check engine DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2848 of 2895

During periods of high manifold vacuum, such as

idle or cruising speeds, vacuum is sufficient to com-

pletely compress spring. It will then pull the plunger

to the top of the valve (Fig. 17). In this position there

is minimal vapor flow through the valve.

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve

(Fig. 18).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PCV VALVE - 3.7L

V-6/ 4.7L V-8

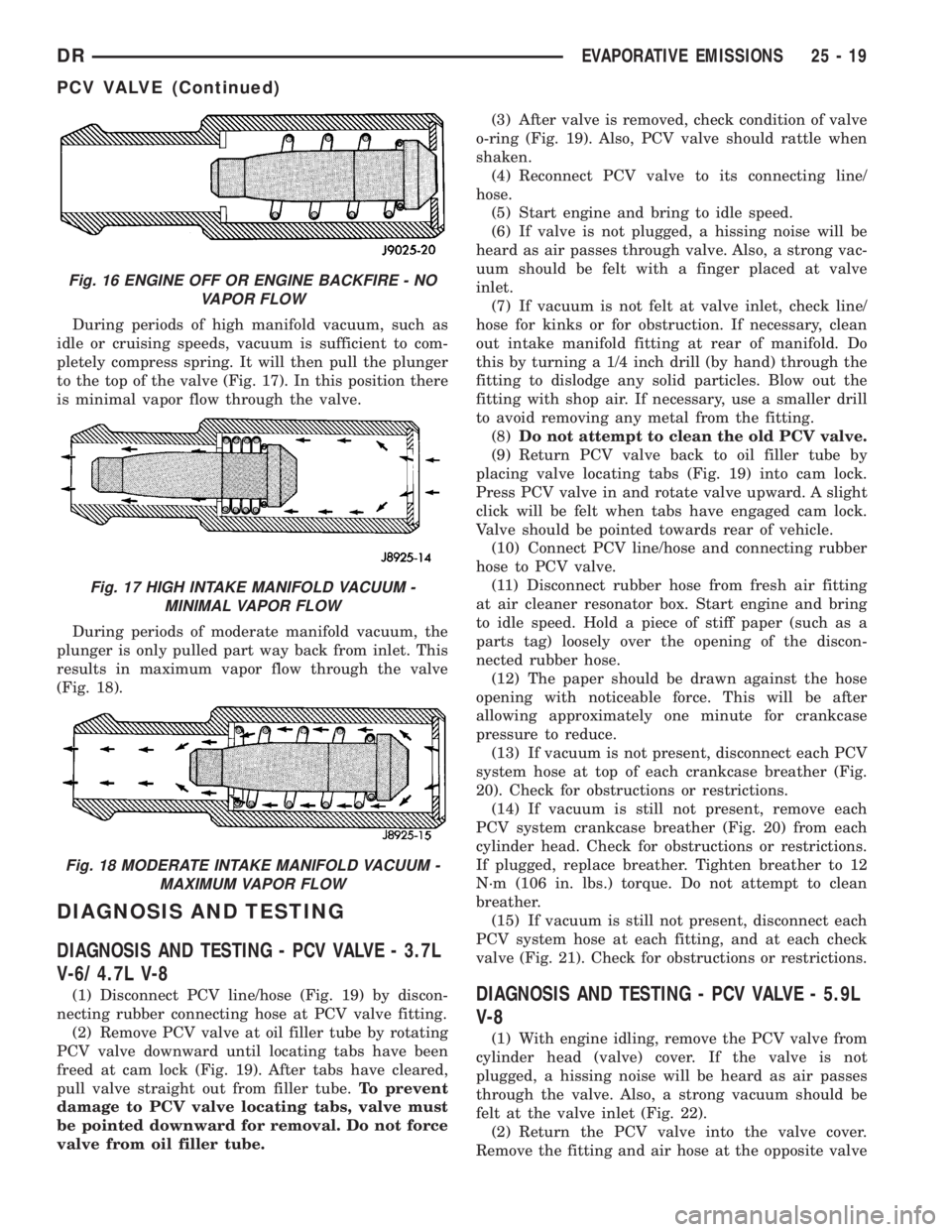

(1) Disconnect PCV line/hose (Fig. 19) by discon-

necting rubber connecting hose at PCV valve fitting.

(2) Remove PCV valve at oil filler tube by rotating

PCV valve downward until locating tabs have been

freed at cam lock (Fig. 19). After tabs have cleared,

pull valve straight out from filler tube.To prevent

damage to PCV valve locating tabs, valve must

be pointed downward for removal. Do not force

valve from oil filler tube.(3) After valve is removed, check condition of valve

o-ring (Fig. 19). Also, PCV valve should rattle when

shaken.

(4) Reconnect PCV valve to its connecting line/

hose.

(5) Start engine and bring to idle speed.

(6) If valve is not plugged, a hissing noise will be

heard as air passes through valve. Also, a strong vac-

uum should be felt with a finger placed at valve

inlet.

(7) If vacuum is not felt at valve inlet, check line/

hose for kinks or for obstruction. If necessary, clean

out intake manifold fitting at rear of manifold. Do

this by turning a 1/4 inch drill (by hand) through the

fitting to dislodge any solid particles. Blow out the

fitting with shop air. If necessary, use a smaller drill

to avoid removing any metal from the fitting.

(8)Do not attempt to clean the old PCV valve.

(9) Return PCV valve back to oil filler tube by

placing valve locating tabs (Fig. 19) into cam lock.

Press PCV valve in and rotate valve upward. A slight

click will be felt when tabs have engaged cam lock.

Valve should be pointed towards rear of vehicle.

(10) Connect PCV line/hose and connecting rubber

hose to PCV valve.

(11) Disconnect rubber hose from fresh air fitting

at air cleaner resonator box. Start engine and bring

to idle speed. Hold a piece of stiff paper (such as a

parts tag) loosely over the opening of the discon-

nected rubber hose.

(12) The paper should be drawn against the hose

opening with noticeable force. This will be after

allowing approximately one minute for crankcase

pressure to reduce.

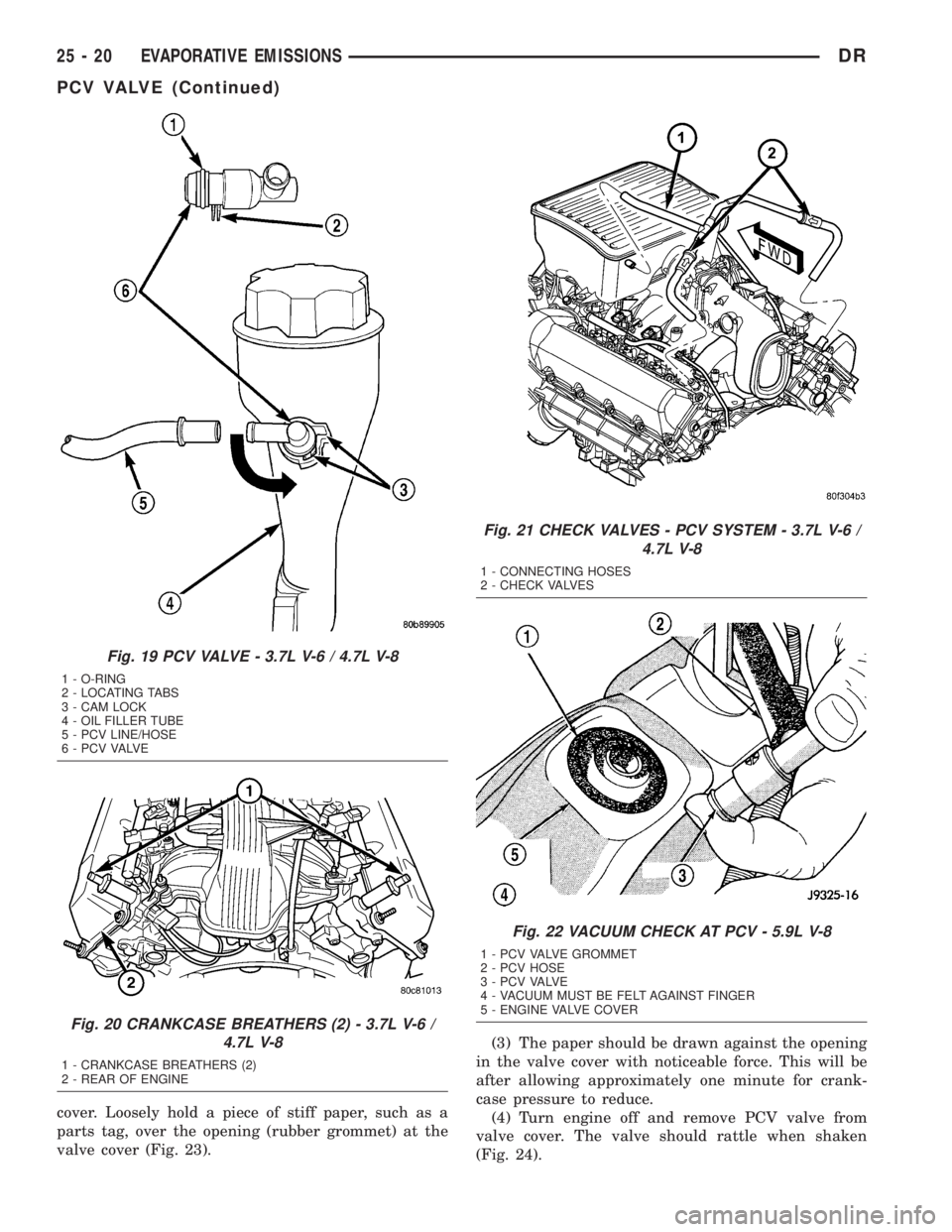

(13) If vacuum is not present, disconnect each PCV

system hose at top of each crankcase breather (Fig.

