engine DODGE RAM 2003 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 34 of 2895

angle while adjusting caster, move one pivot bolt of

the upper control arm in or out. Then move the other

pivot bolt of the upper control arm in the opposite

direction. Install special tool 8876 between the top of

the upper control arm bracket and the upper control

arm (on 1500 series 4X2 & 4X4). Install special tool

8876 between the bottom of the upper control arm

bracket pressing the tool against the frame and the

upper control arm (on 2500/3500 series 4X2) in order

to move the upper control arm outwards for proper

adjustment with the vehicle at normal ride height

(Fig. 3).

To increase positive caster angle, move the rear

position of the upper control arm inward (toward the

engine). Move the front of the upper control arm out-

ward (away from the engine) slightly until the origi-

nal camber angle is obtained using special tool 8876

to move the upper control arm for proper adjustment.

(Fig. 3)

CAMBER

Move both pivot bolts of the upper control arm

together in or out. This will change the camber angle

significantly and little effect on the caster angle

using special tool 8876 to move the upper control

arm for proper adjustment. (Fig. 3)

After adjustment is made tighten the upper control

arm nuts to proper torque specification.

TOE ADJUSTMENT

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.

(2) Loosen the tie rod jam nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

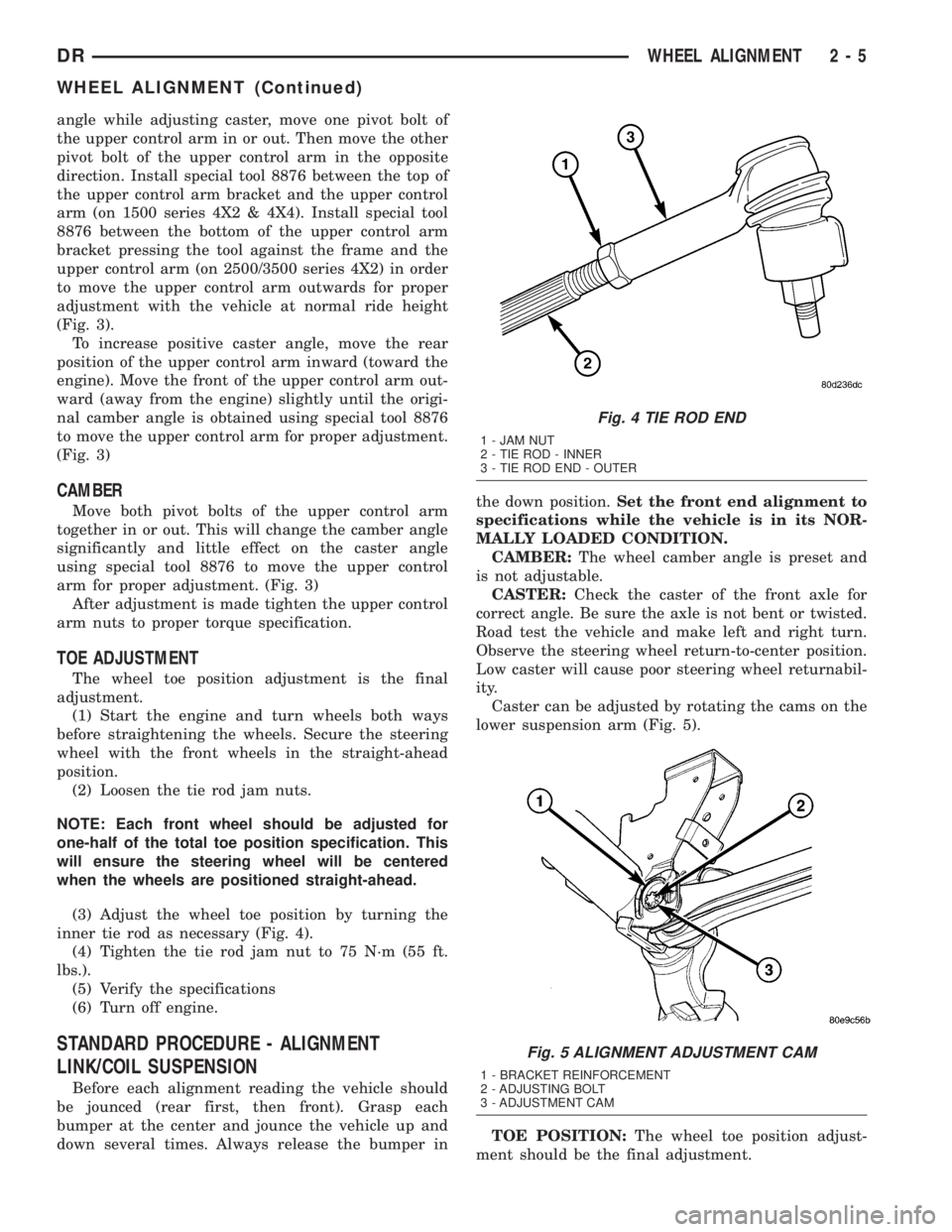

(3) Adjust the wheel toe position by turning the

inner tie rod as necessary (Fig. 4).

(4) Tighten the tie rod jam nut to 75 N´m (55 ft.

lbs.).

(5) Verify the specifications

(6) Turn off engine.

STANDARD PROCEDURE - ALIGNMENT

LINK/COIL SUSPENSION

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down several times. Always release the bumper inthe down position.Set the front end alignment to

specifications while the vehicle is in its NOR-

MALLY LOADED CONDITION.

CAMBER:The wheel camber angle is preset and

is not adjustable.

CASTER:Check the caster of the front axle for

correct angle. Be sure the axle is not bent or twisted.

Road test the vehicle and make left and right turn.

Observe the steering wheel return-to-center position.

Low caster will cause poor steering wheel returnabil-

ity.

