check engine light DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1506 of 2895

UPPER SEALÐCRANKSHAFT INSTALLED

(1) Clean the cylinder block mating surfaces before

oil seal installation. Check for burrs at the oil hole on

the cylinder block mating surface to rear cap.

(2) Lightly oil the new upper seal lips with engine

oil. To allow ease of installation of the seal, loosen at

least the two main bearing caps forward of the rear

bearing cap.

(3) Rotate the new upper seal into the cylinder

block, being careful not to shave or cut the outer sur-

face of the seal. To ensure proper installation, use the

installation tool provided with the kit. Install the

new seal with the white paint facing toward the rear

of the engine.

(4) Install the new lower rear bearing oil seal into

the bearing cap with the white paint facing toward

the rear of the engine.

(5) Apply 5 mm (0.20 in.) drop of MopartGasket

Maker, or equivalent, on each side of the rear main

bearing cap (Fig. 32). DO NOT over-apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application. Be sure the white paint faces

toward the rear of the engine.

(6) To align the bearing cap, use cap slot, align-

ment dowel, and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than two times for proper engagement.(7) Install the rear main bearing cap with cleaned

and oiled cap bolts. Alternately tighten ALL cap bolts

to 115 N´m (85 ft. lbs.) torque.

(8) Install oil pump (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PUMP - INSTALLATION).

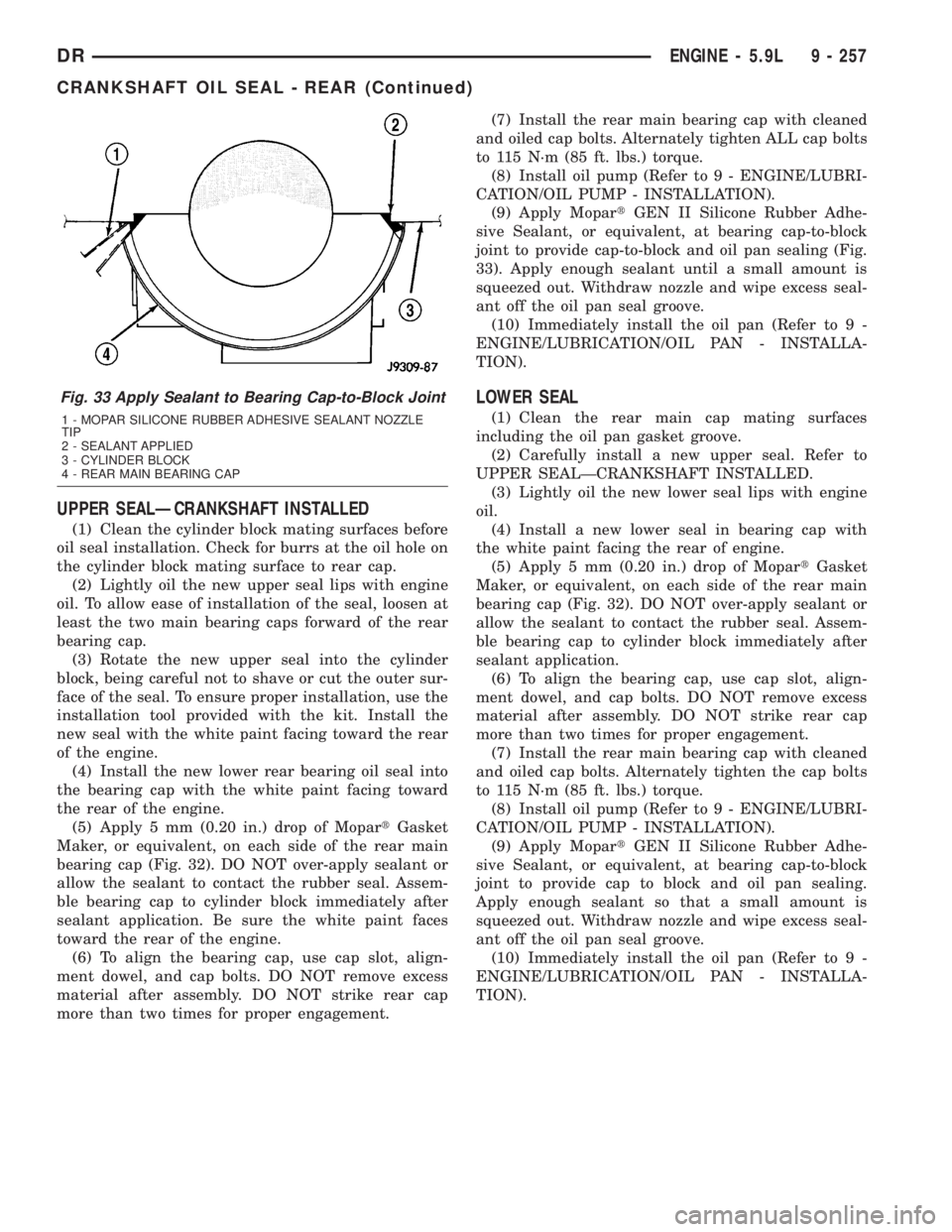

(9) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, at bearing cap-to-block

joint to provide cap-to-block and oil pan sealing (Fig.

33). Apply enough sealant until a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10) Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

LOWER SEAL

(1) Clean the rear main cap mating surfaces

including the oil pan gasket groove.

(2) Carefully install a new upper seal. Refer to

UPPER SEALÐCRANKSHAFT INSTALLED.

(3) Lightly oil the new lower seal lips with engine

oil.

(4) Install a new lower seal in bearing cap with

the white paint facing the rear of engine.

(5) Apply 5 mm (0.20 in.) drop of MopartGasket

Maker, or equivalent, on each side of the rear main

bearing cap (Fig. 32). DO NOT over-apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application.

(6) To align the bearing cap, use cap slot, align-

ment dowel, and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than two times for proper engagement.

(7) Install the rear main bearing cap with cleaned

and oiled cap bolts. Alternately tighten the cap bolts

to 115 N´m (85 ft. lbs.) torque.

(8) Install oil pump (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PUMP - INSTALLATION).

(9) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, at bearing cap-to-block

joint to provide cap to block and oil pan sealing.

Apply enough sealant so that a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10) Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

Fig. 33 Apply Sealant to Bearing Cap-to-Block Joint

1 - MOPAR SILICONE RUBBER ADHESIVE SEALANT NOZZLE

TIP

2 - SEALANT APPLIED

3 - CYLINDER BLOCK

4 - REAR MAIN BEARING CAP

DRENGINE - 5.9L 9 - 257

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1508 of 2895

intake side of oil pump through which air can be

drawn will create the same tappet action. Check the

lubrication system from the intake strainer to the

pump cover, including the relief valve retainer cap.

