timing belt DODGE RAM 2003 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1451 of 2895

(11) Remove the rear oil seal retainer(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT REAR

OIL SEAL RETAINE - REMOVAL).

(12) Remove and discard the crankshaft rear oil

seal.

(13) Remove and discard the front crankshaft oil

seal.

INSTALLATION

(1) Select the proper main bearings(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE).

(2) Install main bearings in block and caps, and

lubricate bearings.

(3) Position the crankshaft into the cylinder block.

(4) Install the thrust washers.

NOTE: The main cap crossbolts are torqued after

final torque of the main cap bolts. Always use a

new washer/seal on crossbolts.

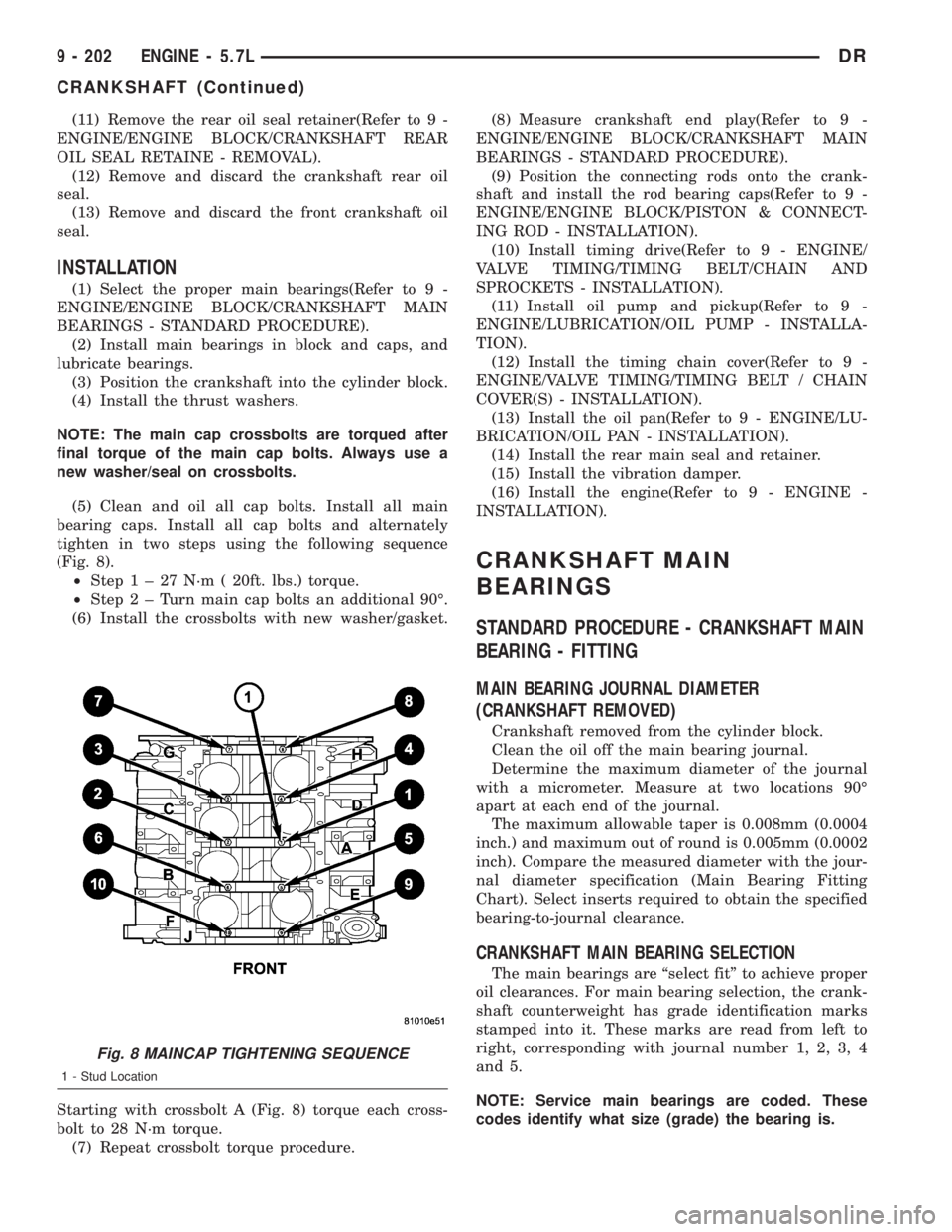

(5) Clean and oil all cap bolts. Install all main

bearing caps. Install all cap bolts and alternately

tighten in two steps using the following sequence

(Fig. 8).

²Step1±27N´m(20ft. lbs.) torque.

²Step2±Turnmain cap bolts an additional 90É.

(6) Install the crossbolts with new washer/gasket.

Starting with crossbolt A (Fig. 8) torque each cross-

bolt to 28 N´m torque.

(7) Repeat crossbolt torque procedure.(8) Measure crankshaft end play(Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE).

(9) Position the connecting rods onto the crank-

shaft and install the rod bearing caps(Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - INSTALLATION).

(10) Install timing drive(Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

(11) Install oil pump and pickup(Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - INSTALLA-

TION).

(12) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(13) Install the oil pan(Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(14) Install the rear main seal and retainer.

(15) Install the vibration damper.

(16) Install the engine(Refer to 9 - ENGINE -

INSTALLATION).

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE - CRANKSHAFT MAIN

BEARING - FITTING

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Crankshaft removed from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.0002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

CRANKSHAFT MAIN BEARING SELECTION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft counterweight has grade identification marks

stamped into it. These marks are read from left to

right, corresponding with journal number 1, 2, 3, 4

and 5.

NOTE: Service main bearings are coded. These

codes identify what size (grade) the bearing is.

Fig. 8 MAINCAP TIGHTENING SEQUENCE

1 - Stud Location

9 - 202 ENGINE - 5.7LDR

CRANKSHAFT (Continued)

Page 1454 of 2895

INSTALLATION

(1) Throughly clean all gasket resdue from the

engine block.

(2) Use extream care and clean all gasket resdue

from the retainer.

(3) Position the gasket onto the retainer.

(4) Position the retainer onto the engine block.

(5) Install the retainer mounting bolts. Tighten the

bolts to 15 N´m (132 in. lbs.) using a crisscross pat-

tern, starting with the bolt on the lower right.

(6) Install a new rear seal(Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT OIL SEAL - REAR

- INSTALLATION).

(7) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(8) Install the drive plate / flywheel.

(9) Install the transmission.

(10) Check and verify engine oil level.

(11) Start engine and check for leaks.

FLEX PLATE

REMOVAL

(1) Remove the transmission.

(2) Remove the bolts and flexplate.

INSTALLATION

(1) Position the flexplate onto the crankshaft and

install the bolts hand tight.

