ad blue DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 533 of 2895

sages to the Front Control Module (FCM) over the

Programmable Communications Interface (PCI) data

bus and flashes the turn signal indicators on and off

accordingly. For further diagnosis of the turn signal

indicators or the instrument cluster circuitry that

controls the indicators, (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the turn signal

and hazard warning system, the multi-function

switch, the FCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the turn signal indicators, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

UPSHIFT INDICATOR

DESCRIPTION

An upshift indicator is standard equipment on all

instrument clusters. However, on vehicles not

equipped with a manual transmission, this indicator

is electronically disabled. The upshift indicator con-

sists of an upward pointed arrow icon, which appears

on the right side of the electronic gear selector indi-

cator Vacuum Fluorescent Display (VFD) unit. The

VFD is soldered onto the cluster electronic circuit

board and is visible through a window with a smoked

clear lens located on the lower edge of the speedom-

eter gauge dial face of the cluster overlay. The dark

lens over the VFD prevents the indicator from being

clearly visible when it is not illuminated. The icon

appears in a blue-green color and at the same light-

ing level as the odometer/trip odometer information

when it is illuminated by the instrument cluster elec-

tronic circuit board. The upshift indicator is serviced

as a unit with the instrument cluster.

OPERATION

The upshift indicator gives an indication to the

vehicle operator when the manual transmission

should be shifted to the next highest gear in order to

achieve the best fuel economy. This indicator is con-

trolled by the instrument cluster circuit board based

upon cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) on vehicles with a gasoline engine, or

from the Engine Control Module (ECM) on vehicles

with a diesel engine over the Programmable Commu-

nications Interface (PCI) data bus. The upshift indi-

cator is completely controlled by the instrument

cluster logic circuit, and that logic will only allow

this indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is inany position except On or Start. The indicator only

illuminates when it is switched to ground by the

instrument cluster circuitry. The instrument cluster

will turn on the upshift indicator for the following

reasons:

²Upshift Lamp-On Message- Each time the

cluster receives an upshift lamp-on message from the

PCM or ECM indicating the engine speed and load

conditions are right for a transmission upshift to

occur, the upshift indicator is illuminated. The indi-

cator remains illuminated until the cluster receives

an upshift lamp-off message from the PCM or ECM,

or until the ignition switch is turned to the Off posi-

tion, whichever occurs first. The PCM or ECM will

normally send an upshift lamp-off message three to

five seconds after a lamp-on message, if an upshift is

not performed. The indicator will then remain off

until the vehicle stops accelerating and is brought

back into the range of indicator operation, or until

the transmission is shifted into another gear.

²Actuator Test- Each time the cluster is put

through the actuator test, the upshift indicator will

be turned on, then off again during the VFD portion

of the test to confirm the functionality of the VFD

and the cluster control circuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the engine speed and load condi-

tions to determine the proper fuel and ignition

requirements. On vehicles with a diesel engine, the

ECM continually monitors the engine speed and load

conditions to determine the proper fuel requirements.

The PCM or ECM then sends the proper upshift indi-

cator lamp-on and lamp-off messages to the instru-

ment cluster. For further diagnosis of the upshift

indicator or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the PCM, the

ECM, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the

upshift indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left quadrant of the instrument cluster,

above the fuel gauge. The voltage gauge consists of a

movable gauge needle or pointer controlled by the

instrument cluster circuitry and a fixed 90 degree

scale on the cluster overlay that reads left-to-right

from ªLº (or Low) to ªHº (or High) for gasoline

engines. On vehicles with a diesel engine, the scale

8J - 40 INSTRUMENT CLUSTERDR

TURN SIGNAL INDICATOR (Continued)

Page 534 of 2895

reads from ª8º to ª18º volts. An International Control

and Display Symbol icon for ªBattery Charging Con-

ditionº is located on the cluster overlay, directly

below the right end of the gauge scale. The voltage

gauge graphics are black against a white field except

for a single red graduation at each end of the gauge

scale, making them clearly visible within the instru-

ment cluster in daylight. When illuminated from

behind by the panel lamps dimmer controlled cluster

illumination lighting with the exterior lamps turned

On, the black graphics appear blue and the red

graphics still appear red. The orange gauge needle is

internally illuminated. Gauge illumination is pro-

vided by replaceable incandescent bulb and bulb

holder units located on the instrument cluster elec-

tronic circuit board. The voltage gauge is serviced as

a unit with the instrument cluster.

OPERATION

The voltage gauge gives an indication to the vehi-

cle operator of the electrical system voltage. This

gauge is controlled by the instrument cluster circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) on vehicles

equipped with a gasoline engine, or from the Engine

Control Module (ECM) on vehicles equipped with a

diesel engine over the Programmable Communica-

tions Interface (PCI) data bus. The voltage gauge is

an air core magnetic unit that receives battery cur-

rent on the instrument cluster electronic circuit

board through the fused ignition switch output (run-

start) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the left end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²System Voltage Message- Each time the clus-

ter receives a system voltage message from the PCM

or ECM indicating the system voltage is between

about 9.5 volts and about 15 volts, the gauge needle

is moved to the relative voltage position on the gauge

scale.

²System Voltage Low (Charge Fail) Message

- Each time the cluster receives three consecutive

messages from the PCM or ECM indicating the elec-

trical system voltage is less than about 9 volts

(charge fail condition), the gauge needle is moved to

the graduation on the far left end of the gauge scale

and the check gauges indicator is illuminated. The

gauge needle remains at the far left end of the gauge

scale and the check gauges indicator remains illumi-

nated until the cluster receives a single message

from the PCM or ECM indicating the electrical sys-tem voltage is greater than about 9.5 volts (but less

than about 15.5 volts), or until the ignition switch is

turned to the Off position, whichever occurs first. On

vehicles equipped with the optional diesel engine, the

ECM is programmed to restrict the voltage gauge

needle to a position above the graduation on the far

left end of the gauge scale and suppress the check

engine indicator operation until after the engine

intake manifold air heater has completed a pre-heat

or post-heat cycle.

²System Voltage High Message- Each time

the cluster receives three consecutive messages from

the PCM or ECM indicating the electrical system

voltage is greater than about 15.5 volts, the gauge

needle is moved to the graduation on the far right

end of the gauge scale and the check gauges indica-

tor is illuminated. The gauge needle remains at the

right end of the gauge scale and the check gauges

indicator remains illuminated until the cluster

receives a message from the PCM or ECM indicating

the electrical system voltage is less than about 15.0

volts (but greater than about 9.5 volts), or until the

ignition switch is turned to the Off position, which-

ever occurs first.