When tappet noise is due to aeration, it may be

intermittent or constant, and usually more than one

tappet will be noisy. When oil level and leaks have

been corrected, operate the engine at fast idle. Run

engine for a sufficient time to allow all of the air

inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger, or by the

plunger partially sticking in the tappet body cylinder.

The tappet should be replaced. A heavy click is

caused by a tappet check valve not seating, or by for-

eign particles wedged between the plunger and the

tappet body. This will cause the plunger to stick in

the down position. This heavy click will be accompa-

nied by excessive clearance between the valve stem

and rocker arm as valve closes. In either case, tappet

assembly should be removed for inspection and clean-

ing.

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

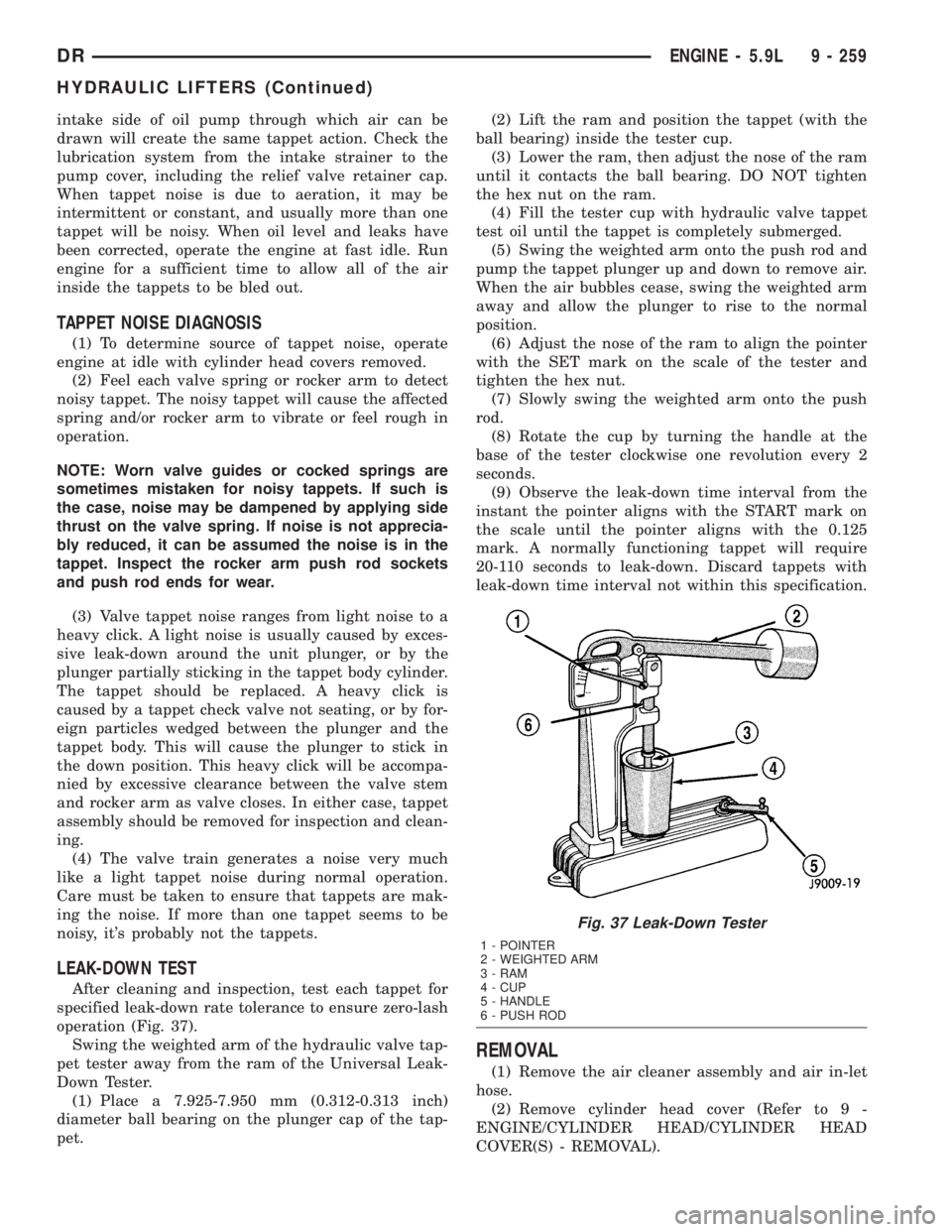

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 37).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tap-

pet.(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

REMOVAL

(1) Remove the air cleaner assembly and air in-let

hose.

(2) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

Fig. 37 Leak-Down Tester

1 - POINTER

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH ROD

DRENGINE - 5.9L 9 - 259

HYDRAULIC LIFTERS (Continued)

Page 1518 of 2895

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil-soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

be sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light source.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat previous step.

(5) If the oil leak source is not positively identified

at this time, proceed with the air leak detection test

method as follows:

(6) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(7) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292. Start engine and record pressure. (Refer to 9

- ENGINE - SPECIFICATIONS).

