATION

..........................7-84

TRANS COOLER - 8.0L - DESCRIPTION

....7-81

TRANS COOLER - 8.0L - OPERATION

......7-81

TRANS OVERTEMP INDICATOR -

DESCRIPTION

.......................8J-31

TRANS OVERTEMP INDICATOR -

OPERATION

.........................8J-31

TRANSFER CASE - DIAGNOSIS AND

TESTING

....................21-431,21-467

TRANSFER CASE - NV241 -

DESCRIPTION

.........................0-5

TRANSFER CASE - NV241HD -

ASSEMBLY

.........................21-480

TRANSFER CASE - NV241HD -

CLEANING

.........................21-476TRANSFER CASE - NV241HD -

DESCRIPTION......................21-465

TRANSFER CASE - NV241HD -

DISASSEMBLY......................21-469

TRANSFER CASE - NV241HD -

INSPECTION.......................21-476

TRANSFER CASE - NV241HD -

INSTALLATION......................21-494

TRANSFER CASE - NV241HD -

OPERATION........................21-467

TRANSFER CASE - NV241HD - REMOVAL . 21-469

TRANSFER CASE - NV241LD -

ASSEMBLY.........................21-445

TRANSFER CASE - NV241LD - CLEANING . 21-441

TRANSFER CASE - NV241LD -

DESCRIPTION......................21-430

TRANSFER CASE - NV241LD -

DISASSEMBLY......................21-432

TRANSFER CASE - NV241LD -

INSPECTION.......................21-442

TRANSFER CASE - NV241LD -

INSTALLATION......................21-458

TRANSFER CASE - NV241LD -

OPERATION........................21-430

TRANSFER CASE - NV241LD - REMOVAL . 21-432

TRANSFER CASE, NV241HD...........21-495

TRANSFER CASE, NV241LD...........21-459

TRANSFER CASE SKID PLATE -

INSTALLATION.......................13-11

TRANSFER CASE SKID PLATE -

REMOVAL..........................13-11

TRANSFER CASE, SPECIFICATIONS . 21-458,21-495

TRANSFER PUMP - DESCRIPTION, FUEL . . 14-83

TRANSFER PUMP - INSTALLATION, FUEL . 14-87

TRANSFER PUMP - OPERATION, FUEL....14-83

TRANSFER PUMP - REMOVAL, FUEL.....14-86

TRANSFER PUMP PRESSURE -

DIAGNOSIS AND TESTING, FUEL........14-84

TRANSMISSION - 46RE - DESCRIPTION,

AUTOMATIC.........................21-89

TRANSMISSION - 46RE - OPERATION,

AUTOMATIC.........................21-91

TRANSMISSION - 47RE - DESCRIPTION,

AUTOMATIC........................21-261

TRANSMISSION - 47RE - OPERATION,

AUTOMATIC........................21-263

TRANSMISSION - DESCRIPTION,

MANUAL.............................0-5

TRANSMISSION - DIAGNOSIS AND

TESTING, AUTOMATIC...........21-268,21-96

TRANSMISSION - INSTALLATION, SHIFT

BOOT - MANUAL....................23-122

TRANSMISSION - REMOVAL, SHIFT

BOOT - MANUAL....................23-122

TRANSMISSION CLUTCH AND BAND

OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING.........21-100,21-272

TRANSMISSION FILL - STANDARD

PROCEDURE

.................21-160,21-330

TRANSMISSION FLUID - DESCRIPTION,

AUTOMATIC

...........................0-6

TRANSMISSION FLUID - OPERATION,

AUTOMATIC

...........................0-6

TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES - WITH

RADIATOR IN-TANK

...........7-78,7-82,7-84

TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES - WITHOUT

RADIATOR IN-TANK

...........7-79,7-82,7-85

TRANSMISSION, SPECIAL TOOLS - RE

. . 21-146,

21-316

TRANSMISSION, SPECIFICATIONS

......21-144,

21-314

TRANSMISSION TEMPERATURE SENSOR

- DESCRIPTION

...............21-218,21-390

TRANSMISSION TEMPERATURE SENSOR

- OPERATION

.................21-218,21-390

TRANSMISSION THROTTLE VALVE

CABLE - ADJUSTMENTS

........21-210,21-382

TRANSMITTER - DESCRIPTION, REMOTE

KEYLESS ENTRY

......................8N-7

TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS ENTRY

......8N-8

TRANSMITTER - OPERATION, REMOTE

KEYLESS ENTRY

......................8N-8

32 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page