check engine light DODGE RAM 2003 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1446 of 2895

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

DESCRIPTION - VALVE GUIDES

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide ream-

ing is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

DESCRIPTION

Both the intake and exhaust valves are made of

steel. The intake valve is 50.93 mm (2.00 inches) in

diameter and the exhaust valve is 39.53 mm (1.55

inches) in diameter. All valves use three bead lock

keepers to retain the springs and promote valve rota-

tion.

STANDARD PROCEDURE - REFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.018 - 1.62 mm (0.0464 -

0.0637 in.) and the exhaust seat must be 1.48 - 1.92

mm (0.058 - 0.075 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 46.0 mm (1.81 in.).

VALVE FACE AND VALVE SEAT ANGLE CHART

DESCRIPTION SPECIFICATION

SEAT WIDTH

INTAKE 1.018 - 1.62 mm

(0.0464 - 0.0637 in.)

EXHAUST 1.48 - 1.92 mm

(0.058 - 0.075 in.)

FACE ANGLE

(INT. AND EXT.) 45É - 45

1¤2É

SEAT ANGLE

(INT. AND EXT.) 44

1¤2É - 45É

(5) The valve seat must maintain an angle of 44.5

± 45.0 degrees angle.

(6) The valve face must maintain a face angle of

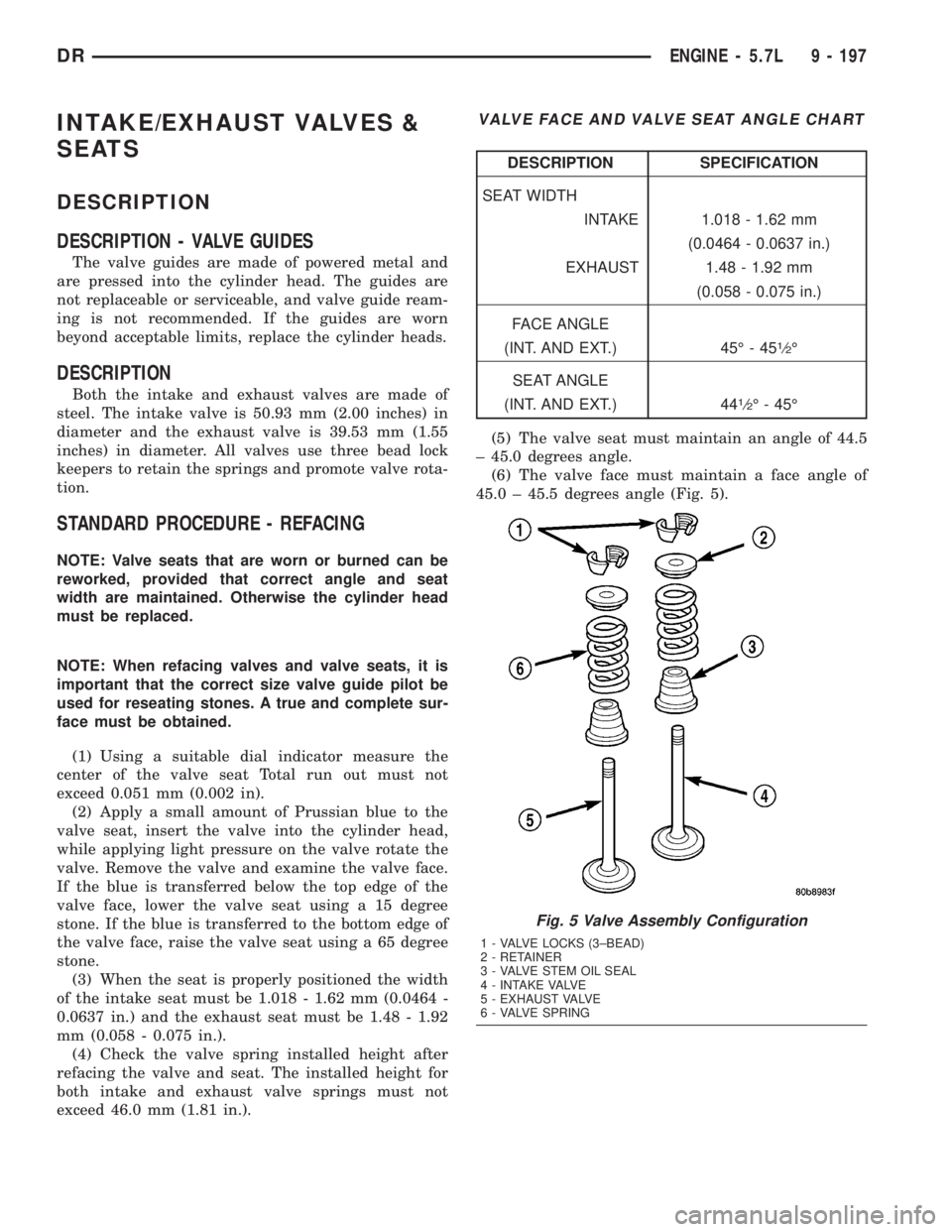

45.0 ± 45.5 degrees angle (Fig. 5).

Fig. 5 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

DRENGINE - 5.7L 9 - 197

Page 1453 of 2895

CRANKSHAFT OIL SEAL -

REAR

DIAGNOSIS AND TESTING - REAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs, oil galley pipe plugs, oil filter runoff,

and main bearing cap to cylinder block mating sur-

faces. See Engine, for proper repair procedures of

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. (Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING), under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

REMOVAL

NOTE: This procedure can be performed in vehicle.

(1) If being preformed in vehicle, remove the

transmission.

(2) Remove the flexplate (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

(3) Using Special Tool 8506, remove the crankshaft

rear oil seal.

INSTALLATION

CAUTION: The rear seal must be installed dry for

proper operation. Do not lubricate the seal lip or

outer edge.

