boot DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2500 of 2895

SHIFT MOTOR ASSEMBLY AND FRONT OUTPUT

SHAFT SEAL

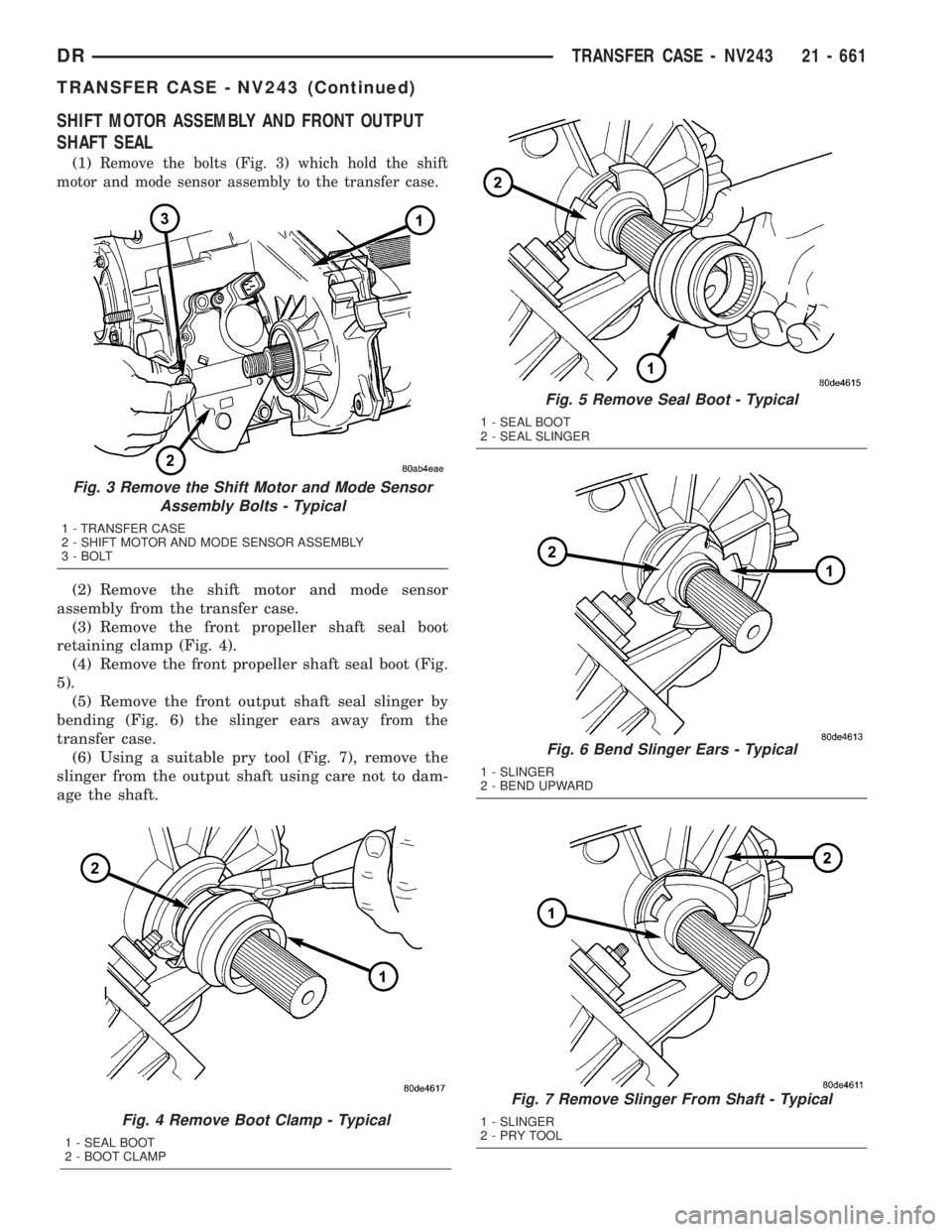

(1)Remove the bolts (Fig. 3) which hold the shift

motor and mode sensor assembly to the transfer case.

(2) Remove the shift motor and mode sensor

assembly from the transfer case.

(3) Remove the front propeller shaft seal boot

retaining clamp (Fig. 4).

(4) Remove the front propeller shaft seal boot (Fig.

5).

(5) Remove the front output shaft seal slinger by

bending (Fig. 6) the slinger ears away from the

transfer case.

(6) Using a suitable pry tool (Fig. 7), remove the

slinger from the output shaft using care not to dam-

age the shaft.

Fig. 4 Remove Boot Clamp - Typical

1 - SEAL BOOT

2 - BOOT CLAMP

Fig. 3 Remove the Shift Motor and Mode Sensor

Assembly Bolts - Typical

1 - TRANSFER CASE

2 - SHIFT MOTOR AND MODE SENSOR ASSEMBLY

3 - BOLT

Fig. 5 Remove Seal Boot - Typical

1 - SEAL BOOT

2 - SEAL SLINGER

Fig. 6 Bend Slinger Ears - Typical

1 - SLINGER

2 - BEND UPWARD

Fig. 7 Remove Slinger From Shaft - Typical

1 - SLINGER

2-PRYTOOL

DRTRANSFER CASE - NV243 21 - 661

TRANSFER CASE - NV243 (Continued)