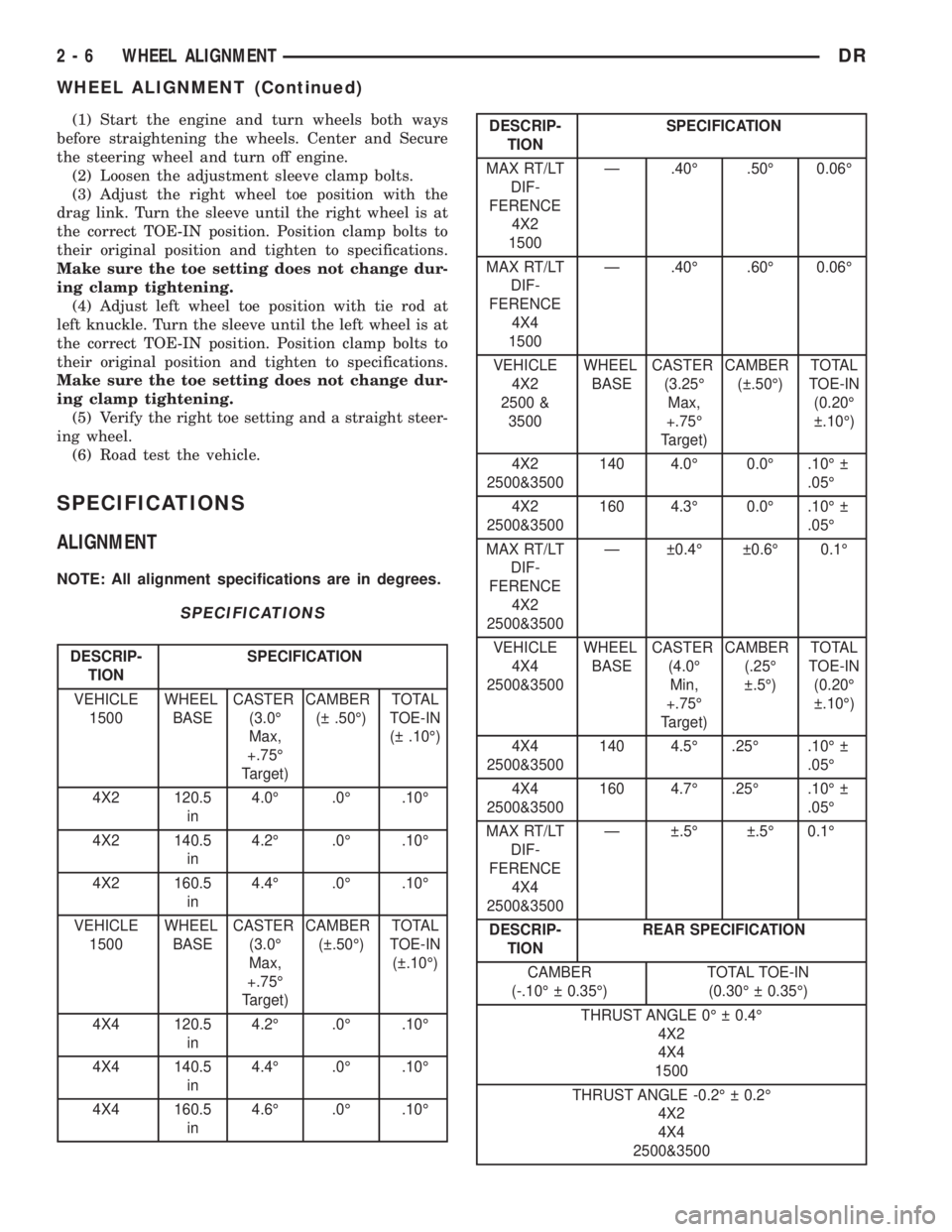

Caster can be adjusted by rotating the cams on the

lower suspension arm (Fig. 5).

TOE POSITION:The wheel toe position adjust-

ment should be the final adjustment.

Fig. 4 TIE ROD END

1 - JAM NUT

2 - TIE ROD - INNER

3 - TIE ROD END - OUTER

Fig. 5 ALIGNMENT ADJUSTMENT CAM

1 - BRACKET REINFORCEMENT

2 - ADJUSTING BOLT

3 - ADJUSTMENT CAM

DRWHEEL ALIGNMENT 2 - 5

WHEEL ALIGNMENT (Continued)

Page 35 of 2895

(1) Start the engine and turn wheels both ways

before straightening the wheels. Center and Secure

the steering wheel and turn off engine.

(2) Loosen the adjustment sleeve clamp bolts.

(3) Adjust the right wheel toe position with the

drag link. Turn the sleeve until the right wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(4) Adjust left wheel toe position with tie rod at

left knuckle. Turn the sleeve until the left wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(5) Verify the right toe setting and a straight steer-

ing wheel.

(6) Road test the vehicle.

SPECIFICATIONS

ALIGNMENT

NOTE: All alignment specifications are in degrees.

SPECIFICATIONS

DESCRIP-

TIONSPECIFICATION

VEHICLE

1500WHEEL

BASECASTER

(3.0É

Max,

+.75É

Target)CAMBER

( .50É)TOTAL

TOE-IN

( .10É)

4X2 120.5

in4.0É .0É .10É

4X2 140.5

in4.2É .0É .10É

4X2 160.5

in4.4É .0É .10É

VEHICLE

1500WHEEL

BASECASTER

(3.0É

Max,

+.75É

Target)CAMBER

( .50É)TOTAL

TOE-IN

( .10É)

4X4 120.5

in4.2É .0É .10É

4X4 140.5

in4.4É .0É .10É

4X4 160.5

in4.6É .0É .10É

DESCRIP-

TIONSPECIFICATION

MAX RT/LT

DIF-

FERENCE

4X2

1500Ð .40É .50É 0.06É

MAX RT/LT

DIF-

FERENCE

4X4

1500Ð .40É .60É 0.06É

VEHICLE

4X2

2500 &

3500WHEEL

BASECASTER

(3.25É

Max,

+.75É

Target)CAMBER

( .50É)TOTAL

TOE-IN

(0.20É

.10É)

