wire diagram of pcm DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 349 of 2255

RADIO NOISE SUPPRESSION

COMPONENTS

DESCRIPTION

Radio Frequency Interference (RFI) and Electro-

Magnetic Interference (EMI) noise suppression is

accomplished primarily through circuitry internal to

the radio receivers. These internal suppression

devices are only serviced as part of the radio receiver.

External suppression devices that are used on this

vehicle to control RFI or EMI noise include the fol-

lowing:

²Radio antenna base ground

²Radio receiver chassis ground wire or strap

²Engine-to-body ground straps

²Cab-to-bed ground strap

²Heater core ground strap

²Resistor-type spark plugs

²Radio suppression-type secondary ignition wir-

ing.

For more information on the spark plugs and sec-

ondary ignition components, refer to Electrical, Igni-

tion Control.

DIAGNOSIS AND TESTING - RADIO NOISE

SUPPRESSION COMPONENTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds. Inspect the ground paths

and connections at the following locations:

²Blower motor

²Cab-to-bed ground strap

²Electric fuel pump

²Engine-to-body ground straps

²Generator

²Ignition module

²Heater core ground strap

²Radio antenna base ground

²Radio receiver chassis ground wire or strap

²Wiper motor.If the source of RFI or EMI noise is identified as a

component on the vehicle (i.e., generator, blower

motor, etc.), the ground path for that component

should be checked. If excessive resistance is found in

any ground circuit, clean, tighten, or repair the

ground circuits or connections to ground as required

before considering any component replacement.

For service and inspection of secondary ignition

components, refer to Electrical, Ignition Control.

Inspect the following secondary ignition system com-

ponents:

²Distributor cap and rotor

²Ignition coil

²Spark plugs

²Spark plug wire routing and condition.

Reroute the spark plug wires or replace the faulty

components as required.

If the source of the RFI or EMI noise is identified

as two-way mobile radio or telephone equipment,

check the equipment installation for the following:

²Power connections should be made directly to

the battery, and fused as closely to the battery as

possible.

²The antenna should be mounted on the roof or

toward the rear of the vehicle. Remember that mag-

netic antenna mounts on the roof panel can adversely

affect the operation of an overhead console compass,

if the vehicle is so equipped.

²The antenna cable should be fully shielded coax-

ial cable, should be as short as is practical, and

should be routed away from the factory-installed

vehicle wire harnesses whenever possible.

²The antenna and cable must be carefully

matched to ensure a low Standing Wave Ratio

(SWR).

Fleet vehicles are available with an extra-cost RFI-

suppressed Powertrain Control Module (PCM). This

unit reduces interference generated by the PCM on

some radio frequencies used in two-way radio com-

munications. However, this unit will not resolve com-

plaints of RFI in the commercial AM or FM radio

frequency ranges.

ENGINE-TO-BODY GROUND

STRAP

REMOVAL

(1) Remove the screw that secures the engine-to-

body ground strap eyelet to the dash panel (Fig. 10).

(2) Remove the screw that secures the engine-to-

body ground strap eyelet to the back of the engine

cylinder head (Fig. 11) or (Fig. 12).

8A - 12 AUDIOBR/BE

Page 369 of 2255

HARD WIRED OUTPUTS

The hard wired outputs of the CTM include the fol-

lowing:

²CCD bus± - high-line/premium version only

²CCD bus+ - high-line/premium version only

²Courtesy lamp switch output - high-line/pre-

mium version only

²Door lock driver - high-line/premium version

only

²Door unlock driver - high-line/premium version

only

²Headlamp relay control - high-line/premium ver-

sion only

²Heated seat relay control - premium version

only

²Horn relay control - high-line/premium version

only

²VTSS indicator driver - high-line/premium ver-

sion only

²Wiper motor relay control

MESSAGING

The high-line/premium CTM uses the following

messages received from other electronic modules over

the CCD data bus:

²Airbag Deploy (ACM)

²Charging System Failure (PCM)

²Engine RPM (PCM)

²System Voltage (PCM)

²Vehicle Speed (PCM)

²Voltage Fault (PCM)

The high-line/premium CTM provides the following

messages to other electronic modules over the CCD

data bus:

²Engine Enable (PCM)

²Radio Seek Up (Radio)

²Radio Seek Down (Radio)

²Radio Volume Up (Radio)

²Radio Volume Down (Radio)

²Preset Scan (Radio)

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE

The hard wired inputs to and outputs from the

Central Timer Module (CTM) may be diagnosed and

tested using conventional diagnostic tools and meth-

ods. Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the high-line/pre-

mium CTM. In order to obtain conclusive testing of

the high-line/premium CTM, the Chrysler CollisionDetection (CCD) data bus network and all of the elec-

tronic modules that provide inputs to or receive out-

puts from the CTM must also be checked. The most

reliable, efficient, and accurate means to diagnose

the high-line/premium CTM, the CCD data bus net-

work, and the electronic modules that provide inputs

to or receive outputs from the high-line/premium

CTM requires the use of a DRBIIItscan tool and the

appropriate diagnostic information. The DRBIIIt

scan tool can provide confirmation that the CCD data

bus network is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages over the CCD data bus, and that the CTM is

receiving the proper hard wired inputs and respond-

ing with the proper hard wired outputs needed to

perform its many functions.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of the high-line or premium

versions of the Central Timer Module (CTM). The

most reliable, efficient, and accurate means to diag-

nose the high-line or premium CTM requires the

use of a DRBIIITscan tool and the appropriate diag-

nostic information.

