air filter DODGE RAM 2003 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1548 of 2895

(24) Remove the engine wire harness attaching

bolt and wire harness push-in fastener from air inlet

housing.

(25) Remove the air inlet housing and intake grid

heater from the intake manifold cover.

(26) Remove the two grid heater harness-to-cylin-

der head attaching bolts at front of cylinder head.(27) Remove the engine lift bracket from the rear

of the cylinder head.

(28)Remove the high pressure pump to fuel

rail fuel line as follows:

(a) Loosen fuel line nuts at fuel pump and at

fuel rail.

(b) Use a back-up wrench on the fitting at the

fuel pump to keep it from loosening.

(29) Remove the fuel rail to cylinder head fuel

lines as follows:

(a) Loosen No. 6 high pressure fuel line shield

and position out of way.

(b) Loosen the fuel line nuts at the fuel rail and

at the cylinder head.

(c) Remove the fuel line bracket bolts at the

intake manifold cover.

(30) Remove the fuel rail as follows:

(a) Remove fuel rail pressure sensor connector.

(b) Remove banjo fitting at pressure limiting

valve.

(c) Remove fuel rail bolts and fuel rail.

(31) Remove the low pressure lines as follows:

(a) Remove the fuel drain banjo fitting on the

front side of fuel filter housing.

(b) Remove the fuel drain banjo fitting on rear

side of fuel filter housing.

(c) Remove the fuel drain line support bracket

on rear side of filter housing.

(d) Remove fuel drain hose.

