windshield wipers DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 694 of 2895

INSTALLATION

The right and left wiper arms are not interchange-

able. The right wiper arm is slightly longer than the

left. Be certain that each wiper arm is installed on

the proper wiper pivot.

(1) Place the wiper arm hinge in its over-center

position prior to attempting installation.

(2) The wiper arms are indexed to the wiper pivot

shafts with integral keys in the wiper arm pivot ends

and keyways in the wiper pivot shafts. Align the key

of the wiper arm to the keyway on the wiper pivot

shaft.

(3) Once the wiper blade is aligned, push the pivot

of the wiper arm down firmly and evenly over the

wiper pivot shaft until it is fully engaged. When the

wiper arm is fully engaged on the wiper pivot, the

spring-loaded latch (Fig. 19) will snap back into place

against the wiper arm pivot end.

(4) Gently lower the wiper arm until the wiper

blade is in position on the windshield glass.

WIPER BLADE

DESCRIPTION

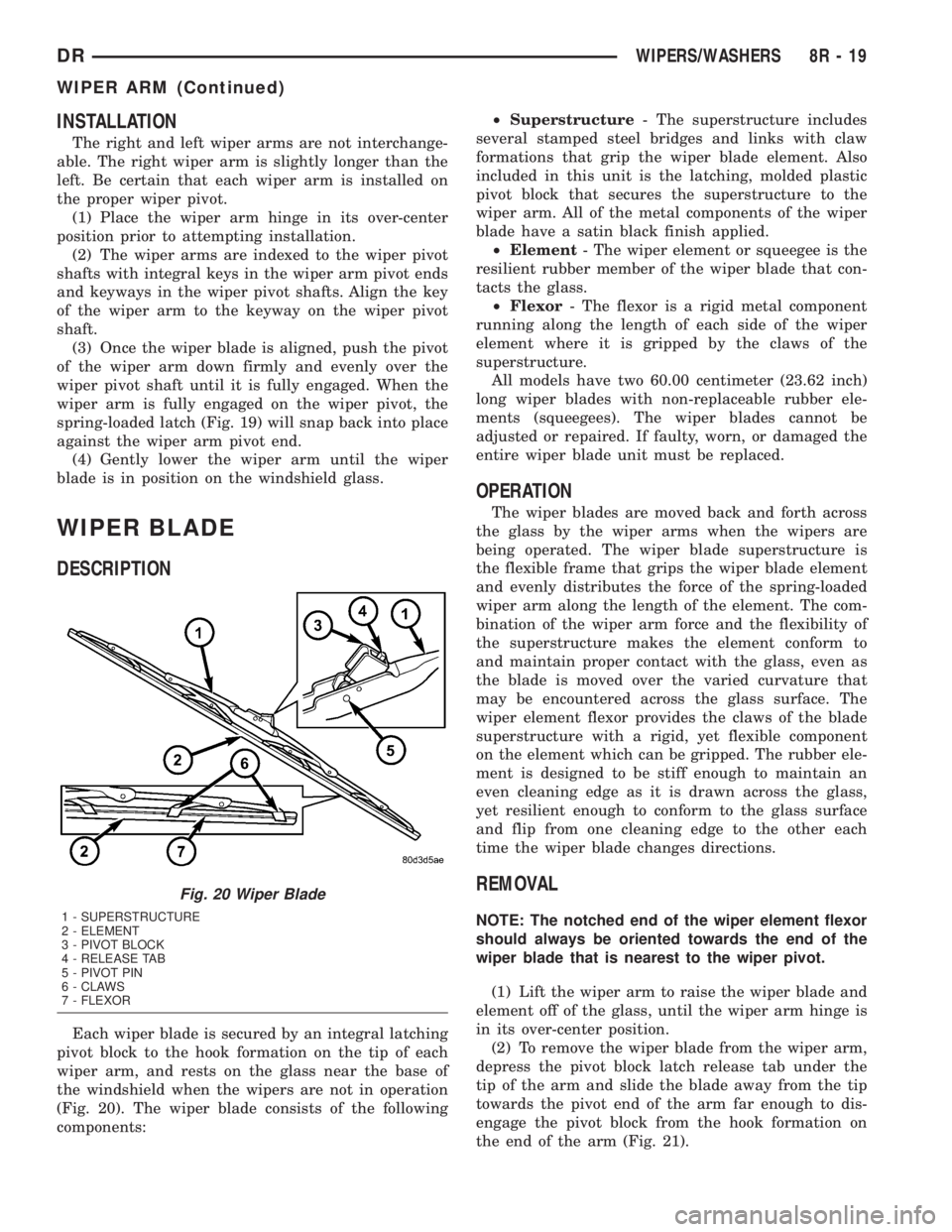

Each wiper blade is secured by an integral latching

pivot block to the hook formation on the tip of each

wiper arm, and rests on the glass near the base of

the windshield when the wipers are not in operation

(Fig. 20). The wiper blade consists of the following

components:²Superstructure- The superstructure includes

several stamped steel bridges and links with claw

formations that grip the wiper blade element. Also

included in this unit is the latching, molded plastic

pivot block that secures the superstructure to the

wiper arm. All of the metal components of the wiper

blade have a satin black finish applied.

²Element- The wiper element or squeegee is the