OIL

STANDARD PROCEDURE - ENGINE OIL

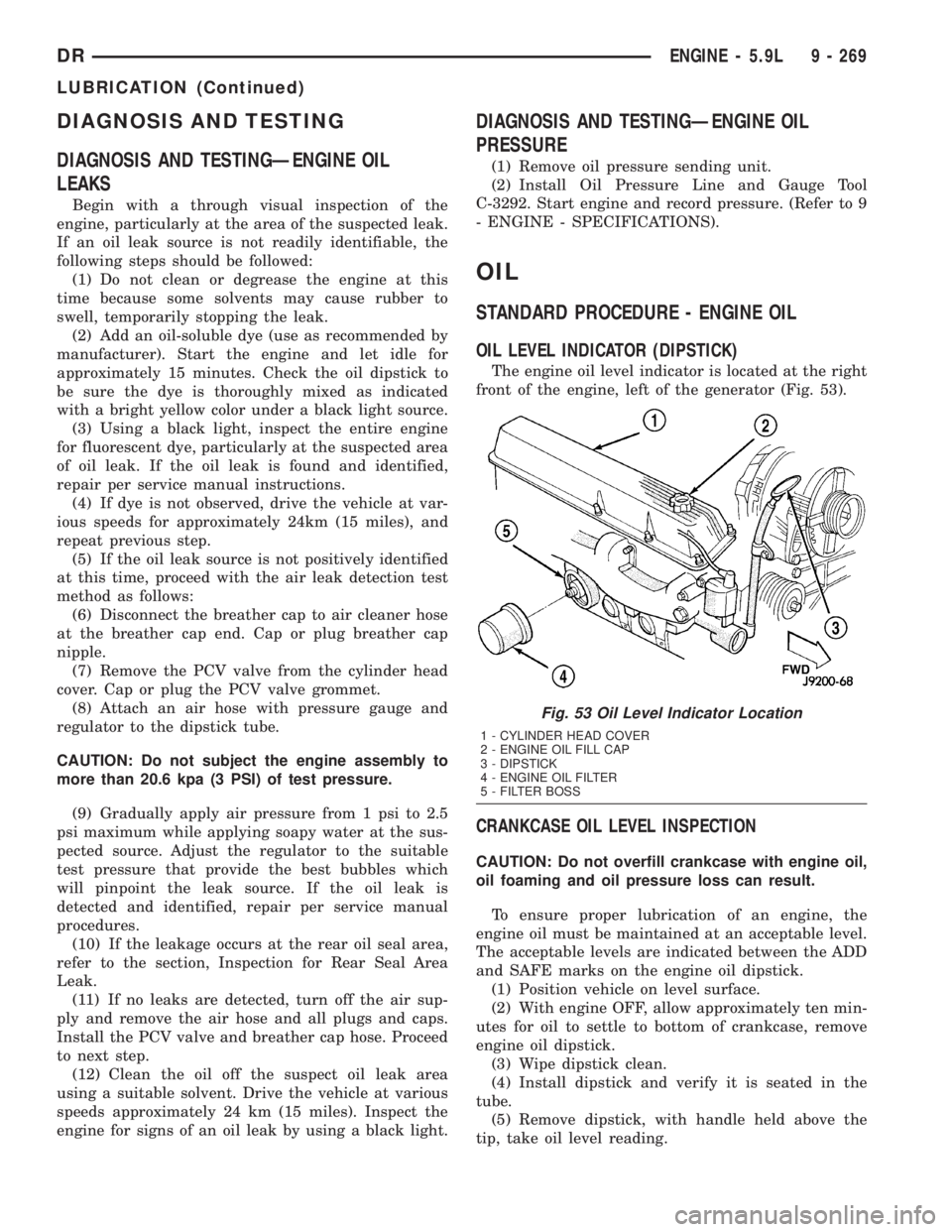

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

front of the engine, left of the generator (Fig. 53).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

Fig. 53 Oil Level Indicator Location

1 - CYLINDER HEAD COVER

2 - ENGINE OIL FILL CAP

3 - DIPSTICK

4 - ENGINE OIL FILTER

5 - FILTER BOSS

DRENGINE - 5.9L 9 - 269

LUBRICATION (Continued)

Page 1551 of 2895

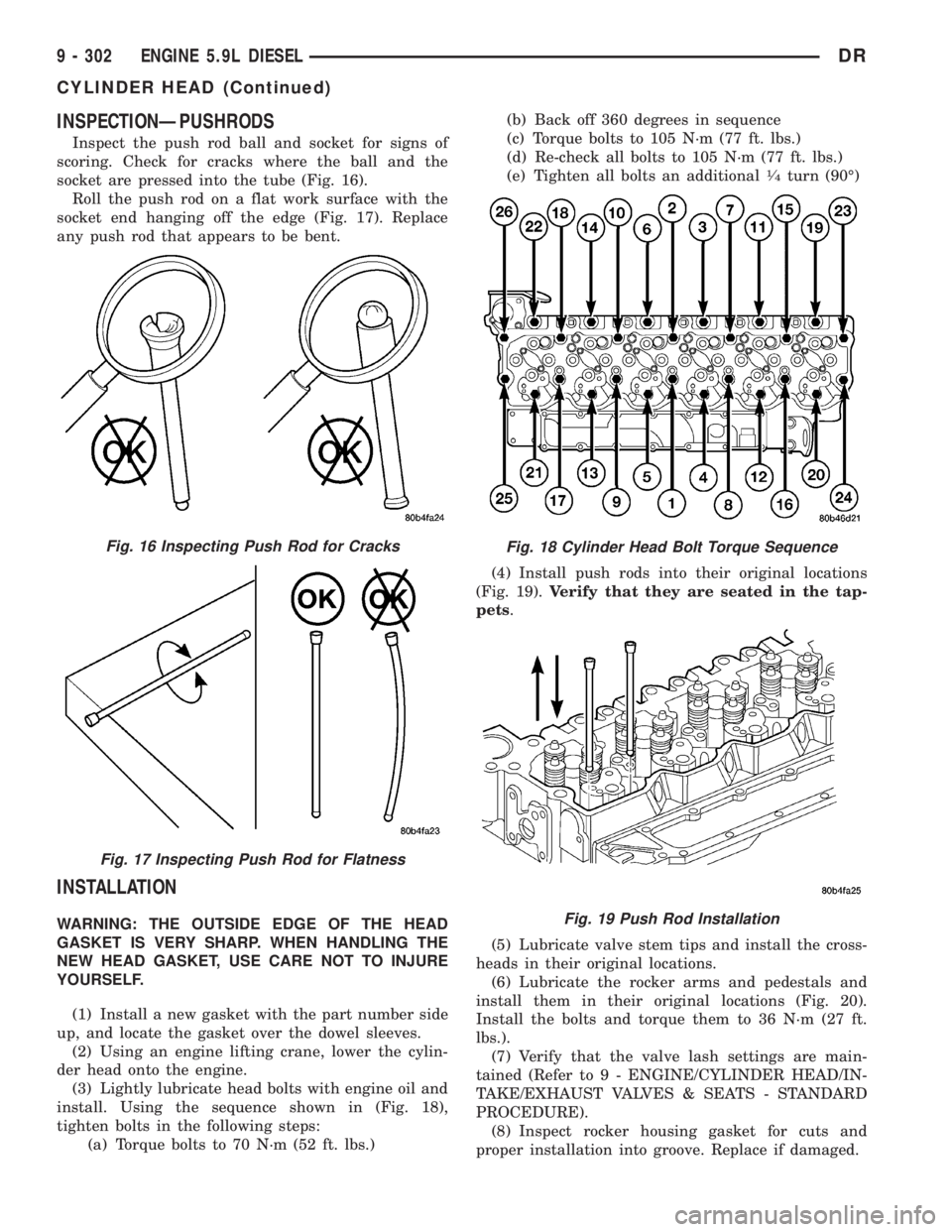

INSPECTIONÐPUSHRODS

Inspect the push rod ball and socket for signs of

scoring. Check for cracks where the ball and the

socket are pressed into the tube (Fig. 16).

Roll the push rod on a flat work surface with the

socket end hanging off the edge (Fig. 17). Replace

any push rod that appears to be bent.

INSTALLATION

WARNING: THE OUTSIDE EDGE OF THE HEAD

GASKET IS VERY SHARP. WHEN HANDLING THE

NEW HEAD GASKET, USE CARE NOT TO INJURE

YOURSELF.

(1) Install a new gasket with the part number side

up, and locate the gasket over the dowel sleeves.

(2) Using an engine lifting crane, lower the cylin-

der head onto the engine.