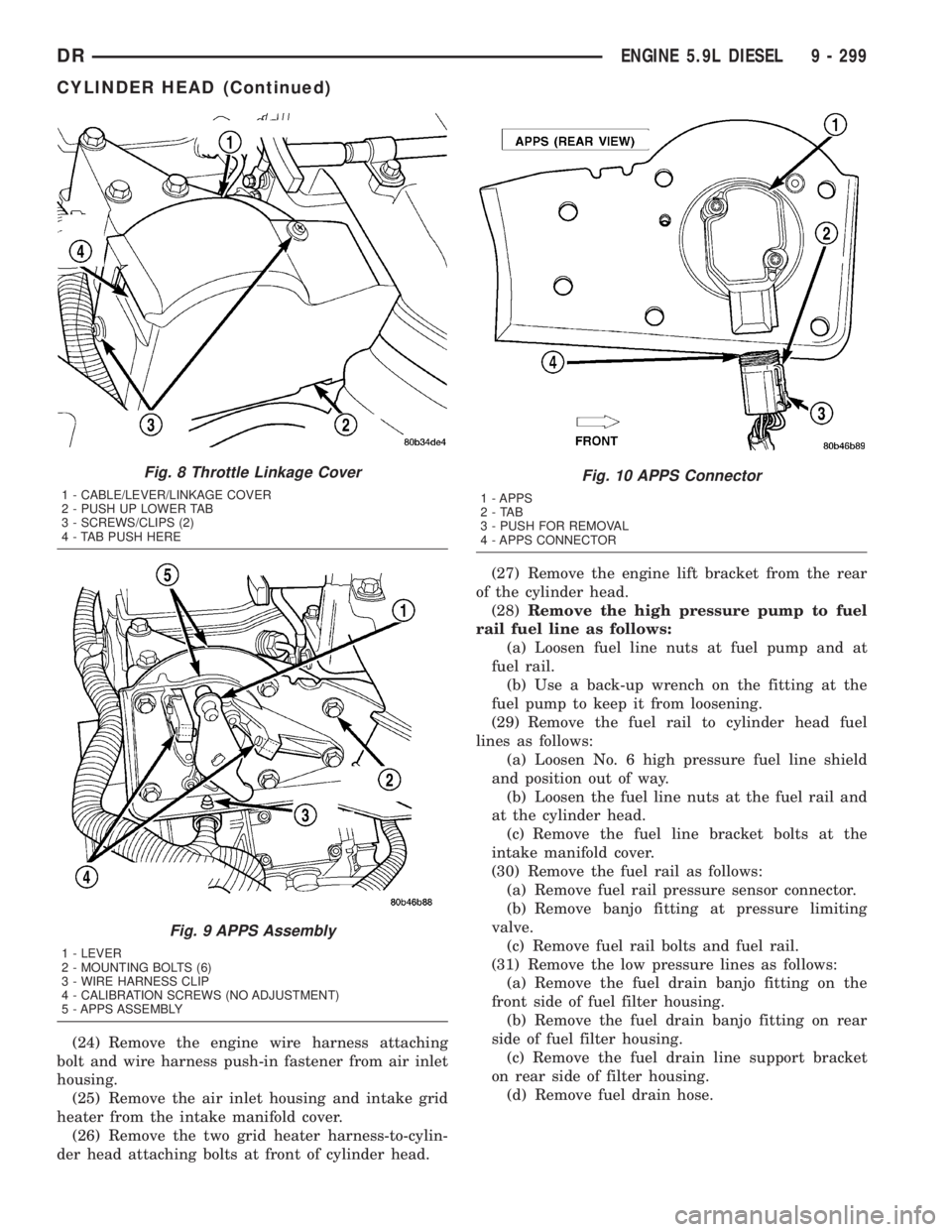

Fig. 8 Throttle Linkage Cover

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

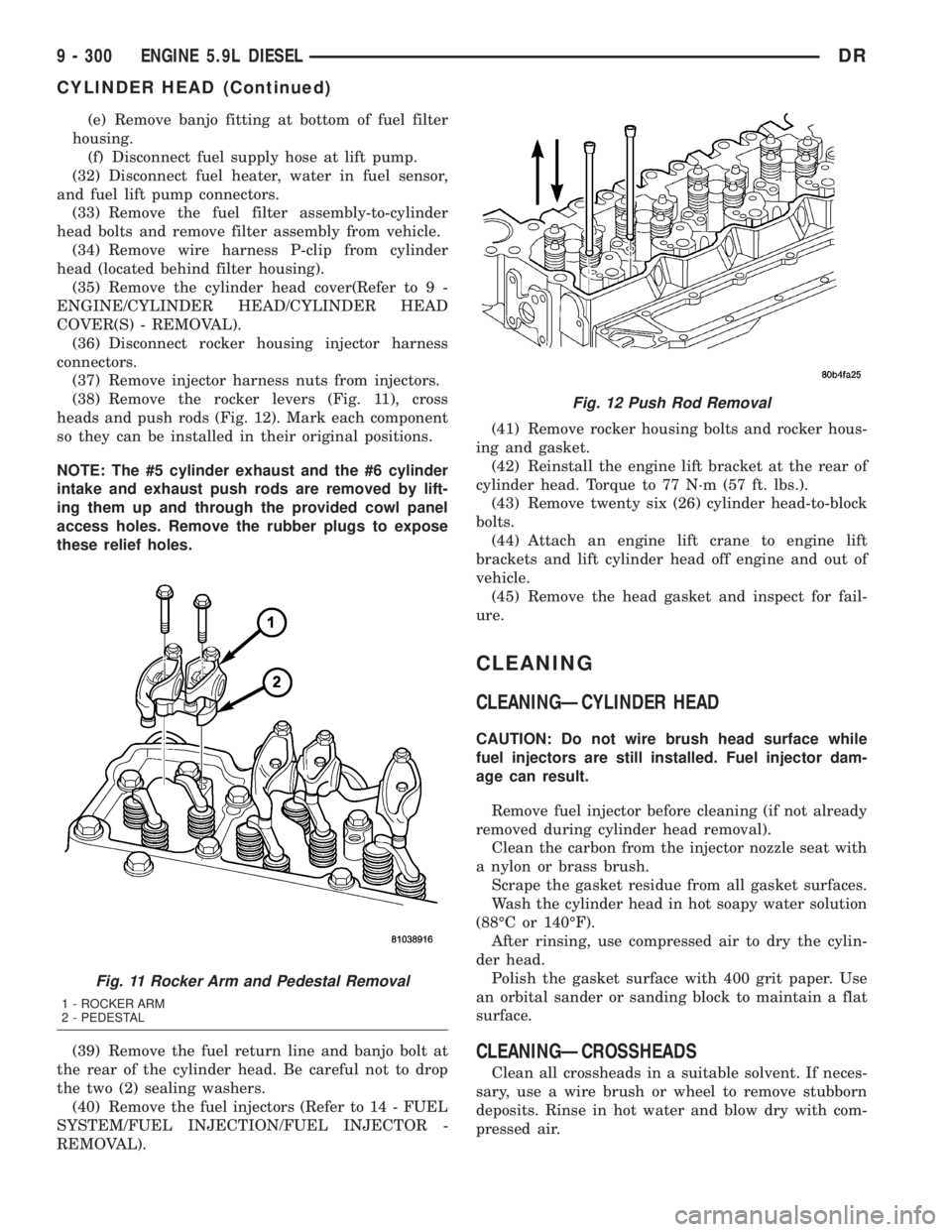

Fig. 9 APPS Assembly

1 - LEVER

2 - MOUNTING BOLTS (6)

3 - WIRE HARNESS CLIP

4 - CALIBRATION SCREWS (NO ADJUSTMENT)

5 - APPS ASSEMBLY

Fig. 10 APPS Connector

1 - APPS

2-TAB

3 - PUSH FOR REMOVAL

4 - APPS CONNECTOR

DRENGINE 5.9L DIESEL 9 - 299

CYLINDER HEAD (Continued)

Page 1549 of 2895

(e) Remove banjo fitting at bottom of fuel filter

housing.

(f) Disconnect fuel supply hose at lift pump.

(32) Disconnect fuel heater, water in fuel sensor,

and fuel lift pump connectors.

(33) Remove the fuel filter assembly-to-cylinder

head bolts and remove filter assembly from vehicle.

(34) Remove wire harness P-clip from cylinder

head (located behind filter housing).

(35) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(36) Disconnect rocker housing injector harness

connectors.

(37) Remove injector harness nuts from injectors.

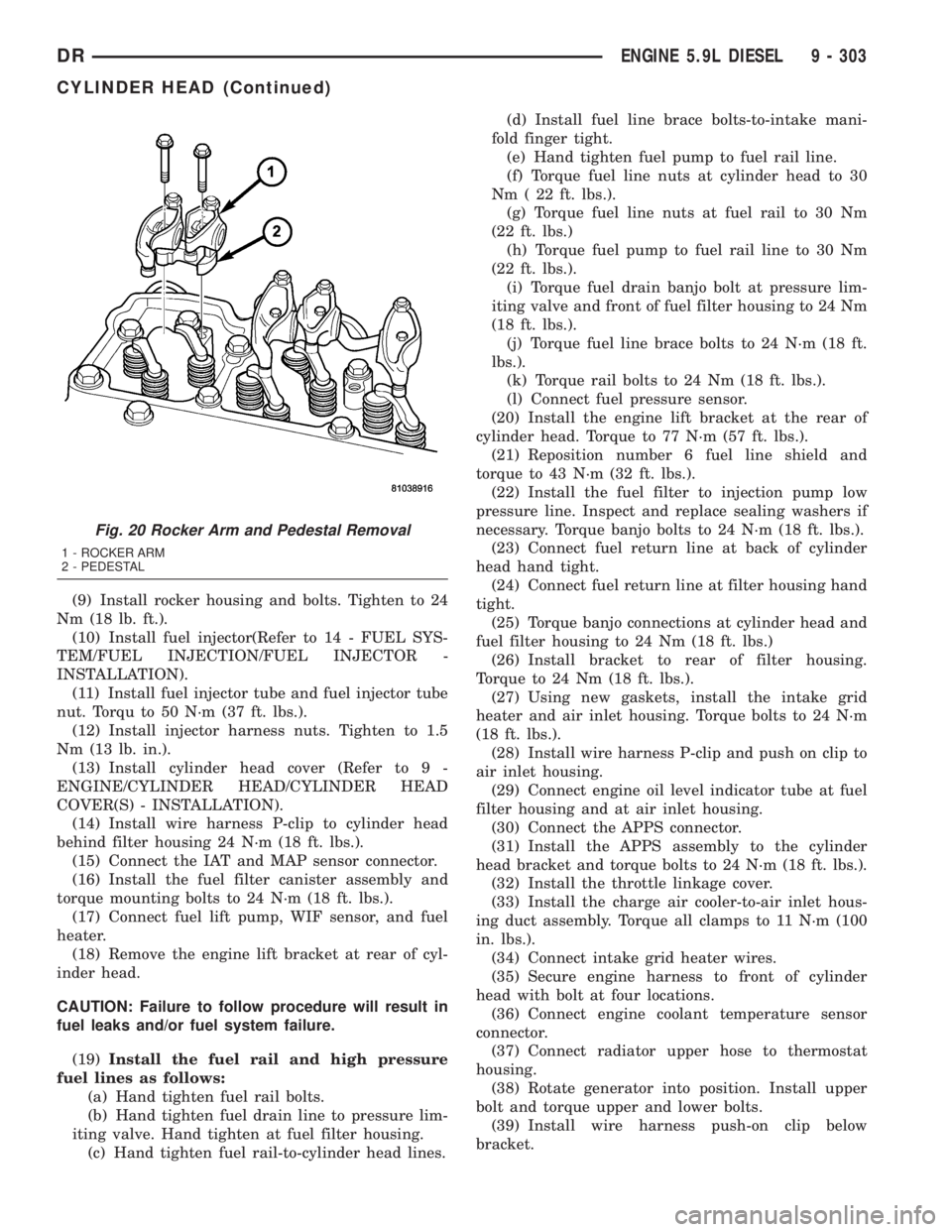

(38) Remove the rocker levers (Fig. 11), cross

heads and push rods (Fig. 12). Mark each component

so they can be installed in their original positions.

NOTE: The #5 cylinder exhaust and the #6 cylinder

intake and exhaust push rods are removed by lift-

ing them up and through the provided cowl panel

access holes. Remove the rubber plugs to expose

these relief holes.

(39) Remove the fuel return line and banjo bolt at

the rear of the cylinder head. Be careful not to drop

the two (2) sealing washers.

(40) Remove the fuel injectors (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/FUEL INJECTOR -

REMOVAL).(41) Remove rocker housing bolts and rocker hous-

ing and gasket.

(42) Reinstall the engine lift bracket at the rear of

cylinder head. Torque to 77 N´m (57 ft. lbs.).

(43) Remove twenty six (26) cylinder head-to-block

bolts.

(44) Attach an engine lift crane to engine lift

brackets and lift cylinder head off engine and out of

vehicle.

(45) Remove the head gasket and inspect for fail-

ure.

CLEANING

CLEANINGÐCYLINDER HEAD

CAUTION: Do not wire brush head surface while

fuel injectors are still installed. Fuel injector dam-

age can result.

Remove fuel injector before cleaning (if not already

removed during cylinder head removal).

Clean the carbon from the injector nozzle seat with

a nylon or brass brush.

Scrape the gasket residue from all gasket surfaces.

Wash the cylinder head in hot soapy water solution

(88ÉC or 140ÉF).

After rinsing, use compressed air to dry the cylin-

der head.

