check engine light DODGE RAM 2003 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2349 of 2895

(55) Install the manual shift lever from the trans-

mission. Torque the retaining cross-bolt to 16 N´m

(140 in.lbs.).

INSTALLATION

(1) Check torque converter hub and hub drive flats

for sharp edges burrs, scratches, or nicks. Polish the

hub and flats with 320/400 grit paper and crocus

cloth if necessary. Verify that the converter hub

o-ring is properly installed and is free of any debris.

The hub must be smooth to avoid damaging pump

seal at installation.

(2) If a replacement transmission is being

installed, transfer any components necessary, such as

the manual shift lever and shift cable bracket, from

the original transmission onto the replacement trans-

mission.

(3) Lubricate oil pump seal lip with transmission

fluid.

(4) Align converter and oil pump.

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

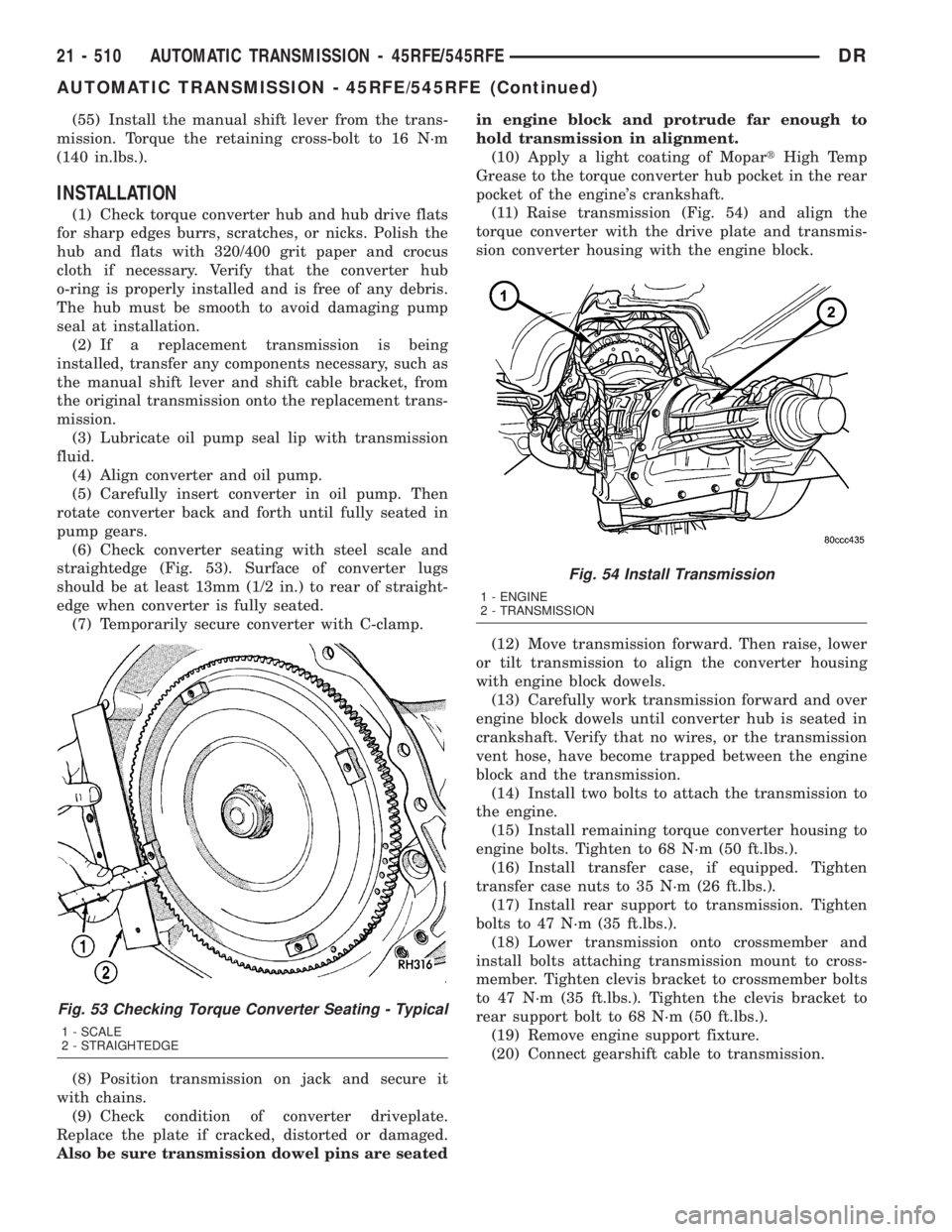

(6) Check converter seating with steel scale and

straightedge (Fig. 53). Surface of converter lugs

should be at least 13mm (1/2 in.) to rear of straight-

edge when converter is fully seated.

(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seatedin engine block and protrude far enough to

hold transmission in alignment.

(10) Apply a light coating of MopartHigh Temp

Grease to the torque converter hub pocket in the rear

pocket of the engine's crankshaft.

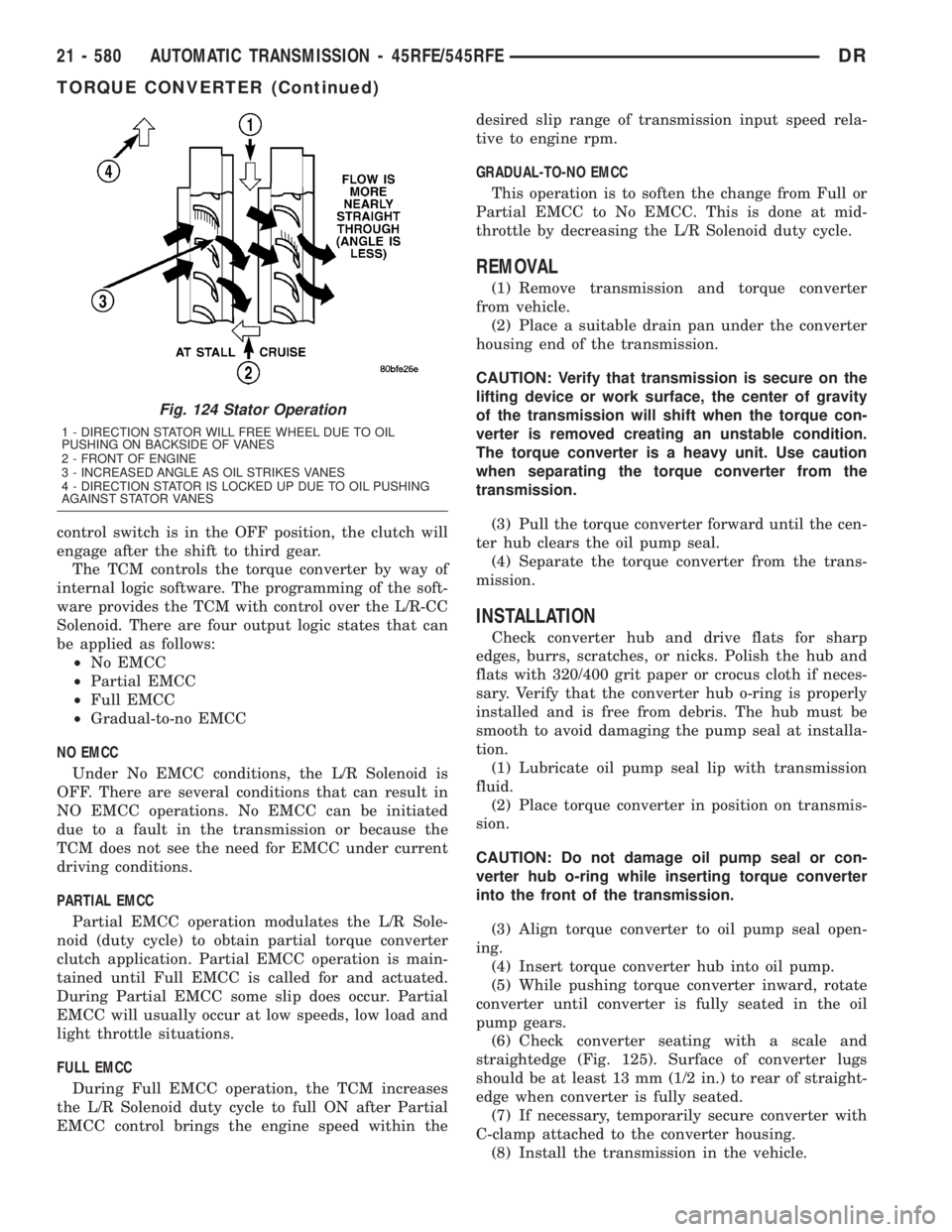

(11) Raise transmission (Fig. 54) and align the

torque converter with the drive plate and transmis-

sion converter housing with the engine block.

(12) Move transmission forward. Then raise, lower

or tilt transmission to align the converter housing

with engine block dowels.

(13) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft. Verify that no wires, or the transmission

vent hose, have become trapped between the engine

block and the transmission.

(14) Install two bolts to attach the transmission to

the engine.

(15) Install remaining torque converter housing to

engine bolts. Tighten to 68 N´m (50 ft.lbs.).

(16) Install transfer case, if equipped. Tighten

transfer case nuts to 35 N´m (26 ft.lbs.).

(17) Install rear support to transmission. Tighten

bolts to 47 N´m (35 ft.lbs.).

(18) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member. Tighten clevis bracket to crossmember bolts

to 47 N´m (35 ft.lbs.). Tighten the clevis bracket to

rear support bolt to 68 N´m (50 ft.lbs.).

(19) Remove engine support fixture.

(20) Connect gearshift cable to transmission.

Fig. 53 Checking Torque Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

Fig. 54 Install Transmission

1 - ENGINE

2 - TRANSMISSION

21 - 510 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2419 of 2895

control switch is in the OFF position, the clutch will

engage after the shift to third gear.