resilient rubber member of the wiper blade that con-

tacts the glass.

²Flexor- The flexor is a rigid metal component

running along the length of each side of the wiper

element where it is gripped by the claws of the

superstructure.

All models have two 60.00 centimeter (23.62 inch)

long wiper blades with non-replaceable rubber ele-

ments (squeegees). The wiper blades cannot be

adjusted or repaired. If faulty, worn, or damaged the

entire wiper blade unit must be replaced.

OPERATION

The wiper blades are moved back and forth across

the glass by the wiper arms when the wipers are

being operated. The wiper blade superstructure is

the flexible frame that grips the wiper blade element

and evenly distributes the force of the spring-loaded

wiper arm along the length of the element. The com-

bination of the wiper arm force and the flexibility of

the superstructure makes the element conform to

and maintain proper contact with the glass, even as

the blade is moved over the varied curvature that

may be encountered across the glass surface. The

wiper element flexor provides the claws of the blade

superstructure with a rigid, yet flexible component

on the element which can be gripped. The rubber ele-

ment is designed to be stiff enough to maintain an

even cleaning edge as it is drawn across the glass,

yet resilient enough to conform to the glass surface

and flip from one cleaning edge to the other each

time the wiper blade changes directions.

REMOVAL

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper pivot.

(1) Lift the wiper arm to raise the wiper blade and

element off of the glass, until the wiper arm hinge is

in its over-center position.