(1) Position the plastic seal guide onto the crank-

shaft rear face. Then position the crankshaft rear oil

seal onto the guide.

(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle, with a

hammer, tap the seal into place. Continue to tap on

the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) Install the transmission.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the transmission.

(3) Remove the drive plate / flywheel.

(4) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(5) Remove the rear oil seal retainer mounting

bolts.

(6) Carefully remove the retainer from the engine

block.

9 - 204 ENGINE - 5.7LDR

Page 1454 of 2895

INSTALLATION

(1) Throughly clean all gasket resdue from the

engine block.

(2) Use extream care and clean all gasket resdue

from the retainer.

(3) Position the gasket onto the retainer.

(4) Position the retainer onto the engine block.

(5) Install the retainer mounting bolts. Tighten the

bolts to 15 N´m (132 in. lbs.) using a crisscross pat-

tern, starting with the bolt on the lower right.

(6) Install a new rear seal(Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT OIL SEAL - REAR

- INSTALLATION).

(7) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(8) Install the drive plate / flywheel.

(9) Install the transmission.

(10) Check and verify engine oil level.

(11) Start engine and check for leaks.

FLEX PLATE

REMOVAL

(1) Remove the transmission.

(2) Remove the bolts and flexplate.

INSTALLATION

(1) Position the flexplate onto the crankshaft and

install the bolts hand tight.

(2) Tighten the flexplate retaining bolts to 95 N´m

(70 ft. lbs.).

(3) Install the transmission.

PISTON & CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

or a scratch awl.

The pistons are made of a high strength aluminum

alloy. Piston skirts are coated with a solid lubricant

(Molykote) to reduce friction and provide scuff resis-

tance. The piston top ring groove and land is anod-

ized. The connecting rods are made of forged

powdered metal, with a ªfractured capº design. A

pressed fit piston pin is used to attach the piston and

connecting rod.

STANDARD PROCEDUREÐPISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm (.0001 in.) INCREMENTS is required. If a bore gauge

is not available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at a point 38.0 mm (1.5 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 11).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled.

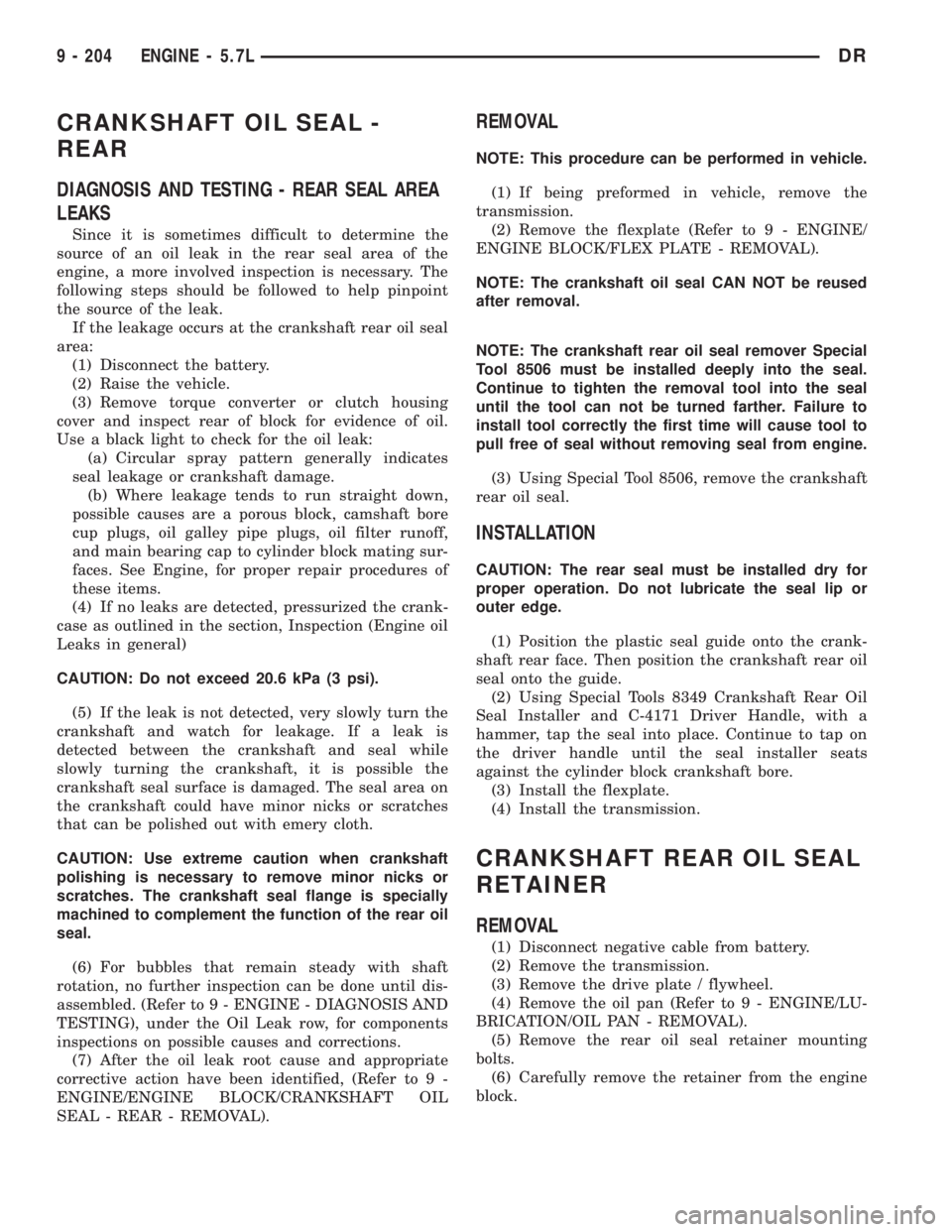

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 10). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components:

²Oil pan and gasket/windage tray (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).

