torque DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 150 of 2895

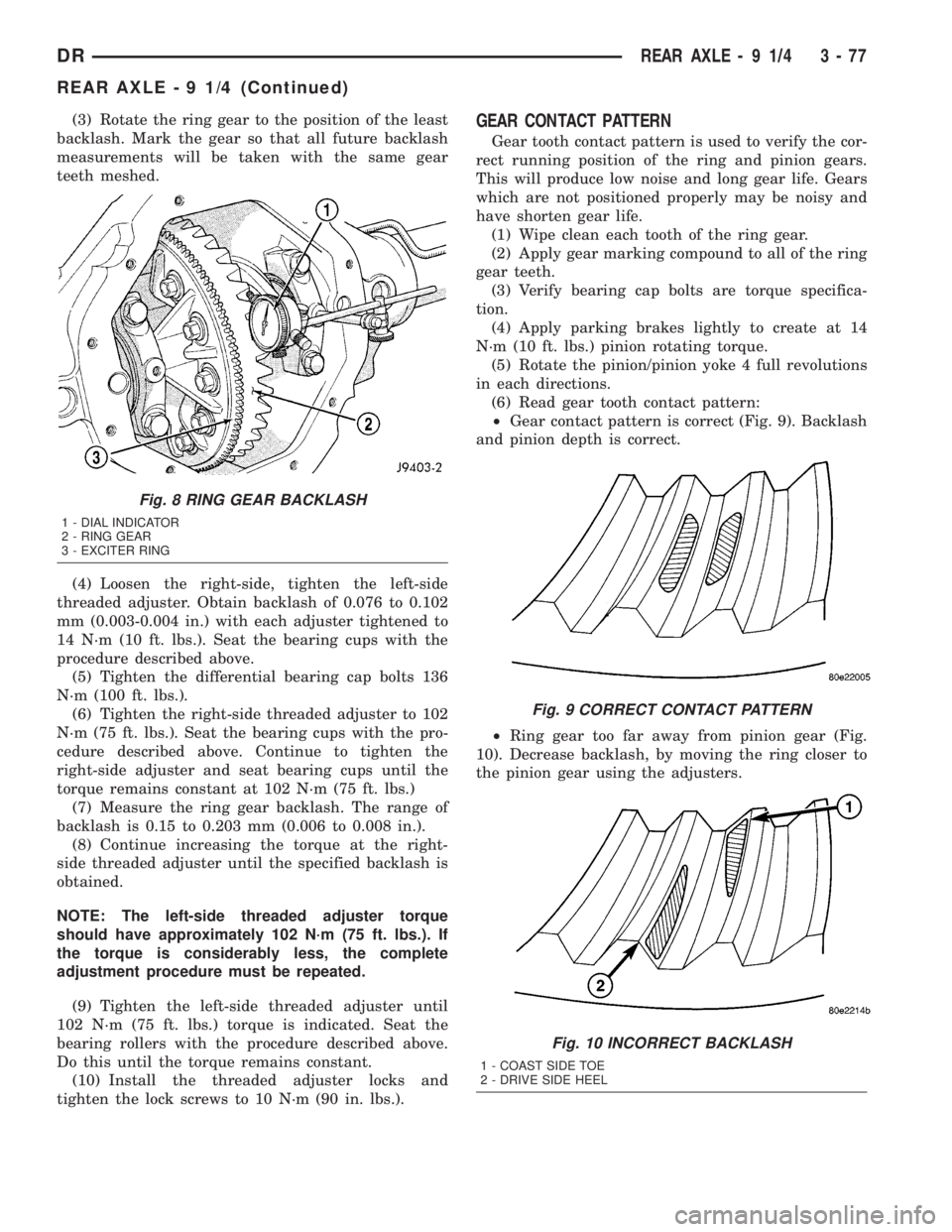

(3) Rotate the ring gear to the position of the least

backlash. Mark the gear so that all future backlash

measurements will be taken with the same gear

teeth meshed.

(4) Loosen the right-side, tighten the left-side

threaded adjuster. Obtain backlash of 0.076 to 0.102

mm (0.003-0.004 in.) with each adjuster tightened to

14 N´m (10 ft. lbs.). Seat the bearing cups with the

procedure described above.

(5) Tighten the differential bearing cap bolts 136

N´m (100 ft. lbs.).

(6) Tighten the right-side threaded adjuster to 102

N´m (75 ft. lbs.). Seat the bearing cups with the pro-

cedure described above. Continue to tighten the

right-side adjuster and seat bearing cups until the

torque remains constant at 102 N´m (75 ft. lbs.)

(7) Measure the ring gear backlash. The range of

backlash is 0.15 to 0.203 mm (0.006 to 0.008 in.).

(8) Continue increasing the torque at the right-

side threaded adjuster until the specified backlash is

obtained.

NOTE: The left-side threaded adjuster torque

should have approximately 102 N´m (75 ft. lbs.). If

the torque is considerably less, the complete

adjustment procedure must be repeated.

(9) Tighten the left-side threaded adjuster until

102 N´m (75 ft. lbs.) torque is indicated. Seat the

bearing rollers with the procedure described above.

Do this until the torque remains constant.

