stop start DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 530 of 2895

air core magnetic unit that receives battery current

on the instrument cluster electronic circuit board

through the fused ignition switch output (run-start)

circuit whenever the ignition switch is in the On or

Start positions. The cluster is programmed to move

the gauge needle back to the low end of the scale

after the ignition switch is turned to the Off position.

The instrument cluster circuitry controls the gauge

needle position and provides the following features:

²Vehicle Speed Message- Each time the clus-

ter receives a vehicle speed message from the PCM it

will calculate the correct vehicle speed reading and

position the gauge needle at that relative speed posi-

tion on the gauge scale. The cluster will receive a

new vehicle speed message and reposition the gauge

pointer accordingly about every 88 milliseconds. The

gauge needle will continue to be positioned at the

actual vehicle speed position on the gauge scale until

the ignition switch is turned to the Off position.

²Communication Error- If the cluster fails to

receive a speedometer message, it will hold the gauge

needle at the last indication for about three seconds,

or until the ignition switch is turned to the Off posi-

tion, whichever occurs first. After three seconds, the

gauge needle will return to the left end of the gauge

scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the speedometer needle

will be swept to several calibration points on the

gauge scale in a prescribed sequence in order to con-

firm the functionality of the gauge and the cluster

control circuitry.

The PCM continually monitors the vehicle speed

sensor to determine the vehicle road speed. The PCM

then sends the proper vehicle speed messages to the

instrument cluster. For further diagnosis of the

speedometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the vehicle speed

sensor, the PCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the speedometer, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

TACHOMETER

DESCRIPTION

A tachometer is standard equipment on all instru-

ment clusters. The tachometer is located to the left of

the speedometer, just to the left of center in the

instrument cluster. The tachometer consists of a

movable gauge needle or pointer controlled by the

instrument cluster circuitry and a fixed 210 degree

scale on the gauge dial face that reads left-to-rightfrom ª0º to ª7º for gasoline engines. On vehicles with

a diesel engine, the scale reads from ª0º to ª5º. The

text ªRPM X 1000º imprinted on the cluster overlay

directly below the hub of the tachometer needle iden-

tifies that each number on the tachometer scale is to

be multiplied by 1000 rpm. The tachometer graphics

are black against a white field, making them clearly

visible within the instrument cluster in daylight.

When illuminated from behind by the panel lamps

dimmer controlled cluster illumination lighting with

the exterior lamps turned On, the black graphics

appear blue. The orange gauge needle is internally

illuminated. Gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. The tachometer is serviced as a unit with the

instrument cluster.

OPERATION

The tachometer gives an indication to the vehicle

operator of the engine speed. This gauge is controlled

by the instrument cluster circuit board based upon

cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) on vehicles with a gasoline engine, or

from the Engine Control Module (ECM) on vehicles

equipped with a diesel engine over the Programma-

ble Communications Interface (PCI) data bus. The

tachometer is an air core magnetic unit that receives

battery current on the instrument cluster electronic

circuit board through the fused ignition switch out-

put (run-start) circuit whenever the ignition switch is

in the On or Start positions. The cluster is pro-

grammed to move the gauge needle back to the low

end of the scale after the ignition switch is turned to

the Off position. The instrument cluster circuitry

controls the gauge needle position and provides the

following features:

²Engine Speed Message- Each time the cluster

receives an engine speed message from the PCM or

ECM it will calculate the correct engine speed read-

ing and position the gauge needle at that relative

speed position on the gauge scale. The cluster will

receive a new engine speed message and reposition

the gauge pointer accordingly about every 88 milli-

seconds. The gauge needle will continually be reposi-

tioned at the relative engine speed position on the

gauge scale until the engine stops running, or until

the ignition switch is turned to the Off position,

whichever occurs first.

²Communication Error- If the cluster fails to

receive an engine speed message, it will hold the

gauge needle at the last indication for about three

seconds, or until the ignition switch is turned to the

Off position, whichever occurs first. After three sec-

DRINSTRUMENT CLUSTER 8J - 37

SPEEDOMETER (Continued)

Page 533 of 2895

sages to the Front Control Module (FCM) over the

Programmable Communications Interface (PCI) data

bus and flashes the turn signal indicators on and off

accordingly. For further diagnosis of the turn signal

indicators or the instrument cluster circuitry that

controls the indicators, (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the turn signal

and hazard warning system, the multi-function

switch, the FCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the turn signal indicators, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

UPSHIFT INDICATOR

DESCRIPTION

An upshift indicator is standard equipment on all

instrument clusters. However, on vehicles not

equipped with a manual transmission, this indicator

is electronically disabled. The upshift indicator con-

sists of an upward pointed arrow icon, which appears

on the right side of the electronic gear selector indi-

cator Vacuum Fluorescent Display (VFD) unit. The

VFD is soldered onto the cluster electronic circuit

board and is visible through a window with a smoked

clear lens located on the lower edge of the speedom-

eter gauge dial face of the cluster overlay. The dark

lens over the VFD prevents the indicator from being

clearly visible when it is not illuminated. The icon

appears in a blue-green color and at the same light-

ing level as the odometer/trip odometer information

when it is illuminated by the instrument cluster elec-

tronic circuit board. The upshift indicator is serviced

as a unit with the instrument cluster.

OPERATION

The upshift indicator gives an indication to the

vehicle operator when the manual transmission

should be shifted to the next highest gear in order to

achieve the best fuel economy. This indicator is con-

trolled by the instrument cluster circuit board based

upon cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) on vehicles with a gasoline engine, or

from the Engine Control Module (ECM) on vehicles

with a diesel engine over the Programmable Commu-

nications Interface (PCI) data bus. The upshift indi-

cator is completely controlled by the instrument

cluster logic circuit, and that logic will only allow

this indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is inany position except On or Start. The indicator only

illuminates when it is switched to ground by the

instrument cluster circuitry. The instrument cluster

will turn on the upshift indicator for the following

reasons:

²Upshift Lamp-On Message- Each time the

cluster receives an upshift lamp-on message from the

PCM or ECM indicating the engine speed and load

conditions are right for a transmission upshift to

occur, the upshift indicator is illuminated. The indi-

cator remains illuminated until the cluster receives

an upshift lamp-off message from the PCM or ECM,

or until the ignition switch is turned to the Off posi-

tion, whichever occurs first. The PCM or ECM will

normally send an upshift lamp-off message three to

five seconds after a lamp-on message, if an upshift is

not performed. The indicator will then remain off

until the vehicle stops accelerating and is brought

back into the range of indicator operation, or until

the transmission is shifted into another gear.

²Actuator Test- Each time the cluster is put

through the actuator test, the upshift indicator will

be turned on, then off again during the VFD portion

of the test to confirm the functionality of the VFD

and the cluster control circuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the engine speed and load condi-

tions to determine the proper fuel and ignition

requirements. On vehicles with a diesel engine, the

ECM continually monitors the engine speed and load

conditions to determine the proper fuel requirements.