(1) Check the fused B(+) fuse (Fuse 13 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 13 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) For a base version CTM, check the fused igni-

tion switch output (st-run) fuse (Fuse 11 - 10 ampere)

in the JB. For a high-line/premium version CTM,

check the fused ignition switch output (run-acc) fuse

(Fuse6-25ampere) in the JB. If OK, go to Step 4. If

not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

8E - 4 ELECTRONIC CONTROL MODULESBR/BE

CENTRAL TIMER MODULE (Continued)

Page 446 of 2255

ical dimensions are smaller than those of the conven-

tional ISO relay.

The heated seat relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact. When the electromagnetic coil is de-ener-

gized, spring pressure returns the movable contact to

the normally closed position. The resistor or diode is

connected in parallel with the electromagnetic coil in

the relay, and helps to dissipate voltage spikes that

are produced when the coil is de-energized.

The heated seat relay is controlled by the premium

version of the Central Timer Module (CTM), which

controls the ground feed to the coil ground terminal

of the relay to energize and de-energize the electro-

magnetic coil of the relay. The CTM monitors engine

operation through messages it receives from the Pow-

ertrain Control Module (PCM) over the Chrysler Col-

lision Detection (CCD) data bus network. The CTM is

programmed to energize the relay only when the

engine is running, and to de-energize the relay when

the engine is not running. Refer toCentral Timer

Modulein the index of this service manual for the

location of more information on the premium CTM.

DIAGNOSIS AND TESTING - HEATED SEAT

RELAY

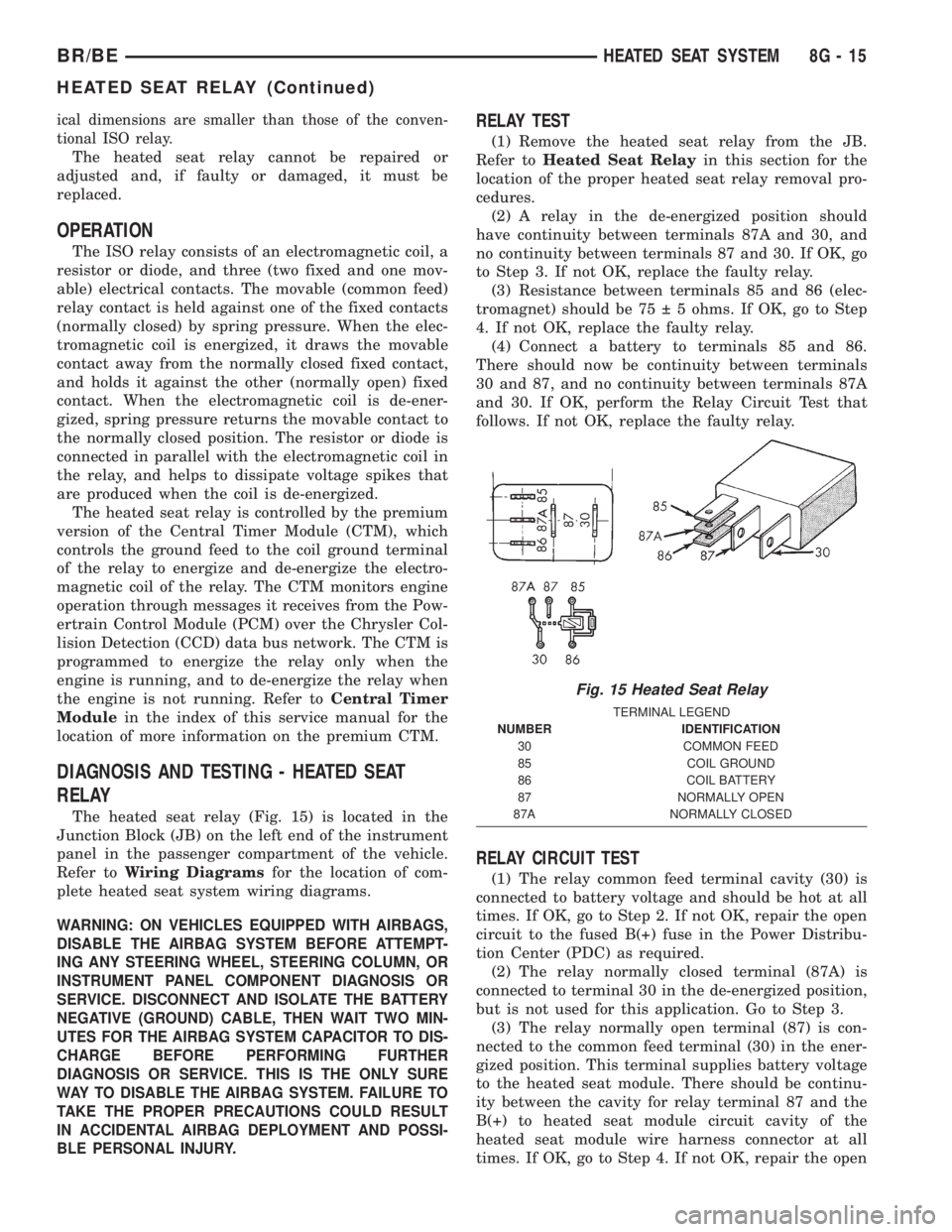

The heated seat relay (Fig. 15) is located in the

Junction Block (JB) on the left end of the instrument

panel in the passenger compartment of the vehicle.

Refer toWiring Diagramsfor the location of com-

plete heated seat system wiring diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE AIRBAG SYSTEM BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO MIN-

UTES FOR THE AIRBAG SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

RELAY TEST

(1) Remove the heated seat relay from the JB.