²Communication Error- If the cluster fails to

receive a system voltage message, it will hold the

gauge needle at the last indication for about five sec-

onds or until the ignition switch is turned to the Off

position, whichever occurs first. After five seconds,

the cluster will move the gauge needle to the far left

end of the gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the voltage gauge needle

will be swept to several calibration points on the

gauge scale in a prescribed sequence in order to con-

firm the functionality of the gauge and the cluster

control circuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the system voltage to control the

generator output. On vehicles with a diesel engine,

the ECM continually monitors the system voltage to

control the generator output. The PCM or ECM then

sends the proper system voltage messages to the

instrument cluster. For further diagnosis of the volt-

age gauge or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). If the instrument cluster turns on the check

gauges indicator due to a charge fail or voltage high

condition, it may indicate that the charging system

requires service. For proper diagnosis of the charging

system, the PCM, the ECM, the PCI data bus, or the

electronic message inputs to the instrument cluster

that control the voltage gauge, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

DRINSTRUMENT CLUSTER 8J - 41

VOLTAGE GAUGE (Continued)

Page 708 of 2895

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD.................Left Hand Drive Vehicles

RHD ...............Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX . . . Manual Transmissions-Front Wheel Drive

AT....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export....... Vehicles Built For Sale In

Markets Other Than North America

Except Built-Up-Export........... Vehicles Built

For Sale In North America

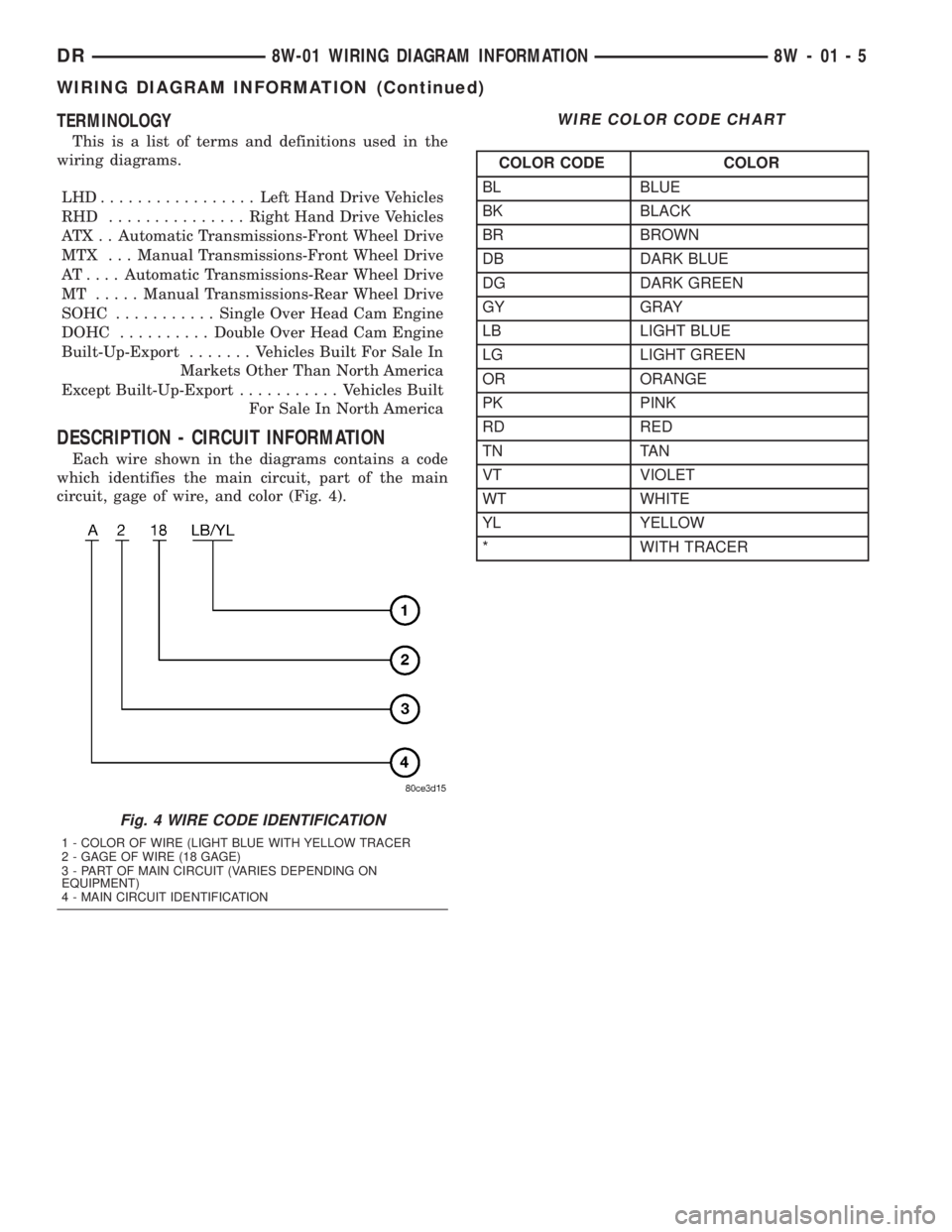

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 4).

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

Fig. 4 WIRE CODE IDENTIFICATION

1 - COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER

2 - GAGE OF WIRE (18 GAGE)

3 - PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 - MAIN CIRCUIT IDENTIFICATION

DR8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 5

WIRING DIAGRAM INFORMATION (Continued)