(2) Tighten the flexplate retaining bolts to 95 N´m

(70 ft. lbs.).

(3) Install the transmission.

PISTON & CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

or a scratch awl.

The pistons are made of a high strength aluminum

alloy. Piston skirts are coated with a solid lubricant

(Molykote) to reduce friction and provide scuff resis-

tance. The piston top ring groove and land is anod-

ized. The connecting rods are made of forged

powdered metal, with a ªfractured capº design. A

pressed fit piston pin is used to attach the piston and

connecting rod.

STANDARD PROCEDUREÐPISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 11).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled.

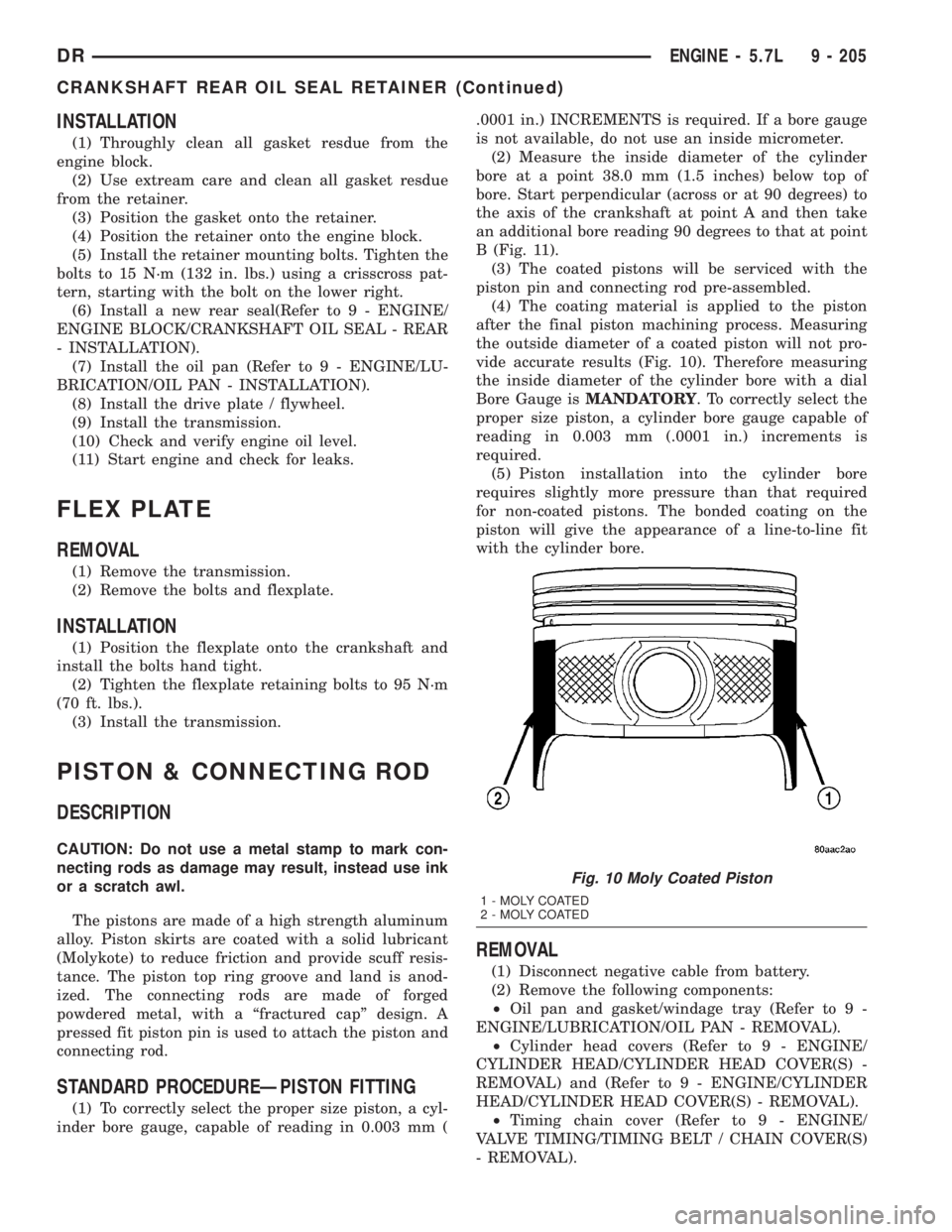

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 10). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components:

²Oil pan and gasket/windage tray (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).

²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

²Timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL).

Fig. 10 Moly Coated Piston

1 - MOLY COATED

2 - MOLY COATED

DRENGINE - 5.7L 9 - 205

CRANKSHAFT REAR OIL SEAL RETAINER (Continued)

Page 1467 of 2895

OIL PUMP

REMOVAL

(1) Remove the oil pan and pick-up tube(Refer to 9

- ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(2) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(3) Remove the four bolts, and the oil pump.

CLEANING

(1) Wash all parts in a suitable solvent.

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump. If

these components are disassembled and or

removed from the pump the entire oil pump assem-

bly must be replaced.

(1) Remove the pump cover.

(2) Clean all parts thoroughly. Mating surface of

the oil pump housing should be smooth. If the pump

cover is scratched or grooved the oil pump assembly

should be replaced.