20). Check for obstructions or restrictions.

(14) If vacuum is still not present, remove each

PCV system crankcase breather (Fig. 20) from each

cylinder head. Check for obstructions or restrictions.

If plugged, replace breather. Tighten breather to 12

N´m (106 in. lbs.) torque. Do not attempt to clean

breather.

(15) If vacuum is still not present, disconnect each

PCV system hose at each fitting, and at each check

valve (Fig. 21). Check for obstructions or restrictions.DIAGNOSIS AND TESTING - PCV VALVE - 5.9L

V-8

(1) With engine idling, remove the PCV valve from

cylinder head (valve) cover. If the valve is not

plugged, a hissing noise will be heard as air passes

through the valve. Also, a strong vacuum should be

felt at the valve inlet (Fig. 22).

(2) Return the PCV valve into the valve cover.

Remove the fitting and air hose at the opposite valve

Fig. 16 ENGINE OFF OR ENGINE BACKFIRE - NO

VAPOR FLOW

Fig. 17 HIGH INTAKE MANIFOLD VACUUM -

MINIMAL VAPOR FLOW

Fig. 18 MODERATE INTAKE MANIFOLD VACUUM -

MAXIMUM VAPOR FLOW

DREVAPORATIVE EMISSIONS 25 - 19

PCV VALVE (Continued)

Page 2849 of 2895

cover. Loosely hold a piece of stiff paper, such as a

parts tag, over the opening (rubber grommet) at the

valve cover (Fig. 23).(3) The paper should be drawn against the opening

in the valve cover with noticeable force. This will be

after allowing approximately one minute for crank-

case pressure to reduce.

(4) Turn engine off and remove PCV valve from

valve cover. The valve should rattle when shaken

(Fig. 24).

Fig. 19 PCV VALVE - 3.7L V-6 / 4.7L V-8

1 - O-RING

2 - LOCATING TABS

3 - CAM LOCK

4 - OIL FILLER TUBE

5 - PCV LINE/HOSE

6 - P C V VA LV E

Fig. 20 CRANKCASE BREATHERS (2) - 3.7L V-6 /

4.7L V-8

1 - CRANKCASE BREATHERS (2)

2 - REAR OF ENGINE

Fig. 21 CHECK VALVES - PCV SYSTEM - 3.7L V-6 /

4.7L V-8

1 - CONNECTING HOSES

2 - CHECK VALVES

Fig. 22 VACUUM CHECK AT PCV - 5.9L V-8

1 - PCV VALVE GROMMET

2 - PCV HOSE

3 - P C V VA LV E

4 - VACUUM MUST BE FELT AGAINST FINGER

5 - ENGINE VALVE COVER

25 - 20 EVAPORATIVE EMISSIONSDR

PCV VALVE (Continued)

Page 2851 of 2895

tabs, valve must be pointed downward for

removal. Do not force valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 25).

5.7L V-8

The PCV valve is mounted into the top of the

intake manifold, located to the right / rear of the

throttle body (Fig. 12). The PCV valve is sealed to

the intake manifold with 2 o-rings (Fig. 13).

(1) Remove PCV valve by rotating counter-clock-

wise 90 degrees until locating tabs have been freed.

After tabs have cleared, pull valve straight up from

intake manifold.

(2) After valve is removed, check condition of 2

valve o-rings.

INSTALLATION

3.7L V6 / 4.7L V-8

The PCV valve is located on the oil filler tube. Two

locating tabs are located on the side of the valve.

These 2 tabs fit into a cam lock in the oil filler tube.

An o-ring seals the valve to the filler tube.

(1) Return PCV valve back to oil filler tube by

placing valve locating tabs into cam lock. Press PCV

valve in and rotate valve upward. A slight click will

be felt when tabs have engaged cam lock. Valve

should be pointed towards rear of vehicle.

(2) Connect PCV line/hose and rubber hose to PCV

valve.

5.7L V-8

(1) Clean out intake manifold opening.

(2) Check condition of 2 o-rings on PCV valve.

(3) Apply engine oil to 2 o-rings.

(4) Place PCV valve into intake manifold and

rotate 90 degrees clockwise for installation.

VACUUM LINES

DESCRIPTION

A vacuum schematic for emission related items can

be found on the vehicles VECI label. Refer to Vehicle

Emission Control Information (VECI) Label for label

location.

VAPOR CANISTER

DESCRIPTION

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

26).

OPERATION

Two, maintenance free, EVAP canisters are

used.The EVAP canisters are filled with granules of

an activated carbon mixture. Fuel vapors entering

the EVAP canisters are absorbed by the charcoal

granules.

Fuel tank pressure vents into the EVAP canisters.

Fuel vapors are temporarily held in the canisters

until they can be drawn into the intake manifold.

The duty cycle EVAP canister purge solenoid allows

the EVAP canisters to be purged at predetermined

times and at certain engine operating conditions.

REMOVAL

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

26).

(1) Raise and support vehicle.

(2) Remove fuel tubes/lines at each EVAP canister.

Note location of tubes/lines before removal for easier

installation.

(3) Remove lower support bracket (Fig. 27).

(4) Remove mounting nuts at top of each canister

(Fig. 27).

Fig. 26 LOCATION, EVAP CANISTERS

1 - LDP

2 - LDP MOUNTING BOLT

3 - ELEC. CONNEC.

4 - FILTER MOUNTING BOLT

5 - LDP FILTER

6 - CONNECTING HOSE

7 - EVAP CANISTER MOUNTING BRACKET

8 - EVAP CANISTERS (2)

25 - 22 EVAPORATIVE EMISSIONSDR

PCV VALVE (Continued)

Page 2852 of 2895

(5) Remove each canister from upper support

bracket.

INSTALLATION

(1) Place each canister into upper support bracket

and install nuts. Refer to Torque Specifications.

(2) Install lower support bracket. Refer to Torque

Specifications.

(3) Carefully install vapor/vacuum lines.The

vapor/vacuum lines and hoses must be firmly

connected. Also check the vapor/vacuum lines

at the LDP, LDP filter and EVAP canister purge

solenoid for damage or leaks. If a leak is

present, a Diagnostic Trouble Code (DTC) may

be set.

NATURAL VAC LEAK

DETECTION ASSY

DESCRIPTION

Vehicles equipped with NGC engine control mod-

ules use an NVLD pump and system.Vehicles

equipped with JTEC engine control modules use an

LDP (leak detection pump). Refer to Leak Detection

Pump (LDP) for additional information.The NVLD pump is located in the same area as the

leak detection pump. Refer to NVLD Removal /

Installation for additional information.

OPERATION

Vehicles equipped with NGC engine control mod-

ules use an NVLD pump and system.Vehicles

equipped with JTEC engine control modules use a

leak detection pump. Refer to Leak Detection Pump

(LDP) for additional information.

The Natural Vacuum Leak Detection (NVLD) sys-

tem is the next generation evaporative leak detection

system that will first be used on vehicles equipped

with the Next Generation Controller (NGC). This

new system replaces the leak detection pump as the

method of evaporative system leak detection. This is

to detect a leak equivalent to a 0.0209(0.5 mm) hole.

This system has the capability to detect holes of this

size very dependably.

The basic leak detection theory employed with

NVLD is the9Gas Law9. This is to say that the pres-

sure in a sealed vessel will change if the temperature

of the gas in the vessel changes. The vessel will only

see this effect if it is indeed sealed. Even small leaks

will allow the pressure in the vessel to come to equi-

librium with the ambient pressure. In addition to the

Fig. 27 EVAP CANISTERS - REMOVAL / INSTALLATION

1 - CANISTER MOUNTING NUTS

2 - CONNECTING HOSE

3 - UPPER SUPPORT BRACKET4 - LOWER SUPPORT BRACKET

5 - OUTER CANISTER

6 - INNER CANISTER

DREVAPORATIVE EMISSIONS 25 - 23

VAPOR CANISTER (Continued)

Page 2853 of 2895

detection of very small leaks, this system has the

capability of detecting medium as well as large evap-

orative system leaks.

A vent valve seals the canister vent during engine

off conditions. If the vapor system has a leak of less

than the failure threshold, the evaporative system

will be pulled into a vacuum, either due to the cool

down from operating temperature or diurnal ambient

temperature cycling. The diurnal effect is considered

one of the primary contributors to the leak determi-

nation by this diagnostic. When the vacuum in the

system exceeds about 19H2O (0.25 KPA), a vacuum

switch closes. The switch closure sends a signal to

the NGC. The NGC, via appropriate logic strategies,

utilizes the switch signal, or lack thereof, to make a

determination of whether a leak is present.

The NVLD device is designed with a normally open

vacuum switch, a normally closed solenoid, and a

seal, which is actuated by both the solenoid and a

diaphragm. The NVLD is located on the atmospheric

vent side of the canister. The NVLD assembly may

be mounted on top of the canister outlet, or in-line

between the canister and atmospheric vent filter. The

normally open vacuum switch will close with about 19

H2O (0.25 KPA) vacuum in the evaporative system.

The diaphragm actuates the switch. This is above the

opening point of the fuel inlet check valve in the fill

tube so cap off leaks can be detected. Submerged fill

systems must have recirculation lines that do not

have the in-line normally closed check valve that pro-

tects the system from failed nozzle liquid ingestion,

in order to detect cap off conditions.