²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

²Timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- REMOVAL).

Fig. 10 Moly Coated Piston

1 - MOLY COATED

2 - MOLY COATED

DRENGINE - 5.7L 9 - 205

CRANKSHAFT REAR OIL SEAL RETAINER (Continued)

Page 1464 of 2895

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Remove the PCV valve from the IAFM. Cap or

plug the PCV valve grommet.

(2) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kPa (3 PSI) of test pressure.

(3) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(4) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(5) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve.

(6) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

DRENGINE - 5.7L 9 - 215

LUBRICATION (Continued)

Page 1466 of 2895

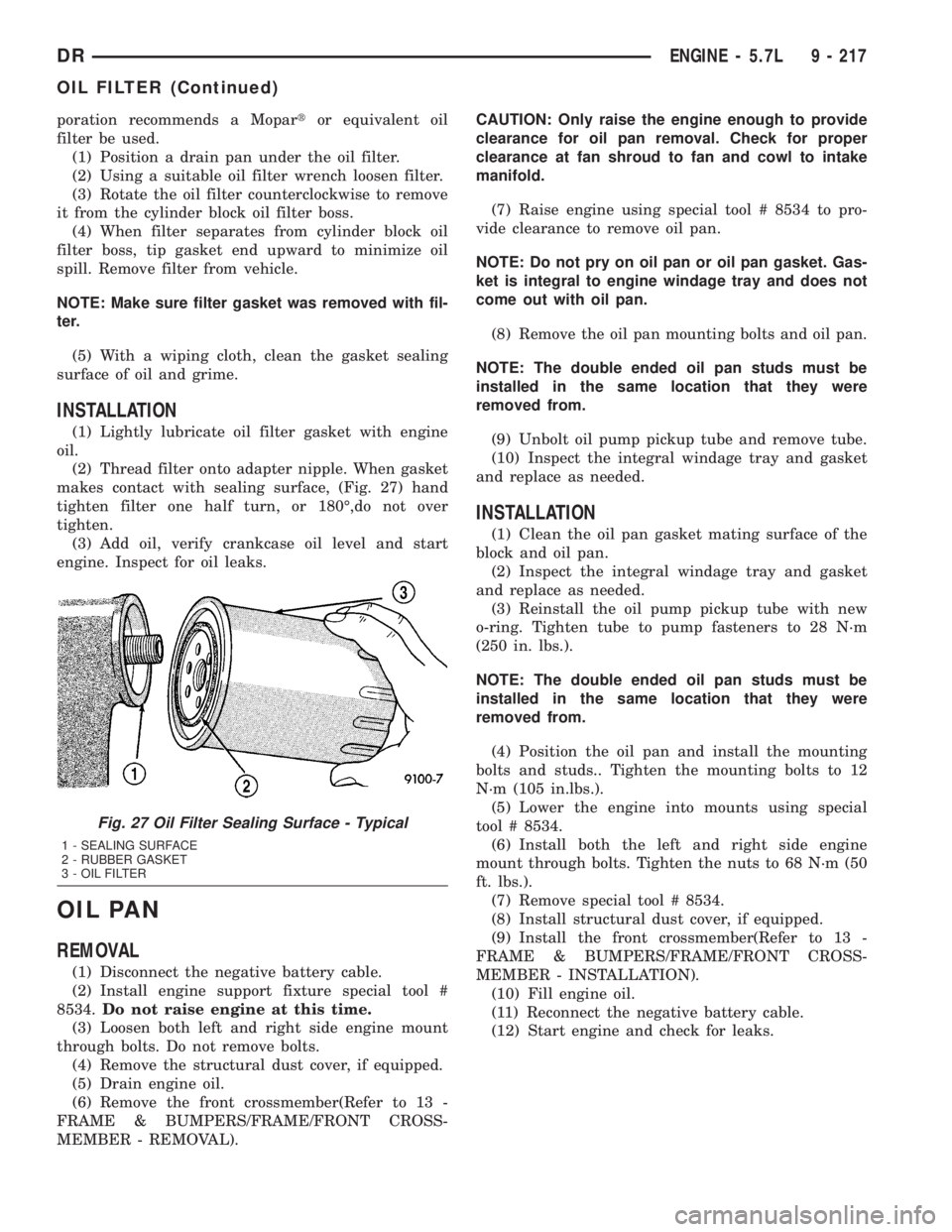

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss.

(4) When filter separates from cylinder block oil

filter boss, tip gasket end upward to minimize oil

spill. Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with fil-

ter.

(5) With a wiping cloth, clean the gasket sealing

surface of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 27) hand

tighten filter one half turn, or 180É,do not over

tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

OIL PAN

REMOVAL

(1) Disconnect the negative battery cable.

(2) Install engine support fixture special tool #

8534.Do not raise engine at this time.

(3) Loosen both left and right side engine mount

through bolts. Do not remove bolts.

(4) Remove the structural dust cover, if equipped.

(5) Drain engine oil.

(6) Remove the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).CAUTION: Only raise the engine enough to provide

clearance for oil pan removal. Check for proper

clearance at fan shroud to fan and cowl to intake

manifold.

(7) Raise engine using special tool # 8534 to pro-

vide clearance to remove oil pan.

NOTE: Do not pry on oil pan or oil pan gasket. Gas-

ket is integral to engine windage tray and does not

come out with oil pan.

(8) Remove the oil pan mounting bolts and oil pan.

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(9) Unbolt oil pump pickup tube and remove tube.

(10) Inspect the integral windage tray and gasket

and replace as needed.

INSTALLATION

(1) Clean the oil pan gasket mating surface of the

block and oil pan.

(2) Inspect the integral windage tray and gasket

and replace as needed.