Refer toHeated Seat Relayin this section for the

location of the proper heated seat relay removal pro-

cedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fused B(+) fuse in the Power Distribu-

tion Center (PDC) as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the heated seat module. There should be continu-

ity between the cavity for relay terminal 87 and the

B(+) to heated seat module circuit cavity of the

heated seat module wire harness connector at all

times. If OK, go to Step 4. If not OK, repair the open

Fig. 15 Heated Seat Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

BR/BEHEATED SEAT SYSTEM 8G - 15

HEATED SEAT RELAY (Continued)

Page 501 of 2255

high beam indicator. If no headlamp system problems

are found, the following procedure will help locate a

short or open in the high beam indicator circuit.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

INDICATOR DOES NOT ILLUMINATE WITH HIGH BEAMS

SELECTED

(1) Check the fused B(+) fuse (Fuse 14 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 14 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) Be certain that the headlamp high beams are

selected with the headlamp beam select switch by

turning the headlamp switch to the On position, pull-

ing the multi-function switch stalk toward the steer-

ing wheel, then inspecting the headlamps at the

front of the vehicle. Once the headlamp high beams

are selected, turn the headlamp switch to the Off

position. Disconnect and isolate the battery negative

cable. Remove the instrument cluster from the

instrument panel. Reconnect the battery negative

cable. Check for battery voltage at the fused B(+) cir-

cuit cavity of the instrument panel wire harness con-

nector (Connector C1) for the instrument cluster. If

OK, go to Step 4. If not OK, repair the open fused

B(+) circuit between the instrument cluster and the

JB as required.

(4) Disconnect and isolate the battery negative

cable. Check for continuity between the high beam

indicator driver circuit cavity of the instrument panel

wire harness connector (Connector C2) for the instru-ment cluster and a good ground. There should be

continuity. If OK, replace the faulty headlamp high

beam indicator bulb and bulb holder unit. If not OK,

repair the open high beam indicator driver circuit

between the instrument cluster and the headlamp

beam select (multi-function) switch as required.

INDICATOR STAYS ILLUMINATED WITH HIGH BEAMS NOT

SELECTED

(1) Be certain that the headlamp low beams are

selected with the headlamp beam select switch by

turning the headlamp switch to the On position, pull-

ing the multi-function switch stalk toward the steer-

ing wheel, then inspecting the headlamps at the

front of the vehicle. Once the headlamp low beams

are selected, turn the headlamp switch to the Off

position. Disconnect and isolate the battery negative

cable. Remove the instrument cluster from the

instrument panel. Check for continuity between the

high beam indicator driver circuit cavity of the

instrument panel wire harness connector (Connector

C2) for the instrument cluster and a good ground.

There should be no continuity. If OK, replace the

faulty instrument cluster. If not OK, repair the

shorted high beam indicator driver circuit between

the instrument cluster and the headlamp beam select

(multi-function) switch as required.

LOW FUEL INDICATOR

DESCRIPTION

A low fuel indicator is standard equipment on all

instrument clusters. The low fuel indicator is located

near the lower edge of the instrument cluster overlay,

to the right of center. The low fuel indicator consists

of a stenciled cutout of the International Control and

Display Symbol icon for ªFuelº in the opaque layer of

the instrument cluster overlay. The dark outer layer

of the overlay prevents the indicator from being

clearly visible when it is not illuminated. An amber

lens behind the cutout in the opaque layer of the

overlay causes the icon to appear in amber through

the translucent outer layer of the overlay when the

indicator is illuminated from behind by a Light Emit-

ting Diode (LED) soldered onto the instrument clus-

ter electronic circuit board. The low fuel indicator is

serviced as a unit with the instrument cluster.

OPERATION

The low fuel indicator gives an indication to the

vehicle operator when the level of fuel in the fuel

tank becomes low. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Powertrain

Control Module (PCM) over the Chrysler Collision

8J - 22 INSTRUMENT CLUSTERBR/BE

HIGH BEAM INDICATOR (Continued)

Page 571 of 2255

OPERATION - REMOTE KEYLESS ENTRY

SYSTEM

On vehicles with the Remote Keyless Entry (RKE)

system, the power locks can be operated remotely

using the RKE transmitter. If the vehicle is so

equipped, the RKE transmitter also arms and dis-

arms the factory-installed Vehicle Theft Security Sys-

tem (VTSS). Three small, recessed buttons on the

outside of the transmitter case labelled Lock, Unlock,

and Panic allow the user to choose the function that

is desired. The RKE transmitter then sends the

appropriate Radio Frequency (RF) signal. An RF

receiver that is integral to the high-line or premium

version of the Central Timer Module (CTM) receives

the transmitted signal, then uses its internal elec-

tronic programming to determine whether the

received signal is valid and what function has been

requested. If the signal is valid, the CTM provides

the programmed features.

Besides operating the power lock system and arm-

ing or disarming the VTSS, the RKE system also

controls the following features:

²Horn Chirp- If this feature is enabled, the

CTM provides a horn chirp by internally pulling the

control coil of the horn relay to ground through a

hard wired circuit output.

²Illuminated Entry- The CTM provides illumi-

nated entry by internally controlling the current flow

to the courtesy lamps in the vehicle through a hard

wired output circuit.

²Panic Mode- The CTM provides the horn pulse

and headlight flash by internally pulling the control

coils of the horn relay and headlamp relay to ground

through hard wired circuit outputs. The CTM con-

trols the current flow to the courtesy lamps in the

vehicle through a hard wired output circuit. The

CTM also monitors the vehicle speed through elec-

tronic messages it receives from the Powertrain Con-

trol Module (PCM) over the Chrysler Collision

Detection (CCD) data bus network.

The RKE system operates on battery current

received through a fused B(+) circuit from a fuse in

the Junction Block (JB) so that the system remains

functional, regardless of the ignition switch position.