The normally closed valve in the NVLD is intended

to maintain the seal on the evaporative system dur-

ing the engine off condition. If vacuum in the evapo-

rative system exceeds 39to 69H2O (0.75 to 1.5 KPA),

the valve will be pulled off the seat, opening the seal.

This will protect the system from excessive vacuum

as well as allowing sufficient purge flow in the event

that the solenoid was to become inoperative.

The solenoid actuates the valve to unseal the can-

ister vent while the engine is running. It also will be

used to close the vent during the medium and large

leak tests and during the purge flow check. This sole-

noid requires initial 1.5 amps of current to pull the

valve open but after 100 ms. will be duty cycled down

to an average of about 150 mA for the remainder of

the drive cycle.

Another feature in the device is a diaphragm that

will open the seal in the NVLD with pressure in the

evaporative system. The device will9blow off9at

about 0.59H2O (0.12 KPA) pressure to permit the

venting of vapors during refueling. An added benefit

to this is that it will also allow the tank to9breathe9

during increasing temperatures, thus limiting the

pressure in the tank to this low level. This is benefi-cial because the induced vacuum during a subse-

quent declining temperature will achieve the switch

closed (pass threshold) sooner than if the tank had to

decay from a built up pressure.

The device itself has 3 wires: Switch sense, sole-

noid driver and ground. It also includes a resistor to

protect the switch from a short to battery or a short

to ground. The NGC utilizes a high-side driver to

energize and duty-cycle the solenoid.

REMOVAL

The NVLD pump and filter are attached to the

front of the EVAP canister mounting bracket (Fig.

28). This is located near the front of the fuel tank.

The pump and filter are replaced (serviced) as one

unit.

(1) Raise and support vehicle.

(2) Carefully remove pump hose clamp and hose at

filter.

(3) Carefully remove other vapor/vacuum hose at

pump.

(4) Disconnect 3±way electrical connector at pump.

(5) The NVLD pump snaps onto the EVAP canister

mounting bracket. Press on release tab (Fig. 29)

while sliding pump from bracket.

INSTALLATION

(1) Install NVLD pump to EVAP canister mount-

ing bracket (snaps on).

Fig. 28 NVLD PUMP LOCATION

1 - EVAP CANISTER MOUNTING BRACKET

2 - NVLD PUMP

3 - FILTER

25 - 24 EVAPORATIVE EMISSIONSDR

NATURAL VAC LEAK DETECTION ASSY (Continued)

Page 2860 of 2895

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-2

BRAKE TRANSMISSION SHIFT

INTERLOCK - ADJUSTMENTS . . . 21-195,21-376,

21-540

BRAKE TRANSMISSION SHIFT

INTERLOCK - DIAGNOSIS AND

TESTING..............21-195,21-375,21-540

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - DESCRIPTION . . . 21-194,

21-375,21-540

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - OPERATION.....21-194,

21-375,21-540

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION.......................8J-18

BRAKE/PARK BRAKE INDICATOR -

OPERATION.........................8J-19

BRAKES - ABS - DESCRIPTION...........5-39

BRAKES - ABS - OPERATION............5-39

BRAKES, SPECIAL TOOLS - BASE.........5-5

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH............24-10

BREATHER - INSTALLATION,

CRANKCASE........................9-292

BREATHER - REMOVAL, CRANKCASE.....9-291

BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT BELT................8O-34

BUCKLE - REMOVAL, FRONT OUTBOARD

SEAT BELT .........................8O-33

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE........................8F-10

BUMPER - INSTALLATION, FRONT........13-2

BUMPER - INSTALLATION, JOUNCE.......2-40

BUMPER - INSTALLATION, REAR.........13-4

BUMPER - REMOVAL, FRONT............13-2

BUMPER - REMOVAL, JOUNCE...........2-40

BUMPER - REMOVAL, REAR.............13-4

BUMPERS (3500) - INSTALLATION,

AUXILIARY SPRING....................2-40

BUMPERS (3500) - REMOVAL,

AUXILIARY SPRING....................2-40

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF....21-201,21-381,21-541

BUSHING - INSTALLATION.............19-18

BUSHING - INSTALLATION,

DISTRIBUTOR.......................9-258

BUSHING - INSTALLATION, EXTENSION

HOUSING..........................21-200

BUSHING - INSTALLATION, TORSION

BAR CROSS MEMBER..................2-14

BUSHING - REMOVAL.................19-18

BUSHING - REMOVAL, DISTRIBUTOR.....9-258

BUSHING - REMOVAL, EXTENSION

HOUSING..........................21-200

BUSHING - REMOVAL, TORSION BAR

CROSSMEMBER......................2-12

BUSHING AND SEAL - INSTALLATION,

EXTENSION HOUSING..........21-616,21-682

BUSHING AND SEAL - REMOVAL,

EXTENSION HOUSING..........21-616,21-682

BUSHINGS - 2WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-14

BUSHINGS - 2WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-12

BUSHINGS - 4WD (LD) - INSTALLATION,

LOWER CONTROL ARM

................2-13

BUSHINGS - 4WD (LD) - REMOVAL,

LOWER CONTROL ARM

................2-12

BUSHINGS - INSTALLATION

.............2-39

BUSHINGS - REMOVAL

.................2-39

BUZZ, SQUEAK & RATTLE - STANDARD

PROCEDURE

........................23-11

BYPASS - DESCRIPTION, WATER PUMP

. . . 7-64

BYPASS - OPERATION, WATER PUMP

.....7-65

BYPASS HOSE WITH AIR CONDITIONING

- INSTALLATION, WATER PUMP

..........7-70

BYPASS HOSE WITH AIR CONDITIONING

- REMOVAL, WATER PUMP

..............7-68

BYPASS HOSE WITHOUT AIR

CONDITIONING - INSTALLATION,

WATER PUMP

........................7-70

BYPASS HOSE WITHOUT AIR

CONDITIONING - REMOVAL, WATER

PUMP

..............................7-69

C205F - ADJUSTMENTS, FRONT AXLE

.....3-21

C205F - DESCRIPTION, FRONT AXLE

......3-18C205F - DIAGNOSIS AND TESTING,

FRONT AXLE.........................3-18

C205F - INSTALLATION, FRONT AXLE.....3-21

C205F - OPERATION, FRONT AXLE........3-18

C205F - REMOVAL, FRONT AXLE.........3-21

C205F - SPECIAL TOOLS, FRONT AXLE....3-30

C205F - SPECIFICATIONS, FRONT AXLE....3-29

CAB - INSTALLATION, QUAD...........8O-32

CAB - INSTALLATION, STANDARD.......8O-31

CAB - REMOVAL, QUAD...............8O-29

CAB - REMOVAL, STANDARD...........8O-28

CAB BACK PANEL TRIM -

INSTALLATION, REAR.................23-70

CAB BACK PANEL TRIM - REMOVAL,

REAR..............................23-70

CAB CLEARANCE LAMP - INSTALLATION . . 8L-10

CAB CLEARANCE LAMP - REMOVAL.....8L-10

CABLE - ADJUSTMENTS, THROTTLE

VALVE ......................21-255,21-432

CABLE - DESCRIPTION.................8P-3

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, SPARK PLUG.....8I-33

CABLE - DESCRIPTION, THROTTLE

VALVE ......................21-254,21-432

CABLE - DIAGNOSIS AND TESTING,

ANTENNA BODY......................8A-4

CABLE - DIAGNOSIS AND TESTING,

GEARSHIFT............21-209,21-389,21-544

CABLE - INSTALLATION..................8P-6

CABLE - INSTALLATION, ANTENNA BODY . . 8A-6

CABLE - INSTALLATION, CHECK.........23-15

CABLE - INSTALLATION, FRONT

PARKING BRAKE......................5-32

CABLE - INSTALLATION, GEARSHIFT....21-210,

21-390,21-545

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA......................8A-7

CABLE - INSTALLATION, LEFT REAR......5-33

CABLE - INSTALLATION, REAR PARK

BRAKE..............................5-32

CABLE - INSTALLATION, RIGHT REAR.....5-32

CABLE - INSTALLATION, SPARK PLUG....8I-35

CABLE - INSTALLATION, THROTTLE

CONTROL.....................14-51,14-96

CABLE - OPERATION...................8P-3

CABLE - OPERATION, ANTENNA BODY.....8A-4

CABLE - OPERATION, SPARK PLUG.......8I-33

CABLE - REMOVAL....................8P-3

CABLE - REMOVAL, ANTENNA BODY......8A-6

CABLE - REMOVAL, CHECK.............23-15

CABLE - REMOVAL, FRONT PARKING

BRAKE..............................5-31

CABLE - REMOVAL, GEARSHIFT . 21-209,21-389,

21-544

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA...........................8A-6