The PCM or ECM then sends the proper upshift indi-

cator lamp-on and lamp-off messages to the instru-

ment cluster. For further diagnosis of the upshift

indicator or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the PCM, the

ECM, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the

upshift indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left quadrant of the instrument cluster,

above the fuel gauge. The voltage gauge consists of a

movable gauge needle or pointer controlled by the

instrument cluster circuitry and a fixed 90 degree

scale on the cluster overlay that reads left-to-right

from ªLº (or Low) to ªHº (or High) for gasoline

engines. On vehicles with a diesel engine, the scale

8J - 40 INSTRUMENT CLUSTERDR

TURN SIGNAL INDICATOR (Continued)

Page 673 of 2895

NOTE: If a PCM is replaced, the unique ªSecret

Keyº data must be transferred from the SKIM to the

PCM. This procedure requires the SKIM to be

placed in SECURED ACCESS MODE using the four

digit PIN code.

SENTRY KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING

Two programmed Sentry Key transponders are

included with the Sentry Key Immobilizer System

(SKIS) when it is shipped from the factory. The Sen-

try Key Immobilizer Module (SKIM) can be pro-

grammed to recognize up to six additional

transponders, for a total of eight Sentry Keys. The

following ªCustomer Learnº programming procedure

for the programming of additional transponders

requires access to at least two of the valid Sentry

Keys. If two valid Sentry Keys are not available, Sen-

try Key programming will require the use of a

DRBIIItscan tool.

CUSTOMER LEARN PROGRAMMING

(1) Obtain the additional Sentry Key transponder

blank(s) that are to be programmed for the vehicle.

Cut the additional Sentry Key transponder blanks to

match the ignition lock cylinder mechanical key

codes.

(2) Insert one of the two valid Sentry Key tran-

sponders into the ignition switch and turn the igni-

tion switch to the ON position.

(3) After the ignition switch has been in the ON

position for about three seconds, but no more than

fifteen seconds, cycle the ignition switch back to the

OFF position. Replace the first valid Sentry Key in

the ignition lock cylinder with the second valid Sen-

try Key and turn the ignition switch back to the ON

position. Both operations must be performed within

15 seconds.

(4) In approximately ten seconds the VTSS indica-

tor LED will start to flash to indicate that the sys-

tem has entered the ªCustomer Learnº programming

mode.

(5) Within approximately sixty seconds of entering

the ªCustomer Learnº programming mode, turn the

ignition switch to the OFF position, replace the valid

Sentry Key with a blank Sentry Key transponder,

and turn the ignition switch back to the ON position.

(6) In approximately ten seconds, the VTSS indica-

tor LED will stop flashing and stay on solid for

approximately three seconds and then turn OFF to

indicate that the blank Sentry Key transponder has

been successfully programmed. The SKIS will imme-

diately return to normal system operation following

exit from the ªCustomer Learnº programming mode.(7) Repeat this process for each additional Sentry

Key transponder blank to be programmed.

If any of the above steps is not completed in the

proper sequence, or within the allotted time, the

SKIS will automatically exit the ªCustomer Learnº

programming mode. The SKIS will also automatically

exit the ªCustomer Learnº programming mode if it

sees a non-blank Sentry Key transponder when it

should see a blank, if it has already programmed

eight valid Sentry Keys, or if the ignition switch is

turned to the OFF position for more than about fifty

seconds.

NOTE: While in Customer Learn mode (LED flash-

ing), the engine will not START and RUN.

PROGRAMMING BLANK SENTRY KEY

TRANSPONDERS WITH A DRBIIITSCAN TOOL

When programming a blank Sentry Key transpon-

der, the key blank must first be cut to match the

ignition lock cylinder. It will also be necessary to

enter the vehicle's four digit PIN code into the

DRBIIItscan tool to enter the Sentry Key Immobi-

lizer Module's (SKIM's) secured access mode.

NOTE: Once a Sentry Key is programmed to a par-

ticular vehicle, it cannot be transferred to another

vehicle.

Insert the blank key into the ignition and turn it to

the RUN position. Using the DRBIIItscan tool,

select ªTheft Alarm,º then ªSKIM,º then ªMiscella-

neous.º Select ªProgram New Key.º Enter the four

digit PIN code using the DRBIIIt. When program-

ming is completed, the SKIM will exit secured access

mode and the DRBIIItwill display the status of the

key. One of five different status messages may be dis-

played as follows:

²ªProgramming Successfulº is displayed if SKIM

Sentry Key programming succeeds.

²ªLearned Key in Ignitionº is displayed if the key

in the ignition has already been programmed into

that vehicle's SKIM.

²ª8 Keys Already Learned (At The Maximum)

Programming Not Doneº is displayed if eight keys

have already been programmed into the SKIM. In

this case, if a new key needs to be added due to a

lost or defective key, the ªErase All Keysº function

(requires entering secured access mode) has to be

performed. Then the customer's seven keys plus the

new key MUST be reprogrammed into the SKIM.

²ªProgramming Not Attemptedº is displayed after

an ªErase All Keysº function is executed.

²ªProgramming Key Failedº is displayed if fur-

ther diagnosis is required.

8Q - 4 VEHICLE THEFT SECURITYDR

VEHICLE THEFT SECURITY (Continued)