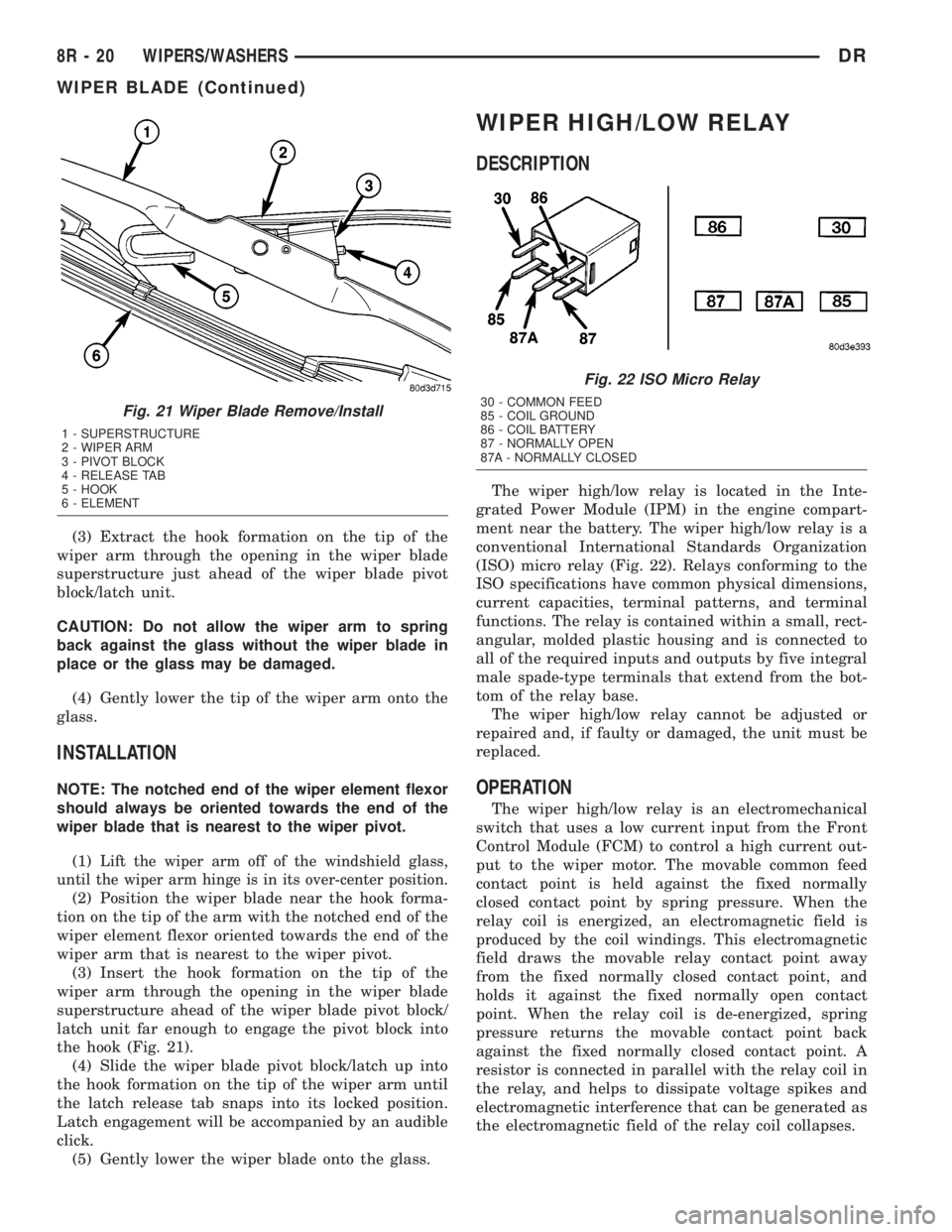

(2) To remove the wiper blade from the wiper arm,

depress the pivot block latch release tab under the

tip of the arm and slide the blade away from the tip

towards the pivot end of the arm far enough to dis-

engage the pivot block from the hook formation on

the end of the arm (Fig. 21).

Fig. 20 Wiper Blade

1 - SUPERSTRUCTURE

2 - ELEMENT

3 - PIVOT BLOCK

4 - RELEASE TAB

5 - PIVOT PIN

6 - CLAWS

7 - FLEXOR

DRWIPERS/WASHERS 8R - 19

WIPER ARM (Continued)

Page 695 of 2895

(3) Extract the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure just ahead of the wiper blade pivot

block/latch unit.

CAUTION: Do not allow the wiper arm to spring

back against the glass without the wiper blade in

place or the glass may be damaged.

(4) Gently lower the tip of the wiper arm onto the

glass.

INSTALLATION

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper pivot.

(1)

Lift the wiper arm off of the windshield glass,

until the wiper arm hinge is in its over-center position.

(2) Position the wiper blade near the hook forma-

tion on the tip of the arm with the notched end of the

wiper element flexor oriented towards the end of the

wiper arm that is nearest to the wiper pivot.

(3) Insert the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure ahead of the wiper blade pivot block/

latch unit far enough to engage the pivot block into

the hook (Fig. 21).

(4) Slide the wiper blade pivot block/latch up into

the hook formation on the tip of the wiper arm until

the latch release tab snaps into its locked position.

Latch engagement will be accompanied by an audible

click.

(5) Gently lower the wiper blade onto the glass.