Page 1074 of 2895

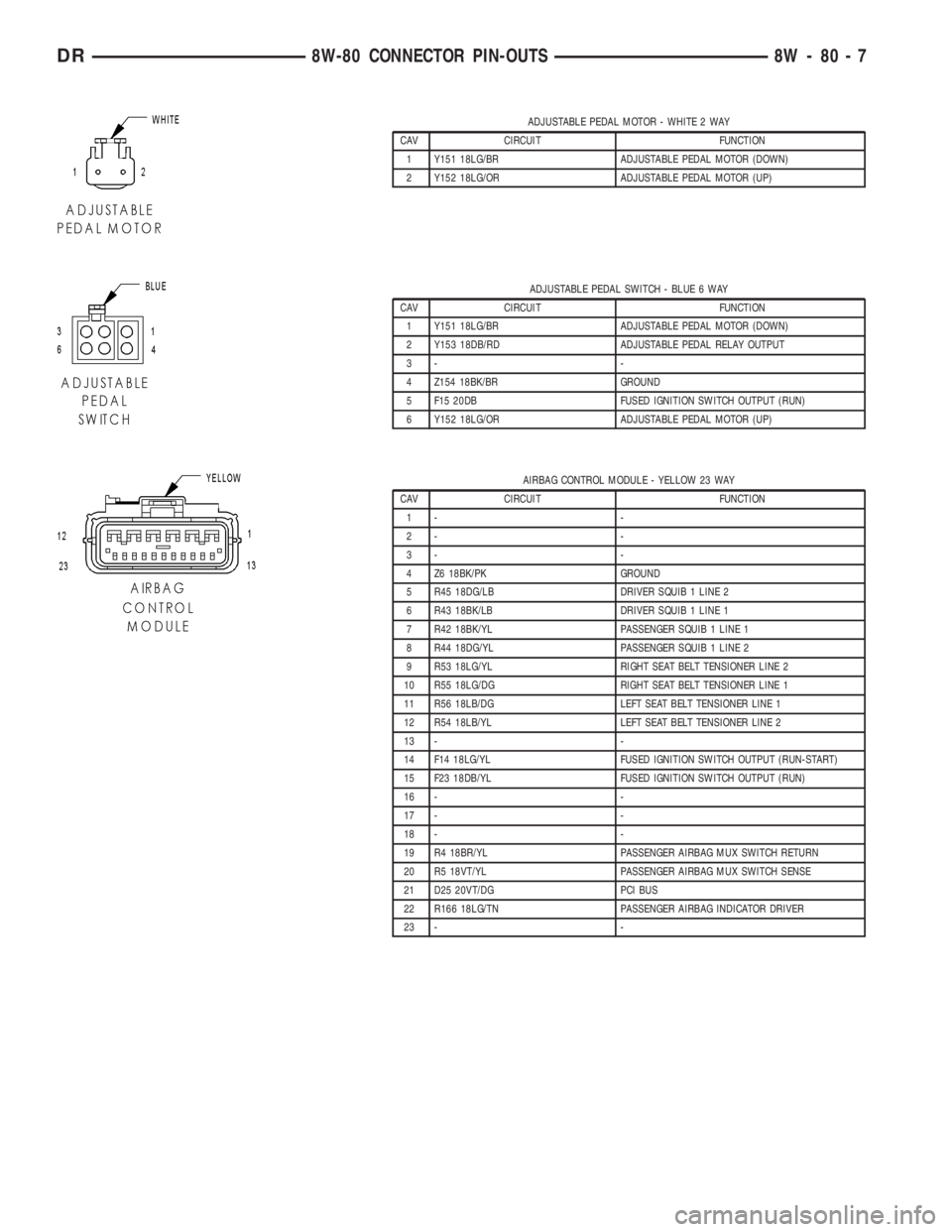

ADJUSTABLE PEDAL MOTOR - WHITE 2 WAY

CAV CIRCUIT FUNCTION

1 Y151 18LG/BR ADJUSTABLE PEDAL MOTOR (DOWN)

2 Y152 18LG/OR ADJUSTABLE PEDAL MOTOR (UP)

ADJUSTABLE PEDAL SWITCH - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Y151 18LG/BR ADJUSTABLE PEDAL MOTOR (DOWN)

2 Y153 18DB/RD ADJUSTABLE PEDAL RELAY OUTPUT

3- -

4 Z154 18BK/BR GROUND

5 F15 20DB FUSED IGNITION SWITCH OUTPUT (RUN)

6 Y152 18LG/OR ADJUSTABLE PEDAL MOTOR (UP)

AIRBAG CONTROL MODULE - YELLOW 23 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3- -