CABLE - REMOVAL, LEFT REAR..........5-32

CABLE - REMOVAL, REAR PARK BRAKE . . . 5-31

CABLE - REMOVAL, RIGHT REAR.........5-31

CABLE - REMOVAL, SPARK PLUG........8I-34

CABLE - REMOVAL, THROTTLE

CONTROL.....................14-49,14-94

CABLE, ADJUSTMENTS - GEARSHIFT . . . 21-211,

21-391,21-546

CABLE ORDER, 8.0L V-10 ENGINE -

SPARK PLUG.........................8I-5

CABLE RESISTANCE, SPECIFICATIONS -

SPARK PLUG.........................8I-5

CABLE ROUTING, 5.7L V-8 ENGINE -

FIRING ORDER........................8I-4

CABLE/HANDLE ASSEMBLY -

INSTALLATION, LATCH RELEASE........23-47

CABLE/HANDLE ASSEMBLY - REMOVAL,

LATCH RELEASE.....................23-47

CABLES - DESCRIPTION, BATTERY.......8F-14

CABLES - DIAGNOSIS AND TESTING,

BATTERY...........................8F-15

CABLES - DIAGNOSIS AND TESTING,

SPARK PLUG........................8I-33

CABLES - INSTALLATION, BATTERY......8F-17

CABLES - OPERATION, BATTERY........8F-14

CABLES - REMOVAL, BATTERY

..........8F-16

CALIBRATION - STANDARD PROCEDURE,

COMPASS

...........................8M-3

CALIPER ADAPTER MOUNT -

INSTALLATION, DISC BRAKE

............5-17

CALIPERS - DESCRIPTION, DISC BRAKE

. . . 5-11

CALIPERS - OPERATION, DISC BRAKE

.....5-12CAM BORE REPAIR - STANDARD

PROCEDURE........................9-315

CAMBER AND CASTER ADJUSTMENT -

STANDARD PROCEDURE.................2-4

CAMBER, CASTER AND TOE

ADJUSTMENT - STANDARD

PROCEDURE..........................2-4

CAM/OVERDRIVE PISTON RETAINER -

ASSEMBLY, OVERRUNNING CLUTCH....21-239,

21-416

CAM/OVERDRIVE PISTON RETAINER -

CLEANING, OVERRUNNING CLUTCH....21-238,

21-416

CAM/OVERDRIVE PISTON RETAINER -

DESCRIPTION, OVERRUNNING CLUTCH . 21-237,

21-415

CAM/OVERDRIVE PISTON RETAINER -

DISASSEMBLY, OVERRUNNING

CLUTCH.....................21-238,21-415

CAM/OVERDRIVE PISTON RETAINER -

INSPECTION, OVERRUNNING CLUTCH . . 21-238,

21-416

CAM/OVERDRIVE PISTON RETAINER -

OPERATION, OVERRUNNING CLUTCH . . . 21-237,

21-415

CAMSHAFT - INSTALLATION . 9-201,9-250,9-320,

9-381

CAMSHAFT - REMOVAL.....9-200,9-250,9-317,

9-380

CAMSHAFT BEARINGS - INSTALLATION . . 9-320,

9-381

CAMSHAFT BEARINGS - REMOVAL . 9-317,9-380

CAMSHAFT CORE HOLE PLUG -

INSTALLATION.......................9-201

CAMSHAFT CORE HOLE PLUG -

REMOVAL............................9-200

CAMSHAFT POSITION SENSOR -

DESCRIPTION.......................14-82

CAMSHAFT POSITION SENSOR -

DESCRIPTION.........................8I-8

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................14-83

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................8I-14

CAMSHAFT POSITION SENSOR -

OPERATION.........................14-82

CAMSHAFT POSITION SENSOR -

OPERATION..........................8I-8

CAMSHAFT POSITION SENSOR -

REMOVAL..........................14-83

CAMSHAFT POSITION SENSOR -

REMOVAL...........................8I-11

CAMSHAFT(S) - DESCRIPTION.......9-24,9-34

CAMSHAFT(S) - INSTALLATION......9-25,9-35

CAMSHAFT(S) - LEFT - DESCRIPTION....9-113

CAMSHAFT(S) - LEFT - INSTALLATION....9-114

CAMSHAFT(S) - LEFT - REMOVAL.......9-113

CAMSHAFT(S) - REMOVAL..........9-24,9-34

CAMSHAFT(S) - RIGHT - DESCRIPTION . . . 9-117

CAMSHAFT(S) - RIGHT - INSTALLATION . . 9-118

CAMSHAFT(S) - RIGHT - REMOVAL......9-117

CANISTER - DESCRIPTION, VAPOR......25-22

CANISTER - INSTALLATION, VAPOR......25-23

CANISTER - OPERATION, VAPOR........25-22

CANISTER - REMOVAL, VAPOR..........25-22

CAP - 5.9L V-8 - DIAGNOSIS AND

TESTING, DISTRIBUTOR...............8I-18

CAP - DESCRIPTION, FUEL FILLER.......25-13

CAP - DESCRIPTION, RADIATOR

PRESSURE..........................7-60

CAP - DIAGNOSIS AND TESTING,

RADIATOR...........................7-61

CAP - OPERATION, FUEL FILLER........25-13

CAP - OPERATION, RADIATOR

PRESSURE..........................7-61

CAPACITIES, SPECIFICATIONS - FLUID......0-5

CAPACITOR - DESCRIPTION, IGNITION

COIL...............................8I-33

CAPACITOR - INSTALLATION, IGNITION

COIL...............................8I-33

CAPACITOR - OPERATION, IGNITION

COIL

...............................8I-33

CAPACITOR - REMOVAL, IGNITION COIL

. . . 8I-33

CAPACITY - SPECIFICATIONS, CHARGE

. . . 24-35

CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING, RADIATOR

.....7-61

CARDAN UNIVERSAL JOINTS -

ASSEMBLY, SINGLE

.....................3-9

DRINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2862 of 2895

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING....9-150,9-214,9-64

CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING, AIR......................21-494

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY........................7-10

CHILD RESTRAINT ANCHOR -

DESCRIPTION.......................8O-14

CHILD RESTRAINT ANCHOR -

INSTALLATION......................8O-17

CHILD RESTRAINT ANCHOR -

OPERATION.........................8O-16

CHILD RESTRAINT ANCHOR - REMOVAL . . 8O-16

CHIME CONDITIONS - DIAGNOSIS AND

TESTING............................8B-2

CHIME/BUZZER - DESCRIPTION..........8B-1

CHIME/BUZZER - OPERATION............8B-1

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR......8M-11

CIRCUIT - OPERATION, FUEL DRAIN.....14-78

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-1

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-10

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-12

CIRCUITS - OPERATION, NON-

MONITORED.........................25-8

CLAMPS - DESCRIPTION, HOSE...........7-3

CLAMPS - OPERATION, HOSE.............7-5

CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-321

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-322

CLEARANCE LAMP - INSTALLATION, CAB . 8L-10

CLEARANCE LAMP - REMOVAL, CAB.....8L-10

CLOCKSPRING - DESCRIPTION.........8O-18

CLOCKSPRING - INSTALLATION.........8O-21

CLOCKSPRING - OPERATION...........8O-18

CLOCKSPRING - REMOVAL............8O-20

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-15

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-10

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-14

CLUSTER - INSTALLATION, INSTRUMENT . 8J-16

CLUSTER - OPERATION, INSTRUMENT.....8J-6

CLUSTER - REMOVAL, INSTRUMENT.....8J-14

CLUSTER BEZEL - INSTALLATION........23-50

CLUSTER BEZEL - REMOVAL...........23-50

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - ASSEMBLY, FRONT....21-206,21-386

CLUTCH - ASSEMBLY, LOW/REVERSE . . . 21-561

CLUTCH - ASSEMBLY, REAR.....21-250,21-428

CLUTCH - CLEANING, LOW/REVERSE....21-561

CLUTCH - CLEANING, REAR.....21-250,21-428

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR........................24-9

CLUTCH - DESCRIPTION, FAN DRIVE

VISCOUS............................7-54

CLUTCH - DESCRIPTION, FRONT . 21-204,21-384

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-218,

21-396

CLUTCH - DESCRIPTION, REAR . . 21-248,21-426

CLUTCH - DIAGNOSIS AND TESTING.......6-2

CLUTCH - DISASSEMBLY, FRONT . 21-205,21-384

CLUTCH - DISASSEMBLY, LOW/REVERSE

. 21-560

CLUTCH - DISASSEMBLY, REAR

. . 21-249,21-427

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-12

CLUTCH - INSPECTION, FRONT

. . 21-206,21-385

CLUTCH - INSPECTION, LOW/REVERSE

. . 21-561CLUTCH - INSPECTION, REAR . . . 21-250,21-428

CLUTCH - INSTALLATION, A/C

COMPRESSOR.......................24-12

CLUTCH - OPERATION..................6-1

CLUTCH - OPERATION, A/C

COMPRESSOR........................24-9

CLUTCH - OPERATION, FAN DRIVE

VISCOUS............................7-54

CLUTCH - OPERATION, FRONT . . . 21-204,21-384

CLUTCH - OPERATION, OVERDRIVE....21-218,

21-396

CLUTCH - OPERATION, REAR....21-249,21-427

CLUTCH - REMOVAL, A/C COMPRESSOR . . 24-10

CLUTCH - SPECIFICATIONS...............6-6

CLUTCH - WARNING....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION.......21-143,21-324

CLUTCH ASSEMBLY - ASSEMBLY, INPUT . 21-552

CLUTCH ASSEMBLY - DESCRIPTION,

INPUT............................21-549

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT............................21-550

CLUTCH ASSEMBLY - OPERATION,

INPUT............................21-549

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR........24-10

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING...............21-239,21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING. . . 21-238,

21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING...............21-237,21-415

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING...............21-238,21-415

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - INSPECTION,

OVERRUNNING...............21-238,21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - OPERATION,