WIPER HIGH/LOW RELAY

DESCRIPTION

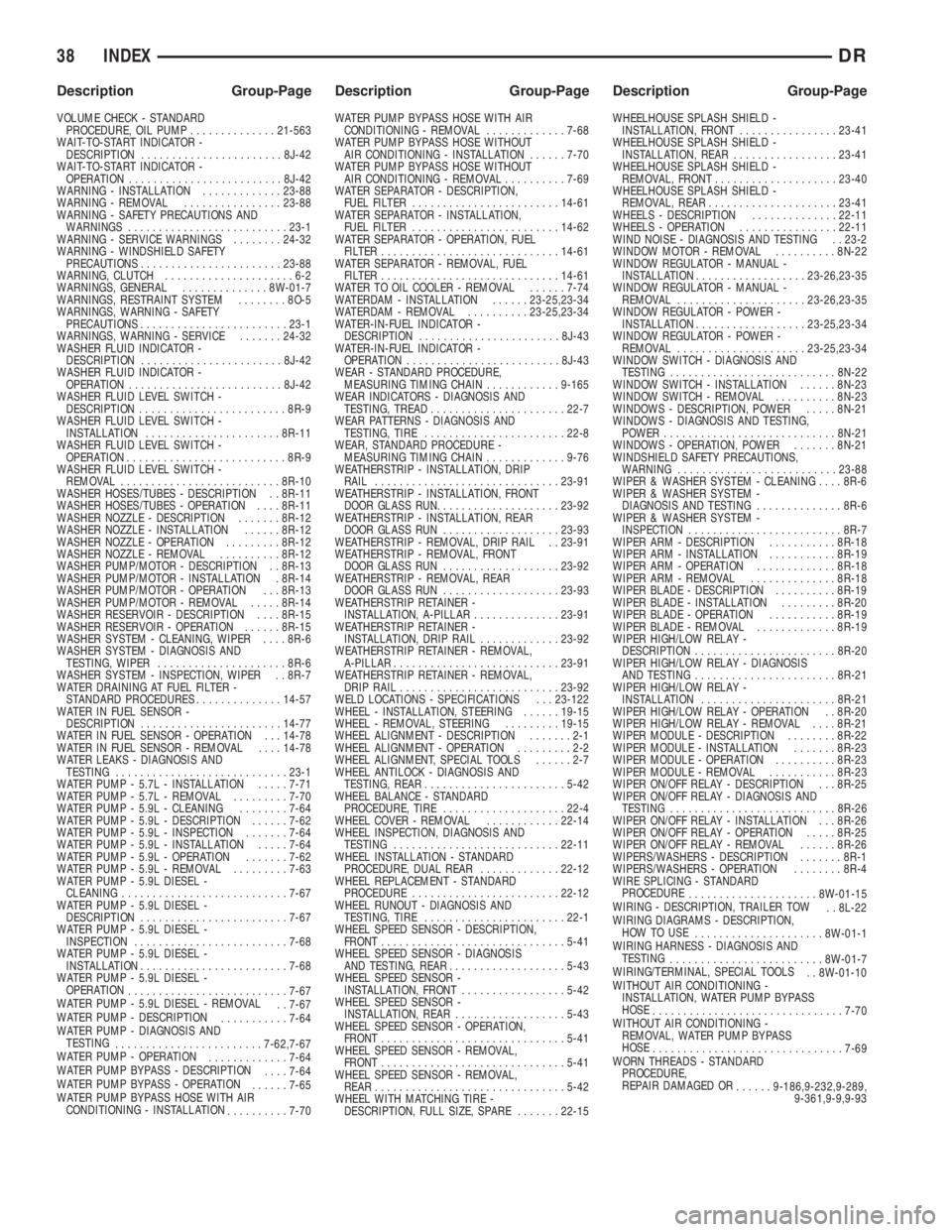

The wiper high/low relay is located in the Inte-

grated Power Module (IPM) in the engine compart-

ment near the battery. The wiper high/low relay is a

conventional International Standards Organization

(ISO) micro relay (Fig. 22). Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The relay is contained within a small, rect-

angular, molded plastic housing and is connected to

all of the required inputs and outputs by five integral

male spade-type terminals that extend from the bot-

tom of the relay base.

