air conditioning DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1483 of 2895

(3) Recover refrigerant from a/c system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(4) Remove the a/c condenser, if equipped (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

(6) Remove the washer bottle from the fan shroud.

(7) Remove the viscous fan/drive (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(8) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(9) Remove the upper crossmember and top core

support.

(10) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Remove the A/C compressor with the lines

attached. Secure compressor out of the way.

(12) Remove generator assembly (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR - REMOV-

AL).

(13) Remove the air cleaner resonator and duct

work as an assembly.

(14) Disconnect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL).

(15) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(16) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(17) Remove the distributor cap and wiring.

(18) Disconnect the heater hoses.

(19) Disconnect the power steering hoses, if

equipped.

(20) Perform the Fuel System Pressure Release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).

(21) Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(22) On Manual Transmission vehicles, remove the

shift lever (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/SHIFT COVER - REMOVAL).

(23) Raise and support the vehicle on a hoist and

drain the engine oil.

(24) Remove engine front mount thru-bolt nuts.

(25) Disconnect the transmission oil cooler lines

from their retainers at the oil pan bolts.

(26) Disconnect exhaust pipe at manifolds.(27) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(28) Remove the dust shield and transmission

inspection cover.

(29) Remove drive plate to converter bolts (Auto-

matic transmission equipped vehicles).

(30) Remove transmission bell housing to engine

block bolts.

(31) Lower the vehicle.

(32) Install an engine lifting fixture.

(33) Separate engine from transmission, remove

engine from vehicle, and install engine assembly on a

repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install engine lifting device.

(3) Lower engine into compartment and align

engine with transmission:

²Manual Transmission: Align clutch disc assem-

bly (if disturbed). Install transmission input shaft

into clutch disc while mating engine and transmis-

sion surfaces. Install two transmission to engine

block mounting bolts finger tight.

²Automatic Transmission: Mate engine and trans-

mission and install two transmission to engine block

mounting bolts finger tight.

(4) Lower engine assembly until engine mount

through bolts rest in mount perches.

(5) Install remaining transmission to engine block

mounting bolts and tighten.

(6) Tighten engine mount through bolts.

(7) Install drive plate to torque converter bolts.

(Automatic transmission models)

(8) Install the dust shield and transmission cover.

(9) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(10) Install exhaust pipe to manifold.

(11) Install the transmission cooler line brackets to

the oil pan.

(12) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(13) Lower the vehicle.

(14) Remove engine lifting fixture.

(15) On Manual Transmission vehicles, install the

shift lever (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/SHIFT COVER - INSTALLATION).

(16) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(17) Connect the power steering hoses, if equipped.

(18) Connect the heater hoses.

9 - 234 ENGINE - 5.9LDR

ENGINE - 5.9L (Continued)

Page 1484 of 2895

(19) Install the distributor cap and wiring.

(20) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(21) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(22) Connect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION).

(23) Install the air cleaner resonator and duct

work..

(24) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(25) Install a/c compressor and lines (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).

(26) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(27) Install upper radiator support crossmember.

(28) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(29) Connect the radiator lower hose.

(30) Connect the transmission oil cooler lines to

the radiator.

(31) Install the fan shroud.

(32) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(33) Connect the radiator upper hose.

(34) Install the washer bottle.

(35) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(36) Connect the transmission cooler lines.

(37) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(38) Evacuate and charge the air conditioning sys-

tem, if equipped (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(39) Add engine oil to crankcase (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES - SPEC-

IFICATIONS).

(40) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(41) Connect battery negative cable.

(42) Start engine and inspect for leaks.

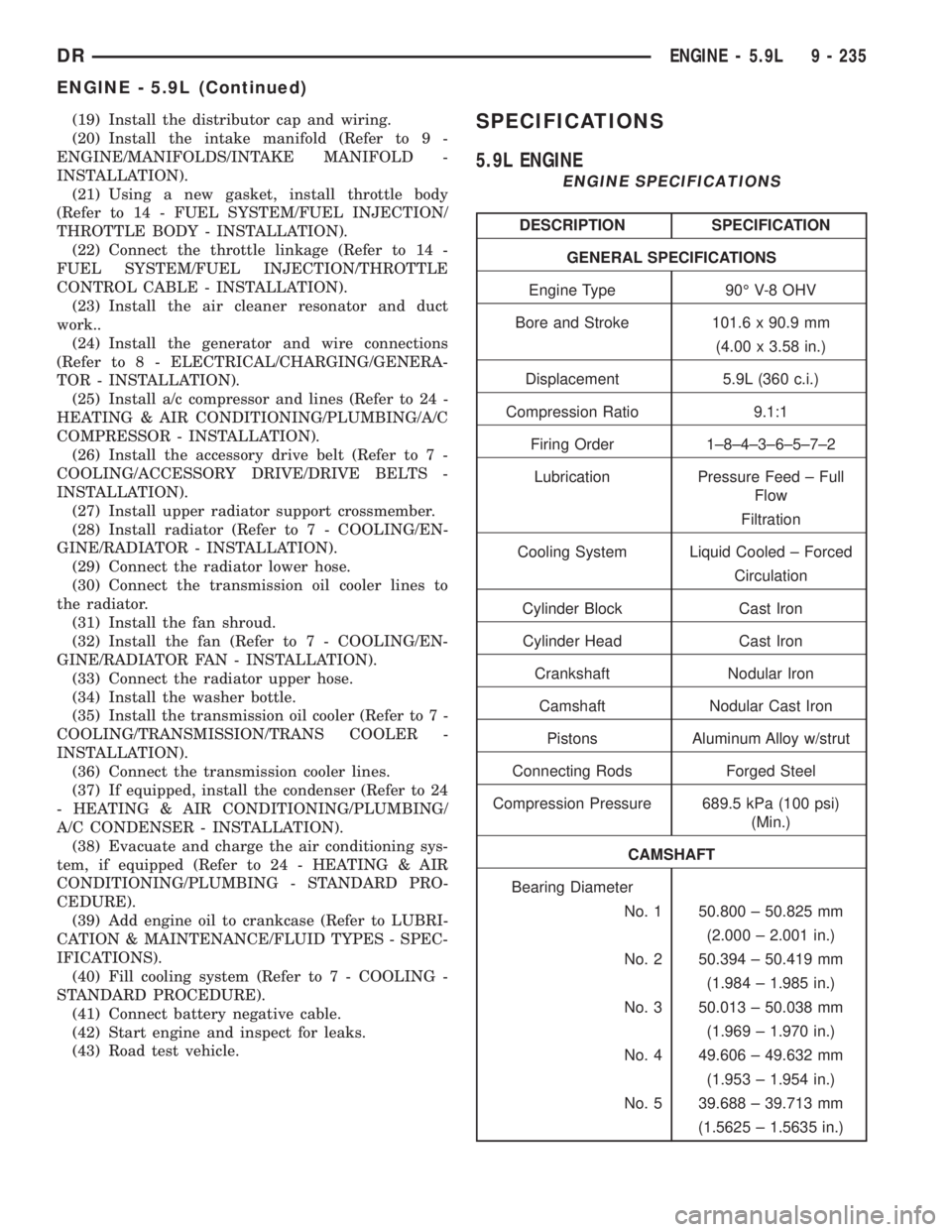

(43) Road test vehicle.SPECIFICATIONS

5.9L ENGINE

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É V-8 OHV

Bore and Stroke 101.6 x 90.9 mm

(4.00 x 3.58 in.)