(10) Install the threaded adjuster locks and

tighten the lock screws to 10 N´m (90 in. lbs.).GEAR CONTACT PATTERN

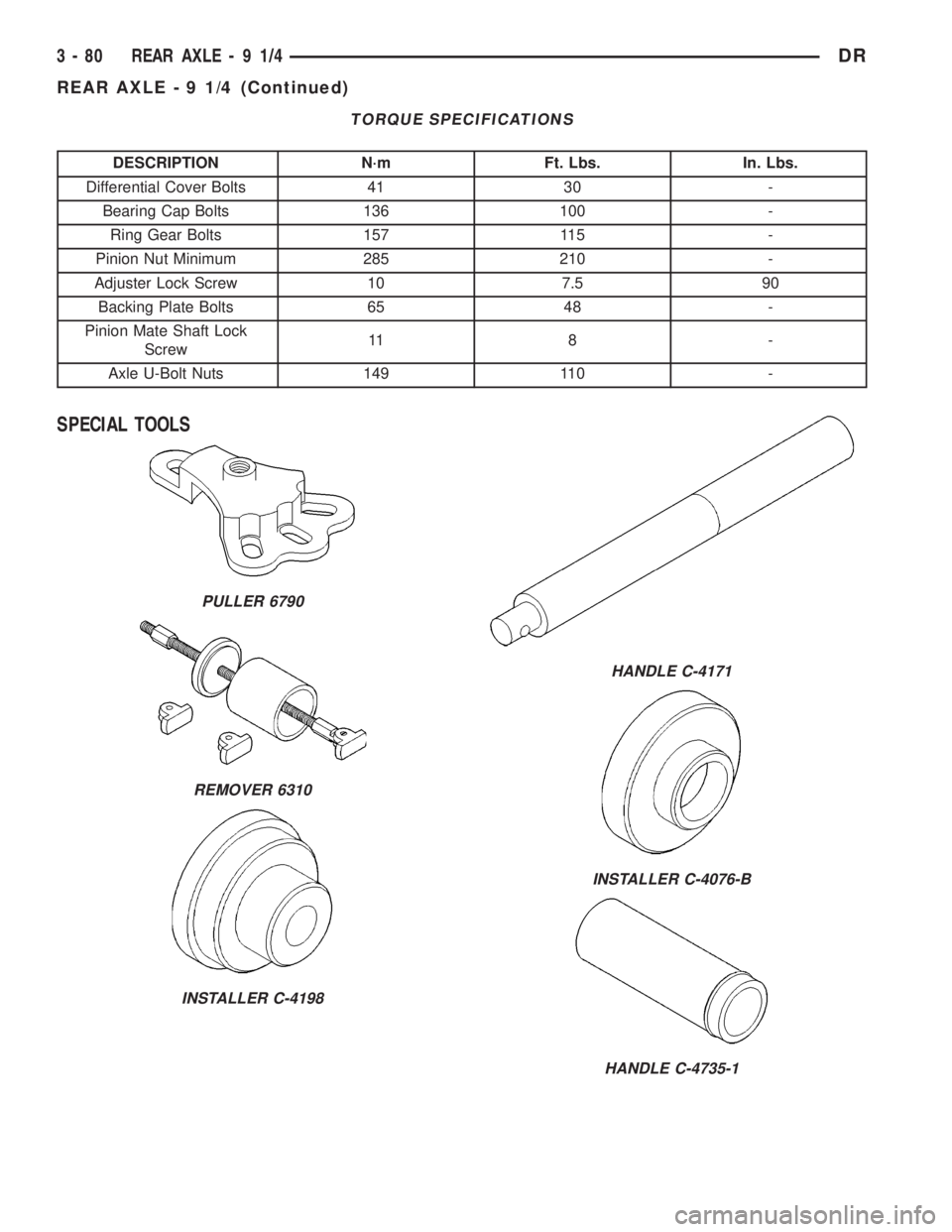

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

²Gear contact pattern is correct (Fig. 9). Backlash

and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig.

10). Decrease backlash, by moving the ring closer to

the pinion gear using the adjusters.

Fig. 8 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

3 - EXCITER RING

Fig. 9 CORRECT CONTACT PATTERN

Fig. 10 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

DRREAR AXLE - 9 1/4 3 - 77

REAR AXLE - 9 1/4 (Continued)

Page 153 of 2895

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Differential Cover Bolts 41 30 -

Bearing Cap Bolts 136 100 -

Ring Gear Bolts 157 115 -

Pinion Nut Minimum 285 210 -

Adjuster Lock Screw 10 7.5 90

Backing Plate Bolts 65 48 -

Pinion Mate Shaft Lock

Screw11 8 -

Axle U-Bolt Nuts 149 110 -

SPECIAL TOOLS

PULLER 6790

REMOVER 6310

INSTALLER C-4198

HANDLE C-4171

INSTALLER C-4076-B

HANDLE C-4735-1

3 - 80 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 158 of 2895

(3) Coat the lip of thenewaxle seal with axle

lubricant and install with Installer C-4076-B and

Handle C-4735-1.

NOTE: When tool contacts the axle tube, the seal is

installed to the correct depth.

(4) Install the axle shaft.

(5) Install differential cover and fill with gear

lubricant to the bottom of the fill plug hole.

PINION SEAL

REMOVAL

(1) Mark universal joint, companion flange and

pinion shaft for installation reference.

(2) Remove propeller shaft from the companion

flange.

(3) Remove the brake rotors to prevent any drag.

(4) Rotate companion flange three or four times

and record pinion rotating torque with an inch pound

torque wrench.

(5) Install two bolts into the companion flange

threaded holes, 180É apart. Position Holder 6719A

against the companion flange and install and tighten

two bolts and washers into the remaining holes.

(6) Hold the companion flange with Holder 6719A

and remove pinion nut and washer.