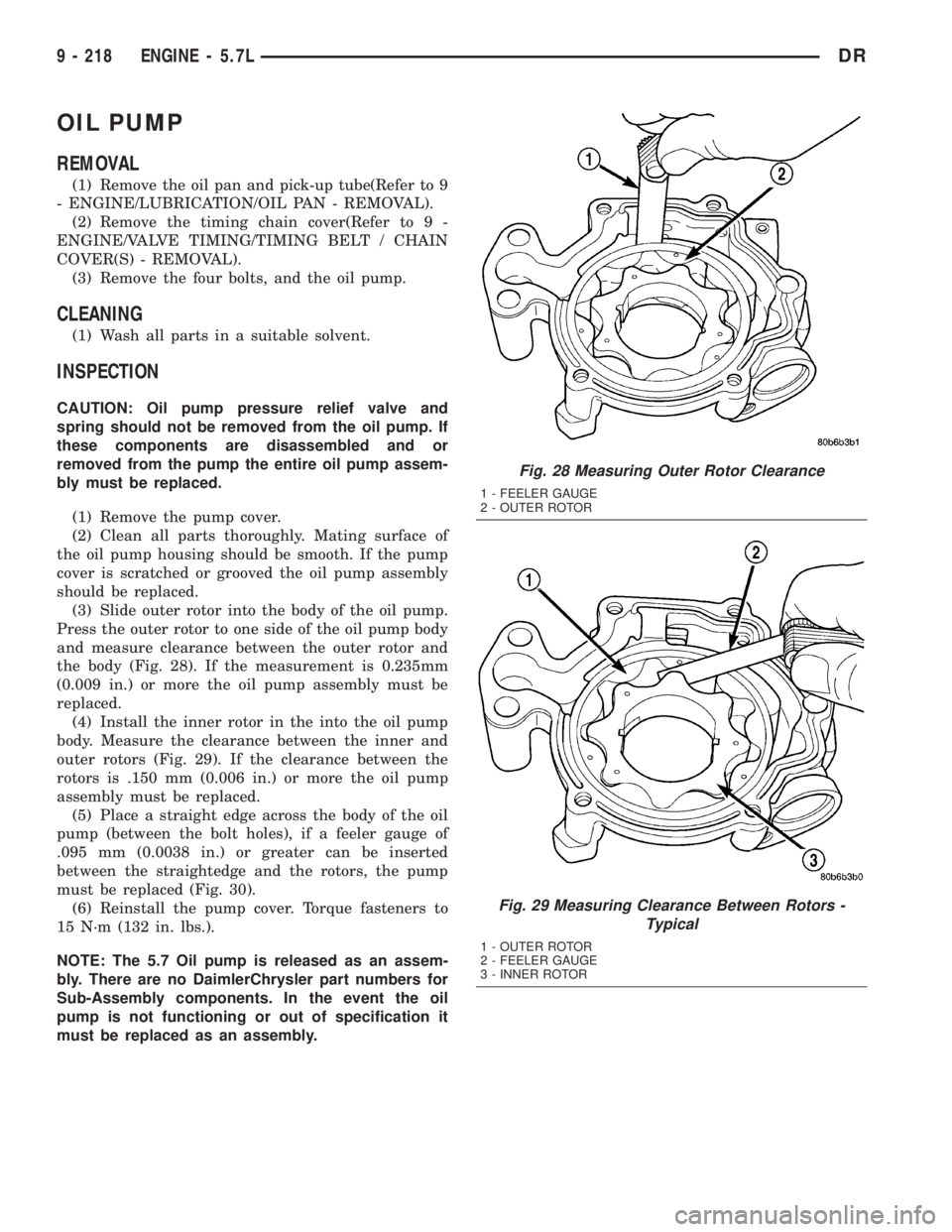

(3) Slide outer rotor into the body of the oil pump.

Press the outer rotor to one side of the oil pump body

and measure clearance between the outer rotor and

the body (Fig. 28). If the measurement is 0.235mm

(0.009 in.) or more the oil pump assembly must be

replaced.

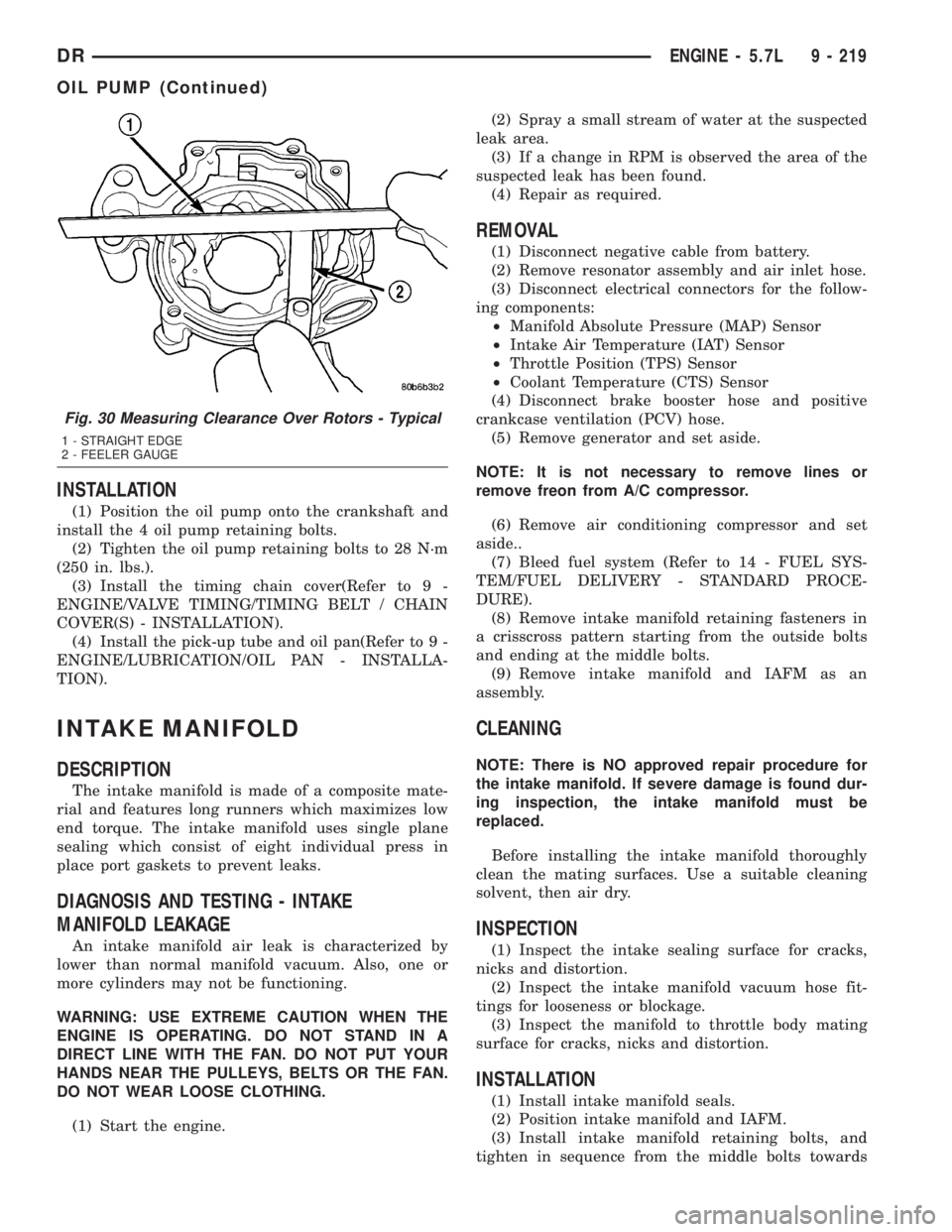

(4) Install the inner rotor in the into the oil pump

body. Measure the clearance between the inner and

outer rotors (Fig. 29). If the clearance between the

rotors is .150 mm (0.006 in.) or more the oil pump

assembly must be replaced.

(5) Place a straight edge across the body of the oil

pump (between the bolt holes), if a feeler gauge of

.095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced (Fig. 30).

(6) Reinstall the pump cover. Torque fasteners to

15 N´m (132 in. lbs.).

NOTE: The 5.7 Oil pump is released as an assem-

bly. There are no DaimlerChrysler part numbers for

Sub-Assembly components. In the event the oil

pump is not functioning or out of specification it

must be replaced as an assembly.