Displacement 5.9L (360 c.i.)

Compression Ratio 9.1:1

Firing Order 1±8±4±3±6±5±7±2

Lubrication Pressure Feed ± Full

Flow

Filtration

Cooling System Liquid Cooled ± Forced

Circulation

Cylinder Block Cast Iron

Cylinder Head Cast Iron

Crankshaft Nodular Iron

Camshaft Nodular Cast Iron

Pistons Aluminum Alloy w/strut

Connecting Rods Forged Steel

Compression Pressure 689.5 kPa (100 psi)

(Min.)

CAMSHAFT

Bearing Diameter

No. 1 50.800 ± 50.825 mm

(2.000 ± 2.001 in.)

No. 2 50.394 ± 50.419 mm

(1.984 ± 1.985 in.)

No. 3 50.013 ± 50.038 mm

(1.969 ± 1.970 in.)

No. 4 49.606 ± 49.632 mm

(1.953 ± 1.954 in.)

No. 5 39.688 ± 39.713 mm

(1.5625 ± 1.5635 in.)

DRENGINE - 5.9L 9 - 235

ENGINE - 5.9L (Continued)

Page 1524 of 2895

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPMs occur, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL).

(4) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(5) Remove the accessory drive bracket.

(6) Remove the air cleaner.

(7) Perform the Fuel System Pressure release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel lines (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect the accelerator linkage (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL) and if so equipped,

the speed control and transmission kickdown cables.

(9) Remove the return spring.

(10) Remove the distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect the heat indicator sending unit

wire.

(13) Disconnect the heater hoses and bypass hose.

(14) Remove the closed crankcase ventilation and

evaporation control systems.

(15) Remove intake manifold bolts.

(16) Lift the intake manifold and throttle body out

of the engine compartment as an assembly.

(17) Remove and discard the flange side gaskets

and the front and rear end seals.

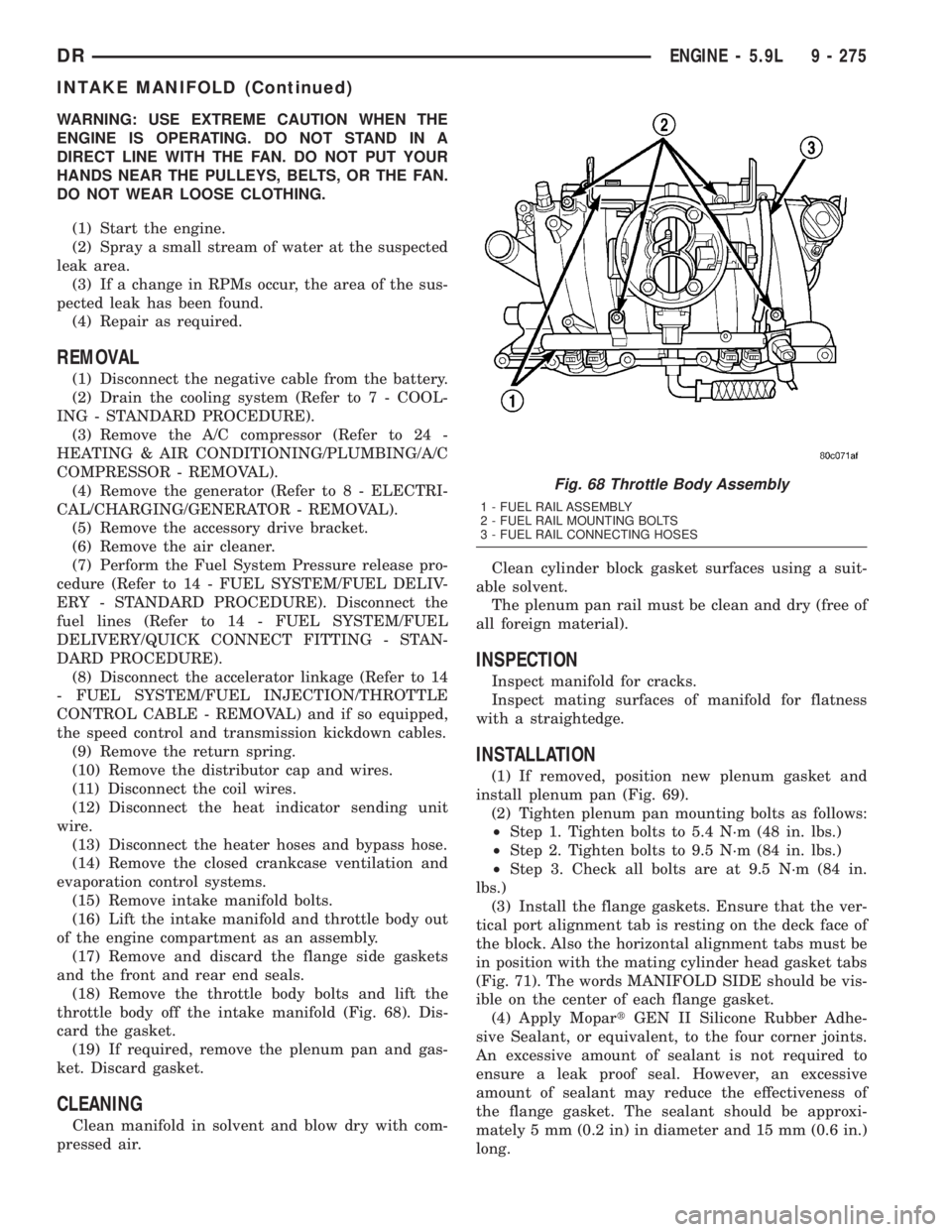

(18) Remove the throttle body bolts and lift the

throttle body off the intake manifold (Fig. 68). Dis-

card the gasket.

(19) If required, remove the plenum pan and gas-

ket. Discard gasket.

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.Clean cylinder block gasket surfaces using a suit-

able solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

INSTALLATION

(1) If removed, position new plenum gasket and

install plenum pan (Fig. 69).