(3) Reinstall the oil pump pickup tube with new

o-ring. Tighten tube to pump fasteners to 28 N´m

(250 in. lbs.).

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(4) Position the oil pan and install the mounting

bolts and studs.. Tighten the mounting bolts to 12

N´m (105 in.lbs.).

(5) Lower the engine into mounts using special

tool # 8534.

(6) Install both the left and right side engine

mount through bolts. Tighten the nuts to 68 N´m (50

ft. lbs.).

(7) Remove special tool # 8534.

(8) Install structural dust cover, if equipped.

(9) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(10) Fill engine oil.

(11) Reconnect the negative battery cable.

(12) Start engine and check for leaks.

Fig. 27 Oil Filter Sealing Surface - Typical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

DRENGINE - 5.7L 9 - 217

OIL FILTER (Continued)

Page 1482 of 2895

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

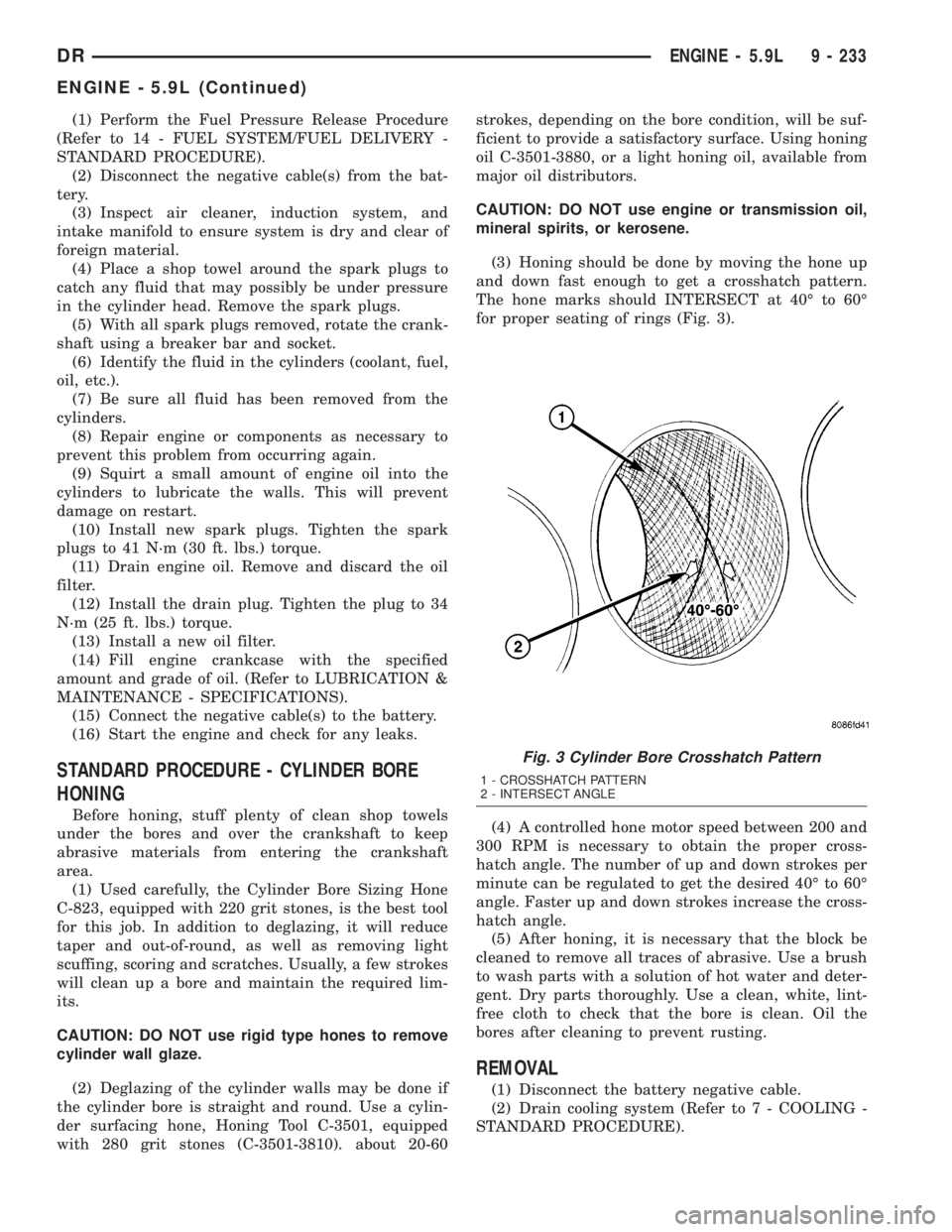

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

DRENGINE - 5.9L 9 - 233

ENGINE - 5.9L (Continued)

Page 1493 of 2895

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the air cleaner resonator and duct

work.

(4) Remove the intake manifold-to-generator

bracket support rod. Remove the generator.

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Perform the Fuel System Pressure Release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel supply line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(9) Remove distributor cap and wires.

(10) Disconnect the coil wires.

(11) Disconnect heat indicator sending unit wire.

(12) Disconnect heater hoses and bypass hose.

(13) Remove the master cylinder and booster

assembly. Refer to section 5 brakes.

(14) Remove cylinder head covers and gaskets

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(15) Remove intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL) and throttle body as an assembly. Dis-

card the flange side gaskets and the front and rear

cross-over gaskets.(16) Remove exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

REMOVAL).

(17) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(18) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

(19) Remove spark plugs.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness

exceeds 0.00075mm/mm (0.0001in/in.) times the span

length in any direction, either replace head or lightly

machine the head surface.

FOR EXAMPLE:ÐA 305 mm (12 in.) span is

0.102 mm (0.004 in.) out-of-flat. The allowable out-of-

flat is 305 x 0.00075 (12 x 0.00075) equals 0.23 mm

(0.009 in.). This amount of out-of-flat is acceptable.