OVERRUNNING...............21-237,21-415

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-10

CLUTCH DISC - INSTALLATION............6-6

CLUTCH DISC - REMOVAL...............6-6

CLUTCH HOUSING - DIAGNOSIS AND

TESTING.............................6-8

CLUTCH HOUSING - INSTALLATION.......6-10

CLUTCH HOUSING - REMOVAL...........6-10

CLUTCH OPERATION - DIAGNOSIS AND

TESTING, AIR CHECKING

TRANSMISSION.....................21-494

CLUTCH PEDAL POSITION SWITCH -

DESCRIPTION........................6-14

CLUTCH PEDAL POSITION SWITCH -

DIAGNOSIS AND TESTING..............6-14

CLUTCH PEDAL POSITION SWITCH -

OPERATION..........................6-14

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR.......................24-13

CLUTCH RELAY - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-13

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR.......................24-14

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR.......................24-13

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR.......................24-14

CLUTCH RELEASE BEARING -

INSTALLATION........................6-11

CLUTCH RELEASE BEARING - REMOVAL . . . 6-11

CLUTCHES - DESCRIPTION, HOLDING . . . 21-546

CLUTCHES - OPERATION, HOLDING.....21-546

COAT HOOK - INSTALLATION...........23-67

COAT HOOK - REMOVAL...............23-67

CODE - DESCRIPTION, PAINT...........23-74

CODE PLATE - DESCRIPTION, BODY

....Intro.-4

CODES - DESCRIPTION, DIAGNOSTIC

TROUBLE

............................25-1

CODES - SPECIFICATIONS, PAINT

........23-74

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER

..............8M-12

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER

..............8M-12COIL - DESCRIPTION, IGNITION.........8I-19

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-10

COIL - INSTALLATION, IGNITION.........8I-24

COIL - OPERATION, IGNITION...........8I-20

COIL - REMOVAL, IGNITION............8I-23

COIL CAPACITOR - DESCRIPTION,

IGNITION...........................8I-33

COIL CAPACITOR - INSTALLATION,

IGNITION...........................8I-33

COIL CAPACITOR - OPERATION,

IGNITION...........................8I-33

COIL CAPACITOR - REMOVAL, IGNITION . . . 8I-33

COIL RESISTANCE, 3.7L V-6 - IGNITION....8I-6

COIL RESISTANCE, 4.7L V-8 - IGNITION....8I-6

COIL RESISTANCE, 5.7L V-8 - IGNITION....8I-6

COIL RESISTANCE, 5.9L - IGNITION.......8I-6

COIL RESISTANCE, 8.0L V-10 ENGINE -

IGNITION............................8I-6

COLUMN - DESCRIPTION...............19-6

COLUMN - DIAGNOSIS AND TESTING,

STEERING...........................19-7

COLUMN - INSTALLATION...............19-9

COLUMN - REMOVAL..................19-7

COLUMN OPENING COVER -

INSTALLATION, STEERING.............23-61

COLUMN OPENING COVER - REMOVAL,

STEERING..........................23-61

COLUMN OPENING SUPPORT BRACKET

- INSTALLATION, STEERING..............23-62

COLUMN OPENING SUPPORT BRACKET

- REMOVAL, STEERING................23-61

COMBUSTION PRESSURE LEAKAGE -

DIAGNOSIS AND TESTING, CYLINDER....9-182,

9-231,9-359,9-8,9-92

COMMUNICATION - DESCRIPTION........8E-1

COMMUNICATION - OPERATION..........8E-2

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING..............8M-7

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-4

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-6

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION.......................8M-7

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-7

COMPASS/MINI-TRIP COMPUTER -

REMOVAL...........................8M-7

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER . . . 9-182,9-231,9-359,

9-8,9-92

COMPRESSION/LEAKAGE TESTS -

DIAGNOSIS AND TESTING, CYLINDER....9-288

COMPRESSOR CLUTCH - DESCRIPTION,

A/C ................................24-9

COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-12

COMPRESSOR CLUTCH - INSTALLATION,

A/C

................................24-12

COMPRESSOR CLUTCH - OPERATION,

A/C

................................24-9

COMPRESSOR CLUTCH - REMOVAL, A/C

. . 24-10

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C

...........24-10

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C

..........24-10

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C

...................24-13

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING

.............24-13

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C

...................24-14

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C

.....................24-13

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C

......................24-14

COMPRESSOR NOISE - DIAGNOSIS AND

TESTING, A/C

.......................24-36

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP

..........................8M-6

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP

..................8M-7

DRINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 2863 of 2895

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP..........................8M-7

COMPUTER - OPERATION, COMPASS/

MINI-TRIP..........................8M-7

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP..........................8M-7

CONDENSER - DESCRIPTION, A/C.......24-39

CONDENSER - OPERATION, A/C.........24-39

CONDENSER FAN (GAS ENGINE ONLY -

3.7, 4.7 & 5.7L) - INSTALLATION........24-43

CONDENSER FAN (GAS ENGINE ONLY -

3.7, 4.7 & 5.7L) - REMOVAL............24-43

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-1

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITH AIR..........7-70

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-70

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITH AIR..........7-68

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-69

CONDITIONS - DIAGNOSIS AND

TESTING, CHIME......................8B-2

CONDITIONS - DIAGNOSIS AND

TESTING, SPARK PLUG................8I-27

CONFIGURING A NEW MODULE /

SWITCH OPERATING MODES,

STANDARD PROCEDURE...............8Q-3

CONNECT FITTING - DESCRIPTION,

QUICK..............................14-8

CONNECTING ROD - CLEANING, PISTON . . 9-331

CONNECTING ROD - CLEANING, PISTON . . 9-138,

9-206,9-261,9-389

CONNECTING ROD - DESCRIPTION,

PISTON....9-137,9-205,9-260,9-329,9-388,9-47

CONNECTING ROD - INSPECTION........9-332

CONNECTING ROD - INSPECTION,

PISTON.............9-138,9-206,9-261,9-389

CONNECTING ROD - INSTALLATION,

PISTON.............9-139,9-207,9-261,9-389

CONNECTING ROD - REMOVAL, PISTON . . 9-137,

9-205,9-261,9-330,9-389

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE...............9-321

CONNECTING ROD BEARING FITTING -

STANDARD PROCEDURE.....9-128,9-251,9-382

CONNECTING ROD BEARING FITTING,

STANDARD PROCEDURE................9-48

CONNECTOR - DESCRIPTION, DATA LINK . . 8E-3

CONNECTOR - INSTALLATION.......8W-01-11

CONNECTOR - OPERATION, DATA LINK....8E-3

CONNECTOR - REMOVAL...........8W-01-11

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION....................8W-91-1

CONSOLE - DESCRIPTION, OVERHEAD....8M-1

CONSOLE - DIAGNOSIS AND TESTING,

OVERHEAD..........................8M-2

CONSOLE - INSTALLATION, FLOOR......23-68

CONSOLE - OPERATION, OVERHEAD

......8M-2

CONSOLE - REMOVAL, FLOOR

..........23-68

CONSOLE REMOVAL, REMOVAL -

OVERHEAD

..........................8M-5

CONSOLE, SPECIAL TOOLS - OVERHEAD

. . 8M-6

CONTAINER-3.7L/4.7L - DESCRIPTION,

COOLANT DEGAS

.....................7-38

CONTAINER-3.7L/4.7L - INSTALLATION,

COOLANT DEGAS

.....................7-39

CONTAINER-3.7L/4.7L - OPERATION,

COOLANT DEGAS

.....................7-38

CONTAINER-3.7L/4.7L - REMOVAL,

COOLANT DEGAS

.....................7-39

CONTAINER-5.9L - DESCRIPTION,

COOLANT RECOVERY

..................7-38

CONTAINER-5.9L - INSTALLATION,

COOLANT RECOVERY

..................7-38

CONTAINER-5.9L - OPERATION,

COOLANT RECOVERY

..................7-38

CONTAINER-5.9L - REMOVAL, COOLANT

RECOVERY

..........................7-38

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID

................5-18CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID........21-201,21-381,21-541