(2) Tighten plenum pan mounting bolts as follows:

²Step 1. Tighten bolts to 5.4 N´m (48 in. lbs.)

²Step 2. Tighten bolts to 9.5 N´m (84 in. lbs.)

²Step 3. Check all bolts are at 9.5 N´m (84 in.

lbs.)

(3) Install the flange gaskets. Ensure that the ver-

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must be

in position with the mating cylinder head gasket tabs

(Fig. 71). The words MANIFOLD SIDE should be vis-

ible on the center of each flange gasket.

(4) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, to the four corner joints.

An excessive amount of sealant is not required to

ensure a leak proof seal. However, an excessive

amount of sealant may reduce the effectiveness of

the flange gasket. The sealant should be approxi-

mately 5 mm (0.2 in) in diameter and 15 mm (0.6 in.)

long.

Fig. 68 Throttle Body Assembly

1 - FUEL RAIL ASSEMBLY

2 - FUEL RAIL MOUNTING BOLTS

3 - FUEL RAIL CONNECTING HOSES

DRENGINE - 5.9L 9 - 275

INTAKE MANIFOLD (Continued)

Page 1539 of 2895

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Disconnect the negative cable(s) from the bat-

tery.

(2) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(3) Place a shop towel around the fuel injectors to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the fuel injectors (Refer

to 14 - FUEL SYSTEM/FUEL INJECTION/FUEL

INJECTOR - REMOVAL).

(4) With all injectors removed, rotate the crank-

shaft using the crankshaft barring tool (PN 7471±B).

(5) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(6) Be sure all fluid has been removed from the

cylinders.

(7) Repair engine or components as necessary to

prevent this problem from occurring again.

(8) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(9) Install fuel injectors (Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(10) Drain engine oil. Remove and discard the oil

filter (Refer to 9 - ENGINE/LUBRICATION/OIL FIL-

TER - REMOVAL).

(11) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(12) Install a new oil filter (Refer to 9 - ENGINE/

LUBRICATION/OIL FILTER - INSTALLATION).

(13) Fill engine crankcase with the specified

amount and grade of oil (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES - SPECIFICA-

TIONS).

(14) Connect the negative cable(s) to the battery.

(15) Start the engine and check for any leaks.

REMOVAL

REMOVALÐENGINE

(1) Disconnect both battery negative cables.

(2) Disconnect engine grid heater harness at grid

heater relays.(3) Disconnect electrical connections from rear of

alternator.

(4) Recover A/C refrigerant. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

(5) Raise vehicle on a hoist.

(6) Drain engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Remove engine oil drain plug and drain engine

oil.

(8) Remove fan/drive assembly. Refer to Section 7

± Fan/Drive Removal

(9) Remove radiator upper hose.

(10) Remove upper fan shroud mounting bolts.

(11) Disconnect the coolant recovery bottle hose

from the radiator fill neck and remove bottle.

(12) Using a 36mm wrench, remove viscous fan/

drive assembly. (Refer to 7 - COOLING/ENGINE/RA-

DIATOR FAN - REMOVAL).

(13) Remove cooling fan and shroud together.

(14) Disconnect heater core supply and return

hoses from the cylinder head fitting and coolant pipe.

(15) Raise vehicle on a hoist.

(16) Remove transmission and transfer case (if

equipped).

(17) Disconnect exhaust pipe from turbocharger

extension pipe.

(18) Disconnect engine harness to vehicle harness

connectors.

(19) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).

(20) Remove flywheel/flexplate.

(21) Remove transmission adapter

(22) Disconnect A/C suction/discharge hose from

the rear of the A/C compressor.

(23) Lower vehicle.

(24) Disconnect lower radiator hose from radiator

outlet.

(25) Automatic transmission models:

(26) Disconnect transmission oil cooler lines from

in front of radiator using special tool #6931

(27) Remove radiator. (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(28) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(29) Disconnect charge air cooler piping.

(30) Remove charge air cooler mounting bolts.

(31) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(32) Remove damper and speed indicator ring from

front of engine.

(33) Disconnect engine block heater connector.

(34) Disconnect A/C compressor and pressure sen-

sor electrical connectors.

9 - 290 ENGINE 5.9L DIESELDR

ENGINE 5.9L DIESEL (Continued)

Page 1566 of 2895

CAMSHAFT & BEARINGS (IN

BLOCK)

REMOVAL

REMOVALÐCAMSHAFT BEARINGS

NOTE: Measure the diameter of each bore. If the

camshaft bore for the first or rear cam bushing is

worn beyond the limit, install a new service bush-

ing. Inspect the rest of the camshaft bores for dam-

age or excessive wear.If the bores without a

bushing are worn beyond the limit, the engine must

be removed for machining and installation of ser-

vice bushings. If badly worn, replace the cylinder

block.

(1) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(2) Remove the bushing from the No.1 bore and

No.7 using a universal cam bushing tool.

(3) Mark the cylinder block so you can align the oil

hole in the cylinder block with the oil hole in the

bushing.

REMOVAL - CAMSHAFT

(1) Disconnect both battery negative cables.

(2) Recover A/C refrigerant (if A/C equipped) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE).

(3) Raise vehicle on hoist.

(4) Drain engine coolant into container suitable for

re-use (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(5) Lower vehicle.

(6) Remove radiator upper hose.

(7) Remove viscous fan/drive assembly and fan

shroud (Refer to 7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL).

(8) Disconnect the coolant recovery bottle hose

from the radiator filler neck.

(9) Disconnect lower radiator hose from radiator

outlet.

(10)Automatic Transmission models:Discon-

nect transmission oil cooler lines from front of radia-

tor using Special Tool 6931 (unless equipped with

finger-release disconnect).

(11) Remove radiator mounting screws and lift

radiator out of engine compartment.

(12) Remove upper radiator support panel.

(13) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(14) Disconnect charge air cooler piping from the

cooler inlet and outlet.(15) Remove the two charge air cooler mounting

bolts.

(16) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(17) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(18) Remove accessory drive belt tensioner.

(19) Remove the fan support/hub assembly.

(20) Remove crankshaft damper and speed indica-

tor ring (Refer to 9 - ENGINE/ENGINE BLOCK/VI-

BRATION DAMPER - REMOVAL).

(21) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the sealing surfaces. Remove dust

seal with cover.

(22) Using Special Tool 7471±B Crankshaft Bar-

ring Tool, rotate the crankshaft to align the timing

marks on the crankshaft and the camshaft gears.