Fig. 28 Measuring Outer Rotor Clearance

1 - FEELER GAUGE

2 - OUTER ROTOR

Fig. 29 Measuring Clearance Between Rotors -

Typical

1 - OUTER ROTOR

2 - FEELER GAUGE

3 - INNER ROTOR

9 - 218 ENGINE - 5.7LDR

Page 1468 of 2895

INSTALLATION

(1) Position the oil pump onto the crankshaft and

install the 4 oil pump retaining bolts.

(2) Tighten the oil pump retaining bolts to 28 N´m

(250 in. lbs.).

(3) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(4) Install the pick-up tube and oil pan(Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is made of a composite mate-

rial and features long runners which maximizes low

end torque. The intake manifold uses single plane

sealing which consist of eight individual press in

place port gaskets to prevent leaks.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect electrical connectors for the follow-

ing components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

(4) Disconnect brake booster hose and positive

crankcase ventilation (PCV) hose.

(5) Remove generator and set aside.

NOTE: It is not necessary to remove lines or

remove freon from A/C compressor.

(6) Remove air conditioning compressor and set

aside..

(7) Bleed fuel system (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY - STANDARD PROCE-

DURE).

(8) Remove intake manifold retaining fasteners in

a crisscross pattern starting from the outside bolts

and ending at the middle bolts.

(9) Remove intake manifold and IAFM as an

assembly.

CLEANING

NOTE: There is NO approved repair procedure for

the intake manifold. If severe damage is found dur-

ing inspection, the intake manifold must be

replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.

(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

INSTALLATION

(1) Install intake manifold seals.

(2) Position intake manifold and IAFM.

(3) Install intake manifold retaining bolts, and

tighten in sequence from the middle bolts towards

Fig. 30 Measuring Clearance Over Rotors - Typical

1 - STRAIGHT EDGE

2 - FEELER GAUGE

DRENGINE - 5.7L 9 - 219

OIL PUMP (Continued)

Page 1469 of 2895

the outside in a crisscross pattern. Torque fasteners

to 12 N´m (105 in. lbs.).

(4) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Install generator.

(6) Install A/C compressor.

(7) Connect Brake booster hose and Positive crank-

case ventilation (PCV) hose.

(8) Install resonator assembly and air inlet hose.

(9) Connect negative cable to battery.

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nut

that is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

exhaust gases to the exhaust pipes attached to the

manifolds.

REMOVAL

EXHAUST MANIFOLD

(1) Disconnect negative battery cable.

(2) Raise vehicle.

(3) Remove exhaust pipe to manifold bolts.

(4) Lower vehicle.

(5) Install engine support fixture special tool

#8534.

(6) Raise engine enough to remove manifolds.

CAUTION: Do not damage engine harness while

raising the engine.

(7) Remove heat shield.

(8) Remove manifold bolts.

(9) Remove manifold and gasket.

CLEANING

Clean mating surfaces on cylinder head and mani-

fold. Wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

EXHAUST MANIFOLD

(1) Install manifold gasket and manifold.

(2) Install manifold bolts and tighten to 25 N´m

(18 ft. lbs.).

(3) Install heat shield and tighten nuts to 15 N´m

(11 ft. lbs.).

(4) Lower engine.

CAUTION: Do not damage engine harness while

lowering the engine.

(5) Remove engine support fixture from engine.

(6) Raise vehicle.

(7) Tighten right and left side engine mount

through bolts.

(8) Install exhaust flange to pipe bolts.

(9) Lower vehicle.

(10) Connect negative battery cable.

TIMING/CHAIN COVER

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove air cleaner assembly.

(3) Drain cooling system.

(4) Remove accessory drive belt.

(5) Remove fan and fan drive assembly (Refer to 7

- COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

(6) Remove coolant bottle and washer bottle.

(7) Remove fan shroud.

NOTE: It is not necessary to disconnect A/C lines or

discharge freon.

(8) Remove A/C compressor and set aside.

(9) Remove the generator.

(10) Remove upper radiator hose.

(11) Disconnect both heater hoses at timing cover.

(12) Disconnect lower radiator hose at engine.

(13) Remove accessory drive belt tensioner and

both idler pulleys.

9 - 220 ENGINE - 5.7LDR

INTAKE MANIFOLD (Continued)

Page 1470 of 2895

(14) Remove crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

NOTE: Do not remove the hoses from the power

steering pump.

(15) Remove power steering pump and set aside.

(16) Remove the dipstick support bolt.

(17) Drain the engine oil.

(18) Remove the oil pan and pick up tube(Refer to

9 - ENGINE/LUBRICATION/OIL PAN - REMOVAL).

NOTE: It is not necessary to remove water pump for

timing cover removal.

(19) Remove timing cover bolts and remove cover.

INSTALLATION

(1) Clean timing chain cover and block surface.

NOTE: Always install a new gasket on timing cover.

(2) Install cover and new gasket. Tighten fasteners

to 28 N´m (250 in. lbs.).

NOTE: The large lifting stud is torqued to 55 N´m

(40 ft. lbs.).

(3) Install the oil pan and pick up tube(Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(4) Install the A/C compressor.

(5) Install the generator.

(6) Install power steering pump.

(7) Install the dipstick support bolt.

(8) Install the thermostat housing.

(9) Install crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(10) Install accessory drive belt tensioner assembly

and both idler pulleys.

(11) Install radiator lower hose.

(12) Install both heater hoses.

(13) Install radiator fan shroud.

(14) Install the fan and fan drive assembly

(15) Install the accessory drive belt.

(16) Install the coolant bottle and washer bottle.

(17) Install the upper radiator hose.

(18) Install the air cleaner assembly.

(19) Fill cooling system.

(20) Refill engine oil.

(21) Connect the battery negative cable.

TIMING/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect battery negative cable.

(2) Drain cooling system.

(3) Remove Timing Chain Cover.

