Ignition switch DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 674 of 2895

²To learn additional keys, turn the ignition OFF,

remove the learned key, and insert the next new

blank key. Turn ignition to the RUN position and re-

enter the secured access mode function and repeat

the ªProgram New Keyº procedure outlined above.

SENTRY KEY IMMOBILIZER

SYSTEM INDICATOR LAMP

DESCRIPTION

The Sentry Key Immobilizer System (SKIS) uses

the Vehicle Theft Security System (VTSS) indicator

in the instrument cluster to give an indication when

the SKIS is faulty or when the vehicle has been

immobilized due to the use of an invalid key. The

indicator is controlled by the instrument cluster

based upon messages received from the Sentry Key

Immobilizer Module (SKIM).

OPERATION

The SKIM sends PCI Bus messages to the instru-

ment cluster, to turn on the 'Securityº indicator for

about 3 seconds when the ignition is turned to theON position, as a ªBulbº test. After completion of the

ªBulbº test, the SKIM sends a PCI bus messages to

keep the LED off for 1 second. Then the SKIM sends

messages to the instrument cluster to turn the LED

off based upon the results if the SKIS self - test. If

the indicator illuminates and remains illuminated

after the ªbulb testº, it indicates that the SKIM has

detected a system malfunction and/or the system has

become inoperative. If the SKIM detects a invalid

key when the ignition switch is turned on, it sends a

message to the instrument cluster to flash the ªSecu-

rityº indicator.

The SKIM can also send messages to the cluster to

flash the LED and generate a chime. These functions

serve as an indication to the customer that the SKIM

is in theCustomer Learnprogramming mode. See

Sentry Key Immobilizer System Transponder Pro-

gramming in this group for more information on the

ªCustomer Learnº programming Mode.

If the VTSS indicator remains on after the ªBulbº

test, the system should be diagnosed using the

DRBIIItscan tool and the proper Powertrain Diag-

nostic Procedures manual.

DRVEHICLE THEFT SECURITY 8Q - 5

VEHICLE THEFT SECURITY (Continued)

Page 679 of 2895

²Wipe-After-Wash Mode- When the control

knob on the control stalk of the multi-function switch

is depressed to the momentary Wash position for

more than about one-half second with the wiper sys-

tem turned Off, the washer pump/motor and the wip-

ers will operate for as long as the washer switch is

held closed up to about thirty seconds, then provide

several additional wipe cycles after the control knob

is released before parking the wiper blades near the

base of the windshield. If the control knob is held in

the depressed Wash position for more than about

thirty seconds, washer system operation will be sus-

pended until the control knob is released for about

two seconds then cycled back to the Wash position.

OPERATION

The wiper and washer system is designed to pro-

vide the vehicle operator with a convenient, safe, and

reliable means of maintaining visibility through the

windshield glass. The various components of this sys-

tem are designed to convert electrical energy pro-

duced by the vehicle electrical system into the

mechanical action of the wiper blades to wipe the

outside surface of the glass, as well as into the

hydraulic action of the washer system to apply

washer fluid stored in an on-board reservoir to the

area of the glass to be wiped. When combined, these

components provide the means to effectively main-

tain clear visibility for the vehicle operator by remov-

ing excess accumulations of rain, snow, bugs, mud, or

other minor debris from the outside windshield glass

surface that might be encountered while driving the

vehicle under numerous types of inclement operating

conditions.

The vehicle operator initiates all wiper and washer

system functions with the control knob on the end of

the control stalk of the multi-function switch that

extends from the left side of the steering column, just

below the steering wheel. Rotating the control knob

on the end of the control stalk, selects the Off, Delay,

Low, or High wiper system operating modes. In the

Delay mode, the control knob also allows the vehicle

operator to select from one of five intermittent wipe

Delay intervals. Depressing the control knob towards

the steering column actuates the momentary washer

system switch, which selects the Wash, Wipe-After-

Wash, and Pulse Wipe Modes depending upon when

and how long the switch is held closed. The multi-

function switch provides hard wired resistor multi-

plexed inputs to the instrument cluster for all of the

wiper and washer system functions. The instrument

cluster then sends electronic messages to the Front

Control Module (FCM) over the Programmable Com-

munications Interface (PCI) data bus requesting the

appropriate wiper and washer system operating

modes.Wiper and washer system operation are completely

controlled by the instrument cluster and FCM logic

circuits, and that logic will only allow these systems

to operate when the ignition switch is in the Acces-

sory or On positions. Battery current is directed from

a B(+) fuse in the Integrated Power Module (IPM) to

the wiper on/off relay and the wiper high/low relay in

the IPM through a fused B(+) circuit. The FCM uses

low side drivers to control wiper system operation by

energizing or de-energizing the wiper high/low and

wiper on/off relays. The FCM uses a high side driver

to control the operation of the washer pump motor

unit. The multi-function switch circuitry receives a

clean ground output from the instrument cluster on a

multi-function switch return circuit, then provides

resistor multiplexed inputs to the instrument cluster

on an intermittent wipe mux circuit to indicate the

selected wiper system mode and on a wash/beam

select mux circuit to indicate the selected washer sys-

tem mode.

The hard wired circuits and components of the

wiper and washer system may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the

instrument cluster, the FCM, or the electronic mes-

sage inputs to or outputs from the instrument cluster

or FCM that control the wiper and washer system

operating modes. The most reliable, efficient, and

accurate means to diagnose the instrument cluster or

the FCM inputs and outputs related to the various

wiper and washer system operating modes requires

the use of a DRBIIItscan tool. Refer to the appro-

priate diagnostic information.

OPERATING MODES

Following are paragraphs that briefly describe the

operation of each of the wiper and washer system

operating modes.

CONTINUOUS WIPE MODE

When the Low position of the control knob on the

control stalk of the multi-function switch is selected

the instrument cluster sends an electronic wiper

switch low message to the FCM, then the FCM ener-

gizes the wiper on/off relay. This directs battery cur-

rent through the normally open contacts of the

energized wiper on/off relay and the normally closed

contacts of the de-energized wiper high/low relay to

the low speed brush of the wiper motor, causing the

wipers to cycle at low speed.

When the High position of the control knob is

selected the instrument cluster sends an electronic

wiper switch high message to the FCM, then the

FCM energizes both the wiper on/off relay and the

wiper high/low relay. This directs battery current

8R - 4 WIPERS/WASHERSDR

WIPERS/WASHERS (Continued)