Page 2517 of 2895

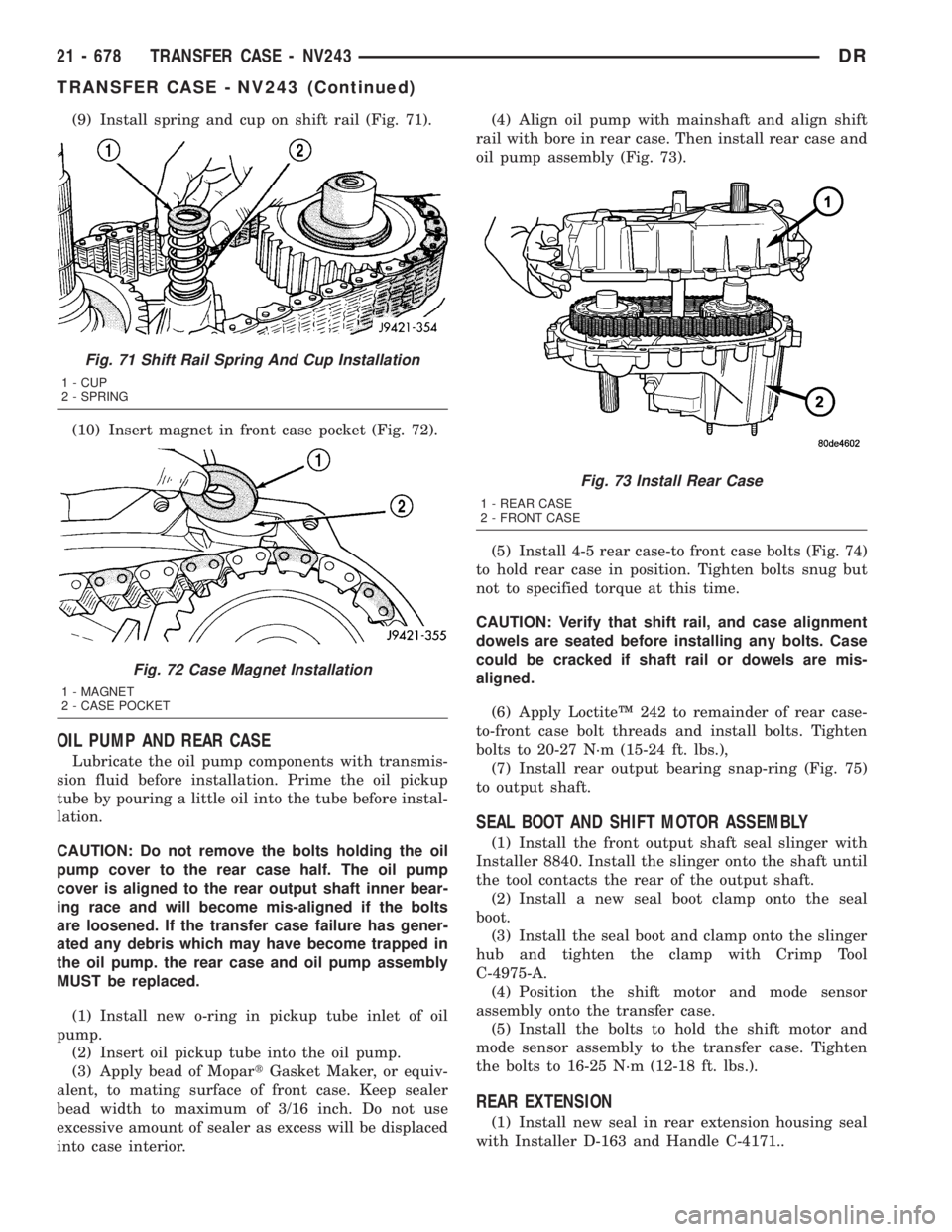

(9) Install spring and cup on shift rail (Fig. 71).

(10) Insert magnet in front case pocket (Fig. 72).

OIL PUMP AND REAR CASE

Lubricate the oil pump components with transmis-

sion fluid before installation. Prime the oil pickup

tube by pouring a little oil into the tube before instal-

lation.

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner bear-

ing race and will become mis-aligned if the bolts

are loosened. If the transfer case failure has gener-

ated any debris which may have become trapped in

the oil pump. the rear case and oil pump assembly

MUST be replaced.

(1) Install new o-ring in pickup tube inlet of oil

pump.

(2) Insert oil pickup tube into the oil pump.

(3) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.(4) Align oil pump with mainshaft and align shift

rail with bore in rear case. Then install rear case and

oil pump assembly (Fig. 73).

(5) Install 4-5 rear case-to front case bolts (Fig. 74)

to hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts. Case

could be cracked if shaft rail or dowels are mis-

aligned.

(6) Apply LoctiteŸ 242 to remainder of rear case-

to-front case bolt threads and install bolts. Tighten

bolts to 20-27 N´m (15-24 ft. lbs.),

(7) Install rear output bearing snap-ring (Fig. 75)

to output shaft.

SEAL BOOT AND SHIFT MOTOR ASSEMBLY

(1) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(2) Install a new seal boot clamp onto the seal

boot.

(3) Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool

C-4975-A.

(4) Position the shift motor and mode sensor

assembly onto the transfer case.

(5) Install the bolts to hold the shift motor and

mode sensor assembly to the transfer case. Tighten

the bolts to 16-25 N´m (12-18 ft. lbs.).

REAR EXTENSION

(1) Install new seal in rear extension housing seal

with Installer D-163 and Handle C-4171..