4 Z6 18BK/PK GROUND

5 R45 18DG/LB DRIVER SQUIB 1 LINE 2

6 R43 18BK/LB DRIVER SQUIB 1 LINE 1

7 R42 18BK/YL PASSENGER SQUIB 1 LINE 1

8 R44 18DG/YL PASSENGER SQUIB 1 LINE 2

9 R53 18LG/YL RIGHT SEAT BELT TENSIONER LINE 2

10 R55 18LG/DG RIGHT SEAT BELT TENSIONER LINE 1

11 R56 18LB/DG LEFT SEAT BELT TENSIONER LINE 1

12 R54 18LB/YL LEFT SEAT BELT TENSIONER LINE 2

13 - -

14 F14 18LG/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

15 F23 18DB/YL FUSED IGNITION SWITCH OUTPUT (RUN)

16 - -

17 - -

18 - -

19 R4 18BR/YL PASSENGER AIRBAG MUX SWITCH RETURN

20 R5 18VT/YL PASSENGER AIRBAG MUX SWITCH SENSE

21 D25 20VT/DG PCI BUS

22 R166 18LG/TN PASSENGER AIRBAG INDICATOR DRIVER

23 - -

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 7

Page 1119 of 2895

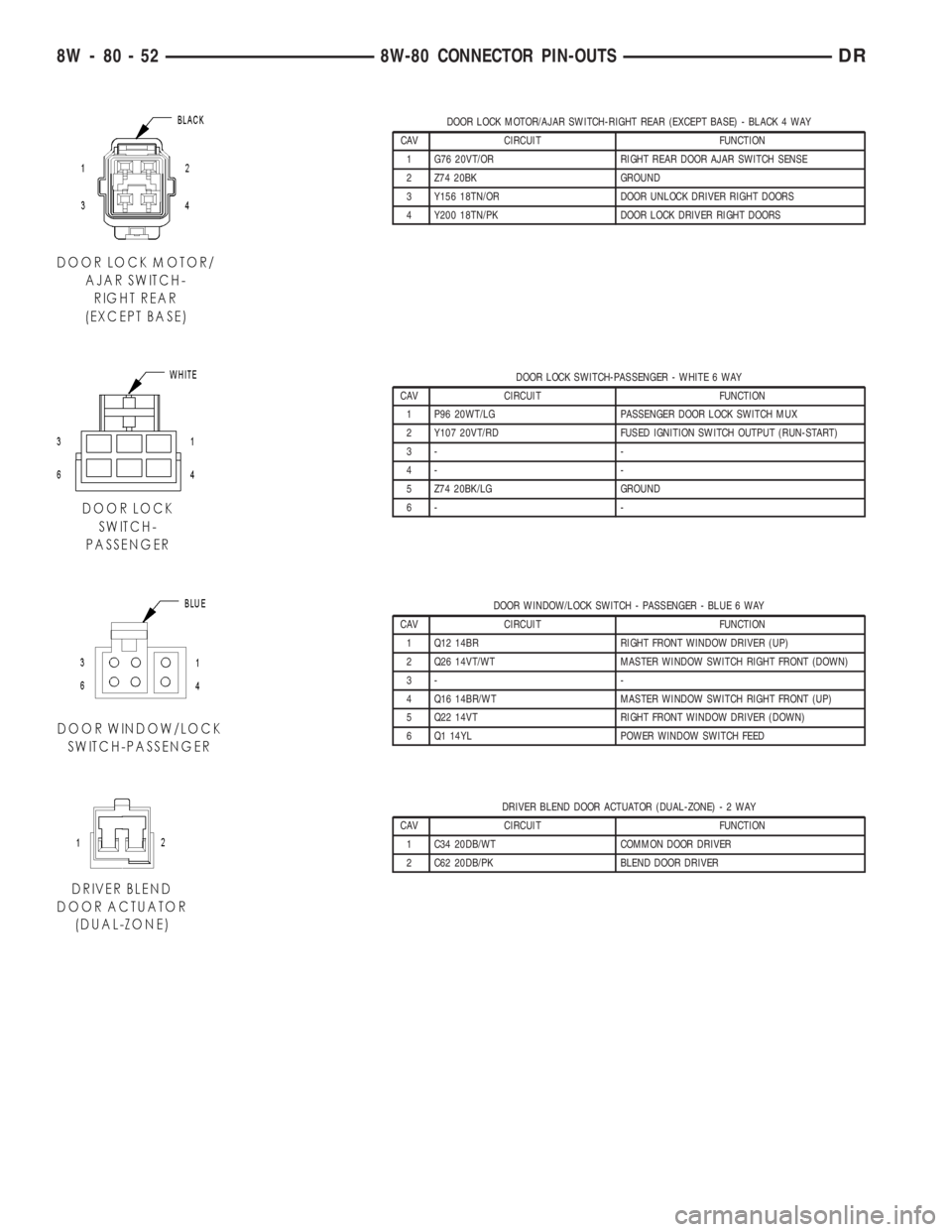

DOOR LOCK MOTOR/AJAR SWITCH-RIGHT REAR (EXCEPT BASE) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 G76 20VT/OR RIGHT REAR DOOR AJAR SWITCH SENSE

2 Z74 20BK GROUND

3 Y156 18TN/OR DOOR UNLOCK DRIVER RIGHT DOORS

4 Y200 18TN/PK DOOR LOCK DRIVER RIGHT DOORS

DOOR LOCK SWITCH-PASSENGER - WHITE 6 WAY

CAV CIRCUIT FUNCTION

1 P96 20WT/LG PASSENGER DOOR LOCK SWITCH MUX

2 Y107 20VT/RD FUSED IGNITION SWITCH OUTPUT (RUN-START)

3- -

4- -

5 Z74 20BK/LG GROUND

6- -

DOOR WINDOW/LOCK SWITCH - PASSENGER - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q12 14BR RIGHT FRONT WINDOW DRIVER (UP)