Page 721 of 2895

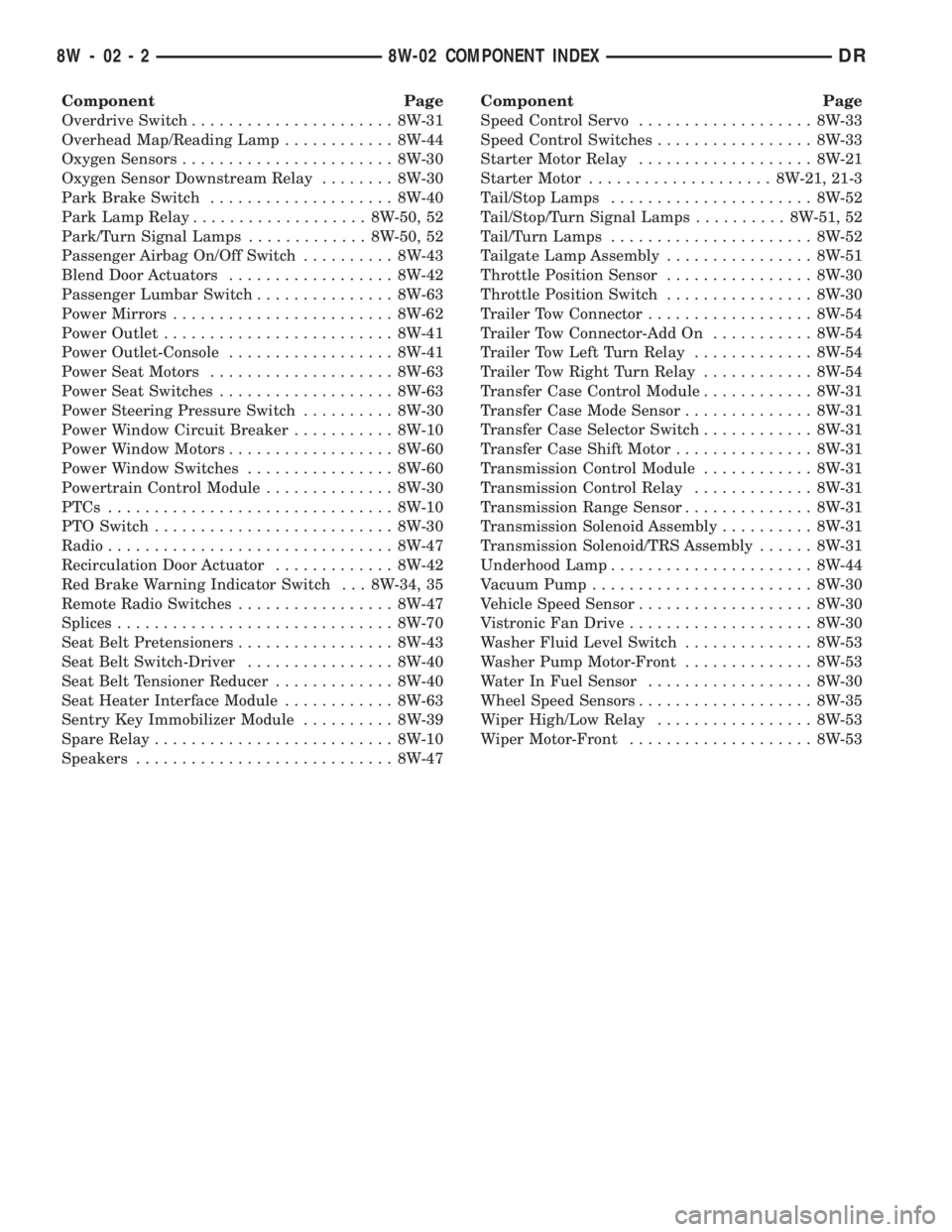

Component Page

Overdrive Switch...................... 8W-31

Overhead Map/Reading Lamp............ 8W-44

Oxygen Sensors....................... 8W-30

Oxygen Sensor Downstream Relay........ 8W-30

Park Brake Switch.................... 8W-40

Park Lamp Relay................... 8W-50, 52

Park/Turn Signal Lamps............. 8W-50, 52

Passenger Airbag On/Off Switch.......... 8W-43

Blend Door Actuators.................. 8W-42

Passenger Lumbar Switch............... 8W-63

Power Mirrors........................ 8W-62

Power Outlet......................... 8W-41

Power Outlet-Console.................. 8W-41

Power Seat Motors.................... 8W-63

Power Seat Switches................... 8W-63

Power Steering Pressure Switch.......... 8W-30

Power Window Circuit Breaker........... 8W-10

Power Window Motors.................. 8W-60

Power Window Switches................ 8W-60

Powertrain Control Module.............. 8W-30

PTCs............................... 8W-10

PTO Switch.......................... 8W-30

Radio............................... 8W-47

Recirculation Door Actuator............. 8W-42

Red Brake Warning Indicator Switch . . . 8W-34, 35

Remote Radio Switches................. 8W-47

Splices.............................. 8W-70

Seat Belt Pretensioners................. 8W-43

Seat Belt Switch-Driver................ 8W-40

Seat Belt Tensioner Reducer............. 8W-40

Seat Heater Interface Module............ 8W-63

Sentry Key Immobilizer Module.......... 8W-39

Spare Relay.......................... 8W-10

Speakers............................ 8W-47Component Page

Speed Control Servo................... 8W-33

Speed Control Switches................. 8W-33

Starter Motor Relay................... 8W-21

Starter Motor.................... 8W-21, 21-3

Tail/Stop Lamps...................... 8W-52

Tail/Stop/Turn Signal Lamps.......... 8W-51, 52

Tail/Turn Lamps...................... 8W-52

Tailgate Lamp Assembly................ 8W-51

Throttle Position Sensor................ 8W-30

Throttle Position Switch................ 8W-30

Trailer Tow Connector.................. 8W-54

Trailer Tow Connector-Add On........... 8W-54

Trailer Tow Left Turn Relay............. 8W-54

Trailer Tow Right Turn Relay............ 8W-54

Transfer Case Control Module............ 8W-31

Transfer Case Mode Sensor.............. 8W-31

Transfer Case Selector Switch............ 8W-31

Transfer Case Shift Motor............... 8W-31

Transmission Control Module............ 8W-31

Transmission Control Relay............. 8W-31

Transmission Range Sensor.............. 8W-31

Transmission Solenoid Assembly.......... 8W-31

Transmission Solenoid/TRS Assembly...... 8W-31

Underhood Lamp...................... 8W-44

Vacuum Pump........................ 8W-30

Vehicle Speed Sensor................... 8W-30

Vistronic Fan Drive.................... 8W-30

Washer Fluid Level Switch.............. 8W-53

Washer Pump Motor-Front.............. 8W-53

Water In Fuel Sensor.................. 8W-30

Wheel Speed Sensors................... 8W-35

Wiper High/Low Relay................. 8W-53

Wiper Motor-Front.................... 8W-53

8W - 02 - 2 8W-02 COMPONENT INDEXDR

Page 722 of 2895

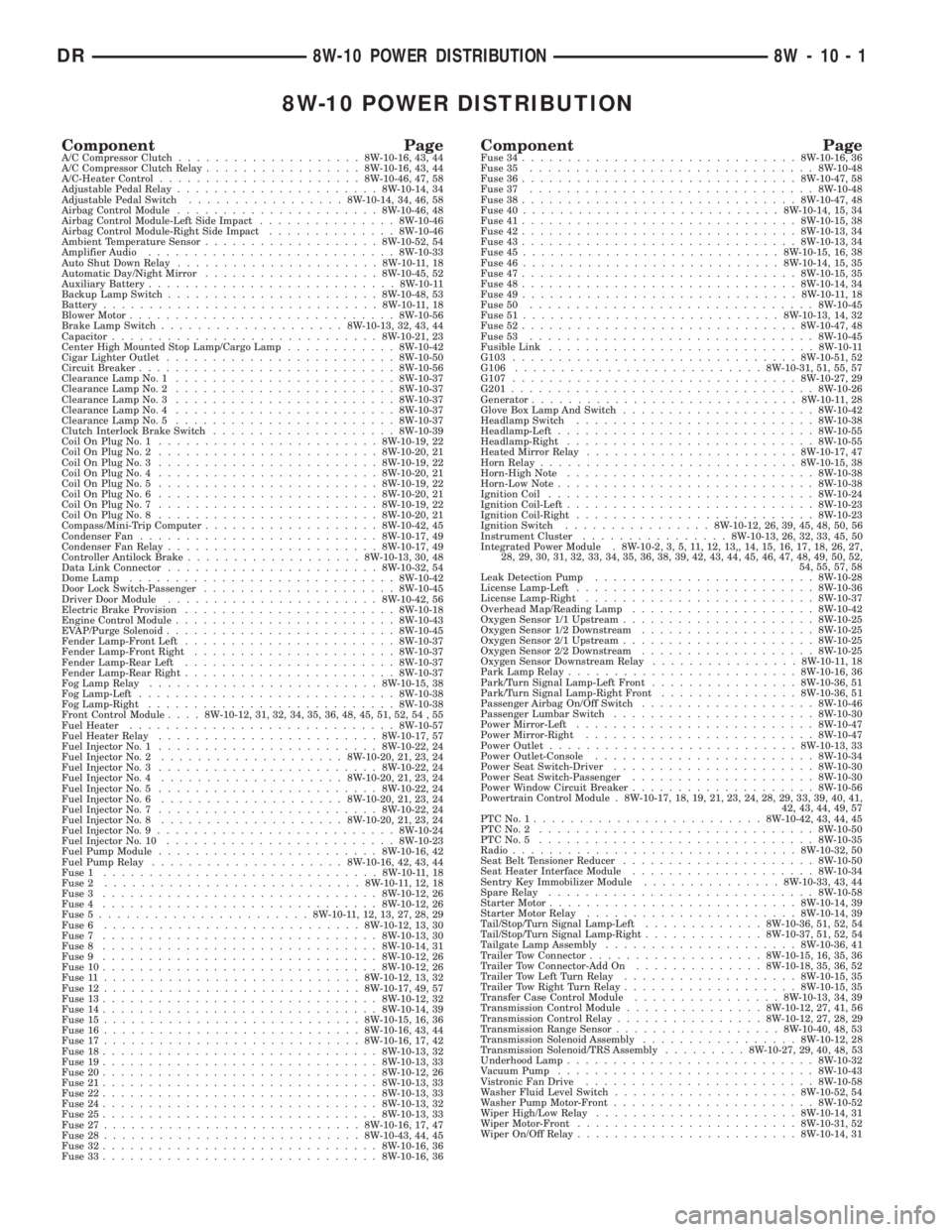

8W-10 POWER DISTRIBUTION

Component PageA/C Compressor Clutch....................8W-10-16, 43, 44

A/C Compressor Clutch Relay.................8W-10-16, 43, 44

A/C-Heater Control......................8W-10-46, 47, 58

Adjustable Pedal Relay......................8W-10-14, 34

Adjustable Pedal Switch.................8W-10-14, 34, 46, 58

Airbag Control Module......................8W-10-46, 48

Airbag Control Module-Left Side Impact...............8W-10-46

Airbag Control Module-Right Side Impact..............8W-10-46

Ambient Temperature Sensor...................8W-10-52, 54

Amplifier Audio...........................8W-10-33

Auto Shut Down Relay......................8W-10-11, 18

Automatic Day/Night Mirror...................8W-10-45, 52

Auxiliary Battery...........................8W-10-11

Backup Lamp Switch.......................8W-10-48, 53

Battery..............................8W-10-11, 18

Blower Motor.............................8W-10-56

Brake Lamp Switch....................8W-10-13, 32, 43, 44

Capacitor.............................8W-10-21, 23