Fig. 71 Shift Rail Spring And Cup Installation

1 - CUP

2 - SPRING

Fig. 72 Case Magnet Installation

1 - MAGNET

2 - CASE POCKET

Fig. 73 Install Rear Case

1 - REAR CASE

2 - FRONT CASE

21 - 678 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2522 of 2895

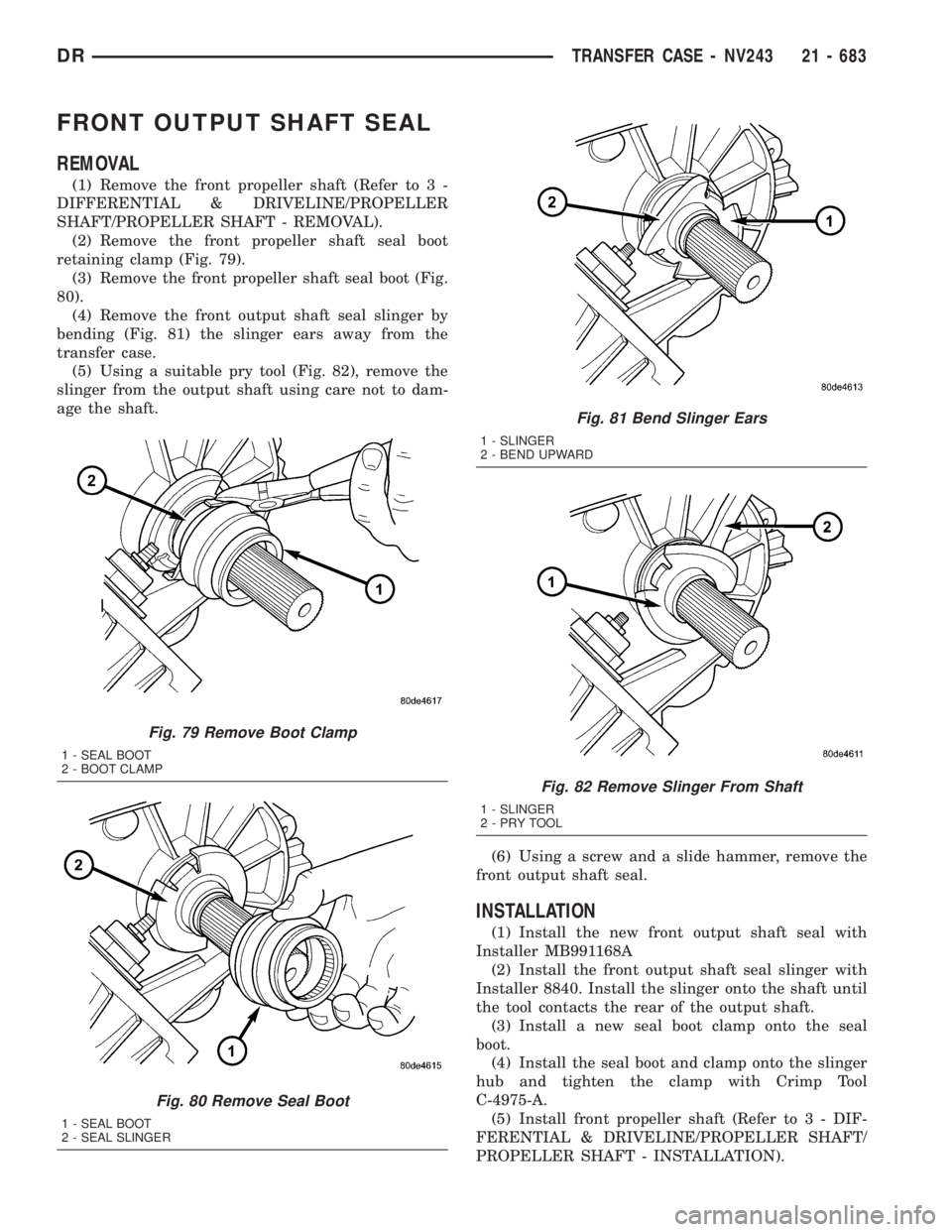

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

(2) Remove the front propeller shaft seal boot

retaining clamp (Fig. 79).

(3) Remove the front propeller shaft seal boot (Fig.

80).

(4) Remove the front output shaft seal slinger by

bending (Fig. 81) the slinger ears away from the

transfer case.

(5) Using a suitable pry tool (Fig. 82), remove the

slinger from the output shaft using care not to dam-

age the shaft.

(6) Using a screw and a slide hammer, remove the

front output shaft seal.

INSTALLATION

(1) Install the new front output shaft seal with

Installer MB991168A

(2) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(3) Install a new seal boot clamp onto the seal

boot.

(4) Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool

C-4975-A.

(5) Install front propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION).

Fig. 79 Remove Boot Clamp

1 - SEAL BOOT

2 - BOOT CLAMP

Fig. 80 Remove Seal Boot

1 - SEAL BOOT

2 - SEAL SLINGER

Fig. 81 Bend Slinger Ears

1 - SLINGER

2 - BEND UPWARD

Fig. 82 Remove Slinger From Shaft

1 - SLINGER

2-PRYTOOL

DRTRANSFER CASE - NV243 21 - 683

Page 2526 of 2895

TRANSFER CASE - NV273

TABLE OF CONTENTS

page page

TRANSFER CASE - NV273

DESCRIPTION........................687

OPERATION..........................688

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV273.......................688

REMOVAL............................689

DISASSEMBLY........................689

CLEANING...........................698

INSPECTION.........................699

ASSEMBLY...........................701

INSTALLATION........................713

SPECIFICATIONS

TRANSFER CASE - NV273.............713

SPECIAL TOOLS

TRANSFER CASE NV271/NV273.........714

EXTENSION HOUSING SEAL AND DUST BOOT

REMOVAL............................716

INSTALLATION........................716FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................716

FRONT OUTPUT SHAFT SEAL

REMOVAL............................717

INSTALLATION........................717

MODE SENSOR

DESCRIPTION........................718

OPERATION..........................718

SELECTOR SWITCH

DESCRIPTION........................719

OPERATION..........................719

SHIFT MOTOR

DESCRIPTION........................720

OPERATION..........................720

REMOVAL............................720

INSTALLATION........................720

TRANSFER CASE - NV273

DESCRIPTION

The NV273 is an electronically controlled part-time

transfer case with a low range gear reduction system.

The NV273 has three operating ranges plus a NEU-

TRAL position. The low range system provides a gear

reduction ratio for increased low speed torque capa-

bility.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum case halves.

OPERATING RANGES

Transfer case operating ranges are:

²2WD (2-wheel drive)

²4HI (4-wheel drive)

²4LO (4-wheel drive low range)

²NEUTRAL

The 2WD range is for use on any road surface at

any time.The 4HI and 4LO ranges are for off road use only.

They are not for use on hard surface roads. The only

exception being when the road surface is wet or slip-

pery or covered by ice and snow.

The low range reduction gear system is operative

in 4LO range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1.