(3) Lightly lubricate head bolts with engine oil and

install. Using the sequence shown in (Fig. 18),

tighten bolts in the following steps:

(a) Torque bolts to 70 N´m (52 ft. lbs.)(b) Back off 360 degrees in sequence

(c) Torque bolts to 105 N´m (77 ft. lbs.)

(d) Re-check all bolts to 105 N´m (77 ft. lbs.)

(e) Tighten all bolts an additional

1¤4turn (90É)

(4) Install push rods into their original locations

(Fig. 19).Verify that they are seated in the tap-

pets.

(5) Lubricate valve stem tips and install the cross-

heads in their original locations.

(6) Lubricate the rocker arms and pedestals and

install them in their original locations (Fig. 20).

Install the bolts and torque them to 36 N´m (27 ft.

lbs.).

(7) Verify that the valve lash settings are main-

tained (Refer to 9 - ENGINE/CYLINDER HEAD/IN-

TAKE/EXHAUST VALVES & SEATS - STANDARD

PROCEDURE).

(8) Inspect rocker housing gasket for cuts and

proper installation into groove. Replace if damaged.

Fig. 16 Inspecting Push Rod for Cracks

Fig. 17 Inspecting Push Rod for Flatness

Fig. 18 Cylinder Head Bolt Torque Sequence

Fig. 19 Push Rod Installation

9 - 302 ENGINE 5.9L DIESELDR

CYLINDER HEAD (Continued)

Page 1562 of 2895

(3) Consult the parts catalog for the proper head

gaskets which must be used with refaced blocks to

ensure proper piston-to-valve clearance.

STANDARD PROCEDURE - CYLINDER BORE -

DE-GLAZE

(1) New piston rings may not seat in glazed cylin-

der bores.

(2) De-glazing gives the bore the correct surface

finish required to seat the rings. The size of the bore

is not changed by proper de-glazing.

(3) Cover the lube and tappet holes in the top of

the block with waterproof tape.

(4) It crankshaft is installed, wrap connecting rod

journals with clean cloth. Cover cloth with water-

proof tape.

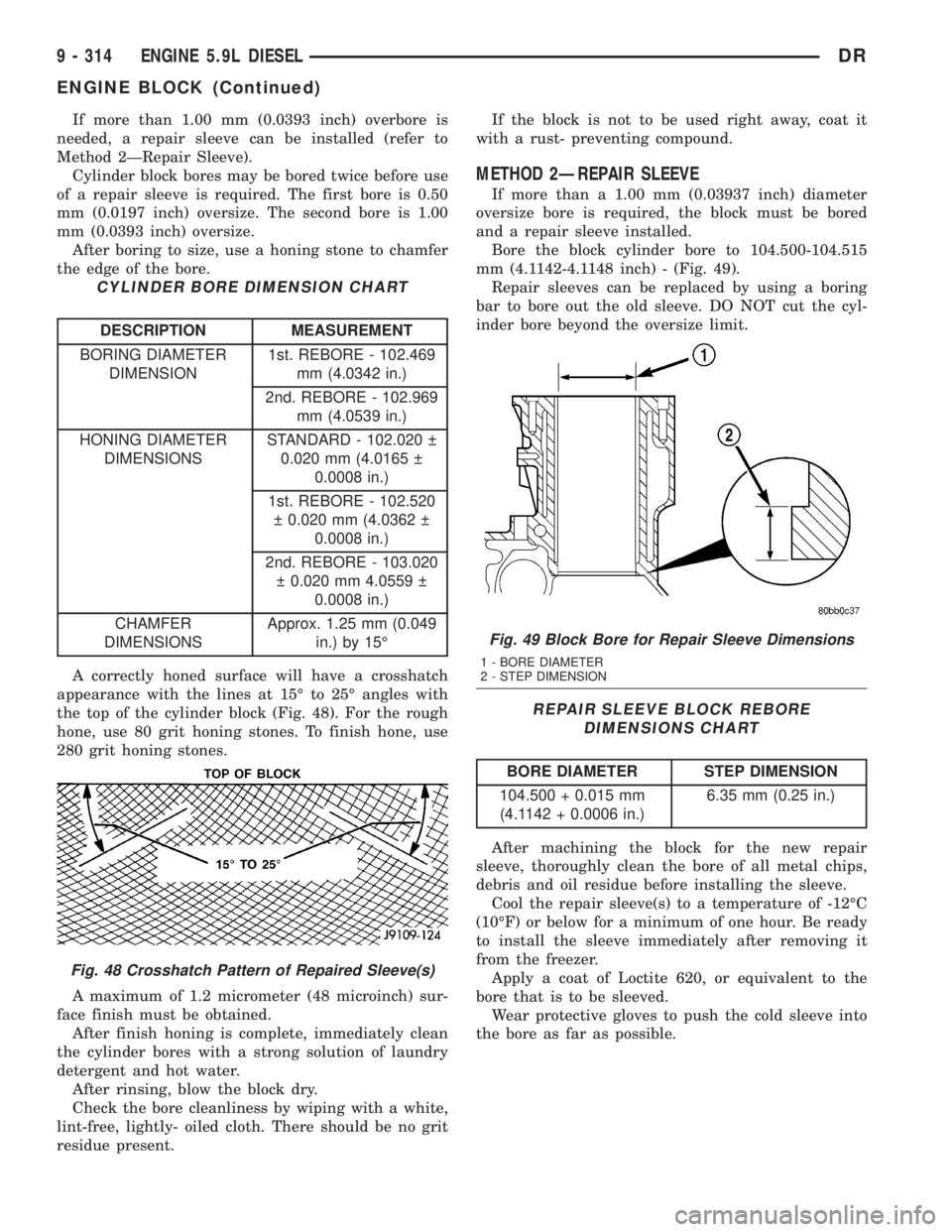

(5) A correctly honed surface will have a cross-

hatch appearance with the lines at 15É to 25É angles

(Fig. 46). For the rough hone, use 80 grit honing

stones. To finish hone, use 280 grit honing stones.

(6) Use a drill, a fine grit Flex-hone and a mixture

of equal parts of mineral spirits and SAE 30W engine

oil to de-glaze the bores.