4X2

2500&3500140 4.0É 0.0É .10É

.05É

4X2

2500&3500160 4.3É 0.0É .10É

.05É

MAX RT/LT

DIF-

FERENCE

4X2

2500&3500Ð 0.4É 0.6É 0.1É

VEHICLE

4X4

2500&3500WHEEL

BASECASTER

(4.0É

Min,

+.75É

Target)CAMBER

(.25É

.5É)TOTAL

TOE-IN

(0.20É

.10É)

4X4

2500&3500140 4.5É .25É .10É

.05É

4X4

2500&3500160 4.7É .25É .10É

.05É

MAX RT/LT

DIF-

FERENCE

4X4

2500&3500Ð .5É .5É 0.1É

DESCRIP-

TIONREAR SPECIFICATION

CAMBER

(-.10É 0.35É)TOTAL TOE-IN

(0.30É 0.35É)

THRUST ANGLE 0É 0.4É

4X2

4X4

1500

THRUST ANGLE -0.2É 0.2É

4X2

4X4

2500&3500

2 - 6 WHEEL ALIGNMENTDR

WHEEL ALIGNMENT (Continued)

Page 64 of 2895

LOWER SUSPENSION ARM

REMOVAL

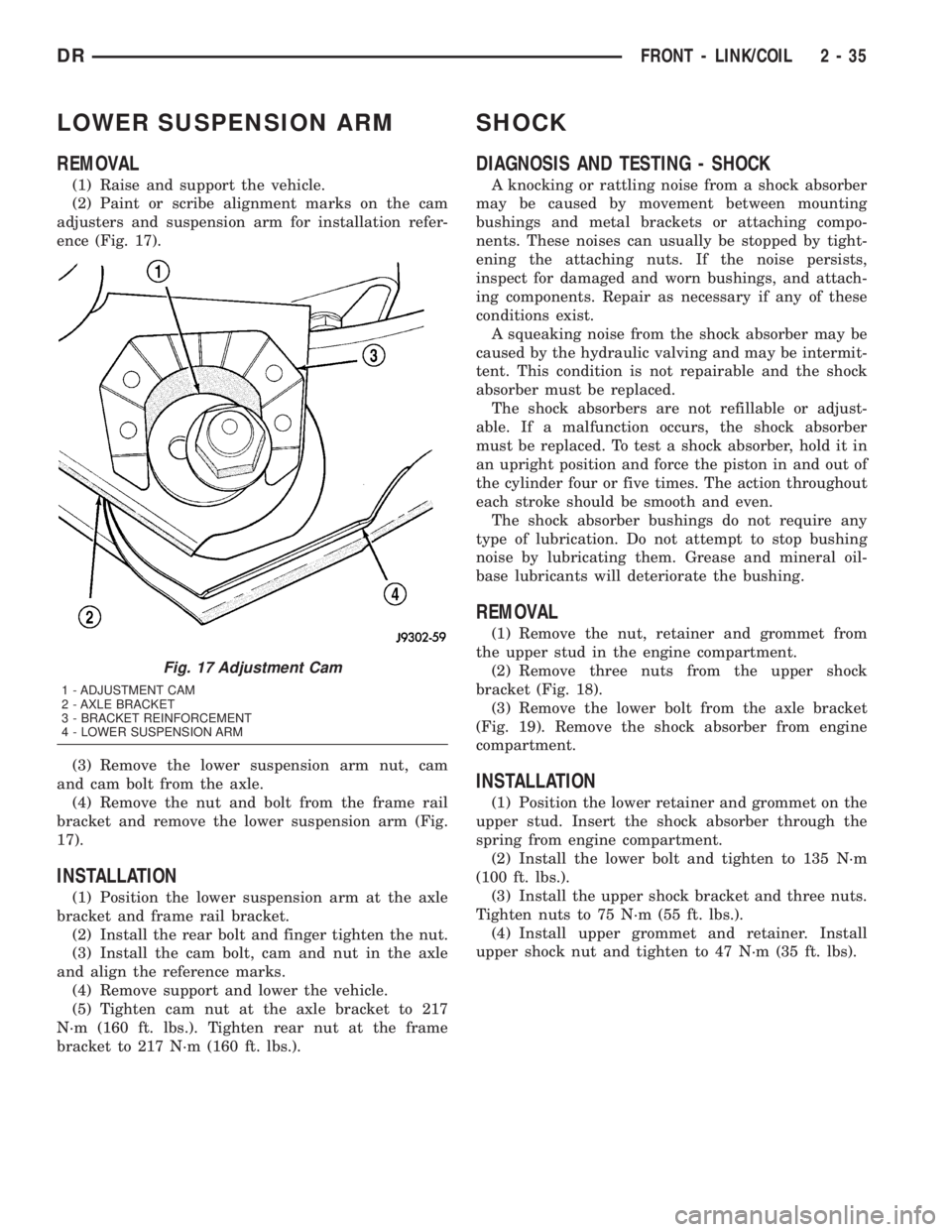

(1) Raise and support the vehicle.

(2) Paint or scribe alignment marks on the cam

adjusters and suspension arm for installation refer-

ence (Fig. 17).

(3) Remove the lower suspension arm nut, cam

and cam bolt from the axle.

(4) Remove the nut and bolt from the frame rail

bracket and remove the lower suspension arm (Fig.

17).

INSTALLATION

(1) Position the lower suspension arm at the axle

bracket and frame rail bracket.

(2) Install the rear bolt and finger tighten the nut.

(3) Install the cam bolt, cam and nut in the axle

and align the reference marks.

(4) Remove support and lower the vehicle.