(23) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

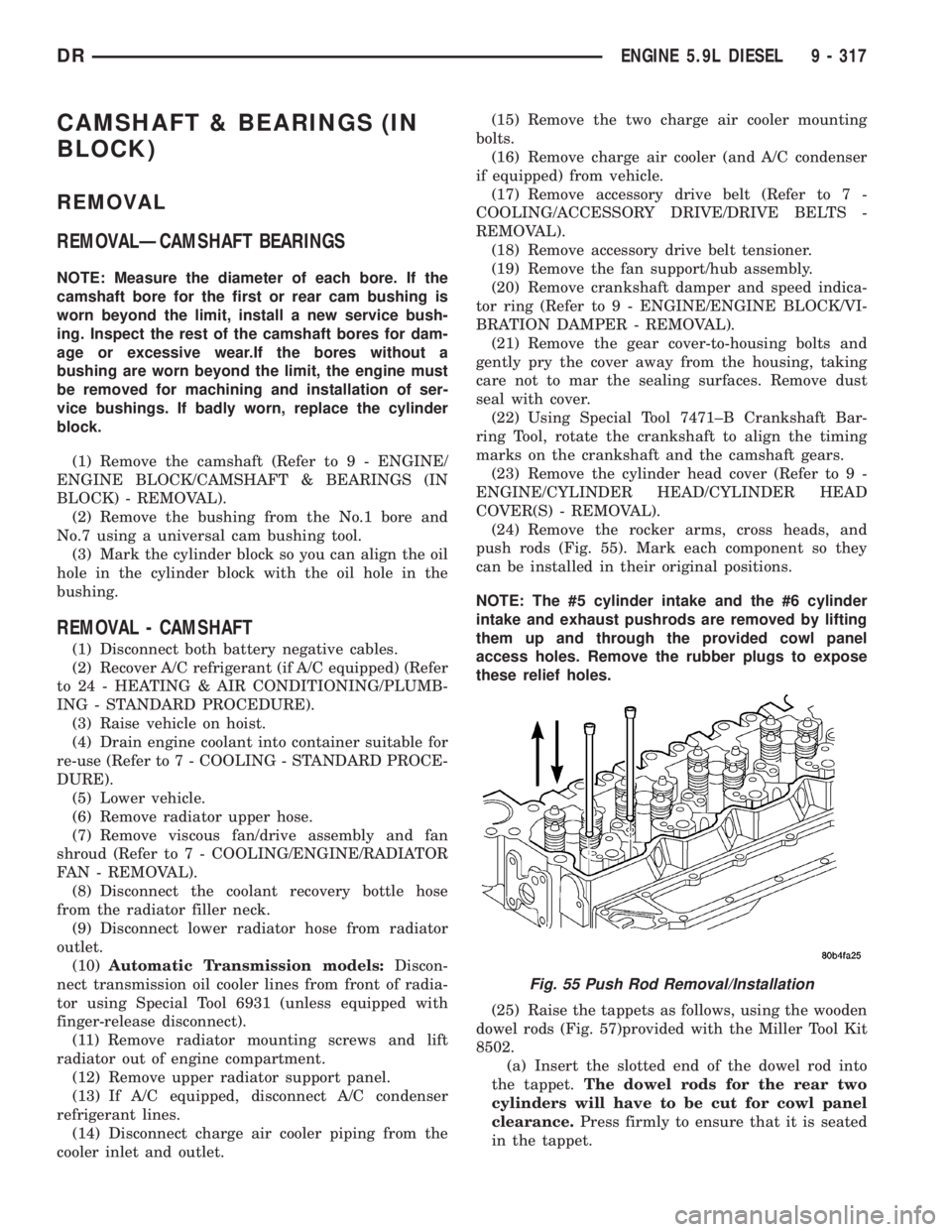

(24) Remove the rocker arms, cross heads, and

push rods (Fig. 55). Mark each component so they

can be installed in their original positions.

NOTE: The #5 cylinder intake and the #6 cylinder

intake and exhaust pushrods are removed by lifting

them up and through the provided cowl panel

access holes. Remove the rubber plugs to expose

these relief holes.

(25) Raise the tappets as follows, using the wooden

dowel rods (Fig. 57)provided with the Miller Tool Kit

8502.

(a) Insert the slotted end of the dowel rod into

the tappet.The dowel rods for the rear two

cylinders will have to be cut for cowl panel

clearance.Press firmly to ensure that it is seated

in the tappet.

Fig. 55 Push Rod Removal/Installation

DRENGINE 5.9L DIESEL 9 - 317

Page 1611 of 2895

(3) Discharge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(4) Remove the upper crossmember.

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

(6) Remove the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(7) Remove the A/C compressor with the lines

attached (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

REMOVAL). Set aside.

(8) If equipped, remove the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(9) Remove the washer fluid reservoir bottle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS -

REMOVAL AND INSTALLATION).

(10) Disconnect the top radiator hose.

(11) Remove the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - REMOVAL).

(12) Remove the fan shroud.

(13) Disconnect the lower radiator hose.

(14) Disconnect the transmission cooler lines.

(15) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(16) Remove the generator with the wire connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - REMOVAL).

(17) Remove the air cleaner.

(18) Disconnect the throttle linkage.

(19) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(20) Remove the upper intake manifold (Refer to 9

- ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(21) Remove the coil assemblies with the ignition

cables.

(22) Disconnect the heater hoses.

(23) Disconnect the power steering hoses, if

equipped.

(24) Perform the Fuel System Pressure release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE). Disconnect

the fuel line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(25) On Manual Transmission vehicles, remove the

shift lever.

(26) Raise and support the vehicle on a hoist.

(27) Remove the drain plug and drain the engine

oil.

(28) Loosen front engine mount thru-bolt nuts.(29) Remove the transmission cooler line brackets

from oil pan.

(30) Disconnect exhaust pipe at manifold.

(31) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(32) Remove transmission.

(33) Lower vehicle.

CAUTION: DO NOT lift the engine by the intake

manifold.

(34) Install an engine lifting fixture.

(35) Remove engine from vehicle and install

engine assembly on a repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install Transmission.

(5) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(6) Install exhaust pipe to manifold.

(7) Install the transmission cooler line brackets

from oil pan.

(8) Tighten the Front mount thru-bolts and nuts to

102N´m (75 ft. lbs.).

(9) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(10) Prime oil pump by squirting oil in the oil fil-

ter mounting hole and filling the J-trap of the front

timing cover. When oil is running out, install oil filter

that has been filled with oil.

(11) Lower the vehicle.

(12) Remove engine lifting fixture.

(13) On Manual Transmission vehicles, install the

shift lever.

(14) Connect the fuel lines (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(15) Connect the heater hoses.

(16) Install the upper intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(17) Install the coil assemblies with the ignition

cables.

(18) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(19) Connect the throttle linkage.

(20) Install the air cleaner box.