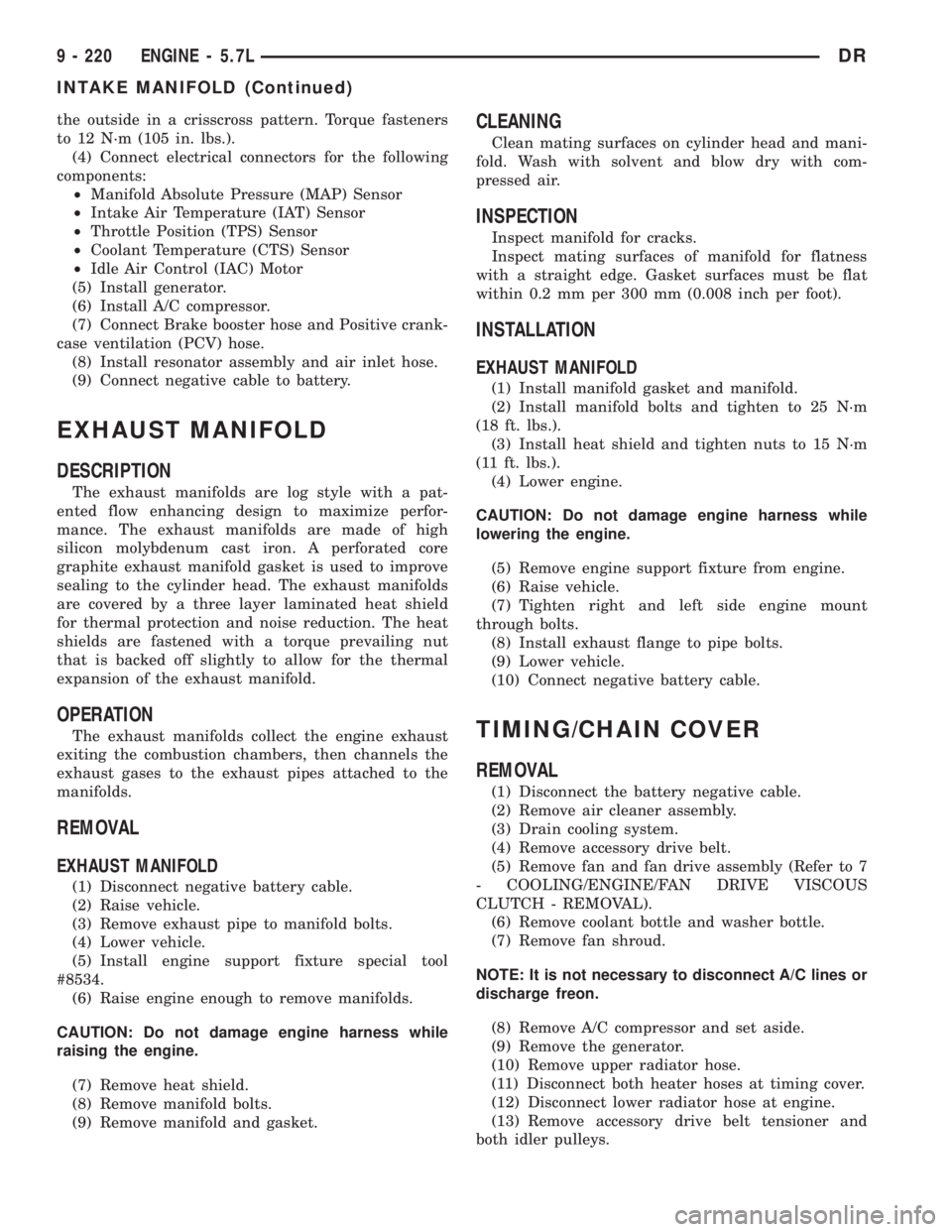

CAUTION: The camshaft pin and the slot in the cam

sprocket must be clocked at 12:00. The crankshaft

keyway must be clocked at 2:00. The crankshaft

sprocket must be installed so that the dots and or

paint marking is at 6:00.

(4) Re-install the vibration damper bolt finger

tight. Using a suitable socket and breaker bar, rotate

the crankshaft to align timing chain sprockets and

keyways as shown (Fig. 31).

(5) Retract tensioner shoe until hole in shoe lines

up with hole in bracket. Slide a suitable pin into the

holes.

(6) Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets.

(7) If tensioner assembly is to be replaced, remove

the tensioner to block bolts and remove tensioner

assembly.

Fig. 31 5.7L TIMING MARK ALIGNMENT

1 - Chain Tensioner

2 - Camshaft Sprocket

3 - Crankshaft Sprocket

DRENGINE - 5.7L 9 - 221

TIMING/CHAIN COVER (Continued)

Page 1471 of 2895

INSTALLATION

(1) If tensioner assembly is being replaced, install

tensioner and mounting bolts. Torque bolts to 28 N´m

(250 in. lbs.).

(2) Retract tensioner if required.