Center High Mounted Stop Lamp/Cargo Lamp............8W-10-42

Cigar Lighter Outlet.........................8W-10-50

Circuit Breaker............................8W-10-56

Clearance Lamp No. 1........................8W-10-37

Clearance Lamp No. 2........................8W-10-37

Clearance Lamp No. 3........................8W-10-37

Clearance Lamp No. 4........................8W-10-37

Clearance Lamp No. 5........................8W-10-37

Clutch Interlock Brake Switch....................8W-10-39

Coil On Plug No. 1........................8W-10-19, 22

Coil On Plug No. 2........................8W-10-20, 21

Coil On Plug No. 3........................8W-10-19, 22

Coil On Plug No. 4........................8W-10-20, 21

Coil On Plug No. 5........................8W-10-19, 22

Coil On Plug No. 6........................8W-10-20, 21

Coil On Plug No. 7........................8W-10-19, 22

Coil On Plug No. 8........................8W-10-20, 21

Compass/Mini-Trip Computer...................8W-10-42, 45

Condenser Fan..........................8W-10-17, 49

Condenser Fan Relay.......................8W-10-17, 49

Controller Antilock Brake...................8W-10-13, 30, 48

Data Link Connector.......................8W-10-32, 54

Dome Lamp.............................8W-10-42

Door Lock Switch-Passenger.....................8W-10-45

Driver Door Module.......................8W-10-42, 56

Electric Brake Provision.......................8W-10-18

Engine Control Module........................8W-10-43

EVAP/Purge Solenoid.........................8W-10-45

Fender Lamp-Front Left.......................8W-10-37

Fender Lamp-Front Right......................8W-10-37

Fender Lamp-Rear Left.......................8W-10-37

Fender Lamp-Rear Right.......................8W-10-37

Fog Lamp Relay.........................8W-10-15, 38

Fog Lamp-Left............................8W-10-38

Fog Lamp-Right...........................8W-10-38

Front Control Module....8W-10-12, 31, 32, 34, 35, 36, 48, 45, 51, 52, 54 , 55

Fuel Heater.............................8W-10-57

Fuel Heater Relay........................8W-10-17, 57

Fuel Injector No. 1........................8W-10-22, 24

Fuel Injector No. 2....................8W-10-20, 21, 23, 24

Fuel Injector No. 3........................8W-10-22, 24

Fuel Injector No. 4....................8W-10-20, 21, 23, 24

Fuel Injector No. 5........................8W-10-22, 24

Fuel Injector No. 6....................8W-10-20, 21, 23, 24

Fuel Injector No. 7........................8W-10-22, 24

Fuel Injector No. 8....................8W-10-20, 21, 23, 24

Fuel Injector No. 9..........................8W-10-24

Fuel Injector No. 10.........................8W-10-23

Fuel Pump Module........................8W-10-16, 42

Fuel Pump Relay.....................8W-10-16, 42, 43, 44

Fuse 1..............................8W-10-11, 18

Fuse 2............................8W-10-11, 12, 18

Fuse 3..............................8W-10-12, 26

Fuse 4..............................8W-10-12, 26

Fuse 5.......................8W-10-11, 12, 13, 27, 28, 29

Fuse 6............................8W-10-12, 13, 30

Fuse 7..............................8W-10-13, 30

Fuse 8..............................8W-10-14, 31

Fuse 9..............................8W-10-12, 26

Fuse 10..............................8W-10-12, 26

Fuse 11............................8W-10-12, 13, 32

Fuse 12............................8W-10-17, 49, 57

Fuse 13..............................8W-10-12, 32

Fuse 14..............................8W-10-14, 39

Fuse 15............................8W-10-15, 16, 36

Fuse 16............................8W-10-16, 43, 44

Fuse 17............................8W-10-16, 17, 42

Fuse 18..............................8W-10-13, 32

Fuse 19..............................8W-10-13, 33

Fuse 20..............................8W-10-12, 26

Fuse 21..............................8W-10-13, 33

Fuse 22..............................8W-10-13, 33

Fuse 24..............................8W-10-13, 32

Fuse 25..............................8W-10-13, 33

Fuse 27............................8W-10-16, 17, 47

Fuse 28............................8W-10-43, 44, 45

Fuse 32..............................8W-10-16, 36

Fuse 33..............................8W-10-16, 36Component PageFuse 34..............................8W-10-16, 36