9 - 362 ENGINE 8.0LDR

ENGINE 8.0L (Continued)

Page 1612 of 2895

(21) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(22) Install the upper crossmember.

(23) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(24) Connect the lower radiator hose.

(25) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(26) Connect the transmission cooler lines.

(27) Connect the power steering hoses, if equipped.

(28) Install the fan shroud.

(29) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(30) Connect the top radiator hose.

(31) Install the washer fluid reservoir bottle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS - INSTAL-

LATION).

(32) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(33) Install the A/C compressor with the lines

attached (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION).

(34) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(35) Evacuate (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE) and charge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(36) Add coolant to the cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(37) Install the battery.

(38) Warm engine and adjust as required.

(39) Road test vehicle.SPECIFICATIONS

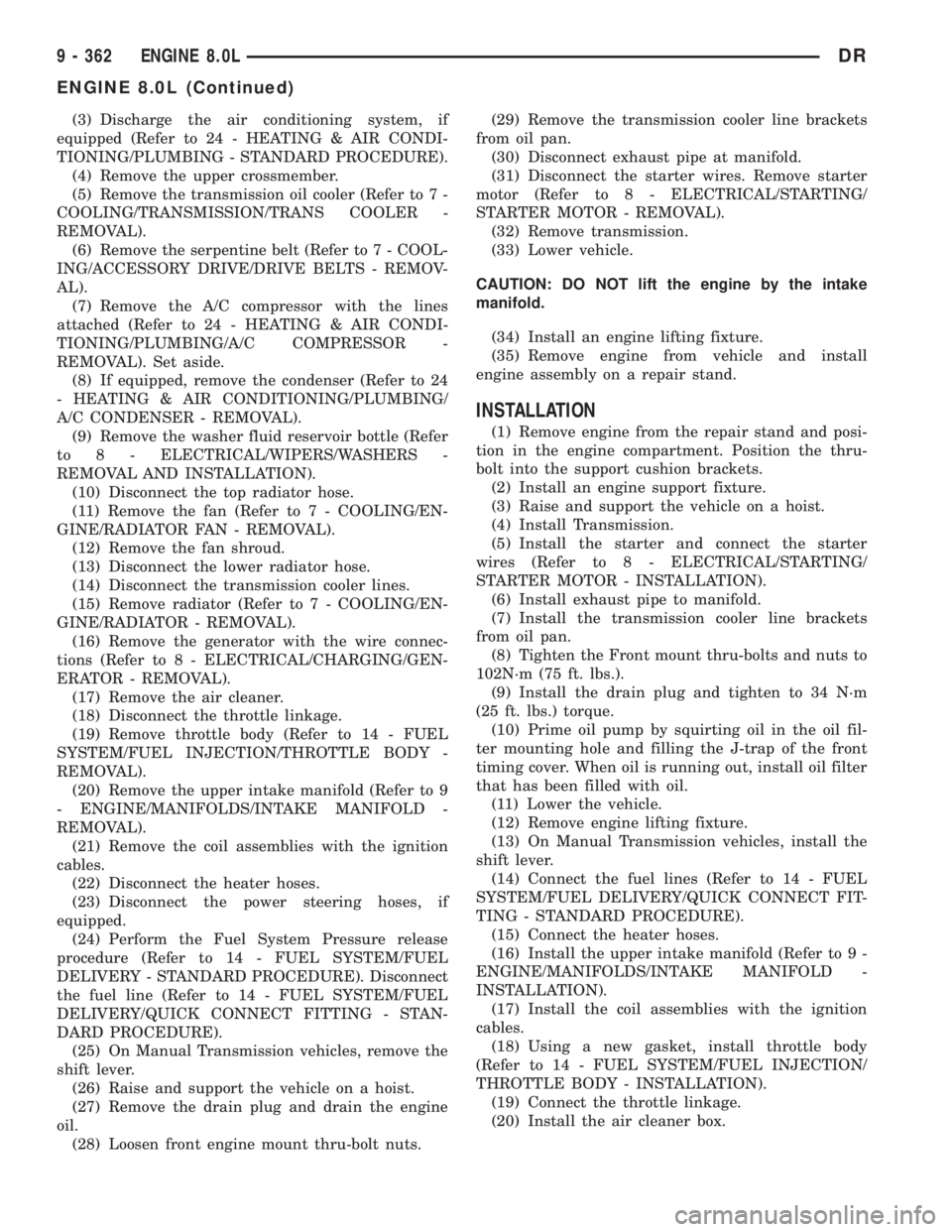

TORQUE

TORQUE CHART 8.0L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Camshaft SprocketÐBolt 75 55 Ð

Camshaft Thrust PlateÐ

Bolts22 16 Ð

Coil Pack BracketÐBolts 21 Ð 190

Connecting Rod CapÐBolts 61 45 Ð

Main BearingÐBolts

Step 1 27 20 Ð

Step 2 115 85 Ð

Crankshaft Pulley/DamperÐ

Bolt312 230 Ð

Crankshaft Rear Seal

RetainerÐ22 16 Ð

Bolts

Cylinder HeadÐBolts

Step 1 58 43 Ð

Step 2 143 105 Ð

Cylinder Head CoverÐBolts 16 Ð 144

Drive Plate to CrankshaftÐ

Bolts75 55 Ð

Drive Plate to Torque

ConverterÐ47 35 Ð

Bolts

EGR TubeÐNut 34 25 Ð

EGR ValveÐBolts 20 Ð 174

Engine Support Bracket/

InsulatorÐ68 50 Ð

Through Bolt

Engine Support Bracket/

Insulator to47 35 Ð

BlockÐBolts

Exhaust Manifold to Cylinder

HeadÐ22 16 Ð

Bolt

Generator MountingÐBolt 41 30 Ð

Generator to Intake Manifold

Bracket41 30 Ð

ÐBolts

DRENGINE 8.0L 9 - 363

ENGINE 8.0L (Continued)