Page 696 of 2895

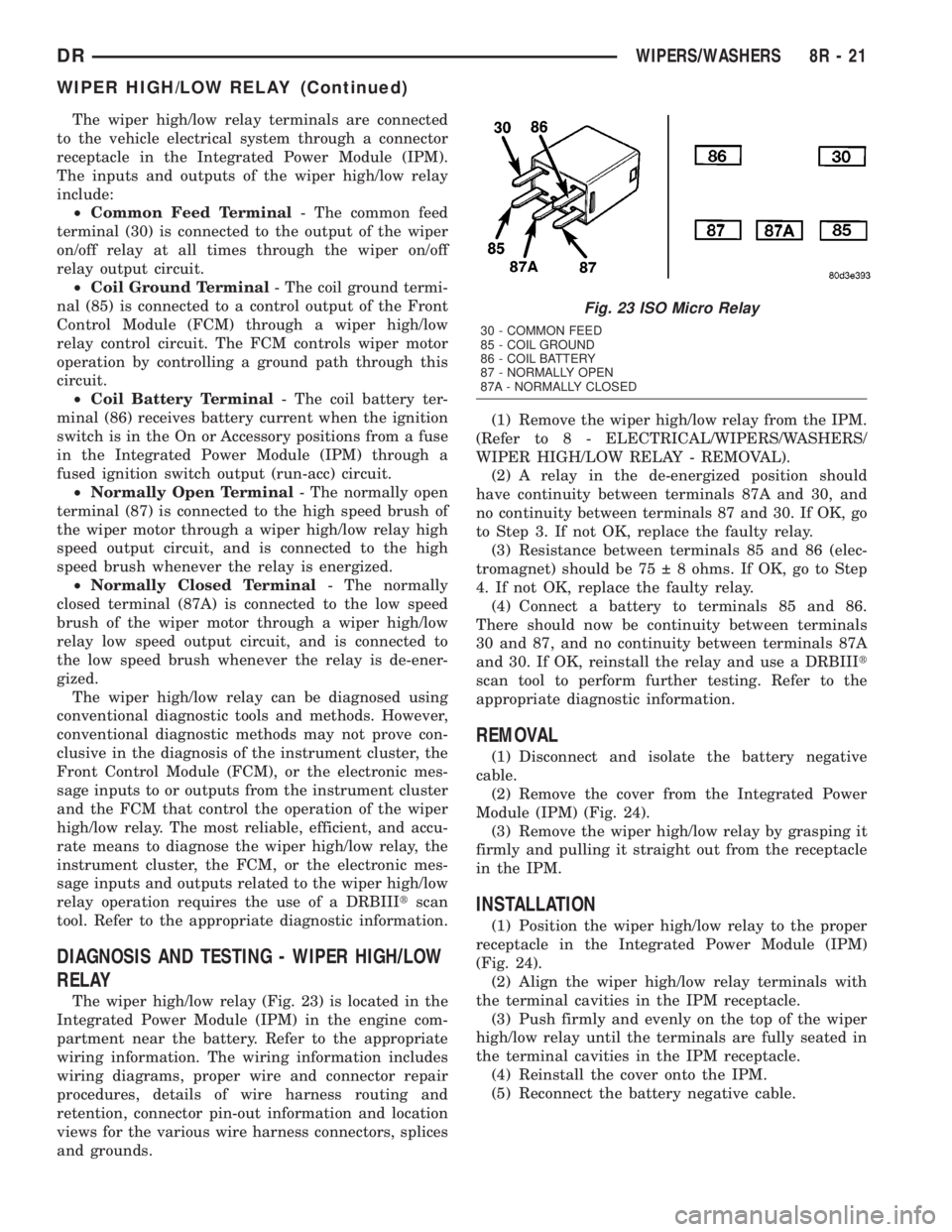

The wiper high/low relay terminals are connected

to the vehicle electrical system through a connector

receptacle in the Integrated Power Module (IPM).

The inputs and outputs of the wiper high/low relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the output of the wiper

on/off relay at all times through the wiper on/off

relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Front

Control Module (FCM) through a wiper high/low

relay control circuit. The FCM controls wiper motor

operation by controlling a ground path through this

circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current when the ignition

switch is in the On or Accessory positions from a fuse

in the Integrated Power Module (IPM) through a

fused ignition switch output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the high speed brush of

the wiper motor through a wiper high/low relay high

speed output circuit, and is connected to the high

speed brush whenever the relay is energized.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to the low speed

brush of the wiper motor through a wiper high/low

relay low speed output circuit, and is connected to

the low speed brush whenever the relay is de-ener-

gized.

The wiper high/low relay can be diagnosed using

conventional diagnostic tools and methods. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the instrument cluster, the

Front Control Module (FCM), or the electronic mes-

sage inputs to or outputs from the instrument cluster

and the FCM that control the operation of the wiper

high/low relay. The most reliable, efficient, and accu-

rate means to diagnose the wiper high/low relay, the

instrument cluster, the FCM, or the electronic mes-

sage inputs and outputs related to the wiper high/low

relay operation requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

DIAGNOSIS AND TESTING - WIPER HIGH/LOW

RELAY

The wiper high/low relay (Fig. 23) is located in the

Integrated Power Module (IPM) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.(1) Remove the wiper high/low relay from the IPM.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER HIGH/LOW RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Integrated Power

Module (IPM) (Fig. 24).

(3) Remove the wiper high/low relay by grasping it

firmly and pulling it straight out from the receptacle

in the IPM.

INSTALLATION

(1) Position the wiper high/low relay to the proper

receptacle in the Integrated Power Module (IPM)

(Fig. 24).

(2) Align the wiper high/low relay terminals with

the terminal cavities in the IPM receptacle.

(3) Push firmly and evenly on the top of the wiper

high/low relay until the terminals are fully seated in

the terminal cavities in the IPM receptacle.

(4) Reinstall the cover onto the IPM.

(5) Reconnect the battery negative cable.

Fig. 23 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DRWIPERS/WASHERS 8R - 21

WIPER HIGH/LOW RELAY (Continued)

Page 700 of 2895

WIPER ON/OFF RELAY

DESCRIPTION

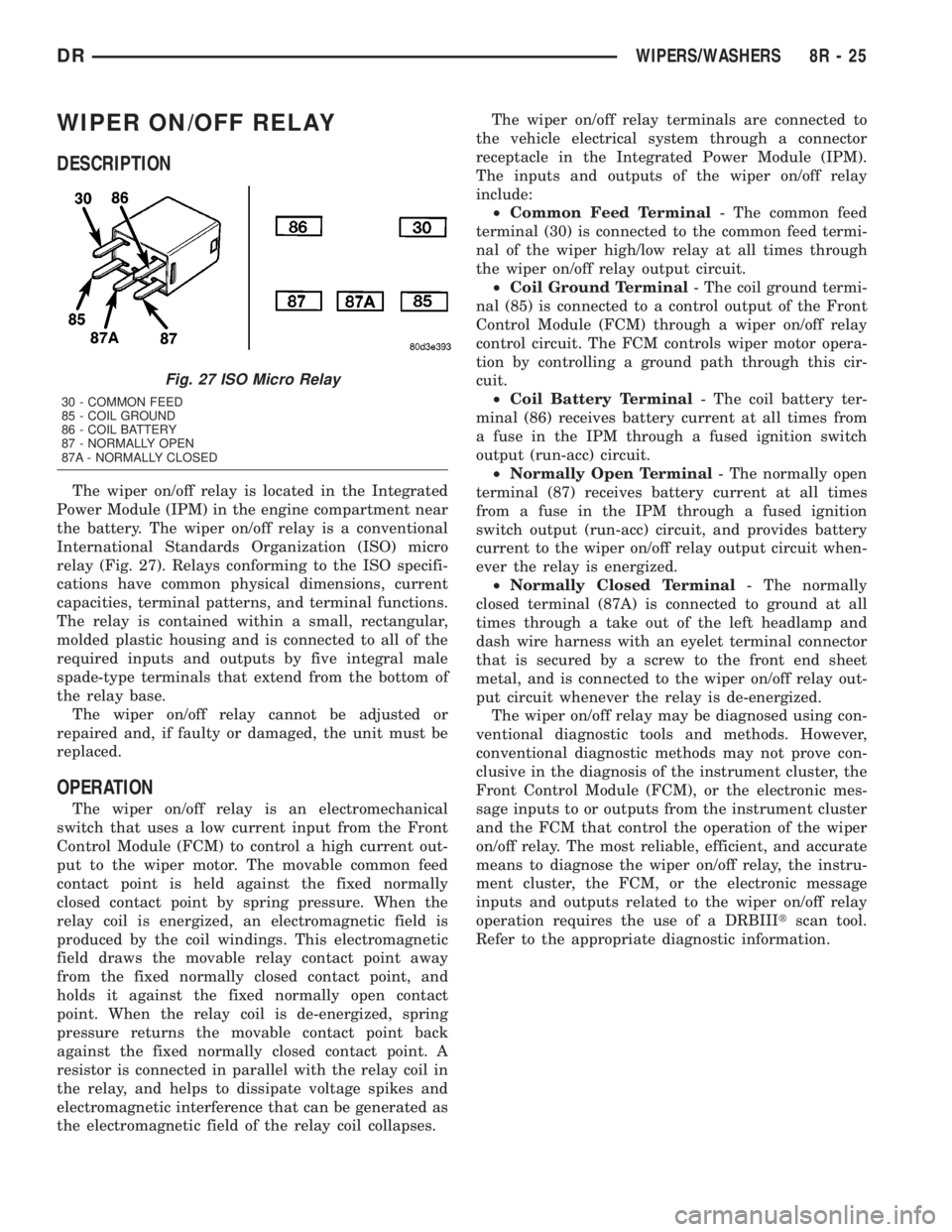

The wiper on/off relay is located in the Integrated

Power Module (IPM) in the engine compartment near

the battery. The wiper on/off relay is a conventional

International Standards Organization (ISO) micro

relay (Fig. 27). Relays conforming to the ISO specifi-

cations have common physical dimensions, current

capacities, terminal patterns, and terminal functions.