The wiper high/low relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper high/low relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control a high current out-

put to the wiper motor. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

Fig. 21 Wiper Blade Remove/Install

1 - SUPERSTRUCTURE

2 - WIPER ARM

3 - PIVOT BLOCK

4 - RELEASE TAB

5 - HOOK

6 - ELEMENT

Fig. 22 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

8R - 20 WIPERS/WASHERSDR

WIPER BLADE (Continued)

Page 2893 of 2895

VOLUME CHECK - STANDARD

PROCEDURE, OIL PUMP..............21-563

WAIT-TO-START INDICATOR -

DESCRIPTION.......................8J-42

WAIT-TO-START INDICATOR -

OPERATION.........................8J-42

WARNING - INSTALLATION.............23-88

WARNING - REMOVAL................23-88

WARNING - SAFETY PRECAUTIONS AND

WARNINGS..........................23-1

WARNING - SERVICE WARNINGS........24-32

WARNING - WINDSHIELD SAFETY

PRECAUTIONS.......................23-88

WARNING, CLUTCH.....................6-2

WARNINGS, GENERAL..............8W-01-7

WARNINGS, RESTRAINT SYSTEM........8O-5

WARNINGS, WARNING - SAFETY

PRECAUTIONS........................23-1

WARNINGS, WARNING - SERVICE.......24-32

WASHER FLUID INDICATOR -

DESCRIPTION.......................8J-42

WASHER FLUID INDICATOR -

OPERATION.........................8J-42

WASHER FLUID LEVEL SWITCH -

DESCRIPTION........................8R-9

WASHER FLUID LEVEL SWITCH -

INSTALLATION......................8R-11

WASHER FLUID LEVEL SWITCH -

OPERATION..........................8R-9

WASHER FLUID LEVEL SWITCH -

REMOVAL..........................8R-10

WASHER HOSES/TUBES - DESCRIPTION . . 8R-11

WASHER HOSES/TUBES - OPERATION....8R-11

WASHER NOZZLE - DESCRIPTION.......8R-12

WASHER NOZZLE - INSTALLATION......8R-12

WASHER NOZZLE - OPERATION.........8R-12

WASHER NOZZLE - REMOVAL..........8R-12

WASHER PUMP/MOTOR - DESCRIPTION . . 8R-13

WASHER PUMP/MOTOR - INSTALLATION . 8R-14

WASHER PUMP/MOTOR - OPERATION . . . 8R-13

WASHER PUMP/MOTOR - REMOVAL.....8R-14

WASHER RESERVOIR - DESCRIPTION....8R-15

WASHER RESERVOIR - OPERATION......8R-15

WASHER SYSTEM - CLEANING, WIPER....8R-6

WASHER SYSTEM - DIAGNOSIS AND

TESTING, WIPER.....................8R-6

WASHER SYSTEM - INSPECTION, WIPER . . 8R-7

WATER DRAINING AT FUEL FILTER -

STANDARD PROCEDURES..............14-57

WATER IN FUEL SENSOR -

DESCRIPTION.......................14-77

WATER IN FUEL SENSOR - OPERATION . . . 14-78

WATER IN FUEL SENSOR - REMOVAL....14-78

WATER LEAKS - DIAGNOSIS AND

TESTING............................23-1

WATER PUMP - 5.7L - INSTALLATION.....7-71

WATER PUMP - 5.7L - REMOVAL.........7-70

WATER PUMP - 5.9L - CLEANING........7-64

WATER PUMP - 5.9L - DESCRIPTION......7-62

WATER PUMP - 5.9L - INSPECTION.......7-64

WATER PUMP - 5.9L - INSTALLATION.....7-64

WATER PUMP - 5.9L - OPERATION.......7-62

WATER PUMP - 5.9L - REMOVAL.........7-63

WATER PUMP - 5.9L DIESEL -

CLEANING...........................7-67

WATER PUMP - 5.9L DIESEL -

DESCRIPTION........................7-67

WATER PUMP - 5.9L DIESEL -

INSPECTION.........................7-68

WATER PUMP - 5.9L DIESEL -

INSTALLATION........................7-68

WATER PUMP - 5.9L DIESEL -

OPERATION

..........................7-67