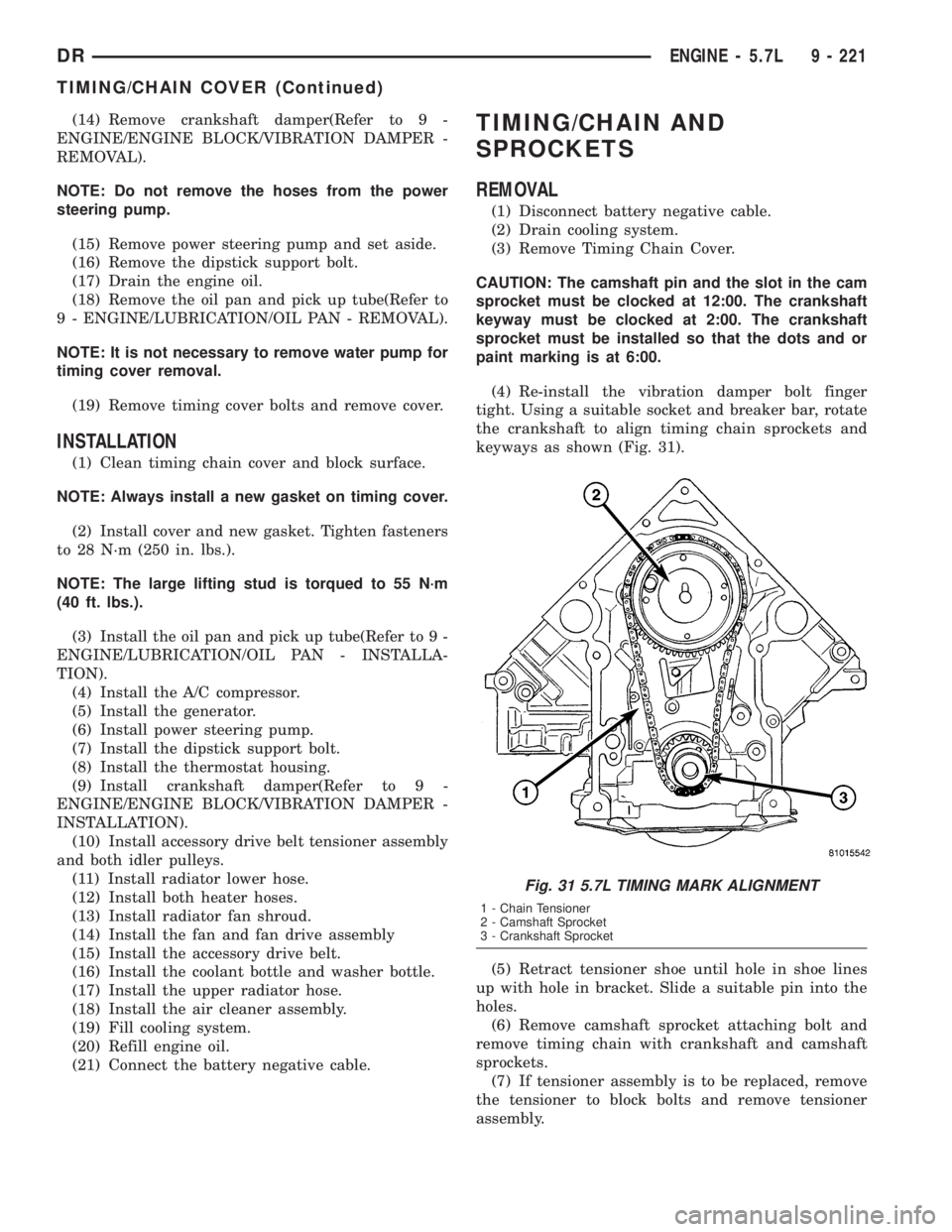

CAUTION: The camshaft pin and the slot in the cam

sprocket must be clocked at 12:00. The crankshaft

keyway must be clocked at 2:00. The crankshaft

sprocket must be installed so that the dots and or

paint marking is at 6:00.

(3) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores (Fig. 32).

CAUTION: The timing chain must be installed with

the single plated link aligned with the dot and or

paint marking on the camshaft sprocket. The crank-

shaft sprocket is aligned with the dot and or paint

marking on the sprocket between two plated timing

chain links.

(4) Place timing chain around both sprockets (Fig.

32).

(5) Lift sprockets and chain (keep sprockets tight

against the chain in position as shown).(6) Slide both sprockets evenly over their respec-

tive shafts and check alignment of timing marks.

(7) Install the camshaft bolt. Tighten the bolt to

122 N´m (90 ft. lbs.) torque.

(8)Remove tensioner pin.Again, verify align-

ment of timing marks.

(9) Install the oil pump(Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(10) Install the oil pan and pick up(Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(11) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(12) Fill cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect battery negative cable.

(14) Start engine and check for oil and coolant

leaks.

TIMING CHAIN/TENSIONER

DESCRIPTION

The timing chain tensioner is a stamped steel con-

stant tension mechanical design. It is mounted to the

front of the engine, behind the timing chain drive.

OPERATION

The timing chain tension is maintained by routing

the timing chain through the tensioner assembly. A

nylon covered spring steel arm presses on the timing

chain maintaining the correct chain tension.

Fig. 32 5.7L TIMING MARK ALIGNMENT

1 - Chain Tensioner

2 - Camshaft Sprocket

3 - Crankshaft Sprocket

9 - 222 ENGINE - 5.7LDR

TIMING/CHAIN AND SPROCKETS (Continued)

Page 1473 of 2895

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTINGÐHYDRAULIC

TAPPETS...........................258

REMOVAL............................259

CLEANING...........................260

INSTALLATION........................260

PISTON & CONNECTING ROD

DESCRIPTION........................260

STANDARD PROCEDURE - PISTON FITTING . 260

REMOVAL............................261

CLEANING...........................261

INSPECTION.........................261

INSTALLATION........................261

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING............................262

VIBRATION DAMPER

REMOVAL............................263

INSTALLATION........................263

FRONT MOUNT

REMOVAL............................264

INSTALLATION........................265

REAR MOUNT

REMOVAL............................266

INSTALLATION........................267

LUBRICATION

DESCRIPTION........................267

OPERATION..........................267

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS.............................269

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE.........................269

OIL

STANDARD PROCEDURE - ENGINE OIL....269

OIL FILTER

REMOVAL............................270INSTALLATION........................270

OIL PAN

REMOVAL............................270

CLEANING...........................270

INSPECTION.........................271

INSTALLATION........................271

OIL PUMP

REMOVAL............................272

DISASSEMBLY........................272

INSPECTION.........................272

ASSEMBLY...........................274

INSTALLATION........................274

INTAKE MANIFOLD

DESCRIPTION........................274

OPERATION..........................274

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE.................274

REMOVAL............................275

CLEANING...........................275

INSPECTION.........................275

INSTALLATION........................275

EXHAUST MANIFOLD

DESCRIPTION........................277

OPERATION..........................277

REMOVAL............................277

CLEANING...........................277

INSPECTION.........................277

INSTALLATION........................277

TIMING BELT / CHAIN COVER(S)

REMOVAL............................278

INSTALLATION........................278

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL............................279