The relay is contained within a small, rectangular,

molded plastic housing and is connected to all of the

required inputs and outputs by five integral male

spade-type terminals that extend from the bottom of

the relay base.

The wiper on/off relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper on/off relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control a high current out-

put to the wiper motor. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.The wiper on/off relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Integrated Power Module (IPM).

The inputs and outputs of the wiper on/off relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the common feed termi-

nal of the wiper high/low relay at all times through

the wiper on/off relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Front

Control Module (FCM) through a wiper on/off relay

control circuit. The FCM controls wiper motor opera-

tion by controlling a ground path through this cir-

cuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a fuse in the IPM through a fused ignition switch

output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) receives battery current at all times

from a fuse in the IPM through a fused ignition

switch output (run-acc) circuit, and provides battery

current to the wiper on/off relay output circuit when-

ever the relay is energized.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to ground at all

times through a take out of the left headlamp and

dash wire harness with an eyelet terminal connector

that is secured by a screw to the front end sheet

metal, and is connected to the wiper on/off relay out-

put circuit whenever the relay is de-energized.

The wiper on/off relay may be diagnosed using con-

ventional diagnostic tools and methods. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the instrument cluster, the

Front Control Module (FCM), or the electronic mes-

sage inputs to or outputs from the instrument cluster

and the FCM that control the operation of the wiper

on/off relay. The most reliable, efficient, and accurate

means to diagnose the wiper on/off relay, the instru-

ment cluster, the FCM, or the electronic message

inputs and outputs related to the wiper on/off relay

operation requires the use of a DRBIIItscan tool.

Refer to the appropriate diagnostic information.

Fig. 27 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DRWIPERS/WASHERS 8R - 25

Page 704 of 2895

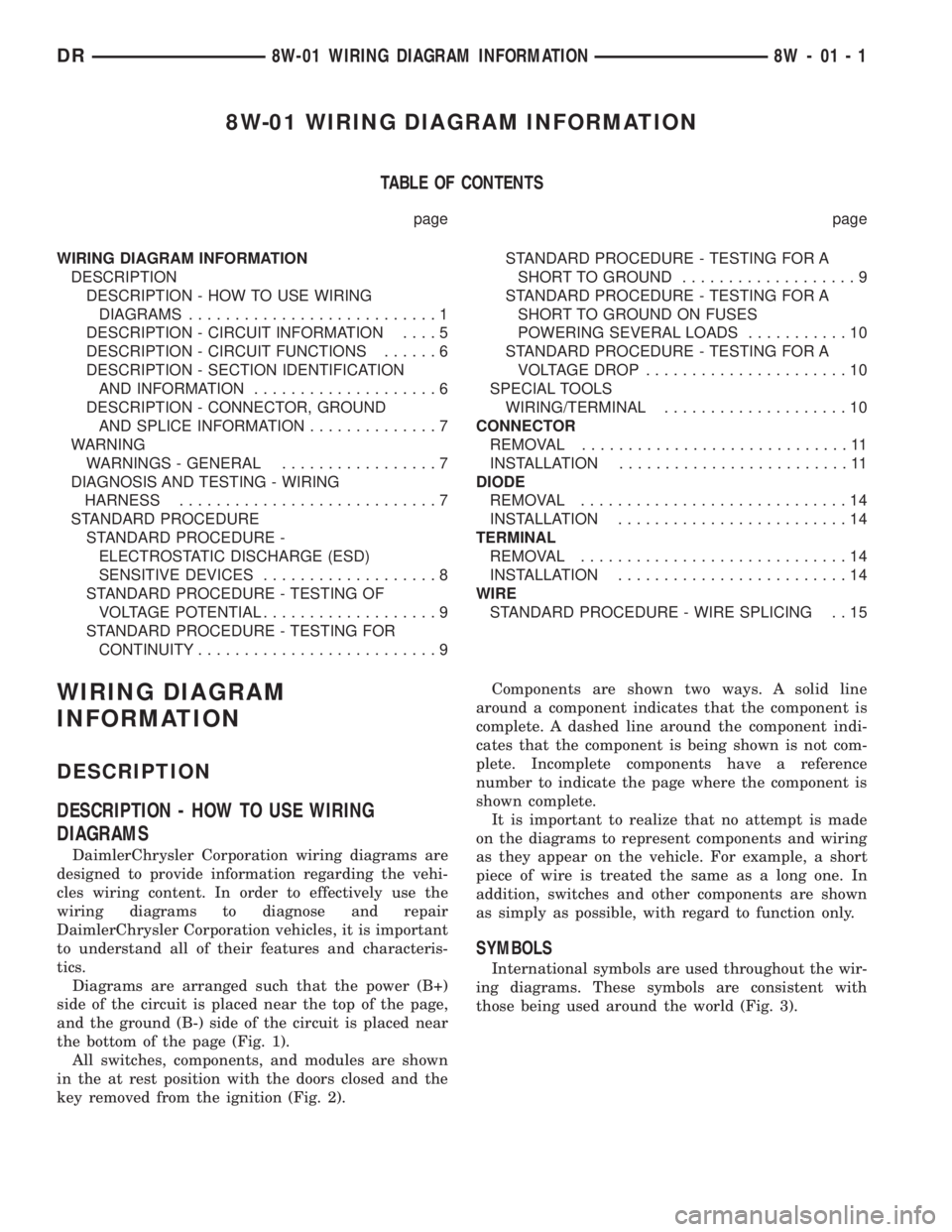

8W-01 WIRING DIAGRAM INFORMATION

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS...........................1

DESCRIPTION - CIRCUIT INFORMATION....5

DESCRIPTION - CIRCUIT FUNCTIONS......6

DESCRIPTION - SECTION IDENTIFICATION

AND INFORMATION....................6

DESCRIPTION - CONNECTOR, GROUND

AND SPLICE INFORMATION..............7

WARNING

WARNINGS - GENERAL.................7

DIAGNOSIS AND TESTING - WIRING

HARNESS............................7

STANDARD PROCEDURE

STANDARD PROCEDURE -

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES...................8

STANDARD PROCEDURE - TESTING OF

VOLTAGE POTENTIAL...................9

STANDARD PROCEDURE - TESTING FOR

CONTINUITY..........................9STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND...................9

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS...........10

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP......................10

SPECIAL TOOLS

WIRING/TERMINAL....................10

CONNECTOR

REMOVAL.............................11

INSTALLATION.........................11

DIODE

REMOVAL.............................14

INSTALLATION.........................14

TERMINAL

REMOVAL.............................14

INSTALLATION.........................14

WIRE

STANDARD PROCEDURE - WIRE SPLICING . . 15

WIRING DIAGRAM

INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS

DaimlerChrysler Corporation wiring diagrams are

designed to provide information regarding the vehi-

cles wiring content. In order to effectively use the

wiring diagrams to diagnose and repair

DaimlerChrysler Corporation vehicles, it is important

to understand all of their features and characteris-

tics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page (Fig. 1).

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition (Fig. 2).Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around the component indi-

cates that the component is being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world (Fig. 3).