The TCM controls the torque converter by way of

internal logic software. The programming of the soft-

ware provides the TCM with control over the L/R-CC

Solenoid. There are four output logic states that can

be applied as follows:

²No EMCC

²Partial EMCC

²Full EMCC

²Gradual-to-no EMCC

NO EMCC

Under No EMCC conditions, the L/R Solenoid is

OFF. There are several conditions that can result in

NO EMCC operations. No EMCC can be initiated

due to a fault in the transmission or because the

TCM does not see the need for EMCC under current

driving conditions.

PARTIAL EMCC

Partial EMCC operation modulates the L/R Sole-

noid (duty cycle) to obtain partial torque converter

clutch application. Partial EMCC operation is main-

tained until Full EMCC is called for and actuated.

During Partial EMCC some slip does occur. Partial

EMCC will usually occur at low speeds, low load and

light throttle situations.

FULL EMCC

During Full EMCC operation, the TCM increases

the L/R Solenoid duty cycle to full ON after Partial

EMCC control brings the engine speed within thedesired slip range of transmission input speed rela-

tive to engine rpm.

GRADUAL-TO-NO EMCC

This operation is to soften the change from Full or

Partial EMCC to No EMCC. This is done at mid-

throttle by decreasing the L/R Solenoid duty cycle.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive flats for sharp

edges, burrs, scratches, or nicks. Polish the hub and

flats with 320/400 grit paper or crocus cloth if neces-

sary. Verify that the converter hub o-ring is properly

installed and is free from debris. The hub must be

smooth to avoid damaging the pump seal at installa-

tion.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or con-

verter hub o-ring while inserting torque converter

into the front of the transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 125). Surface of converter lugs

should be at least 13 mm (1/2 in.) to rear of straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

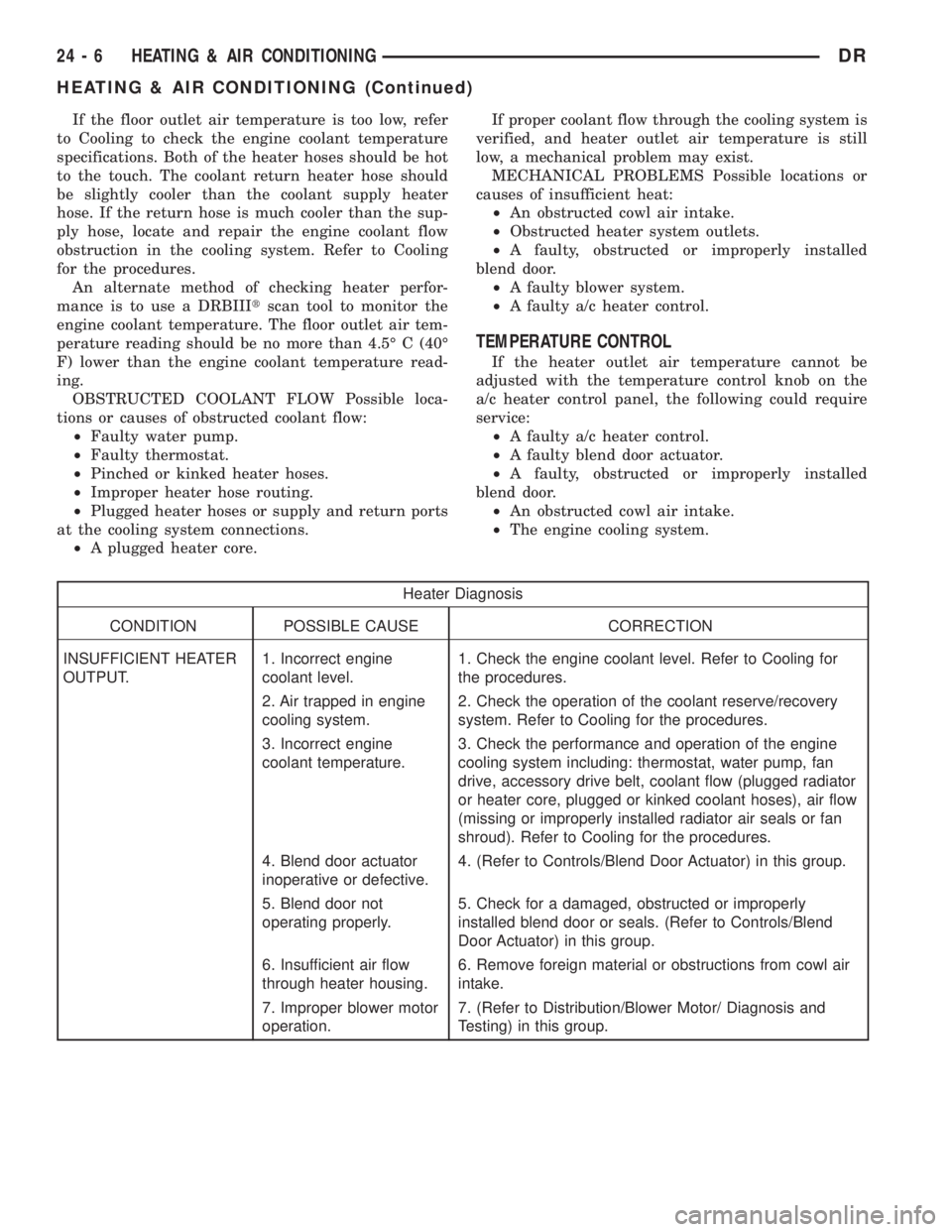

Fig. 124 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

21 - 580 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TORQUE CONVERTER (Continued)

Page 2781 of 2895

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

An alternate method of checking heater perfor-

mance is to use a DRBIIItscan tool to monitor the

engine coolant temperature. The floor outlet air tem-

perature reading should be no more than 4.5É C (40É

F) lower than the engine coolant temperature read-

ing.

OBSTRUCTED COOLANT FLOW Possible loca-

tions or causes of obstructed coolant flow:

²Faulty water pump.

²Faulty thermostat.

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS Possible locations or

causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A faulty, obstructed or improperly installed

blend door.

²A faulty blower system.

²A faulty a/c heater control.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob on the

a/c heater control panel, the following could require

service:

²A faulty a/c heater control.

²A faulty blend door actuator.

²A faulty, obstructed or improperly installed

blend door.

²An obstructed cowl air intake.

²The engine cooling system.

Heater Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

INSUFFICIENT HEATER

OUTPUT.1. Incorrect engine

coolant level.1. Check the engine coolant level. Refer to Cooling for

the procedures.

2. Air trapped in engine

cooling system.2. Check the operation of the coolant reserve/recovery

system. Refer to Cooling for the procedures.

3. Incorrect engine

coolant temperature.3. Check the performance and operation of the engine

cooling system including: thermostat, water pump, fan

drive, accessory drive belt, coolant flow (plugged radiator

or heater core, plugged or kinked coolant hoses), air flow

(missing or improperly installed radiator air seals or fan

shroud). Refer to Cooling for the procedures.

4. Blend door actuator

inoperative or defective.4. (Refer to Controls/Blend Door Actuator) in this group.

5. Blend door not

operating properly.5. Check for a damaged, obstructed or improperly

installed blend door or seals. (Refer to Controls/Blend

Door Actuator) in this group.

6. Insufficient air flow

through heater housing.6. Remove foreign material or obstructions from cowl air

intake.

7. Improper blower motor

operation.7. (Refer to Distribution/Blower Motor/ Diagnosis and

Testing) in this group.

24 - 6 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2823 of 2895

(1) Insert the evaporator coil into the bottom of the

HVAC housing. Make sure that the evaporator drain

is clean and unrestricted and evaporator deflector

shield is also installed.

(2) Reassemble and reinstall the HVAC housing in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

NOTE: If the evaporator is replaced, add 60 millili-

ters (2 fluid ounces) of refrigerant oil to the refrig-

erant system.

A/C ORIFICE TUBE

DESCRIPTION

The fixed orifice tube is installed in the liquid line

between the outlet of the condenser and the inlet of

the evaporator. The fixed orifice tube is only serviced

as an integral part of the liquid line.