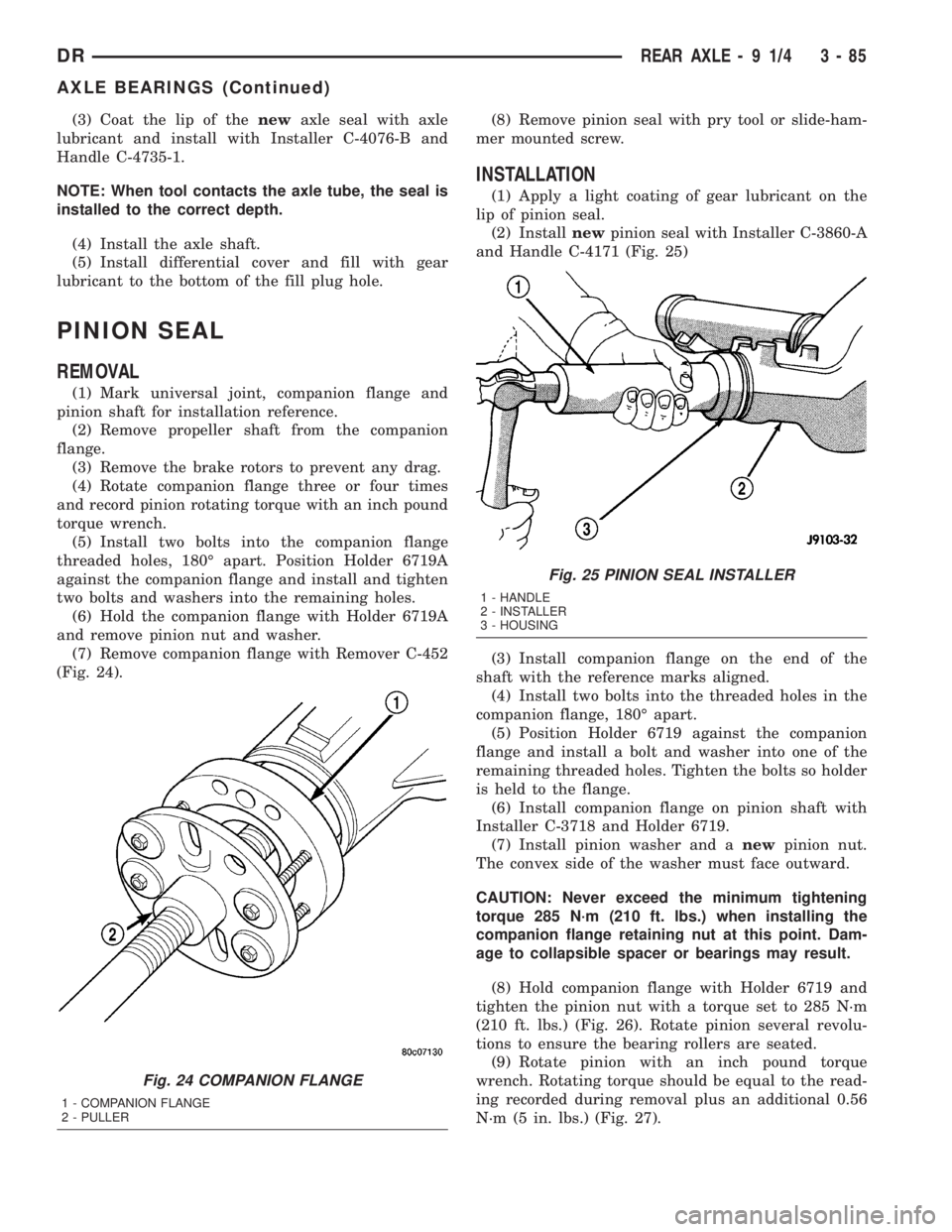

(7) Remove companion flange with Remover C-452

(Fig. 24).(8) Remove pinion seal with pry tool or slide-ham-

mer mounted screw.

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal.

(2) Installnewpinion seal with Installer C-3860-A

and Handle C-4171 (Fig. 25)

(3) Install companion flange on the end of the

shaft with the reference marks aligned.

(4) Install two bolts into the threaded holes in the

companion flange, 180É apart.

(5) Position Holder 6719 against the companion

flange and install a bolt and washer into one of the

remaining threaded holes. Tighten the bolts so holder

is held to the flange.

(6) Install companion flange on pinion shaft with

Installer C-3718 and Holder 6719.

(7) Install pinion washer and anewpinion nut.

The convex side of the washer must face outward.

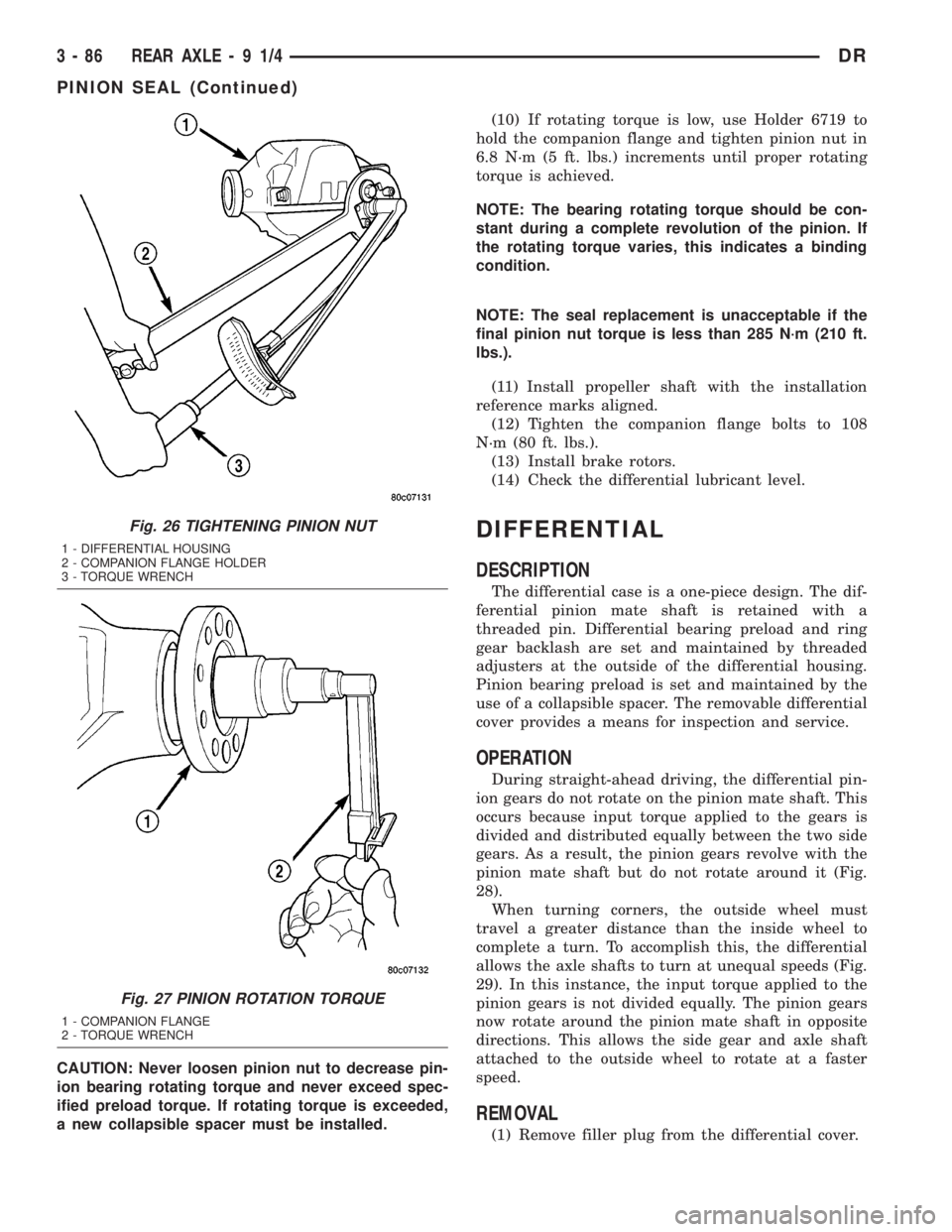

CAUTION: Never exceed the minimum tightening

torque 285 N´m (210 ft. lbs.) when installing the

companion flange retaining nut at this point. Dam-

age to collapsible spacer or bearings may result.

(8) Hold companion flange with Holder 6719 and

tighten the pinion nut with a torque set to 285 N´m

(210 ft. lbs.) (Fig. 26). Rotate pinion several revolu-

tions to ensure the bearing rollers are seated.

(9) Rotate pinion with an inch pound torque

wrench. Rotating torque should be equal to the read-

ing recorded during removal plus an additional 0.56

N´m (5 in. lbs.) (Fig. 27).