SHIFT MECHANISM

Operating ranges are selected with a dash

mounted shift selector switch. The shift selector

switch provides a input to the Transfer Case Control

Module (TCCM) to indicate the driver's desire to

change operating ranges. The TCCM uses this input,

along with input from the transfer case mounted

mode sensor and information from the vehicle's bus,

to determine if a shift is permitted. If the TCCM

decides the shift is permitted, the TCCM controls the

shift motor, mounted to the exterior of the transfer

case, to perform the shift.

DRTRANSFER CASE - NV273 21 - 687

Page 2529 of 2895

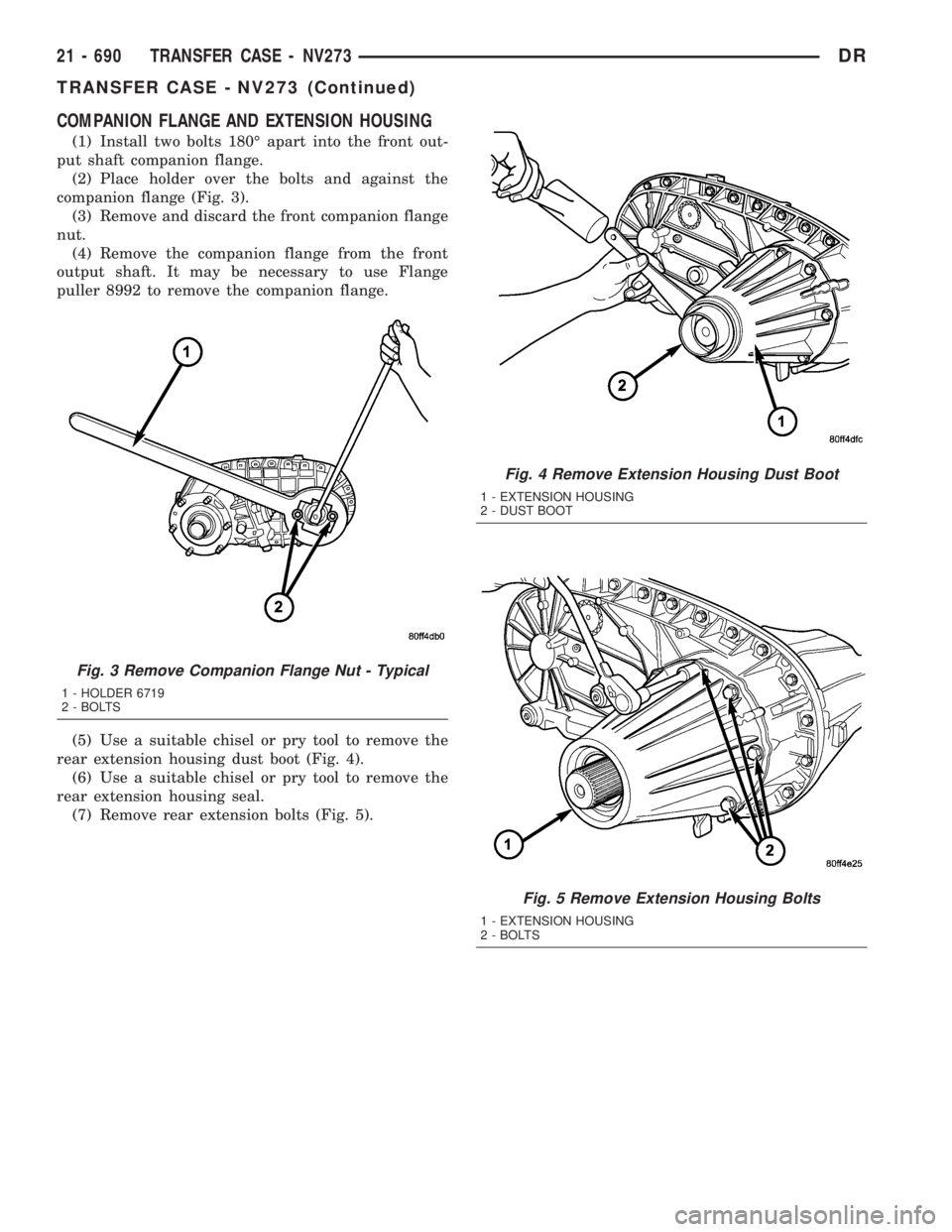

COMPANION FLANGE AND EXTENSION HOUSING

(1) Install two bolts 180É apart into the front out-

put shaft companion flange.

(2) Place holder over the bolts and against the

companion flange (Fig. 3).

(3) Remove and discard the front companion flange

nut.

(4) Remove the companion flange from the front

output shaft. It may be necessary to use Flange

puller 8992 to remove the companion flange.

(5) Use a suitable chisel or pry tool to remove the

rear extension housing dust boot (Fig. 4).

(6) Use a suitable chisel or pry tool to remove the

rear extension housing seal.

(7) Remove rear extension bolts (Fig. 5).