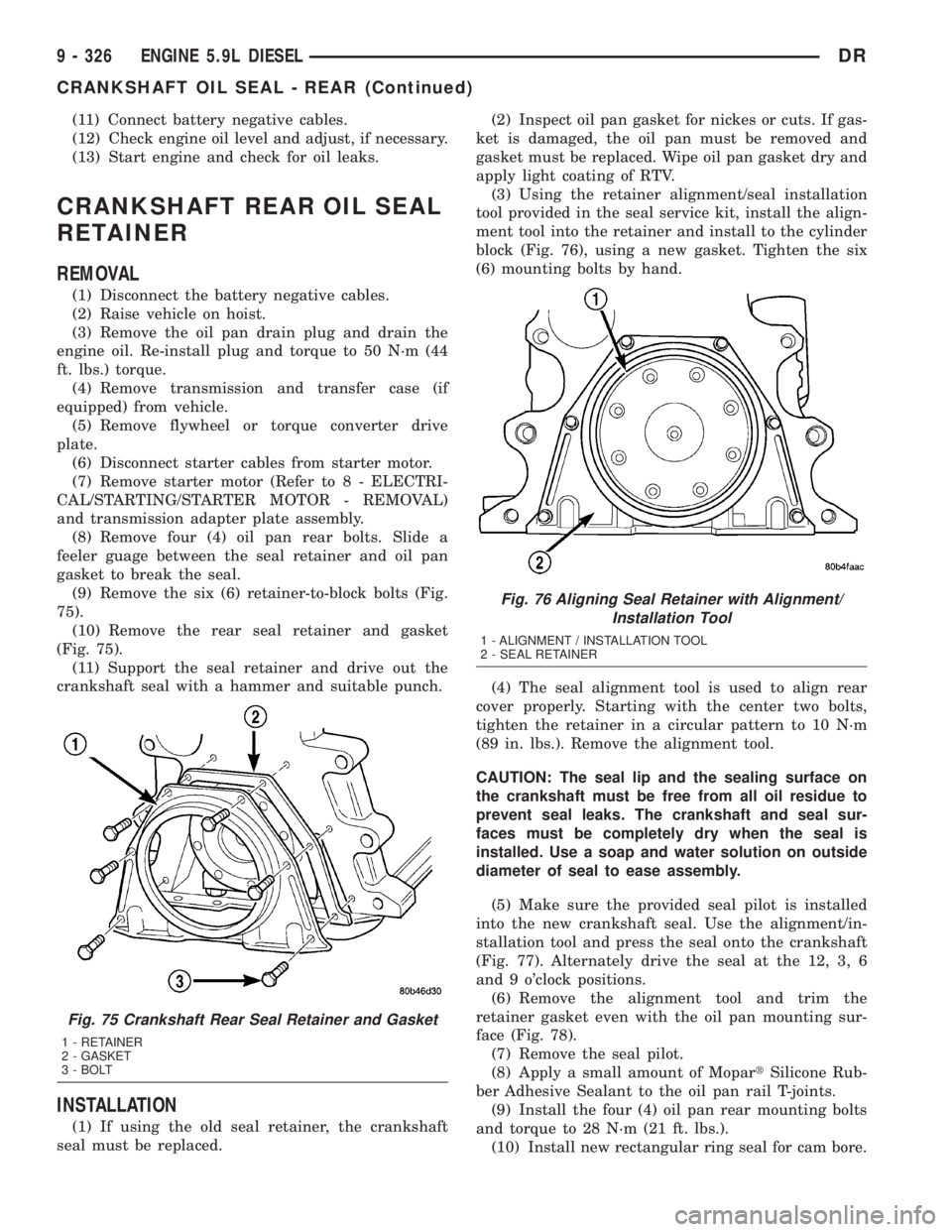

(7) The crosshatch angle is a function of drill

speed and how fast the hone is moved vertically (Fig.

47).

(8) Vertical strokes MUST be smooth continuous

passes along the full length of the bore (Fig. 47).(9) Inspect the bore after 10 strokes.

(10) Use a strong solution of hot water and laun-

dry detergent to clean the bores. Clean the cylinder

bores immediately after de-glazing.

(11) Rinse the bores until the detergent is removed

and blow the block dry with compressed air.

(12) Check the bore cleanliness by wiping with a

white, lint free, lightly oiled cloth. If grit residue is

still present, repeat the cleaning process until all res-

idue is removed. Wash the bores and the complete

block assembly with solvent and dry with compressed

air. Place a clean shop towel around the top main

bearing saddle to deflect water and residue from pis-

ton cooling nozzels. Remove directed piston cooling

nozzles if installed.

(13) Be sure to remove the tape covering the lube

holes, rod journals, and piston cooling nozzles after

the cleaning process is complete.

STANDARD PROCEDUREÐCYLINDER BORE

REPAIR

Cylinder bore(s) can be repaired by one of two

methods:

²Method 1:ÐOver boring and using oversize pis-

tons and rings.

²Method 2:ÐBoring and installing a repair sleeve

to return the bore to standard dimensions.

METHOD 1ÐOVERSIZE BORE

Cylinder bore(s) can be repaired by one of two

methods:

Oversize pistons and rings are available in two

sizes - 0.50 mm (0.0197 inch) and 1.00 mm (0.0393

inch).

Any combination of standard, 0.50 mm (0.0197

inch) or 1.00 mm (0.0393 inch) overbore may be used

in the same engine.