2 Q26 14VT/WT MASTER WINDOW SWITCH RIGHT FRONT (DOWN)

3- -

4 Q16 14BR/WT MASTER WINDOW SWITCH RIGHT FRONT (UP)

5 Q22 14VT RIGHT FRONT WINDOW DRIVER (DOWN)

6 Q1 14YL POWER WINDOW SWITCH FEED

DRIVER BLEND DOOR ACTUATOR (DUAL-ZONE)-2WAY

CAV CIRCUIT FUNCTION

1 C34 20DB/WT COMMON DOOR DRIVER

2 C62 20DB/PK BLEND DOOR DRIVER

8W - 80 - 52 8W-80 CONNECTOR PIN-OUTSDR

Page 1120 of 2895

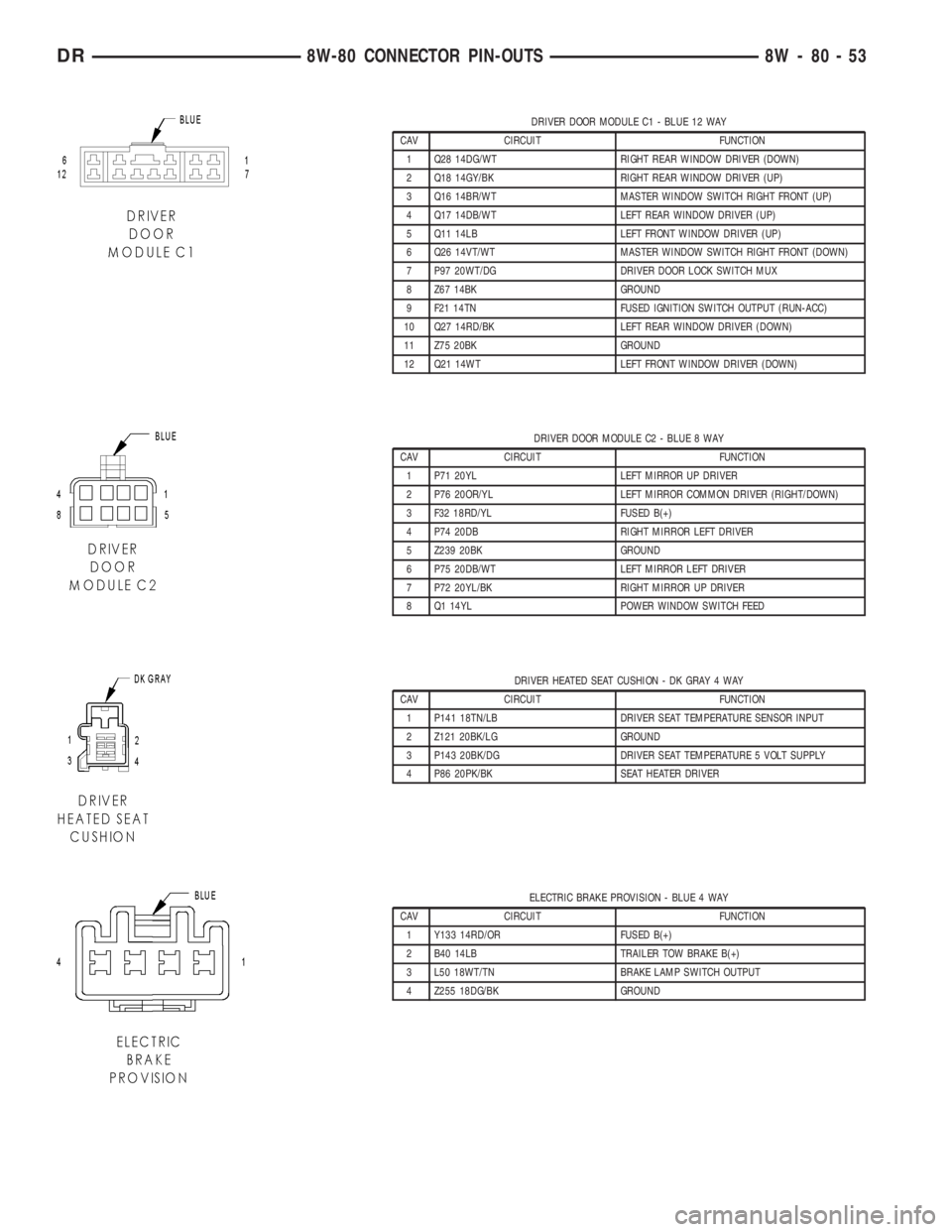

DRIVER DOOR MODULE C1 - BLUE 12 WAY

CAV CIRCUIT FUNCTION

1 Q28 14DG/WT RIGHT REAR WINDOW DRIVER (DOWN)

2 Q18 14GY/BK RIGHT REAR WINDOW DRIVER (UP)

3 Q16 14BR/WT MASTER WINDOW SWITCH RIGHT FRONT (UP)

4 Q17 14DB/WT LEFT REAR WINDOW DRIVER (UP)

5 Q11 14LB LEFT FRONT WINDOW DRIVER (UP)

6 Q26 14VT/WT MASTER WINDOW SWITCH RIGHT FRONT (DOWN)

7 P97 20WT/DG DRIVER DOOR LOCK SWITCH MUX

8 Z67 14BK GROUND

9 F21 14TN FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

10 Q27 14RD/BK LEFT REAR WINDOW DRIVER (DOWN)

11 Z75 20BK GROUND

12 Q21 14WT LEFT FRONT WINDOW DRIVER (DOWN)

DRIVER DOOR MODULE C2 - BLUE 8 WAY

CAV CIRCUIT FUNCTION

1 P71 20YL LEFT MIRROR UP DRIVER

2 P76 20OR/YL LEFT MIRROR COMMON DRIVER (RIGHT/DOWN)

3 F32 18RD/YL FUSED B(+)

4 P74 20DB RIGHT MIRROR LEFT DRIVER

5 Z239 20BK GROUND

6 P75 20DB/WT LEFT MIRROR LEFT DRIVER

7 P72 20YL/BK RIGHT MIRROR UP DRIVER

8 Q1 14YL POWER WINDOW SWITCH FEED

DRIVER HEATED SEAT CUSHION - DK GRAY 4 WAY

CAV CIRCUIT FUNCTION

1 P141 18TN/LB DRIVER SEAT TEMPERATURE SENSOR INPUT

2 Z121 20BK/LG GROUND