The RKE system can retain the vehicle access codes

of up to four RKE transmitters. The transmitter

codes are retained in RKE system memory, even if

the battery is disconnected. If a transmitter is faulty

or is lost, new transmitter vehicle access codes can be

programmed into the system using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

Many of the electronic features in the vehicle con-

trolled or supported by the high-line or premium ver-

sions of the CTM are programmable using the

DRBIIItscan tool. In addition, the high-line/pre-

mium CTM software is Flash compatible, whichmeans it can be reprogrammed using Flash repro-

gramming procedures. However, if any of the CTM

hardware components are damaged or faulty, the

entire CTM unit must be replaced. The hard wired

inputs or outputs of the CTM can be diagnosed using

conventional diagnostic tools and methods; however,

for diagnosis of the high-line or premium versions of

the CTM or the CCD data bus, the use of a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER LOCKS

The following tests provide a preliminary diagnosis

for the power lock system usedonlyon vehicles

equipped with a base version of the Central Timer

Module (CTM). These testsdo notapply to the diag-

nosis of the power lock system used on vehicles

equipped with the optional Remote Keyless Entry

(RKE) system, which includes a high-line or premium

CTM. (Refer to 8 - ELECTRICAL/POWER LOCKS -

DIAGNOSIS AND TESTING - POWER LOCK &

REMOTE KEYLESS ENTRY SYSTEM). Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

PRELIMINARY TESTS

To begin this test, note the system operation while

you actuate both the Lock and Unlock functions with

the power lock switches. Then, proceed as follows:

²If the entire power lock system fails to function

with both of the power lock switches, check the fused

B(+) fuse in the Junction Block (JB). If the fuse is

OK, check the ground circuit between the driver side

power lock switch and ground (G301). If the ground

circuit is OK, proceed to the diagnosis of the power

lock motors. (Refer to 8 - ELECTRICAL/POWER

LOCKS/POWER LOCK MOTOR - DIAGNOSIS AND

TESTING).

²If the entire power lock system fails to function

with only one of the power lock switches, proceed to

diagnosis of the power lock switches. (Refer to 8 -

ELECTRICAL/POWER LOCKS/POWER LOCK

SWITCH - DIAGNOSIS AND TESTING).

²If only one power lock motor fails to operate

with both power lock switches, proceed to diagnosis

of the power lock motor. (Refer to 8 - ELECTRICAL/

POWER LOCKS/POWER LOCK MOTOR - DIAGNO-

SIS AND TESTING).

8N - 4 POWER LOCKSBR/BE

POWER LOCKS (Continued)

Page 642 of 2255

POWER-UP MODE

When the armed VTSS senses that the battery has

been disconnected and reconnected, it enters its pow-

er-up mode. In the power-up mode the alarm system

remains armed following a battery failure or discon-

nect. If the VTSS was armed prior to a battery dis-

connect or failure, the technician or vehicle operator

will have to actively or passively disarm the alarm

system after the battery is reconnected. The pow-

er-up mode will also apply if the battery goes dead

while the system is armed, and battery jump-starting

is attempted. The engine no-run feature will prevent

the engine from starting until the alarm system has

been actively or passively disarmed. The VTSS will

be armed until the technician or vehicle operator has

actively or passively disarmed the alarm system. If

the VTSS is in the disarmed mode prior to a battery

disconnect or failure, it will remain disarmed after

the battery is reconnected or replaced, or if jump-

starting is attempted.

TAMPER ALERT

The VTSS tamper alert feature will sound the horn

three times upon disarming, if the alarm was trig-

gered and has since timed-out (about fifteen min-

utes). This feature alerts the vehicle operator that

the VTSS alarm was activated while the vehicle was

unattended.

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

The VTSS-related hard wired inputs to and out-

puts from the high-line or premium Central Timer

Module (CTM) may be diagnosed and tested using

conventional diagnostic tools and procedures. Refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the CTM, the

Powertrain Control Module (PCM), or the Chrysler

Collision Detection (CCD) data bus network. In order

to obtain conclusive testing of the VTSS, the CTM,

the PCM, and the CCD data bus network must also

be checked. The most reliable, efficient, and accurate

means to diagnose the VTSS requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information. The DRBIIItscan tool can provide

confirmation that the CCD data bus network is func-

tional, that all of the electronic modules are sending

and receiving the proper messages over the CCD

data bus, and that these modules are receiving the

proper hard wired inputs and responding with theproper hard wired outputs needed to perform their

functions. See the ªVehicle Theft Security Systemº

menu item on the DRBIIItscan tool.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

VTSS INDICATOR

DESCRIPTION

The Vehicle Theft Security System (VTSS) indica-

tor consists of a red Light-Emitting Diode (LED)

located on the electronic circuit board of the Compass

Mini-Trip Computer (CMTC) within the overhead

console. The LED extends through a hole in the

CMTC lens located near the forward end of the over-

head console housing near the windshield.

The VTSS indicator cannot be adjusted or repaired

and, if faulty or damaged, the entire CMTC unit

must be replaced. (Refer to 8 - ELECTRICAL/OVER-

HEAD CONSOLE/COMPASS/MINI-TRIP COM-

PUTER - DESCRIPTION).

OPERATION

The Vehicle Theft Security System (VTSS) indica-

tor gives a visible indication of the VTSS arming sta-

tus. One side of Light-Emitting Diode (LED) in the

VTSS indicator is connected to battery current

through a fused B(+) circuit and a fuse in the Junc-

tion Block (JB), so the indicator remains functional

regardless of the ignition switch position. The other

side of the LED is hard wired to the Central Timer

Module (CTM), which controls the operation of the

VTSS indicator by pulling this side of the LED cir-

cuit to ground. When the VTSS arming is in

progress, the CTM will flash the LED rapidly on and

off for about fifteen seconds. When the VTSS has

been successfully armed, the CTM will flash the LED

on and off continually at a much slower rate until

the VTSS has been disarmed. The VTSS indicator

can be diagnosed using conventional diagnostic tools

and methods.

BR/BEVEHICLE THEFT SECURITY 8Q - 3

VEHICLE THEFT SECURITY (Continued)

Page 646 of 2255

activates the washer pump/motor, which dispenses

washer fluid onto the windshield glass through the

washer nozzles.