Fig. 24 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PULLER

Fig. 25 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

3 - HOUSING

DRREAR AXLE - 9 1/4 3 - 85

AXLE BEARINGS (Continued)

Page 159 of 2895

CAUTION: Never loosen pinion nut to decrease pin-

ion bearing rotating torque and never exceed spec-

ified preload torque. If rotating torque is exceeded,

a new collapsible spacer must be installed.(10) If rotating torque is low, use Holder 6719 to

hold the companion flange and tighten pinion nut in

6.8 N´m (5 ft. lbs.) increments until proper rotating

torque is achieved.

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

NOTE: The seal replacement is unacceptable if the

final pinion nut torque is less than 285 N´m (210 ft.

lbs.).

(11) Install propeller shaft with the installation

reference marks aligned.

(12) Tighten the companion flange bolts to 108

N´m (80 ft. lbs.).

(13) Install brake rotors.

(14) Check the differential lubricant level.

DIFFERENTIAL

DESCRIPTION

The differential case is a one-piece design. The dif-

ferential pinion mate shaft is retained with a

threaded pin. Differential bearing preload and ring

gear backlash are set and maintained by threaded

adjusters at the outside of the differential housing.

Pinion bearing preload is set and maintained by the

use of a collapsible spacer. The removable differential

cover provides a means for inspection and service.

OPERATION

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig.

28).

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

29). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

REMOVAL

(1) Remove filler plug from the differential cover.

Fig. 26 TIGHTENING PINION NUT

1 - DIFFERENTIAL HOUSING

2 - COMPANION FLANGE HOLDER

3 - TORQUE WRENCH

Fig. 27 PINION ROTATION TORQUE

1 - COMPANION FLANGE

2 - TORQUE WRENCH

3 - 86 REAR AXLE-91/4DR

PINION SEAL (Continued)

Page 161 of 2895

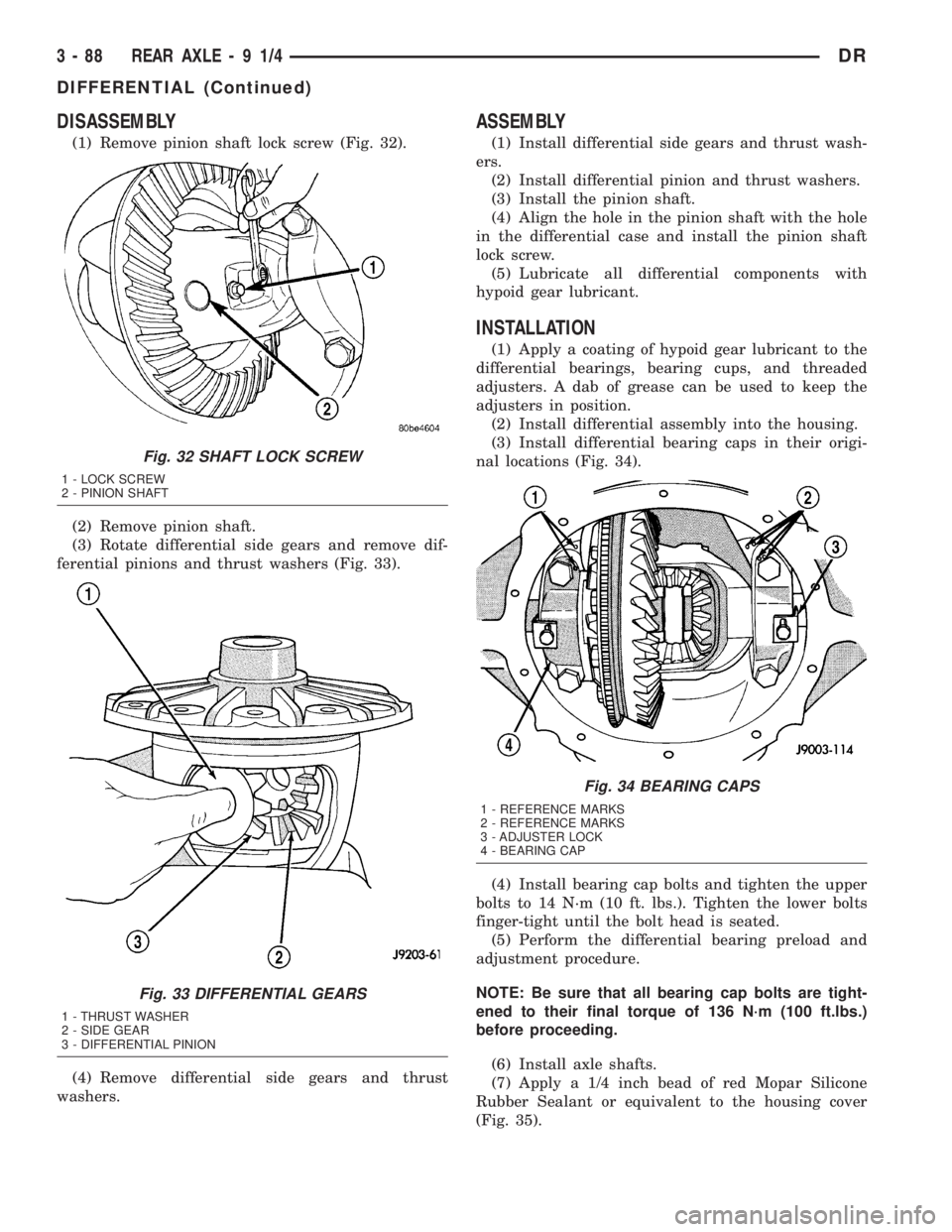

DISASSEMBLY

(1) Remove pinion shaft lock screw (Fig. 32).

(2) Remove pinion shaft.

(3) Rotate differential side gears and remove dif-

ferential pinions and thrust washers (Fig. 33).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install differential pinion and thrust washers.

(3) Install the pinion shaft.

(4) Align the hole in the pinion shaft with the hole

in the differential case and install the pinion shaft

lock screw.

(5) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

(1) Apply a coating of hypoid gear lubricant to the

differential bearings, bearing cups, and threaded

adjusters. A dab of grease can be used to keep the

adjusters in position.

(2) Install differential assembly into the housing.

(3) Install differential bearing caps in their origi-

nal locations (Fig. 34).

(4) Install bearing cap bolts and tighten the upper

bolts to 14 N´m (10 ft. lbs.). Tighten the lower bolts

finger-tight until the bolt head is seated.

(5) Perform the differential bearing preload and

adjustment procedure.

NOTE: Be sure that all bearing cap bolts are tight-

ened to their final torque of 136 N´m (100 ft.lbs.)

before proceeding.

(6) Install axle shafts.