OPERATION

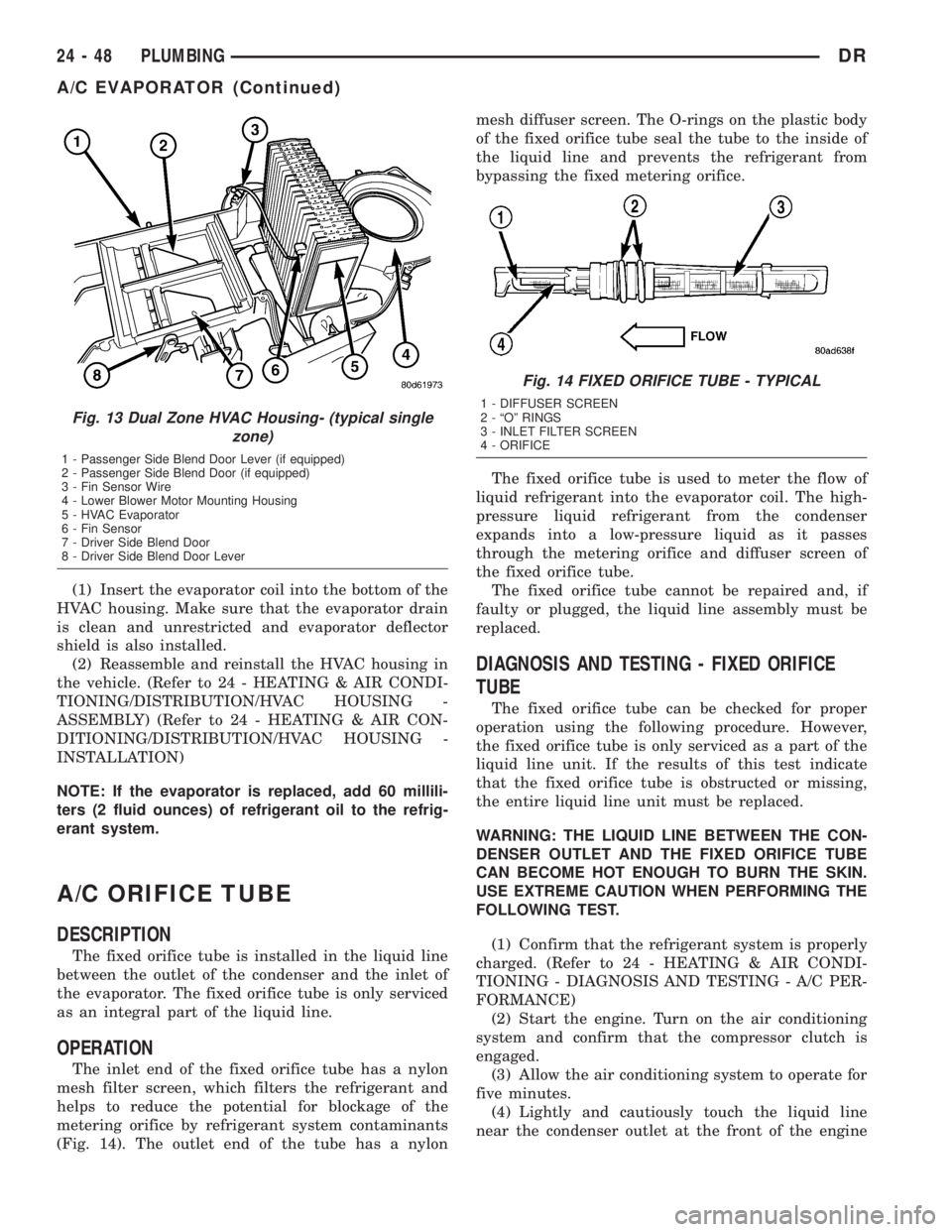

The inlet end of the fixed orifice tube has a nylon

mesh filter screen, which filters the refrigerant and

helps to reduce the potential for blockage of the

metering orifice by refrigerant system contaminants

(Fig. 14). The outlet end of the tube has a nylonmesh diffuser screen. The O-rings on the plastic body

of the fixed orifice tube seal the tube to the inside of

the liquid line and prevents the refrigerant from

bypassing the fixed metering orifice.

The fixed orifice tube is used to meter the flow of

liquid refrigerant into the evaporator coil. The high-

pressure liquid refrigerant from the condenser

expands into a low-pressure liquid as it passes

through the metering orifice and diffuser screen of

the fixed orifice tube.

The fixed orifice tube cannot be repaired and, if

faulty or plugged, the liquid line assembly must be

replaced.

DIAGNOSIS AND TESTING - FIXED ORIFICE

TUBE

The fixed orifice tube can be checked for proper

operation using the following procedure. However,

the fixed orifice tube is only serviced as a part of the

liquid line unit. If the results of this test indicate

that the fixed orifice tube is obstructed or missing,

the entire liquid line unit must be replaced.

WARNING: THE LIQUID LINE BETWEEN THE CON-

DENSER OUTLET AND THE FIXED ORIFICE TUBE

CAN BECOME HOT ENOUGH TO BURN THE SKIN.

USE EXTREME CAUTION WHEN PERFORMING THE

FOLLOWING TEST.

(1) Confirm that the refrigerant system is properly

charged. (Refer to 24 - HEATING & AIR CONDI-

TIONING - DIAGNOSIS AND TESTING - A/C PER-

FORMANCE)

(2) Start the engine. Turn on the air conditioning

system and confirm that the compressor clutch is

engaged.

(3) Allow the air conditioning system to operate for

five minutes.

(4) Lightly and cautiously touch the liquid line

near the condenser outlet at the front of the engine

Fig. 13 Dual Zone HVAC Housing- (typical single

zone)

1 - Passenger Side Blend Door Lever (if equipped)

2 - Passenger Side Blend Door (if equipped)

3 - Fin Sensor Wire

4 - Lower Blower Motor Mounting Housing

5 - HVAC Evaporator

6 - Fin Sensor

7 - Driver Side Blend Door

8 - Driver Side Blend Door Lever

Fig. 14 FIXED ORIFICE TUBE - TYPICAL

1 - DIFFUSER SCREEN

2 - ªOº RINGS

3 - INLET FILTER SCREEN

4 - ORIFICE

24 - 48 PLUMBINGDR

A/C EVAPORATOR (Continued)

Page 2848 of 2895

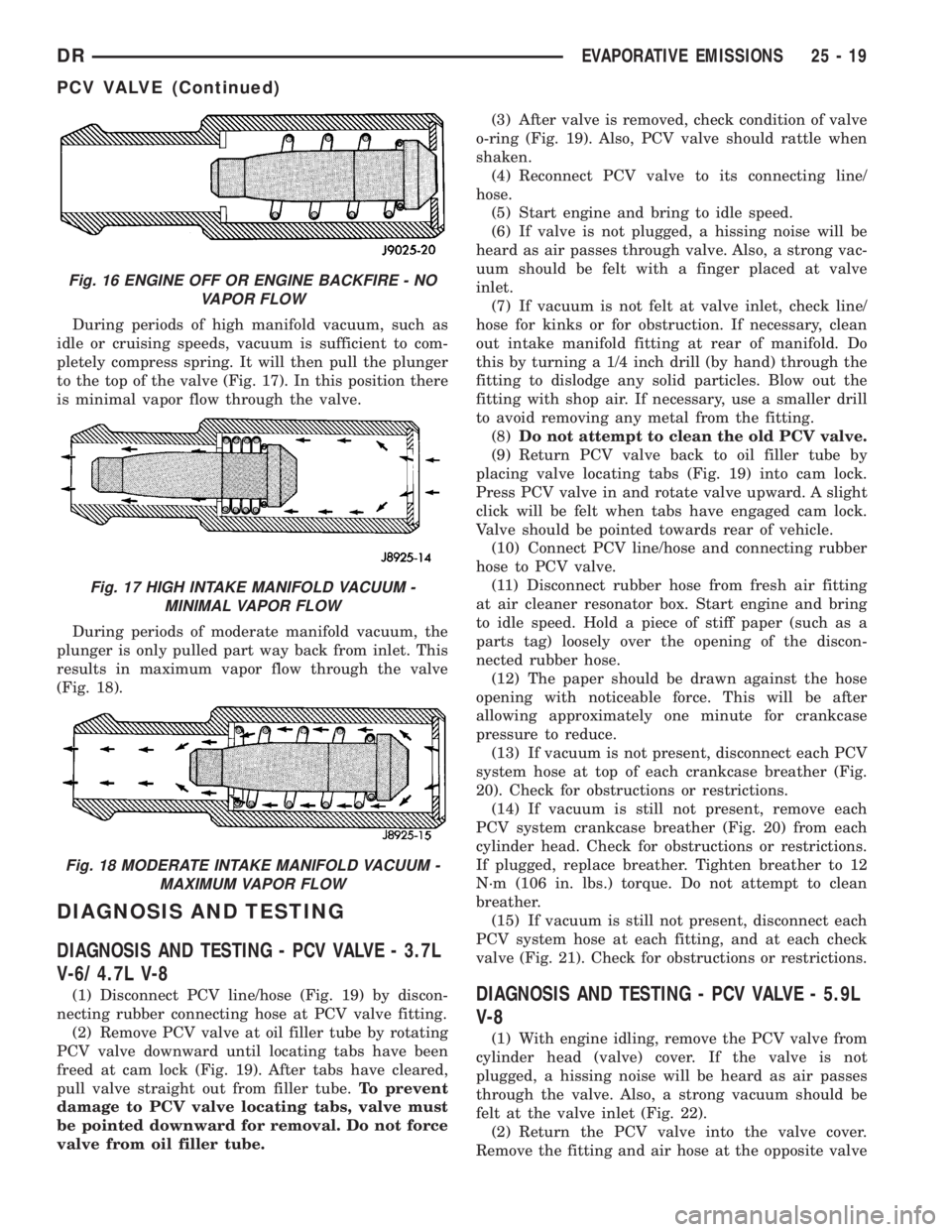

During periods of high manifold vacuum, such as

idle or cruising speeds, vacuum is sufficient to com-

pletely compress spring. It will then pull the plunger

to the top of the valve (Fig. 17). In this position there

is minimal vapor flow through the valve.

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve

(Fig. 18).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PCV VALVE - 3.7L

V-6/ 4.7L V-8

(1) Disconnect PCV line/hose (Fig. 19) by discon-

necting rubber connecting hose at PCV valve fitting.

(2) Remove PCV valve at oil filler tube by rotating

PCV valve downward until locating tabs have been

freed at cam lock (Fig. 19). After tabs have cleared,

pull valve straight out from filler tube.To prevent

damage to PCV valve locating tabs, valve must

be pointed downward for removal. Do not force

valve from oil filler tube.(3) After valve is removed, check condition of valve

o-ring (Fig. 19). Also, PCV valve should rattle when

shaken.

(4) Reconnect PCV valve to its connecting line/

hose.

(5) Start engine and bring to idle speed.

(6) If valve is not plugged, a hissing noise will be

heard as air passes through valve. Also, a strong vac-

uum should be felt with a finger placed at valve

inlet.

(7) If vacuum is not felt at valve inlet, check line/

hose for kinks or for obstruction. If necessary, clean

out intake manifold fitting at rear of manifold. Do

this by turning a 1/4 inch drill (by hand) through the

fitting to dislodge any solid particles. Blow out the

fitting with shop air. If necessary, use a smaller drill

to avoid removing any metal from the fitting.