(5) Tighten cam nut at the axle bracket to 217

N´m (160 ft. lbs.). Tighten rear nut at the frame

bracket to 217 N´m (160 ft. lbs.).

SHOCK

DIAGNOSIS AND TESTING - SHOCK

A knocking or rattling noise from a shock absorber

may be caused by movement between mounting

bushings and metal brackets or attaching compo-

nents. These noises can usually be stopped by tight-

ening the attaching nuts. If the noise persists,

inspect for damaged and worn bushings, and attach-

ing components. Repair as necessary if any of these

conditions exist.

A squeaking noise from the shock absorber may be

caused by the hydraulic valving and may be intermit-

tent. This condition is not repairable and the shock

absorber must be replaced.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston in and out of

the cylinder four or five times. The action throughout

each stroke should be smooth and even.

The shock absorber bushings do not require any

type of lubrication. Do not attempt to stop bushing

noise by lubricating them. Grease and mineral oil-

base lubricants will deteriorate the bushing.

REMOVAL

(1) Remove the nut, retainer and grommet from

the upper stud in the engine compartment.

(2) Remove three nuts from the upper shock

bracket (Fig. 18).

(3) Remove the lower bolt from the axle bracket

(Fig. 19). Remove the shock absorber from engine

compartment.

INSTALLATION

(1) Position the lower retainer and grommet on the

upper stud. Insert the shock absorber through the

spring from engine compartment.

(2) Install the lower bolt and tighten to 135 N´m

(100 ft. lbs.).

(3) Install the upper shock bracket and three nuts.

Tighten nuts to 75 N´m (55 ft. lbs.).

(4) Install upper grommet and retainer. Install

upper shock nut and tighten to 47 N´m (35 ft. lbs).

Fig. 17 Adjustment Cam

1 - ADJUSTMENT CAM

2 - AXLE BRACKET

3 - BRACKET REINFORCEMENT

4 - LOWER SUSPENSION ARM

DRFRONT - LINK/COIL 2 - 35

Page 74 of 2895

DIFFERENTIAL & DRIVELINE

TABLE OF CONTENTS

page page

PROPELLER SHAFT......................1

HALF SHAFT...........................11

FRONT AXLE - C205F....................18

FRONT AXLE - 9 1/4 AA...................45REAR AXLE-91/4.......................69

REAR AXLE - 10 1/2 AA..................100

REAR AXLE - 11 1/2 AA..................127

PROPELLER SHAFT

TABLE OF CONTENTS

page page

PROPELLER SHAFT

DIAGNOSIS AND TESTING................1

STANDARD PROCEDURE.................3

SPECIFICATIONS........................6

SPECIAL TOOLS........................6

FRONT PROPELLER SHAFT

REMOVAL.............................6

INSTALLATION..........................7

REAR PROPELLER SHAFT

REMOVAL.............................7INSTALLATION..........................8

CENTER BEARING

REMOVAL.............................8

INSTALLATION..........................8

ADJUSTMENTS.........................8

SINGLE CARDAN UNIVERSAL JOINTS

DISASSEMBLY..........................9

ASSEMBLY.............................9

PROPELLER SHAFT

DIAGNOSIS AND TESTING

PROPELLER SHAFT VIBRATION

Tires that are out-of-round or wheels that are

unbalanced, will cause a low frequency vibration.

Brake drums that are unbalanced will cause a

harsh, low frequency vibration.Driveline vibration can also result from loose or

damaged engine mounts.

Propeller shaft vibration increases as the vehicle

speed is increased. A vibration that occurs within a

specific speed range is not usually caused by a pro-

peller shaft being unbalanced. Defective universal

joints or an incorrect propeller shaft angle are usu-

ally the cause of such a vibration.

DRDIFFERENTIAL & DRIVELINE 3 - 1

Page 75 of 2895

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign

material on shaft.1) Clean exterior of shaft and wash

with solvent.

2) Loose U-joint clamp screws. 2) Install new clamps and screws

and tighten to proper torque.

3) Loose or bent U-joint yoke or

excessive runout.3) Install new yoke.

4) Incorrect driveline angularity. 4) Measure and correct driveline

angles.

5) Rear spring center bolt not in

seat.5) Loosen spring u-bolts and seat

center bolt.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out

of balance.7) Installl new propeller shaft.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.9) Re-index propeller shaft, test,

and evaluate.

10) Excessive drive pinion gear

shaft runout.10) Re-index propeller shaft and

evaluate.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if

necessary.

12) Excessive transfer case runout. 12) Inspect and repair as necessary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws

and tighten to proper torque.

2) Lack of lubrication. 2) Replace as U-joints as

necessary.

PROPELLER SHAFT BALANCE

NOTE: Removing and re-indexing the propeller

shaft 180É relative to the yoke may eliminate some

vibrations.

If propeller shaft is suspected of being unbalanced,

it can be verified with the following procedure:

(1) Raise the vehicle.

(2) Clean all the foreign material from the propel-

ler shaft and the universal joints.

(3) Inspect the propeller shaft for missing balance

weights, broken welds, and bent areas.If the pro-

peller shaft is bent, it must be replaced.

(4) Inspect the universal joints to ensure that they

are not worn, are properly installed, and are cor-

rectly aligned with the shaft.

(5) Check the universal joint clamp screws torque.

(6) Remove the wheels and tires. Install the wheel

lug nuts to retain the brake drums or rotors.

(7) Mark and number the shaft six inches from the

yoke end at four positions 90É apart.(8) Run and accelerate the vehicle until vibration

occurs. Note the intensity and speed the vibration

occurred. Stop the engine.

(9) Install a screw clamp at position 1 (Fig. 1).

(10) Start the engine and re-check for vibration. If

there is little or no change in vibration, move the

clamp to one of the other three positions. Repeat the

vibration test.