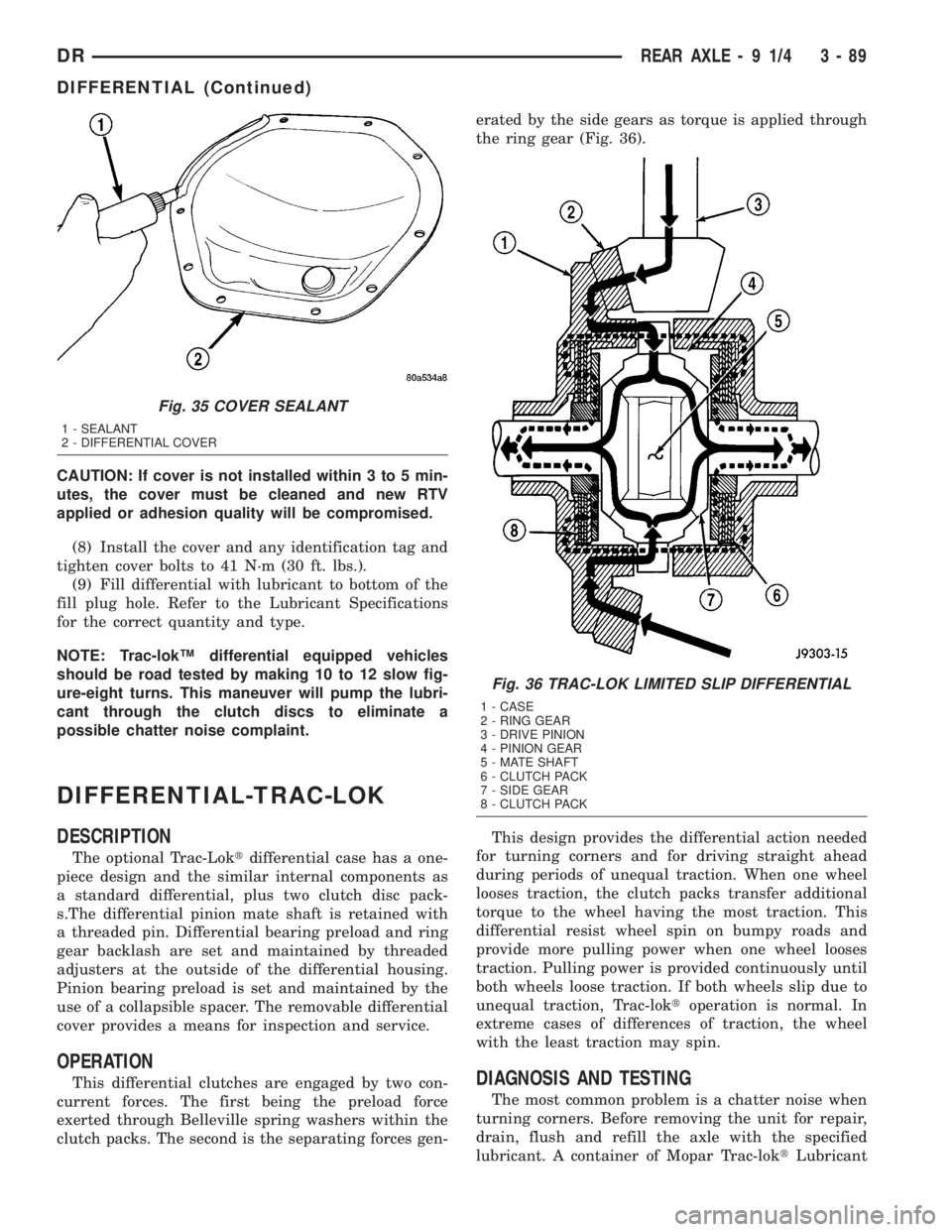

(7) Apply a 1/4 inch bead of red Mopar Silicone

Rubber Sealant or equivalent to the housing cover

(Fig. 35).

Fig. 32 SHAFT LOCK SCREW

1 - LOCK SCREW

2 - PINION SHAFT

Fig. 33 DIFFERENTIAL GEARS

1 - THRUST WASHER

2 - SIDE GEAR

3 - DIFFERENTIAL PINION

Fig. 34 BEARING CAPS

1 - REFERENCE MARKS

2 - REFERENCE MARKS

3 - ADJUSTER LOCK

4 - BEARING CAP

3 - 88 REAR AXLE-91/4DR

DIFFERENTIAL (Continued)

Page 162 of 2895

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(8) Install the cover and any identification tag and

tighten cover bolts to 41 N´m (30 ft. lbs.).

(9) Fill differential with lubricant to bottom of the

fill plug hole. Refer to the Lubricant Specifications

for the correct quantity and type.

NOTE: Trac-lokŸ differential equipped vehicles

should be road tested by making 10 to 12 slow fig-

ure-eight turns. This maneuver will pump the lubri-

cant through the clutch discs to eliminate a

possible chatter noise complaint.

DIFFERENTIAL-TRAC-LOK

DESCRIPTION

The optional Trac-Loktdifferential case has a one-

piece design and the similar internal components as

a standard differential, plus two clutch disc pack-

s.The differential pinion mate shaft is retained with

a threaded pin. Differential bearing preload and ring

gear backlash are set and maintained by threaded

adjusters at the outside of the differential housing.

Pinion bearing preload is set and maintained by the

use of a collapsible spacer. The removable differential

cover provides a means for inspection and service.

OPERATION

This differential clutches are engaged by two con-

current forces. The first being the preload force

exerted through Belleville spring washers within the

clutch packs. The second is the separating forces gen-erated by the side gears as torque is applied through

the ring gear (Fig. 36).

This design provides the differential action needed

for turning corners and for driving straight ahead

during periods of unequal traction. When one wheel

looses traction, the clutch packs transfer additional

torque to the wheel having the most traction. This

differential resist wheel spin on bumpy roads and

provide more pulling power when one wheel looses

traction. Pulling power is provided continuously until

both wheels loose traction. If both wheels slip due to

unequal traction, Trac-loktoperation is normal. In

extreme cases of differences of traction, the wheel

with the least traction may spin.DIAGNOSIS AND TESTING

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. A container of Mopar Trac-loktLubricant

Fig. 35 COVER SEALANT

1 - SEALANT

2 - DIFFERENTIAL COVER

Fig. 36 TRAC-LOK LIMITED SLIP DIFFERENTIAL

1 - CASE

2 - RING GEAR

3 - DRIVE PINION

4 - PINION GEAR

5 - MATE SHAFT

6 - CLUTCH PACK

7 - SIDE GEAR

8 - CLUTCH PACK

DRREAR AXLE - 9 1/4 3 - 89

DIFFERENTIAL (Continued)