Polish the gasket surface with 400 grit paper. Use

an orbital sander or sanding block to maintain a flat

surface.

CLEANINGÐCROSSHEADS

Clean all crossheads in a suitable solvent. If neces-

sary, use a wire brush or wheel to remove stubborn

deposits. Rinse in hot water and blow dry with com-

pressed air.

Fig. 11 Rocker Arm and Pedestal Removal

1 - ROCKER ARM

2 - PEDESTAL

Fig. 12 Push Rod Removal

9 - 300 ENGINE 5.9L DIESELDR

CYLINDER HEAD (Continued)

Page 1552 of 2895

(9) Install rocker housing and bolts. Tighten to 24

Nm (18 lb. ft.).

(10) Install fuel injector(Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(11) Install fuel injector tube and fuel injector tube

nut. Torqu to 50 N´m (37 ft. lbs.).

(12) Install injector harness nuts. Tighten to 1.5

Nm (13 lb. in.).

(13) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(14) Install wire harness P-clip to cylinder head

behind filter housing 24 N´m (18 ft. lbs.).

(15) Connect the IAT and MAP sensor connector.

(16) Install the fuel filter canister assembly and

torque mounting bolts to 24 N´m (18 ft. lbs.).

(17) Connect fuel lift pump, WIF sensor, and fuel

heater.

(18) Remove the engine lift bracket at rear of cyl-

inder head.

CAUTION: Failure to follow procedure will result in

fuel leaks and/or fuel system failure.

(19)Install the fuel rail and high pressure

fuel lines as follows:

(a) Hand tighten fuel rail bolts.

(b) Hand tighten fuel drain line to pressure lim-

iting valve. Hand tighten at fuel filter housing.

(c) Hand tighten fuel rail-to-cylinder head lines.(d) Install fuel line brace bolts-to-intake mani-

fold finger tight.

(e) Hand tighten fuel pump to fuel rail line.

(f) Torque fuel line nuts at cylinder head to 30

Nm ( 22 ft. lbs.).

(g) Torque fuel line nuts at fuel rail to 30 Nm

(22 ft. lbs.)

(h) Torque fuel pump to fuel rail line to 30 Nm

(22 ft. lbs.).

(i) Torque fuel drain banjo bolt at pressure lim-

iting valve and front of fuel filter housing to 24 Nm

(18 ft. lbs.).

(j) Torque fuel line brace bolts to 24 N´m (18 ft.

lbs.).

(k) Torque rail bolts to 24 Nm (18 ft. lbs.).

(l) Connect fuel pressure sensor.

(20) Install the engine lift bracket at the rear of

cylinder head. Torque to 77 N´m (57 ft. lbs.).

(21) Reposition number 6 fuel line shield and

torque to 43 N´m (32 ft. lbs.).

(22) Install the fuel filter to injection pump low

pressure line. Inspect and replace sealing washers if

necessary. Torque banjo bolts to 24 N´m (18 ft. lbs.).

(23) Connect fuel return line at back of cylinder

head hand tight.

(24) Connect fuel return line at filter housing hand

tight.

(25) Torque banjo connections at cylinder head and

fuel filter housing to 24 Nm (18 ft. lbs.)

(26) Install bracket to rear of filter housing.

Torque to 24 Nm (18 ft. lbs.).

(27) Using new gaskets, install the intake grid

heater and air inlet housing. Torque bolts to 24 N´m

(18 ft. lbs.).

(28) Install wire harness P-clip and push on clip to

air inlet housing.

(29) Connect engine oil level indicator tube at fuel

filter housing and at air inlet housing.

(30) Connect the APPS connector.

(31) Install the APPS assembly to the cylinder

head bracket and torque bolts to 24 N´m (18 ft. lbs.).

(32) Install the throttle linkage cover.

(33) Install the charge air cooler-to-air inlet hous-

ing duct assembly. Torque all clamps to 11 N´m (100

in. lbs.).

(34) Connect intake grid heater wires.

(35) Secure engine harness to front of cylinder

head with bolt at four locations.

(36) Connect engine coolant temperature sensor

connector.

(37) Connect radiator upper hose to thermostat

housing.

(38) Rotate generator into position. Install upper

bolt and torque upper and lower bolts.

(39) Install wire harness push-on clip below

bracket.

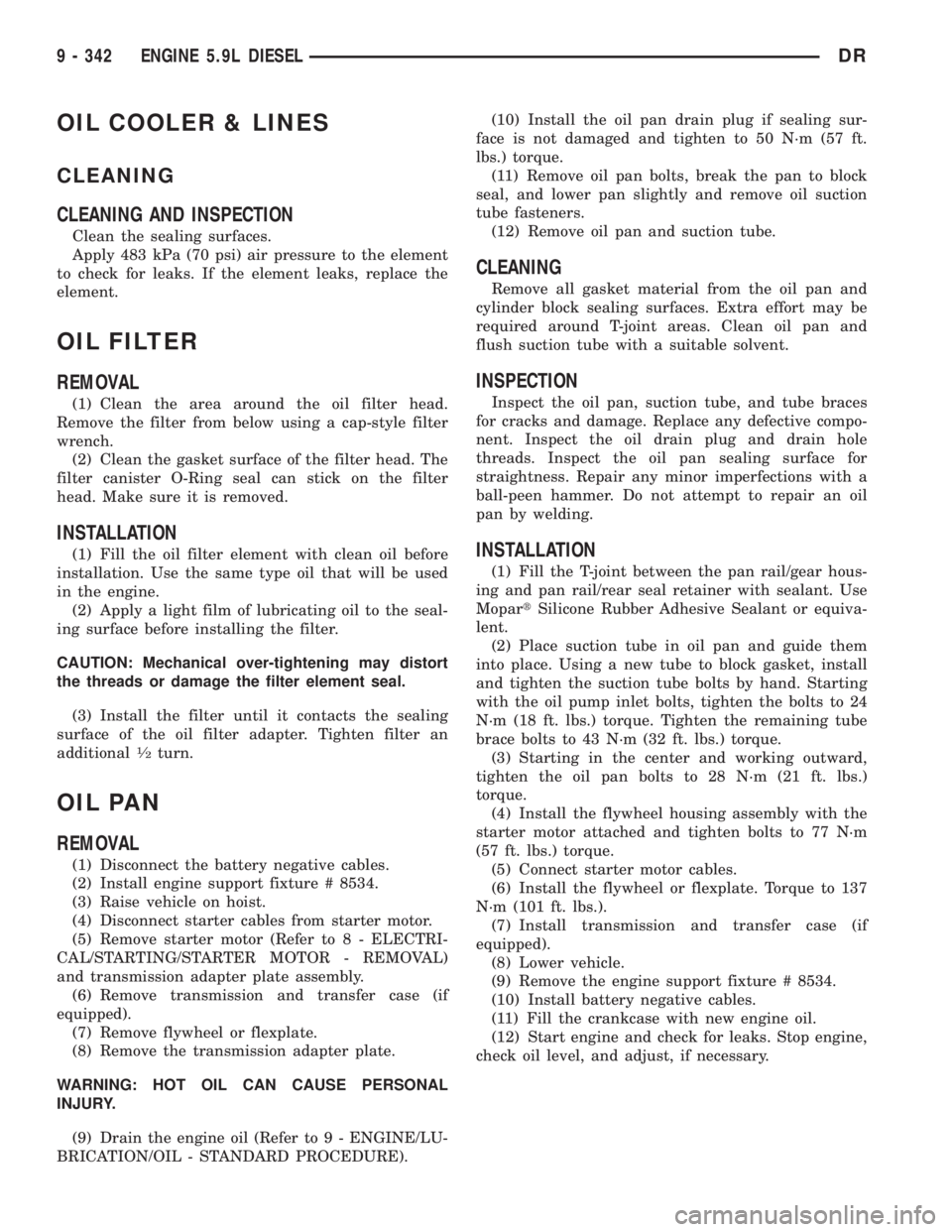

Fig. 20 Rocker Arm and Pedestal Removal

1 - ROCKER ARM

2 - PEDESTAL

DRENGINE 5.9L DIESEL 9 - 303

CYLINDER HEAD (Continued)

Page 1591 of 2895

OIL COOLER & LINES

CLEANING

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter from below using a cap-style filter

wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional

1¤2turn.