The cylinder head surface finish should be

1.78-3.00 microns (70-125 microinches).

Inspect push rods. Replace worn or bent rods.

INSTALLATION

(1) Clean all surfaces of cylinder block and cylin-

der heads.

(2) Clean cylinder block front and rear gasket sur-

faces using a suitable solvent.

(3) Position new cylinder head gaskets onto the

cylinder block.

(4) Position cylinder heads onto head gaskets and

cylinder block.

(5) Starting at top center, tighten all cylinder head

bolts, in sequence (Fig. 8).

CAUTION: When tightening the rocker arm bolts,

make sure the piston in that cylinder is NOT at

TDC. Contact between the valves and piston could

occur.

(6) Install push rods and rocker arm assemblies in

their original position. Tighten the bolts to 28 N´m

(21 ft. lbs.) torque.

(7) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION) and throttle body assembly.

(8) Install exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSTALLATION).

9 - 244 ENGINE - 5.9LDR

CYLINDER HEAD (Continued)

Page 1497 of 2895

ing stones. A true and complete surface must be

obtained.

(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 in.) total indicator reading.

(3) Inspect the valve seat with Prussian blue, to

determine where the valve contacts the seat. To do

this, coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to the top edge of valve face, lower valve seat

with a 15É stone. If the blue is transferred to bottom

edge of valve face raise valve seat with a 60É stone.

(4) When seat is properly positioned the width of

intake seats should be 1.016-1.524 mm (0.040-0.060

in.). The width of the exhaust seats should be 1.524-

2.032 mm (0.060-0.080 in.).

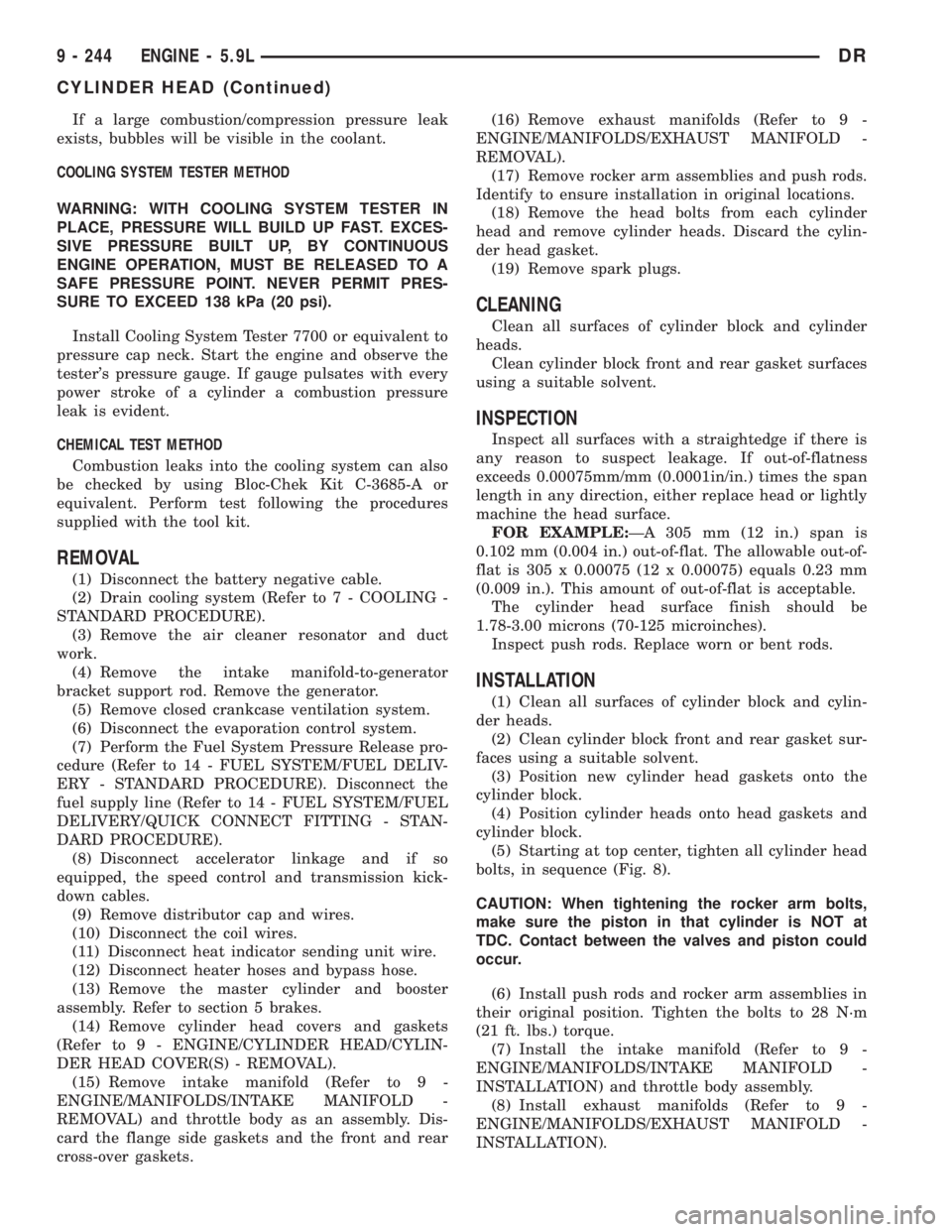

VALVE SPRINGS

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested. As an example the compression length of

the spring to be tested is 1-5/16 in.. Turn table of

Universal Valve Spring Tester Tool until surface is in

line with the 1-5/16 in. mark on the threaded stud.

Be sure the zero mark is to the front (Fig. 15). Place

spring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by 2. This will give the

spring load at test length. Fractional measurements

are indicated on the table for finer adjustments.