DR8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 1

Page 710 of 2895

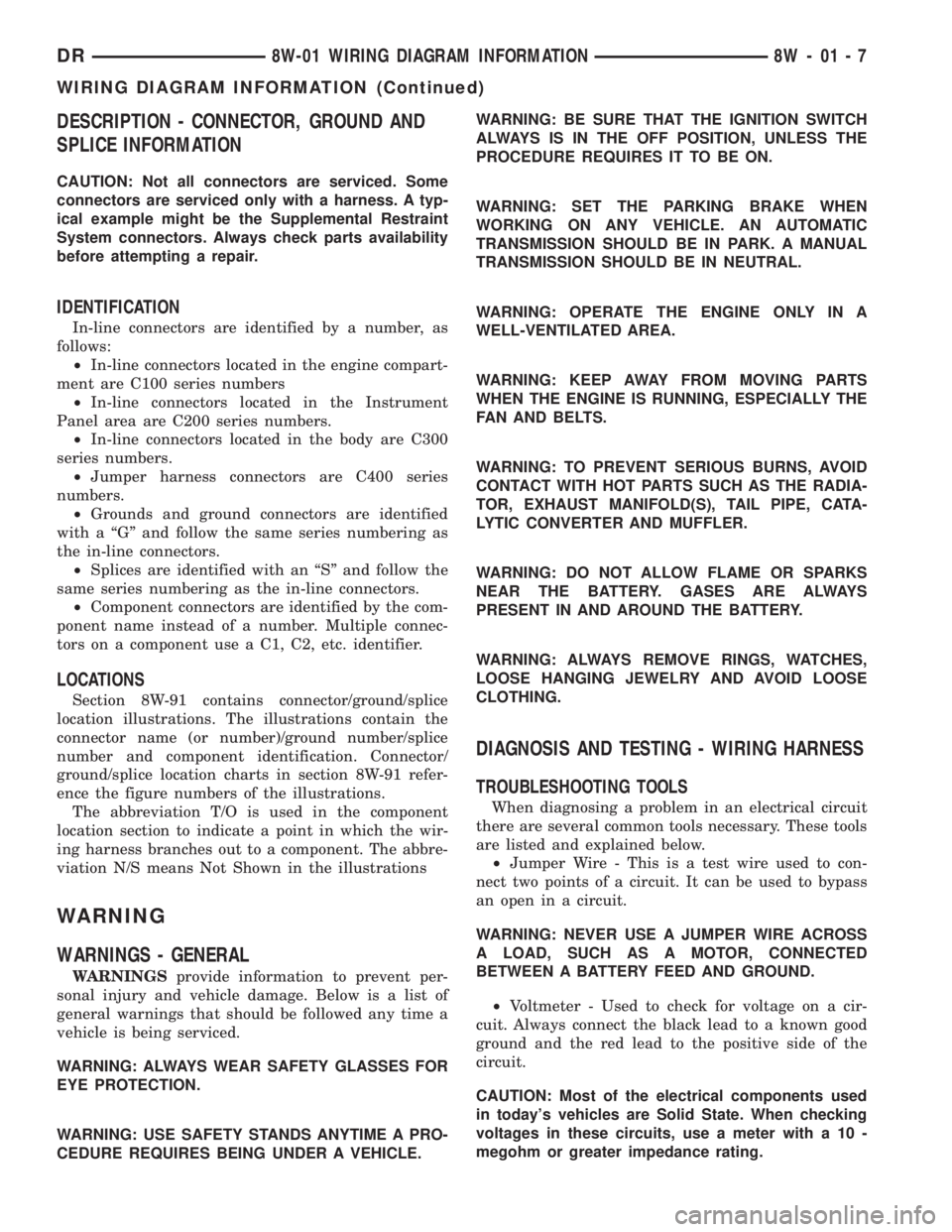

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

DR8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 713 of 2895

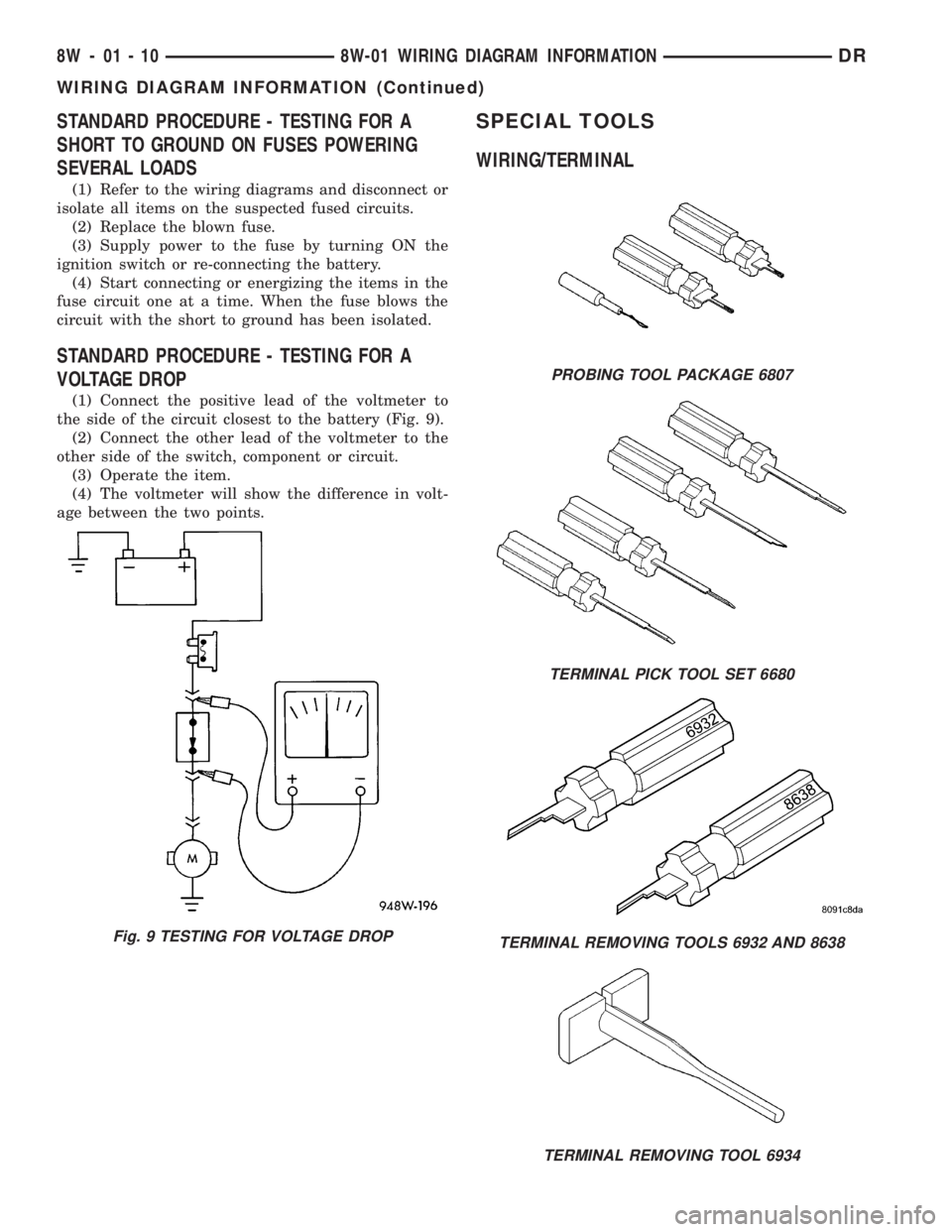

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES POWERING

SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the suspected fused circuits.

(2) Replace the blown fuse.

(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting or energizing the items in the

fuse circuit one at a time. When the fuse blows the

circuit with the short to ground has been isolated.

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 9).

(2) Connect the other lead of the voltmeter to the

other side of the switch, component or circuit.

(3) Operate the item.

(4) The voltmeter will show the difference in volt-

age between the two points.