(8)Do not attempt to clean the old PCV valve.

(9) Return PCV valve back to oil filler tube by

placing valve locating tabs (Fig. 19) into cam lock.

Press PCV valve in and rotate valve upward. A slight

click will be felt when tabs have engaged cam lock.

Valve should be pointed towards rear of vehicle.

(10) Connect PCV line/hose and connecting rubber

hose to PCV valve.

(11) Disconnect rubber hose from fresh air fitting

at air cleaner resonator box. Start engine and bring

to idle speed. Hold a piece of stiff paper (such as a

parts tag) loosely over the opening of the discon-

nected rubber hose.

(12) The paper should be drawn against the hose

opening with noticeable force. This will be after

allowing approximately one minute for crankcase

pressure to reduce.

(13) If vacuum is not present, disconnect each PCV

system hose at top of each crankcase breather (Fig.

20). Check for obstructions or restrictions.

(14) If vacuum is still not present, remove each

PCV system crankcase breather (Fig. 20) from each

cylinder head. Check for obstructions or restrictions.

If plugged, replace breather. Tighten breather to 12

N´m (106 in. lbs.) torque. Do not attempt to clean

breather.

(15) If vacuum is still not present, disconnect each

PCV system hose at each fitting, and at each check

valve (Fig. 21). Check for obstructions or restrictions.DIAGNOSIS AND TESTING - PCV VALVE - 5.9L

V-8

(1) With engine idling, remove the PCV valve from

cylinder head (valve) cover. If the valve is not

plugged, a hissing noise will be heard as air passes

through the valve. Also, a strong vacuum should be

felt at the valve inlet (Fig. 22).

(2) Return the PCV valve into the valve cover.

Remove the fitting and air hose at the opposite valve

Fig. 16 ENGINE OFF OR ENGINE BACKFIRE - NO

VAPOR FLOW

Fig. 17 HIGH INTAKE MANIFOLD VACUUM -

MINIMAL VAPOR FLOW

Fig. 18 MODERATE INTAKE MANIFOLD VACUUM -

MAXIMUM VAPOR FLOW

DREVAPORATIVE EMISSIONS 25 - 19

PCV VALVE (Continued)

Page 2851 of 2895

tabs, valve must be pointed downward for

removal. Do not force valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 25).

5.7L V-8

The PCV valve is mounted into the top of the

intake manifold, located to the right / rear of the

throttle body (Fig. 12). The PCV valve is sealed to

the intake manifold with 2 o-rings (Fig. 13).

(1) Remove PCV valve by rotating counter-clock-

wise 90 degrees until locating tabs have been freed.

After tabs have cleared, pull valve straight up from

intake manifold.

(2) After valve is removed, check condition of 2

valve o-rings.

INSTALLATION

3.7L V6 / 4.7L V-8

The PCV valve is located on the oil filler tube. Two

locating tabs are located on the side of the valve.

These 2 tabs fit into a cam lock in the oil filler tube.

An o-ring seals the valve to the filler tube.

(1) Return PCV valve back to oil filler tube by

placing valve locating tabs into cam lock. Press PCV

valve in and rotate valve upward. A slight click will

be felt when tabs have engaged cam lock. Valve

should be pointed towards rear of vehicle.

(2) Connect PCV line/hose and rubber hose to PCV

valve.

5.7L V-8

(1) Clean out intake manifold opening.

(2) Check condition of 2 o-rings on PCV valve.

(3) Apply engine oil to 2 o-rings.

(4) Place PCV valve into intake manifold and

rotate 90 degrees clockwise for installation.

VACUUM LINES

DESCRIPTION

A vacuum schematic for emission related items can

be found on the vehicles VECI label. Refer to Vehicle

Emission Control Information (VECI) Label for label

location.

VAPOR CANISTER

DESCRIPTION

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

26).

OPERATION

Two, maintenance free, EVAP canisters are

used.The EVAP canisters are filled with granules of

an activated carbon mixture. Fuel vapors entering

the EVAP canisters are absorbed by the charcoal

granules.

Fuel tank pressure vents into the EVAP canisters.

Fuel vapors are temporarily held in the canisters

until they can be drawn into the intake manifold.

The duty cycle EVAP canister purge solenoid allows

the EVAP canisters to be purged at predetermined

times and at certain engine operating conditions.

REMOVAL

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

26).

(1) Raise and support vehicle.

(2) Remove fuel tubes/lines at each EVAP canister.

Note location of tubes/lines before removal for easier

installation.

(3) Remove lower support bracket (Fig. 27).

(4) Remove mounting nuts at top of each canister

(Fig. 27).

Fig. 26 LOCATION, EVAP CANISTERS

1 - LDP

2 - LDP MOUNTING BOLT

3 - ELEC. CONNEC.

4 - FILTER MOUNTING BOLT

5 - LDP FILTER

6 - CONNECTING HOSE

7 - EVAP CANISTER MOUNTING BRACKET

8 - EVAP CANISTERS (2)

25 - 22 EVAPORATIVE EMISSIONSDR

PCV VALVE (Continued)

Page 2862 of 2895

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING....9-150,9-214,9-64

CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING, AIR......................21-494

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY........................7-10

CHILD RESTRAINT ANCHOR -

DESCRIPTION.......................8O-14

CHILD RESTRAINT ANCHOR -

INSTALLATION......................8O-17

CHILD RESTRAINT ANCHOR -

OPERATION.........................8O-16

CHILD RESTRAINT ANCHOR - REMOVAL . . 8O-16

CHIME CONDITIONS - DIAGNOSIS AND

TESTING............................8B-2

CHIME/BUZZER - DESCRIPTION..........8B-1

CHIME/BUZZER - OPERATION............8B-1

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR......8M-11

CIRCUIT - OPERATION, FUEL DRAIN.....14-78

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-1

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-10

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-12

CIRCUITS - OPERATION, NON-

MONITORED.........................25-8

CLAMPS - DESCRIPTION, HOSE...........7-3

CLAMPS - OPERATION, HOSE.............7-5

CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-321

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-322

CLEARANCE LAMP - INSTALLATION, CAB . 8L-10

CLEARANCE LAMP - REMOVAL, CAB.....8L-10

CLOCKSPRING - DESCRIPTION.........8O-18

CLOCKSPRING - INSTALLATION.........8O-21

CLOCKSPRING - OPERATION...........8O-18

CLOCKSPRING - REMOVAL............8O-20

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-15

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-10

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-14

CLUSTER - INSTALLATION, INSTRUMENT . 8J-16

CLUSTER - OPERATION, INSTRUMENT.....8J-6

CLUSTER - REMOVAL, INSTRUMENT.....8J-14

CLUSTER BEZEL - INSTALLATION........23-50

CLUSTER BEZEL - REMOVAL...........23-50

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - ASSEMBLY, FRONT....21-206,21-386

CLUTCH - ASSEMBLY, LOW/REVERSE . . . 21-561

CLUTCH - ASSEMBLY, REAR.....21-250,21-428

CLUTCH - CLEANING, LOW/REVERSE....21-561

CLUTCH - CLEANING, REAR.....21-250,21-428

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR........................24-9

CLUTCH - DESCRIPTION, FAN DRIVE

VISCOUS............................7-54

CLUTCH - DESCRIPTION, FRONT . 21-204,21-384

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-218,

21-396

CLUTCH - DESCRIPTION, REAR . . 21-248,21-426

CLUTCH - DIAGNOSIS AND TESTING.......6-2

CLUTCH - DISASSEMBLY, FRONT . 21-205,21-384

CLUTCH - DISASSEMBLY, LOW/REVERSE

. 21-560

CLUTCH - DISASSEMBLY, REAR

. . 21-249,21-427

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-12

CLUTCH - INSPECTION, FRONT

. . 21-206,21-385

CLUTCH - INSPECTION, LOW/REVERSE

. . 21-561CLUTCH - INSPECTION, REAR . . . 21-250,21-428

CLUTCH - INSTALLATION, A/C

COMPRESSOR.......................24-12

CLUTCH - OPERATION..................6-1

CLUTCH - OPERATION, A/C

COMPRESSOR........................24-9

CLUTCH - OPERATION, FAN DRIVE

VISCOUS............................7-54

CLUTCH - OPERATION, FRONT . . . 21-204,21-384

CLUTCH - OPERATION, OVERDRIVE....21-218,

21-396

CLUTCH - OPERATION, REAR....21-249,21-427

CLUTCH - REMOVAL, A/C COMPRESSOR . . 24-10

CLUTCH - SPECIFICATIONS...............6-6

CLUTCH - WARNING....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION.......21-143,21-324

CLUTCH ASSEMBLY - ASSEMBLY, INPUT . 21-552

CLUTCH ASSEMBLY - DESCRIPTION,

INPUT............................21-549

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT............................21-550

CLUTCH ASSEMBLY - OPERATION,

INPUT............................21-549

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR........24-10

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING...............21-239,21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING. . . 21-238,

21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING...............21-237,21-415

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING...............21-238,21-415

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - INSPECTION,

OVERRUNNING...............21-238,21-416

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - OPERATION,

OVERRUNNING...............21-237,21-415

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-10

CLUTCH DISC - INSTALLATION............6-6

CLUTCH DISC - REMOVAL...............6-6

CLUTCH HOUSING - DIAGNOSIS AND

TESTING.............................6-8

CLUTCH HOUSING - INSTALLATION.......6-10

CLUTCH HOUSING - REMOVAL...........6-10

CLUTCH OPERATION - DIAGNOSIS AND

TESTING, AIR CHECKING

TRANSMISSION.....................21-494

CLUTCH PEDAL POSITION SWITCH -

DESCRIPTION........................6-14

CLUTCH PEDAL POSITION SWITCH -

DIAGNOSIS AND TESTING..............6-14

CLUTCH PEDAL POSITION SWITCH -

OPERATION..........................6-14

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR.......................24-13