Refer to specifications to obtain specified height and

allowable tensions. Discard the springs that do not

meet specifications.

REMOVAL

(1) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(2) Compress valve springs using Valve Spring

Compressor Tool MD- 998772A and adapter 6716A.

(3) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(4) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

valve guides. Identify valves to ensure installation in

original location.

CLEANING

Clean valves thoroughly. Discard burned, warped,

or cracked valves.

Remove carbon and varnish deposits from inside of

valve guides with a reliable guide cleaner.

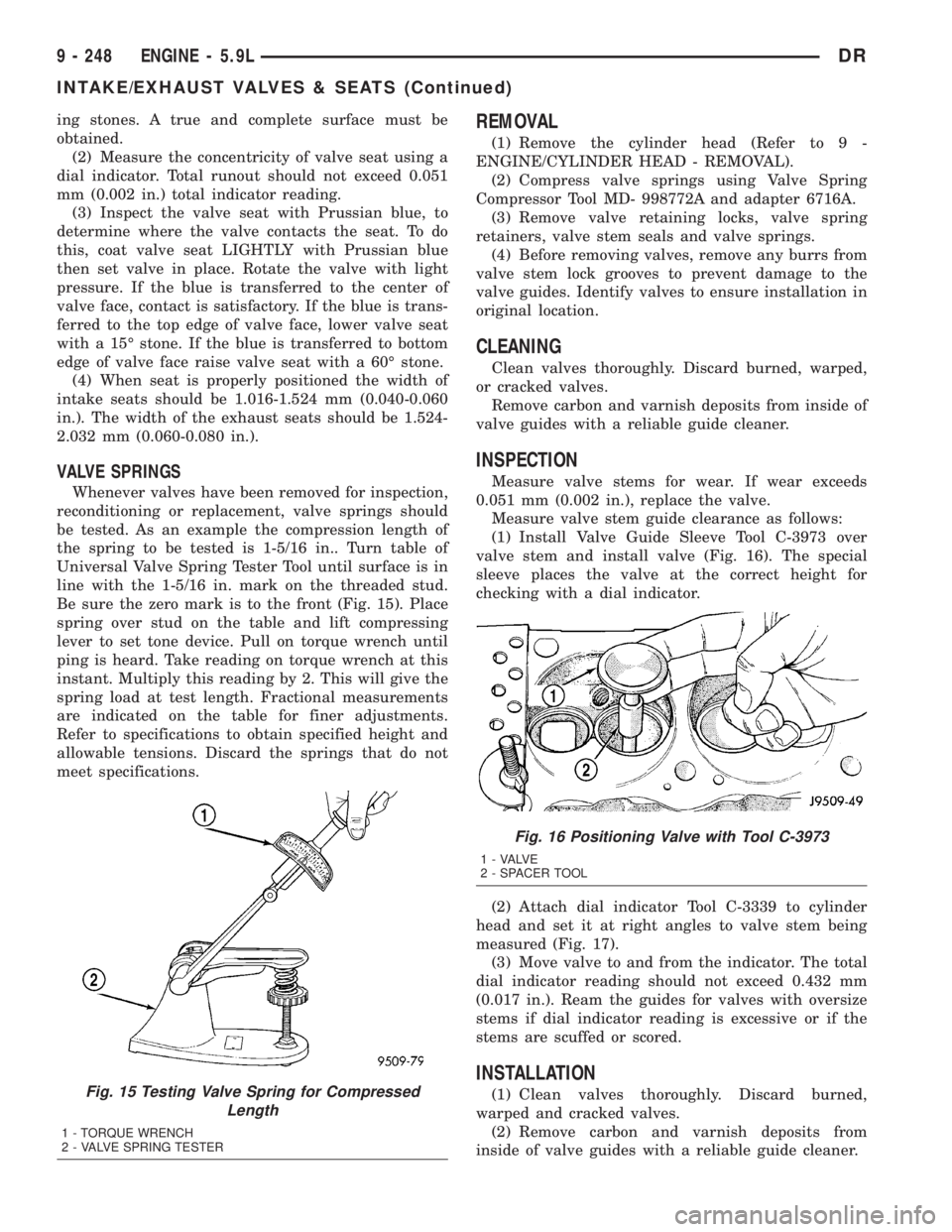

INSPECTION

Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 in.), replace the valve.

Measure valve stem guide clearance as follows:

(1) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 16). The special

sleeve places the valve at the correct height for

checking with a dial indicator.

(2) Attach dial indicator Tool C-3339 to cylinder

head and set it at right angles to valve stem being

measured (Fig. 17).

(3) Move valve to and from the indicator. The total

dial indicator reading should not exceed 0.432 mm

(0.017 in.). Ream the guides for valves with oversize

stems if dial indicator reading is excessive or if the

stems are scuffed or scored.

INSTALLATION

(1) Clean valves thoroughly. Discard burned,

warped and cracked valves.

(2) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.Fig. 15 Testing Valve Spring for Compressed

Length

1 - TORQUE WRENCH

2 - VALVE SPRING TESTER

Fig. 16 Positioning Valve with Tool C-3973

1 - VALVE

2 - SPACER TOOL

9 - 248 ENGINE - 5.9LDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1503 of 2895