SPECIAL TOOLS

WIRING/TERMINAL

Fig. 9 TESTING FOR VOLTAGE DROP

PROBING TOOL PACKAGE 6807

TERMINAL PICK TOOL SET 6680

TERMINAL REMOVING TOOLS 6932 AND 8638

TERMINAL REMOVING TOOL 6934

8W - 01 - 10 8W-01 WIRING DIAGRAM INFORMATIONDR

WIRING DIAGRAM INFORMATION (Continued)

Page 720 of 2895

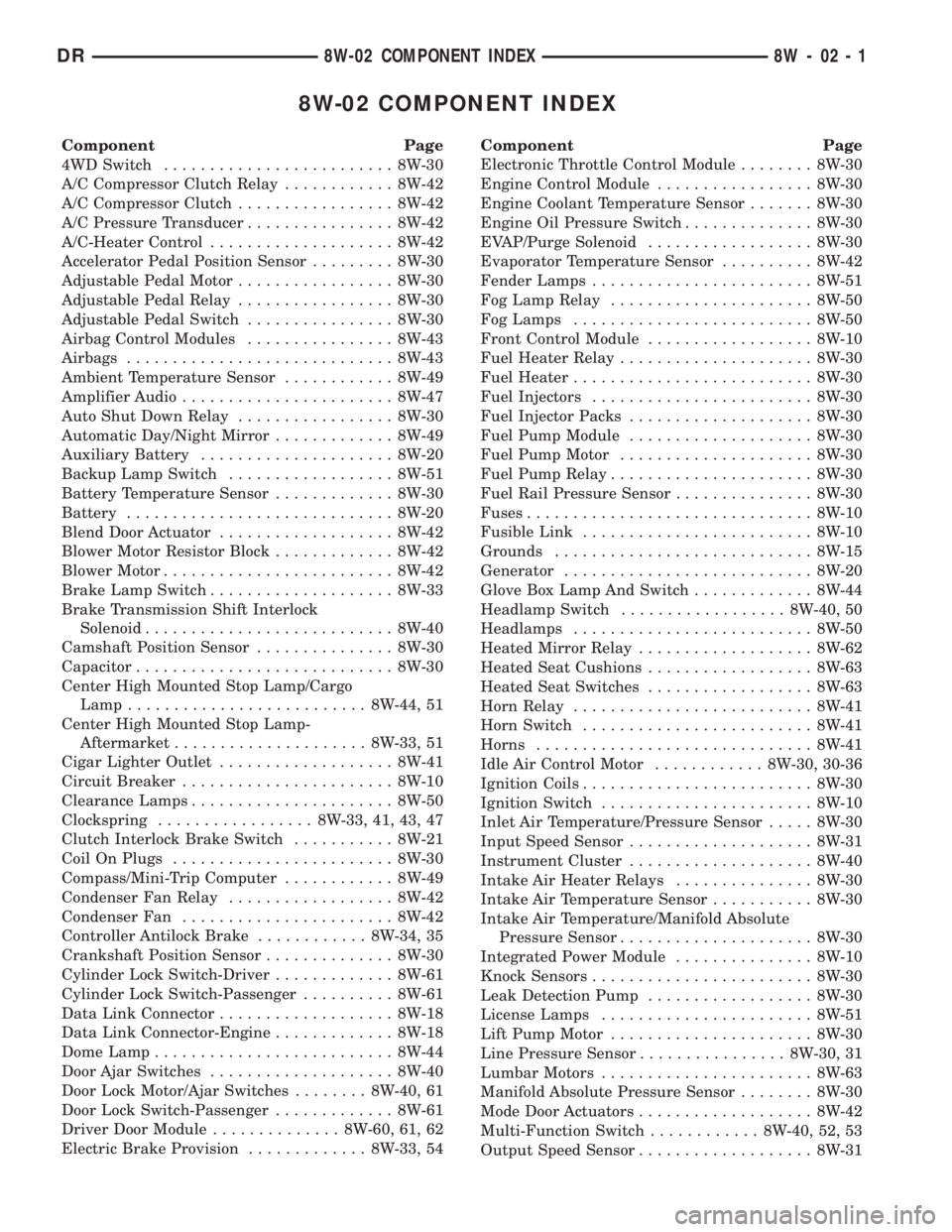

8W-02 COMPONENT INDEX

Component Page

4WD Switch......................... 8W-30

A/C Compressor Clutch Relay............ 8W-42

A/C Compressor Clutch................. 8W-42

A/C Pressure Transducer................ 8W-42

A/C-Heater Control.................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Adjustable Pedal Motor................. 8W-30

Adjustable Pedal Relay................. 8W-30

Adjustable Pedal Switch................ 8W-30

Airbag Control Modules................ 8W-43

Airbags............................. 8W-43

Ambient Temperature Sensor............ 8W-49

Amplifier Audio....................... 8W-47

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror............. 8W-49

Auxiliary Battery..................... 8W-20

Backup Lamp Switch.................. 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Actuator................... 8W-42

Blower Motor Resistor Block............. 8W-42

Blower Motor......................... 8W-42

Brake Lamp Switch.................... 8W-33

Brake Transmission Shift Interlock

Solenoid........................... 8W-40

Camshaft Position Sensor............... 8W-30

Capacitor............................ 8W-30

Center High Mounted Stop Lamp/Cargo

Lamp.......................... 8W-44, 51

Center High Mounted Stop Lamp-

Aftermarket..................... 8W-33, 51

Cigar Lighter Outlet................... 8W-41

Circuit Breaker....................... 8W-10

Clearance Lamps...................... 8W-50

Clockspring................. 8W-33, 41, 43, 47

Clutch Interlock Brake Switch........... 8W-21

Coil On Plugs........................ 8W-30

Compass/Mini-Trip Computer............ 8W-49

Condenser Fan Relay.................. 8W-42

Condenser Fan....................... 8W-42

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switch-Driver............. 8W-61

Cylinder Lock Switch-Passenger.......... 8W-61

Data Link Connector................... 8W-18

Data Link Connector-Engine............. 8W-18

Dome Lamp.......................... 8W-44

Door Ajar Switches.................... 8W-40

Door Lock Motor/Ajar Switches........ 8W-40, 61

Door Lock Switch-Passenger............. 8W-61

Driver Door Module.............. 8W-60, 61, 62

Electric Brake Provision............. 8W-33, 54Component Page

Electronic Throttle Control Module........ 8W-30

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Switch.............. 8W-30

EVAP/Purge Solenoid.................. 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fender Lamps........................ 8W-51

Fog Lamp Relay...................... 8W-50

Fog Lamps.......................... 8W-50

Front Control Module.................. 8W-10

Fuel Heater Relay..................... 8W-30

Fuel Heater.......................... 8W-30

Fuel Injectors........................ 8W-30

Fuel Injector Packs.................... 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Motor..................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuel Rail Pressure Sensor............... 8W-30

Fuses............................... 8W-10

Fusible Link......................... 8W-10

Grounds............................ 8W-15

Generator........................... 8W-20

Glove Box Lamp And Switch............. 8W-44

Headlamp Switch.................. 8W-40, 50

Headlamps.......................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Seat Cushions.................. 8W-63

Heated Seat Switches.................. 8W-63

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horns.............................. 8W-41

Idle Air Control Motor............ 8W-30, 30-36

Ignition Coils......................... 8W-30

Ignition Switch....................... 8W-10

Inlet Air Temperature/Pressure Sensor..... 8W-30

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Heater Relays............... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor..................... 8W-30