CLUTCH RELAY - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-13

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR.......................24-14

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR.......................24-13

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR.......................24-14

CLUTCH RELEASE BEARING -

INSTALLATION........................6-11

CLUTCH RELEASE BEARING - REMOVAL . . . 6-11

CLUTCHES - DESCRIPTION, HOLDING . . . 21-546

CLUTCHES - OPERATION, HOLDING.....21-546

COAT HOOK - INSTALLATION...........23-67

COAT HOOK - REMOVAL...............23-67

CODE - DESCRIPTION, PAINT...........23-74

CODE PLATE - DESCRIPTION, BODY

....Intro.-4

CODES - DESCRIPTION, DIAGNOSTIC

TROUBLE

............................25-1

CODES - SPECIFICATIONS, PAINT

........23-74

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER

..............8M-12

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER

..............8M-12COIL - DESCRIPTION, IGNITION.........8I-19

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-10

COIL - INSTALLATION, IGNITION.........8I-24

COIL - OPERATION, IGNITION...........8I-20

COIL - REMOVAL, IGNITION............8I-23

COIL CAPACITOR - DESCRIPTION,

IGNITION...........................8I-33

COIL CAPACITOR - INSTALLATION,

IGNITION...........................8I-33

COIL CAPACITOR - OPERATION,

IGNITION...........................8I-33

COIL CAPACITOR - REMOVAL, IGNITION . . . 8I-33

COIL RESISTANCE, 3.7L V-6 - IGNITION....8I-6

COIL RESISTANCE, 4.7L V-8 - IGNITION....8I-6

COIL RESISTANCE, 5.7L V-8 - IGNITION....8I-6

COIL RESISTANCE, 5.9L - IGNITION.......8I-6

COIL RESISTANCE, 8.0L V-10 ENGINE -

IGNITION............................8I-6

COLUMN - DESCRIPTION...............19-6

COLUMN - DIAGNOSIS AND TESTING,

STEERING...........................19-7

COLUMN - INSTALLATION...............19-9

COLUMN - REMOVAL..................19-7

COLUMN OPENING COVER -

INSTALLATION, STEERING.............23-61

COLUMN OPENING COVER - REMOVAL,

STEERING..........................23-61

COLUMN OPENING SUPPORT BRACKET

- INSTALLATION, STEERING..............23-62

COLUMN OPENING SUPPORT BRACKET

- REMOVAL, STEERING................23-61

COMBUSTION PRESSURE LEAKAGE -

DIAGNOSIS AND TESTING, CYLINDER....9-182,

9-231,9-359,9-8,9-92

COMMUNICATION - DESCRIPTION........8E-1

COMMUNICATION - OPERATION..........8E-2

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING..............8M-7

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-4

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-6

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION.......................8M-7

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-7

COMPASS/MINI-TRIP COMPUTER -

REMOVAL...........................8M-7

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER . . . 9-182,9-231,9-359,

9-8,9-92

COMPRESSION/LEAKAGE TESTS -

DIAGNOSIS AND TESTING, CYLINDER....9-288

COMPRESSOR CLUTCH - DESCRIPTION,

A/C ................................24-9

COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-12

COMPRESSOR CLUTCH - INSTALLATION,

A/C

................................24-12

COMPRESSOR CLUTCH - OPERATION,

A/C

................................24-9

COMPRESSOR CLUTCH - REMOVAL, A/C

. . 24-10

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C

...........24-10

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C

..........24-10

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C

...................24-13

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING

.............24-13

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C

...................24-14

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C

.....................24-13

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C

......................24-14

COMPRESSOR NOISE - DIAGNOSIS AND

TESTING, A/C

.......................24-36

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP

..........................8M-6

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP

..................8M-7

DRINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 2867 of 2895

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE...........8W-01-10

DRUM IN HAT BRAKE - CLEANING,

REAR...............................5-33

DRUM IN HAT BRAKE - INSPECTION,

REAR...............................5-33

DUAL REAR WHEEL INSTALLATION -

STANDARD PROCEDURE...............22-12

DUCTS - INSTALLATION, FLOOR

DISTRIBUTION.......................24-27

DUCTS - INSTALLATION, INSTRUMENT

PANEL.............................24-29

DUCTS - REMOVAL, FLOOR

DISTRIBUTION.......................24-27

DUCTS - REMOVAL, INSTRUMENT

PANEL.............................24-29

DUST BOOT - INSTALLATION,

EXTENSION HOUSING SEAL.....21-652,21-716

DUST BOOT - REMOVAL, EXTENSION

HOUSING SEAL...............21-652,21-716

DUTY FRONT FRAME RAIL TIP

REPLACEMENT - STANDARD

PROCEDURE, LIGHT...................13-4

ECM - DESCRIPTION...................8E-4

ECM - OPERATION....................8E-4

EFFECTS OF INCORRECT FLUID LEVEL -

DIAGNOSIS AND TESTING......21-201,21-381,

21-541

ELECTRICAL CONTROLS - DIAGNOSIS

AND TESTING, OVERDRIVE......21-219,21-397

ELECTRONIC GOVERNOR -

DESCRIPTION................21-196,21-376

ELECTRONIC GOVERNOR -

INSTALLATION.................21-199,21-379

ELECTRONIC GOVERNOR - OPERATION . 21-196,

21-377

ELECTRONIC GOVERNOR - REMOVAL . . . 21-198,

21-378

ELECTRONIC VARIABLE BRAKE

PROPORTIONING - DESCRIPTION........5-43

ELECTRONIC VARIABLE BRAKE

PROPORTIONING - OPERATION..........5-43

ELECTRONIC VEHICLE INFO CENTER -

DESCRIPTION........................8M-7

ELECTRONIC VEHICLE INFO CENTER -

INSTALLATION......................8M-10

ELECTRONIC VEHICLE INFO CENTER -

OPERATION.........................8M-8

ELECTRONIC VEHICLE INFO CENTER -

REMOVAL..........................8M-10

ELECTRONIC VEHICLE INFORMATION

CENTER - DIAGNOSIS AND TESTING......8M-8

ELECTRONIC VEHICLE INFORMATION

CENTER PROGRAMMING - STANDARD

PROCEDURE.........................8M-8

ELECTRONICLY CONTOLLED VISCOUS

FAN DRIVE - DIAGNOSIS AND TESTING....7-56

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES - STANDARD

PROCEDURE......................8W-01-8

ELEMENT - DESCRIPTION, HEATED SEAT . . 8G-5

ELEMENT - DIAGNOSIS AND TESTING,

HEATED SEAT ........................8G-6

ELEMENT - INSTALLATION, AIR

CLEANER........9-105,9-20,9-242,9-298,9-370

ELEMENT - INSTALLATION, HEATED

SEAT ...............................8G-6

ELEMENT - OPERATION, HEATED SEAT....8G-6

ELEMENT - REMOVAL, AIR CLEANER....9-105,

9-20,9-242,9-297,9-370

ELEMENT - REMOVAL, HEATED SEAT.....8G-6

EMISSION CONTROL INFORMATION

(VECI) - DESCRIPTION, VEHICLE.......Intro.-3

END - DIAGNOSIS AND TESTING, OUTER

TIE ROD............................19-31

END - INSTALLATION, OUTER TIE ROD . . . 19-32

END - INSTALLATION, TIE ROD.........19-37

END - REMOVAL, OUTER TIE ROD.......19-31

END - REMOVAL, TIE ROD.............19-36

ENGINE - 3.7L - DESCRIPTION............9-3

ENGINE - 5.7L - DESCRIPTION

..........9-178

ENGINE - 5.9L - DESCRIPTION

..........9-224

ENGINE - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L

...................7-1

ENGINE - DESCRIPTION, COOLING

SYSTEM FLOW 3.7L/4.7L

................7-1

ENGINE - DESCRIPTION, FUEL

REQUIREMENTS - DIESEL

...............0-1ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIESEL...............7-7

ENGINE - DIAGNOSIS AND TESTING,

DIESEL.............................11-3

ENGINE - DIAGNOSIS AND TESTING,

GAS................................11-2

ENGINE - FIRING ORDER / CABLE

ROUTING, 5.7L V-8....................8I-4

ENGINE - IGNITION COIL RESISTANCE,

8.0L V-10............................8I-6

ENGINE - INSTALLATION...............9-291

ENGINE - INSTALLATION, 5.9L DIESEL . . . 24-39,

24-42,24-44

ENGINE - INSTALLATION, 8.0L..........24-42

ENGINE - INSTALLATION, EXCEPT V-10

OR DIESEL.........................8R-17

ENGINE - INSTALLATION, GAS..........19-24

ENGINE - INSTALLATION, V-10 OR

DIESEL............................8R-17

ENGINE - REMOVAL..................9-290

ENGINE - REMOVAL, 5.9L DIESEL . . 24-37,24-40,

24-43,24-46

ENGINE - REMOVAL, 8.0L..............24-40

ENGINE - REMOVAL, EXCEPT V-10 OR

DIESEL............................8R-16

ENGINE - REMOVAL, GAS..............19-23

ENGINE - REMOVAL, V-10 OR DIESEL....8R-16

ENGINE - SPARK PLUG CABLE ORDER,

8.0L V-10............................8I-5

ENGINE - SPECIFICATIONS, 3.7L.........9-12

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM

3.7L/4.7L/5.7L........................7-18

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM 5.9L

DIESEL.............................7-19

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM

5.9L/8.0L............................7-18

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM

3.7L/4.7L/5.7L........................7-18

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM 5.9L

DIESEL.............................7-19

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM

5.9L/8.0L............................7-18

ENGINE 5.9L DIESEL - DESCRIPTION.....9-282

ENGINE 8.0L - DESCRIPTION...........9-353

ENGINE BLOCK - CLEANING . 9-127,9-200,9-249,

9-38,9-380

ENGINE BLOCK - DESCRIPTION.....9-126,9-37

ENGINE BLOCK - INSPECTION.....9-127,9-200,

9-249,9-38,9-380

ENGINE BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION........................7-43