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Install engine support fixture # 8534.

(3) Raise vehicle on hoist.

(4) Disconnect starter cables from starter motor.

(5) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(6) Remove transmission and transfer case (if

equipped).

(7) Remove flywheel or flexplate.

(8) Remove the transmission adapter plate.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(9) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).(10) Install the oil pan drain plug if sealing sur-

face is not damaged and tighten to 50 N´m (57 ft.

lbs.) torque.

(11) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(12) Remove oil pan and suction tube.

CLEANING

Remove all gasket material from the oil pan and

cylinder block sealing surfaces. Extra effort may be

required around T-joint areas. Clean oil pan and

flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces

for cracks and damage. Replace any defective compo-

nent. Inspect the oil drain plug and drain hole

threads. Inspect the oil pan sealing surface for

straightness. Repair any minor imperfections with a

ball-peen hammer. Do not attempt to repair an oil

pan by welding.

INSTALLATION

(1) Fill the T-joint between the pan rail/gear hous-

ing and pan rail/rear seal retainer with sealant. Use

MopartSilicone Rubber Adhesive Sealant or equiva-

lent.

(2) Place suction tube in oil pan and guide them

into place. Using a new tube to block gasket, install

and tighten the suction tube bolts by hand. Starting

with the oil pump inlet bolts, tighten the bolts to 24

N´m (18 ft. lbs.) torque. Tighten the remaining tube

brace bolts to 43 N´m (32 ft. lbs.) torque.

(3) Starting in the center and working outward,

tighten the oil pan bolts to 28 N´m (21 ft. lbs.)

torque.

(4) Install the flywheel housing assembly with the

starter motor attached and tighten bolts to 77 N´m

(57 ft. lbs.) torque.

(5) Connect starter motor cables.

(6) Install the flywheel or flexplate. Torque to 137

N´m (101 ft. lbs.).

(7) Install transmission and transfer case (if

equipped).

(8) Lower vehicle.

(9) Remove the engine support fixture # 8534.

(10) Install battery negative cables.

(11) Fill the crankcase with new engine oil.

(12) Start engine and check for leaks. Stop engine,

check oil level, and adjust, if necessary.

9 - 342 ENGINE 5.9L DIESELDR

Page 1592 of 2895

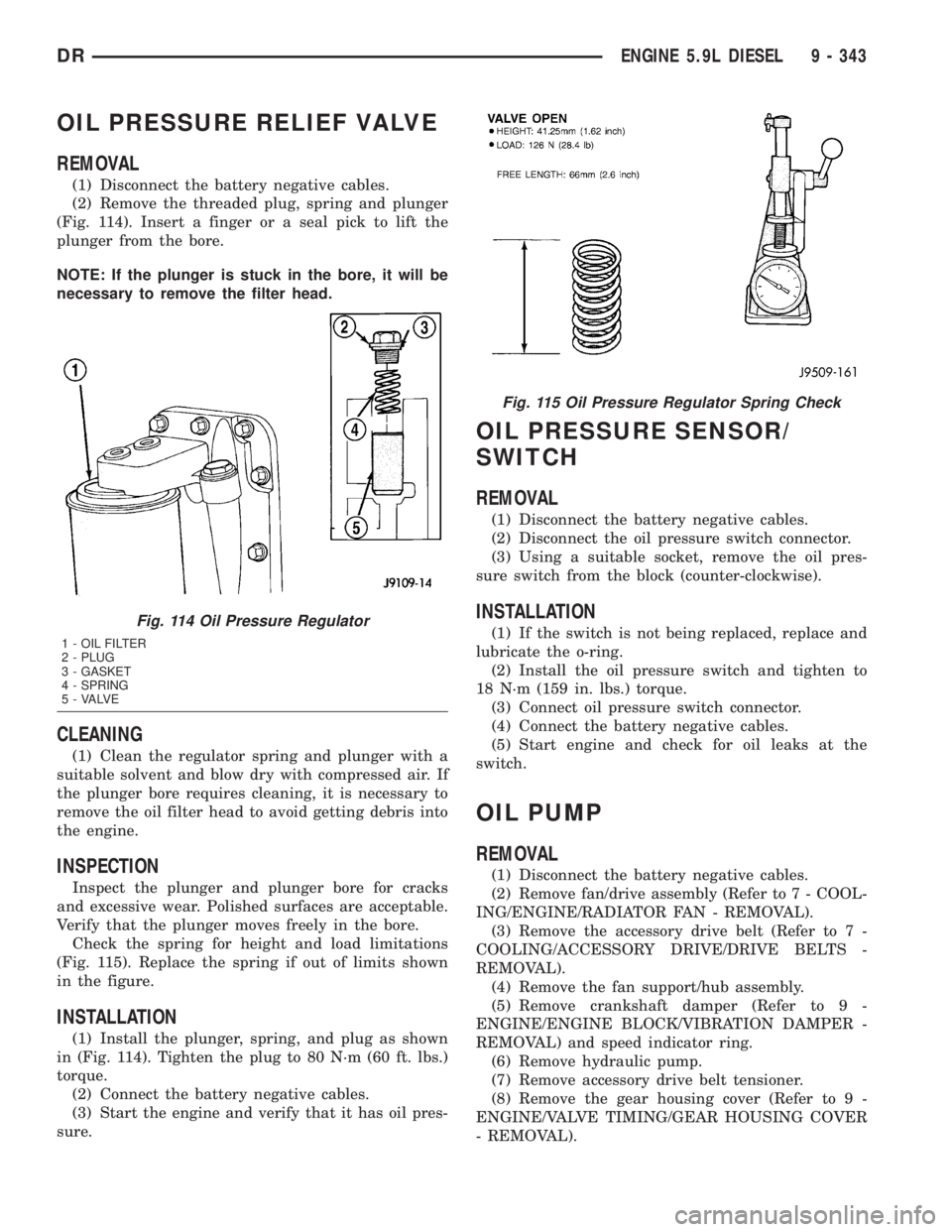

OIL PRESSURE RELIEF VALVE

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the threaded plug, spring and plunger

(Fig. 114). Insert a finger or a seal pick to lift the

plunger from the bore.

NOTE: If the plunger is stuck in the bore, it will be

necessary to remove the filter head.

CLEANING

(1) Clean the regulator spring and plunger with a

suitable solvent and blow dry with compressed air. If

the plunger bore requires cleaning, it is necessary to

remove the oil filter head to avoid getting debris into

the engine.

INSPECTION

Inspect the plunger and plunger bore for cracks

and excessive wear. Polished surfaces are acceptable.

Verify that the plunger moves freely in the bore.

Check the spring for height and load limitations

(Fig. 115). Replace the spring if out of limits shown

in the figure.

INSTALLATION

(1) Install the plunger, spring, and plug as shown

in (Fig. 114). Tighten the plug to 80 N´m (60 ft. lbs.)

torque.

(2) Connect the battery negative cables.

(3) Start the engine and verify that it has oil pres-

sure.