When the ignition switch is in the Accessory or On

positions, battery current from a fuse in the Junction

Block (JB) is provided through a fused ignition

switch output (run-acc) circuit to the wiper motor

park switch, the wiper relay, and the multi-function

switch. The internal circuitry of the multi-function

switch provides a direct hard wired battery current

output to the low speed or high speed brushes of the

wiper motor when the Lo or Hi switch setting is

selected, which causes the wipers to cycle at the

selected speed. The intermittent wipe, and wipe-af-

ter-wash features of the wiper and washer system

are provided by the electronic intermittent wipe logic

circuit within the Central Timer Module (CTM). In

order to provide the intermittent wipe feature, the

CTM monitors the wiper switch state and the wiper

motor park switch state. In order to provide the

wipe-after-wash feature, the CTM monitors both the

washer switch state and the wiper motor park switch

state. When a Delay position is selected with the

multi-function switch control knob, the CTM logic cir-

cuit responds by calculating the correct delay inter-

val. The CTM then energizes the wiper relay by

pulling the relay control coil to ground. The ener-

gized wiper relay directs battery current through the

normally open contact of the relay back through the

internal circuitry of the multi-function switch to the

low speed brush of the wiper motor. The CTM moni-

tors the wiper motor operation through the wiper

park switch sense circuit, which allows the CTM to

determine the proper timing to begin the next wiper

blade sweep. The normal delay intervals are driver

adjustable from about one-half second to about eigh-

teen seconds.

The high-line and premium CTM also provides a

speed sensitive intermittent wipe feature. By moni-

toring vehicle speed messages received from the Pow-

ertrain Control Module (PCM) over the Chrysler

Collision Detection (CCD) data bus network, the

high-line or premium CTM is able to adjust the delay

intervals to compensate for vehicle speed. Above

about sixteen kilometers-per-hour (ten miles-per-

hour) the delay is driver adjustable from about one-

half second to about eighteen seconds. Below about

sixteen kilometers-per-hour (ten miles-per-hour) the

delay times are doubled by the CTM, from about one

second to about thirty-six seconds.

When the Off position of the multi-function switch

wiper control knob is selected, one of two events is

possible. The event that will occur depends upon the

position of the wiper blades on the windshield at the

moment that the Off position is selected. If the wiper

blades are in the down position on the windshieldwhen the Off position is selected, the park switch

that is integral to the wiper motor is closed to ground

and the wiper motor ceases to operate. If the wiper

blades are not in the down position on the windshield

at the moment the Off position is selected, the park

switch is closed to battery current through a fused

ignition switch output (run-acc) circuit. The park

switch sense circuit directs this battery current to

the low speed brush of the wiper motor through the

normally closed contact of the wiper relay and the

internal Off position circuitry of the multi-function

switch. This causes the wiper motor to continue run-

ning until the wiper blades are in the down position

on the windshield and the park switch is again

closed to ground.

When the Wash position of the multi-function

switch is selected, the Wash position circuitry within

the switch directs battery current to the washer

pump/motor. The CTM monitors the washer switch

state through a washer switch sense input. When the

washer switch is closed with the wiper system turned

Off, the CTM operates the wiper motor through the

wiper relay in the same manner as it does to provide

the Delay mode operation. After the state of the

washer switch changes to open, the CTM monitors

the wiper motor through the wiper park switch sense

circuit, which allows the CTM to monitor the number

of wiper blade sweeps.

Proper testing of the CTM, the PCM, or the CCD

data bus vehicle speed messages requires a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Refer to the owner's manual in the vehicle

glove box for more information on the features and

operation of the wiper and washer system.

DIAGNOSIS AND TESTING - WIPER &

WASHER SYSTEM

WIPER SYSTEM

The diagnosis found here addresses an electrically

inoperative wiper system. If the wiper motor oper-

ates, but the wipers do not move on the windshield,

replace the faulty wiper module. If the wipers oper-

ate, but chatter, lift, or do not clear the glass, clean

and inspect the wiper system components as

required. (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS - INSPECTION) and (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS - CLEANING). Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

The following tests will help to diagnose the hard

wired components and circuits of the wiper system.

BR/BEWIPERS/WASHERS 8R - 3

WIPERS/WASHERS (Continued)