Fuse 35...............................8W-10-48

Fuse 36..............................8W-10-47, 58

Fuse 37...............................8W-10-48

Fuse 38..............................8W-10-47, 48

Fuse 40............................8W-10-14, 15, 34

Fuse 41..............................8W-10-15, 38

Fuse 42..............................8W-10-13, 34

Fuse 43..............................8W-10-13, 34

Fuse 45............................8W-10-15, 16, 38

Fuse 46............................8W-10-14, 15, 35

Fuse 47..............................8W-10-15, 35

Fuse 48..............................8W-10-14, 34

Fuse 49..............................8W-10-11, 18

Fuse 50...............................8W-10-45

Fuse 51............................8W-10-13, 14, 32

Fuse 52..............................8W-10-47, 48

Fuse 53...............................8W-10-45

Fusible Link.............................8W-10-11

G103...............................8W-10-51, 52

G106...........................8W-10-31, 51, 55, 57

G107...............................8W-10-27, 29

G201.................................8W-10-26

Generator.............................8W-10-11, 28

Glove Box Lamp And Switch.....................8W-10-42

Headlamp Switch..........................8W-10-38

Headlamp-Left............................8W-10-55

Headlamp-Right...........................8W-10-55

Heated Mirror Relay.......................8W-10-17, 47

Horn Relay............................8W-10-15, 38

Horn-High Note...........................8W-10-38

Horn-Low Note............................8W-10-38

Ignition Coil.............................8W-10-24

Ignition Coil-Left...........................8W-10-23

Ignition Coil-Right..........................8W-10-23

Ignition Switch................8W-10-12, 26, 39, 45, 48, 50, 56

Instrument Cluster................8W-10-13, 26, 32, 33, 45, 50

Integrated Power Module . 8W-10-2, 3, 5, 11, 12, 13,, 14, 15, 16, 17, 18, 26, 27,

28, 29, 30, 31, 32, 33, 34, 35, 36, 38, 39, 42, 43, 44, 45, 46, 47, 48, 49, 50, 52,

54, 55, 57, 58

Leak Detection Pump........................8W-10-28

License Lamp-Left..........................8W-10-36

License Lamp-Right.........................8W-10-37

Overhead Map/Reading Lamp....................8W-10-42

Oxygen Sensor 1/1 Upstream.....................8W-10-25

Oxygen Sensor 1/2 Downstream...................8W-10-25

Oxygen Sensor 2/1 Upstream.....................8W-10-25

Oxygen Sensor 2/2 Downstream...................8W-10-25

Oxygen Sensor Downstream Relay................8W-10-11, 18

Park Lamp Relay.........................8W-10-16, 36

Park/Turn Signal Lamp-Left Front................8W-10-36, 51

Park/Turn Signal Lamp-Right Front...............8W-10-36, 51

Passenger Airbag On/Off Switch...................8W-10-46

Passenger Lumbar Switch......................8W-10-30

Power Mirror-Left..........................8W-10-47

Power Mirror-Right.........................8W-10-47

Power Outlet...........................8W-10-13, 33

Power Outlet-Console........................8W-10-34

Power Seat Switch-Driver......................8W-10-30

Power Seat Switch-Passenger....................8W-10-30

Power Window Circuit Breaker....................8W-10-56

Powertrain Control Module . 8W-10-17, 18, 19, 21, 23, 24, 28, 29, 33, 39, 40, 41,