(11) If there is no difference in vibration at the

other positions, the source of the vibration may not

be propeller shaft.

(12) If the vibration decreased, install a second

clamp (Fig. 2) and repeat the test.

(13) If the additional clamp causes an additional

vibration, separate the clamps (1/2 inch above and

below the mark). Repeat the vibration test (Fig. 3).

(14) Increase distance between the clamp screws

and repeat the test until the amount of vibration is

at the lowest level. Bend the slack end of the clamps

so the screws will not loosen.

3 - 2 PROPELLER SHAFTDR

PROPELLER SHAFT (Continued)

Page 81 of 2895

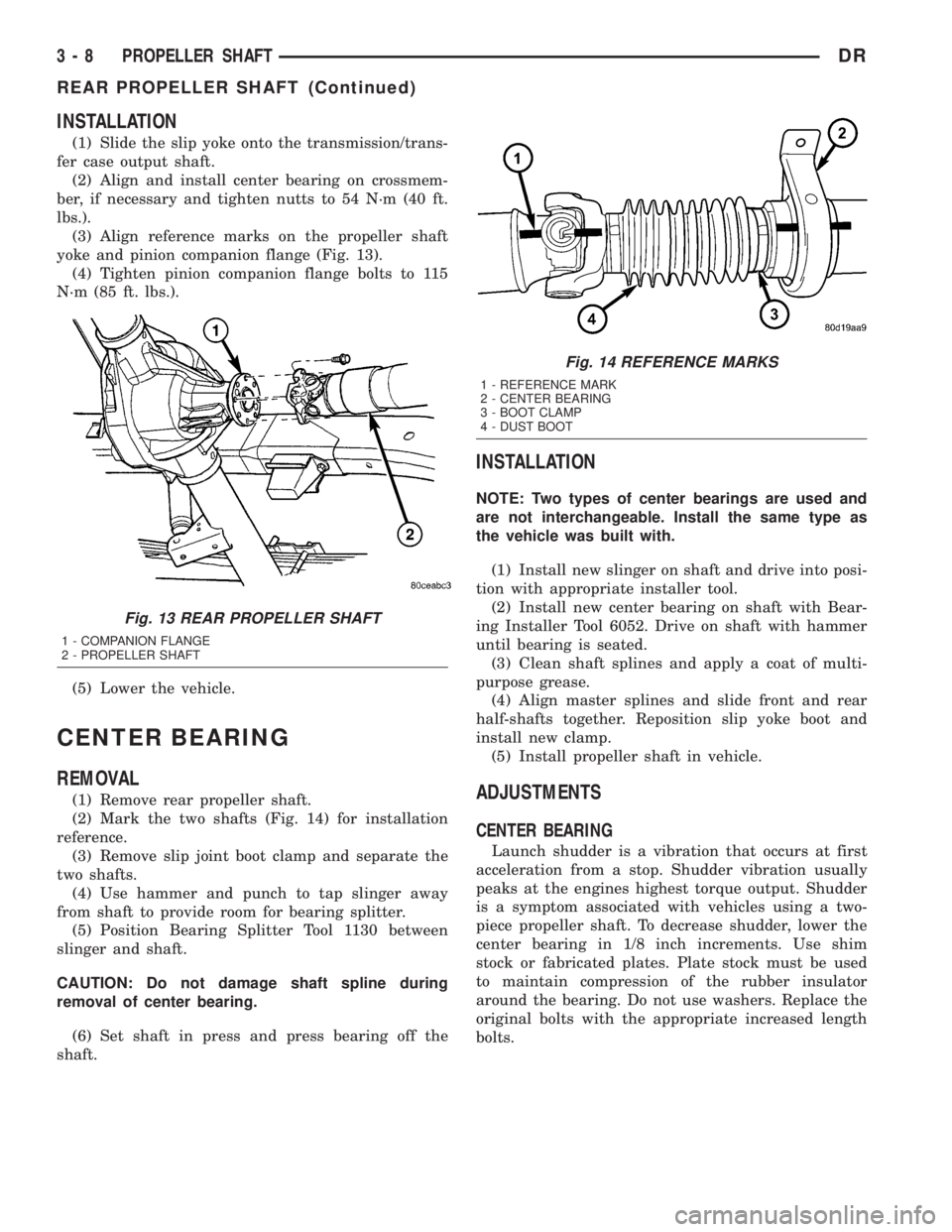

INSTALLATION

(1) Slide the slip yoke onto the transmission/trans-

fer case output shaft.

(2) Align and install center bearing on crossmem-

ber, if necessary and tighten nutts to 54 N´m (40 ft.

lbs.).

(3) Align reference marks on the propeller shaft

yoke and pinion companion flange (Fig. 13).

(4) Tighten pinion companion flange bolts to 115

N´m (85 ft. lbs.).

(5) Lower the vehicle.