OIL PRESSURE SENSOR/

SWITCH

REMOVAL

(1) Disconnect the battery negative cables.

(2) Disconnect the oil pressure switch connector.

(3) Using a suitable socket, remove the oil pres-

sure switch from the block (counter-clockwise).

INSTALLATION

(1) If the switch is not being replaced, replace and

lubricate the o-ring.

(2) Install the oil pressure switch and tighten to

18 N´m (159 in. lbs.) torque.

(3) Connect oil pressure switch connector.

(4) Connect the battery negative cables.

(5) Start engine and check for oil leaks at the

switch.

OIL PUMP

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove fan/drive assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove the fan support/hub assembly.

(5) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(6) Remove hydraulic pump.

(7) Remove accessory drive belt tensioner.

(8) Remove the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- REMOVAL).

Fig. 114 Oil Pressure Regulator

1 - OIL FILTER

2 - PLUG

3 - GASKET

4 - SPRING

5 - VALVE

Fig. 115 Oil Pressure Regulator Spring Check

DRENGINE 5.9L DIESEL 9 - 343

Page 1595 of 2895

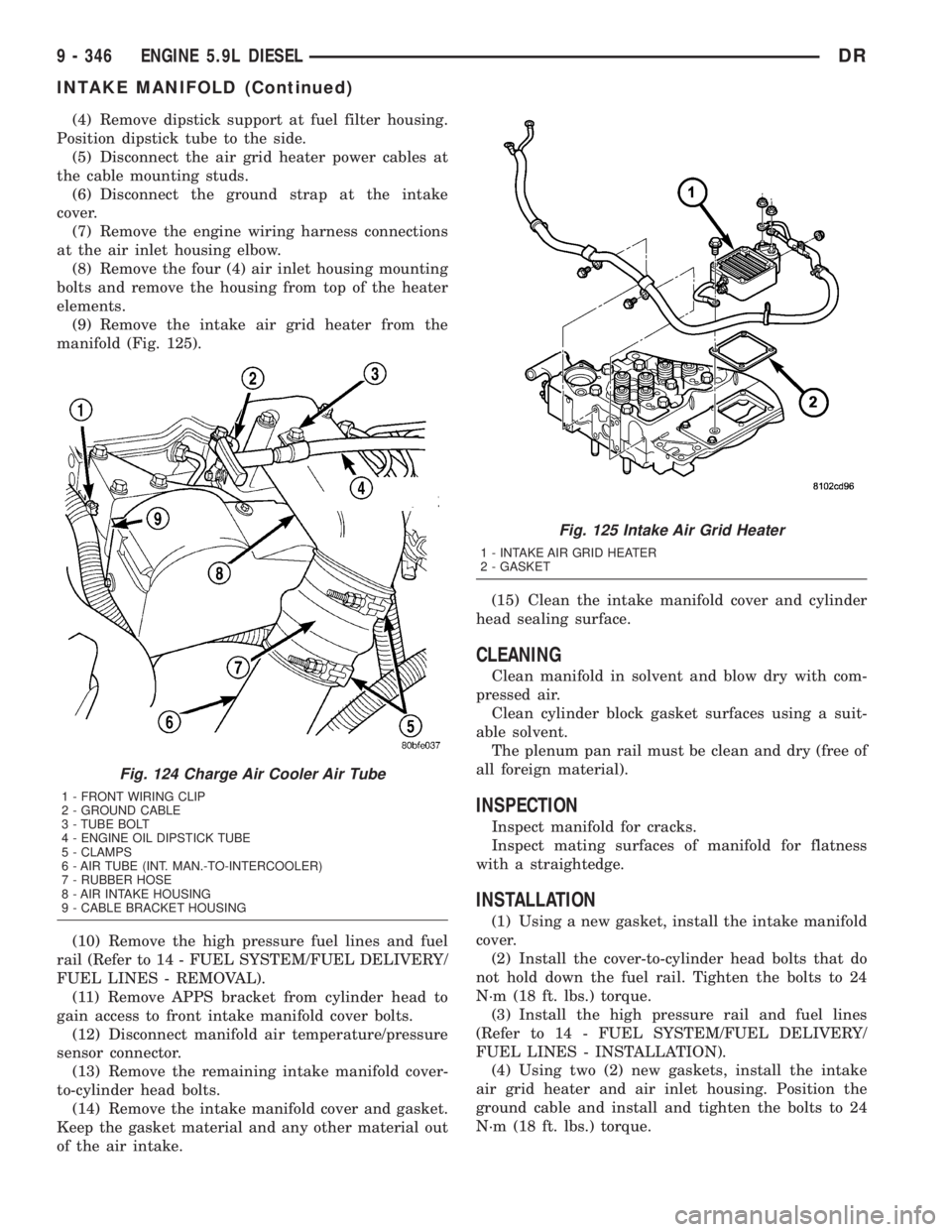

(4) Remove dipstick support at fuel filter housing.

Position dipstick tube to the side.

(5) Disconnect the air grid heater power cables at

the cable mounting studs.

(6) Disconnect the ground strap at the intake

cover.

(7) Remove the engine wiring harness connections

at the air inlet housing elbow.

(8) Remove the four (4) air inlet housing mounting

bolts and remove the housing from top of the heater

elements.

(9) Remove the intake air grid heater from the

manifold (Fig. 125).

(10) Remove the high pressure fuel lines and fuel

rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL LINES - REMOVAL).

(11) Remove APPS bracket from cylinder head to

gain access to front intake manifold cover bolts.

(12) Disconnect manifold air temperature/pressure

sensor connector.

(13) Remove the remaining intake manifold cover-

to-cylinder head bolts.

(14) Remove the intake manifold cover and gasket.

Keep the gasket material and any other material out

of the air intake.(15) Clean the intake manifold cover and cylinder

head sealing surface.

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.

Clean cylinder block gasket surfaces using a suit-

able solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

INSTALLATION

(1) Using a new gasket, install the intake manifold

cover.

(2) Install the cover-to-cylinder head bolts that do

not hold down the fuel rail. Tighten the bolts to 24

N´m (18 ft. lbs.) torque.

(3) Install the high pressure rail and fuel lines

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL LINES - INSTALLATION).

(4) Using two (2) new gaskets, install the intake

air grid heater and air inlet housing. Position the

ground cable and install and tighten the bolts to 24

N´m (18 ft. lbs.) torque.

Fig. 124 Charge Air Cooler Air Tube

1 - FRONT WIRING CLIP

2 - GROUND CABLE

3 - TUBE BOLT

4 - ENGINE OIL DIPSTICK TUBE

5 - CLAMPS

6 - AIR TUBE (INT. MAN.-TO-INTERCOOLER)

7 - RUBBER HOSE

8 - AIR INTAKE HOUSING

9 - CABLE BRACKET HOUSING

Fig. 125 Intake Air Grid Heater

1 - INTAKE AIR GRID HEATER

2 - GASKET

9 - 346 ENGINE 5.9L DIESELDR

INTAKE MANIFOLD (Continued)

Page 1596 of 2895

(5) Connect the manifold air temperature/pressure

sensor connector.

(6) Install and tighten the air intake heater power

supply nuts to 14 N´m (120 in. lbs.) torque.

(7) Install the APPS bracket. Torque fasteners to

43 N´m (32ft lbs.) torque.

(8) Install oil dipstick tube support at fuel filter

housing.

(9) Install the engine oil dipstick tube and mount-

ing bolt.

(10) Position the charge air cooler outlet tube onto

the air inlet housing. Tighten the clamps to 8 N´m

(72 in. lbs.) torque.

(11) Attach the engine wire harness to the air inlet

housing at two locations.