Fig. 3 Remove Companion Flange Nut - Typical

1 - HOLDER 6719

2 - BOLTS

Fig. 4 Remove Extension Housing Dust Boot

1 - EXTENSION HOUSING

2 - DUST BOOT

Fig. 5 Remove Extension Housing Bolts

1 - EXTENSION HOUSING

2 - BOLTS

21 - 690 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2551 of 2895

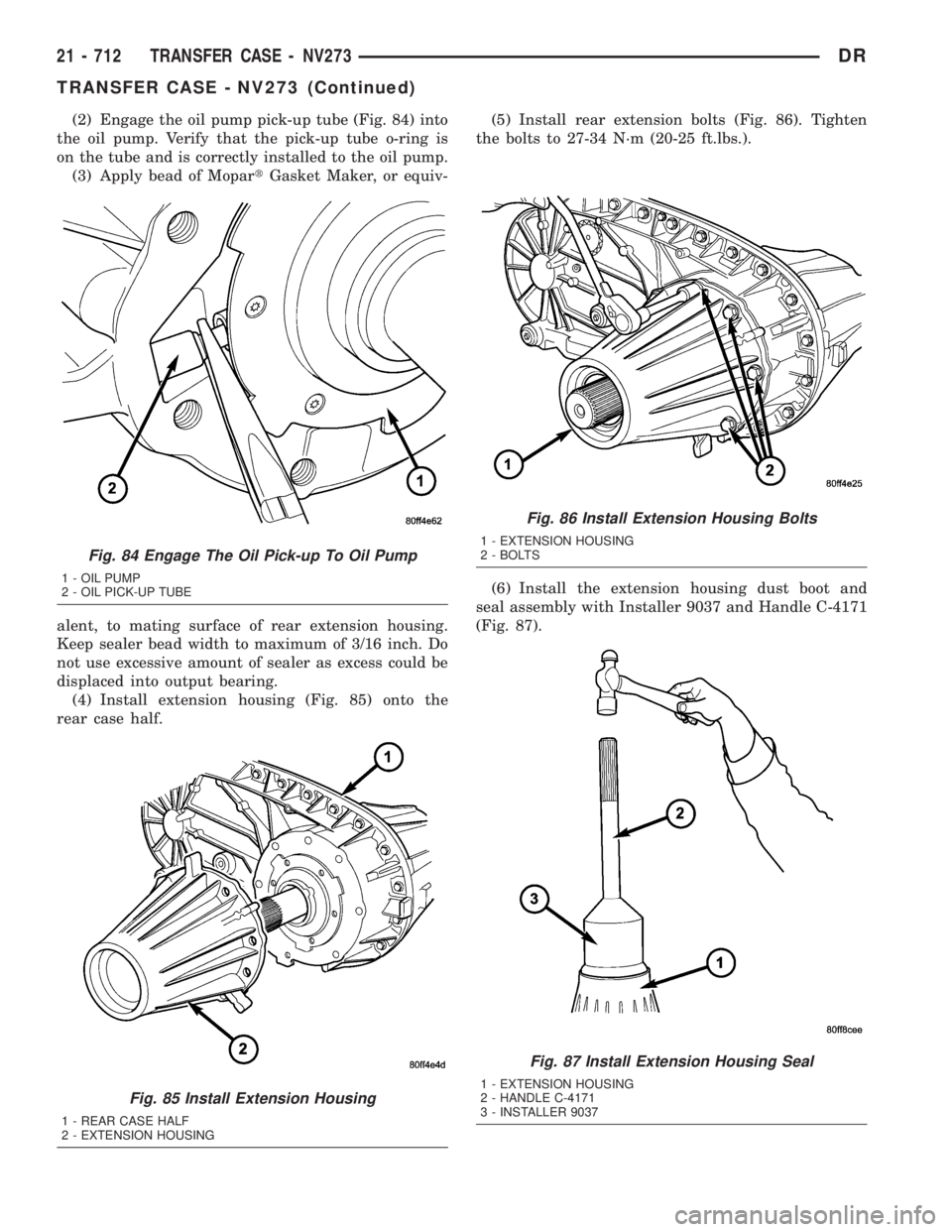

(2) Engage the oil pump pick-up tube (Fig. 84) into

the oil pump. Verify that the pick-up tube o-ring is

on the tube and is correctly installed to the oil pump.

(3) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of rear extension housing.

Keep sealer bead width to maximum of 3/16 inch. Do

not use excessive amount of sealer as excess could be

displaced into output bearing.

(4) Install extension housing (Fig. 85) onto the

rear case half.(5) Install rear extension bolts (Fig. 86). Tighten

the bolts to 27-34 N´m (20-25 ft.lbs.).

(6) Install the extension housing dust boot and

seal assembly with Installer 9037 and Handle C-4171

(Fig. 87).