ENGINE BLOCK HEATER - 5.9L DIESEL -

INSTALLATION........................7-44

ENGINE BLOCK HEATER - 5.9L DIESEL -

OPERATION..........................7-43

ENGINE BLOCK HEATER - 5.9L DIESEL -

REMOVAL...........................7-43

ENGINE BLOCK HEATER - DESCRIPTION . . . 7-42

ENGINE BLOCK HEATER - DIAGNOSIS

AND TESTING........................7-42

ENGINE BLOCK HEATER - INSTALLATION . . . 7-43

ENGINE BLOCK HEATER - OPERATION.....7-42

ENGINE BLOCK HEATER - REMOVAL......7-43

ENGINE CONTROL MODULE -

INSTALLATION........................8E-5

ENGINE CONTROL MODULE - REMOVAL . . . 8E-4

ENGINE COOLANT - DESCRIPTION........7-36

ENGINE COOLANT - DESCRIPTION.........0-3

ENGINE COOLANT TEMPERATURE

SENSOR - DESCRIPTION...............7-44

ENGINE COOLANT TEMPERATURE

SENSOR - INSTALLATION...............7-47

ENGINE COOLANT TEMPERATURE

SENSOR - OPERATION

.................7-44

ENGINE COOLANT TEMPERATURE

SENSOR - REMOVAL

...................7-44

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - DESCRIPTION

...............7-50

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - INSTALLATION

..............7-51

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - OPERATION

.................7-51ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - REMOVAL..................7-51

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - DESCRIPTION................7-52

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - INSTALLATION................7-53

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - OPERATION..................7-52

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - REMOVAL....................7-53

ENGINE COOLANT THERMOSTAT-

5.7L/5.9L - DESCRIPTION...............7-47

ENGINE COOLANT THERMOSTAT-

5.7L/5.9L - INSTALLATION..............7-49

ENGINE COOLANT THERMOSTAT-

5.7L/5.9L - OPERATION.................7-48

ENGINE COOLANT THERMOSTAT-

5.7L/5.9L - REMOVAL..................7-48

ENGINE DATA PLATE - DESCRIPTION.....9-297

ENGINE DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING . . . 9-178,9-225,9-353,

9-4,9-93

ENGINE DIAGNOSIS - LUBRICATION -

DIAGNOSIS AND TESTING . . . 9-183,9-230,9-358,

9-7

ENGINE DIAGNOSIS - MECHANICAL -

DIAGNOSIS AND TESTING . . . 9-181,9-184,9-228,

9-283,9-356,9-6,9-91

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING . . . 9-179,9-226,9-354,

9-4,9-89

ENGINE FIRING ORDER, 3.7L V-6.........8I-4

ENGINE FIRING ORDER, 4.7L V-8.........8I-4

ENGINE FIRING ORDER, 5.9L V-8...........8I-4

ENGINE GASKET SURFACE

PREPARATION - STANDARD

PROCEDURE.........................9-10

ENGINE OIL - STANDARD PROCEDURE . . . 9-269,

9-396

ENGINE OIL AND LUBRICANTS -

DESCRIPTION.........................0-2

ENGINE OIL LEAK - DIAGNOSIS AND

TESTING..................9-150,9-214,9-63

ENGINE OIL LEAKS - DIAGNOSIS AND

TESTING......................9-269,9-394

ENGINE OIL LEVEL - STANDARD

PROCEDURE........................9-341

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING.............9-269,9-338,9-396

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING, CHECKING.....9-150,9-214,9-64

ENGINE OIL SERVICE - STANDARD

PROCEDURE..........9-151,9-215,9-341,9-70

ENGINE, SPECIAL TOOLS - 4.7L.........9-102

ENGINE, SPECIAL TOOLS - 5.7L.........9-192

ENGINE, SPECIAL TOOLS - 5.9L.........9-240

ENGINE, SPECIAL TOOLS - 5.9L DIESEL . . 9-294

ENGINE, SPECIAL TOOLS - 8.0L.........9-367

ENGINE, SPECIFICATIONS - 4.7L.........9-98

ENGINE, SPECIFICATIONS - 5.7L........9-188

ENGINE, SPECIFICATIONS - 5.9L........9-235

ENGINE, SPECIFICATIONS - 8.OL........9-364

ENGINE TEMPERATURE GAUGE -

DESCRIPTION

.......................8J-23

ENGINE TEMPERATURE GAUGE -

OPERATION

.........................8J-23

ENGINE TIMING - VERIFICATION -

STANDARD PROCEDURE

...............9-165

ENGINES - INSTALLATION, 3.7, 4.7 AND

5.7L

...............................24-41

ENGINES - REMOVAL, 3.7, 4.7 AND 5.7L

. . 24-39

ENTRY MODULE - DESCRIPTION,

REMOTE KEYLESS

....................8N-7

ENTRY MODULE - DIAGNOSIS AND

TESTING, REMOTE KEYLESS

............8N-8

ENTRY MODULE - INSTALLATION,

REMOTE KEYLESS

....................8N-8

ENTRY MODULE - OPERATION, REMOTE

KEYLESS

............................8N-8

ENTRY MODULE - REMOVAL, REMOTE

KEYLESS

............................8N-8

ENTRY TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS

............8N-8

ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE KEYLESS

.....8N-10

EQUIPMENT - STANDARD PROCEDURE,

REFRIGERANT SYSTEM SERVICE

........24-34

12 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2868 of 2895

ERASING TRANSMITTER CODES -

STANDARD PROCEDURE..............8M-12

ETC INDICATOR - DESCRIPTION.........8J-24

ETC INDICATOR - OPERATION..........8J-25

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM..........24-35,24-51

EVAP SYSTEM - DESCRIPTION..........25-10

EVAP SYSTEM - TORQUE..............25-12

EVAPORATOR - DESCRIPTION, A/C.......24-47

EVAPORATOR - INSTALLATION, A/C......24-47

EVAPORATOR - OPERATION, A/C........24-47

EVAPORATOR - REMOVAL, A/C..........24-47

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-12

EVAP/PURGE SOLENOID - INSTALLATION . 25-13

EVAP/PURGE SOLENOID - OPERATION....25-12

EVAP/PURGE SOLENOID - REMOVAL.....25-13

EXCEPT 4X4 HD - INSTALLATION, ALL

LD & HD ...........................19-15

EXCEPT 4X4 HD - REMOVAL, ALL LD &

HD................................19-14

EXCEPT DIESEL - INSTALLATION........14-22

EXCEPT DIESEL - REMOVAL............14-20

EXCEPT HYDROBOOST - INSTALLATION,

ALL ................................5-22

EXCEPT HYDROBOOST - REMOVAL, ALL . . . 5-21

EXCEPT V-10 OR DIESEL ENGINE -

INSTALLATION......................8R-17

EXCEPT V-10 OR DIESEL ENGINE -

REMOVAL............................8R-16

EXHAUST MANIFOLD - CLEANING . . 9-161,9-220,

9-277,9-347,9-404

EXHAUST MANIFOLD - DESCRIPTION....9-159,

9-220,9-277,9-403,9-73

EXHAUST MANIFOLD - INSPECTION.....9-161,

9-220,9-277,9-347,9-404

EXHAUST MANIFOLD - INSTALLATION . . . 9-162,

9-220,9-277,9-347,9-404,9-74

EXHAUST MANIFOLD - OPERATION . 9-220,9-277,

9-403

EXHAUST MANIFOLD - REMOVAL . . 9-159,9-220,

9-277,9-347,9-404,9-73

EXHAUST PIPE - INSPECTION...........11-7

EXHAUST PIPE - INSTALLATION..........11-7

EXHAUST PIPE - REMOVAL.............11-7

EXTENSION HOUSING BUSHING -

INSTALLATION......................21-200

EXTENSION HOUSING BUSHING -

REMOVAL.........................21-200

EXTENSION HOUSING BUSHING AND

SEAL - INSTALLATION..........21-616,21-682

EXTENSION HOUSING BUSHING AND

SEAL - REMOVAL.............21-616,21-682

EXTENSION HOUSING SEAL -

INSTALLATION.....21-127,21-200,21-380,21-83

EXTENSION HOUSING SEAL - REMOVAL . 21-127,

21-200,21-380,21-83

EXTENSION HOUSING SEAL AND DUST

BOOT - INSTALLATION.........21-652,21-716

EXTENSION HOUSING SEAL AND DUST

BOOT - REMOVAL.............21-652,21-716

EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING.....................8L-3

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR HANDLE - INSTALLATION.....23-20,

23-30

EXTERIOR HANDLE - REMOVAL

....23-20,23-30

EXTERIOR LAMPS, SPECIFICATIONS

......8L-7

EXTERIOR NAME PLATES -

INSTALLATION

.......................23-38

EXTERIOR NAME PLATES - REMOVAL

....23-38

FAILURE - DIAGNOSIS AND TESTING,

CYLINDER HEAD GASKET

....9-194,9-243,9-370

FAN - 5.9L DIESEL - CLEANING,

RADIATOR

...........................7-41

FAN - 5.9L DIESEL - INSPECTION,

RADIATOR

...........................7-41

FAN - 5.9L DIESEL - INSTALLATION,

RADIATOR

...........................7-41

FAN - 5.9L DIESEL - REMOVAL,

RADIATOR

...........................7-41

FAN - CLEANING, RADIATOR

............7-40

FAN - INSPECTION, RADIATOR

...........7-40

FAN - INSTALLATION, RADIATOR

.........7-40

FAN - REMOVAL, RADIATOR

.............7-39FAN DRIVE - DIAGNOSIS AND TESTING,

ELECTRONICLY CONTOLLED VISCOUS.....7-56

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS............................7-54