Integrated Power Module............... 8W-10

Knock Sensors........................ 8W-30

Leak Detection Pump.................. 8W-30

License Lamps....................... 8W-51

Lift Pump Motor...................... 8W-30

Line Pressure Sensor................ 8W-30, 31

Lumbar Motors....................... 8W-63

Manifold Absolute Pressure Sensor........ 8W-30

Mode Door Actuators................... 8W-42

Multi-Function Switch............ 8W-40, 52, 53

Output Speed Sensor................... 8W-31

DR8W-02 COMPONENT INDEX 8W - 02 - 1

Page 722 of 2895

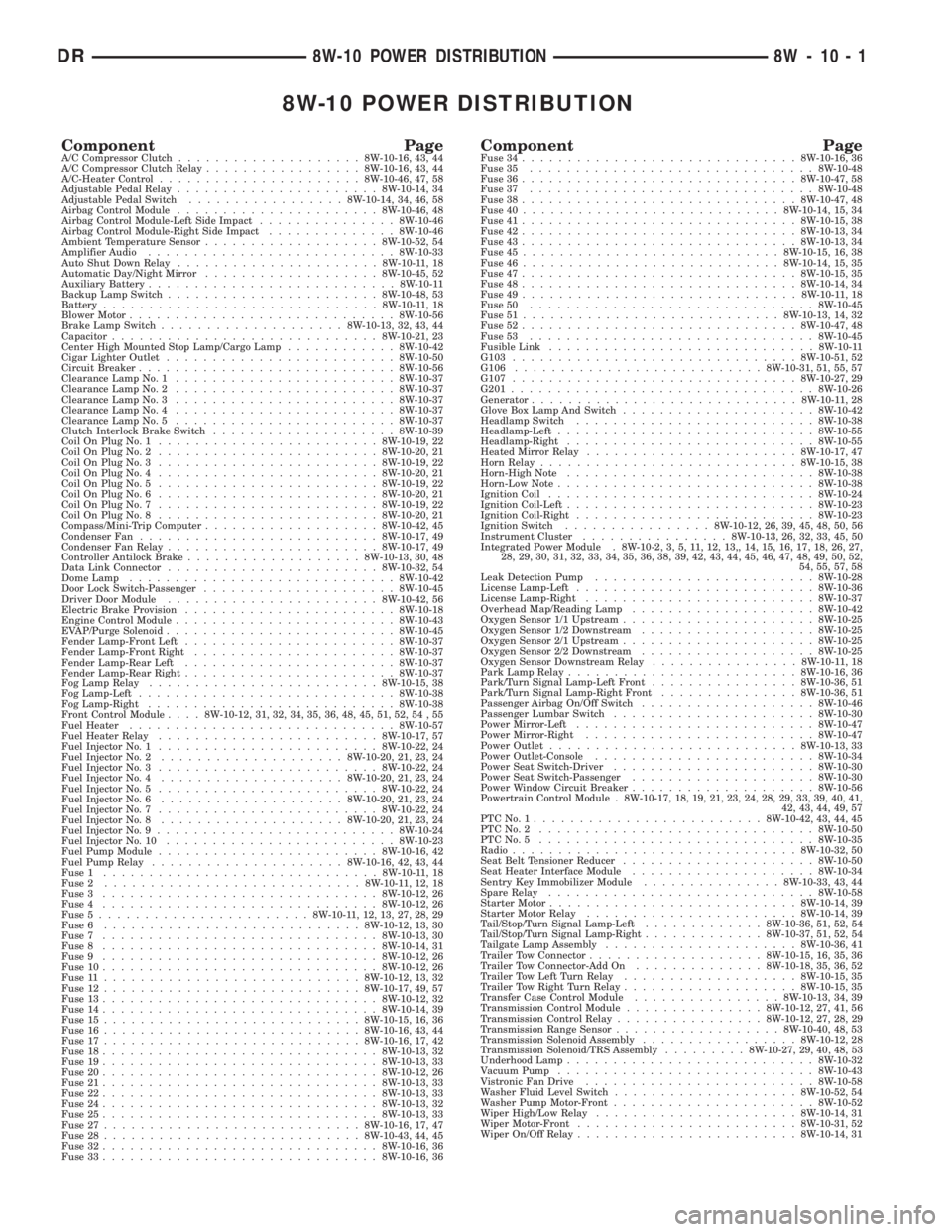

8W-10 POWER DISTRIBUTION

Component PageA/C Compressor Clutch....................8W-10-16, 43, 44

A/C Compressor Clutch Relay.................8W-10-16, 43, 44

A/C-Heater Control......................8W-10-46, 47, 58

Adjustable Pedal Relay......................8W-10-14, 34

Adjustable Pedal Switch.................8W-10-14, 34, 46, 58

Airbag Control Module......................8W-10-46, 48

Airbag Control Module-Left Side Impact...............8W-10-46

Airbag Control Module-Right Side Impact..............8W-10-46

Ambient Temperature Sensor...................8W-10-52, 54

Amplifier Audio...........................8W-10-33

Auto Shut Down Relay......................8W-10-11, 18

Automatic Day/Night Mirror...................8W-10-45, 52

Auxiliary Battery...........................8W-10-11

Backup Lamp Switch.......................8W-10-48, 53

Battery..............................8W-10-11, 18

Blower Motor.............................8W-10-56

Brake Lamp Switch....................8W-10-13, 32, 43, 44

Capacitor.............................8W-10-21, 23

Center High Mounted Stop Lamp/Cargo Lamp............8W-10-42

Cigar Lighter Outlet.........................8W-10-50

Circuit Breaker............................8W-10-56

Clearance Lamp No. 1........................8W-10-37

Clearance Lamp No. 2........................8W-10-37

Clearance Lamp No. 3........................8W-10-37

Clearance Lamp No. 4........................8W-10-37

Clearance Lamp No. 5........................8W-10-37

Clutch Interlock Brake Switch....................8W-10-39

Coil On Plug No. 1........................8W-10-19, 22

Coil On Plug No. 2........................8W-10-20, 21

Coil On Plug No. 3........................8W-10-19, 22

Coil On Plug No. 4........................8W-10-20, 21

Coil On Plug No. 5........................8W-10-19, 22

Coil On Plug No. 6........................8W-10-20, 21

Coil On Plug No. 7........................8W-10-19, 22

Coil On Plug No. 8........................8W-10-20, 21

Compass/Mini-Trip Computer...................8W-10-42, 45

Condenser Fan..........................8W-10-17, 49

Condenser Fan Relay.......................8W-10-17, 49

Controller Antilock Brake...................8W-10-13, 30, 48

Data Link Connector.......................8W-10-32, 54

Dome Lamp.............................8W-10-42

Door Lock Switch-Passenger.....................8W-10-45

Driver Door Module.......................8W-10-42, 56

Electric Brake Provision.......................8W-10-18

Engine Control Module........................8W-10-43

EVAP/Purge Solenoid.........................8W-10-45

Fender Lamp-Front Left.......................8W-10-37

Fender Lamp-Front Right......................8W-10-37

Fender Lamp-Rear Left.......................8W-10-37

Fender Lamp-Rear Right.......................8W-10-37

Fog Lamp Relay.........................8W-10-15, 38

Fog Lamp-Left............................8W-10-38

Fog Lamp-Right...........................8W-10-38

Front Control Module....8W-10-12, 31, 32, 34, 35, 36, 48, 45, 51, 52, 54 , 55

Fuel Heater.............................8W-10-57

Fuel Heater Relay........................8W-10-17, 57

Fuel Injector No. 1........................8W-10-22, 24

Fuel Injector No. 2....................8W-10-20, 21, 23, 24

Fuel Injector No. 3........................8W-10-22, 24

Fuel Injector No. 4....................8W-10-20, 21, 23, 24

Fuel Injector No. 5........................8W-10-22, 24

Fuel Injector No. 6....................8W-10-20, 21, 23, 24

Fuel Injector No. 7........................8W-10-22, 24

Fuel Injector No. 8....................8W-10-20, 21, 23, 24

Fuel Injector No. 9..........................8W-10-24

Fuel Injector No. 10.........................8W-10-23

Fuel Pump Module........................8W-10-16, 42

Fuel Pump Relay.....................8W-10-16, 42, 43, 44

Fuse 1..............................8W-10-11, 18

Fuse 2............................8W-10-11, 12, 18

Fuse 3..............................8W-10-12, 26

Fuse 4..............................8W-10-12, 26

Fuse 5.......................8W-10-11, 12, 13, 27, 28, 29

Fuse 6............................8W-10-12, 13, 30

Fuse 7..............................8W-10-13, 30

Fuse 8..............................8W-10-14, 31

Fuse 9..............................8W-10-12, 26

Fuse 10..............................8W-10-12, 26

Fuse 11............................8W-10-12, 13, 32

Fuse 12............................8W-10-17, 49, 57

Fuse 13..............................8W-10-12, 32

Fuse 14..............................8W-10-14, 39

Fuse 15............................8W-10-15, 16, 36

Fuse 16............................8W-10-16, 43, 44

Fuse 17............................8W-10-16, 17, 42

Fuse 18..............................8W-10-13, 32

Fuse 19..............................8W-10-13, 33

Fuse 20..............................8W-10-12, 26

Fuse 21..............................8W-10-13, 33

Fuse 22..............................8W-10-13, 33

Fuse 24..............................8W-10-13, 32

Fuse 25..............................8W-10-13, 33

Fuse 27............................8W-10-16, 17, 47

Fuse 28............................8W-10-43, 44, 45

Fuse 32..............................8W-10-16, 36

Fuse 33..............................8W-10-16, 36Component PageFuse 34..............................8W-10-16, 36