Page 1652 of 2895

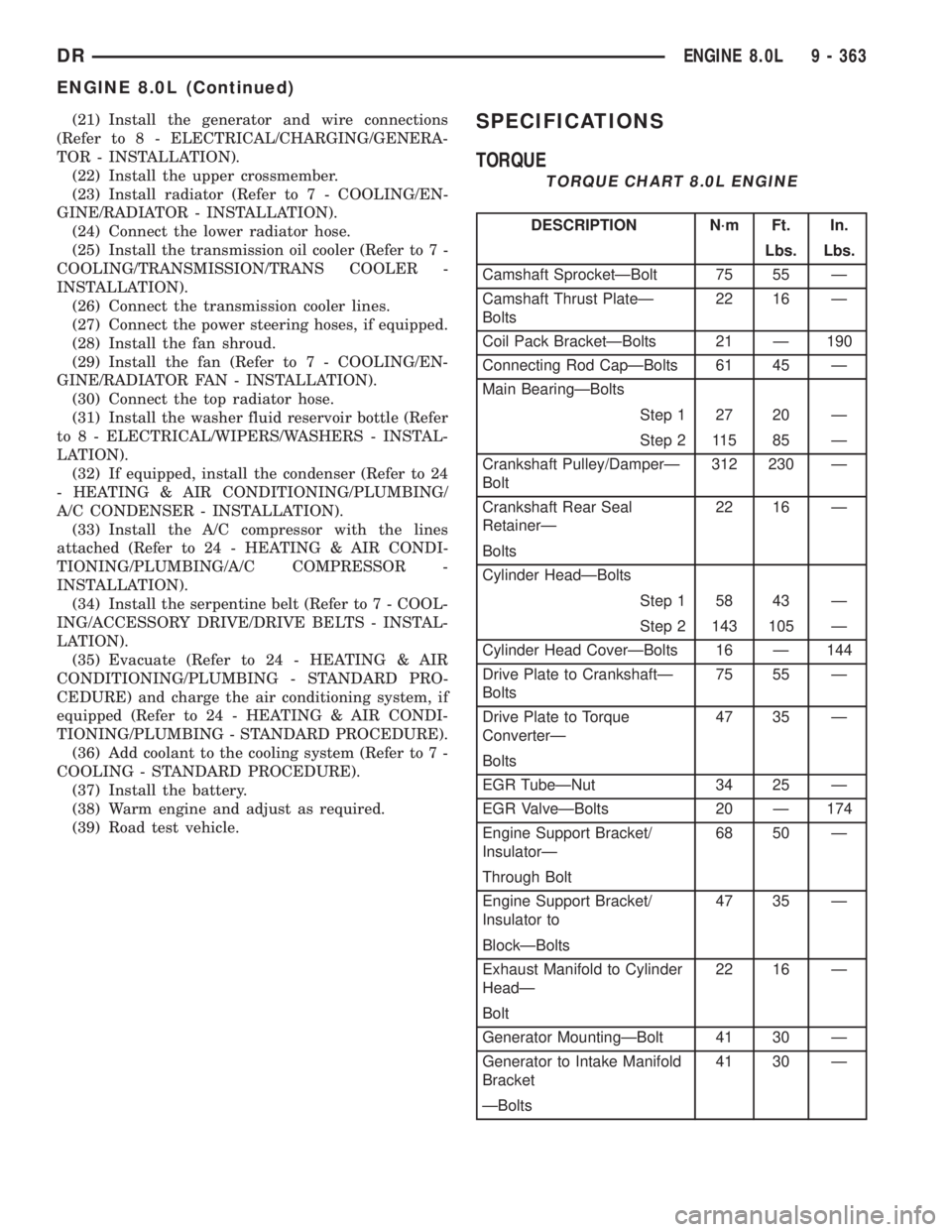

(2) Insert MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, into the four corner joints

an excessive amount of sealant is not required to

ensure a leak proof seal. However, an excessive

amount of sealant may reduce the effectiveness of

the flange gasket. The sealant should be approxi-

mately 5 mm (0.2 in.) in diameter. (Fig. 70).

(3) Position the cross-over gaskets and press firmly

onto the block (Fig. 70).BE SURE THE BLOCK IS

OIL FREE..

(4) The lower intake manifold MUST be installed

within 3 minutes of sealant application. Carefully

lower intake manifold into position on the cylinder

block and heads. After intake manifold is in place,

inspect to make sure seals and gaskets are in place.

Finger start all the lower intake bolts.

(5) Tighten the lower intake manifold bolts in

sequence to 54 N´m (40 ft. lbs.) torque (Fig. 69).

Recheck all bolts are tightened to 54 N´m (40 ft. lbs.)

torque.

(6) Using a new gasket, position the upper intake

manifold onto the lower intake manifold.

(7) Finger start all bolts, alternate one side to the

other.

(8) Tighten upper intake manifold bolts in

sequence to 22 N´m (16 ft. lbs.) torque (Fig. 68).

(9) Using a new gasket, install the throttle body

onto the upper intake manifold. Tighten the bolts to

23 N´m (200 in. lbs.) torque.

(10) Install closed crankcase ventilation and evap-

oration control systems.

(11) Connect the heater hoses and bypass hose.

(12) Connect the vacuum lines.

(13) Install the coil assemblies and the ignition

wires.

(14) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.(15) Install the fuel lines (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(16) Using a new gasket, install the air cleaner

housing. Tighten the nuts to 11 N´m (96 in. lbs.)

torque. Install the air cleaner filter and cover.

(17) Install the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION). Position the com-

pressor brace and install the bolts. Tighten the brace

bolts to 41 N´m (30 ft. lbs.) torque.

(18) Install the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - INSTALLATION).

Position the generator brace and install the bolts.

Tighten the brace bolts to 41 N´m (30 ft. lbs.) torque.

(19) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(20) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(21) Connect the negative cable to the battery.

(22) Start engine check for leaks.