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-9

CONTOLLED VISCOUS FAN DRIVE -

DIAGNOSIS AND TESTING,

ELECTRONICLY.......................7-56

CONTROL ACTUATOR - DESCRIPTION,

FUEL..............................14-85

CONTROL ACTUATOR - INSTALLATION,

FUEL..............................14-85

CONTROL ACTUATOR - OPERATION,

FUEL..............................14-85

CONTROL ACTUATOR - REMOVAL, FUEL . . 14-85

CONTROL ARM - INSTALLATION, UPPER . . . 2-27

CONTROL ARM - REMOVAL, UPPER......2-27

CONTROL ARM BUSHINGS - 2WD (LD) -

INSTALLATION, LOWER.................2-14

CONTROL ARM BUSHINGS - 2WD (LD) -

REMOVAL, LOWER....................2-12

CONTROL ARM BUSHINGS - 4WD (LD) -

INSTALLATION, LOWER.................2-13

CONTROL ARM BUSHINGS - 4WD (LD) -

REMOVAL, LOWER....................2-12

CONTROL CABLE - INSTALLATION,

THROTTLE.....................14-51,14-96

CONTROL CABLE - REMOVAL,

THROTTLE.....................14-49,14-94

CONTROL INFORMATION (VECI) -

DESCRIPTION, VEHICLE EMISSION.....Intro.-3

CONTROL MODULE - DESCRIPTION,

AIRBAG............................8O-10

CONTROL MODULE - DESCRIPTION,

FRONT...........................8W-97-4

CONTROL MODULE - DESCRIPTION,

FRONT..............................8E-5

CONTROL MODULE - DESCRIPTION,

SIDE IMPACT AIRBAG.................8O-53

CONTROL MODULE - DESCRIPTION,

TRANSFER CASE.....................8E-15

CONTROL MODULE - DESCRIPTION,

TRANSMISSION......................8E-19

CONTROL MODULE - DIAGNOSIS AND

TESTING, FRONT...................8W-97-5

CONTROL MODULE - DIAGNOSIS AND

TESTING, FRONT......................8E-6

CONTROL MODULE - INSTALLATION,

AIRBAG............................8O-12

CONTROL MODULE - INSTALLATION,

ENGINE.............................8E-5

CONTROL MODULE - INSTALLATION,

FRONT...........................8W-97-5

CONTROL MODULE - INSTALLATION,

FRONT..............................8E-6

CONTROL MODULE - OPERATION,

AIRBAG............................8O-10

CONTROL MODULE - OPERATION,

FRONT...........................8W-97-5

CONTROL MODULE - OPERATION,

FRONT..............................8E-5

CONTROL MODULE - OPERATION, SIDE

IMPACT AIRBAG.....................8O-54

CONTROL MODULE - OPERATION,

TRANSFER CASE.....................8E-15

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-19

CONTROL MODULE - REMOVAL, AIRBAG

. 8O-11

CONTROL MODULE - REMOVAL, ENGINE

. . . 8E-4

CONTROL MODULE - REMOVAL, FRONT

. 8W-97-5

CONTROL MODULE - REMOVAL, FRONT

. . . 8E-6

CONTROL MOTOR - DESCRIPTION, IDLE

AIR

...............................14-33

CONTROL MOTOR - INSTALLATION, IDLE

AIR

...............................14-35

CONTROL MOTOR - OPERATION, IDLE

AIR

...............................14-33

CONTROL MOTOR - REMOVAL, IDLE AIR

. . 14-34

CONTROL RELAY - DESCRIPTION,

TRANSMISSION

.....................21-581

CONTROL RELAY - OPERATION,

TRANSMISSION

.....................21-581

CONTROL SWITCH - DESCRIPTION,

LUMBAR

...........................8N-19

CONTROL SWITCH - OPERATION,

LUMBAR

...........................8N-19

CONTROL SWITCH - REMOVAL,

LUMBAR

...........................8N-19CONTROLLER ANTILOCK BRAKE -

DESCRIPTION........................8E-3

CONTROLLER ANTILOCK BRAKE -

INSTALLATION........................8E-3

CONTROLLER ANTILOCK BRAKE -

OPERATION..........................8E-3

CONTROLLER ANTILOCK BRAKE -

REMOVAL...........................8E-3

CONTROLS - DIAGNOSIS AND TESTING,

OVERDRIVE ELECTRICAL.......21-219,21-397

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-4

CONVERTER - DESCRIPTION, TORQUE . . 21-257,

21-434,21-575

CONVERTER - INSTALLATION, TORQUE . . 21-262,

21-439,21-580

CONVERTER - OPERATION, CATALYTIC....11-4

CONVERTER - OPERATION, TORQUE....21-261,

21-438,21-579

CONVERTER - REMOVAL, TORQUE.....21-262,

21-439,21-580

CONVERTER DRAINBACK VALVE -

DESCRIPTION, TORQUE........21-262,21-440

CONVERTER DRAINBACK VALVE -

OPERATION, TORQUE..........21-262,21-440

CONVERTER DRAINBACK VALVE -

STANDARD PROCEDURE, TORQUE.....21-262,

21-440

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND TESTING......21-143,21-324,

21-495

COOLANT - DESCRIPTION, ENGINE.......7-36

COOLANT - DESCRIPTION, ENGINE........0-3

COOLANT - DESCRIPTION, HOAT...........7-37

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL..................7-19

COOLANT DEGAS CONTAINER-3.7L/4.7L

- DESCRIPTION.......................7-38

COOLANT DEGAS CONTAINER-3.7L/4.7L

- INSTALLATION......................7-39

COOLANT DEGAS CONTAINER-3.7L/4.7L

- OPERATION.........................7-38

COOLANT DEGAS CONTAINER-3.7L/4.7L

- REMOVAL..........................7-39

COOLANT FLOW - DIAGNOSIS AND

TESTING, RADIATOR...............7-57,7-59

COOLANT LEVEL CHECK - STANDARD

PROCEDURE.........................7-17

COOLANT RECOVERY CONTAINER-5.9L -

DESCRIPTION........................7-38

COOLANT RECOVERY CONTAINER-5.9L -

INSTALLATION........................7-38

COOLANT RECOVERY CONTAINER-5.9L -

OPERATION..........................7-38

COOLANT RECOVERY CONTAINER-5.9L -

REMOVAL...........................7-38

COOLANT TEMPERATURE SENSOR -

DESCRIPTION, ENGINE.................7-44

COOLANT TEMPERATURE SENSOR -

INSTALLATION, ENGINE................7-47

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-44

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE

....................7-44

COOLANT THERMOSTAT - 3.7L/4.7L -

DESCRIPTION, ENGINE

.................7-50

COOLANT THERMOSTAT - 3.7L/4.7L -

INSTALLATION, ENGINE

................7-51

COOLANT THERMOSTAT - 3.7L/4.7L -

OPERATION, ENGINE

...................7-51

COOLANT THERMOSTAT - 3.7L/4.7L -

REMOVAL, ENGINE

....................7-51

COOLANT THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE

.................7-52

COOLANT THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE

................7-53

COOLANT THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE

...................7-52

COOLANT THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE

....................7-53

COOLANT THERMOSTAT-5.7L/5.9L -

DESCRIPTION, ENGINE

.................7-47

COOLANT THERMOSTAT-5.7L/5.9L -

INSTALLATION, ENGINE

................7-49

COOLANT THERMOSTAT-5.7L/5.9L -

OPERATION, ENGINE

...................7-48

COOLANT THERMOSTAT-5.7L/5.9L -

REMOVAL, ENGINE

....................7-48

8 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2867 of 2895

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE...........8W-01-10

DRUM IN HAT BRAKE - CLEANING,

REAR...............................5-33

DRUM IN HAT BRAKE - INSPECTION,

REAR...............................5-33

DUAL REAR WHEEL INSTALLATION -

STANDARD PROCEDURE...............22-12

DUCTS - INSTALLATION, FLOOR

DISTRIBUTION.......................24-27

DUCTS - INSTALLATION, INSTRUMENT

PANEL.............................24-29

DUCTS - REMOVAL, FLOOR

DISTRIBUTION.......................24-27

DUCTS - REMOVAL, INSTRUMENT

PANEL.............................24-29

DUST BOOT - INSTALLATION,

EXTENSION HOUSING SEAL.....21-652,21-716

DUST BOOT - REMOVAL, EXTENSION

HOUSING SEAL...............21-652,21-716

DUTY FRONT FRAME RAIL TIP

REPLACEMENT - STANDARD

PROCEDURE, LIGHT...................13-4

ECM - DESCRIPTION...................8E-4

ECM - OPERATION....................8E-4

EFFECTS OF INCORRECT FLUID LEVEL -

DIAGNOSIS AND TESTING......21-201,21-381,

21-541

ELECTRICAL CONTROLS - DIAGNOSIS

AND TESTING, OVERDRIVE......21-219,21-397

ELECTRONIC GOVERNOR -

DESCRIPTION................21-196,21-376

ELECTRONIC GOVERNOR -

INSTALLATION.................21-199,21-379

ELECTRONIC GOVERNOR - OPERATION . 21-196,

21-377

ELECTRONIC GOVERNOR - REMOVAL . . . 21-198,

21-378

ELECTRONIC VARIABLE BRAKE

PROPORTIONING - DESCRIPTION........5-43

ELECTRONIC VARIABLE BRAKE

PROPORTIONING - OPERATION..........5-43

ELECTRONIC VEHICLE INFO CENTER -

DESCRIPTION........................8M-7

ELECTRONIC VEHICLE INFO CENTER -

INSTALLATION......................8M-10

ELECTRONIC VEHICLE INFO CENTER -

OPERATION.........................8M-8

ELECTRONIC VEHICLE INFO CENTER -

REMOVAL..........................8M-10

ELECTRONIC VEHICLE INFORMATION

CENTER - DIAGNOSIS AND TESTING......8M-8

ELECTRONIC VEHICLE INFORMATION

CENTER PROGRAMMING - STANDARD

PROCEDURE.........................8M-8

ELECTRONICLY CONTOLLED VISCOUS

FAN DRIVE - DIAGNOSIS AND TESTING....7-56

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES - STANDARD

PROCEDURE......................8W-01-8

ELEMENT - DESCRIPTION, HEATED SEAT . . 8G-5

ELEMENT - DIAGNOSIS AND TESTING,

HEATED SEAT ........................8G-6

ELEMENT - INSTALLATION, AIR

CLEANER........9-105,9-20,9-242,9-298,9-370

ELEMENT - INSTALLATION, HEATED

SEAT ...............................8G-6

ELEMENT - OPERATION, HEATED SEAT....8G-6

ELEMENT - REMOVAL, AIR CLEANER....9-105,

9-20,9-242,9-297,9-370

ELEMENT - REMOVAL, HEATED SEAT.....8G-6

EMISSION CONTROL INFORMATION

(VECI) - DESCRIPTION, VEHICLE.......Intro.-3

END - DIAGNOSIS AND TESTING, OUTER

TIE ROD............................19-31

END - INSTALLATION, OUTER TIE ROD . . . 19-32

END - INSTALLATION, TIE ROD.........19-37

END - REMOVAL, OUTER TIE ROD.......19-31

END - REMOVAL, TIE ROD.............19-36

ENGINE - 3.7L - DESCRIPTION............9-3

ENGINE - 5.7L - DESCRIPTION

..........9-178

ENGINE - 5.9L - DESCRIPTION

..........9-224

ENGINE - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L

...................7-1

ENGINE - DESCRIPTION, COOLING

SYSTEM FLOW 3.7L/4.7L

................7-1

ENGINE - DESCRIPTION, FUEL

REQUIREMENTS - DIESEL

...............0-1ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIESEL...............7-7