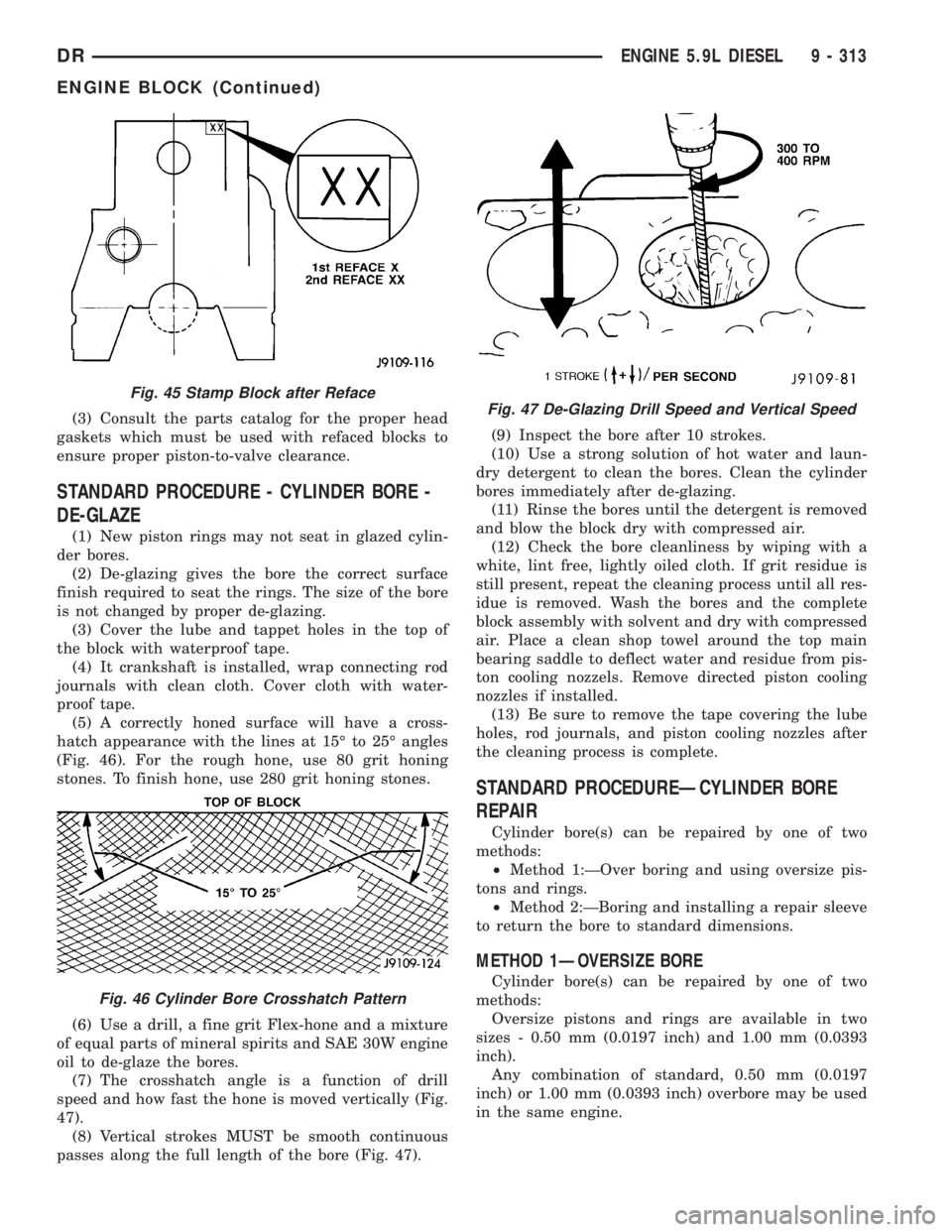

Fig. 45 Stamp Block after Reface

Fig. 46 Cylinder Bore Crosshatch Pattern

Fig. 47 De-Glazing Drill Speed and Vertical Speed

DRENGINE 5.9L DIESEL 9 - 313

ENGINE BLOCK (Continued)

Page 1563 of 2895

If more than 1.00 mm (0.0393 inch) overbore is

needed, a repair sleeve can be installed (refer to

Method 2ÐRepair Sleeve).

Cylinder block bores may be bored twice before use

of a repair sleeve is required. The first bore is 0.50

mm (0.0197 inch) oversize. The second bore is 1.00

mm (0.0393 inch) oversize.

After boring to size, use a honing stone to chamfer

the edge of the bore.

CYLINDER BORE DIMENSION CHART

DESCRIPTION MEASUREMENT

BORING DIAMETER

DIMENSION1st. REBORE - 102.469

mm (4.0342 in.)

2nd. REBORE - 102.969

mm (4.0539 in.)

HONING DIAMETER

DIMENSIONSSTANDARD - 102.020

0.020 mm (4.0165

0.0008 in.)

1st. REBORE - 102.520

0.020 mm (4.0362

0.0008 in.)

2nd. REBORE - 103.020

0.020 mm 4.0559

0.0008 in.)

CHAMFER

DIMENSIONSApprox. 1.25 mm (0.049

in.) by 15É

A correctly honed surface will have a crosshatch

appearance with the lines at 15É to 25É angles with

the top of the cylinder block (Fig. 48). For the rough

hone, use 80 grit honing stones. To finish hone, use

280 grit honing stones.

A maximum of 1.2 micrometer (48 microinch) sur-

face finish must be obtained.

After finish honing is complete, immediately clean

the cylinder bores with a strong solution of laundry

detergent and hot water.

After rinsing, blow the block dry.

Check the bore cleanliness by wiping with a white,

lint-free, lightly- oiled cloth. There should be no grit

residue present.If the block is not to be used right away, coat it

with a rust- preventing compound.

METHOD 2ÐREPAIR SLEEVE

If more than a 1.00 mm (0.03937 inch) diameter

oversize bore is required, the block must be bored

and a repair sleeve installed.

Bore the block cylinder bore to 104.500-104.515

mm (4.1142-4.1148 inch) - (Fig. 49).

Repair sleeves can be replaced by using a boring

bar to bore out the old sleeve. DO NOT cut the cyl-

inder bore beyond the oversize limit.

REPAIR SLEEVE BLOCK REBORE

DIMENSIONS CHART

BORE DIAMETER STEP DIMENSION

104.500 + 0.015 mm

(4.1142 + 0.0006 in.)6.35 mm (0.25 in.)

After machining the block for the new repair

sleeve, thoroughly clean the bore of all metal chips,

debris and oil residue before installing the sleeve.

Cool the repair sleeve(s) to a temperature of -12ÉC

(10ÉF) or below for a minimum of one hour. Be ready

to install the sleeve immediately after removing it

from the freezer.

Apply a coat of Loctite 620, or equivalent to the

bore that is to be sleeved.

Wear protective gloves to push the cold sleeve into

the bore as far as possible.

Fig. 48 Crosshatch Pattern of Repaired Sleeve(s)

Fig. 49 Block Bore for Repair Sleeve Dimensions

1 - BORE DIAMETER

2 - STEP DIMENSION

9 - 314 ENGINE 5.9L DIESELDR

ENGINE BLOCK (Continued)

Page 1575 of 2895

(11) Connect battery negative cables.

(12) Check engine oil level and adjust, if necessary.

(13) Start engine and check for oil leaks.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Remove the oil pan drain plug and drain the

engine oil. Re-install plug and torque to 50 N´m (44

ft. lbs.) torque.

(4) Remove transmission and transfer case (if

equipped) from vehicle.

(5) Remove flywheel or torque converter drive

plate.

(6) Disconnect starter cables from starter motor.

(7) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(8) Remove four (4) oil pan rear bolts. Slide a

feeler guage between the seal retainer and oil pan

gasket to break the seal.