(12) Prime the fuel system. Refer to the fuel prim-

ing procedure in Group 14, Fuel System.

(13) Connect the battery negative cables.

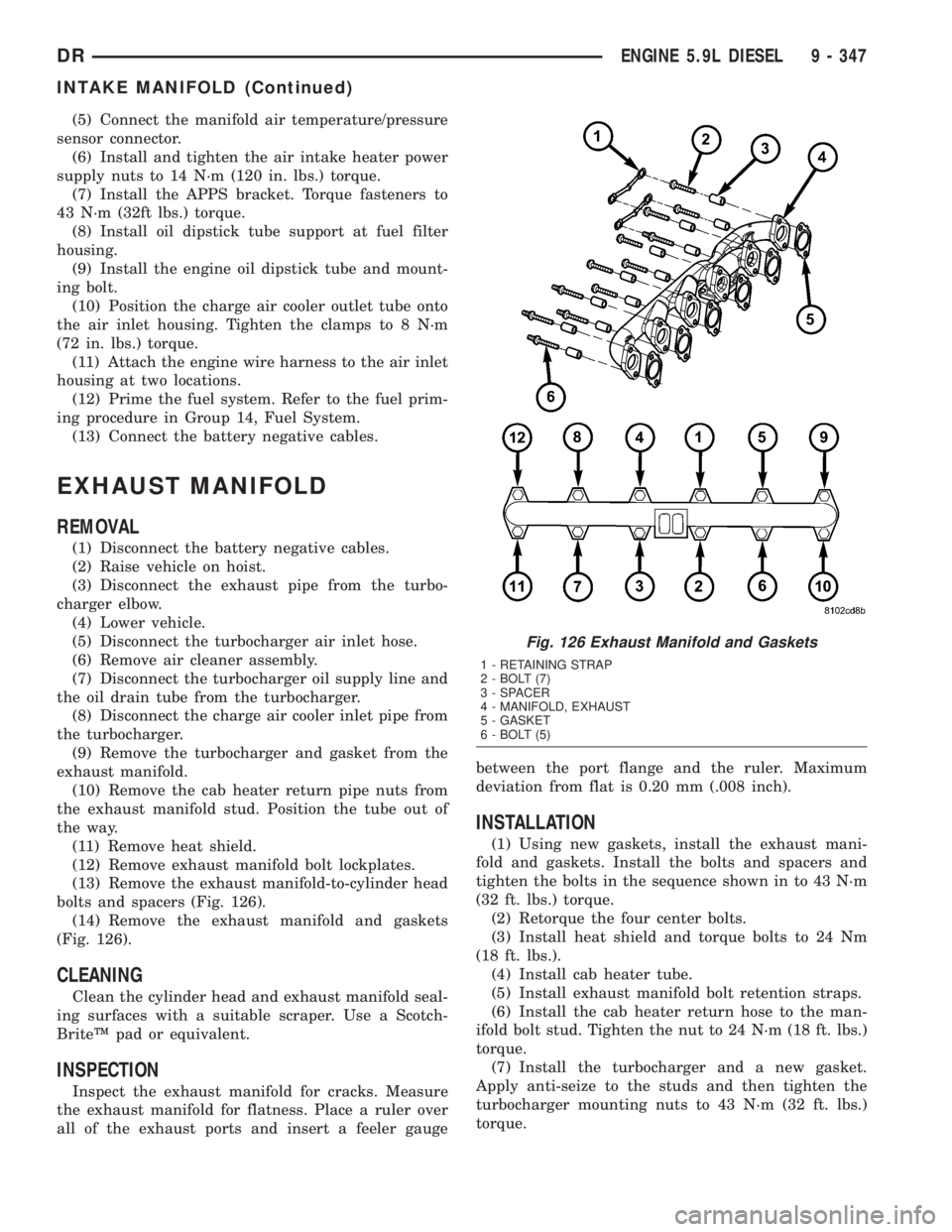

EXHAUST MANIFOLD

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Disconnect the exhaust pipe from the turbo-

charger elbow.

(4) Lower vehicle.

(5) Disconnect the turbocharger air inlet hose.

(6) Remove air cleaner assembly.

(7) Disconnect the turbocharger oil supply line and

the oil drain tube from the turbocharger.

(8) Disconnect the charge air cooler inlet pipe from

the turbocharger.

(9) Remove the turbocharger and gasket from the

exhaust manifold.

(10) Remove the cab heater return pipe nuts from

the exhaust manifold stud. Position the tube out of

the way.

(11) Remove heat shield.

(12) Remove exhaust manifold bolt lockplates.

(13) Remove the exhaust manifold-to-cylinder head

bolts and spacers (Fig. 126).

(14) Remove the exhaust manifold and gaskets

(Fig. 126).

CLEANING

Clean the cylinder head and exhaust manifold seal-

ing surfaces with a suitable scraper. Use a Scotch-

BriteŸ pad or equivalent.

INSPECTION

Inspect the exhaust manifold for cracks. Measure

the exhaust manifold for flatness. Place a ruler over

all of the exhaust ports and insert a feeler gaugebetween the port flange and the ruler. Maximum

deviation from flat is 0.20 mm (.008 inch).

INSTALLATION

(1) Using new gaskets, install the exhaust mani-

fold and gaskets. Install the bolts and spacers and

tighten the bolts in the sequence shown in to 43 N´m

(32 ft. lbs.) torque.

(2) Retorque the four center bolts.

(3) Install heat shield and torque bolts to 24 Nm

(18 ft. lbs.).

(4) Install cab heater tube.

(5) Install exhaust manifold bolt retention straps.

(6) Install the cab heater return hose to the man-

ifold bolt stud. Tighten the nut to 24 N´m (18 ft. lbs.)

torque.

(7) Install the turbocharger and a new gasket.

Apply anti-seize to the studs and then tighten the

turbocharger mounting nuts to 43 N´m (32 ft. lbs.)

torque.

Fig. 126 Exhaust Manifold and Gaskets

1 - RETAINING STRAP

2 - BOLT (7)

3 - SPACER

4 - MANIFOLD, EXHAUST

5 - GASKET

6 - BOLT (5)

DRENGINE 5.9L DIESEL 9 - 347

INTAKE MANIFOLD (Continued)