Page 1344 of 2255

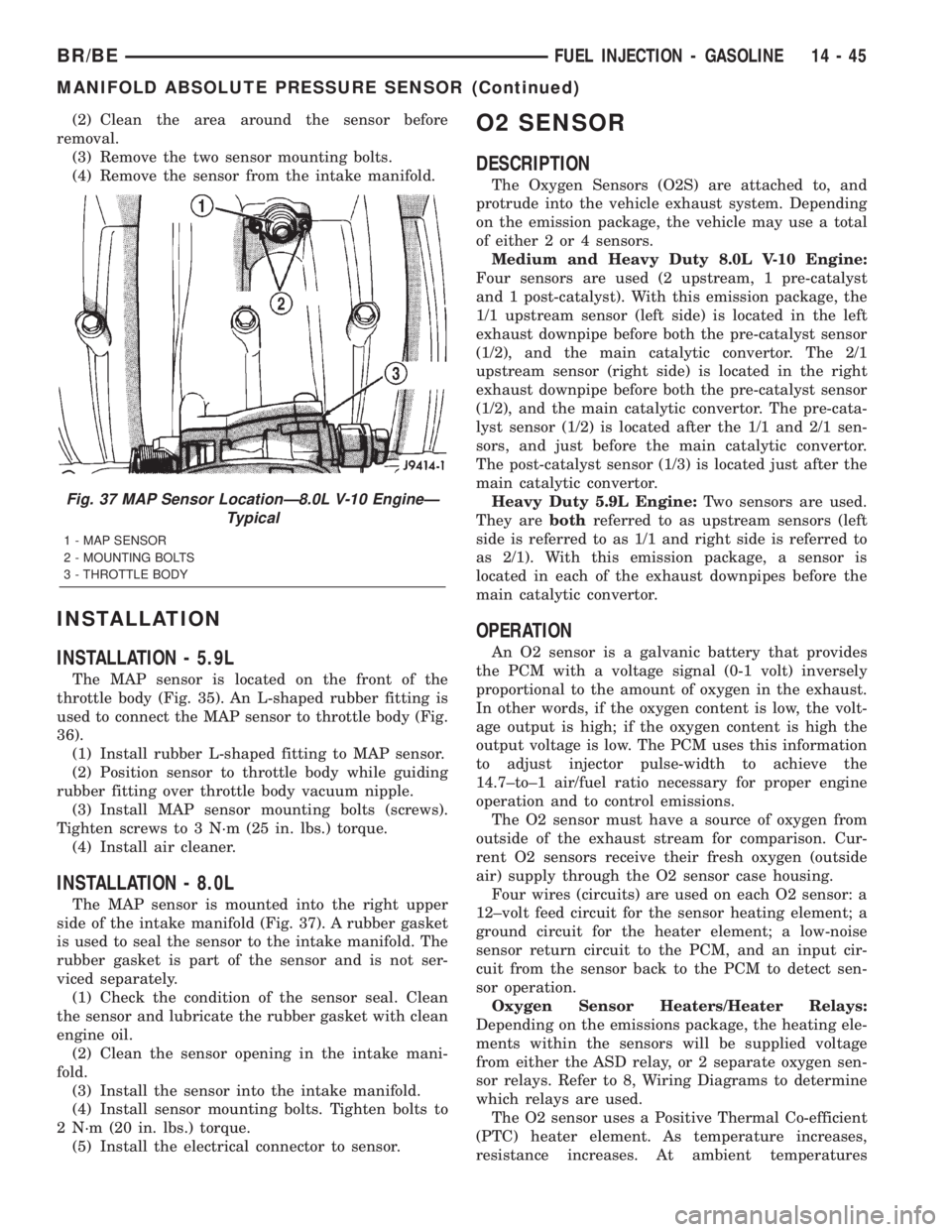

(2) Clean the area around the sensor before

removal.

(3) Remove the two sensor mounting bolts.

(4) Remove the sensor from the intake manifold.

INSTALLATION

INSTALLATION - 5.9L

The MAP sensor is located on the front of the

throttle body (Fig. 35). An L-shaped rubber fitting is

used to connect the MAP sensor to throttle body (Fig.

36).

(1) Install rubber L-shaped fitting to MAP sensor.

(2) Position sensor to throttle body while guiding

rubber fitting over throttle body vacuum nipple.

(3) Install MAP sensor mounting bolts (screws).

Tighten screws to 3 N´m (25 in. lbs.) torque.

(4) Install air cleaner.

INSTALLATION - 8.0L

The MAP sensor is mounted into the right upper

side of the intake manifold (Fig. 37). A rubber gasket

is used to seal the sensor to the intake manifold. The

rubber gasket is part of the sensor and is not ser-

viced separately.

(1) Check the condition of the sensor seal. Clean

the sensor and lubricate the rubber gasket with clean

engine oil.

(2) Clean the sensor opening in the intake mani-

fold.

(3) Install the sensor into the intake manifold.

(4) Install sensor mounting bolts. Tighten bolts to

2 N´m (20 in. lbs.) torque.

(5) Install the electrical connector to sensor.

O2 SENSOR

DESCRIPTION

The Oxygen Sensors (O2S) are attached to, and

protrude into the vehicle exhaust system. Depending

on the emission package, the vehicle may use a total

of either 2 or 4 sensors.

Medium and Heavy Duty 8.0L V-10 Engine:

Four sensors are used (2 upstream, 1 pre-catalyst

and 1 post-catalyst). With this emission package, the

1/1 upstream sensor (left side) is located in the left

exhaust downpipe before both the pre-catalyst sensor

(1/2), and the main catalytic convertor. The 2/1

upstream sensor (right side) is located in the right

exhaust downpipe before both the pre-catalyst sensor

(1/2), and the main catalytic convertor. The pre-cata-

lyst sensor (1/2) is located after the 1/1 and 2/1 sen-

sors, and just before the main catalytic convertor.

The post-catalyst sensor (1/3) is located just after the

main catalytic convertor.

Heavy Duty 5.9L Engine:Two sensors are used.

They arebothreferred to as upstream sensors (left

side is referred to as 1/1 and right side is referred to

as 2/1). With this emission package, a sensor is

located in each of the exhaust downpipes before the

main catalytic convertor.

OPERATION

An O2 sensor is a galvanic battery that provides

the PCM with a voltage signal (0-1 volt) inversely

proportional to the amount of oxygen in the exhaust.

In other words, if the oxygen content is low, the volt-

age output is high; if the oxygen content is high the

output voltage is low. The PCM uses this information

to adjust injector pulse-width to achieve the

14.7±to±1 air/fuel ratio necessary for proper engine

operation and to control emissions.

The O2 sensor must have a source of oxygen from

outside of the exhaust stream for comparison. Cur-

rent O2 sensors receive their fresh oxygen (outside

air) supply through the O2 sensor case housing.

Four wires (circuits) are used on each O2 sensor: a

12±volt feed circuit for the sensor heating element; a

ground circuit for the heater element; a low-noise

sensor return circuit to the PCM, and an input cir-

cuit from the sensor back to the PCM to detect sen-

sor operation.