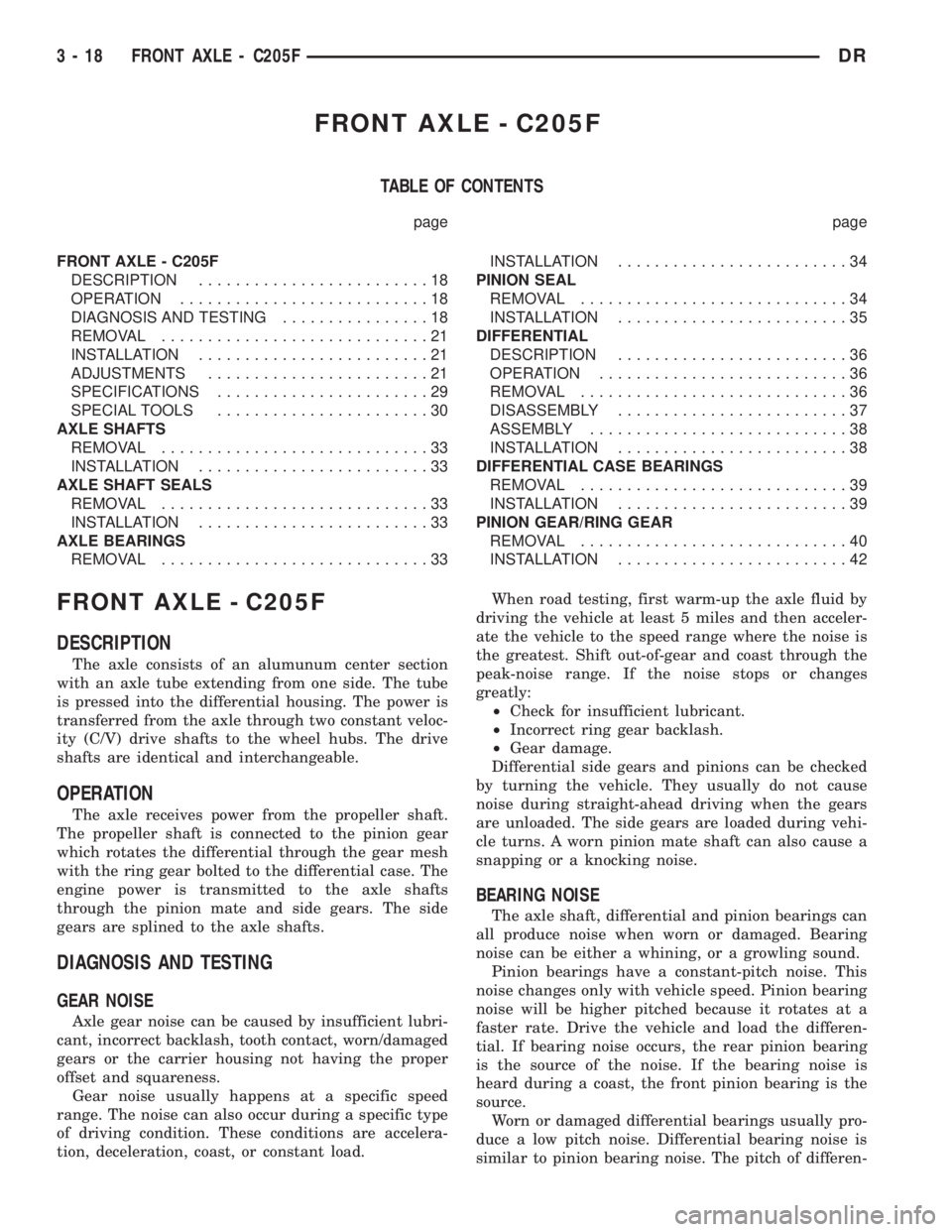

CENTER BEARING

REMOVAL

(1) Remove rear propeller shaft.

(2) Mark the two shafts (Fig. 14) for installation

reference.

(3) Remove slip joint boot clamp and separate the

two shafts.

(4) Use hammer and punch to tap slinger away

from shaft to provide room for bearing splitter.

(5) Position Bearing Splitter Tool 1130 between

slinger and shaft.

CAUTION: Do not damage shaft spline during

removal of center bearing.

(6) Set shaft in press and press bearing off the

shaft.

INSTALLATION

NOTE: Two types of center bearings are used and

are not interchangeable. Install the same type as

the vehicle was built with.

(1) Install new slinger on shaft and drive into posi-

tion with appropriate installer tool.

(2) Install new center bearing on shaft with Bear-

ing Installer Tool 6052. Drive on shaft with hammer

until bearing is seated.

(3) Clean shaft splines and apply a coat of multi-

purpose grease.

(4) Align master splines and slide front and rear

half-shafts together. Reposition slip yoke boot and

install new clamp.

(5) Install propeller shaft in vehicle.

ADJUSTMENTS

CENTER BEARING

Launch shudder is a vibration that occurs at first

acceleration from a stop. Shudder vibration usually

peaks at the engines highest torque output. Shudder

is a symptom associated with vehicles using a two-

piece propeller shaft. To decrease shudder, lower the

center bearing in 1/8 inch increments. Use shim

stock or fabricated plates. Plate stock must be used

to maintain compression of the rubber insulator

around the bearing. Do not use washers. Replace the

original bolts with the appropriate increased length

bolts.

Fig. 13 REAR PROPELLER SHAFT

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

Fig. 14 REFERENCE MARKS

1 - REFERENCE MARK

2 - CENTER BEARING

3 - BOOT CLAMP

4 - DUST BOOT

3 - 8 PROPELLER SHAFTDR

REAR PROPELLER SHAFT (Continued)

Page 91 of 2895

FRONT AXLE - C205F

TABLE OF CONTENTS

page page

FRONT AXLE - C205F

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING................18

REMOVAL.............................21

INSTALLATION.........................21

ADJUSTMENTS........................21

SPECIFICATIONS.......................29

SPECIAL TOOLS.......................30

AXLE SHAFTS

REMOVAL.............................33

INSTALLATION.........................33

AXLE SHAFT SEALS

REMOVAL.............................33

INSTALLATION.........................33

AXLE BEARINGS

REMOVAL.............................33INSTALLATION.........................34

PINION SEAL

REMOVAL.............................34

INSTALLATION.........................35

DIFFERENTIAL

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

DISASSEMBLY.........................37

ASSEMBLY............................38

INSTALLATION.........................38

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................39

INSTALLATION.........................39

PINION GEAR/RING GEAR

REMOVAL.............................40

INSTALLATION.........................42

FRONT AXLE - C205F

DESCRIPTION

The axle consists of an alumunum center section

with an axle tube extending from one side. The tube

is pressed into the differential housing. The power is

transferred from the axle through two constant veloc-

ity (C/V) drive shafts to the wheel hubs. The drive

shafts are identical and interchangeable.