42, 43, 44, 49, 57

PTCNo.1.........................8W-10-42, 43, 44, 45

PTCNo.2 ..............................8W-10-50

PTCNo.5 ..............................8W-10-35

Radio...............................8W-10-32, 50

Seat Belt Tensioner Reducer.....................8W-10-50

Seat Heater Interface Module....................8W-10-34

Sentry Key Immobilizer Module...............8W-10-33, 43, 44

Spare Relay.............................8W-10-58

Starter Motor...........................8W-10-14, 39

Starter Motor Relay.......................8W-10-14, 39

Tail/Stop/Turn Signal Lamp-Left.............8W-10-36, 51, 52, 54

Tail/Stop/Turn Signal Lamp-Right.............8W-10-37, 51, 52, 54

Tailgate Lamp Assembly.....................8W-10-36, 41

Trailer Tow Connector...................8W-10-15, 16, 35, 36

Trailer Tow Connector-Add On..............8W-10-18, 35, 36, 52

Trailer Tow Left Turn Relay...................8W-10-15, 35

Trailer Tow Right Turn Relay...................8W-10-15, 35

Transfer Case Control Module................8W-10-13, 34, 39

Transmission Control Module...............8W-10-12, 27, 41, 56

Transmission Control Relay................8W-10-12, 27, 28, 29

Transmission Range Sensor..................8W-10-40, 48, 53

Transmission Solenoid Assembly.................8W-10-12, 28

Transmission Solenoid/TRS Assembly.........8W-10-27, 29, 40, 48, 53

Underhood Lamp...........................8W-10-32

Vacuum Pump............................8W-10-43

Vistronic Fan Drive.........................8W-10-58

Washer Fluid Level Switch....................8W-10-52, 54

Washer Pump Motor-Front......................8W-10-52

Wiper High/Low Relay......................8W-10-14, 31

Wiper Motor-Front........................8W-10-31, 52

Wiper On/Off Relay........................8W-10-14, 31

DR8W-10 POWER DISTRIBUTION 8W - 10 - 1

Page 908 of 2895

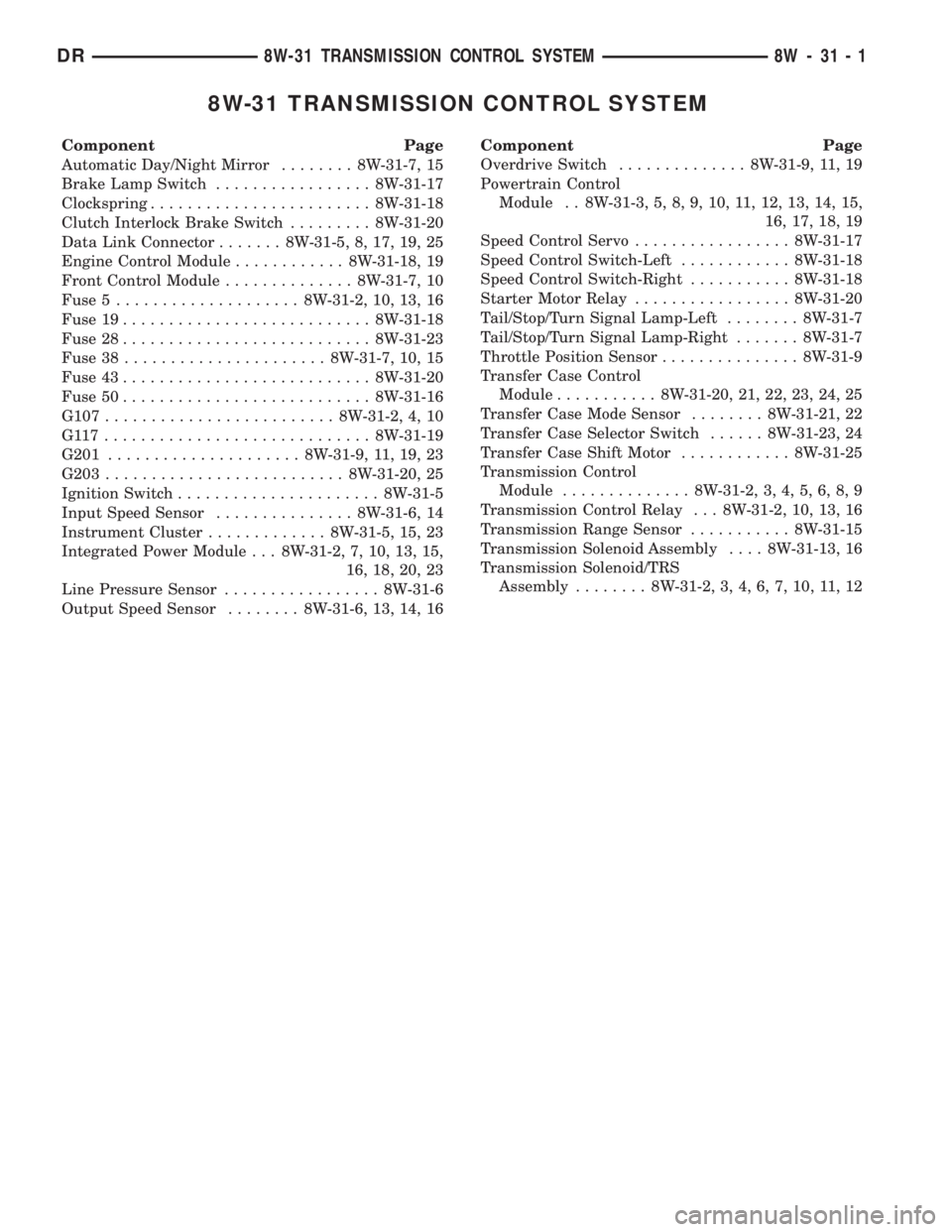

8W-31 TRANSMISSION CONTROL SYSTEM

Component Page

Automatic Day/Night Mirror........ 8W-31-7, 15

Brake Lamp Switch................. 8W-31-17

Clockspring........................ 8W-31-18

Clutch Interlock Brake Switch......... 8W-31-20

Data Link Connector....... 8W-31-5, 8, 17, 19, 25

Engine Control Module............ 8W-31-18, 19

Front Control Module.............. 8W-31-7, 10

Fuse 5.................... 8W-31-2, 10, 13, 16

Fuse 19........................... 8W-31-18

Fuse 28........................... 8W-31-23

Fuse 38...................... 8W-31-7, 10, 15

Fuse 43........................... 8W-31-20

Fuse 50........................... 8W-31-16

G107......................... 8W-31-2, 4, 10

G117............................. 8W-31-19

G201..................... 8W-31-9, 11, 19, 23