Oxygen Sensor Heaters/Heater Relays:

Depending on the emissions package, the heating ele-

ments within the sensors will be supplied voltage

from either the ASD relay, or 2 separate oxygen sen-

sor relays. Refer to 8, Wiring Diagrams to determine

which relays are used.

The O2 sensor uses a Positive Thermal Co-efficient

(PTC) heater element. As temperature increases,

resistance increases. At ambient temperatures

Fig. 37 MAP Sensor LocationÐ8.0L V-10 EngineÐ

Typical

1 - MAP SENSOR

2 - MOUNTING BOLTS

3 - THROTTLE BODY

BR/BEFUEL INJECTION - GASOLINE 14 - 45

MANIFOLD ABSOLUTE PRESSURE SENSOR (Continued)

Page 2141 of 2255

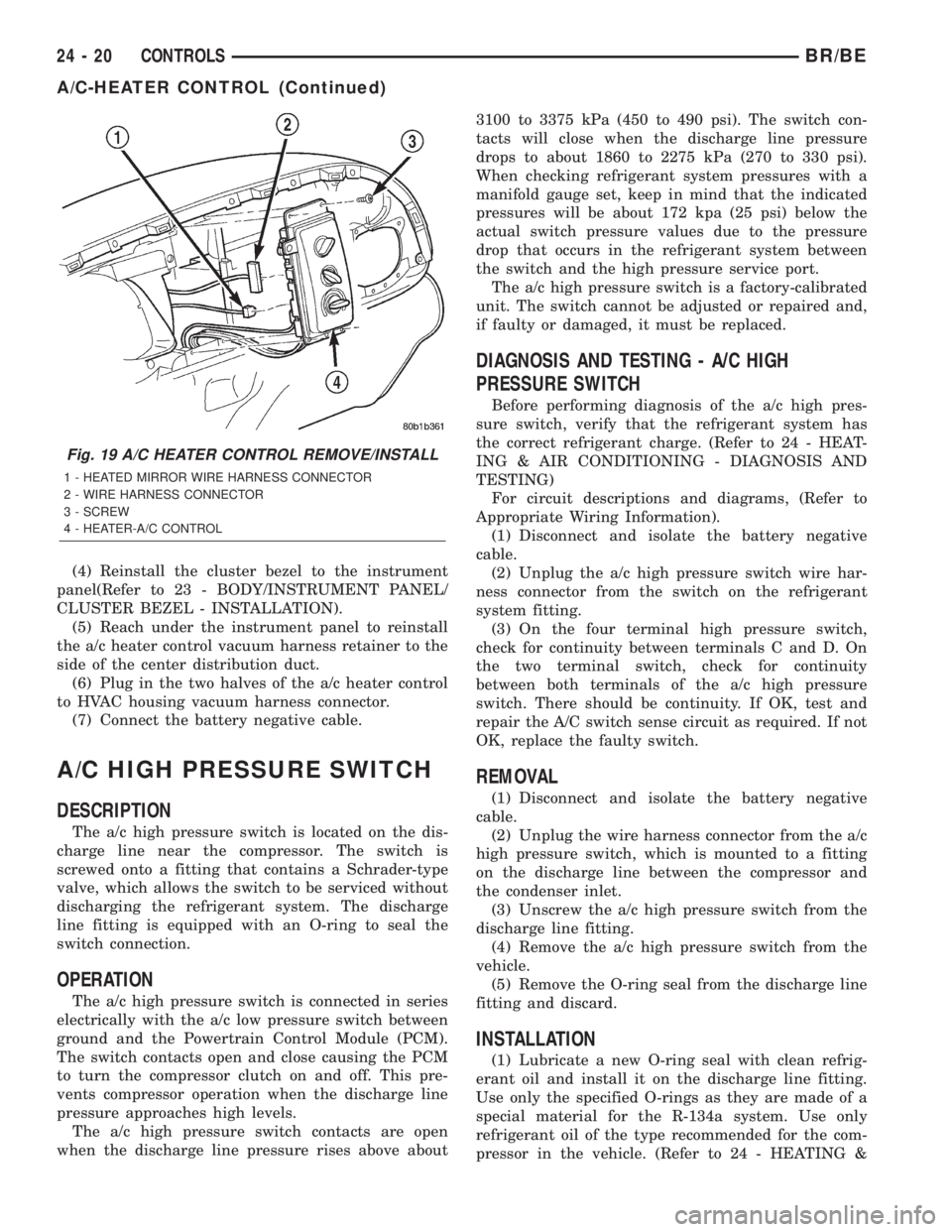

(4) Reinstall the cluster bezel to the instrument

panel(Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - INSTALLATION).

(5) Reach under the instrument panel to reinstall

the a/c heater control vacuum harness retainer to the

side of the center distribution duct.

(6) Plug in the two halves of the a/c heater control

to HVAC housing vacuum harness connector.

(7) Connect the battery negative cable.

A/C HIGH PRESSURE SWITCH

DESCRIPTION

The a/c high pressure switch is located on the dis-

charge line near the compressor. The switch is

screwed onto a fitting that contains a Schrader-type

valve, which allows the switch to be serviced without

discharging the refrigerant system. The discharge

line fitting is equipped with an O-ring to seal the

switch connection.

OPERATION

The a/c high pressure switch is connected in series

electrically with the a/c low pressure switch between

ground and the Powertrain Control Module (PCM).

The switch contacts open and close causing the PCM

to turn the compressor clutch on and off. This pre-

vents compressor operation when the discharge line

pressure approaches high levels.

The a/c high pressure switch contacts are open

when the discharge line pressure rises above about3100 to 3375 kPa (450 to 490 psi). The switch con-

tacts will close when the discharge line pressure

drops to about 1860 to 2275 kPa (270 to 330 psi).

When checking refrigerant system pressures with a

manifold gauge set, keep in mind that the indicated

pressures will be about 172 kpa (25 psi) below the

actual switch pressure values due to the pressure

drop that occurs in the refrigerant system between

the switch and the high pressure service port.