OPERATION

The axle receives power from the propeller shaft.

The propeller shaft is connected to the pinion gear

which rotates the differential through the gear mesh

with the ring gear bolted to the differential case. The

engine power is transmitted to the axle shafts

through the pinion mate and side gears. The side

gears are splined to the axle shafts.

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, tooth contact, worn/damaged

gears or the carrier housing not having the proper

offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion mate shaft can also cause a

snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

3 - 18 FRONT AXLE - C205FDR

Page 92 of 2895

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out of balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).Check for loose or damaged front end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear end

vibration. Do not overlook engine accessories, brack-

ets and drive belts.

All driveline components should be examined

before starting any repair.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged) can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

3. End-play in pinion bearings. 3. Refer to pinion pre-load

information and correct as

necessary.

4. Excessive gear backlash

between the ring gear and pinion.4. Check adjustment of the ring

gear and pinion backlash. Correct

as necessary.

5. Improper adjustment of pinion

gear bearings.5. Adjust the pinion bearings

pre-load.

6. Loose pinion yoke nut. 6. Tighten the pinion yoke nut.

7. Scuffed gear tooth contact

surfaces.7. Inspect and replace as

necessary.

DRFRONT AXLE - C205F 3 - 19

FRONT AXLE - C205F (Continued)

Page 118 of 2895

FRONT AXLE - 9 1/4 AA

TABLE OF CONTENTS

page page

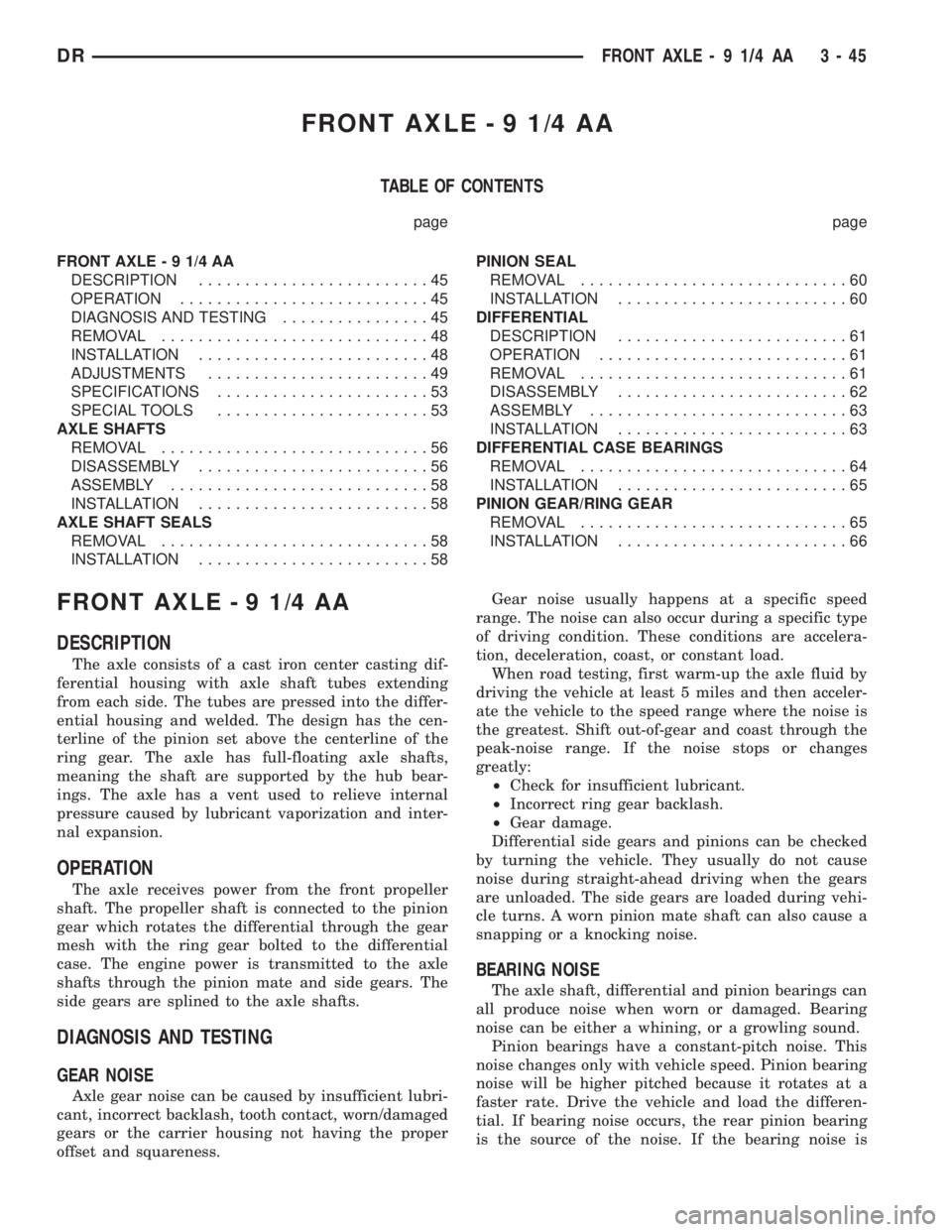

FRONT AXLE - 9 1/4 AA

DESCRIPTION.........................45

OPERATION...........................45

DIAGNOSIS AND TESTING................45

REMOVAL.............................48

INSTALLATION.........................48

ADJUSTMENTS........................49

SPECIFICATIONS.......................53

SPECIAL TOOLS.......................53

AXLE SHAFTS

REMOVAL.............................56

DISASSEMBLY.........................56

ASSEMBLY............................58

INSTALLATION.........................58

AXLE SHAFT SEALS

REMOVAL.............................58

INSTALLATION.........................58PINION SEAL

REMOVAL.............................60

INSTALLATION.........................60

DIFFERENTIAL

DESCRIPTION.........................61

OPERATION...........................61

REMOVAL.............................61

DISASSEMBLY.........................62

ASSEMBLY............................63

INSTALLATION.........................63

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................64

INSTALLATION.........................65

PINION GEAR/RING GEAR

REMOVAL.............................65

INSTALLATION.........................66

FRONT AXLE - 9 1/4 AA

DESCRIPTION

The axle consists of a cast iron center casting dif-

ferential housing with axle shaft tubes extending

from each side. The tubes are pressed into the differ-

ential housing and welded. The design has the cen-

terline of the pinion set above the centerline of the

ring gear. The axle has full-floating axle shafts,

meaning the shaft are supported by the hub bear-

ings. The axle has a vent used to relieve internal

pressure caused by lubricant vaporization and inter-

nal expansion.