Page 1603 of 2895

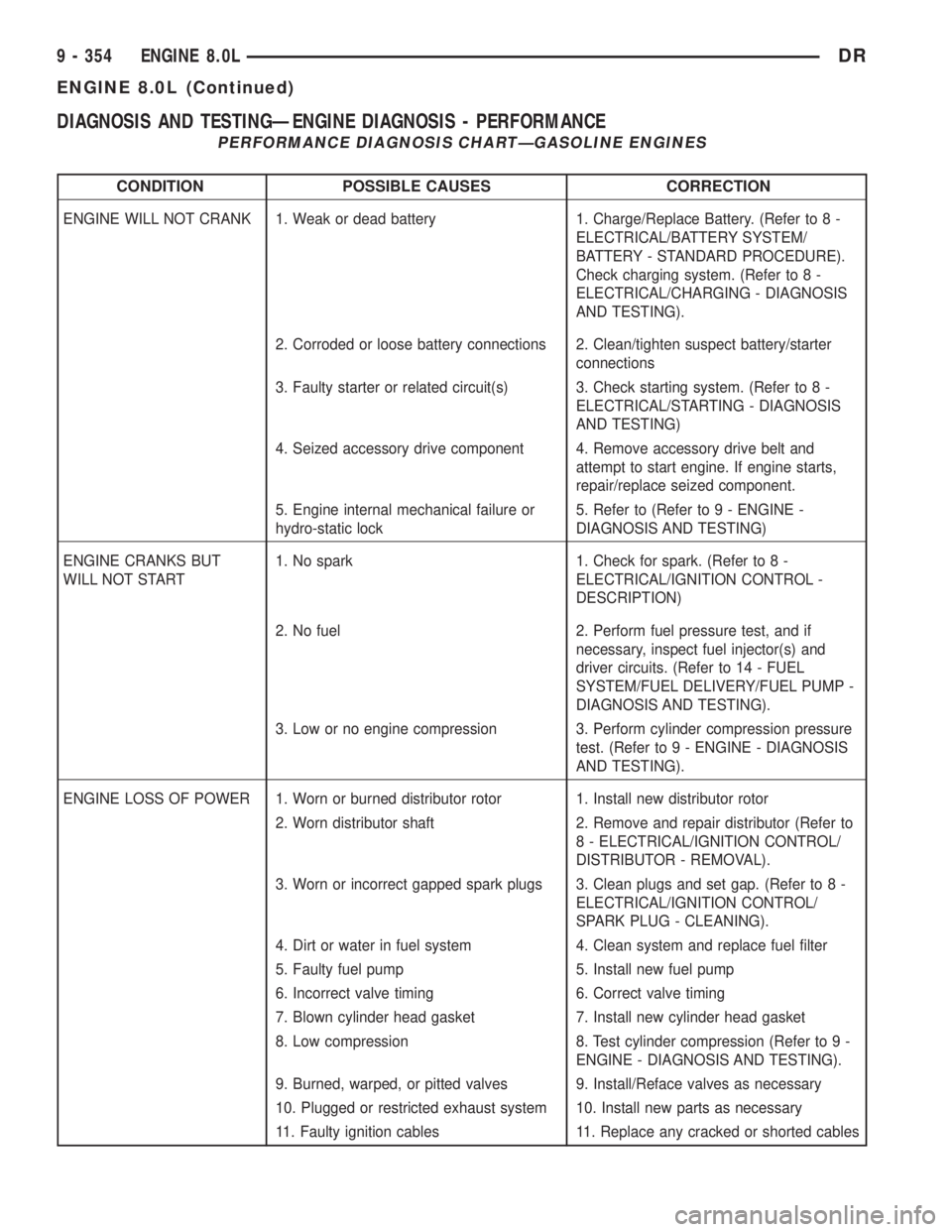

DIAGNOSIS AND TESTINGÐENGINE DIAGNOSIS - PERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE).

Check charging system. (Refer to 8 -

ELECTRICAL/CHARGING - DIAGNOSIS

AND TESTING).

2. Corroded or loose battery connections 2. Clean/tighten suspect battery/starter

connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8 -

ELECTRICAL/STARTING - DIAGNOSIS

AND TESTING)

4. Seized accessory drive component 4. Remove accessory drive belt and

attempt to start engine. If engine starts,

repair/replace seized component.

5. Engine internal mechanical failure or

hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT

WILL NOT START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING).

3. Low or no engine compression 3. Perform cylinder compression pressure

test. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor (Refer to

8 - ELECTRICAL/IGNITION CONTROL/

DISTRIBUTOR - REMOVAL).

3. Worn or incorrect gapped spark plugs 3. Clean plugs and set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG - CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

9. Burned, warped, or pitted valves 9. Install/Reface valves as necessary

10. Plugged or restricted exhaust system 10. Install new parts as necessary

11. Faulty ignition cables 11. Replace any cracked or shorted cables

9 - 354 ENGINE 8.0LDR

ENGINE 8.0L (Continued)