Page 163 of 2895

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

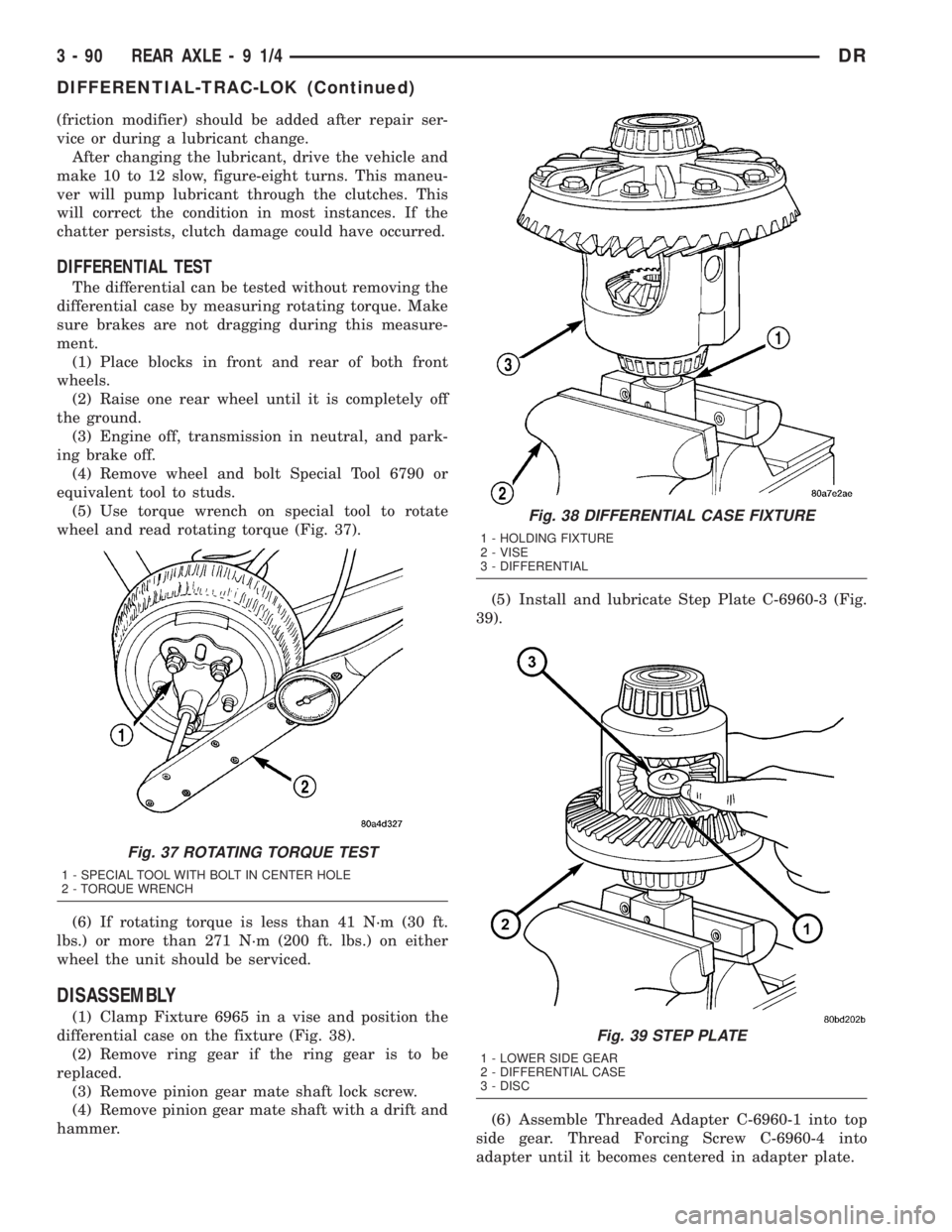

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 37).

(6) If rotating torque is less than 41 N´m (30 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

DISASSEMBLY

(1) Clamp Fixture 6965 in a vise and position the

differential case on the fixture (Fig. 38).

(2) Remove ring gear if the ring gear is to be

replaced.

(3) Remove pinion gear mate shaft lock screw.

(4) Remove pinion gear mate shaft with a drift and

hammer.(5) Install and lubricate Step Plate C-6960-3 (Fig.

39).

(6) Assemble Threaded Adapter C-6960-1 into top

side gear. Thread Forcing Screw C-6960-4 into

adapter until it becomes centered in adapter plate.

Fig. 37 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 38 DIFFERENTIAL CASE FIXTURE

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

Fig. 39 STEP PLATE

1 - LOWER SIDE GEAR

2 - DIFFERENTIAL CASE

3 - DISC

3 - 90 REAR AXLE-91/4DR

DIFFERENTIAL-TRAC-LOK (Continued)