WATER PUMP - 5.9L DIESEL - REMOVAL

. . 7-67

WATER PUMP - DESCRIPTION

...........7-64

WATER PUMP - DIAGNOSIS AND

TESTING

........................7-62,7-67

WATER PUMP - OPERATION

.............7-64

WATER PUMP BYPASS - DESCRIPTION

....7-64

WATER PUMP BYPASS - OPERATION

......7-65

WATER PUMP BYPASS HOSE WITH AIR

CONDITIONING - INSTALLATION

..........7-70WATER PUMP BYPASS HOSE WITH AIR

CONDITIONING - REMOVAL.............7-68

WATER PUMP BYPASS HOSE WITHOUT

AIR CONDITIONING - INSTALLATION......7-70

WATER PUMP BYPASS HOSE WITHOUT

AIR CONDITIONING - REMOVAL..........7-69

WATER SEPARATOR - DESCRIPTION,

FUEL FILTER........................14-61

WATER SEPARATOR - INSTALLATION,

FUEL FILTER........................14-62

WATER SEPARATOR - OPERATION, FUEL

FILTER.............................14-61

WATER SEPARATOR - REMOVAL, FUEL

FILTER.............................14-61

WATER TO OIL COOLER - REMOVAL......7-74

WATERDAM - INSTALLATION......23-25,23-34

WATERDAM - REMOVAL..........23-25,23-34

WATER-IN-FUEL INDICATOR -

DESCRIPTION.......................8J-43

WATER-IN-FUEL INDICATOR -

OPERATION.........................8J-43

WEAR - STANDARD PROCEDURE,

MEASURING TIMING CHAIN............9-165

WEAR INDICATORS - DIAGNOSIS AND

TESTING, TREAD......................22-7

WEAR PATTERNS - DIAGNOSIS AND

TESTING, TIRE.......................22-8

WEAR, STANDARD PROCEDURE -

MEASURING TIMING CHAIN.............9-76

WEATHERSTRIP - INSTALLATION, DRIP

RAIL..............................23-91

WEATHERSTRIP - INSTALLATION, FRONT

DOOR GLASS RUN.....................23-92

WEATHERSTRIP - INSTALLATION, REAR

DOOR GLASS RUN...................23-93

WEATHERSTRIP - REMOVAL, DRIP RAIL . . 23-91

WEATHERSTRIP - REMOVAL, FRONT

DOOR GLASS RUN...................23-92

WEATHERSTRIP - REMOVAL, REAR

DOOR GLASS RUN...................23-93

WEATHERSTRIP RETAINER -

INSTALLATION, A-PILLAR..............23-91

WEATHERSTRIP RETAINER -

INSTALLATION, DRIP RAIL.............23-92

WEATHERSTRIP RETAINER - REMOVAL,

A-PILLAR...........................23-91

WEATHERSTRIP RETAINER - REMOVAL,

DRIP RAIL..........................23-92

WELD LOCATIONS - SPECIFICATIONS . . . 23-122

WHEEL - INSTALLATION, STEERING......19-15

WHEEL - REMOVAL, STEERING.........19-15

WHEEL ALIGNMENT - DESCRIPTION.......2-1

WHEEL ALIGNMENT - OPERATION.........2-2

WHEEL ALIGNMENT, SPECIAL TOOLS......2-7

WHEEL ANTILOCK - DIAGNOSIS AND

TESTING, REAR.......................5-42

WHEEL BALANCE - STANDARD

PROCEDURE, TIRE....................22-4

WHEEL COVER - REMOVAL............22-14

WHEEL INSPECTION, DIAGNOSIS AND

TESTING...........................22-11

WHEEL INSTALLATION - STANDARD

PROCEDURE, DUAL REAR.............22-12

WHEEL REPLACEMENT - STANDARD

PROCEDURE........................22-12

WHEEL RUNOUT - DIAGNOSIS AND

TESTING, TIRE.......................22-1

WHEEL SPEED SENSOR - DESCRIPTION,

FRONT..............................5-41

WHEEL SPEED SENSOR - DIAGNOSIS

AND TESTING, REAR...................5-43

WHEEL SPEED SENSOR -

INSTALLATION, FRONT.................5-42

WHEEL SPEED SENSOR -

INSTALLATION, REAR..................5-43

WHEEL SPEED SENSOR - OPERATION,

FRONT..............................5-41

WHEEL SPEED SENSOR - REMOVAL,