Page 1606 of 2895

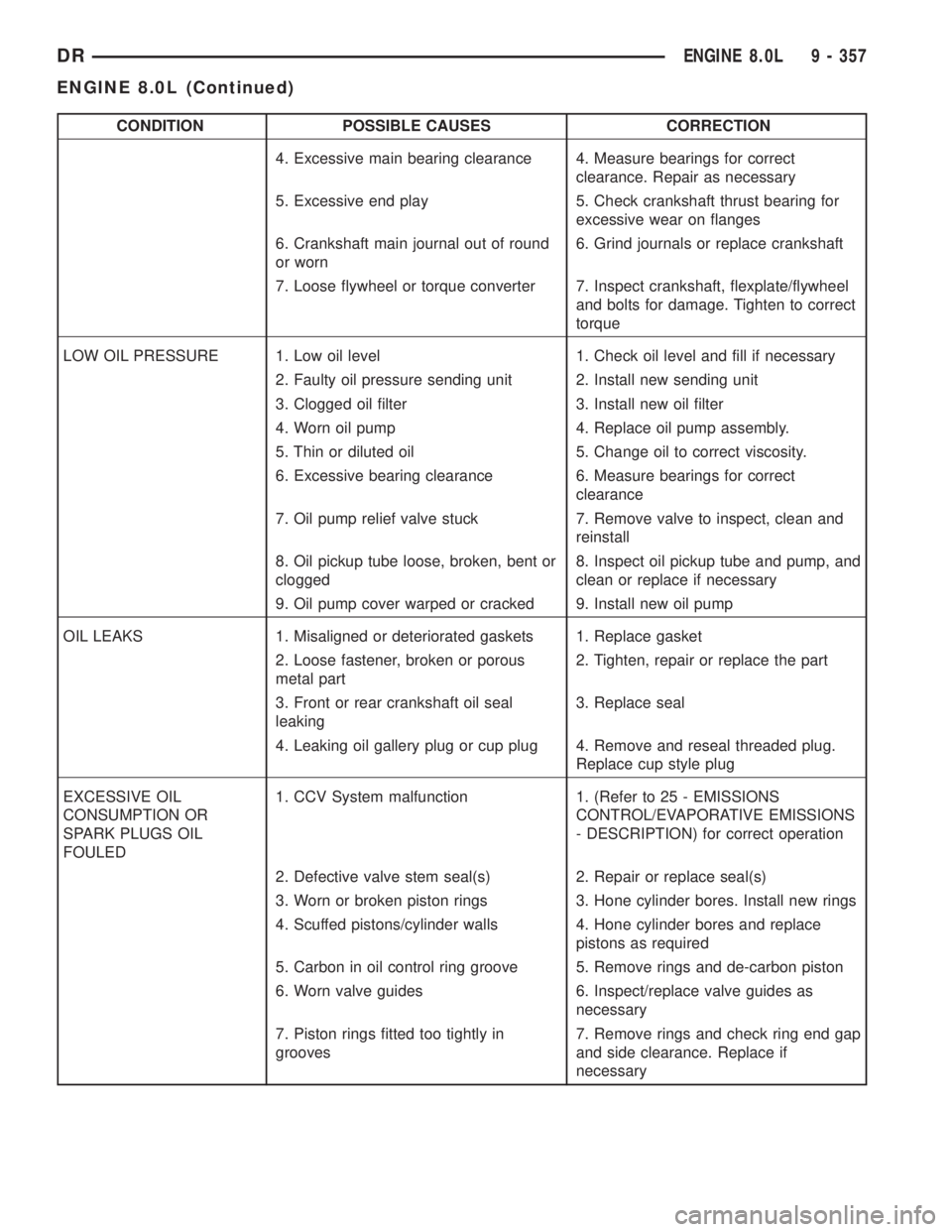

CONDITION POSSIBLE CAUSES CORRECTION

4. Excessive main bearing clearance 4. Measure bearings for correct

clearance. Repair as necessary

5. Excessive end play 5. Check crankshaft thrust bearing for

excessive wear on flanges

6. Crankshaft main journal out of round

or worn6. Grind journals or replace crankshaft

7. Loose flywheel or torque converter 7. Inspect crankshaft, flexplate/flywheel

and bolts for damage. Tighten to correct

torque

LOW OIL PRESSURE 1. Low oil level 1. Check oil level and fill if necessary

2. Faulty oil pressure sending unit 2. Install new sending unit

3. Clogged oil filter 3. Install new oil filter

4. Worn oil pump 4. Replace oil pump assembly.

5. Thin or diluted oil 5. Change oil to correct viscosity.

6. Excessive bearing clearance 6. Measure bearings for correct

clearance

7. Oil pump relief valve stuck 7. Remove valve to inspect, clean and

reinstall

8. Oil pickup tube loose, broken, bent or

clogged8. Inspect oil pickup tube and pump, and

clean or replace if necessary

9. Oil pump cover warped or cracked 9. Install new oil pump

OIL LEAKS 1. Misaligned or deteriorated gaskets 1. Replace gasket

2. Loose fastener, broken or porous

metal part2. Tighten, repair or replace the part

3. Front or rear crankshaft oil seal

leaking3. Replace seal

4. Leaking oil gallery plug or cup plug 4. Remove and reseal threaded plug.

Replace cup style plug

EXCESSIVE OIL

CONSUMPTION OR

SPARK PLUGS OIL

FOULED1. CCV System malfunction 1. (Refer to 25 - EMISSIONS

CONTROL/EVAPORATIVE EMISSIONS

- DESCRIPTION) for correct operation

2. Defective valve stem seal(s) 2. Repair or replace seal(s)

3. Worn or broken piston rings 3. Hone cylinder bores. Install new rings

4. Scuffed pistons/cylinder walls 4. Hone cylinder bores and replace

pistons as required

5. Carbon in oil control ring groove 5. Remove rings and de-carbon piston

6. Worn valve guides 6. Inspect/replace valve guides as

necessary

7. Piston rings fitted too tightly in

grooves7. Remove rings and check ring end gap

and side clearance. Replace if

necessary

DRENGINE 8.0L 9 - 357

ENGINE 8.0L (Continued)

Page 1607 of 2895

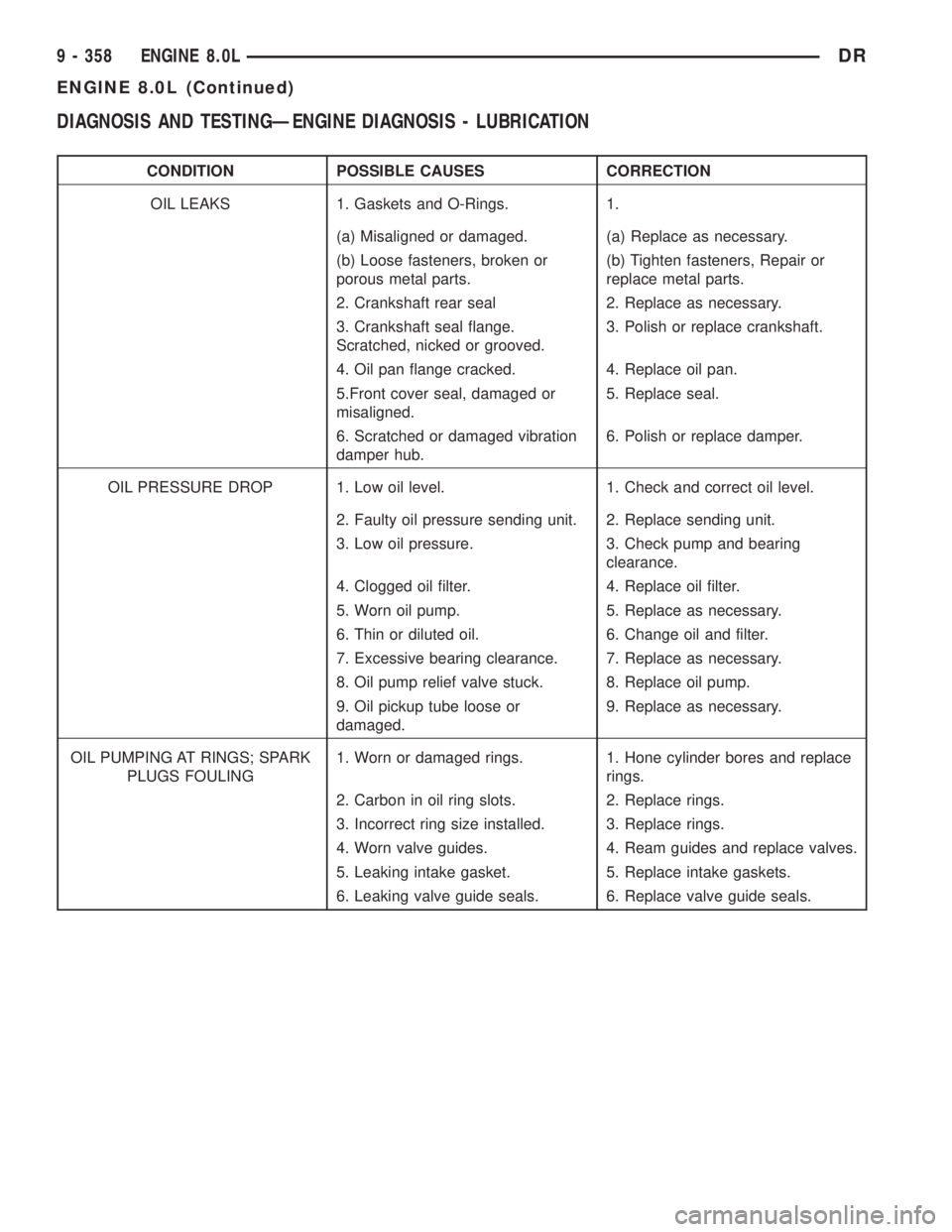

DIAGNOSIS AND TESTINGÐENGINE DIAGNOSIS - LUBRICATION

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS 1. Gaskets and O-Rings. 1.

(a) Misaligned or damaged. (a) Replace as necessary.

(b) Loose fasteners, broken or

porous metal parts.(b) Tighten fasteners, Repair or

replace metal parts.

2. Crankshaft rear seal 2. Replace as necessary.

3. Crankshaft seal flange.

Scratched, nicked or grooved.3. Polish or replace crankshaft.

4. Oil pan flange cracked. 4. Replace oil pan.

5.Front cover seal, damaged or

misaligned.5. Replace seal.

6. Scratched or damaged vibration

damper hub.6. Polish or replace damper.

OIL PRESSURE DROP 1. Low oil level. 1. Check and correct oil level.

2. Faulty oil pressure sending unit. 2. Replace sending unit.

3. Low oil pressure. 3. Check pump and bearing

clearance.

4. Clogged oil filter. 4. Replace oil filter.

5. Worn oil pump. 5. Replace as necessary.

6. Thin or diluted oil. 6. Change oil and filter.

7. Excessive bearing clearance. 7. Replace as necessary.

8. Oil pump relief valve stuck. 8. Replace oil pump.

9. Oil pickup tube loose or

damaged.9. Replace as necessary.

OIL PUMPING AT RINGS; SPARK

PLUGS FOULING1. Worn or damaged rings. 1. Hone cylinder bores and replace

rings.

2. Carbon in oil ring slots. 2. Replace rings.

3. Incorrect ring size installed. 3. Replace rings.

4. Worn valve guides. 4. Ream guides and replace valves.

5. Leaking intake gasket. 5. Replace intake gaskets.

6. Leaking valve guide seals. 6. Replace valve guide seals.

9 - 358 ENGINE 8.0LDR

ENGINE 8.0L (Continued)