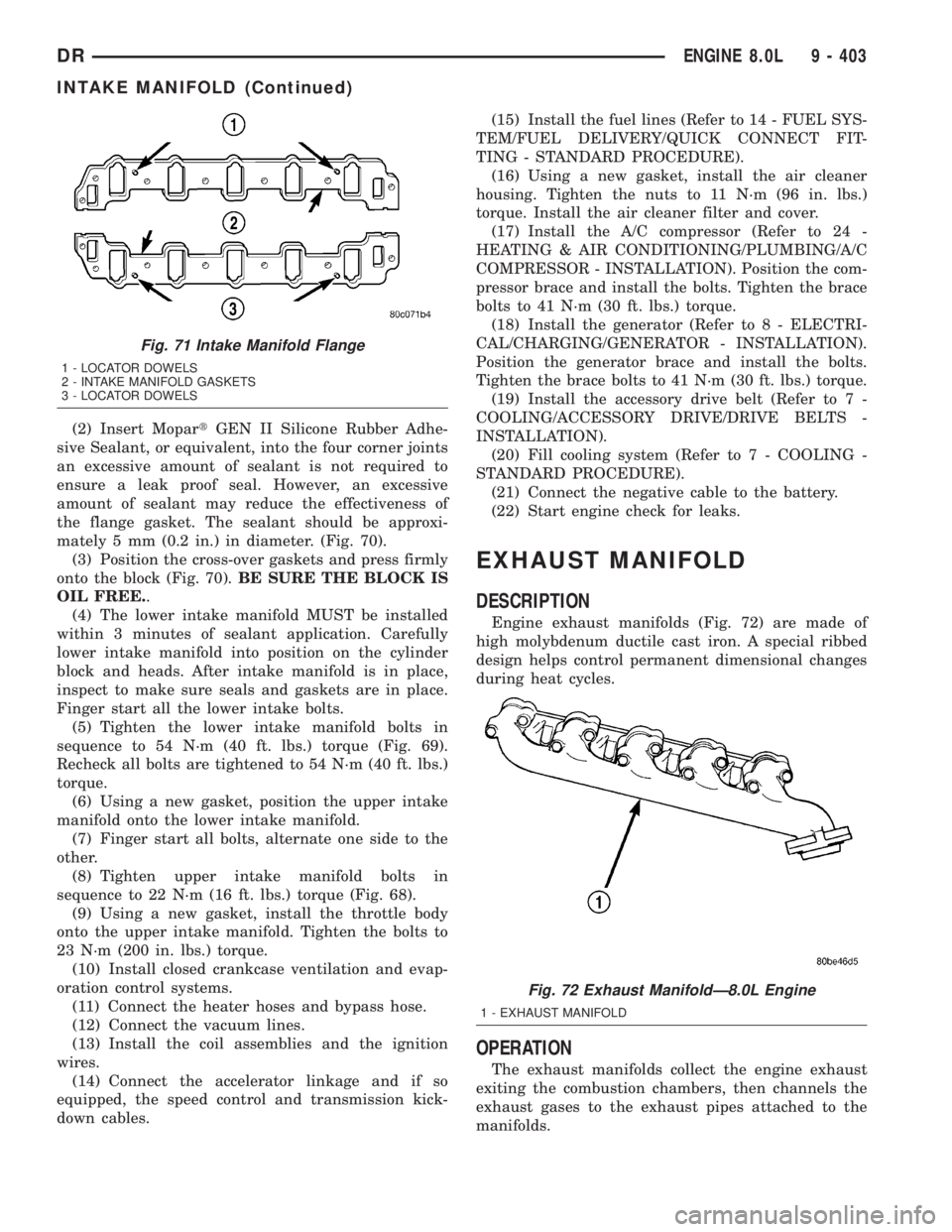

EXHAUST MANIFOLD

DESCRIPTION

Engine exhaust manifolds (Fig. 72) are made of

high molybdenum ductile cast iron. A special ribbed

design helps control permanent dimensional changes

during heat cycles.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

exhaust gases to the exhaust pipes attached to the

manifolds.

Fig. 71 Intake Manifold Flange

1 - LOCATOR DOWELS

2 - INTAKE MANIFOLD GASKETS

3 - LOCATOR DOWELS

Fig. 72 Exhaust ManifoldÐ8.0L Engine

1 - EXHAUST MANIFOLD

DRENGINE 8.0L 9 - 403

INTAKE MANIFOLD (Continued)

Page 1654 of 2895

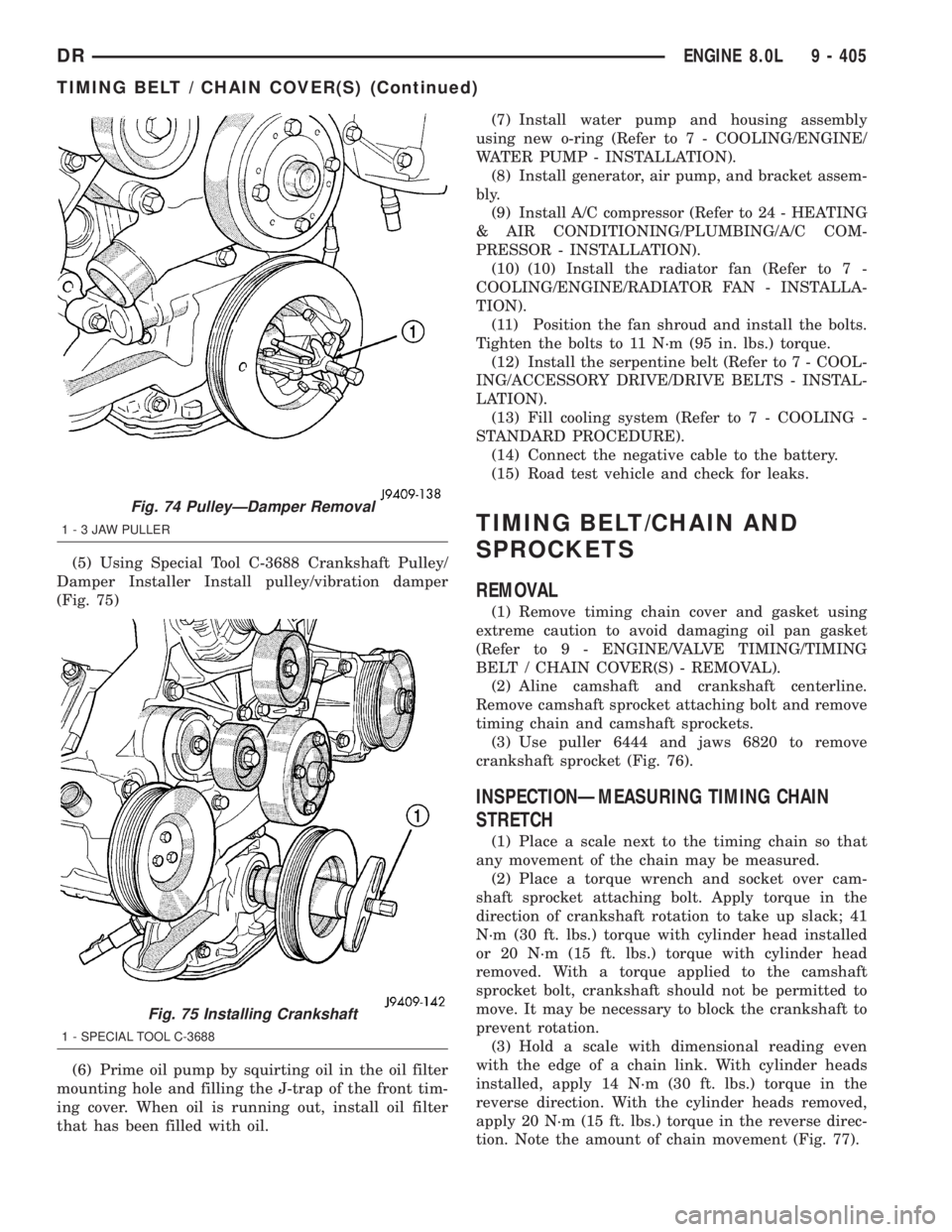

(5) Using Special Tool C-3688 Crankshaft Pulley/

Damper Installer Install pulley/vibration damper

(Fig. 75)

(6) Prime oil pump by squirting oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.(7) Install water pump and housing assembly

using new o-ring (Refer to 7 - COOLING/ENGINE/

WATER PUMP - INSTALLATION).