Fig. 84 Engage The Oil Pick-up To Oil Pump

1 - OIL PUMP

2 - OIL PICK-UP TUBE

Fig. 85 Install Extension Housing

1 - REAR CASE HALF

2 - EXTENSION HOUSING

Fig. 86 Install Extension Housing Bolts

1 - EXTENSION HOUSING

2 - BOLTS

Fig. 87 Install Extension Housing Seal

1 - EXTENSION HOUSING

2 - HANDLE C-4171

3 - INSTALLER 9037

21 - 712 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2555 of 2895

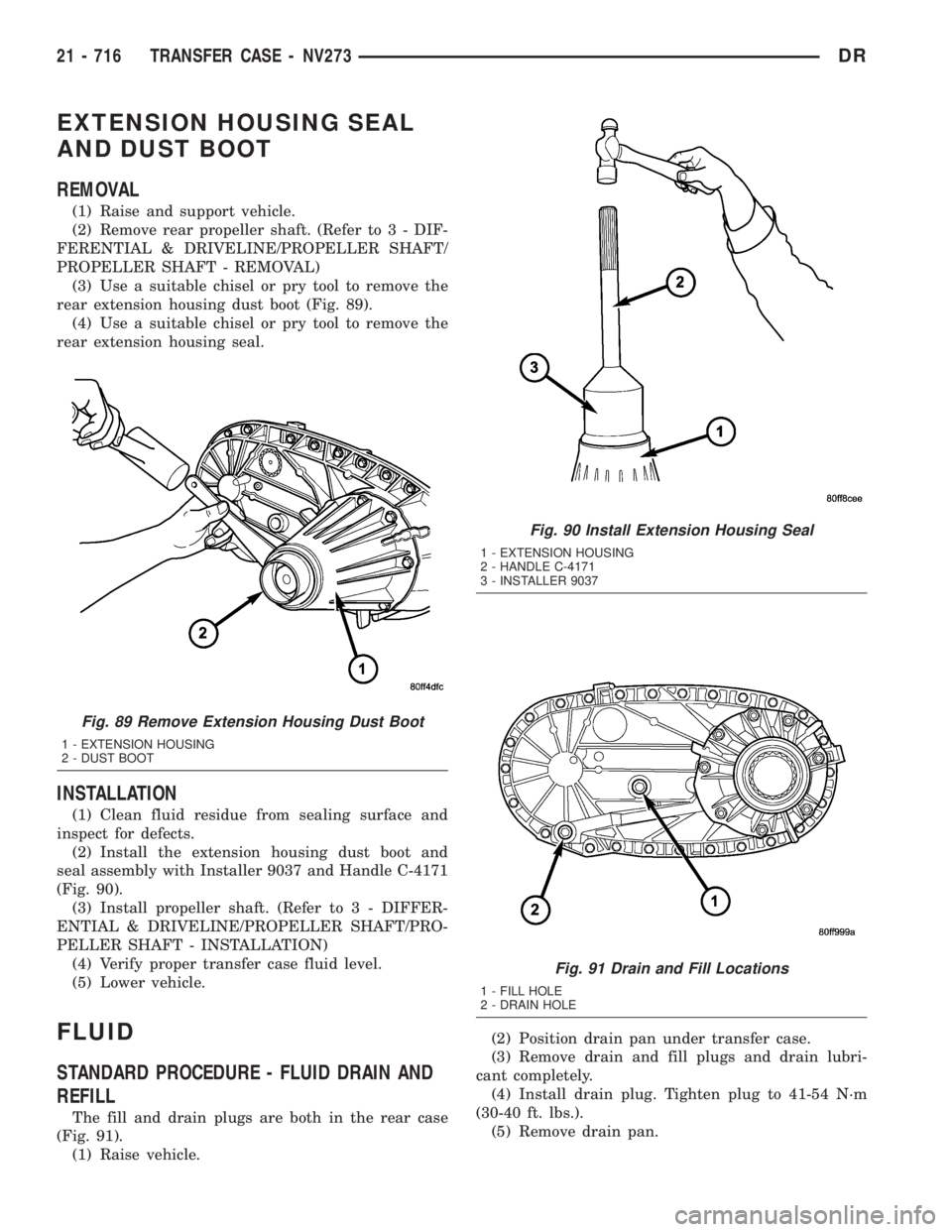

EXTENSION HOUSING SEAL

AND DUST BOOT

REMOVAL

(1) Raise and support vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Use a suitable chisel or pry tool to remove the

rear extension housing dust boot (Fig. 89).

(4) Use a suitable chisel or pry tool to remove the

rear extension housing seal.

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Install the extension housing dust boot and

seal assembly with Installer 9037 and Handle C-4171

(Fig. 90).

(3) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

(4) Verify proper transfer case fluid level.

(5) Lower vehicle.

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

The fill and drain plugs are both in the rear case

(Fig. 91).

(1) Raise vehicle.(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 41-54 N´m

(30-40 ft. lbs.).

(5) Remove drain pan.

Fig. 89 Remove Extension Housing Dust Boot

1 - EXTENSION HOUSING

2 - DUST BOOT

Fig. 90 Install Extension Housing Seal

1 - EXTENSION HOUSING

2 - HANDLE C-4171

3 - INSTALLER 9037

Fig. 91 Drain and Fill Locations

1 - FILL HOLE

2 - DRAIN HOLE

21 - 716 TRANSFER CASE - NV273DR

Page 2638 of 2895

INTERIOR

TABLE OF CONTENTS

page page

INTERIOR

CAUTION.............................63

4WD FLOOR SHIFT BOOT

REMOVAL.............................63

INSTALLATION.........................64

A-PILLAR TRIM/GRAB HANDLE

REMOVAL.............................64

INSTALLATION.........................64

B-PILLAR LOWER TRIM

REMOVAL.............................64

INSTALLATION.........................65

B-PILLAR UPPER TRIM

REMOVAL.............................65

INSTALLATION.........................65

CARPETS AND FLOOR MATS

REMOVAL.............................66

INSTALLATION.........................66

COAT HOOK

REMOVAL.............................67

INSTALLATION.........................67

COWL TRIM

REMOVAL.............................67

INSTALLATION.........................67

C-PILLAR LOWER TRIM

REMOVAL.............................67

INSTALLATION.........................68

C-PILLAR UPPER TRIM

REMOVAL.............................68

INSTALLATION.........................68

FLOOR CONSOLE

REMOVAL.............................68

INSTALLATION.........................68

HEADLINER

REMOVAL.............................69INSTALLATION.........................69

B-PILLAR GRAB HANDLE

REMOVAL.............................69

INSTALLATION.........................69

REAR CAB BACK PANEL TRIM

REMOVAL.............................70

INSTALLATION.........................70

REAR VIEW MIRROR

REMOVAL.............................71

INSTALLATION

INSTALLATION.......................71

INSTALLATION - REARVIEW MIRROR

SUPPORT BRACKET...................71

SUN VISOR

REMOVAL.............................71

INSTALLATION.........................71

SUN VISOR SUPPORT

REMOVAL.............................72

INSTALLATION.........................72

BODY VENT

REMOVAL.............................72

INSTALLATION.........................72

REAR DOOR SILL TRIM COVER

REMOVAL.............................72

INSTALLATION.........................72

LOAD FLOOR

REMOVAL.............................73

INSTALLATION.........................73

LOAD FLOOR SUPPORT CYLINDER

REMOVAL.............................73

INSTALLATION.........................73

INTERIOR

CAUTION

CAUTION:: Do not attempt to remove interior trim

panels/moldings without first removing the neces-

sary adjacent panels. To avoid damaging the pan-

els, ensure that all the screws and clips are

removed before attempting to remove an interior

trim panel/molding. Trim panels are somewhat flex-

ible but can be damaged if handled improperly.

4WD FLOOR SHIFT BOOT

REMOVAL

(1) Using a small pry bar or equivalent, remove

the insert, the nut and remove the shifter knob. (Fig.