Fuse 35...............................8W-10-48

Fuse 36..............................8W-10-47, 58

Fuse 37...............................8W-10-48

Fuse 38..............................8W-10-47, 48

Fuse 40............................8W-10-14, 15, 34

Fuse 41..............................8W-10-15, 38

Fuse 42..............................8W-10-13, 34

Fuse 43..............................8W-10-13, 34

Fuse 45............................8W-10-15, 16, 38

Fuse 46............................8W-10-14, 15, 35

Fuse 47..............................8W-10-15, 35

Fuse 48..............................8W-10-14, 34

Fuse 49..............................8W-10-11, 18

Fuse 50...............................8W-10-45

Fuse 51............................8W-10-13, 14, 32

Fuse 52..............................8W-10-47, 48

Fuse 53...............................8W-10-45

Fusible Link.............................8W-10-11

G103...............................8W-10-51, 52

G106...........................8W-10-31, 51, 55, 57

G107...............................8W-10-27, 29

G201.................................8W-10-26

Generator.............................8W-10-11, 28

Glove Box Lamp And Switch.....................8W-10-42

Headlamp Switch..........................8W-10-38

Headlamp-Left............................8W-10-55

Headlamp-Right...........................8W-10-55

Heated Mirror Relay.......................8W-10-17, 47

Horn Relay............................8W-10-15, 38

Horn-High Note...........................8W-10-38

Horn-Low Note............................8W-10-38

Ignition Coil.............................8W-10-24

Ignition Coil-Left...........................8W-10-23

Ignition Coil-Right..........................8W-10-23

Ignition Switch................8W-10-12, 26, 39, 45, 48, 50, 56

Instrument Cluster................8W-10-13, 26, 32, 33, 45, 50

Integrated Power Module . 8W-10-2, 3, 5, 11, 12, 13,, 14, 15, 16, 17, 18, 26, 27,

28, 29, 30, 31, 32, 33, 34, 35, 36, 38, 39, 42, 43, 44, 45, 46, 47, 48, 49, 50, 52,

54, 55, 57, 58

Leak Detection Pump........................8W-10-28

License Lamp-Left..........................8W-10-36

License Lamp-Right.........................8W-10-37

Overhead Map/Reading Lamp....................8W-10-42

Oxygen Sensor 1/1 Upstream.....................8W-10-25

Oxygen Sensor 1/2 Downstream...................8W-10-25

Oxygen Sensor 2/1 Upstream.....................8W-10-25

Oxygen Sensor 2/2 Downstream...................8W-10-25

Oxygen Sensor Downstream Relay................8W-10-11, 18

Park Lamp Relay.........................8W-10-16, 36

Park/Turn Signal Lamp-Left Front................8W-10-36, 51

Park/Turn Signal Lamp-Right Front...............8W-10-36, 51

Passenger Airbag On/Off Switch...................8W-10-46

Passenger Lumbar Switch......................8W-10-30

Power Mirror-Left..........................8W-10-47

Power Mirror-Right.........................8W-10-47

Power Outlet...........................8W-10-13, 33

Power Outlet-Console........................8W-10-34

Power Seat Switch-Driver......................8W-10-30

Power Seat Switch-Passenger....................8W-10-30

Power Window Circuit Breaker....................8W-10-56

Powertrain Control Module . 8W-10-17, 18, 19, 21, 23, 24, 28, 29, 33, 39, 40, 41,