INSPECTIONÐMEASURING TIMING CHAIN

STRETCH..........................279

INSTALLATION........................279

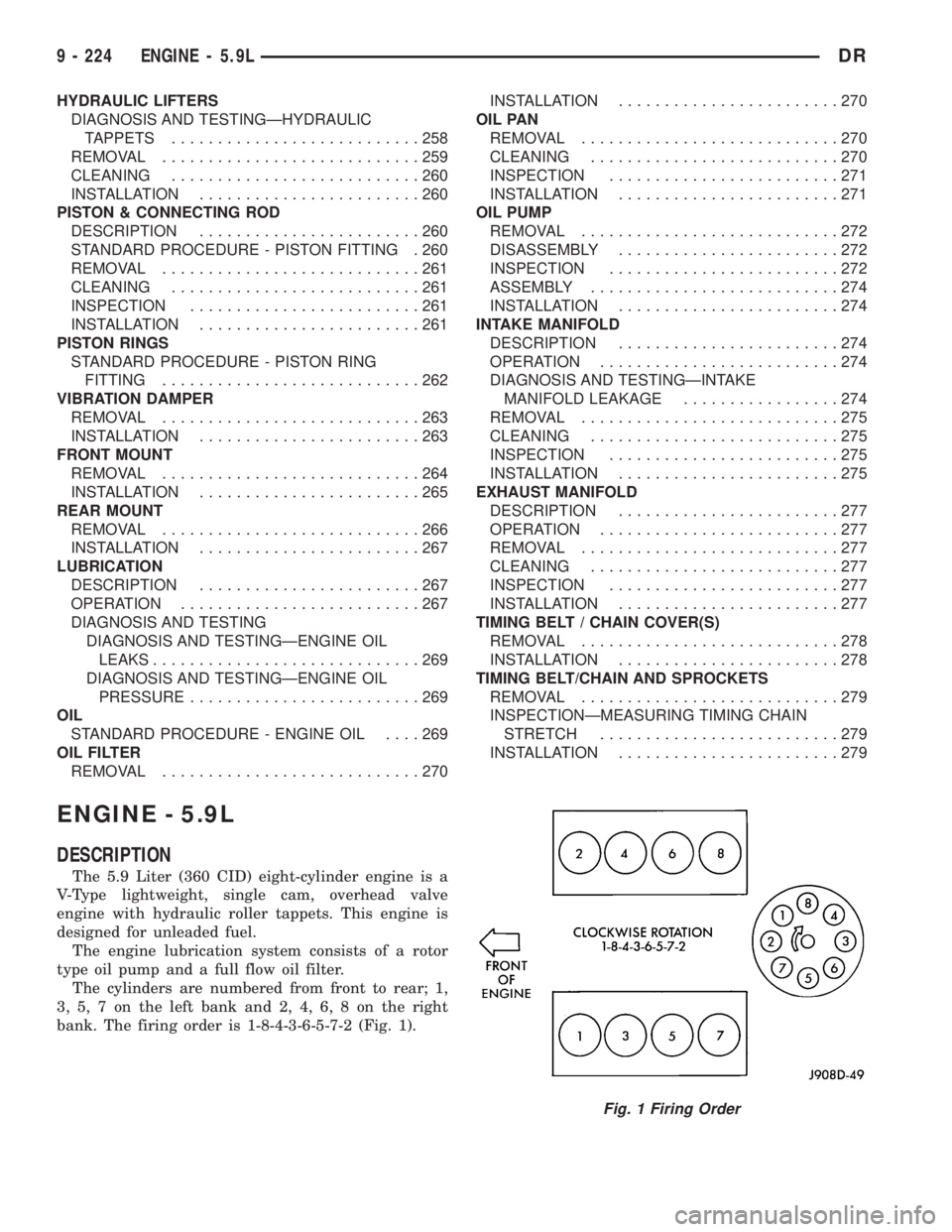

ENGINE - 5.9L

DESCRIPTION

The 5.9 Liter (360 CID) eight-cylinder engine is a

V-Type lightweight, single cam, overhead valve

engine with hydraulic roller tappets. This engine is

designed for unleaded fuel.

The engine lubrication system consists of a rotor

type oil pump and a full flow oil filter.

The cylinders are numbered from front to rear; 1,

3, 5, 7 on the left bank and 2, 4, 6, 8 on the right

bank. The firing order is 1-8-4-3-6-5-7-2 (Fig. 1).

Fig. 1 Firing Order

9 - 224 ENGINE - 5.9LDR

Page 1475 of 2895

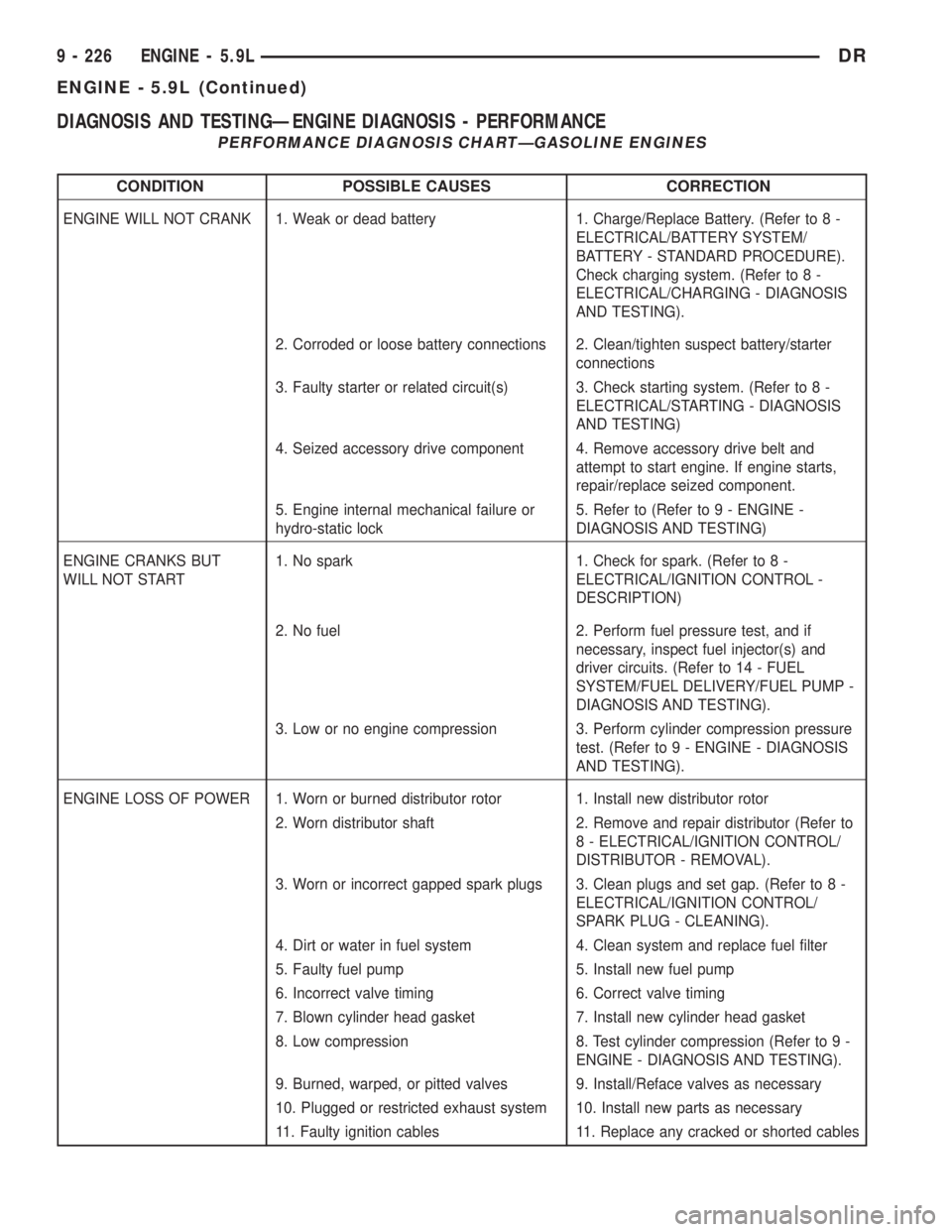

DIAGNOSIS AND TESTINGÐENGINE DIAGNOSIS - PERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE).

Check charging system. (Refer to 8 -

ELECTRICAL/CHARGING - DIAGNOSIS

AND TESTING).

2. Corroded or loose battery connections 2. Clean/tighten suspect battery/starter

connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8 -

ELECTRICAL/STARTING - DIAGNOSIS

AND TESTING)

4. Seized accessory drive component 4. Remove accessory drive belt and

attempt to start engine. If engine starts,

repair/replace seized component.

5. Engine internal mechanical failure or

hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT

WILL NOT START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING).