2)

(2) Using a trim stick C-4755 or equivalent, pry up

the boot from the console. (Fig. 1)

DRINTERIOR 23 - 63

Page 2639 of 2895

INSTALLATION

(1) Position the shift boot over the shifter lever

fully seat onto the console.

(2) Install the shifter knob and nut and tighten to

27 N´m (20 ft. lbs.).

(3) Position the insert and seat into the knob fully.

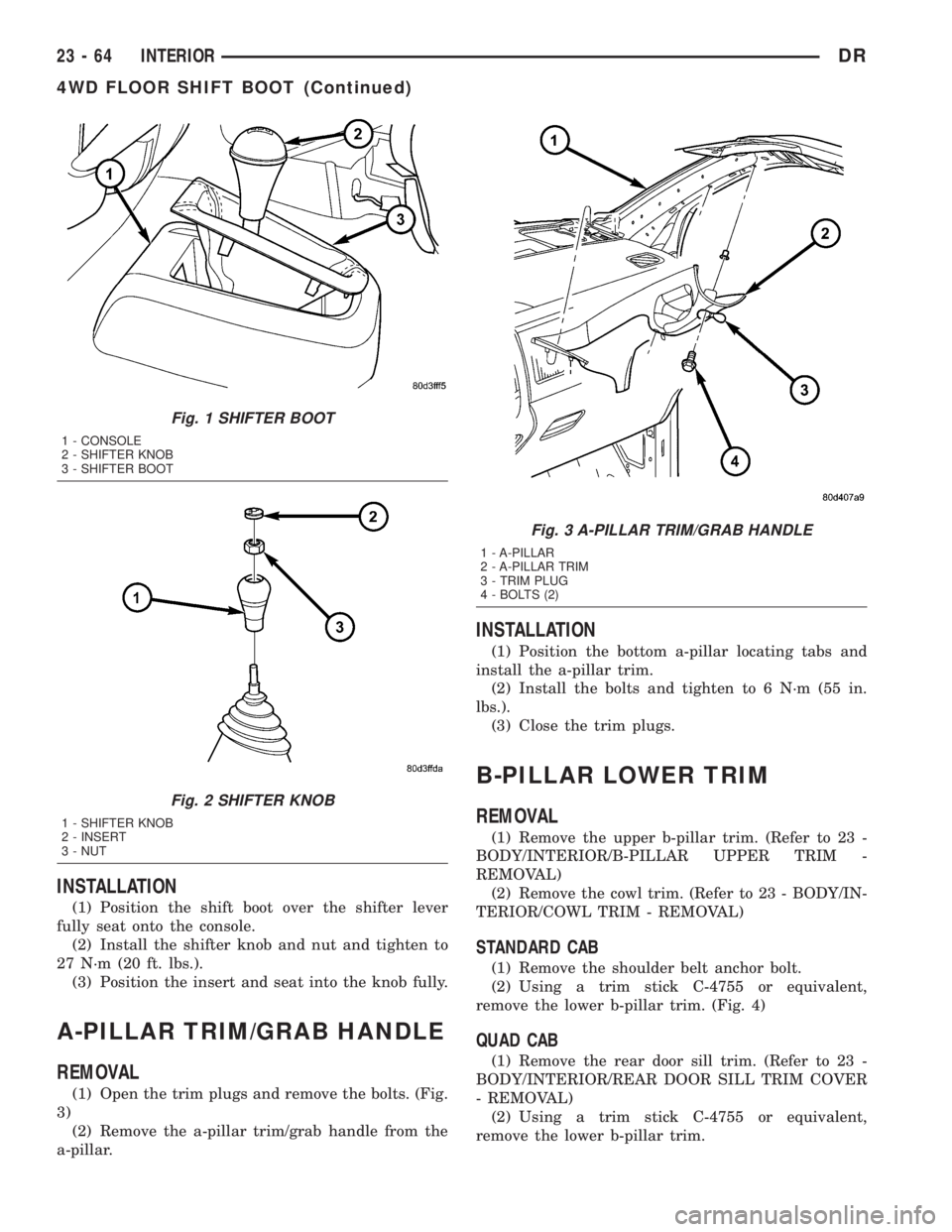

A-PILLAR TRIM/GRAB HANDLE

REMOVAL

(1) Open the trim plugs and remove the bolts. (Fig.

3)

(2) Remove the a-pillar trim/grab handle from the

a-pillar.

INSTALLATION

(1) Position the bottom a-pillar locating tabs and

install the a-pillar trim.

(2) Install the bolts and tighten to 6 N´m (55 in.

lbs.).

(3) Close the trim plugs.

B-PILLAR LOWER TRIM

REMOVAL

(1) Remove the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL)

(2) Remove the cowl trim. (Refer to 23 - BODY/IN-

TERIOR/COWL TRIM - REMOVAL)

STANDARD CAB

(1) Remove the shoulder belt anchor bolt.

(2) Using a trim stick C-4755 or equivalent,

remove the lower b-pillar trim. (Fig. 4)

QUAD CAB

(1) Remove the rear door sill trim. (Refer to 23 -

BODY/INTERIOR/REAR DOOR SILL TRIM COVER

- REMOVAL)

(2) Using a trim stick C-4755 or equivalent,

remove the lower b-pillar trim.

Fig. 1 SHIFTER BOOT

1 - CONSOLE

2 - SHIFTER KNOB

3 - SHIFTER BOOT

Fig. 2 SHIFTER KNOB

1 - SHIFTER KNOB

2 - INSERT

3 - NUT

Fig. 3 A-PILLAR TRIM/GRAB HANDLE

1 - A-PILLAR

2 - A-PILLAR TRIM

3 - TRIM PLUG

4 - BOLTS (2)

23 - 64 INTERIORDR

4WD FLOOR SHIFT BOOT (Continued)

Page 2643 of 2895

INSTALLATION

(1) Route the shoulder belt through the slot in the

trim.

(2) Position the trim and seat the attachment clips

fully.