ENGINE - DIAGNOSIS AND TESTING,

DIESEL.............................11-3

ENGINE - DIAGNOSIS AND TESTING,

GAS................................11-2

ENGINE - FIRING ORDER / CABLE

ROUTING, 5.7L V-8....................8I-4

ENGINE - IGNITION COIL RESISTANCE,

8.0L V-10............................8I-6

ENGINE - INSTALLATION...............9-291

ENGINE - INSTALLATION, 5.9L DIESEL . . . 24-39,

24-42,24-44

ENGINE - INSTALLATION, 8.0L..........24-42

ENGINE - INSTALLATION, EXCEPT V-10

OR DIESEL.........................8R-17

ENGINE - INSTALLATION, GAS..........19-24

ENGINE - INSTALLATION, V-10 OR

DIESEL............................8R-17

ENGINE - REMOVAL..................9-290

ENGINE - REMOVAL, 5.9L DIESEL . . 24-37,24-40,

24-43,24-46

ENGINE - REMOVAL, 8.0L..............24-40

ENGINE - REMOVAL, EXCEPT V-10 OR

DIESEL............................8R-16

ENGINE - REMOVAL, GAS..............19-23

ENGINE - REMOVAL, V-10 OR DIESEL....8R-16

ENGINE - SPARK PLUG CABLE ORDER,

8.0L V-10............................8I-5

ENGINE - SPECIFICATIONS, 3.7L.........9-12

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM

3.7L/4.7L/5.7L........................7-18

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM 5.9L

DIESEL.............................7-19

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM

5.9L/8.0L............................7-18

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM

3.7L/4.7L/5.7L........................7-18

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM 5.9L

DIESEL.............................7-19

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM

5.9L/8.0L............................7-18

ENGINE 5.9L DIESEL - DESCRIPTION.....9-282

ENGINE 8.0L - DESCRIPTION...........9-353

ENGINE BLOCK - CLEANING . 9-127,9-200,9-249,

9-38,9-380

ENGINE BLOCK - DESCRIPTION.....9-126,9-37

ENGINE BLOCK - INSPECTION.....9-127,9-200,

9-249,9-38,9-380

ENGINE BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION........................7-43

ENGINE BLOCK HEATER - 5.9L DIESEL -

INSTALLATION........................7-44

ENGINE BLOCK HEATER - 5.9L DIESEL -

OPERATION..........................7-43

ENGINE BLOCK HEATER - 5.9L DIESEL -

REMOVAL...........................7-43

ENGINE BLOCK HEATER - DESCRIPTION . . . 7-42

ENGINE BLOCK HEATER - DIAGNOSIS

AND TESTING........................7-42

ENGINE BLOCK HEATER - INSTALLATION . . . 7-43

ENGINE BLOCK HEATER - OPERATION.....7-42

ENGINE BLOCK HEATER - REMOVAL......7-43

ENGINE CONTROL MODULE -

INSTALLATION........................8E-5

ENGINE CONTROL MODULE - REMOVAL . . . 8E-4

ENGINE COOLANT - DESCRIPTION........7-36

ENGINE COOLANT - DESCRIPTION.........0-3

ENGINE COOLANT TEMPERATURE

SENSOR - DESCRIPTION...............7-44

ENGINE COOLANT TEMPERATURE

SENSOR - INSTALLATION...............7-47

ENGINE COOLANT TEMPERATURE

SENSOR - OPERATION

.................7-44

ENGINE COOLANT TEMPERATURE

SENSOR - REMOVAL

...................7-44

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - DESCRIPTION

...............7-50

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - INSTALLATION

..............7-51

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - OPERATION

.................7-51ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - REMOVAL..................7-51

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - DESCRIPTION................7-52

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - INSTALLATION................7-53

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - OPERATION..................7-52

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - REMOVAL....................7-53

ENGINE COOLANT THERMOSTAT-

5.7L/5.9L - DESCRIPTION...............7-47

ENGINE COOLANT THERMOSTAT-

5.7L/5.9L - INSTALLATION..............7-49

ENGINE COOLANT THERMOSTAT-

5.7L/5.9L - OPERATION.................7-48

ENGINE COOLANT THERMOSTAT-

5.7L/5.9L - REMOVAL..................7-48

ENGINE DATA PLATE - DESCRIPTION.....9-297

ENGINE DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING . . . 9-178,9-225,9-353,

9-4,9-93

ENGINE DIAGNOSIS - LUBRICATION -

DIAGNOSIS AND TESTING . . . 9-183,9-230,9-358,

9-7

ENGINE DIAGNOSIS - MECHANICAL -

DIAGNOSIS AND TESTING . . . 9-181,9-184,9-228,

9-283,9-356,9-6,9-91

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING . . . 9-179,9-226,9-354,

9-4,9-89

ENGINE FIRING ORDER, 3.7L V-6.........8I-4

ENGINE FIRING ORDER, 4.7L V-8.........8I-4

ENGINE FIRING ORDER, 5.9L V-8...........8I-4

ENGINE GASKET SURFACE

PREPARATION - STANDARD

PROCEDURE.........................9-10

ENGINE OIL - STANDARD PROCEDURE . . . 9-269,

9-396

ENGINE OIL AND LUBRICANTS -

DESCRIPTION.........................0-2

ENGINE OIL LEAK - DIAGNOSIS AND

TESTING..................9-150,9-214,9-63

ENGINE OIL LEAKS - DIAGNOSIS AND

TESTING......................9-269,9-394

ENGINE OIL LEVEL - STANDARD

PROCEDURE........................9-341

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING.............9-269,9-338,9-396

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING, CHECKING.....9-150,9-214,9-64