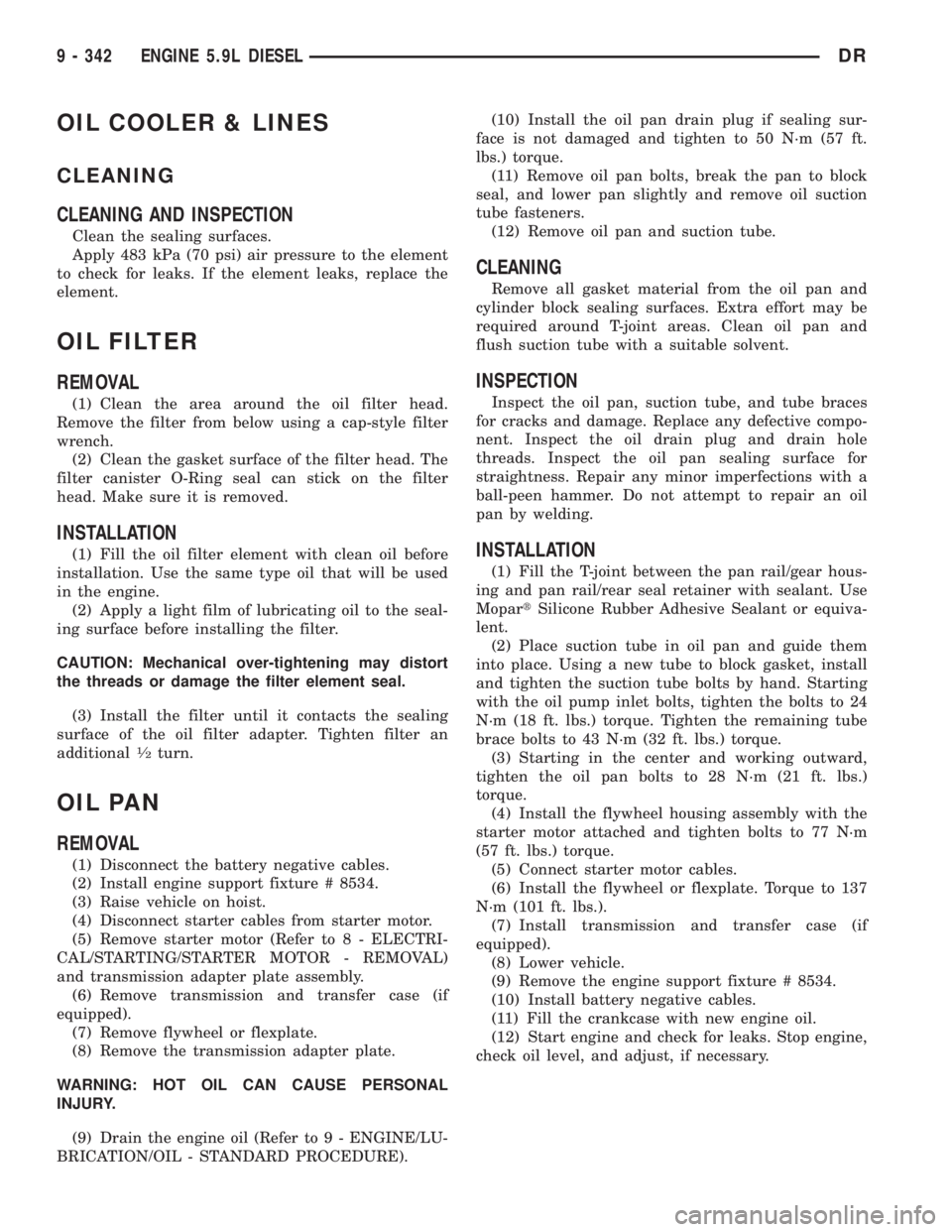

(9) Remove the six (6) retainer-to-block bolts (Fig.

75).

(10) Remove the rear seal retainer and gasket

(Fig. 75).

(11) Support the seal retainer and drive out the

crankshaft seal with a hammer and suitable punch.

INSTALLATION

(1) If using the old seal retainer, the crankshaft

seal must be replaced.(2) Inspect oil pan gasket for nickes or cuts. If gas-

ket is damaged, the oil pan must be removed and

gasket must be replaced. Wipe oil pan gasket dry and

apply light coating of RTV.

(3) Using the retainer alignment/seal installation

tool provided in the seal service kit, install the align-

ment tool into the retainer and install to the cylinder

block (Fig. 76), using a new gasket. Tighten the six

(6) mounting bolts by hand.

(4) The seal alignment tool is used to align rear

cover properly. Starting with the center two bolts,

tighten the retainer in a circular pattern to 10 N´m

(89 in. lbs.). Remove the alignment tool.

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(5) Make sure the provided seal pilot is installed

into the new crankshaft seal. Use the alignment/in-

stallation tool and press the seal onto the crankshaft

(Fig. 77). Alternately drive the seal at the 12, 3, 6

and 9 o'clock positions.

(6) Remove the alignment tool and trim the

retainer gasket even with the oil pan mounting sur-

face (Fig. 78).

(7) Remove the seal pilot.

(8) Apply a small amount of MopartSilicone Rub-

ber Adhesive Sealant to the oil pan rail T-joints.

(9) Install the four (4) oil pan rear mounting bolts

and torque to 28 N´m (21 ft. lbs.).

(10) Install new rectangular ring seal for cam bore.

Fig. 75 Crankshaft Rear Seal Retainer and Gasket

1 - RETAINER

2 - GASKET

3 - BOLT

Fig. 76 Aligning Seal Retainer with Alignment/

Installation Tool

1 - ALIGNMENT / INSTALLATION TOOL

2 - SEAL RETAINER

9 - 326 ENGINE 5.9L DIESELDR

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1591 of 2895

OIL COOLER & LINES

CLEANING

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter from below using a cap-style filter

wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional

1¤2turn.

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Install engine support fixture # 8534.

(3) Raise vehicle on hoist.

(4) Disconnect starter cables from starter motor.

(5) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(6) Remove transmission and transfer case (if

equipped).

(7) Remove flywheel or flexplate.

(8) Remove the transmission adapter plate.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(9) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).(10) Install the oil pan drain plug if sealing sur-

face is not damaged and tighten to 50 N´m (57 ft.

lbs.) torque.

(11) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(12) Remove oil pan and suction tube.

CLEANING

Remove all gasket material from the oil pan and

cylinder block sealing surfaces. Extra effort may be

required around T-joint areas. Clean oil pan and

flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces

for cracks and damage. Replace any defective compo-

nent. Inspect the oil drain plug and drain hole

threads. Inspect the oil pan sealing surface for

straightness. Repair any minor imperfections with a

ball-peen hammer. Do not attempt to repair an oil

pan by welding.

INSTALLATION

(1) Fill the T-joint between the pan rail/gear hous-

ing and pan rail/rear seal retainer with sealant. Use

MopartSilicone Rubber Adhesive Sealant or equiva-

lent.

(2) Place suction tube in oil pan and guide them

into place. Using a new tube to block gasket, install

and tighten the suction tube bolts by hand. Starting

with the oil pump inlet bolts, tighten the bolts to 24

N´m (18 ft. lbs.) torque. Tighten the remaining tube

brace bolts to 43 N´m (32 ft. lbs.) torque.

(3) Starting in the center and working outward,

tighten the oil pan bolts to 28 N´m (21 ft. lbs.)

torque.

(4) Install the flywheel housing assembly with the

starter motor attached and tighten bolts to 77 N´m

(57 ft. lbs.) torque.

(5) Connect starter motor cables.

(6) Install the flywheel or flexplate. Torque to 137

N´m (101 ft. lbs.).

(7) Install transmission and transfer case (if

equipped).

(8) Lower vehicle.

(9) Remove the engine support fixture # 8534.

(10) Install battery negative cables.

(11) Fill the crankcase with new engine oil.