G203.......................... 8W-31-20, 25

Ignition Switch...................... 8W-31-5

Input Speed Sensor............... 8W-31-6, 14

Instrument Cluster............. 8W-31-5, 15, 23

Integrated Power Module . . . 8W-31-2, 7, 10, 13, 15,

16, 18, 20, 23

Line Pressure Sensor................. 8W-31-6

Output Speed Sensor........ 8W-31-6, 13, 14, 16Component Page

Overdrive Switch.............. 8W-31-9, 11, 19

Powertrain Control

Module . . 8W-31-3, 5, 8, 9, 10, 11, 12, 13, 14, 15,

16, 17, 18, 19

Speed Control Servo................. 8W-31-17

Speed Control Switch-Left............ 8W-31-18

Speed Control Switch-Right........... 8W-31-18

Starter Motor Relay................. 8W-31-20

Tail/Stop/Turn Signal Lamp-Left........ 8W-31-7

Tail/Stop/Turn Signal Lamp-Right....... 8W-31-7

Throttle Position Sensor............... 8W-31-9

Transfer Case Control

Module........... 8W-31-20, 21, 22, 23, 24, 25

Transfer Case Mode Sensor........ 8W-31-21, 22

Transfer Case Selector Switch...... 8W-31-23, 24

Transfer Case Shift Motor............ 8W-31-25

Transmission Control

Module.............. 8W-31-2, 3, 4, 5, 6, 8, 9

Transmission Control Relay . . . 8W-31-2, 10, 13, 16

Transmission Range Sensor........... 8W-31-15

Transmission Solenoid Assembly.... 8W-31-13, 16

Transmission Solenoid/TRS

Assembly........ 8W-31-2, 3, 4, 6, 7, 10, 11, 12

DR8W-31 TRANSMISSION CONTROL SYSTEM 8W - 31 - 1

Page 1138 of 2895

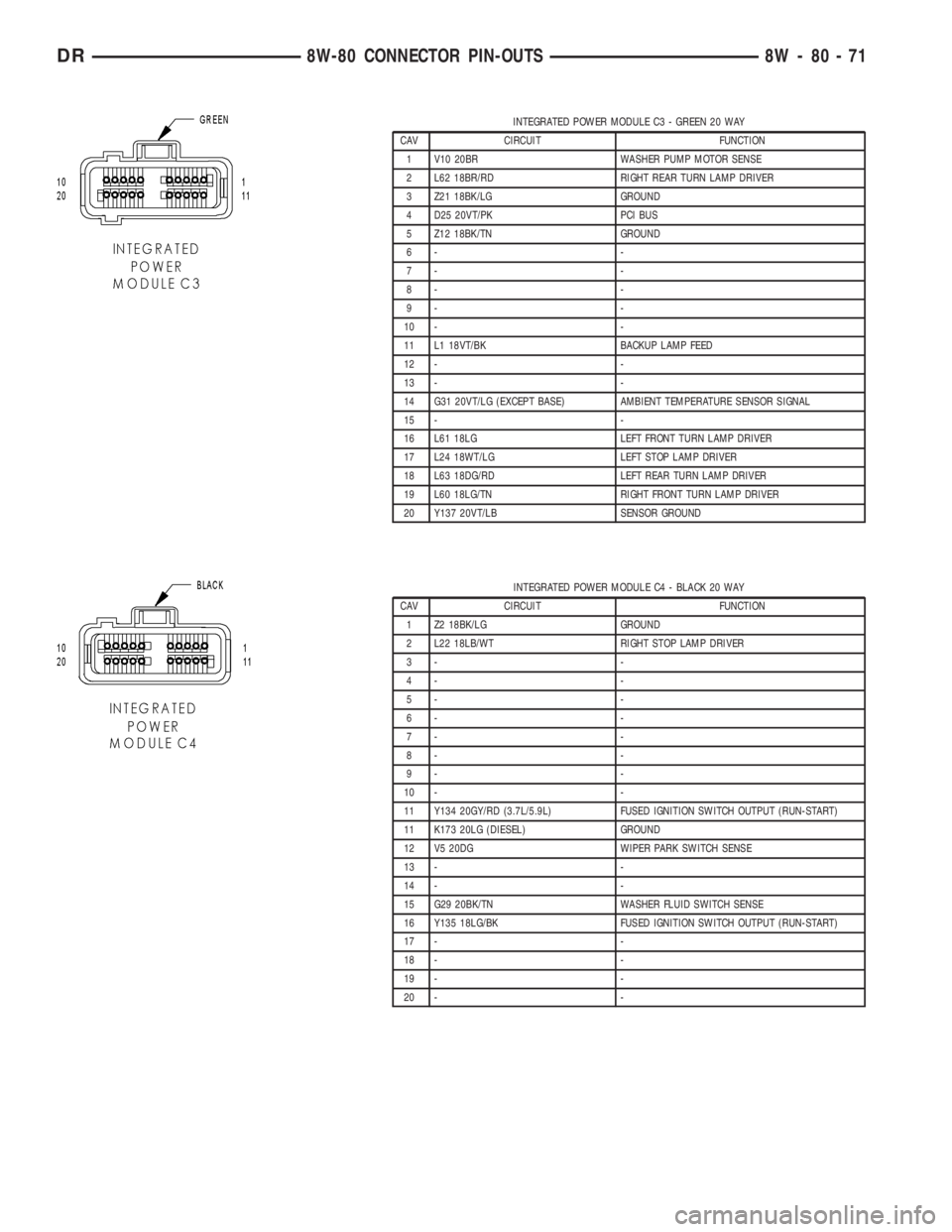

INTEGRATED POWER MODULE C3 - GREEN 20 WAY

CAV CIRCUIT FUNCTION

1 V10 20BR WASHER PUMP MOTOR SENSE

2 L62 18BR/RD RIGHT REAR TURN LAMP DRIVER

3 Z21 18BK/LG GROUND

4 D25 20VT/PK PCI BUS

5 Z12 18BK/TN GROUND

6- -

7- -

8- -

9- -

10 - -

11 L1 18VT/BK BACKUP LAMP FEED

12 - -

13 - -

14 G31 20VT/LG (EXCEPT BASE) AMBIENT TEMPERATURE SENSOR SIGNAL

15 - -

16 L61 18LG LEFT FRONT TURN LAMP DRIVER

17 L24 18WT/LG LEFT STOP LAMP DRIVER

18 L63 18DG/RD LEFT REAR TURN LAMP DRIVER

19 L60 18LG/TN RIGHT FRONT TURN LAMP DRIVER

20 Y137 20VT/LB SENSOR GROUND

INTEGRATED POWER MODULE C4 - BLACK 20 WAY

CAV CIRCUIT FUNCTION

1 Z2 18BK/LG GROUND

2 L22 18LB/WT RIGHT STOP LAMP DRIVER

3- -

4- -

5- -

6- -

7- -

8- -

9- -

10 - -

11 Y134 20GY/RD (3.7L/5.9L) FUSED IGNITION SWITCH OUTPUT (RUN-START)

11 K173 20LG (DIESEL) GROUND

12 V5 20DG WIPER PARK SWITCH SENSE

13 - -

14 - -

15 G29 20BK/TN WASHER FLUID SWITCH SENSE

16 Y135 18LG/BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

17 - -

18 - -

19 - -

20 - -

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 71

Page 1166 of 2895

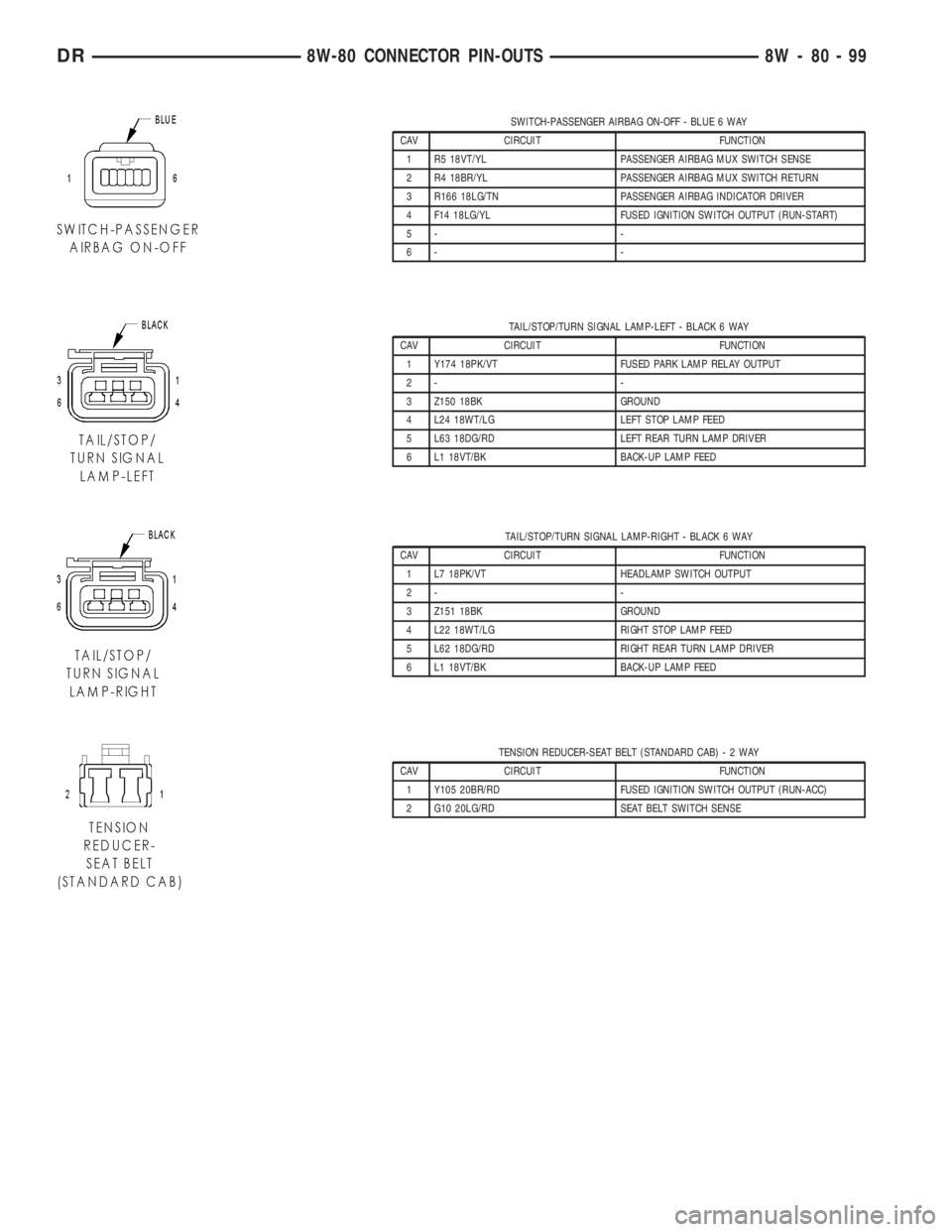

SWITCH-PASSENGER AIRBAG ON-OFF - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 R5 18VT/YL PASSENGER AIRBAG MUX SWITCH SENSE