ENGINE OIL SERVICE - STANDARD

PROCEDURE..........9-151,9-215,9-341,9-70

ENGINE, SPECIAL TOOLS - 4.7L.........9-102

ENGINE, SPECIAL TOOLS - 5.7L.........9-192

ENGINE, SPECIAL TOOLS - 5.9L.........9-240

ENGINE, SPECIAL TOOLS - 5.9L DIESEL . . 9-294

ENGINE, SPECIAL TOOLS - 8.0L.........9-367

ENGINE, SPECIFICATIONS - 4.7L.........9-98

ENGINE, SPECIFICATIONS - 5.7L........9-188

ENGINE, SPECIFICATIONS - 5.9L........9-235

ENGINE, SPECIFICATIONS - 8.OL........9-364

ENGINE TEMPERATURE GAUGE -

DESCRIPTION

.......................8J-23

ENGINE TEMPERATURE GAUGE -

OPERATION

.........................8J-23

ENGINE TIMING - VERIFICATION -

STANDARD PROCEDURE

...............9-165

ENGINES - INSTALLATION, 3.7, 4.7 AND

5.7L

...............................24-41

ENGINES - REMOVAL, 3.7, 4.7 AND 5.7L

. . 24-39

ENTRY MODULE - DESCRIPTION,

REMOTE KEYLESS

....................8N-7

ENTRY MODULE - DIAGNOSIS AND

TESTING, REMOTE KEYLESS

............8N-8

ENTRY MODULE - INSTALLATION,

REMOTE KEYLESS

....................8N-8

ENTRY MODULE - OPERATION, REMOTE

KEYLESS

............................8N-8

ENTRY MODULE - REMOVAL, REMOTE

KEYLESS

............................8N-8

ENTRY TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS

............8N-8

ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE KEYLESS

.....8N-10

EQUIPMENT - STANDARD PROCEDURE,

REFRIGERANT SYSTEM SERVICE

........24-34

12 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2868 of 2895

ERASING TRANSMITTER CODES -

STANDARD PROCEDURE..............8M-12

ETC INDICATOR - DESCRIPTION.........8J-24

ETC INDICATOR - OPERATION..........8J-25

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM..........24-35,24-51

EVAP SYSTEM - DESCRIPTION..........25-10

EVAP SYSTEM - TORQUE..............25-12

EVAPORATOR - DESCRIPTION, A/C.......24-47

EVAPORATOR - INSTALLATION, A/C......24-47

EVAPORATOR - OPERATION, A/C........24-47

EVAPORATOR - REMOVAL, A/C..........24-47

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-12

EVAP/PURGE SOLENOID - INSTALLATION . 25-13

EVAP/PURGE SOLENOID - OPERATION....25-12

EVAP/PURGE SOLENOID - REMOVAL.....25-13

EXCEPT 4X4 HD - INSTALLATION, ALL

LD & HD ...........................19-15

EXCEPT 4X4 HD - REMOVAL, ALL LD &

HD................................19-14

EXCEPT DIESEL - INSTALLATION........14-22

EXCEPT DIESEL - REMOVAL............14-20

EXCEPT HYDROBOOST - INSTALLATION,

ALL ................................5-22

EXCEPT HYDROBOOST - REMOVAL, ALL . . . 5-21

EXCEPT V-10 OR DIESEL ENGINE -

INSTALLATION......................8R-17

EXCEPT V-10 OR DIESEL ENGINE -

REMOVAL............................8R-16

EXHAUST MANIFOLD - CLEANING . . 9-161,9-220,

9-277,9-347,9-404

EXHAUST MANIFOLD - DESCRIPTION....9-159,

9-220,9-277,9-403,9-73

EXHAUST MANIFOLD - INSPECTION.....9-161,

9-220,9-277,9-347,9-404

EXHAUST MANIFOLD - INSTALLATION . . . 9-162,

9-220,9-277,9-347,9-404,9-74

EXHAUST MANIFOLD - OPERATION . 9-220,9-277,

9-403

EXHAUST MANIFOLD - REMOVAL . . 9-159,9-220,

9-277,9-347,9-404,9-73

EXHAUST PIPE - INSPECTION...........11-7

EXHAUST PIPE - INSTALLATION..........11-7

EXHAUST PIPE - REMOVAL.............11-7

EXTENSION HOUSING BUSHING -

INSTALLATION......................21-200

EXTENSION HOUSING BUSHING -

REMOVAL.........................21-200

EXTENSION HOUSING BUSHING AND

SEAL - INSTALLATION..........21-616,21-682

EXTENSION HOUSING BUSHING AND

SEAL - REMOVAL.............21-616,21-682

EXTENSION HOUSING SEAL -

INSTALLATION.....21-127,21-200,21-380,21-83

EXTENSION HOUSING SEAL - REMOVAL . 21-127,

21-200,21-380,21-83

EXTENSION HOUSING SEAL AND DUST

BOOT - INSTALLATION.........21-652,21-716

EXTENSION HOUSING SEAL AND DUST

BOOT - REMOVAL.............21-652,21-716

EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING.....................8L-3

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR HANDLE - INSTALLATION.....23-20,

23-30

EXTERIOR HANDLE - REMOVAL

....23-20,23-30

EXTERIOR LAMPS, SPECIFICATIONS

......8L-7

EXTERIOR NAME PLATES -

INSTALLATION

.......................23-38

EXTERIOR NAME PLATES - REMOVAL

....23-38

FAILURE - DIAGNOSIS AND TESTING,

CYLINDER HEAD GASKET

....9-194,9-243,9-370

FAN - 5.9L DIESEL - CLEANING,

RADIATOR

...........................7-41

FAN - 5.9L DIESEL - INSPECTION,

RADIATOR

...........................7-41

FAN - 5.9L DIESEL - INSTALLATION,

RADIATOR

...........................7-41

FAN - 5.9L DIESEL - REMOVAL,

RADIATOR

...........................7-41

FAN - CLEANING, RADIATOR

............7-40

FAN - INSPECTION, RADIATOR

...........7-40

FAN - INSTALLATION, RADIATOR

.........7-40

FAN - REMOVAL, RADIATOR

.............7-39FAN DRIVE - DIAGNOSIS AND TESTING,

ELECTRONICLY CONTOLLED VISCOUS.....7-56

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS............................7-54

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION................7-55

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION..................7-55

FAN DRIVE VISCOUS CLUTCH -

DESCRIPTION........................7-54

FAN DRIVE VISCOUS CLUTCH -

OPERATION..........................7-54

FAN (GAS ENGINE ONLY - 3.7, 4.7 &

5.7L) - INSTALLATION, CONDENSER.....24-43

FAN (GAS ENGINE ONLY - 3.7, 4.7 &

5.7L) - REMOVAL, CONDENSER.........24-43

FASCIA - INSTALLATION, FRONT.........13-3

FASCIA - REMOVAL, FRONT.............13-3

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-6

FASTENER USAGE - DESCRIPTION......Intro.-9

FENDER - INSTALLATION, FRONT........23-39

FENDER - INSTALLATION, REAR.........23-44

FENDER - REMOVAL, FRONT...........23-39

FENDER - REMOVAL, REAR............23-44

FENDER RAIL REPAIR - STANDARD

PROCEDURE, HYDROFORM............13-12

FILL - STANDARD PROCEDURE,

TRANSMISSION.........21-203,21-383,21-544

FILL DOOR - INSTALLATION, FUEL.......23-39

FILL DOOR - REMOVAL, FUEL............23-39

FILLER CAP - DESCRIPTION, FUEL.......25-13

FILLER CAP - OPERATION, FUEL........25-13

FILTER - INSTALLATION, INLET..........14-23

FILTER - INSTALLATION, OIL . 9-153,9-217,9-270,

9-342,9-397,9-70

FILTER - REMOVAL, INLET.............14-23

FILTER - REMOVAL, OIL.....9-152,9-216,9-270,

9-342,9-397,9-69

FILTER - STANDARD PROCEDURES,

WATER DRAINING AT FUEL............14-57

FILTER / WATER SEPARATOR -

DESCRIPTION, FUEL..................14-61

FILTER / WATER SEPARATOR -

INSTALLATION, FUEL.................14-62

FILTER / WATER SEPARATOR -

OPERATION, FUEL....................14-61

FILTER / WATER SEPARATOR -

REMOVAL, FUEL.....................14-61

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID.....21-203,21-383,21-542

FILTER/PRESSURE REGULATOR -

DESCRIPTION, FUEL...................14-6

FILTER/PRESSURE REGULATOR -

OPERATION, FUEL.....................14-6

FINESSE SANDING/BUFFING &

POLISHING - DESCRIPTION............23-75

FINISH - DESCRIPTION, BASECOAT/

CLEARCOAT.........................23-74

FIRING ORDER / CABLE ROUTING, 5.7L

V-8 ENGINE..........................8I-4

FIRING ORDER, 3.7L V-6 - ENGINE........8I-4

FIRING ORDER, 4.7L V-8 - ENGINE........8I-4

FIRING ORDER, 5.9L V-8 - ENGINE........8I-4

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-60

FITTING - DESCRIPTION, QUICK

CONNECT............................14-8

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING . 9-128,9-251,9-382

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING..........9-253

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING.....9-133,9-202

FITTING - STANDARD PROCEDURE,

PISTON.........9-137,9-205,9-260,9-389,9-50

FITTING - STANDARD PROCEDURE,

PISTON RING....9-140,9-207,9-262,9-333,9-52

FITTING CRANKSHAFT MAIN BEARINGS

- STANDARD PROCEDURE

.............9-383

FITTING PISTON RINGS - STANDARD

PROCEDURE

........................9-390

FITTING, STANDARD PROCEDURE -

CONNECTING ROD BEARING

............9-48

FITTING, STANDARD PROCEDURE -

MAIN BEARING

.......................9-43

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT

......................14-8FIXED ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-48

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-27

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-27

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED.....................5-7

FLARING - STANDARD PROCEDURE, ISO....5-7

FLEX PLATE - INSTALLATION . . 9-137,9-205,9-47

FLEX PLATE - REMOVAL......9-137,9-205,9-47

FLOOR - DEFROST DOOR -

INSTALLATION.......................24-30

FLOOR - DEFROST DOOR - REMOVAL....24-30

FLOOR - DEFROST DOOR ACTUATOR -

INSTALLATION.......................24-20

FLOOR - DEFROST DOOR ACTUATOR -

REMOVAL..........................24-19

FLOOR - INSTALLATION, LOAD..........23-73

FLOOR - REMOVAL, LOAD.............23-73

FLOOR CONSOLE - INSTALLATION.......23-68

FLOOR CONSOLE - REMOVAL...........23-68

FLOOR DISTRIBUTION DUCTS -

INSTALLATION.......................24-27

FLOOR DISTRIBUTION DUCTS -

REMOVAL..........................24-27

FLOOR MATS - INSTALLATION, CARPETS . 23-66

FLOOR MATS - REMOVAL, CARPETS.....23-66

FLOOR SHIFT BOOT - INSTALLATION,

4WD ..............................23-64

FLOOR SHIFT BOOT - REMOVAL, 4WD.....23-63

FLOOR SUPPORT CYLINDER -

INSTALLATION, LOAD.................23-73

FLOOR SUPPORT CYLINDER -

REMOVAL, LOAD.....................23-73

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-2

FLOW - 5.9L ENGINE - DESCRIPTION,

COOLING SYSTEM.....................7-1

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..............7-57,7-59

FLOW 3.7L/4.7L ENGINE - DESCRIPTION,

COOLING SYSTEM.....................7-1

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION................19-42

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-4

FLUID - DESCRIPTION, POWER

STEERING............................0-3

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT......21-201,21-381,21-541

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE . . 21-203,21-383,21-542

FLUID CAPACITIES, SPECIFICATIONS.......0-5

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING..........21-201,21-381,21-541

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-18

FLUID COOLER - INSTALLATION.........19-42

FLUID COOLER - REMOVAL............19-42

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE.....21-617,21-652,21-682,21-716

FLUID INDICATOR - DESCRIPTION,

WASHER...........................8J-42

FLUID INDICATOR - OPERATION,

WASHER...........................8J-42

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING . . . 21-143,21-324,21-495

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT.....21-201,

21-381,21-541

FLUID LEVEL - STANDARD PROCEDURE,

BRAKE..............................5-18

FLUID LEVEL CHECK - STANDARD

PROCEDURE...........21-201,21-381,21-542

FLUID LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING........19-42

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER

............................8R-9

FLUID LEVEL SWITCH - INSTALLATION,

WASHER

...........................8R-11

FLUID LEVEL SWITCH - OPERATION,

WASHER

............................8R-9

FLUID LEVEL SWITCH - REMOVAL,

WASHER

...........................8R-10

FLUID RESERVOIR - INSTALLATION

.......5-19

DRINDEX 13

Description Group-Page Description Group-Page Description Group-Page