(12) Start engine and check for leaks. Stop engine,

check oil level, and adjust, if necessary.

9 - 342 ENGINE 5.9L DIESELDR

Page 1609 of 2895

STANDARD PROCEDURE

STANDARD PROCEDUREÐCYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

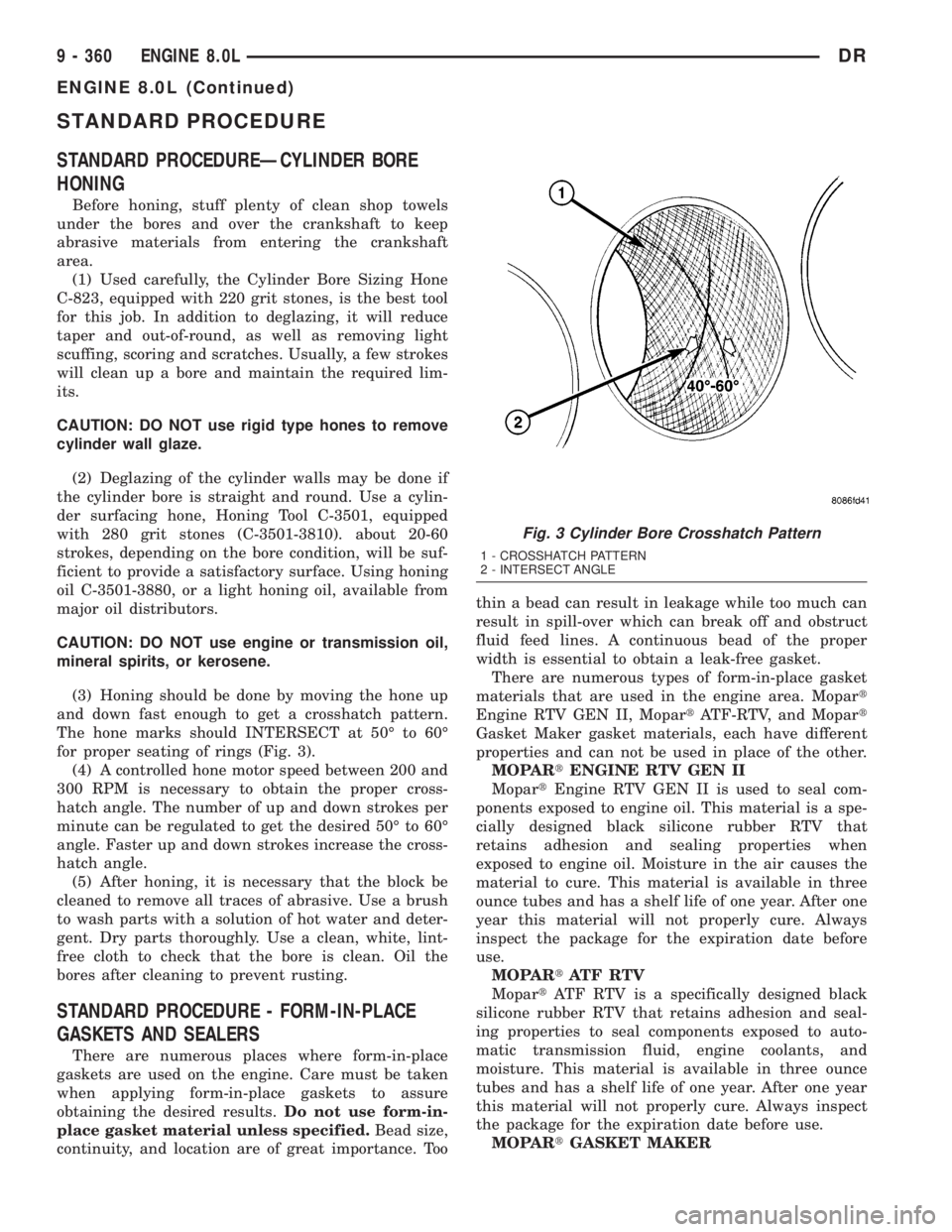

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Toothin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

9 - 360 ENGINE 8.0LDR

ENGINE 8.0L (Continued)

Page 1635 of 2895

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the transmission.

(3) Remove the drive plate / flywheel.

(4) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(5) Remove the rear oil seal retainer mounting

bolts.

(6) Carefully remove the retainer from the engine

block.

INSTALLATION

(1) Throughly clean all gasket resdue from the

engine block.

(2) Use extream care and clean all gasket resdue

from the retainer.

(3) Apply a small amount of MopartSilicone Rub-

ber Adhesive Sealant to the retainer gasket. Position

the gasket onto the retainer.

(4) Position Special Tool 6687 Seal Guide onto the

crankshaft.

(5) Position the retainer and seal over the guide

and onto the engine block.

(6) Install the retainer mounting bolts. Tighten the

bolts to 22 N´m (16 ft. lbs.).

(7) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(8) Install the drive plate / flywheel.

(9) Install the transmission.

(10) Check and verify engine oil level.

(11) Start engine and check for leaks.

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTINGÐHYDRAULIC

TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, check the oil pressure. If vehicle

has no oil pressure gauge, install a reliable gauge at

the pressure sending-unit. The pressure should be

between 207-552 kPa (30-80 psi) at 3,000 RPM.

Check the oil level after the engine reaches normal

operating temperature. Allow 5 minutes to stabilize

oil level, check dipstick. The oil level in the pan

should never be above the FULL mark or below the

ADD OIL mark on dipstick. Either of these two con-

ditions could be responsible for noisy tappets.

OIL LEVEL

HIGH

If oil level is above the FULL mark, it is possible

for the connecting rods to dip into the oil. With the

engine running, this condition could create foam in

the oil pan. Foam in oil pan would be fed to the

hydraulic tappets by the oil pump causing them to

lose length and allow valves to seat noisily.

LOW

Low oil level may allow oil pump to take in air.

When air is fed to the tappets, they lose length,

which allows valves to seat noisily. Any leaks on

intake side of oil pump through which air can be

drawn will create the same tappet action. Check the

lubrication system from the intake strainer to the

pump cover, including the relief valve retainer cap.

When tappet noise is due to aeration, it may be

intermittent or constant, and usually more than one

tappet will be noisy. When oil level and leaks have

been corrected, operate the engine at fast idle. Run

engine for a sufficient time to allow all of the air

inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger, or by the

plunger partially sticking in the tappet body cylinder.

The tappet should be replaced. A heavy click is

caused by a tappet check valve not seating, or by for-

eign particles wedged between the plunger and the

tappet body. This will cause the plunger to stick in

the down position. This heavy click will be accompa-

nied by excessive clearance between the valve stem

and rocker arm as valve closes. In either case, tappet

assembly should be removed for inspection and clean-

ing.

9 - 386 ENGINE 8.0LDR