FRONT..............................5-41

WHEEL SPEED SENSOR - REMOVAL,

REAR...............................5-42

WHEEL WITH MATCHING TIRE -

DESCRIPTION, FULL SIZE, SPARE.......22-15WHEELHOUSE SPLASH SHIELD -

INSTALLATION, FRONT................23-41

WHEELHOUSE SPLASH SHIELD -

INSTALLATION, REAR.................23-41

WHEELHOUSE SPLASH SHIELD -

REMOVAL, FRONT....................23-40

WHEELHOUSE SPLASH SHIELD -

REMOVAL, REAR.....................23-41

WHEELS - DESCRIPTION..............22-11

WHEELS - OPERATION................22-11

WIND NOISE - DIAGNOSIS AND TESTING . . 23-2

WINDOW MOTOR - REMOVAL..........8N-22

WINDOW REGULATOR - MANUAL -

INSTALLATION..................23-26,23-35

WINDOW REGULATOR - MANUAL -

REMOVAL.....................23-26,23-35

WINDOW REGULATOR - POWER -

INSTALLATION..................23-25,23-34

WINDOW REGULATOR - POWER -

REMOVAL.....................23-25,23-34

WINDOW SWITCH - DIAGNOSIS AND

TESTING...........................8N-22

WINDOW SWITCH - INSTALLATION......8N-23

WINDOW SWITCH - REMOVAL..........8N-23

WINDOWS - DESCRIPTION, POWER.....8N-21

WINDOWS - DIAGNOSIS AND TESTING,

POWER............................8N-21

WINDOWS - OPERATION, POWER.......8N-21

WINDSHIELD SAFETY PRECAUTIONS,

WARNING..........................23-88

WIPER & WASHER SYSTEM - CLEANING....8R-6

WIPER & WASHER SYSTEM -

DIAGNOSIS AND TESTING..............8R-6

WIPER & WASHER SYSTEM -

INSPECTION.........................8R-7

WIPER ARM - DESCRIPTION...........8R-18

WIPER ARM - INSTALLATION...........8R-19

WIPER ARM - OPERATION.............8R-18

WIPER ARM - REMOVAL..............8R-18

WIPER BLADE - DESCRIPTION..........8R-19

WIPER BLADE - INSTALLATION.........8R-20

WIPER BLADE - OPERATION...........8R-19

WIPER BLADE - REMOVAL.............8R-19

WIPER HIGH/LOW RELAY -

DESCRIPTION.......................8R-20

WIPER HIGH/LOW RELAY - DIAGNOSIS

AND TESTING.......................8R-21

WIPER HIGH/LOW RELAY -

INSTALLATION......................8R-21

WIPER HIGH/LOW RELAY - OPERATION . . 8R-20

WIPER HIGH/LOW RELAY - REMOVAL....8R-21

WIPER MODULE - DESCRIPTION........8R-22

WIPER MODULE - INSTALLATION.......8R-23

WIPER MODULE - OPERATION..........8R-23

WIPER MODULE - REMOVAL...........8R-23

WIPER ON/OFF RELAY - DESCRIPTION . . . 8R-25

WIPER ON/OFF RELAY - DIAGNOSIS AND

TESTING...........................8R-26

WIPER ON/OFF RELAY - INSTALLATION . . . 8R-26

WIPER ON/OFF RELAY - OPERATION.....8R-25

WIPER ON/OFF RELAY - REMOVAL......8R-26

WIPERS/WASHERS - DESCRIPTION.......8R-1

WIPERS/WASHERS - OPERATION........8R-4

WIRE SPLICING - STANDARD

PROCEDURE

.....................8W-01-15

WIRING - DESCRIPTION, TRAILER TOW

. . 8L-22

WIRING DIAGRAMS - DESCRIPTION,

HOW TO USE

.....................8W-01-1

WIRING HARNESS - DIAGNOSIS AND

TESTING

.........................8W-01-7

WIRING/TERMINAL, SPECIAL TOOLS

. . 8W-01-10

WITHOUT AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS

HOSE

...............................7-70

WITHOUT AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS

HOSE

...............................7-69

WORN THREADS - STANDARD

PROCEDURE,

REPAIR DAMAGED OR

......9-186,9-232,9-289,

9-361,9-9,9-93

38 INDEXDR

Description Group-Page Description Group-Page Description Group-Page