3 P143 20BK/DG DRIVER SEAT TEMPERATURE 5 VOLT SUPPLY

4 P86 20PK/BK SEAT HEATER DRIVER

ELECTRIC BRAKE PROVISION - BLUE 4 WAY

CAV CIRCUIT FUNCTION

1 Y133 14RD/OR FUSED B(+)

2 B40 14LB TRAILER TOW BRAKE B(+)

3 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

4 Z255 18DG/BK GROUND

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 53

Page 1131 of 2895

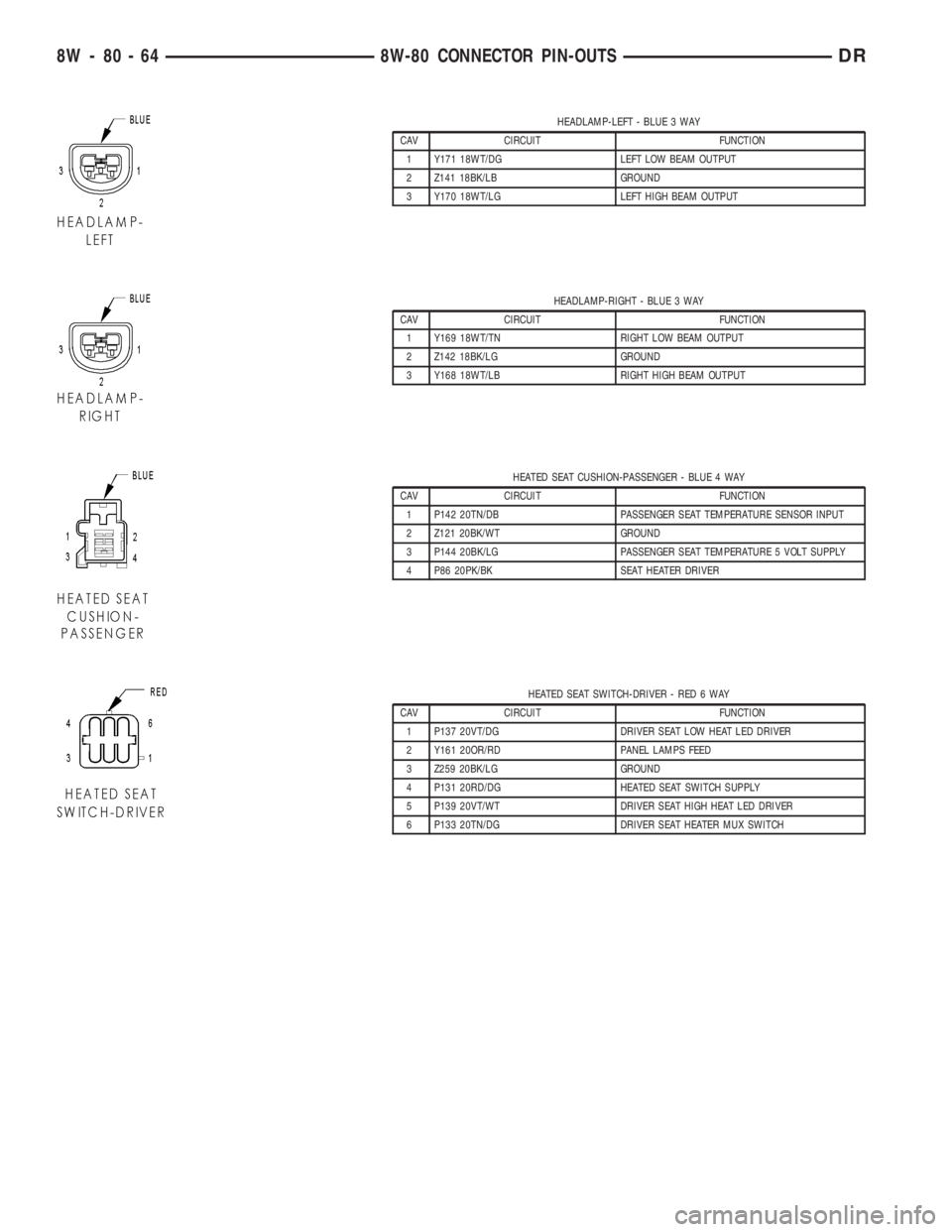

HEADLAMP-LEFT - BLUE 3 WAY

CAV CIRCUIT FUNCTION

1 Y171 18WT/DG LEFT LOW BEAM OUTPUT

2 Z141 18BK/LB GROUND

3 Y170 18WT/LG LEFT HIGH BEAM OUTPUT

HEADLAMP-RIGHT - BLUE 3 WAY

CAV CIRCUIT FUNCTION

1 Y169 18WT/TN RIGHT LOW BEAM OUTPUT

2 Z142 18BK/LG GROUND

3 Y168 18WT/LB RIGHT HIGH BEAM OUTPUT

HEATED SEAT CUSHION-PASSENGER - BLUE 4 WAY

CAV CIRCUIT FUNCTION

1 P142 20TN/DB PASSENGER SEAT TEMPERATURE SENSOR INPUT

2 Z121 20BK/WT GROUND

3 P144 20BK/LG PASSENGER SEAT TEMPERATURE 5 VOLT SUPPLY

4 P86 20PK/BK SEAT HEATER DRIVER

HEATED SEAT SWITCH-DRIVER - RED 6 WAY

CAV CIRCUIT FUNCTION

1 P137 20VT/DG DRIVER SEAT LOW HEAT LED DRIVER

2 Y161 20OR/RD PANEL LAMPS FEED

3 Z259 20BK/LG GROUND

4 P131 20RD/DG HEATED SEAT SWITCH SUPPLY

5 P139 20VT/WT DRIVER SEAT HIGH HEAT LED DRIVER

6 P133 20TN/DG DRIVER SEAT HEATER MUX SWITCH

8W - 80 - 64 8W-80 CONNECTOR PIN-OUTSDR

Page 1132 of 2895

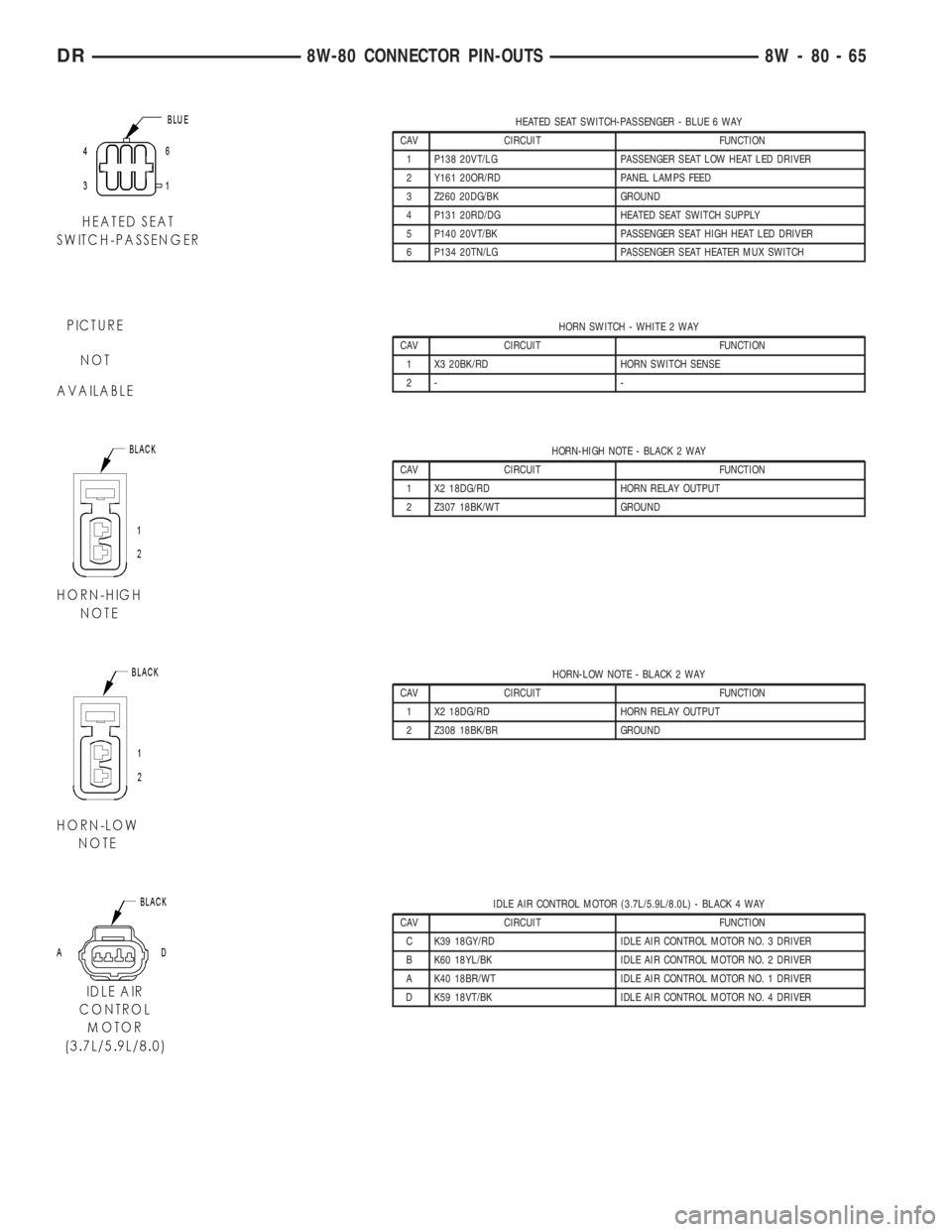

HEATED SEAT SWITCH-PASSENGER - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 P138 20VT/LG PASSENGER SEAT LOW HEAT LED DRIVER