3. Low or no engine compression 3. Perform cylinder compression pressure

test. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor (Refer to

8 - ELECTRICAL/IGNITION CONTROL/

DISTRIBUTOR - REMOVAL).

3. Worn or incorrect gapped spark plugs 3. Clean plugs and set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG - CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

9. Burned, warped, or pitted valves 9. Install/Reface valves as necessary

10. Plugged or restricted exhaust system 10. Install new parts as necessary

11. Faulty ignition cables 11. Replace any cracked or shorted cables

9 - 226 ENGINE - 5.9LDR

ENGINE - 5.9L (Continued)

Page 1499 of 2895

(1) Remove oil pressure sending unit from back of

block.

(2) Insert a 3.175 mm (1/8 in.) finish wire, or

equivalent, into passage.

(3) Plug should be 190.0 to 195.2 mm (7-1/2 to

7-11/16 in.) from machined surface of block (Fig. 19).

If plug is too high, use a suitable flat dowel to posi-

tion properly.

(4) If plug is too low, remove oil pan and No. 4

main bearing cap. Use suitable flat dowel to position

properly. Coat outside diameter of plug with Mopart

Stud and Bearing Mount Adhesive. Plug should be

54.0 to 57.7 mm (2-1/8 to 2-5/16 in.) from bottom of

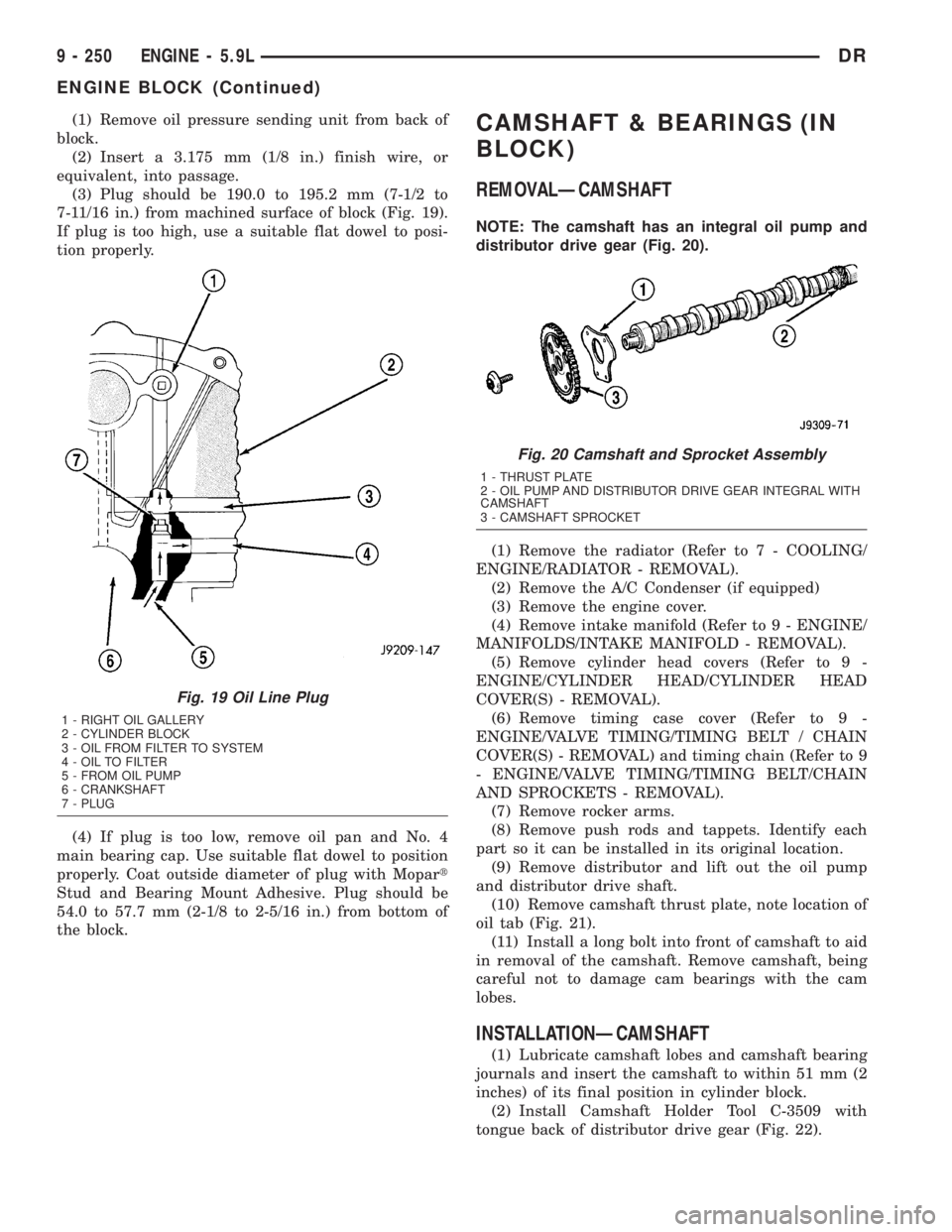

the block.CAMSHAFT & BEARINGS (IN

BLOCK)

REMOVALÐCAMSHAFT

NOTE: The camshaft has an integral oil pump and

distributor drive gear (Fig. 20).

(1) Remove the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - REMOVAL).

(2) Remove the A/C Condenser (if equipped)

(3) Remove the engine cover.

(4) Remove intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

(5) Remove cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(6) Remove timing case cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL) and timing chain (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - REMOVAL).

(7) Remove rocker arms.

(8) Remove push rods and tappets. Identify each

part so it can be installed in its original location.

(9) Remove distributor and lift out the oil pump

and distributor drive shaft.

(10) Remove camshaft thrust plate, note location of

oil tab (Fig. 21).

(11) Install a long bolt into front of camshaft to aid

in removal of the camshaft. Remove camshaft, being

careful not to damage cam bearings with the cam

lobes.

INSTALLATIONÐCAMSHAFT

(1) Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft to within 51 mm (2

inches) of its final position in cylinder block.

(2) Install Camshaft Holder Tool C-3509 with

tongue back of distributor drive gear (Fig. 22).

Fig. 19 Oil Line Plug

1 - RIGHT OIL GALLERY

2 - CYLINDER BLOCK

3 - OIL FROM FILTER TO SYSTEM

4 - OIL TO FILTER

5 - FROM OIL PUMP

6 - CRANKSHAFT

7 - PLUG

Fig. 20 Camshaft and Sprocket Assembly

1 - THRUST PLATE

2 - OIL PUMP AND DISTRIBUTOR DRIVE GEAR INTEGRAL WITH

CAMSHAFT

3 - CAMSHAFT SPROCKET

9 - 250 ENGINE - 5.9LDR

ENGINE BLOCK (Continued)