(8) Install generator, air pump, and bracket assem-

bly.

(9) Install A/C compressor (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(10) (10) Install the radiator fan (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(11) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(12) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect the negative cable to the battery.

(15) Road test vehicle and check for leaks.

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Remove timing chain cover and gasket using

extreme caution to avoid damaging oil pan gasket

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(2) Aline camshaft and crankshaft centerline.

Remove camshaft sprocket attaching bolt and remove

timing chain and camshaft sprockets.

(3) Use puller 6444 and jaws 6820 to remove

crankshaft sprocket (Fig. 76).

INSPECTIONÐMEASURING TIMING CHAIN

STRETCH

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2) Place a torque wrench and socket over cam-

shaft sprocket attaching bolt. Apply torque in the

direction of crankshaft rotation to take up slack; 41

N´m (30 ft. lbs.) torque with cylinder head installed

or 20 N´m (15 ft. lbs.) torque with cylinder head

removed. With a torque applied to the camshaft

sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3) Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads

installed, apply 14 N´m (30 ft. lbs.) torque in the

reverse direction. With the cylinder heads removed,

apply 20 N´m (15 ft. lbs.) torque in the reverse direc-

tion. Note the amount of chain movement (Fig. 77).

Fig. 74 PulleyÐDamper Removal

1-3JAWPULLER

Fig. 75 Installing Crankshaft

1 - SPECIAL TOOL C-3688

DRENGINE 8.0L 9 - 405

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1671 of 2895

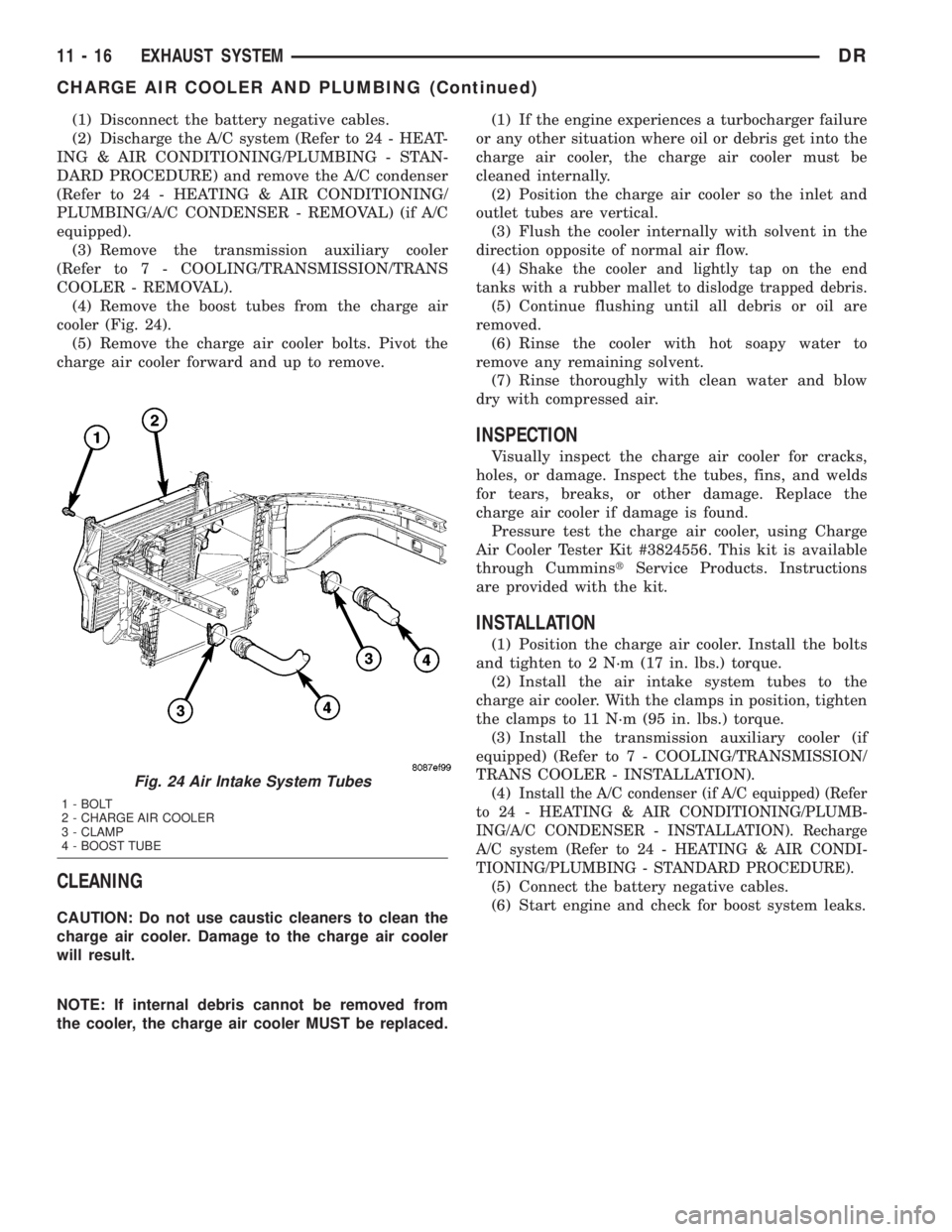

(1) Disconnect the battery negative cables.

(2) Discharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE) and remove the A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) (if A/C

equipped).

(3) Remove the transmission auxiliary cooler

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - REMOVAL).

(4) Remove the boost tubes from the charge air

cooler (Fig. 24).

(5) Remove the charge air cooler bolts. Pivot the

charge air cooler forward and up to remove.

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.

(4)

Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit #3824556. This kit is available

through CumminstService Products. Instructions

are provided with the kit.

INSTALLATION

(1) Position the charge air cooler. Install the bolts

and tighten to 2 N´m (17 in. lbs.) torque.

(2) Install the air intake system tubes to the

charge air cooler. With the clamps in position, tighten

the clamps to 11 N´m (95 in. lbs.) torque.

(3) Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - INSTALLATION).

(4)

Install the A/C condenser (if A/C equipped) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - INSTALLATION). Recharge

A/C system (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(5) Connect the battery negative cables.

(6) Start engine and check for boost system leaks.

Fig. 24 Air Intake System Tubes

1 - BOLT

2 - CHARGE AIR COOLER

3 - CLAMP

4 - BOOST TUBE

11 - 16 EXHAUST SYSTEMDR

CHARGE AIR COOLER AND PLUMBING (Continued)