Page 164 of 2895

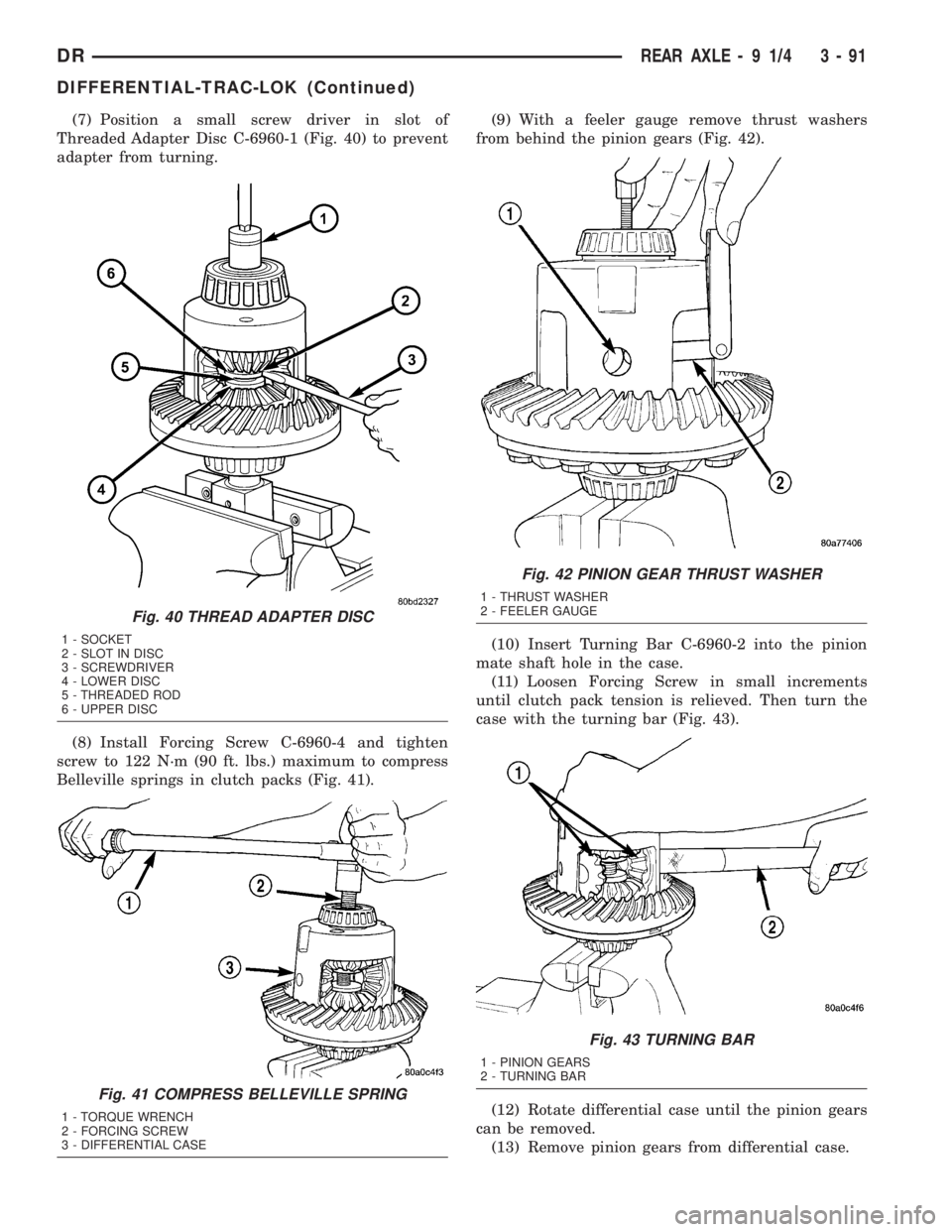

(7) Position a small screw driver in slot of

Threaded Adapter Disc C-6960-1 (Fig. 40) to prevent

adapter from turning.

(8) Install Forcing Screw C-6960-4 and tighten

screw to 122 N´m (90 ft. lbs.) maximum to compress

Belleville springs in clutch packs (Fig. 41).(9) With a feeler gauge remove thrust washers

from behind the pinion gears (Fig. 42).

(10) Insert Turning Bar C-6960-2 into the pinion

mate shaft hole in the case.

(11) Loosen Forcing Screw in small increments

until clutch pack tension is relieved. Then turn the

case with the turning bar (Fig. 43).

(12) Rotate differential case until the pinion gears

can be removed.

(13) Remove pinion gears from differential case.

Fig. 40 THREAD ADAPTER DISC

1 - SOCKET

2 - SLOT IN DISC

3 - SCREWDRIVER

4 - LOWER DISC

5 - THREADED ROD

6 - UPPER DISC

Fig. 41 COMPRESS BELLEVILLE SPRING

1 - TORQUE WRENCH

2 - FORCING SCREW

3 - DIFFERENTIAL CASE

Fig. 42 PINION GEAR THRUST WASHER

1 - THRUST WASHER

2 - FEELER GAUGE

Fig. 43 TURNING BAR

1 - PINION GEARS

2 - TURNING BAR

DRREAR AXLE - 9 1/4 3 - 91

DIFFERENTIAL-TRAC-LOK (Continued)

Page 171 of 2895

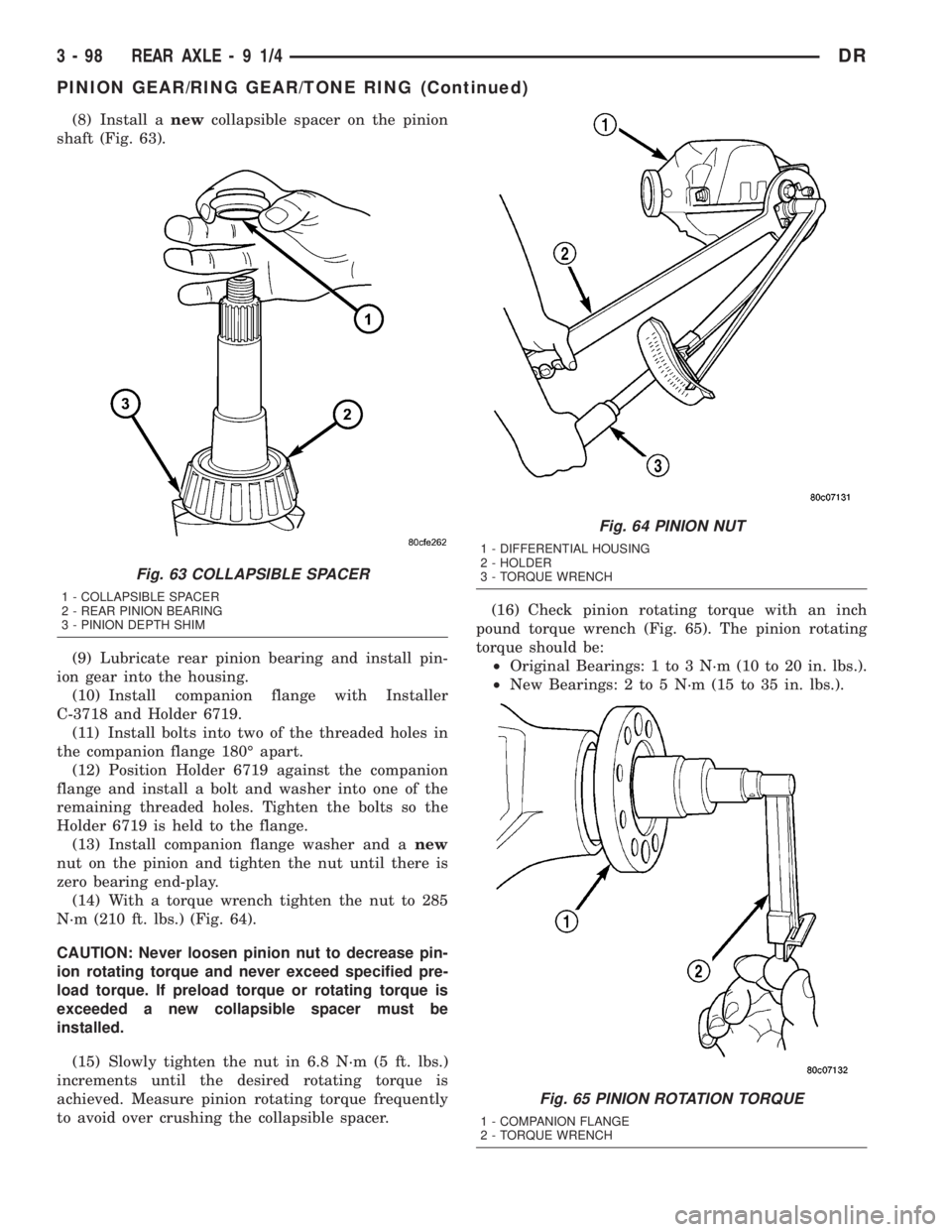

(8) Install anewcollapsible spacer on the pinion

shaft (Fig. 63).