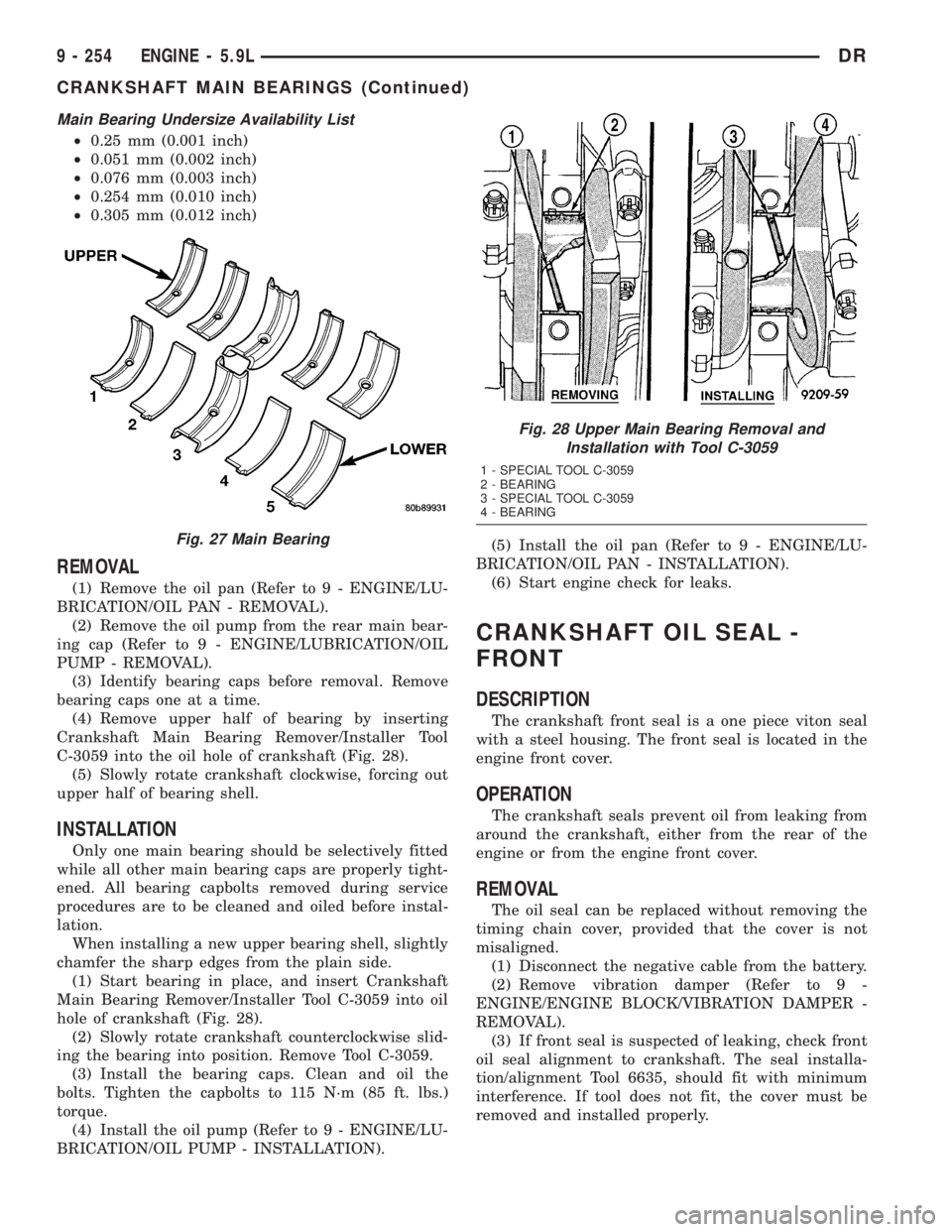

Main Bearing Undersize Availability List

²0.25 mm (0.001 inch)

²0.051 mm (0.002 inch)

²0.076 mm (0.003 inch)

²0.254 mm (0.010 inch)

²0.305 mm (0.012 inch)

REMOVAL

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump from the rear main bear-

ing cap (Refer to 9 - ENGINE/LUBRICATION/OIL

PUMP - REMOVAL).

(3) Identify bearing caps before removal. Remove

bearing caps one at a time.

(4) Remove upper half of bearing by inserting

Crankshaft Main Bearing Remover/Installer Tool

C-3059 into the oil hole of crankshaft (Fig. 28).

(5) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION

Only one main bearing should be selectively fitted

while all other main bearing caps are properly tight-

ened. All bearing capbolts removed during service

procedures are to be cleaned and oiled before instal-

lation.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

(1) Start bearing in place, and insert Crankshaft

Main Bearing Remover/Installer Tool C-3059 into oil

hole of crankshaft (Fig. 28).

(2) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Tool C-3059.

(3) Install the bearing caps. Clean and oil the

bolts. Tighten the capbolts to 115 N´m (85 ft. lbs.)

torque.

(4) Install the oil pump (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).(5) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(6) Start engine check for leaks.

CRANKSHAFT OIL SEAL -

FRONT

DESCRIPTION

The crankshaft front seal is a one piece viton seal

with a steel housing. The front seal is located in the

engine front cover.

OPERATION

The crankshaft seals prevent oil from leaking from

around the crankshaft, either from the rear of the

engine or from the engine front cover.

REMOVAL

The oil seal can be replaced without removing the

timing chain cover, provided that the cover is not

misaligned.

(1) Disconnect the negative cable from the battery.

(2) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(3) If front seal is suspected of leaking, check front

oil seal alignment to crankshaft. The seal installa-

tion/alignment Tool 6635, should fit with minimum

interference. If tool does not fit, the cover must be

removed and installed properly.

Fig. 27 Main Bearing

Fig. 28 Upper Main Bearing Removal and

Installation with Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARING

9 - 254 ENGINE - 5.9LDR

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1505 of 2895

lower seal. The lower seal half can be installed only

with the rear main bearing cap removed.

UPPER SEAL ÐCRANKSHAFT REMOVED

(1) Remove the crankshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT - REMOVAL). Dis-

card the old upper seal.

UPPER SEALÐCRANKSHAFT INSTALLED

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL).

(3) Remove the rear main bearing cap. Remove

and discard the old lower oil seal.

(4) Carefully remove and discard the old upper oil

seal.

LOWER SEAL

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL).

(3) Remove the rear main bearing cap and discard

the old lower seal.