2 Y161 20OR/RD PANEL LAMPS FEED

3 Z260 20DG/BK GROUND

4 P131 20RD/DG HEATED SEAT SWITCH SUPPLY

5 P140 20VT/BK PASSENGER SEAT HIGH HEAT LED DRIVER

6 P134 20TN/LG PASSENGER SEAT HEATER MUX SWITCH

HORN SWITCH - WHITE 2 WAY

CAV CIRCUIT FUNCTION

1 X3 20BK/RD HORN SWITCH SENSE

2- -

HORN-HIGH NOTE - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X2 18DG/RD HORN RELAY OUTPUT

2 Z307 18BK/WT GROUND

HORN-LOW NOTE - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X2 18DG/RD HORN RELAY OUTPUT

2 Z308 18BK/BR GROUND

IDLE AIR CONTROL MOTOR (3.7L/5.9L/8.0L) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

C K39 18GY/RD IDLE AIR CONTROL MOTOR NO. 3 DRIVER

B K60 18YL/BK IDLE AIR CONTROL MOTOR NO. 2 DRIVER

A K40 18BR/WT IDLE AIR CONTROL MOTOR NO. 1 DRIVER

D K59 18VT/BK IDLE AIR CONTROL MOTOR NO. 4 DRIVER

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 65

Page 1144 of 2895

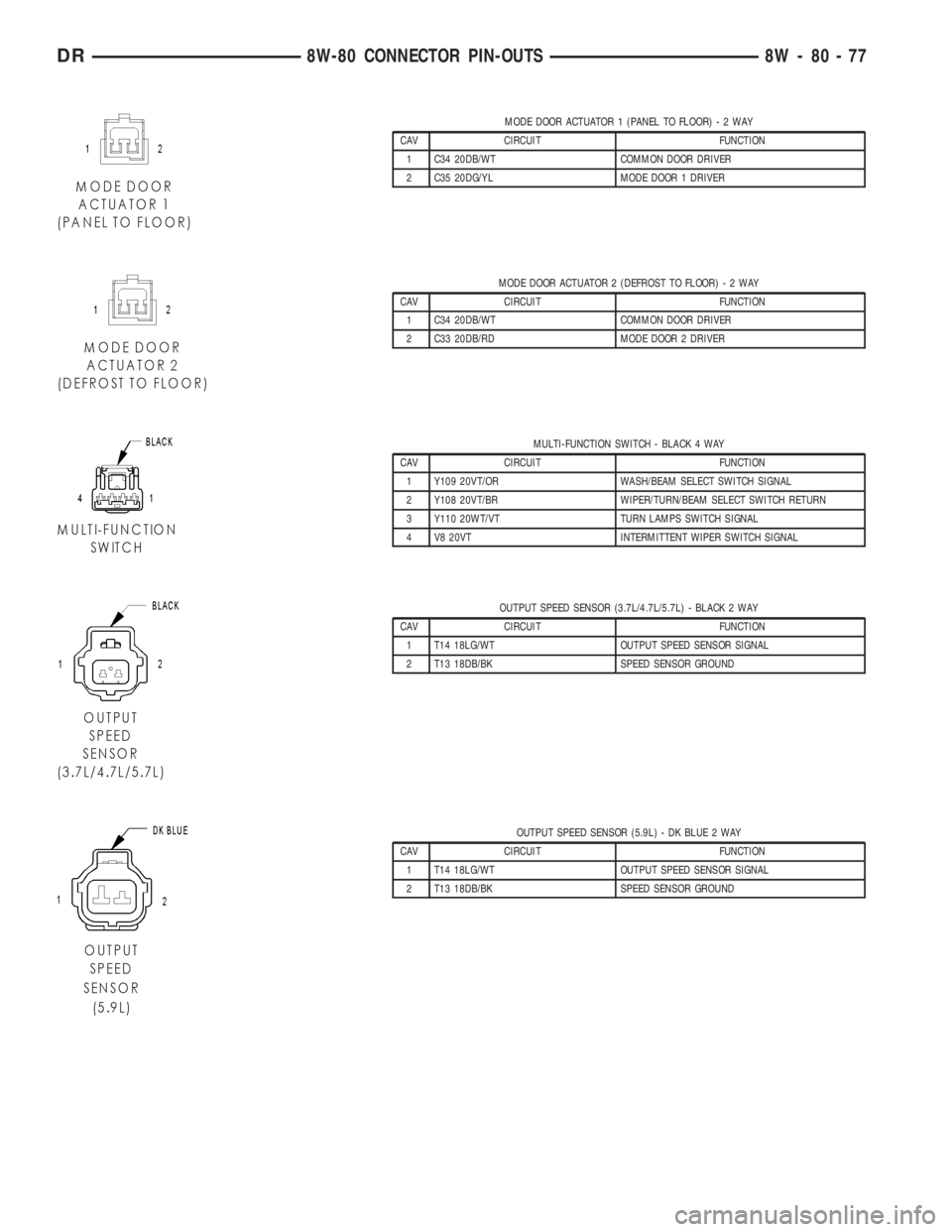

MODE DOOR ACTUATOR 1 (PANEL TO FLOOR)-2WAY

CAV CIRCUIT FUNCTION

1 C34 20DB/WT COMMON DOOR DRIVER

2 C35 20DG/YL MODE DOOR 1 DRIVER

MODE DOOR ACTUATOR 2 (DEFROST TO FLOOR)-2WAY

CAV CIRCUIT FUNCTION

1 C34 20DB/WT COMMON DOOR DRIVER

2 C33 20DB/RD MODE DOOR 2 DRIVER

MULTI-FUNCTION SWITCH - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 Y109 20VT/OR WASH/BEAM SELECT SWITCH SIGNAL

2 Y108 20VT/BR WIPER/TURN/BEAM SELECT SWITCH RETURN

3 Y110 20WT/VT TURN LAMPS SWITCH SIGNAL

4 V8 20VT INTERMITTENT WIPER SWITCH SIGNAL

OUTPUT SPEED SENSOR (3.7L/4.7L/5.7L) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 T14 18LG/WT OUTPUT SPEED SENSOR SIGNAL