The a/c high pressure switch is a factory-calibrated

unit. The switch cannot be adjusted or repaired and,

if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - A/C HIGH

PRESSURE SWITCH

Before performing diagnosis of the a/c high pres-

sure switch, verify that the refrigerant system has

the correct refrigerant charge. (Refer to 24 - HEAT-

ING & AIR CONDITIONING - DIAGNOSIS AND

TESTING)

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the a/c high pressure switch wire har-

ness connector from the switch on the refrigerant

system fitting.

(3) On the four terminal high pressure switch,

check for continuity between terminals C and D. On

the two terminal switch, check for continuity

between both terminals of the a/c high pressure

switch. There should be continuity. If OK, test and

repair the A/C switch sense circuit as required. If not

OK, replace the faulty switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the wire harness connector from the a/c

high pressure switch, which is mounted to a fitting

on the discharge line between the compressor and

the condenser inlet.

(3) Unscrew the a/c high pressure switch from the

discharge line fitting.

(4) Remove the a/c high pressure switch from the

vehicle.

(5) Remove the O-ring seal from the discharge line

fitting and discard.

INSTALLATION

(1) Lubricate a new O-ring seal with clean refrig-

erant oil and install it on the discharge line fitting.

Use only the specified O-rings as they are made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the com-

pressor in the vehicle. (Refer to 24 - HEATING &

Fig. 19 A/C HEATER CONTROL REMOVE/INSTALL

1 - HEATED MIRROR WIRE HARNESS CONNECTOR

2 - WIRE HARNESS CONNECTOR

3 - SCREW

4 - HEATER-A/C CONTROL

24 - 20 CONTROLSBR/BE

A/C-HEATER CONTROL (Continued)

Page 2142 of 2255

AIR CONDITIONING/PLUMBING/REFRIGERANT

OIL - DESCRIPTION)

(2) Install and tighten the high pressure cut-off

switch on the discharge line fitting. The switch

should be hand-tightened onto the discharge line fit-

ting.

(3) Plug the wire harness connector into the high

pressure cut-off switch.

(4) Connect the battery negative cable.

A/C LOW PRESSURE SWITCH

DESCRIPTION

The a/c low pressure switch is located on the top of

the accumulator. The switch is screwed onto an accu-

mulator fitting that contains a Schrader-type valve,

which allows the switch to be serviced without dis-

charging the refrigerant system. The accumulator fit-

ting is equipped with an O-ring to seal the switch

connection.

OPERATION

The a/c low pressure switch is connected in series

electrically with the a/c high pressure switch and the

a/c heater control, between ground and the Power-

train Control Module (PCM). The switch contacts

open and close causing the PCM to turn the compres-

sor clutch on and off. This regulates the refrigerant

system pressure and controls evaporator tempera-

ture. Controlling evaporator temperature prevents

condensate water on the evaporator fins from freez-

ing and obstructing air conditioning system air flow.

The a/c low pressure switch contacts are open

when the suction pressure is about 152-165 kPa

(22-24 psi) or lower. The switch contacts will close

when the suction pressure rises to about 255-296 kPa

(37-43 psi) or above. Lower ambient temperatures,

below about -1É C (30É F), will also cause the switch

contacts to open. This is due to the pressure/temper-

ature relationship of the refrigerant in the system.

The a/c low pressure switch is a factory-calibrated

unit. It cannot be adjusted or repaired and, if faulty

or damaged, it must be replaced.

DIAGNOSIS AND TESTING - A/C LOW

PRESSURE SWITCH

Before performing diagnosis of the a/c low pressure

switch, be certain that the switch is properly

installed on the accumulator fitting. If the switch is

too loose it may not open the Schrader-type valve in

the accumulator fitting, which will prevent the

switch from correctly monitoring the refrigerant sys-

tem pressure. Also verify that the refrigerant system

has the correct refrigerant charge. (Refer to 24 -HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE)

Remember that lower ambient temperatures, below

about -1É C (30É F), during cold weather will open the

switch contacts and prevent compressor operation

due to the pressure/temperature relationship of the

refrigerant. For circuit descriptions and diagrams,

(Refer to Appropriate Wiring Information).

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the a/c low pressure switch wire har-

ness connector from the switch on the accumulator

fitting.

(3) Install a jumper wire between the two cavities

of the a/c low pressure switch wire harness connector.

(4) Connect a manifold gauge set to the refrigerant

system service ports. (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM SERVICE

EQUIPMENT)

(5) Connect the battery negative cable.

(6) Place the a/c heater mode control switch knob

in any A/C position and start the engine.

(7) Check for continuity between the two terminals

of the low pressure cycling clutch switch. There

should be continuity with a suction pressure reading

of 296 kPa (43 psi) or above, and no continuity with a

suction pressure reading of 172 kPa (25 psi) or below.

If OK, test and repair the A/C switch sense circuit as

required. If not OK, replace the faulty switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the wire harness connector from the a/c

low pressure switch on the top of the accumulator

(Fig. 20).

(3) Unscrew the a/c low pressure switch from the

fitting on the top of the accumulator.

(4) Remove the O-ring seal from the accumulator

fitting and discard.

INSTALLATION

(1) Lubricate a new O-ring seal with clean refrig-

erant oil and install it on the accumulator fitting.

Use only the specified O-rings as they are made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the com-

pressor in the vehicle. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/REFRIGERANT

OIL - DESCRIPTION)

(2) Install and tighten the a/c low pressure switch

on the accumulator fitting. The switch should be

hand-tightened onto the accumulator fitting.

(3) Plug the wire harness connector into the a/c

low pressure switch.

BR/BECONTROLS 24 - 21

A/C HIGH PRESSURE SWITCH (Continued)