42, 43, 44, 49, 57

PTCNo.1.........................8W-10-42, 43, 44, 45

PTCNo.2 ..............................8W-10-50

PTCNo.5 ..............................8W-10-35

Radio...............................8W-10-32, 50

Seat Belt Tensioner Reducer.....................8W-10-50

Seat Heater Interface Module....................8W-10-34

Sentry Key Immobilizer Module...............8W-10-33, 43, 44

Spare Relay.............................8W-10-58

Starter Motor...........................8W-10-14, 39

Starter Motor Relay.......................8W-10-14, 39

Tail/Stop/Turn Signal Lamp-Left.............8W-10-36, 51, 52, 54

Tail/Stop/Turn Signal Lamp-Right.............8W-10-37, 51, 52, 54

Tailgate Lamp Assembly.....................8W-10-36, 41

Trailer Tow Connector...................8W-10-15, 16, 35, 36

Trailer Tow Connector-Add On..............8W-10-18, 35, 36, 52

Trailer Tow Left Turn Relay...................8W-10-15, 35

Trailer Tow Right Turn Relay...................8W-10-15, 35

Transfer Case Control Module................8W-10-13, 34, 39

Transmission Control Module...............8W-10-12, 27, 41, 56

Transmission Control Relay................8W-10-12, 27, 28, 29

Transmission Range Sensor..................8W-10-40, 48, 53

Transmission Solenoid Assembly.................8W-10-12, 28

Transmission Solenoid/TRS Assembly.........8W-10-27, 29, 40, 48, 53

Underhood Lamp...........................8W-10-32

Vacuum Pump............................8W-10-43

Vistronic Fan Drive.........................8W-10-58

Washer Fluid Level Switch....................8W-10-52, 54

Washer Pump Motor-Front......................8W-10-52

Wiper High/Low Relay......................8W-10-14, 31

Wiper Motor-Front........................8W-10-31, 52

Wiper On/Off Relay........................8W-10-14, 31

DR8W-10 POWER DISTRIBUTION 8W - 10 - 1

Page 780 of 2895

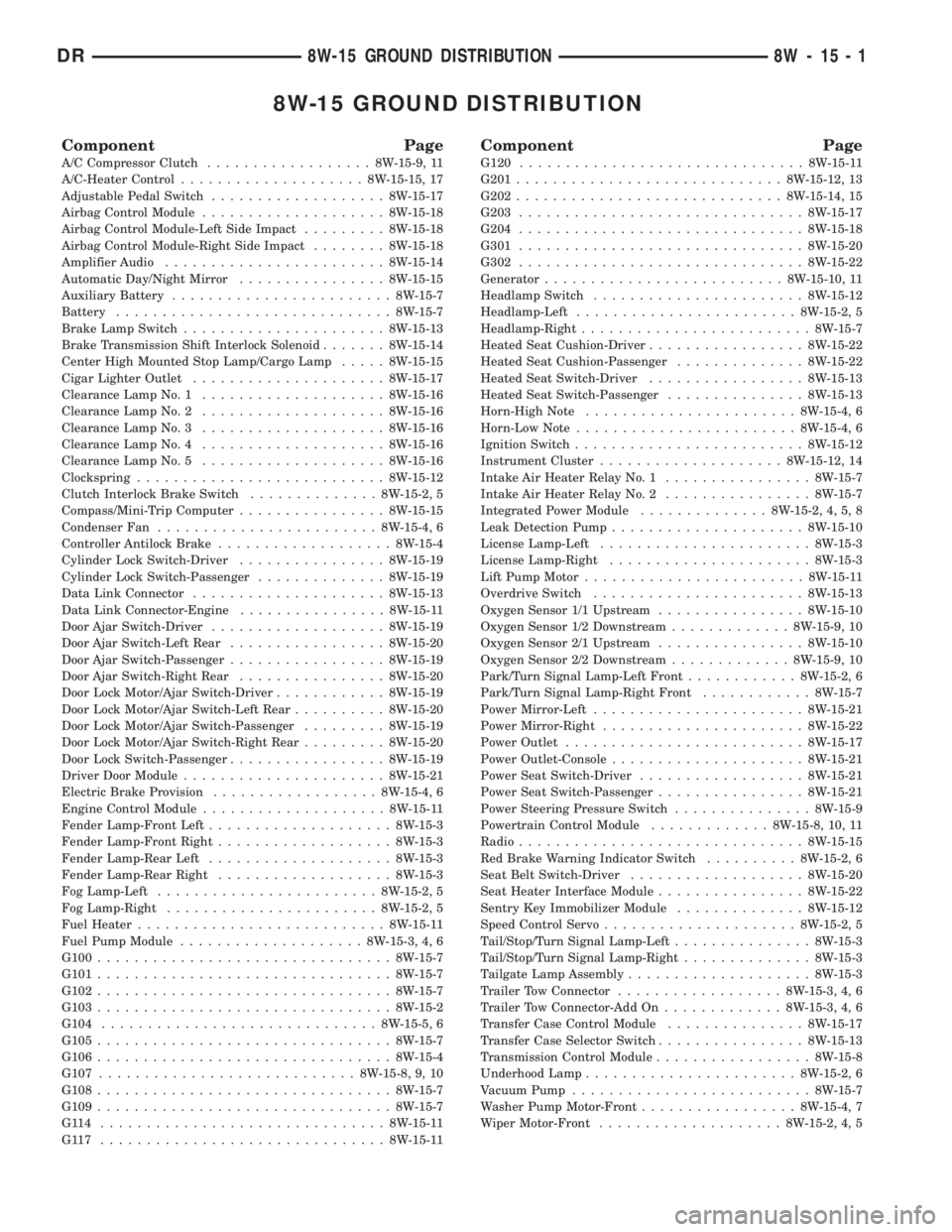

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch..................8W-15-9, 11

A/C-Heater Control....................8W-15-15, 17

Adjustable Pedal Switch...................8W-15-17

Airbag Control Module....................8W-15-18

Airbag Control Module-Left Side Impact.........8W-15-18

Airbag Control Module-Right Side Impact........8W-15-18

Amplifier Audio........................8W-15-14

Automatic Day/Night Mirror................8W-15-15

Auxiliary Battery........................8W-15-7

Battery..............................8W-15-7

Brake Lamp Switch......................8W-15-13

Brake Transmission Shift Interlock Solenoid.......8W-15-14

Center High Mounted Stop Lamp/Cargo Lamp.....8W-15-15

Cigar Lighter Outlet.....................8W-15-17

Clearance Lamp No. 1....................8W-15-16

Clearance Lamp No. 2....................8W-15-16

Clearance Lamp No. 3....................8W-15-16

Clearance Lamp No. 4....................8W-15-16

Clearance Lamp No. 5....................8W-15-16

Clockspring...........................8W-15-12

Clutch Interlock Brake Switch..............8W-15-2, 5

Compass/Mini-Trip Computer................8W-15-15

Condenser Fan........................8W-15-4, 6

Controller Antilock Brake...................8W-15-4

Cylinder Lock Switch-Driver................8W-15-19

Cylinder Lock Switch-Passenger..............8W-15-19

Data Link Connector.....................8W-15-13

Data Link Connector-Engine................8W-15-11

Door Ajar Switch-Driver...................8W-15-19

Door Ajar Switch-Left Rear.................8W-15-20

Door Ajar Switch-Passenger.................8W-15-19

Door Ajar Switch-Right Rear................8W-15-20

Door Lock Motor/Ajar Switch-Driver............8W-15-19

Door Lock Motor/Ajar Switch-Left Rear..........8W-15-20

Door Lock Motor/Ajar Switch-Passenger.........8W-15-19

Door Lock Motor/Ajar Switch-Right Rear.........8W-15-20

Door Lock Switch-Passenger.................8W-15-19

Driver Door Module......................8W-15-21

Electric Brake Provision..................8W-15-4, 6

Engine Control Module....................8W-15-11

Fender Lamp-Front Left....................8W-15-3

Fender Lamp-Front Right...................8W-15-3

Fender Lamp-Rear Left....................8W-15-3

Fender Lamp-Rear Right...................8W-15-3

Fog Lamp-Left........................8W-15-2, 5

Fog Lamp-Right.......................8W-15-2, 5

Fuel Heater...........................8W-15-11

Fuel Pump Module....................8W-15-3, 4, 6

G100................................8W-15-7

G101................................8W-15-7

G102................................8W-15-7

G103................................8W-15-2

G104..............................8W-15-5, 6

G105................................8W-15-7

G106................................8W-15-4

G107............................8W-15-8, 9, 10

G108................................8W-15-7

G109................................8W-15-7

G114 ...............................8W-15-11

G117 ...............................8W-15-11

Component Page

G120...............................8W-15-11

G201.............................8W-15-12, 13

G202.............................8W-15-14, 15

G203...............................8W-15-17

G204...............................8W-15-18

G301...............................8W-15-20

G302...............................8W-15-22

Generator..........................8W-15-10, 11

Headlamp Switch.......................8W-15-12

Headlamp-Left........................8W-15-2, 5

Headlamp-Right.........................8W-15-7

Heated Seat Cushion-Driver.................8W-15-22

Heated Seat Cushion-Passenger..............8W-15-22

Heated Seat Switch-Driver.................8W-15-13

Heated Seat Switch-Passenger...............8W-15-13

Horn-High Note.......................8W-15-4, 6

Horn-Low Note........................8W-15-4, 6

Ignition Switch.........................8W-15-12

Instrument Cluster....................8W-15-12, 14

Intake Air Heater Relay No. 1................8W-15-7

Intake Air Heater Relay No. 2................8W-15-7

Integrated Power Module..............8W-15-2, 4, 5, 8

Leak Detection Pump.....................8W-15-10

License Lamp-Left.......................8W-15-3

License Lamp-Right......................8W-15-3

Lift Pump Motor........................8W-15-11

Overdrive Switch.......................8W-15-13

Oxygen Sensor 1/1 Upstream................8W-15-10

Oxygen Sensor 1/2 Downstream.............8W-15-9, 10

Oxygen Sensor 2/1 Upstream................8W-15-10

Oxygen Sensor 2/2 Downstream.............8W-15-9, 10

Park/Turn Signal Lamp-Left Front............8W-15-2, 6

Park/Turn Signal Lamp-Right Front............8W-15-7

Power Mirror-Left.......................8W-15-21

Power Mirror-Right......................8W-15-22

Power Outlet..........................8W-15-17

Power Outlet-Console.....................8W-15-21

Power Seat Switch-Driver..................8W-15-21

Power Seat Switch-Passenger................8W-15-21

Power Steering Pressure Switch...............8W-15-9

Powertrain Control Module.............8W-15-8, 10, 11

Radio...............................8W-15-15

Red Brake Warning Indicator Switch..........8W-15-2, 6

Seat Belt Switch-Driver...................8W-15-20

Seat Heater Interface Module................8W-15-22

Sentry Key Immobilizer Module..............8W-15-12

Speed Control Servo.....................8W-15-2, 5

Tail/Stop/Turn Signal Lamp-Left...............8W-15-3

Tail/Stop/Turn Signal Lamp-Right..............8W-15-3

Tailgate Lamp Assembly....................8W-15-3

Trailer Tow Connector..................8W-15-3, 4, 6

Trailer Tow Connector-Add On.............8W-15-3, 4, 6

Transfer Case Control Module...............8W-15-17

Transfer Case Selector Switch................8W-15-13

Transmission Control Module.................8W-15-8

Underhood Lamp.......................8W-15-2, 6

Vacuum Pump..........................8W-15-7

Washer Pump Motor-Front.................8W-15-4, 7

Wiper Motor-Front....................8W-15-2, 4, 5

DR8W-15 GROUND DISTRIBUTION 8W - 15 - 1