OPERATION

The axle receives power from the front propeller

shaft. The propeller shaft is connected to the pinion

gear which rotates the differential through the gear

mesh with the ring gear bolted to the differential

case. The engine power is transmitted to the axle

shafts through the pinion mate and side gears. The

side gears are splined to the axle shafts.

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, tooth contact, worn/damaged

gears or the carrier housing not having the proper

offset and squareness.Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion mate shaft can also cause a

snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

DRFRONT AXLE - 9 1/4 AA 3 - 45

Page 119 of 2895

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the front/rear of the vehicle is usually

caused by:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out of balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front end components

or engine/transmission mounts. These components

can contribute to what appears to be a vibration. Do

not overlook engine accessories, brackets and drive

belts.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged) can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

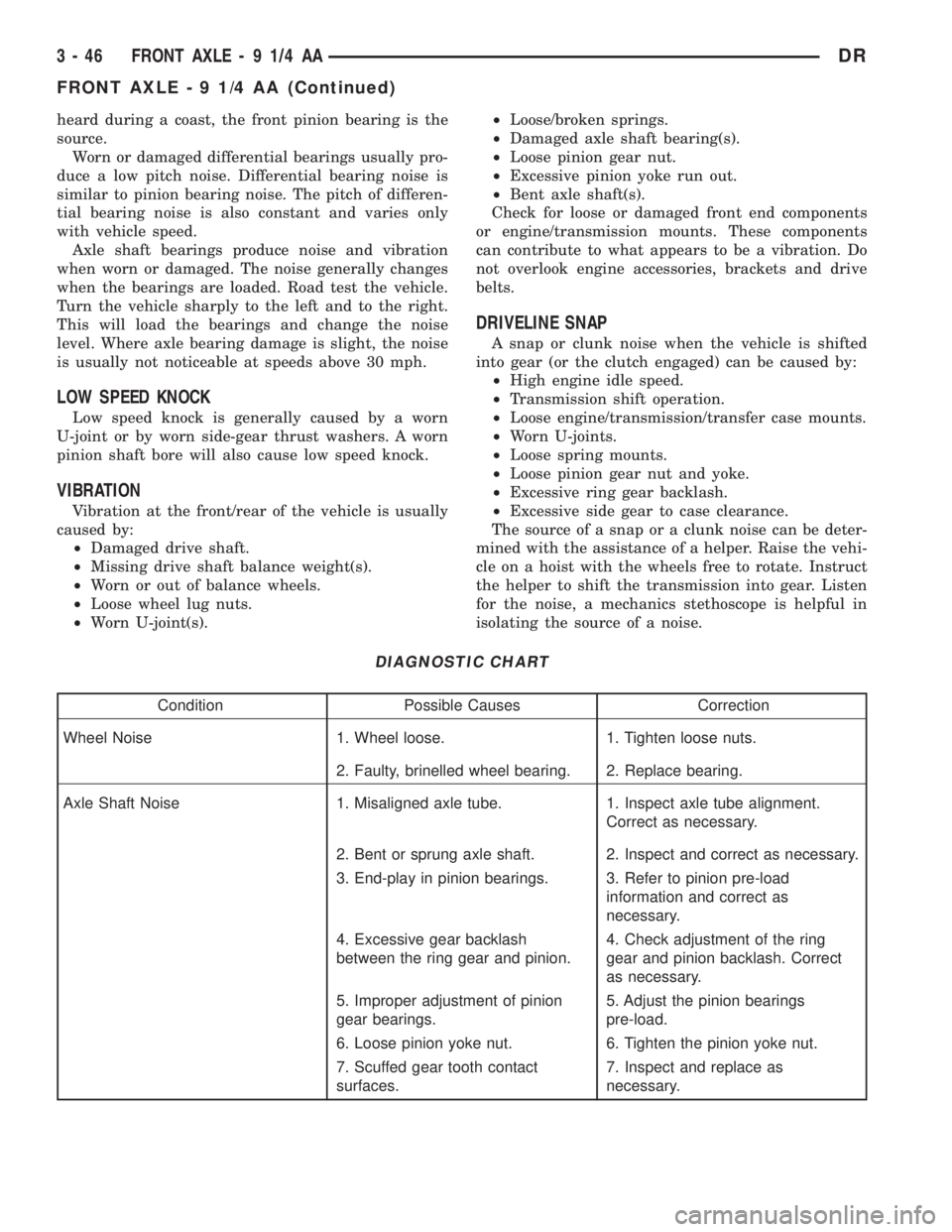

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

3. End-play in pinion bearings. 3. Refer to pinion pre-load

information and correct as

necessary.

4. Excessive gear backlash

between the ring gear and pinion.4. Check adjustment of the ring

gear and pinion backlash. Correct

as necessary.

5. Improper adjustment of pinion

gear bearings.5. Adjust the pinion bearings

pre-load.

6. Loose pinion yoke nut. 6. Tighten the pinion yoke nut.

7. Scuffed gear tooth contact

surfaces.7. Inspect and replace as

necessary.

3 - 46 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)