(9) Lubricate rear pinion bearing and install pin-

ion gear into the housing.

(10) Install companion flange with Installer

C-3718 and Holder 6719.

(11) Install bolts into two of the threaded holes in

the companion flange 180É apart.

(12) Position Holder 6719 against the companion

flange and install a bolt and washer into one of the

remaining threaded holes. Tighten the bolts so the

Holder 6719 is held to the flange.

(13) Install companion flange washer and anew

nut on the pinion and tighten the nut until there is

zero bearing end-play.

(14) With a torque wrench tighten the nut to 285

N´m (210 ft. lbs.) (Fig. 64).

CAUTION: Never loosen pinion nut to decrease pin-

ion rotating torque and never exceed specified pre-

load torque. If preload torque or rotating torque is

exceeded a new collapsible spacer must be

installed.

(15) Slowly tighten the nut in 6.8 N´m (5 ft. lbs.)

increments until the desired rotating torque is

achieved. Measure pinion rotating torque frequently

to avoid over crushing the collapsible spacer.(16) Check pinion rotating torque with an inch

pound torque wrench (Fig. 65). The pinion rotating

torque should be:

²Original Bearings: 1 to 3 N´m (10 to 20 in. lbs.).

²New Bearings: 2 to 5 N´m (15 to 35 in. lbs.).

Fig. 63 COLLAPSIBLE SPACER

1 - COLLAPSIBLE SPACER

2 - REAR PINION BEARING

3 - PINION DEPTH SHIM

Fig. 64 PINION NUT

1 - DIFFERENTIAL HOUSING

2 - HOLDER

3 - TORQUE WRENCH

Fig. 65 PINION ROTATION TORQUE

1 - COMPANION FLANGE

2 - TORQUE WRENCH

3 - 98 REAR AXLE-91/4DR

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 172 of 2895

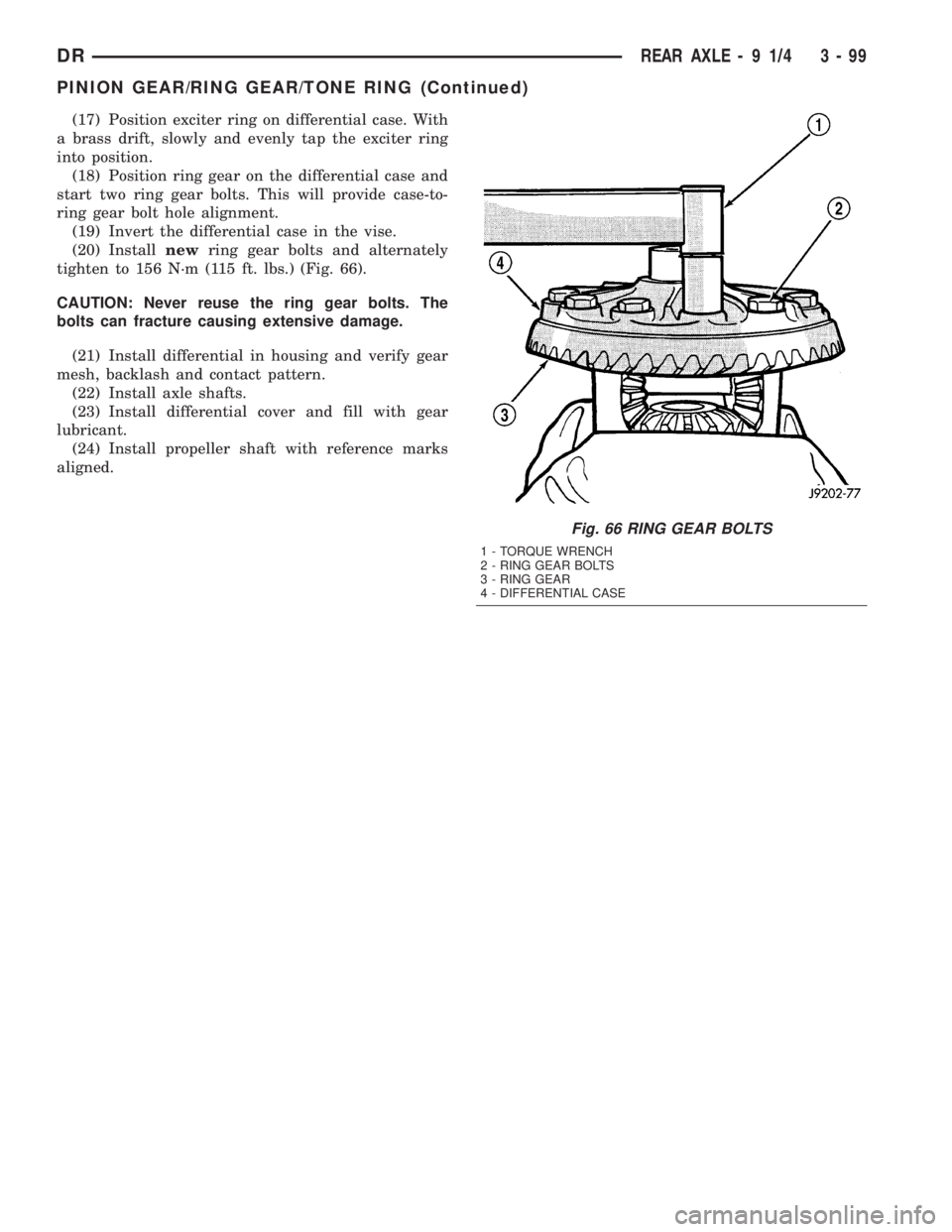

(17) Position exciter ring on differential case. With

a brass drift, slowly and evenly tap the exciter ring

into position.

(18) Position ring gear on the differential case and

start two ring gear bolts. This will provide case-to-

ring gear bolt hole alignment.

(19) Invert the differential case in the vise.

(20) Installnewring gear bolts and alternately

tighten to 156 N´m (115 ft. lbs.) (Fig. 66).

CAUTION: Never reuse the ring gear bolts. The

bolts can fracture causing extensive damage.

(21) Install differential in housing and verify gear

mesh, backlash and contact pattern.

(22) Install axle shafts.

(23) Install differential cover and fill with gear

lubricant.

(24) Install propeller shaft with reference marks

aligned.

Fig. 66 RING GEAR BOLTS

1 - TORQUE WRENCH

2 - RING GEAR BOLTS

3 - RING GEAR

4 - DIFFERENTIAL CASE

DRREAR AXLE - 9 1/4 3 - 99

PINION GEAR/RING GEAR/TONE RING (Continued)