(3) Install the seat belt anchor bolt and tighten to

40 N´m (30 ft. lbs.).

(4) Install the upper c-pillar trim. (Refer to 23 -

BODY/INTERIOR/C-PILLAR UPPER TRIM -

INSTALLATION)

C-PILLAR UPPER TRIM

REMOVAL

(1) Remove the seat belt turning loop. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT TURNING

LOOP ADJUSTER - REMOVAL)

(2) Using a trim stick C-4755 or equivalent,

remove the upper c-pillar trim. (Fig. 11)

INSTALLATION

(1) Position the upper c-pillar trim and seat the

attachment clips fully.

(2) Install the seat belt turning loop. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT TURNING

LOOP ADJUSTER - INSTALLATION)

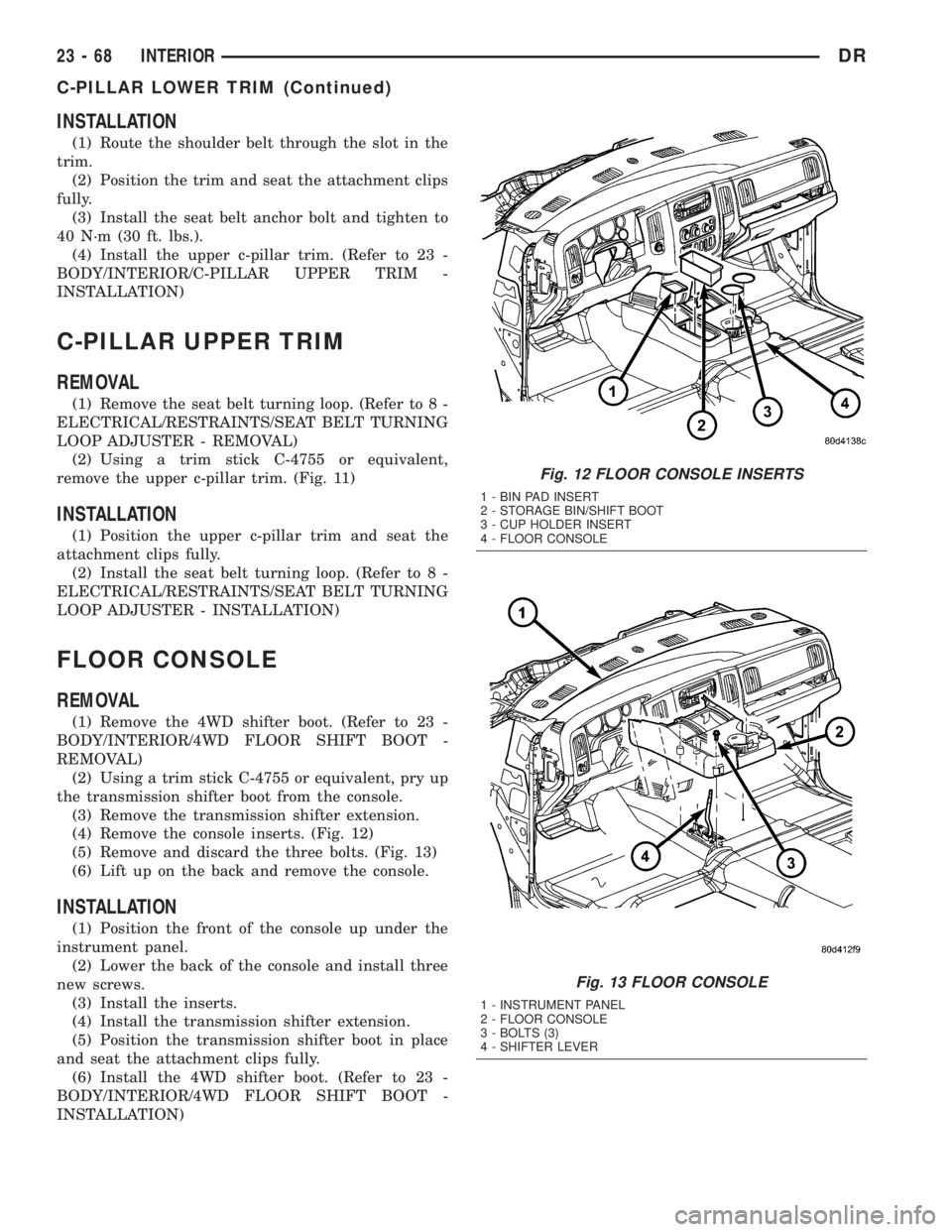

FLOOR CONSOLE

REMOVAL

(1) Remove the 4WD shifter boot. (Refer to 23 -

BODY/INTERIOR/4WD FLOOR SHIFT BOOT -

REMOVAL)

(2) Using a trim stick C-4755 or equivalent, pry up

the transmission shifter boot from the console.

(3) Remove the transmission shifter extension.

(4) Remove the console inserts. (Fig. 12)

(5) Remove and discard the three bolts. (Fig. 13)

(6) Lift up on the back and remove the console.

INSTALLATION

(1) Position the front of the console up under the

instrument panel.

(2) Lower the back of the console and install three

new screws.

(3) Install the inserts.

(4) Install the transmission shifter extension.

(5) Position the transmission shifter boot in place

and seat the attachment clips fully.

(6) Install the 4WD shifter boot. (Refer to 23 -

BODY/INTERIOR/4WD FLOOR SHIFT BOOT -

INSTALLATION)

Fig. 12 FLOOR CONSOLE INSERTS

1 - BIN PAD INSERT

2 - STORAGE BIN/SHIFT BOOT

3 - CUP HOLDER INSERT

4 - FLOOR CONSOLE

Fig. 13 FLOOR CONSOLE

1 - INSTRUMENT PANEL

2 - FLOOR CONSOLE

3 - BOLTS (3)

4 - SHIFTER LEVER

23 - 68 INTERIORDR

C-PILLAR LOWER TRIM (Continued)