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION................7-55

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION..................7-55

FAN DRIVE VISCOUS CLUTCH -

DESCRIPTION........................7-54

FAN DRIVE VISCOUS CLUTCH -

OPERATION..........................7-54

FAN (GAS ENGINE ONLY - 3.7, 4.7 &

5.7L) - INSTALLATION, CONDENSER.....24-43

FAN (GAS ENGINE ONLY - 3.7, 4.7 &

5.7L) - REMOVAL, CONDENSER.........24-43

FASCIA - INSTALLATION, FRONT.........13-3

FASCIA - REMOVAL, FRONT.............13-3

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-6

FASTENER USAGE - DESCRIPTION......Intro.-9

FENDER - INSTALLATION, FRONT........23-39

FENDER - INSTALLATION, REAR.........23-44

FENDER - REMOVAL, FRONT...........23-39

FENDER - REMOVAL, REAR............23-44

FENDER RAIL REPAIR - STANDARD

PROCEDURE, HYDROFORM............13-12

FILL - STANDARD PROCEDURE,

TRANSMISSION.........21-203,21-383,21-544

FILL DOOR - INSTALLATION, FUEL.......23-39

FILL DOOR - REMOVAL, FUEL............23-39

FILLER CAP - DESCRIPTION, FUEL.......25-13

FILLER CAP - OPERATION, FUEL........25-13

FILTER - INSTALLATION, INLET..........14-23

FILTER - INSTALLATION, OIL . 9-153,9-217,9-270,

9-342,9-397,9-70

FILTER - REMOVAL, INLET.............14-23

FILTER - REMOVAL, OIL.....9-152,9-216,9-270,

9-342,9-397,9-69

FILTER - STANDARD PROCEDURES,

WATER DRAINING AT FUEL............14-57

FILTER / WATER SEPARATOR -

DESCRIPTION, FUEL..................14-61

FILTER / WATER SEPARATOR -

INSTALLATION, FUEL.................14-62

FILTER / WATER SEPARATOR -

OPERATION, FUEL....................14-61

FILTER / WATER SEPARATOR -

REMOVAL, FUEL.....................14-61

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID.....21-203,21-383,21-542

FILTER/PRESSURE REGULATOR -

DESCRIPTION, FUEL...................14-6

FILTER/PRESSURE REGULATOR -

OPERATION, FUEL.....................14-6

FINESSE SANDING/BUFFING &

POLISHING - DESCRIPTION............23-75

FINISH - DESCRIPTION, BASECOAT/

CLEARCOAT.........................23-74

FIRING ORDER / CABLE ROUTING, 5.7L

V-8 ENGINE..........................8I-4

FIRING ORDER, 3.7L V-6 - ENGINE........8I-4

FIRING ORDER, 4.7L V-8 - ENGINE........8I-4

FIRING ORDER, 5.9L V-8 - ENGINE........8I-4

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-60

FITTING - DESCRIPTION, QUICK

CONNECT............................14-8

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING . 9-128,9-251,9-382

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING..........9-253

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING.....9-133,9-202

FITTING - STANDARD PROCEDURE,

PISTON.........9-137,9-205,9-260,9-389,9-50

FITTING - STANDARD PROCEDURE,

PISTON RING....9-140,9-207,9-262,9-333,9-52

FITTING CRANKSHAFT MAIN BEARINGS

- STANDARD PROCEDURE

.............9-383

FITTING PISTON RINGS - STANDARD

PROCEDURE

........................9-390

FITTING, STANDARD PROCEDURE -

CONNECTING ROD BEARING

............9-48

FITTING, STANDARD PROCEDURE -

MAIN BEARING

.......................9-43

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT

......................14-8FIXED ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-48

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-27

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-27

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED.....................5-7

FLARING - STANDARD PROCEDURE, ISO....5-7

FLEX PLATE - INSTALLATION . . 9-137,9-205,9-47

FLEX PLATE - REMOVAL......9-137,9-205,9-47

FLOOR - DEFROST DOOR -

INSTALLATION.......................24-30

FLOOR - DEFROST DOOR - REMOVAL....24-30

FLOOR - DEFROST DOOR ACTUATOR -

INSTALLATION.......................24-20

FLOOR - DEFROST DOOR ACTUATOR -

REMOVAL..........................24-19

FLOOR - INSTALLATION, LOAD..........23-73

FLOOR - REMOVAL, LOAD.............23-73

FLOOR CONSOLE - INSTALLATION.......23-68

FLOOR CONSOLE - REMOVAL...........23-68

FLOOR DISTRIBUTION DUCTS -

INSTALLATION.......................24-27

FLOOR DISTRIBUTION DUCTS -

REMOVAL..........................24-27

FLOOR MATS - INSTALLATION, CARPETS . 23-66

FLOOR MATS - REMOVAL, CARPETS.....23-66

FLOOR SHIFT BOOT - INSTALLATION,

4WD ..............................23-64

FLOOR SHIFT BOOT - REMOVAL, 4WD.....23-63

FLOOR SUPPORT CYLINDER -

INSTALLATION, LOAD.................23-73

FLOOR SUPPORT CYLINDER -

REMOVAL, LOAD.....................23-73

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-2

FLOW - 5.9L ENGINE - DESCRIPTION,

COOLING SYSTEM.....................7-1

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..............7-57,7-59

FLOW 3.7L/4.7L ENGINE - DESCRIPTION,

COOLING SYSTEM.....................7-1

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION................19-42

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-4

FLUID - DESCRIPTION, POWER

STEERING............................0-3

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT......21-201,21-381,21-541

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE . . 21-203,21-383,21-542

FLUID CAPACITIES, SPECIFICATIONS.......0-5

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING..........21-201,21-381,21-541

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-18

FLUID COOLER - INSTALLATION.........19-42

FLUID COOLER - REMOVAL............19-42

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE.....21-617,21-652,21-682,21-716

FLUID INDICATOR - DESCRIPTION,

WASHER...........................8J-42

FLUID INDICATOR - OPERATION,

WASHER...........................8J-42

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING . . . 21-143,21-324,21-495

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT.....21-201,

21-381,21-541

FLUID LEVEL - STANDARD PROCEDURE,

BRAKE..............................5-18

FLUID LEVEL CHECK - STANDARD

PROCEDURE...........21-201,21-381,21-542

FLUID LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING........19-42

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER

............................8R-9

FLUID LEVEL SWITCH - INSTALLATION,

WASHER

...........................8R-11

FLUID LEVEL SWITCH - OPERATION,

WASHER

............................8R-9

FLUID LEVEL SWITCH - REMOVAL,

WASHER

...........................8R-10

FLUID RESERVOIR - INSTALLATION

.......5-19

DRINDEX 13

Description Group-Page Description Group-Page Description Group-Page

Page 2875 of 2895

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL...................24-54

LEVEL CHECK - STANDARD

PROCEDURE, COOLANT................7-17

LEVEL CHECK - STANDARD

PROCEDURE, FLUID.....21-201,21-381,21-542

LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING FLUID . . . 19-42

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL..............14-68,14-7

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL..................14-8

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL................14-68,14-7

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL......................14-7

LEVEL SWITCH - DESCRIPTION,

WASHER FLUID......................8R-9

LEVEL SWITCH - INSTALLATION,

WASHER FLUID.....................8R-11

LEVEL SWITCH - OPERATION, WASHER

FLUID..............................8R-9

LEVEL SWITCH - REMOVAL, WASHER

FLUID.............................8R-10

LEVER - ADJUSTMENT, SHIFT . . . 21-622,21-657

LEVER - INSTALLATION, GEAR SHIFT.....19-12

LEVER - INSTALLATION, SHIFT . . . 21-621,21-656

LEVER - REMOVAL, GEAR SHIFT........19-12

LEVER - REMOVAL, SHIFT......21-620,21-655

LICENSE PLATE LAMP - INSTALLATION . . . 8L-16

LICENSE PLATE LAMP - REMOVAL.......8L-16

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-16

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-16

LID - INSTALLATION, CENTER SEAT

BACK..............................23-80

LID - REMOVAL, CENTER SEAT BACK....23-80

LIFTERS - CLEANING, HYDRAULIC . . 9-260,9-388

LIFTERS - INSTALLATION, HYDRAULIC . . . 9-260,

9-388

LIFTERS - REMOVAL, HYDRAULIC . . 9-259,9-387

LIFTERS/TAPPETS - CLEANING, SOLID....9-328

LIFTERS/TAPPETS - INSPECTION, SOLID . . 9-328

LIFTERS/TAPPETS - INSTALLATION,

SOLID.............................9-328

LIFTERS/TAPPETS - REMOVAL, SOLID....9-327

LIGHT DUTY FRONT FRAME RAIL TIP

REPLACEMENT - STANDARD

PROCEDURE.........................13-4

LIGHTER OUTLET - DESCRIPTION,

CIGAR...........................8W-97-2

LIGHTER OUTLET - DIAGNOSIS AND

TESTING, CIGAR...................8W-97-2

LIGHTER OUTLET - OPERATION, CIGAR . 8W-97-2

LIMITING VALVE - DESCRIPTION, FUEL

PRESSURE.........................14-72

LIMITING VALVE - INSTALLATION, FUEL

PRESSURE.........................14-73

LIMITING VALVE - OPERATION, FUEL

PRESSURE.........................14-72

LIMITING VALVE - REMOVAL, FUEL

PRESSURE.........................14-72

LINE - DESCRIPTION, REFRIGERANT.....24-32

LINE - INSTALLATION, LIQUID..........24-45

LINE - REMOVAL, LIQUID..............24-45

LINE COUPLER - DESCRIPTION,

REFRIGERANT.......................24-52

LINE COUPLER - INSTALLATION,

REFRIGERANT.......................24-53

LINE COUPLER - OPERATION,

REFRIGERANT.......................24-52

LINE COUPLER - REMOVAL,

REFRIGERANT.......................24-52

LINE LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL................14-69