2 R4 18BR/YL PASSENGER AIRBAG MUX SWITCH RETURN

3 R166 18LG/TN PASSENGER AIRBAG INDICATOR DRIVER

4 F14 18LG/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

5- -

6- -

TAIL/STOP/TURN SIGNAL LAMP-LEFT - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 Y174 18PK/VT FUSED PARK LAMP RELAY OUTPUT

2- -

3 Z150 18BK GROUND

4 L24 18WT/LG LEFT STOP LAMP FEED

5 L63 18DG/RD LEFT REAR TURN LAMP DRIVER

6 L1 18VT/BK BACK-UP LAMP FEED

TAIL/STOP/TURN SIGNAL LAMP-RIGHT - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 L7 18PK/VT HEADLAMP SWITCH OUTPUT

2- -

3 Z151 18BK GROUND

4 L22 18WT/LG RIGHT STOP LAMP FEED

5 L62 18DG/RD RIGHT REAR TURN LAMP DRIVER

6 L1 18VT/BK BACK-UP LAMP FEED

TENSION REDUCER-SEAT BELT (STANDARD CAB)-2WAY

CAV CIRCUIT FUNCTION

1 Y105 20BR/RD FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

2 G10 20LG/RD SEAT BELT SWITCH SENSE

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 99

Page 1312 of 2895

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kPa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose.(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

DRENGINE - 3.7L 9 - 63

LUBRICATION (Continued)

Page 1320 of 2895

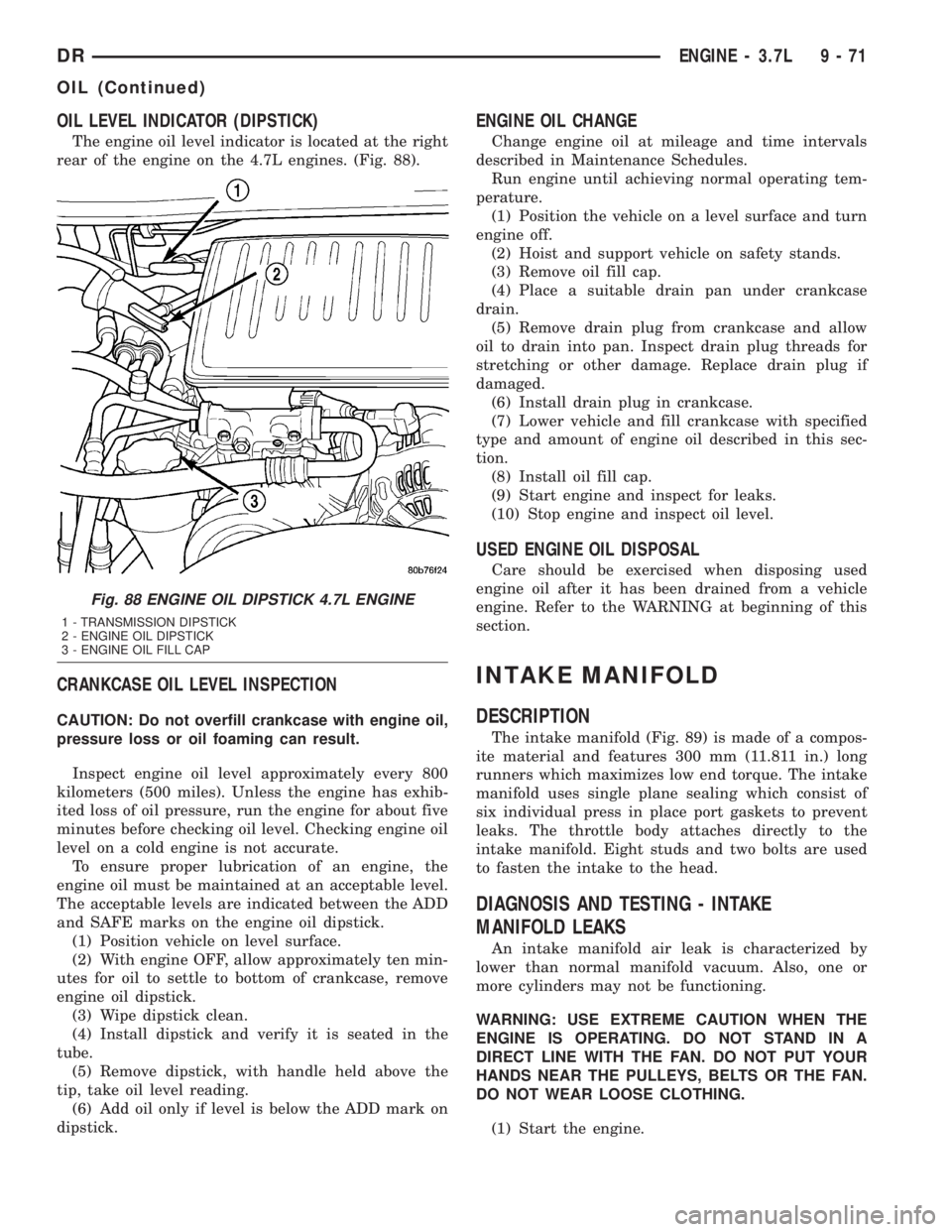

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

rear of the engine on the 4.7L engines. (Fig. 88).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about five

minutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING at beginning of this

section.

INTAKE MANIFOLD

DESCRIPTION

The intake manifold (Fig. 89) is made of a compos-

ite material and features 300 mm (11.811 in.) long

runners which maximizes low end torque. The intake

manifold uses single plane sealing which consist of

six individual press in place port gaskets to prevent

leaks. The throttle body attaches directly to the

intake manifold. Eight studs and two bolts are used

to fasten the intake to the head.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

Fig. 88 ENGINE OIL DIPSTICK 4.7L ENGINE

1 - TRANSMISSION DIPSTICK

2 - ENGINE OIL DIPSTICK

3 - ENGINE OIL FILL CAP

DRENGINE - 3.7L 9 - 71

OIL (Continued)