INSTALLATION

The service seal is a two piece, Viton seal. The

upper seal half can be installed with crankshaft

removed from engine or with crankshaft installed.

When a new upper seal is installed, install a new

lower seal. The lower seal half can be installed only

with the rear main bearing cap removed.

UPPER SEAL ÐCRANKSHAFT REMOVED

(1) Clean the cylinder block rear cap mating sur-

face. Be sure the seal groove is free of debris. Check

for burrs at the oil hole on the cylinder block mating

surface to rear cap.

(2) Lightly oil the new upper seal lips with engine

oil.

(3) Install the new upper rear bearing oil seal with

the white paint facing toward the rear of the engine.

(4) Position the crankshaft into the cylinder block.

(5)

Lightly oil the new lower seal lips with engine oil.

(6) Install the new lower rear bearing oil seal into

the bearing cap with the white paint facing towards

the rear of the engine.

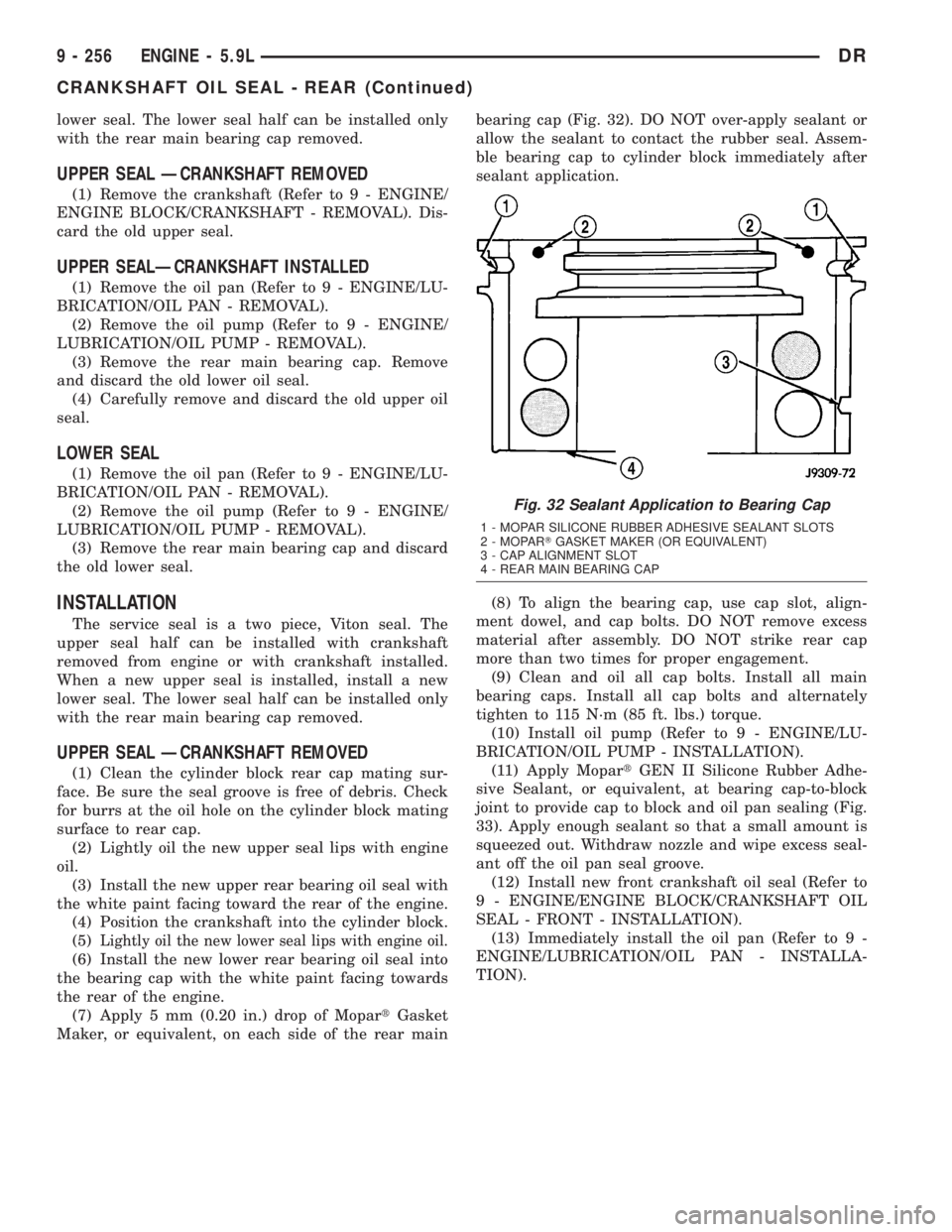

(7) Apply 5 mm (0.20 in.) drop of MopartGasket

Maker, or equivalent, on each side of the rear mainbearing cap (Fig. 32). DO NOT over-apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application.

(8) To align the bearing cap, use cap slot, align-

ment dowel, and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than two times for proper engagement.

(9) Clean and oil all cap bolts. Install all main

bearing caps. Install all cap bolts and alternately

tighten to 115 N´m (85 ft. lbs.) torque.

(10) Install oil pump (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(11) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, at bearing cap-to-block

joint to provide cap to block and oil pan sealing (Fig.

33). Apply enough sealant so that a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(12) Install new front crankshaft oil seal (Refer to

9 - ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION).

(13) Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

Fig. 32 Sealant Application to Bearing Cap

1 - MOPAR SILICONE RUBBER ADHESIVE SEALANT SLOTS

2 - MOPARTGASKET MAKER (OR EQUIVALENT)

3 - CAP ALIGNMENT SLOT

4 - REAR MAIN BEARING CAP

9 - 256 ENGINE - 5.9LDR

CRANKSHAFT OIL SEAL - REAR (Continued)