LINE PRESSURE (LP) SENSOR -

DESCRIPTION......................21-559

LINE PRESSURE (LP) SENSOR -

INSTALLATION......................21-560

LINE PRESSURE (LP) SENSOR -

OPERATION........................21-559

LINE PRESSURE (LP) SENSOR -

REMOVAL.........................21-559

LINES - DESCRIPTION, FUEL

.......14-69,14-8

LINES - DESCRIPTION, VACUUM

........25-22

LINES - INSTALLATION, FUEL

...........14-71

LINES - OPERATION, FUEL

.............14-69

LINES - OPERATION, REFRIGERANT

......24-32LINES - REMOVAL, FUEL..............14-69

LINK - INSTALLATION, DRAG...........19-35

LINK - REMOVAL, DRAG...............19-35

LINK CONNECTOR - DESCRIPTION, DATA . . 8E-3

LINK CONNECTOR - OPERATION, DATA....8E-3

LINKAGE - INSTALLATION...............6-13

LINKAGE - LINK/COIL - DESCRIPTION....19-33

LINKAGE - REMOVAL..................6-13

LINKAGE, SPECIAL TOOLS - STEERING . . . 19-35

LINK/COIL - DESCRIPTION, GEAR........19-19

LINK/COIL - DESCRIPTION, LINKAGE.....19-33

LINK/COIL - INSTALLATION, GEAR.......19-20

LINK/COIL - OPERATION, GEAR.........19-19

LINK/COIL - REMOVAL, GEAR...........19-19

LINK/COIL SUSPENSION - STANDARD

PROCEDURE, ALIGNMENT...............2-5

LIQUID LINE - INSTALLATION...........24-45

LIQUID LINE - REMOVAL..............24-45

LOAD FLOOR - INSTALLATION..........23-73

LOAD FLOOR - REMOVAL..............23-73

LOAD FLOOR SUPPORT CYLINDER -

INSTALLATION.......................23-73

LOAD FLOOR SUPPORT CYLINDER -

REMOVAL..........................23-73

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL.....8W-01-10

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE...................8W-91-1

LOCATIONS - SPECIFICATIONS, SEALER . 23-103

LOCATIONS - SPECIFICATIONS,

STRUCTURAL ADHESIVE..............23-113

LOCATIONS - SPECIFICATIONS, WELD . . . 23-122

LOCK - STANDARD PROCEDURE,

HYDROSTATIC........9-186,9-232,9-290,9-361

LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH AND KEY....19-11

LOCK CYLINDER - INSTALLATION.......23-24

LOCK CYLINDER - REMOVAL...........23-24

LOCK MOTOR - DESCRIPTION, DOOR.....8N-5

LOCK MOTOR - DIAGNOSIS AND

TESTING, DOOR......................8N-5

LOCK MOTOR - OPERATION, DOOR.......8N-5

LOCK SWITCH - DIAGNOSIS AND

TESTING, POWER.....................8N-4

LOCK SWITCH - INSTALLATION, POWER . . . 8N-4

LOCK SWITCH - REMOVAL, POWER......8N-4

LOCKING RETRACTOR - DESCRIPTION,

AUTOMATIC........................8O-13

LOCKING RETRACTOR - OPERATION,

AUTOMATIC........................8O-14

LOCKS - DESCRIPTION, POWER.........8N-1

LOCKS - DIAGNOSIS AND TESTING,

POWER.............................8N-3

LOCKS - OPERATION, POWER...........8N-2

LOOP ADJUSTER - INSTALLATION, SEAT

BELT TURNING......................8O-50

LOOP ADJUSTER - REMOVAL, SEAT

BELT TURNING......................8O-50

LOOP BRACKETS - INSTALLATION, SEAT

BACK REAR - FOOTMANS..............23-85

LOOP BRACKETS - REMOVAL, SEAT

BACK REAR - FOOTMANS..............23-85

LOW FUEL INDICATOR - DESCRIPTION . . . 8J-29

LOW FUEL INDICATOR - OPERATION.....8J-29

LOWER BALL JOINT - DIAGNOSIS AND

TESTING............................2-18

LOWER BALL JOINT - INSTALLATION . 2-19,2-33

LOWER BALL JOINT - REMOVAL.....2-18,2-32

LOWER CONTROL ARM BUSHINGS -

2WD (LD) - INSTALLATION..............2-14

LOWER CONTROL ARM BUSHINGS -

2WD (LD) - REMOVAL.................2-12

LOWER CONTROL ARM BUSHINGS -

4WD (LD) - INSTALLATION..............2-13

LOWER CONTROL ARM BUSHINGS -

4WD (LD) - REMOVAL.................2-12

LOWER SURROUND - INSTALLATION,

INSTRUMENT PANEL..................23-60

LOWER SURROUND - REMOVAL,

INSTRUMENT PANEL

..................23-60

LOWER SUSPENSION ARM -

INSTALLATION

........................2-35

LOWER SUSPENSION ARM - REMOVAL

....2-35

LOWER TRIM - INSTALLATION,

B-PILLAR

...........................23-65

LOWER TRIM - INSTALLATION,

C-PILLAR

...........................23-68LOWER TRIM - REMOVAL, B-PILLAR.....23-64

LOWER TRIM - REMOVAL, C-PILLAR.....23-67

LOW/REVERSE CLUTCH - ASSEMBLY....21-561

LOW/REVERSE CLUTCH - CLEANING....21-561

LOW/REVERSE CLUTCH - DISASSEMBLY . 21-560

LOW/REVERSE CLUTCH - INSPECTION . . 21-561

LUBRICANTS - DESCRIPTION, ENGINE

OIL .................................0-2

LUBRICATION - DESCRIPTION.....9-148,9-214,

9-267,9-337,9-393,9-60

LUBRICATION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS.....9-183,9-230,

9-358,9-7

LUBRICATION - OPERATION . 9-148,9-267,9-337,

9-393,9-60

LUBRICATION - STANDARD PROCEDURE . . 19-34

LUBRICATION - STANDARD PROCEDURE,

BODY...............................23-3

LUMBAR CONTROL SWITCH -

DESCRIPTION.......................8N-19

LUMBAR CONTROL SWITCH -

OPERATION.........................8N-19

LUMBAR CONTROL SWITCH - REMOVAL . 8N-19

LUMBAR MOTOR - DESCRIPTION.......8N-19

LUMBAR MOTOR - DIAGNOSIS AND

TESTING...........................8N-20

LUMBAR MOTOR - OPERATION.........8N-20

MAIN BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT.......9-133,9-202

MAIN BEARING CLEARANCE -

STANDARD PROCEDURE................9-322

MAIN BEARING FITTING - STANDARD

PROCEDURE, CRANKSHAFT............9-253

MAIN BEARING FITTING, STANDARD

PROCEDURE.........................9-43

MAIN BEARINGS - DESCRIPTION,

CRANKSHAFT.......................9-253

MAIN BEARINGS - INSPECTION,

CRANKSHAFT..................9-133,9-203

MAIN BEARINGS - INSTALLATION,

CRANKSHAFT..................9-254,9-383

MAIN BEARINGS - OPERATION,

CRANKSHAFT.......................9-253

MAIN BEARINGS - REMOVAL,

CRANKSHAFT..................9-254,9-383

MAIN BEARINGS - STANDARD

PROCEDURE, FITTING CRANKSHAFT.....9-383

MAINTENANCE SCHEDULES -

DESCRIPTION.........................0-6

MALFUNCTION INDICATOR LAMP (MIL) -

DESCRIPTION.......................8J-30

MALFUNCTION INDICATOR LAMP (MIL) -

OPERATION.........................8J-30

MANAGER - DESCRIPTION, TASK.........25-1

MANAGER - OPERATION, TASK..........25-5

MANIFOLD - CLEANING, EXHAUST . 9-161,9-220,

9-277,9-347,9-404

MANIFOLD - CLEANING, INTAKE . . . 9-158,9-219,

9-275,9-346,9-402

MANIFOLD - DESCRIPTION, EXHAUST . . . 9-159,

9-220,9-277,9-403,9-73

MANIFOLD - DESCRIPTION, INTAKE.....9-157,

9-219,9-274,9-401,9-71

MANIFOLD - INSPECTION, EXHAUST.....9-161,

9-220,9-277,9-347,9-404

MANIFOLD - INSPECTION, INTAKE . 9-158,9-219,

9-275,9-346,9-402

MANIFOLD - INSTALLATION, EXHAUST . . . 9-162,

9-220,9-277,9-347,9-404,9-74

MANIFOLD - INSTALLATION, INTAKE.....9-158,

9-219,9-275,9-346,9-402,9-72

MANIFOLD - OPERATION, EXHAUST.....9-220,

9-277,9-403

MANIFOLD - OPERATION, INTAKE........9-274

MANIFOLD - REMOVAL, EXHAUST . . 9-159,9-220,

9-277,9-347,9-404,9-73

MANIFOLD - REMOVAL, INTAKE . . . 9-157,9-219,

9-275,9-345,9-401,9-72

MANIFOLD LEAKAGE - DIAGNOSIS AND

TESTING, INTAKE

.....9-157,9-219,9-274,9-401

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE

.....................9-71

MANUAL - INSTALLATION, WINDOW

REGULATOR

...................23-26,23-35

MANUAL - REMOVAL, WINDOW

REGULATOR

...................23-26,23-35

MANUAL BLEEDING - STANDARD

PROCEDURE

..........................5-5

20 INDEXDR

Description Group-Page Description Group-Page Description Group-Page