2 T13 18DB/BK SPEED SENSOR GROUND

OUTPUT SPEED SENSOR (5.9L) - DK BLUE 2 WAY

CAV CIRCUIT FUNCTION

1 T14 18LG/WT OUTPUT SPEED SENSOR SIGNAL

2 T13 18DB/BK SPEED SENSOR GROUND

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 77

Page 1151 of 2895

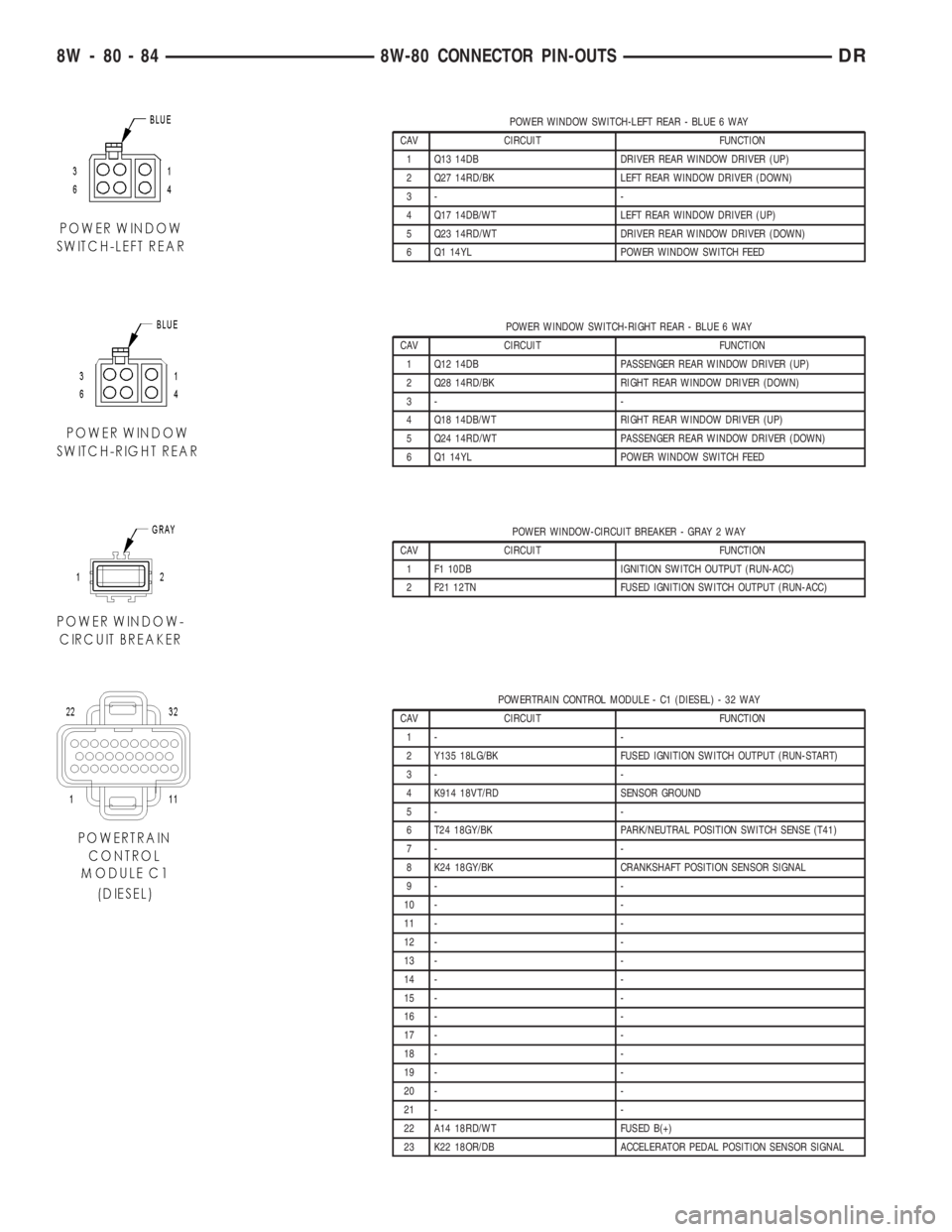

POWER WINDOW SWITCH-LEFT REAR - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q13 14DB DRIVER REAR WINDOW DRIVER (UP)

2 Q27 14RD/BK LEFT REAR WINDOW DRIVER (DOWN)

3- -

4 Q17 14DB/WT LEFT REAR WINDOW DRIVER (UP)

5 Q23 14RD/WT DRIVER REAR WINDOW DRIVER (DOWN)

6 Q1 14YL POWER WINDOW SWITCH FEED

POWER WINDOW SWITCH-RIGHT REAR - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q12 14DB PASSENGER REAR WINDOW DRIVER (UP)

2 Q28 14RD/BK RIGHT REAR WINDOW DRIVER (DOWN)

3- -

4 Q18 14DB/WT RIGHT REAR WINDOW DRIVER (UP)

5 Q24 14RD/WT PASSENGER REAR WINDOW DRIVER (DOWN)

6 Q1 14YL POWER WINDOW SWITCH FEED

POWER WINDOW-CIRCUIT BREAKER - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 F1 10DB IGNITION SWITCH OUTPUT (RUN-ACC)

2 F21 12TN FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

POWERTRAIN CONTROL MODULE - C1 (DIESEL) - 32 WAY

CAV CIRCUIT FUNCTION

1- -

2 Y135 18LG/BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

3- -

4 K914 18VT/RD SENSOR GROUND

5- -

6 T24 18GY/BK PARK/NEUTRAL POSITION SWITCH SENSE (T41)

7- -

8 K24 18GY/BK CRANKSHAFT POSITION SENSOR SIGNAL

9- -

10 - -

11 - -

12 - -

13 - -

14 - -

15 - -

16 - -

17 - -

18 - -

19 - -

20 - -

21 - -

22 A14 18RD/WT FUSED B(+)

23 K22 18OR/DB ACCELERATOR PEDAL POSITION SENSOR SIGNAL

8W - 80 - 84 8W-80 CONNECTOR PIN-OUTSDR